Automatic Screwdrivers

An automatic screwdriver is a piece of equipment that automatically inserts screws into a product during assembly and production. Since every production operation is unique and requires a...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at warehouse automation.

The article will provide more detail on topics such as:

This section delves into the essence of warehouse automation and its operational dynamics.

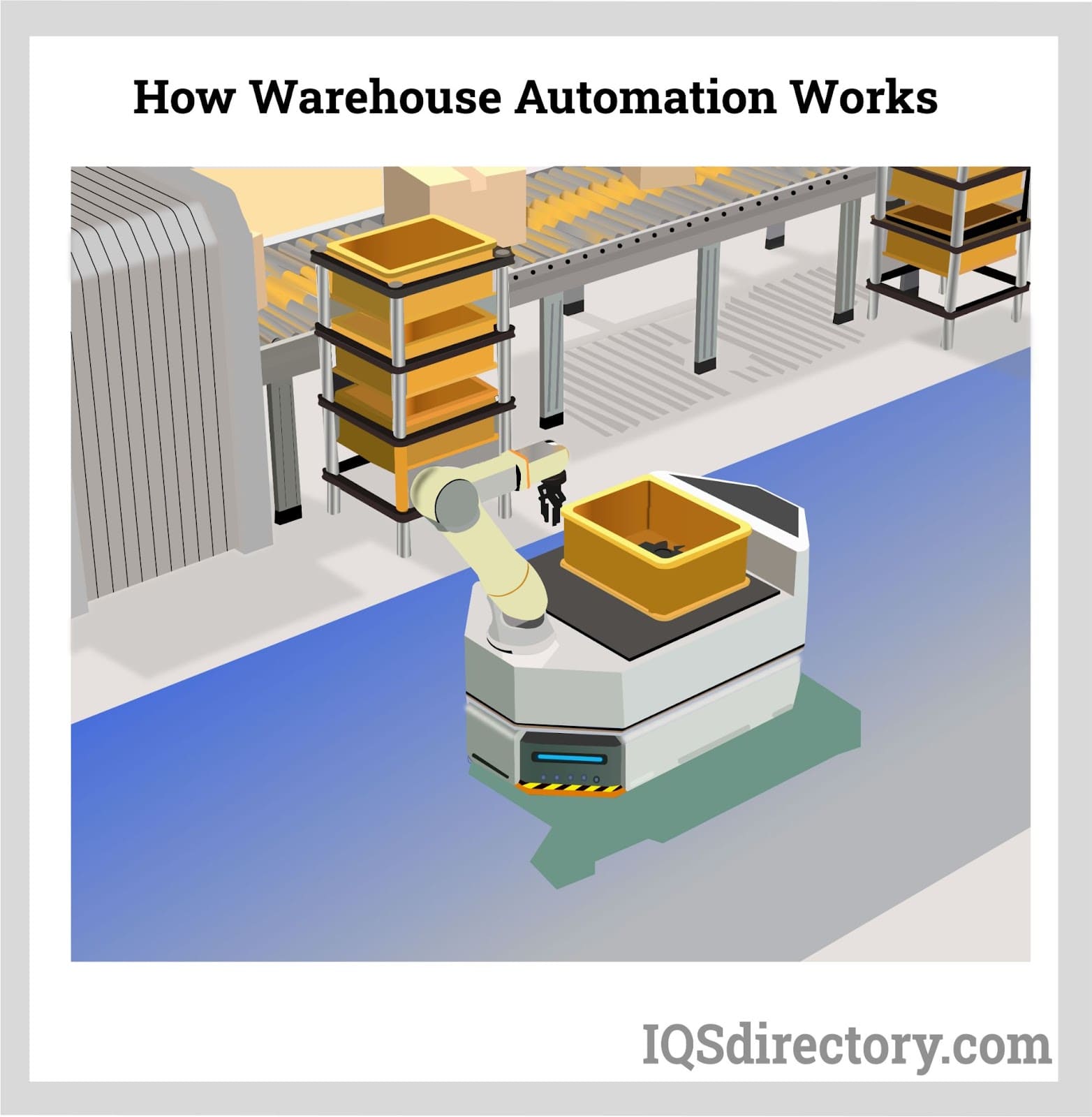

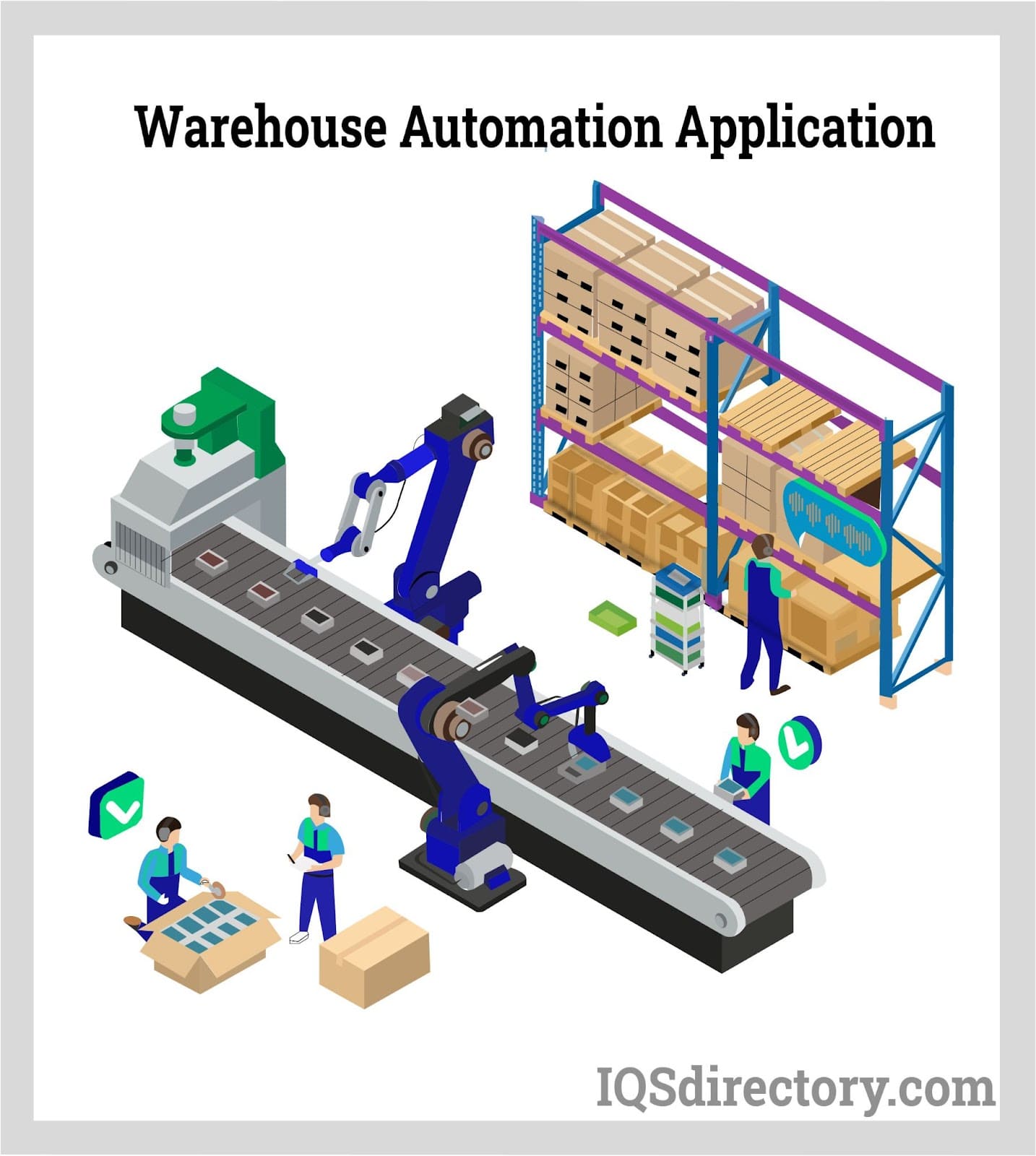

Warehouse automation is the process of substituting labor-intensive, repetitive duties with automated systems. This shift prioritizes freeing up workers to focus on essential tasks, like quality control, instead.

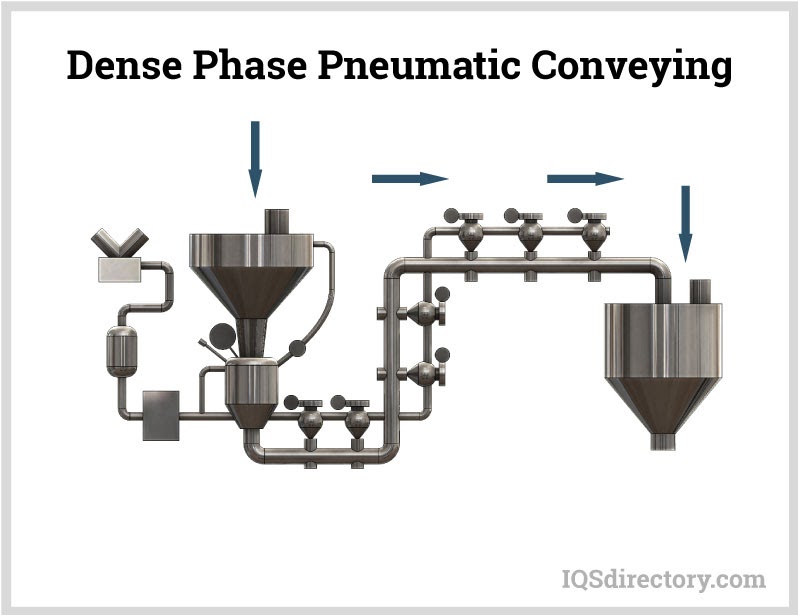

The integration of material handling and warehouse automation involves software that executes simple tasks requiring minimal human input. Bulk material handling automation equipment is capable of conveying, loading, unloading, weighing, processing, and feeding various bulk solids. These systems act much like robots in manufacturing, enhancing the efficiency of materials handling.

Digital automation through robotics mitigates manual operations by utilizing data, software, and automatic data capture technology like mobile barcoding. Key advantages include its smooth alignment with ERP systems, improved safety, boosted security, and more adept data handling. By reducing human error and manual tasks, digital robotics boost efficiency in material handling, uplift customer service, enhance employee morale, and cut costs related to human mistakes. Technologies like mobile barcode scanning and RFID bolster these positive impacts further.

Adopting digital automation systems entails initial expenses, covering deployment, employee training, necessary hardware, software, and maintenance agreements. However, there are risks of data loss, potential damage, and heightened cybersecurity concerns.

