Air Pollution Control

Air pollution control equipment is designed to remove and eliminate a range of pollutants, including volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), such as sulfuric fumes, gases, odors, and vapors, from the atmosphere. By reducing or eliminating these harmful substances, this equipment helps mitigate serious environmental and biological impacts, including smog, acid rain, carbon emissions, and global warming.

Air Pollution Control FAQ

What is air pollution control equipment used for?

Air pollution control equipment removes harmful pollutants such as VOCs, sulfuric fumes, and hazardous gases. It reduces environmental risks like smog, acid rain, and global warming while protecting human health.

How do thermal oxidizers reduce air pollution?

Thermal oxidizers use high heat to convert hazardous compounds into harmless gases like carbon dioxide and water. Many designs recover 90–95% of heat, making them energy-efficient for industrial applications.

What pollutants are commonly targeted by scrubbers?

Scrubbers remove acid gases, particulates, and toxic fumes. Wet scrubbers use liquid sprays to clean flue gas, while dry scrubbers rely on sorbents such as alkaline compounds to neutralize harmful emissions.

What role did the Clean Air Act play in pollution control?

The 1970 Clean Air Act empowered the EPA to regulate industrial emissions of hazardous pollutants. It established accountability for manufacturers and drove the adoption of modern pollution control technologies in the U.S.

How do electrostatic precipitators clean emissions?

Electrostatic precipitators charge fine particles in an airstream and separate them using an electric field. With efficiencies above 99%, they capture dust and ash in power plants and industrial processes.

What health risks are linked to air pollution exposure?

Air pollution is tied to asthma, COPD, lung cancer, and cardiovascular disease. Long-term exposure to nitrogen oxides and fine particulates increases risks, particularly for children, pregnant women, and vulnerable communities.

Why are regenerative thermal oxidizers popular in U.S. facilities?

Regenerative thermal oxidizers reuse up to 97% of thermal energy, cutting operating costs. Their catalyst-free design reduces maintenance, making them a preferred choice for American manufacturing and power plants.

The History of Air Pollution

The Industrial Revolution marked a significant turning point in the history of air pollution. Large factories with assembly lines released thick plumes of smoke into the atmosphere. Simultaneously, automobiles, boats, and airplanes began emitting exhaust gases, adding to the growing problem. Many have argued that air pollution is an inevitable cost of progress.

However, the consequences of air pollution can be devastating. In 1948, a disaster in Donora, Pennsylvania, claimed 20 lives and injured 7,000 individuals, marking the worst air pollution tragedy in U.S. history. Globally, the 1984 Bhopal disaster in India remains infamous, where a Union Carbide factory gas leak killed at least 3,787 people and injured between 150,000 and 600,000. Similarly, London's Great Smog of 1952 caused an estimated 4,000 to 12,000 deaths.

In the United States, the 1970 Clean Air Act introduced a new era of environmental responsibility. It tasked the Environmental Protection Agency (EPA) with regulating emissions of hazardous chemicals, ensuring businesses kept them within safe thresholds. This legislation also established long-term accountability, holding manufacturers responsible for the air quality impacts of their operations.

The development of air pollution control technology has a long history. In 1824, Hohlfeld in Germany invented the electrostatic precipitator (ESP), a crucial air pollution control device, although it remained without industrial application until after the Clean Air Act. In 1907, Professor Frederick Gardner Cottrell patented the first commercially viable ESP, primarily for removing sulfuric acid from emissions. He placed his patent in a foundation that could not financially benefit until 1970, reflecting the delayed prioritization of environmental health.

What is Air Pollution?

Air pollution refers to the contamination of ambient air, which naturally consists of gases, liquids, and solids. Government regulators have established acceptable levels for various airborne chemicals, aiming to ensure emissions remain below these thresholds. Industrial advancements have introduced harmful substances like carbon monoxide, sulfur dioxide, and nitrogen oxides into the atmosphere, significantly altering its composition since pre-industrial times. Soil sample analysis reveals that atmospheric carbon dioxide levels have risen from 280 parts per million (ppm) in pre-industrial society to approximately 405 ppm today.

The atmosphere has a limited capacity to neutralize pollutants. Excessive amounts of sulfur dioxide or carbon monoxide can render ambient air toxic, posing serious health risks.

