55 Gallon Drums

55-gallon drums are large, cylindrical industrial containers designed for the storage and transport of bulk goods. With a nominal capacity of 55 gallons, these containers are widely used across industries for shipping and storage applications, providing a standardized solution for handling liquids, powders, and other materials.

A note on terminology: The terms "drum" and "barrel" are used interchangeably in industrial settings. There is no structural distinction between the two, as both can be made from materials such as plastic, fiberglass, or metal. Regardless of composition, both serve the same fundamental purpose—transporting and storing goods in standardized sizes, with the 55-gallon drum being one of the most common.

However, there are two specific industries where a slight distinction exists between the terms. In the oil industry, petroleum products are transported in standard 42-gallon metal containers referred to as "oil barrels," not "drums." This differentiation helps clarify volume specifications, as a standard drum holds 55 gallons. Similarly, in the alcoholic beverage industry, the term "barrel" is traditionally used instead of "drum." Historically, alcoholic beverages were stored and aged in wooden barrels, and while modern manufacturing has largely replaced wooden containers with sanitary-grade stainless steel, the industry continues to use the term "barrel" for beer, wine, and liquor storage. This distinction is both a nod to tradition and a means of verbally identifying the contents of these specialized containers. Outside of these industry-specific nuances, "drum" and "barrel" remain interchangeable, referring to the same type of industrial container.

55 Gallon Drums FAQ

What is a 55-gallon drum used for?

A 55-gallon drum is an industrial container used for storing and transporting liquids, powders, chemicals, food products, and hazardous materials. Its standardized size makes it essential for bulk shipping and storage across industries worldwide.

Are drums and barrels the same thing?

Yes, the terms drum and barrel are generally interchangeable. However, in the oil industry, a barrel equals 42 gallons, and in the beverage industry, “barrel” traditionally refers to wooden or stainless containers for aging beer, wine, or liquor.

What materials are 55-gallon drums made from?

55-gallon drums are manufactured from steel, high-density polyethylene (plastic), or fiberboard. Each material is chosen based on application needs, such as corrosion resistance, food-grade storage, or lightweight dry goods transport.

