Air Filters

Air filters are devices designed to reduce or eliminate unwanted particles from the air. These filters can be used in ventilation systems or in air circulating through open indoor spaces. Industrial air filtration systems help enhance indoor air quality while also extending the lifespan of machinery, engines, and appliances.

The History of Air Filters

The idea of air filters dates back to the 16th century when workers began using protective respirators over their noses and mouths to prevent inhalation of harmful fumes, gases, vapors, and dust particles. In the 1700s and 1800s, engineers like Alexander von Humboldt and Lewis P. Haslett further developed air-purifying respirators. Haslett’s invention, called “Haslett’s Lung Protector,” used moistened wool and a one-way clapper valve to filter dust.

In the late 1940s, the U.S. Army Chemical Corps and the U.S. Atomic Energy Commission collaborated to create the first HEPA (High-Efficiency Particulate Air) filter. Initially known as “collective protector filters,” these HEPA filters were developed to protect against radioactive chemical agents during the Manhattan Project. After World War II, the U.S. government declassified the technology, and manufacturers began producing HEPA filters for residential and commercial applications. The early filters included asbestos components, but by the late 1950s, these were discontinued due to health risks associated with asbestos.

In the 1960s, following complaints about defective filters, the Atomic Energy Commission introduced quality assurance testing. In 1963, Klaus Hammes, a German mechanical engineer, and his brother Manfred designed the first clean air filter for residential ovens. Their system, which included a filter pad and magnets, attached to an oven’s air outlet, trapping dust as cold air entered and heated. This reduced the “black dust buildup” on oven walls. As users noticed improvements in allergy and asthma symptoms, the popularity of the Hammes system grew. Hammes went on to design similar filters for other heating equipment, including radiators and forced air systems, and developed the first cabin air filter for the American division of Mercedes-Benz.

Over the following decades, engineers continued to develop new materials and construction techniques for air filters. As research into harmful airborne particles and substances advanced, the importance of air filters in safeguarding long-term health became even more apparent. Today, air filters provide a wide variety of filtration levels suitable for numerous environments.

Advantages of Air Filters

Air filtration systems have become essential for modern manufacturers, driven by the increasing levels of pollutants in our environment. These systems not only help businesses manage their emission rates but also assist in meeting the pollution control standards set by the EPA.

In addition to their environmental benefits, air filtration systems offer several advantages over other purification methods. They are highly efficient and simple to maintain, making them an ideal choice for businesses. Another key benefit is that air filters not only remove harmful particles but also help reduce odors in the air. Lastly, air filtration systems are affordable and versatile, providing a cost-effective solution for various industries.

Air Filter Uses

Air filters are essential in any environment where air needs to be cleaned, and with air pollution being widespread, their demand is high. Key industries that require air filtration include wastewater and sewage treatment, oil and gas, paper and plastic manufacturing, fertilizer production, aerospace, pharmaceuticals, tobacco, transportation, rubber, chemical treatment, meat processing, automotive manufacturing, and many others.

Within these industries, clean air filters are crucial for both manufacturers and workers. However, they are equally important in home environments. Air filters are commonly found in furnaces, vacuum cleaners, air conditioners, and humidifiers. In homes with pets or issues like mold, mildew, and dust, air filters are particularly beneficial for reducing allergens. They help remove particles that cause allergies, allowing families to breathe easier. This is especially important for individuals with asthma or other respiratory difficulties.

In medical settings, air filters play a critical role in eliminating bacteria, viruses, and other harmful microbes that can be transmitted through airborne particles, contributing to a healthier environment.

Design of Air Filters

-

Materials Found in Filters

Air filter manufacturers use a diverse range of materials to create their products. These materials include fabrics, paper, metal, plastics, and specialized alternatives like charcoal. The selection of material depends entirely on the specific application. For instance, fabrics are often used to filter particulate matter in gas flows. Fabric filters, such as filter bag houses, can be reused multiple times. Paper is typically chosen for disposable filters, offering a single-use option for customers. Metals like stainless steel are preferred for filter screens that handle more demanding filtration tasks. Plastics are utilized in electrostatic filters to generate a natural static charge from friction, which attracts dust particles. Charcoal or active carbon is used in filters designed for water treatment, as the carbon causes chemical reactions that attract and remove harmful air elements.