What is Air Pollution Control Equipment?

To comply with emissions regulations, facilities install air pollution control systems to manage pollutant output. Oxidizers, for instance, break down pollutants like hydrogen sulfide into non-toxic components through oxidation, often involving high heat or catalytic processes. Facilities also employ wet and dry scrubbers, mist collectors, electrostatic precipitators, and odor control systems, depending on the specific pollutants involved.

Oxidizers come in various types, such as thermal or catalytic. Catalytic oxidizers use elements like platinum or palladium to facilitate the breakdown of volatile organic compounds (VOCs), creating non-toxic byproducts like nitrogen and oxygen. Both thermal and catalytic oxidizers may include regenerative or recuperative designs to maximize energy efficiency, with heat recovery rates reaching 90-95%.

Non-oxidizing systems, such as scrubbers, utilize different filtration methods. Dry scrubbers use alkaline sorbents to remove acid gases, while wet scrubbers employ liquids to clean flue gases of large particulates. Electrostatic precipitators use electrical ionization to remove fine particles, often in processes like mist collection. Additional technologies include selective catalytic and non-catalytic reduction systems for nitrogen oxide emissions and carbon adsorption methods for VOC recovery.

How Air Pollution is Created

Man-made contaminants like carbon monoxide, nitrogen oxides, and sulfur dioxide are byproducts of activities such as transportation, manufacturing, and power generation. These pollutants can accumulate to dangerous levels if not properly controlled. The ban on chlorofluorocarbons (CFCs) due to their ozone-depleting effects exemplifies efforts to curb air pollution.

- Carbon Monoxide (CO): A toxic, odorless gas primarily emitted by vehicles and incomplete combustion from wood stoves or coal-fired power plants. Without proper ventilation, CO can reach lethal levels indoors.

- Nitrogen Oxides (NOx): Generated by high-temperature combustion, these emissions are common in power plants and refineries.

- Sulfur Dioxide (SO2): Emitted from coal or oil refineries, contributing to smog and acid rain.

Air Pollution by Smog

Smog, a visible indicator of poor air quality, can be categorized into traditional smog, caused by fossil fuel burning, and photochemical smog, formed when pollutants react with ultraviolet rays. California frequently issues smog warnings due to high pollution levels. Businesses often need scientists to monitor emissions and ensure compliance with air quality regulations.

Air Pollution and Human Health

Air pollution significantly impacts human health, causing symptoms ranging from mild discomfort to severe respiratory and cardiovascular issues. Studies have linked increased nitrogen oxide levels to higher cancer rates and identified risks for pregnant women and children exposed to fine particulate matter. Chronic exposure can lead to conditions such as asthma, COPD, and lung cancer.

Indoor air quality (IAQ) is also affected by outdoor pollutants. Green building practices and regulatory measures aim to improve IAQ by minimizing hazardous chemicals in construction materials and equipment emissions.

How Air Cleaning Devices Work

Air pollution control devices function through three primary mechanisms:

- Destroying contaminants: Technologies like flue gas desulfurization transform hazardous chemicals into inert forms.

- Modifying chemicals: Electrostatic precipitators convert harmful gases into safer compounds.

- Removing hazards from the air: Devices like scrubbers and collectors capture and dispose of pollutants.

Air Pollution Control Equipment

The scientific consensus is clear: climate change is real, and human activities are a primary cause. Since the Industrial Revolution, Earth's average temperature has risen by approximately 0.8 degrees Celsius. While this may seem insignificant, this increase is linked to severe consequences, including recurring droughts, hurricanes such as Katrina, and accelerated glacier melting.

Governments at federal and state levels have responded by enacting regulations to control emissions from various sources, including coal-based power plants, vehicles of all sizes, and industries.

Purpose of Air Pollution Control Equipment

Air pollution control equipment is designed to remove a wide range of pollutants, such as volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), from the atmosphere. These pollutants, including sulfuric fumes, gases, odors, and vapors, contribute to environmental and health issues like smog, acid rain, and global warming. By employing air pollution control equipment, VOCs and HAPs can be significantly reduced or eliminated. Among the most commonly used technologies are carbon absorbers and oxidizers.