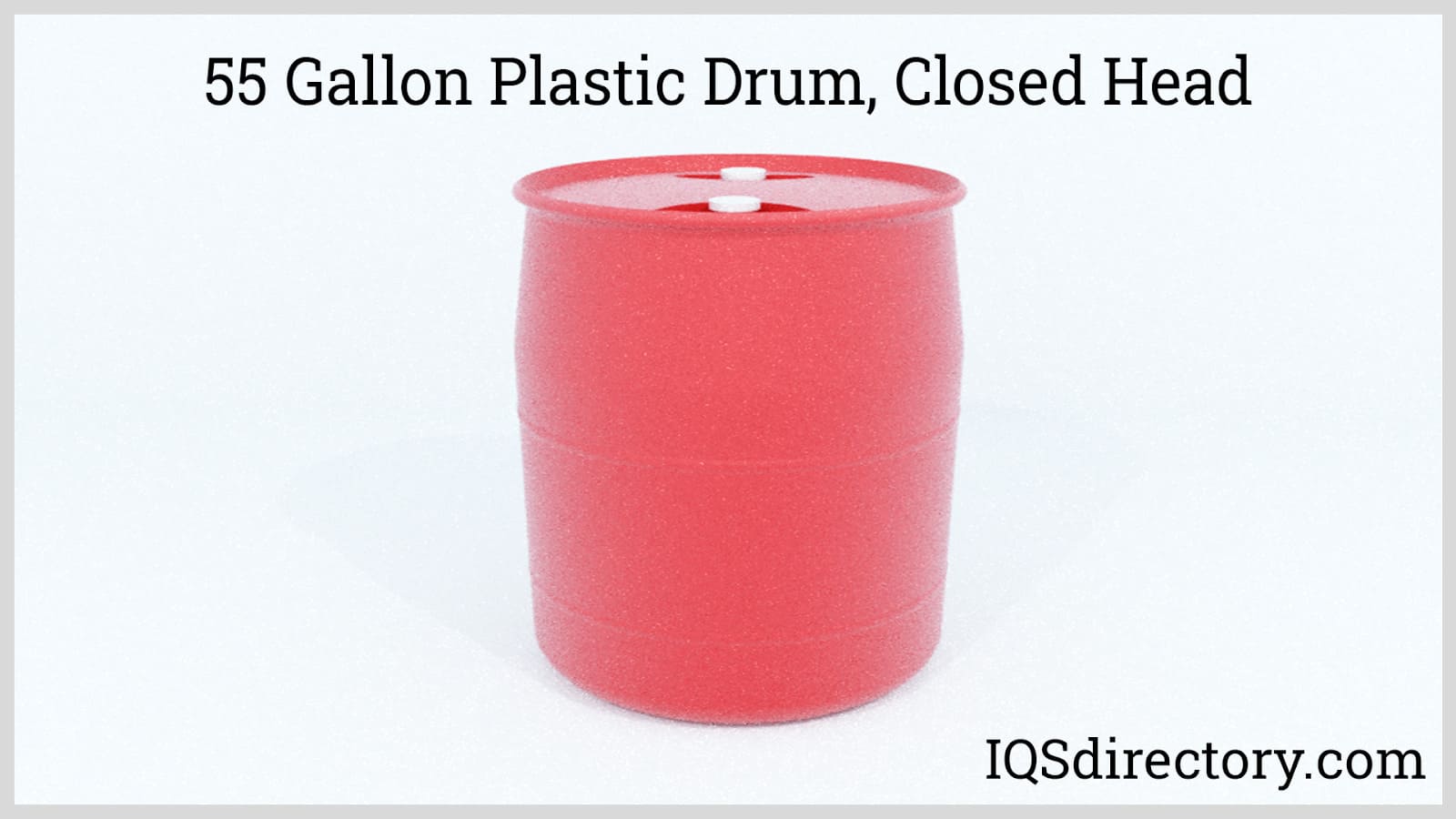

What is the difference between open-head and closed-head drums?

Open-head drums have removable lids for easy access, making them ideal for solids or frequent use. Closed-head drums, also called tight-head drums, feature permanently sealed tops with small openings, ensuring secure storage of liquids and hazardous materials.

Why are many plastic drums blue?

Plastic drums are often manufactured in blue to indicate FDA approval for food, water, and regulated substance storage. The color also helps distinguish them from non-food-grade containers in industrial and commercial applications.