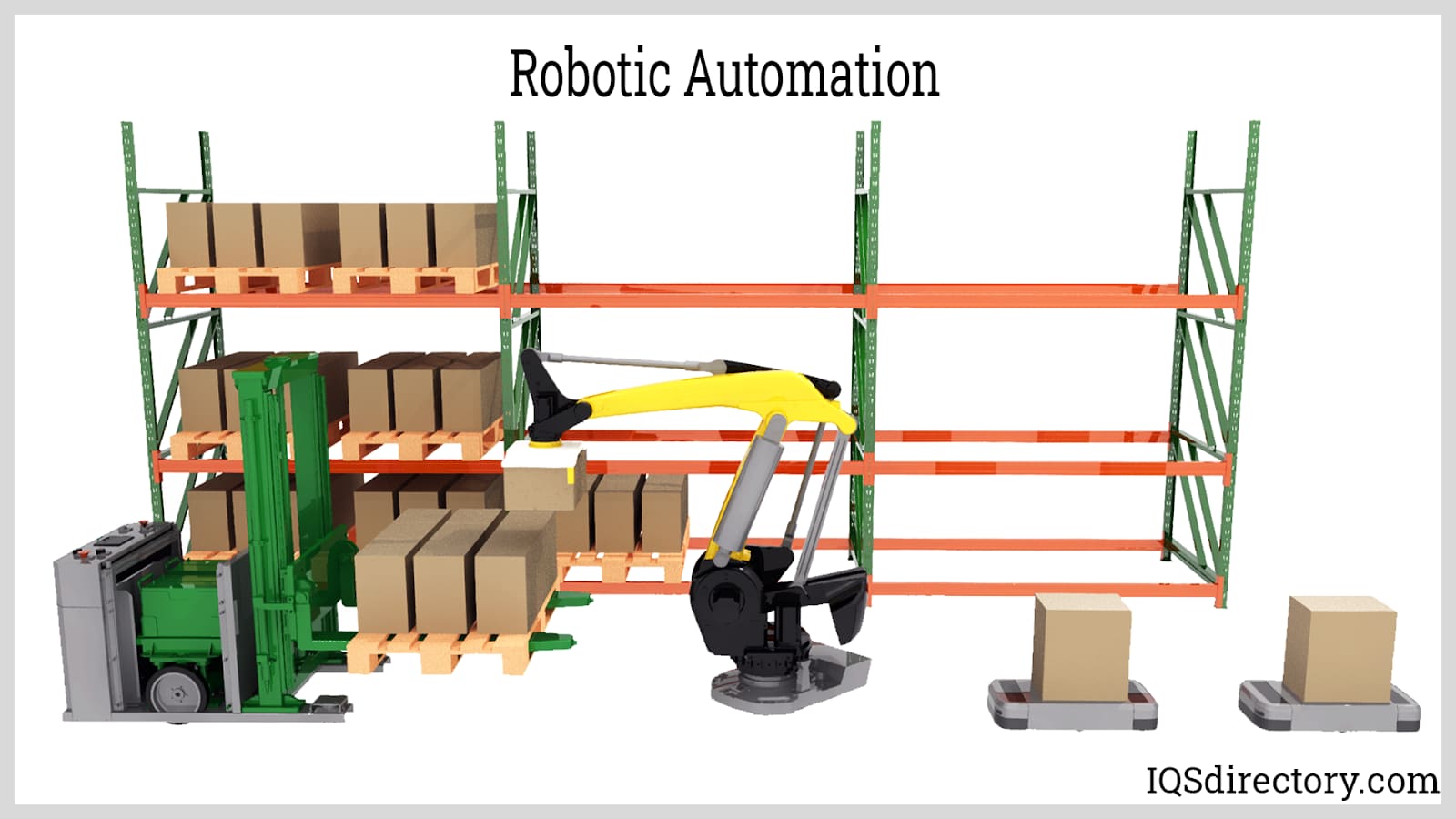

Physical automation technology reduces the time spent by staff moving around the warehouse, leading to more efficient workflow setups. Robotics enhance both the warehouse's capacity and efficiency, fortifying service reliability and scalability. Nevertheless, it comes with high upfront costs, a lack of skilled operators, and costly maintenance for equipment often designed for specialized applications.

For organizations to leverage automated warehouse systems effectively, careful planning and strategic organization are essential. Such systems are particularly beneficial for large-volume warehouses and distribution centers that can accommodate specialized automation equipment.

Warehouse automation is broadly classified into physical and digital categories. Digital automation harnesses electronics and software to reduce manual work and streamline vendor and customer management. Digital automation examples include warehouse management systems and automatic identification and data capture (AIDC) technologies.

In practice, digital automation enhances security features, reduces risks—both legal and operational—and provides more efficient enterprise resource planning alongside improved safety. Though it decreases human errors and the need for manual work, implementing digital robotics involves substantial initial investments, including support contracts and training for staff, as well as system setup costs.