Oxidizers for Pollution Control

Thermal Oxidizers

Thermal oxidizers use heat to convert polluted air into clean air. This principle extends to variations like thermal recuperative oxidizers, afterburners, rotor concentrator systems, regenerative catalytic oxidizers, and regenerative thermal oxidizers. Polluted emissions are subjected to high heat, inducing a chemical reaction with a metal catalyst bed that removes harmful contaminants.

Catalytic Oxidizers

Catalytic oxidizers wash polluted air with platinum or palladium, causing oxygen to separate from VOCs and form non-toxic byproducts like nitrogen and oxygen instead of harmful nitric oxide.

Both catalytic and thermal oxidizers can be regenerative or recuperative. Recuperative oxidizers use ceramic heat transfer beds to recover 90-95% of energy from oxidation processes, while regenerative thermal oxidizers achieve similar efficiency with ceramic heat transfer beds.

Carbon Absorbers for Pollution Control

Carbon absorbers, also known as air pollution scrubbers, remove VOCs from contaminated air by passing it over an activated carbon bed. The bed absorbs VOCs, releasing clean air. These systems utilize various chemical technologies, including:

- Amines: Such as monoethanolamine.

- Minerals and Zeolites: Including serpentinite and olivine.

- Sodium Hydroxide: Using methods like Zeman and Lackner.

- Lithium Hydroxide

Although costly to install and operate, carbon absorbers are increasingly mandated under stricter regulations.

Other Types of Pollution Control Equipment

Electrostatic Precipitators

Designed to remove particulate matter, these systems charge particles in an airstream and separate them using an electric field. With efficiencies exceeding 99%, they capture particles as small as 1 micrometer and are commonly used in fossil-fuel furnace applications.

Cyclones

Cyclones use spiral paths to create cyclonic motion, separating larger particles through inertia. While efficient for particles around 20 micrometers, modern regulations often require additional measures, making cyclones effective pre-cleaners rather than standalone solutions.

Scrubbers absorb suspended particles by exposing an airstream to a spray of water or solvents. Designs such as venturi scrubbers are highly effective, achieving up to 98% efficiency. However, maintenance can be challenging, and the cleaning process should factor into equipment selection.

These systems use long, narrow fabric-filter bags to trap particulates from ascending dust-laden air. With efficiencies nearing 100% for larger particulates, baghouses represent some of the most effective solutions but require significant investment and maintenance.

Key Considerations for Purchasing Air Pollution Control Systems

Quality Equipment Selection

Selecting the right equipment depends on your industry's pollutant types and emission levels. High-quality systems ensure effective pollutant reduction and long-term reliability.

Reputable Suppliers

Choose suppliers with strong reputations for quality products and services. Review product lists, client testimonials, and service offerings to ensure competence.

Cost vs. Quality

While affordability is important, prioritize quality to avoid inefficient or non-durable systems. Compare quotes across suppliers to balance cost and performance.

Installation and Maintenance

Proper installation and regular maintenance are vital for the longevity of pollution control systems. Many reputable suppliers include expert installation and offer maintenance contracts to ensure optimal operation.

Air Pollution Equipment Images, Diagrams and Visual Concepts

Thermal oxidizers break down organic or hydrocarbon-based HAPs and VOCs into carbon dioxide and water.