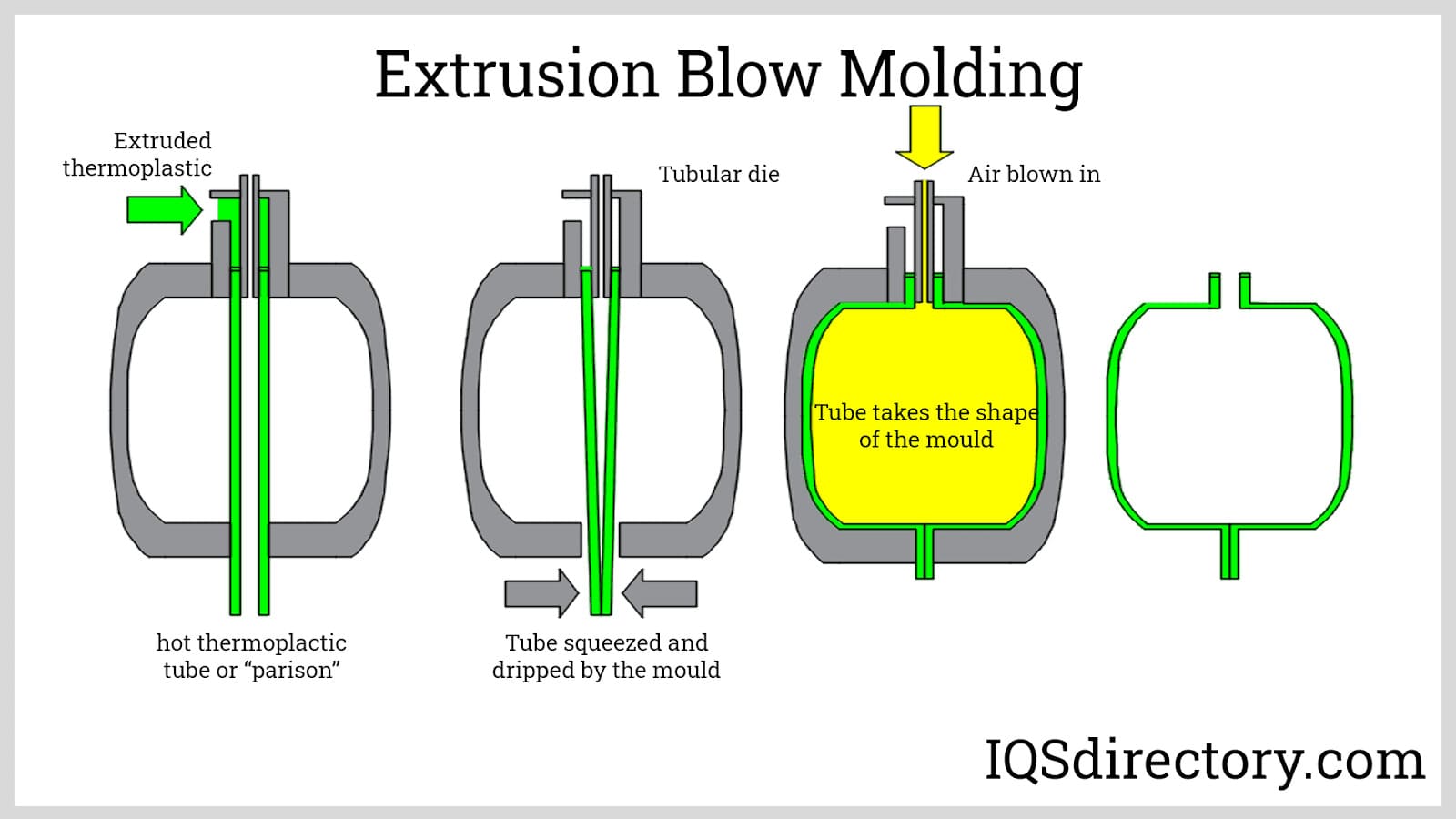

How are plastic 55-gallon drums manufactured?

Plastic 55-gallon drums are typically produced using blow molding. Molten plastic is expanded with air inside a mold cavity, forming the drum’s shape. Once cooled, the container is durable, seamless, and resistant to chemicals and impacts.

What industries rely on 55-gallon drums?

Industries such as petroleum, chemical processing, food and beverage, pharmaceuticals, agriculture, and hazardous waste management all depend on 55-gallon drums for safe, standardized bulk storage and shipping solutions.

The History of 55 Gallon Drums

Barrels and drums have been in use for centuries, originally serving as wine and beer casks since at least medieval times. By the 1700s, they had become standard shipping containers for imports and exports between English colonies, and by the mid-to-late 1800s, they were widely used in the United States for storing and aging whiskey. These early containers were crafted from wood, which remained the primary material for barrels and drums for centuries.

The modern 55-gallon drum, however, did not emerge until the 1900s. In 1905, an employee of Nellie Bly’s Iron Clad Manufacturing Company of New York received two patents that would lead to the development of the steel 55-gallon drum as it exists today. Nellie Bly sought this innovation due to the shortcomings of the metal drum used at the time, which were both heavy and prone to leaks when transporting oil.

Steel 55-gallon drums played an important role during both World War I and World War II. In WWI, they were used to ship sulfuric acid from the United States to Europe, while in WWII, they became a crucial means of transporting aviation fuel and were even repurposed to help small vessels stay afloat. Throughout and between these conflicts, the steel drum underwent continual improvements, becoming stronger and more reliable.

While steel drums proved effective for transporting products like gasoline, manufacturers and consumers soon realized they were not always ideal for food storage. Steel drums had a tendency to rust, posing a risk of contamination to food products. In response, manufacturers introduced fiber drums, which were lightweight, disposable, and free from the contamination risks associated with metal.

The 1960s marked another major shift with the introduction of high-density polyethylene (HDPE) containers. Manufacturers found this plastic alternative to be not only more affordable and easier to work with than steel but also more durable than fiber. HDPE proved particularly well-suited for food storage, as it is largely inert, resistant to acidic substances, and highly durable. Its ability to be repurposed also contributed to its widespread adoption. Today, most food-grade drums are made from plastic, while steel, fiber, and plastic 55-gallon drums all remain in use, each serving distinct applications based on their material properties.

Applications of 55 Gallon Drums

One of the oldest types of containers, 55-gallon drums are primarily designed for the transportation and storage of bulk goods, with liquids being the most commonly stored materials. These industrial-grade containers provide a reliable and standardized solution for safely handling a wide variety of substances.

55-gallon drums serve a broad spectrum of industries, including petroleum, chemical processing, food and beverage, pharmaceuticals, hazardous waste collection, wastewater treatment, and agriculture. Their versatility allows them to contain an extensive range of materials, from gasoline and carbonated beverages to ice cream, plastisols, chemical compounds, and various powdered substances. Their durability and adaptability make them an essential component in modern industrial storage and logistics.