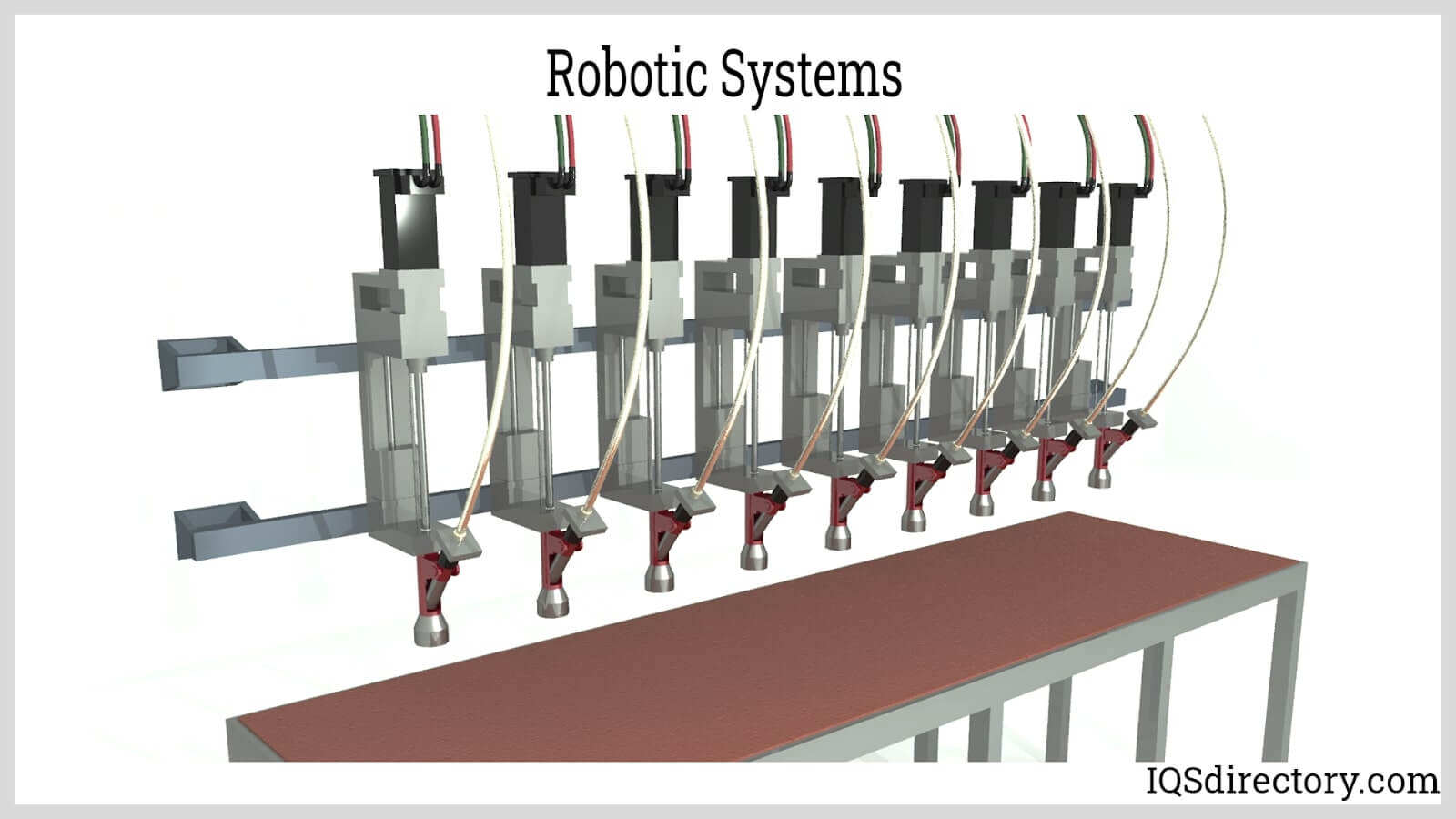

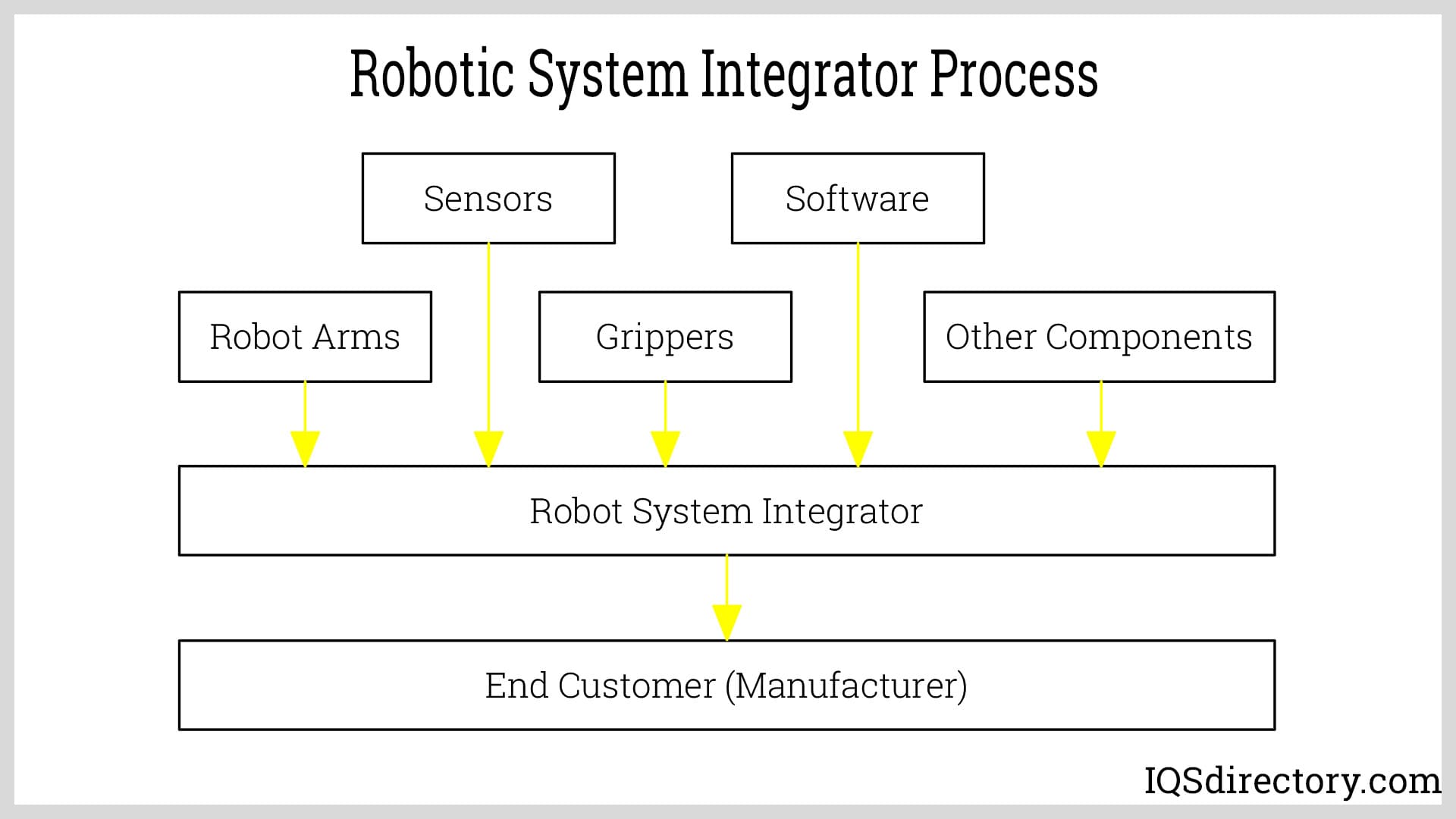

In contrast, physical automation lessens the labor demand on employees through advanced warehouse equipment. Examples encompass automated guided vehicles, manufacturing robots, and robotic systems integration, facilitating the transport of goods with minimal employee effort, thus boosting efficiency and storage capacity.

Physical automation with robotics also lends scalability, enhances reliability, and boosts performance levels. Yet challenges include a limited skilled workforce to operate and handle the technology, large initial financial outlays, and elevated maintenance expenses.

This chapter explores the different levels of warehouse automation and the primary drivers behind its adoption in modern supply chain management and intralogistics environments.

The evolution of warehouse automation can be segmented into multiple levels, each defined by the degree to which technology streamlines warehouse operations.

Low automation in a warehouse or factory is characterized by manual processes that heavily rely on human personnel. Warehouse workers are responsible for physically moving inventory, data collection, operating equipment, and constructing products. While low-automation facilities may feature some basic automated tools—such as barcode scanners or conveyor belts—they often suffer from inconsistent productivity, higher risk of human error, limited working hours, elevated labor costs, high worker turnover, defective parts, and unexpected production stoppages. In environments with limited automation, supply chain optimization is challenging, leading many companies to explore advanced material handling equipment and automation solutions.