Filter Design Considerations

When selecting the appropriate filter for a specific application, manufacturers must consider several important factors. These include the required filtration efficiency, which is determined by the size of the filter fibers, the fiber density, and the velocity of air passing through the filter. Other considerations include the size and density of the particles to be captured, the potential for adhesive use, and any space or power limitations. It’s important to note that denser filters capture more particles and provide higher air purification, but they also require more power to push air through.

Customization of Air Filters

Many manufacturers offer custom options to meet specific needs. Customizations can include adjustments to filter length, thickness, width, and frame shape, ensuring that the filter is tailored to fit the unique requirements of each application.

Air Filtration Images, Diagrams and Visual Concepts

Air filters are used to remove airborne particles, pollutants, and microorganisms hazardous to health and the ecosystem.

Air filters are used to remove airborne particles, pollutants, and microorganisms hazardous to health and the ecosystem.

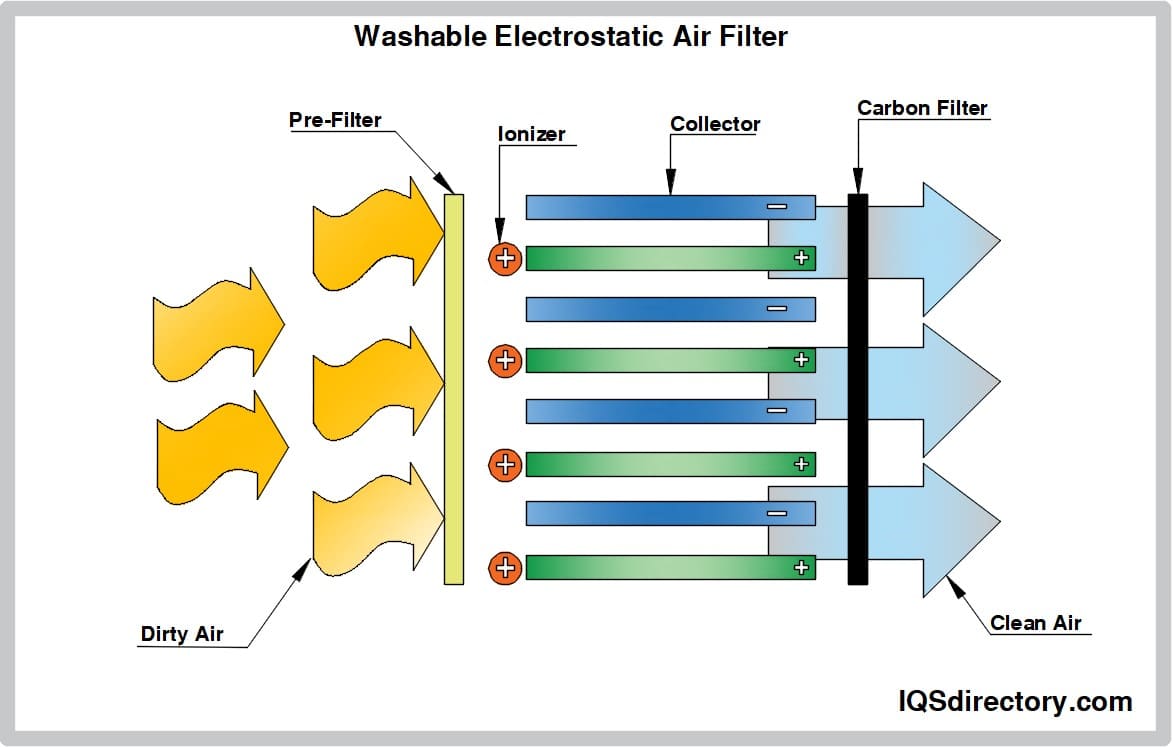

Washable electrostatic air filters operates electrostatic filter media, when the air encounter friction the media holds the particles with static electricity until the filter is washed.