Advantages of 55 Gallon Drums

55-gallon drums offer an efficient solution for shipping cargo in bulk, thanks to their high capacity and stackability. Their durable design allows for secure transport and optimized storage, making them a preferred choice for industries that require reliable bulk packaging.

Drums and barrels also contribute to sustainability, as they are frequently reused, reducing waste and promoting eco-friendly practices. Their versatility makes them ideal for repurposing in countless creative ways, from rain barrels and garden planters to dock floats, trash bins, and barriers. Among them, 55-gallon plastic drums stand out for their strong reputation as an environmentally friendly packaging option, offering both durability and reusability across a wide range of applications.

55 Gallon Drum Manufacturing and Customization

Drums, also known as barrels, are constructed from three primary materials: steel, plastic, or paperboard, commonly referred to as fiber drums. Steel drums are typically made from PVC, and high-density polyethylene (HDPE), offering lightweight, corrosion-resistant alternatives. Fiber drums are composed of fiberboard or dense paper, providing an economical and environmentally friendly option for dry goods and certain liquids.

Steel Drum Design

Manufacturers produce steel drums using a combination of roll forming and welding. During roll forming, metal sheets are passed through rollers, which bend them along their linear axis until they take on a ring shape. Once formed, the sheets are welded together and a base is attached to one or both ends, depending on the drum’s intended use. This manufacturing process ensures the structural integrity required for transporting and storing industrial materials.

Creating Plastic Drums

Plastic drums are typically made through blow molding, a process that shapes hollow products from molten plastic. The process begins with melting plastic and forming it into a tube-like piece called a parison, which has a hole at one end for air passage. A blow mold machine then pushes a metal ram into the parison, expanding it to the desired height. Using a blow pin, compressed air is introduced into the parison, causing it to inflate and conform to the shape of the mold cavity. Once the drum reaches its final form, it is cooled either through conduction, by running cold water through the mold cavity, or through the evaporation of volatile fluids inside the container.

Manufacturing Fiber Drums

Fiber drum manufacturing is the least energy-intensive of the three processes, as it requires no melting, heating, or welding. Instead, fiber drums are produced on a specialized production line that includes body makers, ring fixing machines, lid fixing machines, and disc cutting machines. This method allows for efficient and sustainable drum production, making fiber drums a cost-effective option for certain storage and transport applications.

Drum Customization

To enhance durability, manufacturers can reinforce drums by welding steel rings, or corrugations, around the drum’s base, as well as at points a quarter of the way from the bottom and the top. These reinforcements strengthen the drum’s sides, preventing dents or punctures during transport and handling.

A key feature shared by steel, plastic, and fiber drums is the option for either an open or closed top. Closed-top drums are typically welded shut for maximum security, which is especially critical when shipping hazardous materials. Open-top drums, also known as open-head drums, feature removable lids, allowing for easier access to the drum’s contents. Closed-head drums, also referred to as tight-head drums, have a permanently sealed lid with a small opening for controlled pouring.

Customization options allow for further modifications to 55-gallon drums. They can be painted in custom colors, labeled with designs or company branding, and configured with additional bung holes or specific bung hole placements to suit various applications. Whether for industrial, commercial, or specialized use, these customization features enhance functionality and adaptability, ensuring that 55-gallon drums meet the precise needs of different industries.

Features of 55 Gallon Drums

55-gallon drums function in a straightforward manner, serving as secure containers for various materials. If a drum has a closed top, materials are poured in through a bung hole at the top, which can then be sealed with a plug to prevent spills or contamination. Open-top drums, by contrast, have removable lids, allowing for easy access when filling or emptying the container. Regardless of the configuration, the drum lid ensures that the contents remain securely enclosed.

When preparing drums for shipment or storage, manufacturers stack them on pallets, making them easy to transport using forklifts. To retrieve the contents, users can either remove the bung plug and pour the material out or lift the lid—either completely or on a hinged mechanism—to scoop, pour, or dump the contents as needed.

Thanks to their reinforced sides, drums can also be maneuvered by rolling them on their side or, for short distances, by tipping them and rolling them at an angle on their bottom edge. This design makes them not only durable but also highly transportable across different settings.