Implementing a warehouse management system (WMS) combined with robotics transforms traditional processes. A WMS is a comprehensive software platform that manages warehouse operations and logistics flows, optimizing inventory tracking, inventory control, and storage location assignment. The integration of robotics with a WMS—such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs)—allows for seamless movement of goods, improved picking accuracy, and streamlined replenishment processes. From goods receipt to order fulfillment, robotics-powered WMS maximizes warehouse efficiency, space utilization, and real-time data access, while reducing labor costs and minimizing product handling errors. This level of automation is crucial for e-commerce fulfillment centers, third-party logistics providers, and manufacturers seeking scalable solutions.

Advanced warehouse automation leverages sophisticated technology such as industrial robots, collaborative robots (cobots), automated storage and retrieval systems (AS/RS), and conveyor automation to manage complex operations. With programmable automation protocols executed throughout the work cycle, these systems handle everything from picking and sorting to packaging and shipping. Advanced automation is often enabled by machine learning, artificial intelligence (AI), and warehouse execution systems (WES) that orchestrate the movement of products across the facility. The result is higher throughput, faster order processing, improved inventory accuracy, increased safety, and significant cost reductions. This level of automation is especially prevalent in high-volume distribution centers, omnichannel warehouses, and manufacturers with just-in-time logistics requirements.

Modern business demands, rising labor costs, changing consumer expectations, and the need for operational efficiency are prompting companies to adopt warehouse automation solutions. Automated storage and retrieval systems (AS/RS), coupled with advanced inventory management, not only boost receiving, storage, and distribution productivity but also minimize warehousing costs, enhance workplace safety, and support supply chain resilience in dynamic markets.

Key automated warehousing technologies and trends currently impacting the industry include:

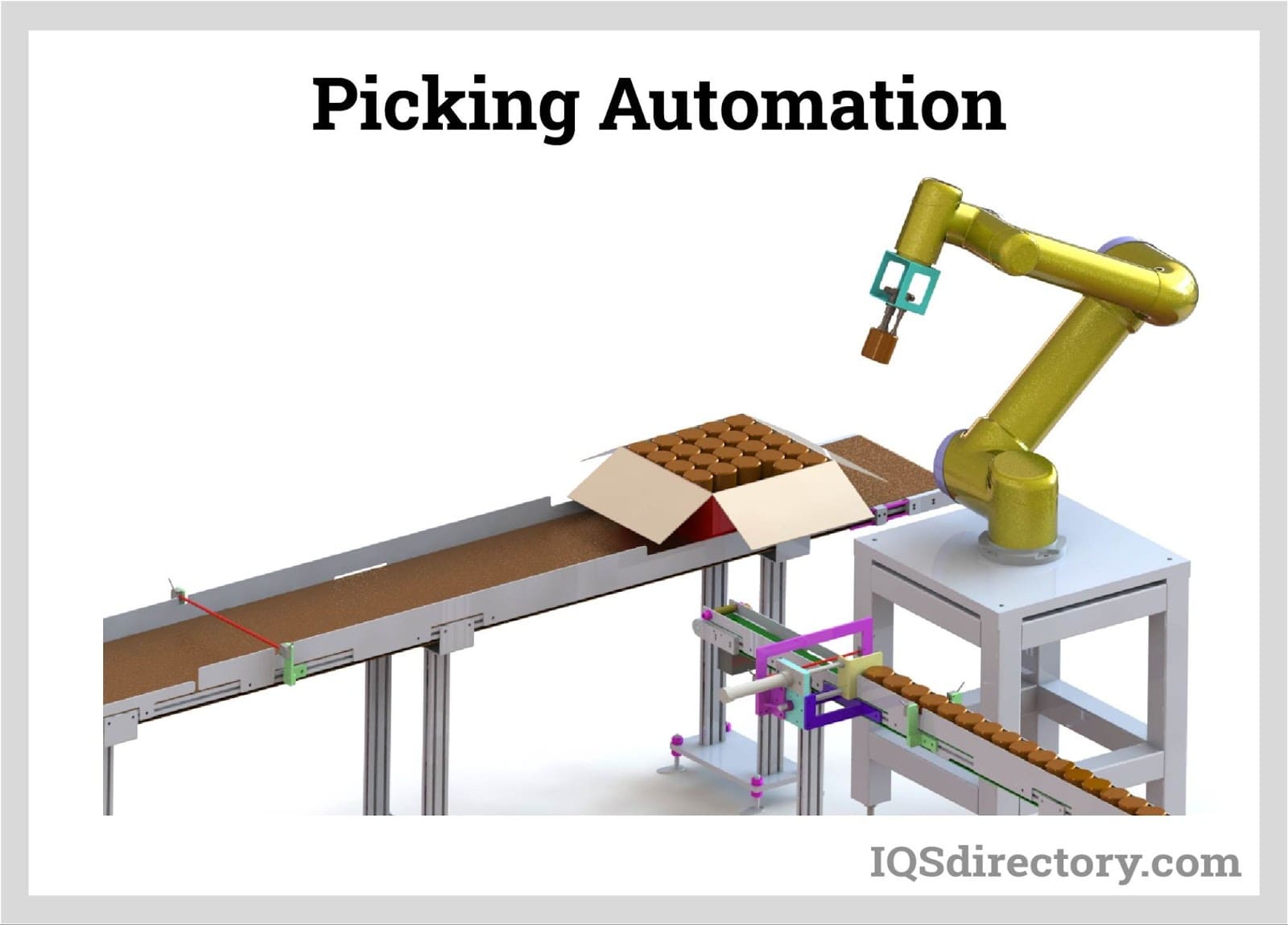

Order fulfillment and picking remain some of the most labor-intensive warehouse activities, with direct impacts on delivery speed and accuracy. Traditionally, staff members manually locate and retrieve required SKUs, using carts or other manual material handling equipment, before packaging and shipping orders. Automated order picking systems—such as Goods-to-Person (GTP) solutions, automated picking robots, and robotic shuttle systems—transform this process by reducing travel time, boosting picking accuracy, and speeding up order assembly. By leveraging picking automation and robotics integration, warehouses can maximize throughput, reduce errors, and meet rising e-commerce demands for rapid order fulfillment. Mini-load AS/RS systems and carton flow systems are particularly effective for operations with high SKU counts and frequent order turnover.