Washable electrostatic air filters operates electrostatic filter media, when the air encounter friction the media holds the particles with static electricity until the filter is washed.

Air filters are manufactured in different shapes and sizes to remove particles and pollutants from ambient air.

Air filters are manufactured in different shapes and sizes to remove particles and pollutants from ambient air.

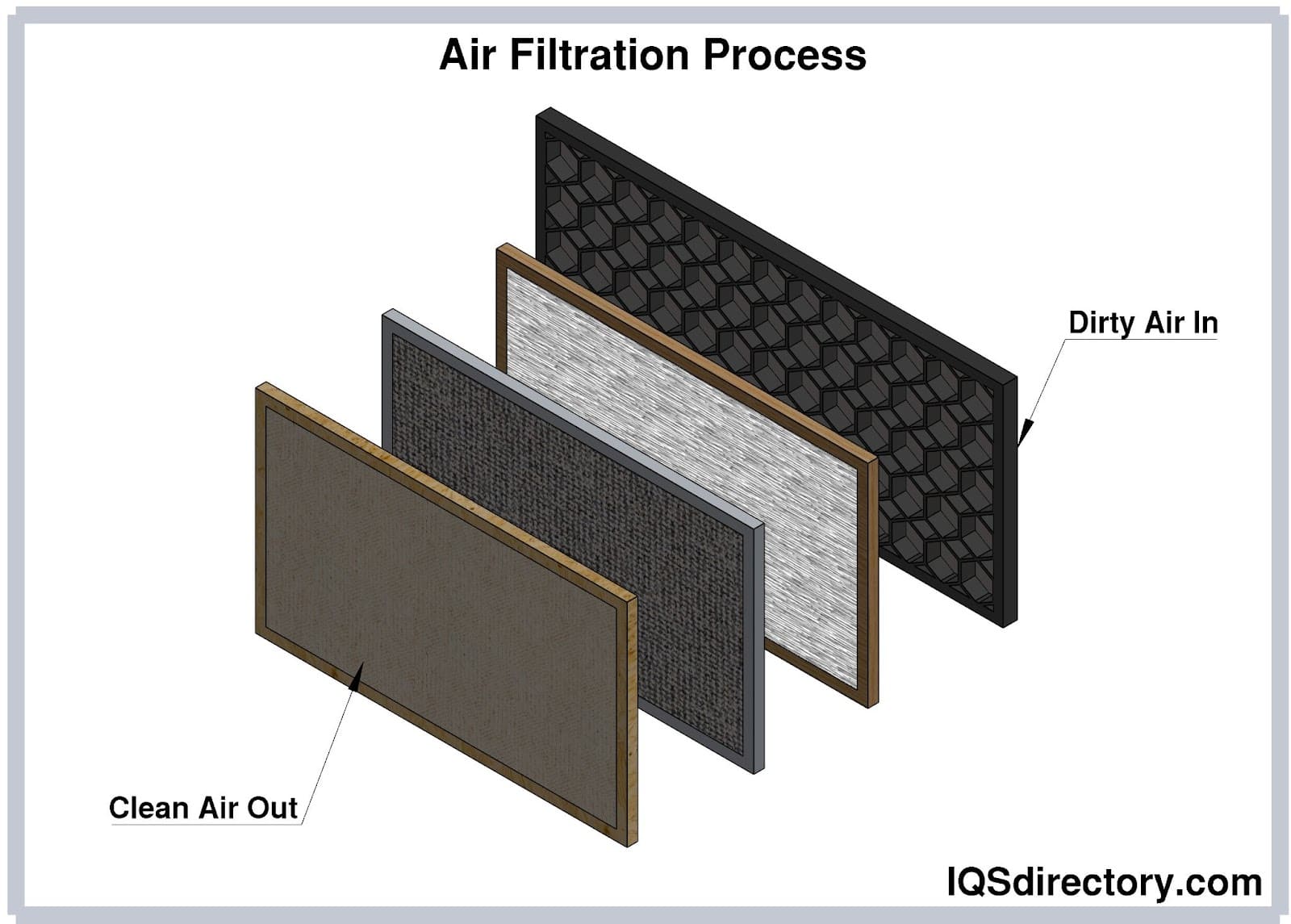

How air filters work by drawing unclean air to pass through a filtered medium with fine openings.