Among gallon drums, the 55-gallon drum holds a unique distinction as the international standard size. Its precise volume meets the specifications required for global trade, making it the preferred choice for industries that rely on standardized bulk packaging.

55 Gallon Drum Images, Diagrams and Visual Concepts

A 55 gallon drum is a cylindrical container made from a variety of materials for shipping large quantities of liquids, chemicals, powders, granule compounds, and food ingredients.

A 55 gallon drum is a cylindrical container made from a variety of materials for shipping large quantities of liquids, chemicals, powders, granule compounds, and food ingredients.

Stainless steel drums have interior linings to protect the contents from contaminants from corrosive or acidic components.

Stainless steel drums have interior linings to protect the contents from contaminants from corrosive or acidic components.

Open head drums are normally used for storage or shipping and designed for harsh conditions to survive the demands of shipping.

Open head drums are normally used for storage or shipping and designed for harsh conditions to survive the demands of shipping.

Closed head drums are used for hazardous waste and are tested to meet drop, stack, leak, hydrostatic, and vibration requirements.

Closed head drums are used for hazardous waste and are tested to meet drop, stack, leak, hydrostatic, and vibration requirements.

The production of plastic 55 gallon drums involves the usage of plastic blow molding where molten plastic is blown into a die or mold.

The production of plastic 55 gallon drums involves the usage of plastic blow molding where molten plastic is blown into a die or mold.

55 Gallon Drum Types

-

Agitator Drums

Designed for mixing and blending substances such as paint and concrete, these drums feature an opening in the cover to accommodate the blades of an agitator, which thoroughly combines the contents. They are most commonly made from durable metal alloys like steel or aluminum.

Blue Barrels

Constructed from high-quality plastic materials, these barrels are typically blue to signify their suitability for FDA-approved transport and storage of food, water, and other regulated substances.

Closed Head Drums

Also known as "tight head drums," these containers feature a permanently sealed lid with a small opening, allowing for controlled pouring while ensuring the secure containment of the material inside.

Fiber Drums

Made from heavy-duty paperboard, these drums provide a lightweight and cost-effective solution for the shipping and storage of dry goods and certain liquids.

Hazardous Waste Containers

Designed for the safe handling, storage, and transport of hazardous materials, these portable containers prevent exposure to substances that pose risks to human health and the environment.

Industrial Drums

Large, cylindrical containers widely used across industries for bulk shipping and storage applications, offering versatility for liquids, powders, and solids.

Metal Drums

Durable, cylindrical containers made from metallic materials, primarily used for storing and transporting liquids, although they can also accommodate solid materials when necessary.

Open Head Drums

Featuring removable lids, these drums provide easy access to contents, making them ideal for applications that require frequent filling or dispensing.

Plastic Barrels

Lightweight, corrosion-resistant containers used for the safe transportation and storage of liquids across various industries.

Plastic Drums

A rust-proof alternative to steel drums, these containers offer durability and chemical resistance, making them ideal for food-grade, industrial, and hazardous material applications.

Reconditioned Drums

Plastic or steel drums that have undergone refurbishment to ensure safe and optimal reuse. The reconditioning process often involves replacing or repairing the drum lid to extend its lifespan.

Salvage Drums

Specially designed for the safe transport and storage of damaged or leaking drums. These secondary containment drums provide a temporary yet secure solution for hazardous materials in the event of a spill or mechanical impact.

Seamless Drums

Manufactured with a smooth, creaseless interior to prevent material entrapment, these drums enhance cleanliness and efficiency in handling sensitive substances. They are similar to process drums, which feature a welded top curl for additional protection against entrapment.

Steel Barrels

Closed-top containers designed specifically for the secure storage and transportation of liquids, offering durability and corrosion resistance.

Steel Drums

Versatile, cylindrical containers used for transporting and storing both liquid and solid materials, prized for their strength and ability to withstand harsh industrial conditions.

Used Drums and Barrels

A cost-effective and environmentally responsible option that promotes reuse and sustainability by extending the life cycle of industrial containers.

Used 55-Gallon Drums

Repurposed for a variety of applications beyond disposal, including uses in lawn care, gardening, agriculture, recreation, and emergency preparedness. Their continued use helps reduce waste and supports environmental conservation efforts.

Water Barrels

Designed to collect and store water, these barrels are often integrated with ductwork from rooftops of warehouses, manufacturing facilities, and residential buildings to support water conservation and emergency preparedness.