Automated material handling systems, such as conveyors and robotic arms, perform pick and place operations, precisely moving products between storage, sorting, and shipping areas. Integrated warehouse automation systems not only accelerate product movement but also provide real-time inventory monitoring and quality management, crucial for ensuring order accuracy and customer satisfaction.

The repetitive nature of transferring goods within warehouses and distribution centers requires substantial labor resources. By streamlining transportation activities and adopting automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and overhead conveyor systems, companies can significantly reduce manual handling and improve operational flow. These automated transportation solutions enable warehouses to reassign workers to higher-value tasks such as process improvement and exception management.

Popular internal transportation technologies include roller conveyors for cases and totes, and pallet conveyor systems for bulk movement. Automated guided vehicles and AMRs efficiently navigate warehouse aisles, transport products between storage and production zones, and enhance material flow without the need for human intervention. These automation strategies are key for facilities aiming to optimize space, reduce transit times, and maintain consistent throughput.

Dark warehouses represent the pinnacle of full-scale warehouse automation, operating without the need for human intervention or lighting. These highly automated distribution centers utilize a combination of robotics, AS/RS, conveyor networks, and advanced control software to achieve 24/7 operation and maximum throughput. As businesses pursue supply chain digitalization and resilience, dark warehouses offer advantages such as lower energy consumption, reduced labor requirements, improved resource utilization, and enhanced security.

Additionally, dark warehouse automation supports sustainable supply chain initiatives by optimizing energy use (since lighting is unnecessary), reducing carbon footprints, and minimizing errors that lead to waste. Companies deploying these solutions achieve greater control over inventory, increased productivity, and improved order accuracy—all critical for industries like automotive, pharmaceuticals, and retail facing increasing competition and demand volatility.

Truck loading and unloading are among the most time-sensitive and labor-intensive logistics activities. Automated truck loading and unloading systems—such as telescopic conveyors, robotic palletizers, and automated dock equipment—drastically reduce loading cycle times and limit manual material handling. These conveyor-based and robotic solutions streamline inbound/outbound freight operations, minimize damage, lower labor costs, and improve dock safety.

Often integrated at docking stations, these automated systems rapidly transfer cargo between trucks and the warehouse, supporting higher shipping volumes and more efficient cross-docking operations. This technology is crucial for companies seeking to scale their distribution capacity, reduce lead times, and improve overall warehouse productivity in competitive markets.

Cloud-based SaaS warehouse management systems are transforming logistics by delivering scalable, flexible, and real-time inventory control tools accessible from anywhere. Companies seeking precise control over inventory operations, order tracking, and supply chain visibility increasingly digitize their facilities with advanced WMS software. SaaS WMS platforms allow for rapid deployment, reduced IT overhead, and seamless integration with other enterprise resource planning (ERP) and supply chain management (SCM) systems.

For growing businesses and omnichannel retailers, adopting a cloud-based WMS simplifies automation integration, supports multi-location operations, and empowers data-driven decision-making. According to Grand View Research, the shift toward SaaS WMS is accelerating due to its cost-effectiveness, scalability, security, and ability to provide advanced analytics for inventory and labor optimization.