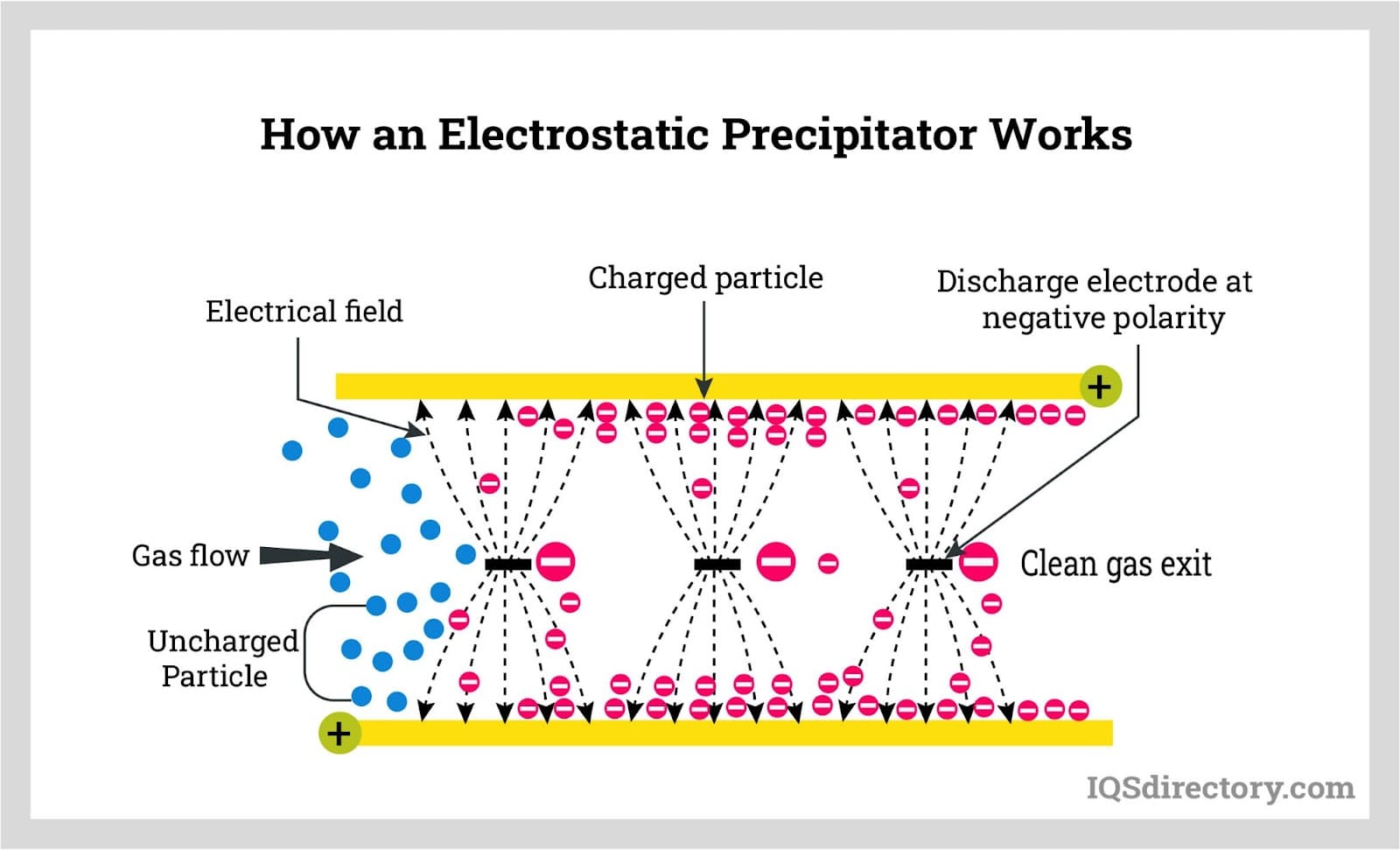

Electrostatic precipitator is a dry scrubber that uses static electricity to remove soot and ash.

An air scrubber is an air purification system that removes particulate matter from the air.

An air scrubber is to make air breathable after it has been contaminated by toxic fumes, chemicals, gases, and pollutants.

Utilizing Emission Control Systems

The U.S. Energy Information Administration (EIA) published a report revealing a 21% reduction in carbon dioxide (CO2) emissions from electricity generation in 2015 compared to 2005 levels. This achievement reflects the fruition of federal efforts to regulate greenhouse gas emissions. The EIA attributes the decrease to the adoption of cleaner fuel sources, marking a clear shift in the U.S. electricity generation mix toward renewable and natural gas-fired power.

A similar trend is evident in the air pollution control equipment sector, with new-generation emission control systems efficiently reducing sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and particulate emissions from incineration, power, and chemical plants.

Demand Increase for Emission Control Systems

Compliance with the EPA's Mercury and Air Toxics Standards (MATS) rule has driven a 6.47% growth in the demand for new emission control systems. Many coal-based power plants have adopted these systems, including the Lon D. Wright Power Plant in Fremont, Nebraska, which recently upgraded its air quality control system (AQCS). The plant integrated pulse jet fabric filters, an activated carbon injection system, and a spray dryer absorber.