30-Gallon Barrels

Mid-sized barrels suitable for diverse industries, with their utility determined by their material composition, making them a flexible option for storage and transport needs.

Uses of 55 Gallon Drums

-

Steel Drum Uses

Often referred to as fuel drums, steel drums are widely used for storing and transporting pharmaceuticals, fragrances, flammable chemicals, and other hazardous substances. Stainless steel drums are particularly valued for their anti-corrosive properties, making them ideal for sanitary applications in industries that require contamination-free storage. While the 55-gallon drum is the most common size, 30-gallon steel drum are also available for non-bulk applications, frequently used in the food industry. However, exposure to the elements can lead to rust, prompting many companies to opt for non-corrosive plastic alternatives.

Plastic Drum Uses

Known for their strength, rigidity, and lightweight construction, plastic drums are often referred to as blue barrels due to their characteristic color. These durable containers are well-suited for transporting and storing acidic and caustic liquids, powders, and other industrial materials. Their chemical resistance makes them ideal for holding liquid and low-viscosity food products, high-viscosity substances, lubricating oils, and chemicals, providing a reliable alternative to steel drums.

Fiber Drum Uses

As a cost-effective alternative to steel drums, fiber drums are commonly used for transporting food products, including frozen and refrigerated goods such as cheese and ice cream. Their lightweight and stackable design makes them ideal for storing dry or solid materials, and their fully incinerable composition allows for easy disposal. As the most easily recycled drum type, fiber drums are an environmentally friendly choice for various storage and shipping needs.

In addition to these main drum categories, there are specialized 55-gallon storage containers designed for specific applications, such as water barrels, hazardous waste containers, and reconditioned drums.

Other Uses for 55-Gallon Drums

Water Barrels

Primarily used for collecting and storing water, these drums are often integrated with ductwork from rooftops of industrial buildings to facilitate water conservation. Many are also used as rain barrels, specifically designed to collect rainwater runoff for irrigation and other non-potable applications. Most water barrels are made from plastic due to their durability and resistance to environmental conditions.

Hazardous Waste Containers

A broad category encompassing chemical drums, salvage drums, 55-gallon steel drums, and 55-gallon plastic drums, hazardous waste containers are designed to store materials that cannot be disposed of in regular trash or drainage systems. These drums safely contain hazardous substances such as nitric oxide, aerosol cans, caustic solutions, ceramic glazes, fertilizers, grease, disinfectants, and gasoline, ensuring compliance with environmental and safety regulations.

Used Drums

Also known as reconditioned drums, used drums include previously utilized steel, fiber, and plastic drums that have been cleaned and restored for continued use. Reconditioning involves flushing and stripping the interior to remove residual materials, making it one of the safest and most environmentally responsible methods for managing hazardous waste while extending the lifespan of industrial containers.

Accessories for Drums

In addition to the various types of industrial drums, 55-gallon drums can be paired with a range of accessories to enhance their functionality. One essential accessory is the drum pump, a pneumatic pump designed to fit through a standard drum opening. This tool is particularly useful for applications that require transferring plastisols from industrial drums to dip molding tank reservoirs, ensuring a controlled and efficient material transfer process.

For applications that involve mixing concrete or other substances, a drum mixer is a valuable addition. Drum mixers allow for thorough blending of materials inside a revolving drum, making them indispensable in construction and manufacturing settings where uniform consistency is essential.

Another highly useful accessory is the drum dolly, a must-have for any worksite handling heavy drums. As a specialized type of drum handler, a drum dolly is equipped with wheels for easy maneuverability, allowing drums to be transported effortlessly across a facility. Many models also feature locking drum straps to secure the container in place during movement, providing both convenience and safety in industrial environments.

55 Gallon Drum Standards and Specifications

Users of 55-gallon drums must ensure that both their containers and contents comply with all applicable local, state, national, and industry-specific regulations. Adhering to these standards is essential for safety, environmental protection, and legal compliance.

For instance, steel drums intended for defense applications must meet military specifications, commonly referred to as Mil Spec, ensuring they conform to rigorous durability and security requirements. Similarly, drums and their contents crossing international borders must comply with United Nations (UN) regulation standards, which govern the transportation of hazardous and non-hazardous materials worldwide.