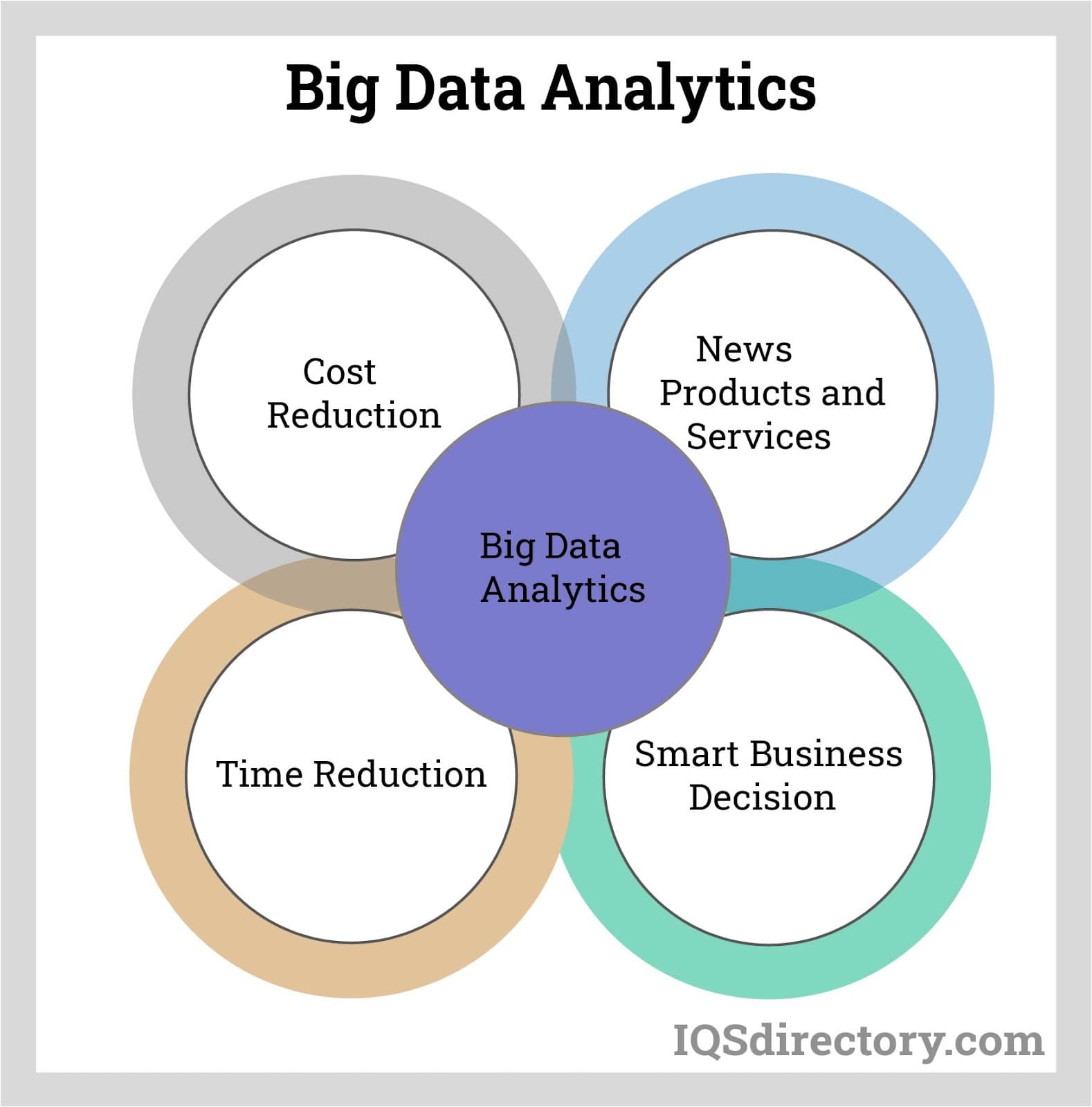

One of the core advantages of warehouse automation is the ability to collect, manage, and analyze large volumes of data—commonly referred to as “big data”—within logistics and supply chain operations. Automated warehouses generate detailed data sets on inventory movement, order cycles, equipment utilization, and workforce efficiency. Leveraging data analytics, artificial intelligence, and machine learning algorithms, companies can conduct predictive analytics, demand forecasting, and process optimization.

Big data is integral to the performance of Automated Storage and Retrieval Systems (AS/RS), supporting enhanced equipment scheduling, route optimization, and real-time KPI monitoring. Access to actionable insights—such as sales trends, SKU velocity, and equipment uptime—enables supply chain managers to proactively address bottlenecks, balance inventory levels, and improve service levels. As the logistics industry adopts Internet of Things (IoT) sensors and connected devices, the ability to harness big data is essential for future-ready warehouse operations and sustainable logistics growth.

When evaluating warehouse automation technologies for your facility, consider factors such as operational complexity, picking volume, SKU diversity, and integration with existing systems. Leading solutions include modular conveyor systems, scalable robotic picking platforms, and cloud-based WMS software. Consult with experienced automation integrators to assess your warehouse’s unique needs and to identify options that support business growth, operational agility, and future scalability. Don’t forget to analyze the return on investment (ROI), implementation timelines, and compatibility with technologies such as RFID, IoT, and machine learning. By taking a strategic approach to automation adoption, you can transform warehouse productivity, boost customer satisfaction, and gain a sustained competitive edge in an evolving supply chain landscape.

The various types of warehouse automation solutions have evolved to address the growing demands of modern supply chain management. Integrating technology-driven innovations not only increases efficiency but also transforms warehouse operations across industries such as e-commerce, manufacturing, and retail. Below, we outline the most prevalent and impactful types of warehouse automation systems, along with their key benefits and considerations.

Goods-to-person (GTP) automation is one of the most commonly utilized methods for reducing warehouse congestion and maximizing operational efficiency. These systems rely on technologies such as carousels, automated conveyors, shuttle systems, and vertical lift modules to streamline fulfillment processes. By bringing goods directly to operators at ergonomic workstations, GTP solutions significantly enhance warehouse picking speed and throughput rates.

Lightweight products are efficiently stored within the automated system and are automatically transported to the picking station. This drastically reduces walk time, ensuring optimal productivity and accurate pick and inventory tracking. Advanced GTP systems can be seamlessly integrated with robotics, artificial intelligence, and warehouse management software (WMS) for fully automated, data-driven piece picking and order fulfillment operations.

In addition to providing real-time visibility on workstation screens—which guides operators to the exact items and quantities needed—GTP automation minimizes costly order errors common in high-velocity fulfillment centers. Its scalable architecture enables easy adaptation to changing business needs and fluctuating order volumes.

Some of the core advantages of goods-to-person automation include improved warehouse space utilization, faster order processing, dynamic system functionality, and robust integration with other warehouse technologies. Other benefits include storage density consolidation, increased uptime, and predictive analytics for continuous process improvement. Key considerations for successful GTP implementation involve evaluating peak season requirements, facility layout constraints, IT infrastructure compatibility, floor slab load bearing, throughput targets, and long-term business goals.

Warehouses considering GTP should also assess maintenance requirements, anticipated ROI, and the potential for future automation upgrades to stay competitive.