Utilizing the Regenerative Thermal Oxidizer (RTO) System

The Regenerative Thermal Oxidizer (RTO) has emerged as one of the most efficient and cost-effective emission control systems. Capable of reusing approximately 97% of thermal energy, the RTO includes a Hot Gas Bypass to handle higher exhaust gas concentrations and emission spikes. Its catalyst-free design reduces maintenance and replacement costs, making it a preferred choice in challenging industrial environments.

Rotary Concentrator System

The Rotary Concentrator System is a hybrid air pollution control solution designed for efficiently removing pollutants from exhaust air streams. Using a hydrophobic zeolite rotating wheel, it is particularly effective in applications limited to exhaust air stream pollutants.

Secondary Recovery Units

Secondary recovery units can be retrofitted to existing or new oxidizer systems to enhance efficiency. These units capture heat ranging from 250°F to 1,500°F, which would otherwise be lost to the atmosphere. Designed to minimize pressure drop, they optimize operational efficiency while offering significant energy savings.

Air Pollution Control Equipment Options

To achieve effective air pollution control, it is essential to consider the following devices based on specific needs:

- Air Filtration Systems: Remove impurities using various filtration and purification methods.

- Air Scrubbers: Use fans and filters to separate contaminants and recirculate clean air.

- Catalytic Oxidizers: Employ metal catalysts (e.g., platinum) to break down hazardous compounds at lower temperatures.

- Dust Collectors: Remove granular solids from exhaust gases for reuse or disposal.

- Electrostatic Precipitators: Ionize and capture particulate matter using grounded electrodes.

- Emission Control Systems: Monitor and reduce combustion byproducts.

- Gas Scrubbers: Eliminate gaseous pollutants via absorption or chemical reactions.

- Heat Recovery Systems: Capture and reuse heat from industrial processes.

- Ionizing Wet Scrubbers : Remove acid gases and heavy metals from air streams.

- Emission Control Systems: Capture water and oil mists from industrial applications.

- Odor Control Systems: Neutralize unpleasant odors.

- Oxidizers: Use oxygen to break down hazardous substances.

- Particulate Control Systems: Manage ash and particulate emissions using various technologies.

- Rotary Concentrators: Concentrate VOCs for efficient oxidation.

- Thermal oxidizers: Break down hazardous compounds through high-temperature oxidation.

- Venturi Scrubbers: Remove fine dust particles using a water spray in a vortex system.

- VOC Abatement and Destruction Systems: Mitigate volatile organic compounds using incineration or biodegradation.

Economic and Environmental Impacts

Air pollution poses significant economic and environmental costs. Reduced worker productivity and crop damage, such as sulfur-tainted wine from nearby factories, exemplify the tangible effects of unchecked emissions. Additionally, the "greenhouse effect" and climate change may lead to severe weather events, such as hurricanes, linked to rising global temperatures.

Regulatory Standards and Innovations

The EPA enforces strict regulations under the Clean Air Act to limit emissions of VOCs and Hazardous Air Pollutants (HAPs), protecting human health and the environment. Continuous Emissions Monitoring Systems (CEMS) aid in tracking and reporting compliance. While VOC and HAP emissions have decreased significantly, carbon emissions remain a growing concern, prompting further regulatory focus and innovation in emission control technologies.

Technical Terms and Concepts

Key terms relevant to air pollution control include:

- Adsorption: Surface attachment of molecules, distinct from absorption.

- Baghouse Collectors: Fabric-based dust collectors.

- Catalysts: Substances speeding chemical reactions without consumption.

- Cyclone Separators: Devices using centrifugal force to separate particles.

- Electrostatic Precipitators: Equipment capturing particulate matter via ionization.

- HEPA Filters: Traps 99.97% of particles ≥0.3 microns.

- Nitrogen Oxides (NOₓ): Pollutants contributing to smog and acid rain.

- VOC Concentrators: Systems enhancing VOC oxidation efficiency.

Through advanced technologies and stringent regulations, industries can achieve cleaner operations while addressing environmental challenges.

More Air Pollution Control Information