Most steel drums used in industrial manufacturing must not only meet UN regulations but also adhere to standards set by the U.S. Department of Transportation (DOT). DOT classifies hazardous materials into nine primary divisions, each with further subclassifications. Drums containing any of these substances must be clearly labeled to reflect their classification, ensuring proper handling and transport. The main divisions established by DOT include:

- Class 1: Explosives

- Class 2: Gases

- Class 3: Flammable Liquid/Combustible Liquid

- Class 4: Solids

- Class 5: Oxidizers and Peroxides

- Class 6: Toxic and Infectious Substances

- Class 7: Radioactive Materials

- Class 8: Corrosive Substances

- Class 9: Miscellaneous Hazardous Materials

Proper labeling and compliance with these classifications are critical in ensuring the safe and legal transport of materials stored in 55-gallon drums.

Things to Consider When Purchasing a Drum

To decide what type of 55 gallon drum is best for your application, start by asking yourself the following questions: Is your product a liquid or a solid? Is your product considered a hazardous material? Is your product a food grade product? How heavy is your product (gallons/liters for liquid, and lbs/kg for solids)? The answers to these questions will help you decide if you need a steel, plastic or fiber drum.

Once you’ve figured out the type of drum you need, reach out to a manufacturer. Find an experienced and knowledgeable manufacturer by browsing the list posted near the top of this page. When searching and reaching out, keep in mind the qualities of the manufacturer you want. The right manufacturer will not only be able to provide a solution to your application, but they will care about the solution to your application. They’ll put you at ease and put your needs above the bottom line. So, check out our list and find your match today!

To determine the best type of 55-gallon drum for your application, start by considering key factors. Ask yourself whether your product is a liquid or a solid, whether it is classified as a hazardous material, and whether it requires food-grade certification. Additionally, assess the weight of your product—measured in gallons or liters for liquids and pounds or kilograms for solids. The answers to these questions will guide you in selecting the most suitable drum material, whether steel, plastic, or fiber.

Once you have identified the type of drum you need, the next step is to connect with a manufacturer. Finding an experienced and knowledgeable supplier is essential to ensuring that you receive a reliable, high-quality solution. When searching for the right manufacturer, consider their expertise, commitment to customer service, and willingness to provide tailored solutions that meet your specific needs. The right manufacturer won’t just sell you a product—they will prioritize your application’s success and provide guidance that instills confidence in your choice. Explore your options today and find the perfect match for your storage and transport needs.

55 Gallon Drum Terms

-

Barrel

A unit of volume that varies between 31 and 42 gallons, depending on the industry standard. In the oil and gas sector, a barrel equals 42 gallons, while a barrel of beer holds 31 gallons.

Bulk Tanks

Large storage containers designed for holding substantial volumes of liquids or solids, typically exceeding 2,000 gallons in capacity.

Capacity

The total internal volume available within a container, such as a steel or plastic drum, for storing a specific quantity of product.

Closure

A sealing mechanism on a container's opening, designed to secure the contents and prevent leakage.

Cocking

An improperly applied closure on a container, which can lead to leaks or compromised sealing integrity.

Dome

A closure with a rounded top surface, commonly found on steel and plastic drums.

Gasket

A protective seal, typically made from soft materials such as cork or rubber, that enhances the container’s ability to prevent leaks.

Hazardous Material

A substance classified by regulatory agencies such as the EPA or OSHA as toxic, radioactive, or corrosive, requiring strict handling, storage, and transportation regulations to ensure safety.

Hazardous Waste

A material deemed unsuitable for recycling or reuse due to its hazardous nature. Strict disposal guidelines are in place to prevent health and environmental risks.

Impact Resistance

A measure of how well plastic containers withstand shock and sudden force without breaking.

Lining

A protective coating applied to the interior surfaces of steel and plastic drums to prevent contamination and corrosion. Common lining materials include polyethylene (PE), polyester, and silicone.

Overseal

An additional closure, often made from foil or aluminum, that provides tamper-proof security for the primary closure on steel and plastic drums.

Reconditioning

A process that restores steel and plastic drums for reuse by cleaning, rinsing, and applying protective coatings. This may involve abrasive cleaning, painting, and structural inspections.

Removal Torque

The amount of force, measured in pounds per inch, required to unscrew a closure from a container.

Spout Cap

A cover designed to seal the spout on the lid of a steel or plastic drum, controlling the pouring process and preventing spills.

Seam

The point where two material edges are joined to form a complete container.

Tight Head Container

A drum configuration in which the lid is permanently attached to the body, preventing removal. Tight head steel and plastic drums are commonly used for liquid storage to enhance security and leak prevention.

More 55 Gallon Drums Information