How air filters work by drawing unclean air to pass through a filtered medium with fine openings.

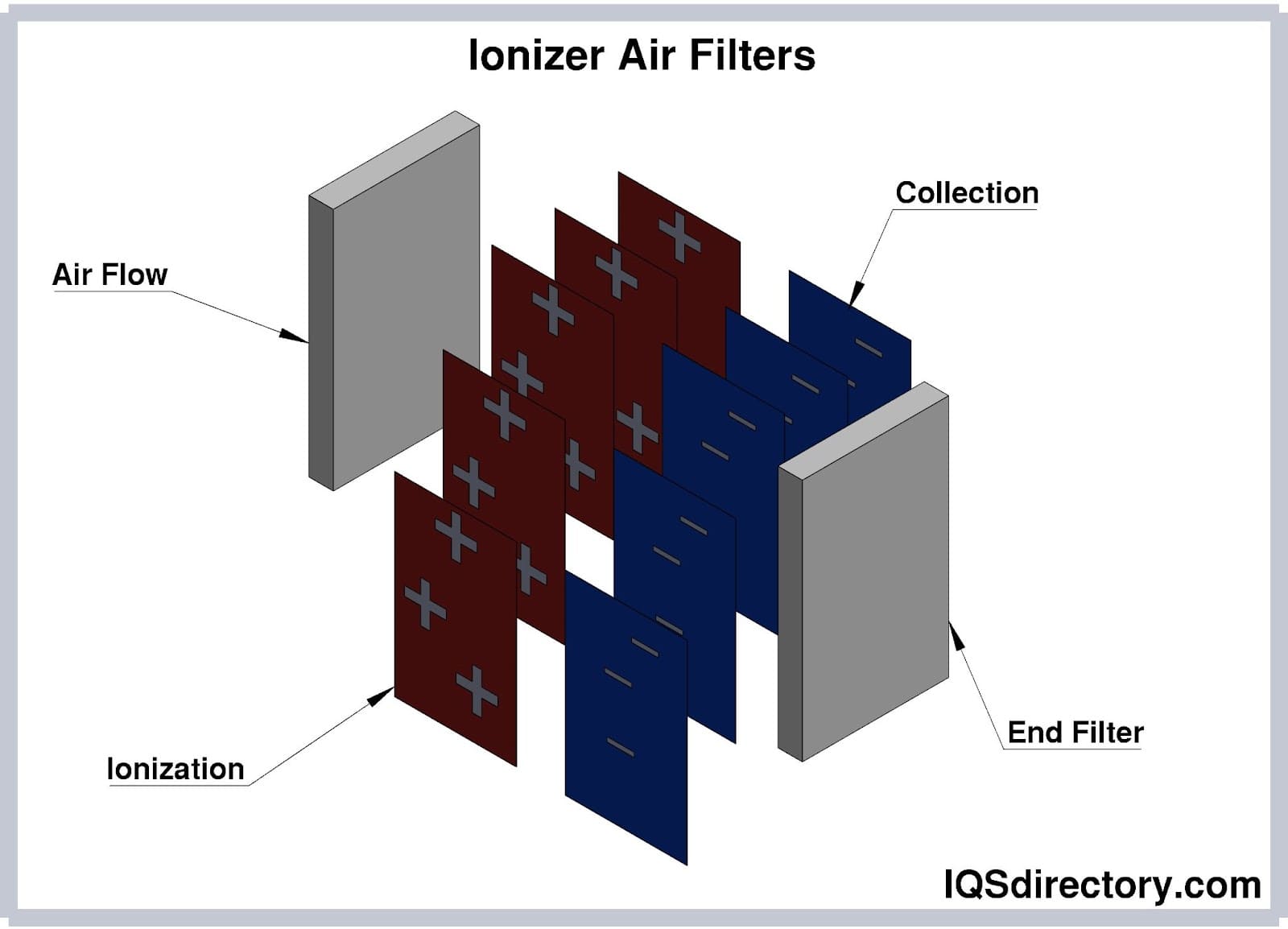

An ionizer air filters the air passes through a prefilter then an ionizer where the airborne particles are electrical charged.

An ionizer air filters the air passes through a prefilter then an ionizer where the airborne particles are electrical charged.

HVAC filters prevent particulates and other contaminants from entering the internal components of a HVAC system which could damage the system.

HVAC filters prevent particulates and other contaminants from entering the internal components of a HVAC system which could damage the system.

Air Filtration Types

Air Filtration System Categories

Air filtration systems generally fall into two main categories: electrical and mechanical. However, there are several specialized air filtration systems, each designed to provide unique functions. Below are some common types of filters and their applications.

Flat-Paneled Fiberglass Filter

These filters offer medium-level efficiency with ratings between 1 and 4. Their durable metal-like body protects the filter from breakage. While effective for catching larger airborne particles, they are not as efficient at capturing smaller elements such as dust or bacteria.

Pleated Filter

Pleated polyester filters are disposable and can capture both small and large particles. They are rated between 7 and 13 in terms of efficiency, making them an ideal option for both domestic and commercial use. They approach the efficiency levels of HEPA filters but are available at a more affordable price.

HVAC Filter

High-efficiency Particulate Arrestance (HEPA) filters have an efficiency rating of 14 to 16 and are commonly used in home and commercial heating, ventilation, and air conditioning systems (HVAC). These filters offer higher airflow resistance and operate quietly.

HEPA Filter

HEPA filters are known for providing excellent air quality by removing 99.97% of all particles from indoor air. With an efficiency rating of 17 to 20, they are frequently used in HVAC systems, hospital operating rooms, and pharmaceutical facilities to remove allergens and other irritants.

Ulpa Filter

The Ultra-Low Particulate Air (ULPA) filter is similar to the HEPA filter but offers even more precise filtration. ULPA filters are used in applications requiring extremely high air quality standards, such as in laboratories or environments with strict air quality requirements.

Inline Filter

Inline or line filters are used in ductwork or tubing to remove impurities and liquids from an air stream.

Membrane Filter

These filters use thin, microporous films to trap or retain particulate impurities from an air source drawn through them.

Air Compressor Filter

Air compressor filters remove contaminants like water, oil, dust, and vapors from a compressed air supply, ensuring clean air for machinery and operations.

Electrostatic Filter

Electrostatic filters provide a nearly permanent solution for filtration and do not require an external power source to be effective.

Furnace Filter

Furnace filters are installed inside both residential and commercial furnaces to capture dust, dirt, mold spores, pet dander, and other potential allergens. These filters are easy to install and replace.

Carbon Air Filter

Carbon air filters are specialized filters designed to remove gases and odors from air streams, improving air quality in various settings.

Exhaust Filter

Exhaust filters remove soot and particulate matter from vehicle exhaust before it is released into the atmosphere, helping to minimize pollution.

Cabin Air Filter

Cabin air filters are used in vehicles to clean the outside air entering the passenger compartment, ensuring a fresher and healthier cabin environment.

Oil Filter

Oil filters remove contaminants from oil in machinery, especially in hydraulic systems. Examples include filters for engine oil, transmission oil, hydraulic oil, and lubricating oil.

Thermodynamic Sterilization

Thermodynamic sterilization devices use heat, up to 200°C, to sterilize an airflow. These devices can eliminate around 99% of organisms such as bacteria, allergens, molds, and mildews. However, they are primarily considered air purifiers, not air filters, as they do not capture particulate matter or gaseous elements. These sterilization units are ideal for homes and offices without significant levels of noxious gases.

UV Germicidal Technique

Ultraviolet Germicidal Irradiation (UVGI) uses UV rays to eliminate contaminants from exhaust streams. A UV lamp and a fan direct air toward the lamp, which treats the stream, followed by a filter that traps and removes the dead bacteria.

Polarized-Media Electronic Air Cleaner

This filtration technology uses an enhanced electronic medium to remove contaminants from an environment or airstream. The system creates a polarized field by converting AC to DC, which attracts and captures particles on a fiber pad. This method is effective for removing even the smallest contaminants, and is widely used in industrial settings to maintain clean, odor-free environments.

Photocatalytic Oxidation Filter

PCO filtration is a newer technique that not only filters air but also helps save on energy consumption by preventing unconditioned air from entering ducts and the environment. It is an effective solution for building management and energy efficiency.

Ionizer

Ionizers filter the air by ionizing particles in the airflow, which are then caught by a negatively charged electrode. This safe and robust technique is commonly used in industrial and environmental applications to maintain air quality.

Standards and Specifications for Air Filters

The American Society for Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) has established a rating standard called the Minimum Efficiency Reporting Value (MERV) to evaluate the efficiency of air filtration systems. The MERV scale ranges from 1 (lowest efficiency) to 20 (highest efficiency). This rating system is designed to assess a filter’s ability to remove particles, its resistance to airflow, and its overall durability.

Things to Consider When Purchasing an Air Filter

With so many air filter products available, it’s important to have a reliable resource to help you find the right one. The best guidance comes from trusted air filter manufacturers or suppliers, and fortunately, you’re just a few clicks away from discovering them!

At IQS, we've compiled a list of top industry manufacturers, complete with their contact details and websites, all in one convenient location. To find the right provider, browse through their websites, which are listed at the top of this page. As you explore their sites, make note of three or four manufacturers that catch your attention. Then, reach out to these companies, providing your specifications and asking about lead times, prices, and customization options. Compare their responses and select the manufacturer that best aligns with your needs and values. This approach will help you find the best fit for your requirements.

Proper Care for Air Filters

Air filters typically perform effectively when they are designed to handle the appropriate type of particulate. With proper maintenance and regular cleaning, many filters can exceed their expected replacement date, delivering years of reliable performance and improving air quality.

Filter Accessories

Air filter accessories include items such as adaptor flanges, hardware kits, valve covers, filter vent tubes, and vent hose adaptors. To determine which products are compatible with your filter, consult with your supplier.

Air Filter Terms

-

Adsorption

The process in which gas, liquid, or solid molecules are retained on a surface due to positive interactions or attraction between the surface and the adsorbed material.

Air Borne

Referring to particles or substances that are suspended in the air.

Air Stream

A flow or current of air.

Allergen

A substance that causes an immediate immune system response in sensitive individuals.

Arrestance

An air filter’s ability to capture synthetic dust during testing.

Backpressure

The reverse surge of pressure from downstream to upstream in an air filter, often caused by valve closures or air trapped in a liquid system.

Certified Energy Manager (CEM)

A professional designation awarded through training and testing by the Association of Energy Engineers (AEE), indicating expertise in energy management.

CFC (Chlorofluorocarbon)

A group of chemicals once widely used as refrigerants. They are now tightly regulated and phased out due to their role in ozone depletion. Examples include R-11, R-12, R-113, R-114, and R-115.

Containment

The act of preventing an agent from spreading or being transmitted from one location to another.

Contamination

The presence of harmful or unwanted particles, often in the air.

Decontamination

The process of removing harmful airborne particles to neutralize the air.

Filter Medium

The material used in filters that allows substances to pass through while trapping unwanted particles. This is often foam or a membrane material.

Filter Penetration

The occurrence of particles passing through an air filter without being trapped.

Filtrate

The substance that has been filtered.

Indoor Air Quality

A measure of the level of pollutants present in the air within a confined space.

Ionizer

A device that uses a filament, grid, or porous material to remove an electron from the outer shell of an atom, turning it into a positively charged ion.

Membrane

A continuous matrix with pores of defined size, used to filter substances.

Negative Pressure

A pressure condition in a space that causes air to flow inward.

Ozone

A molecule composed of three oxygen atoms. While harmful at ground level, ozone is crucial in the stratosphere for blocking ultraviolet radiation.

Particulate

Small solid particles suspended in air or water, varying in size, shape, density, and electrical charge.

Positive Pressure

A pressure condition that causes air to flow outward from a space.

Pressure Drop

The decrease in air pressure as air flows through a filter, a measure of the filter's resistance to airflow.

Upstream

The direction opposite to the airflow.