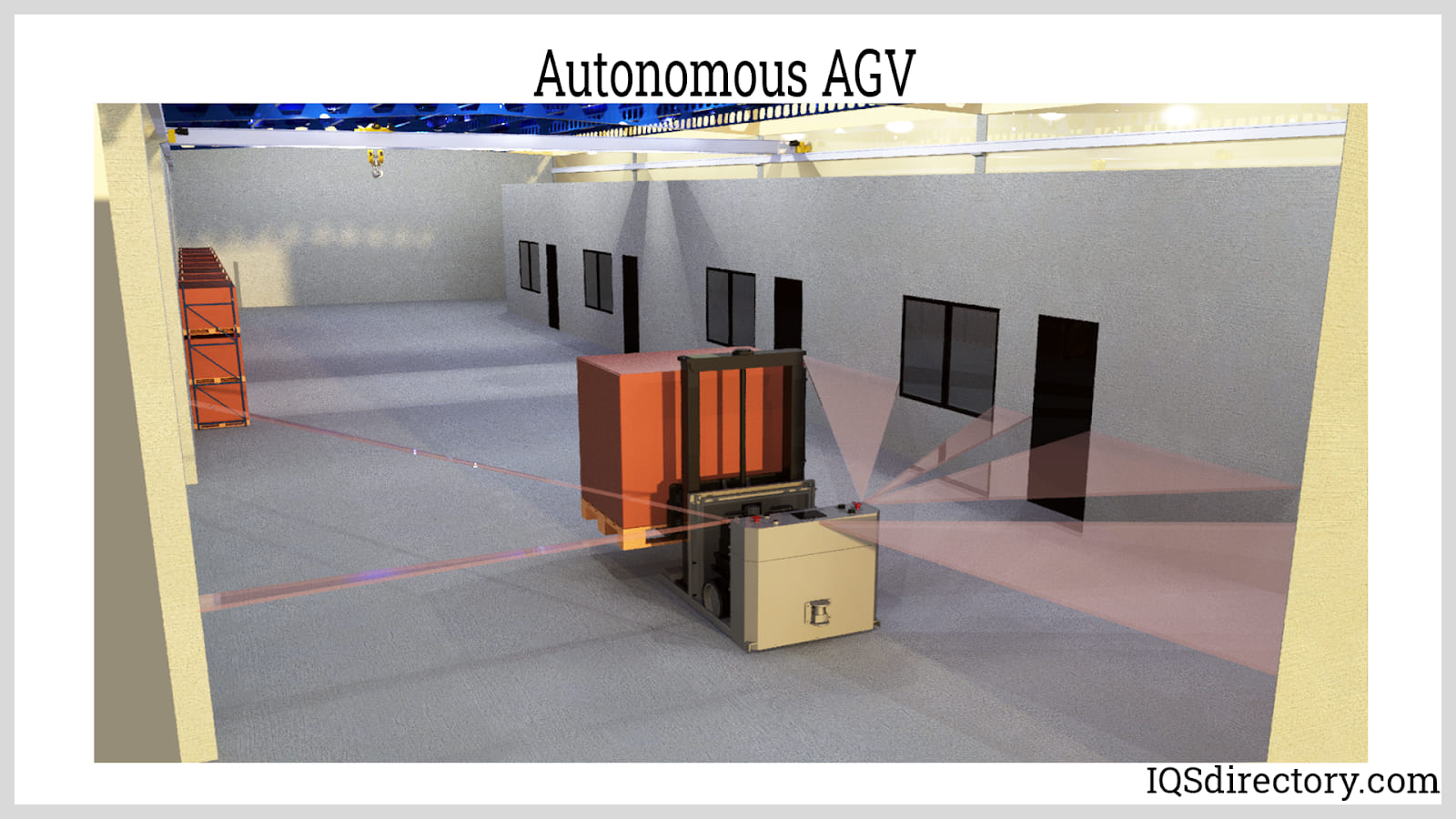

Automated Guided Vehicles (AGVs)—also referred to as mobile robots—are self-contained load carriers engineered to move autonomously throughout warehouse facilities. Unlike fixed robotic arms, AGVs are not confined to stationary tasks, enabling agile, flexible movement across diverse operational zones. These automation platforms are commonly integrated with material handling systems to streamline warehouse transport, reduce labor costs, and facilitate end-to-end process automation.

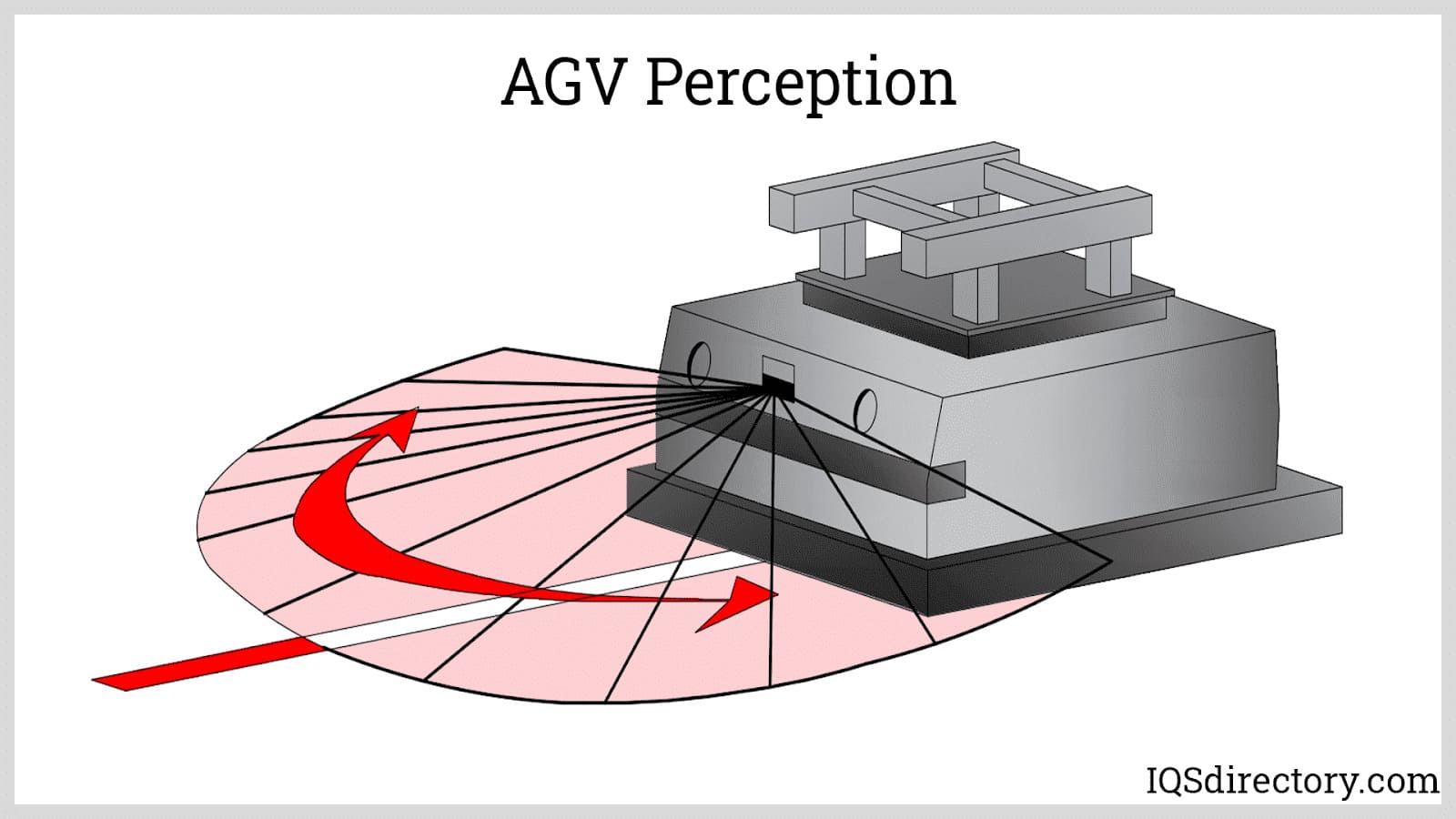

The sophisticated design of AGVs incorporates cutting-edge guidance and navigation systems, including path planning algorithms, obstacle detection sensors, localization capabilities, and motion control technologies. Automated guided vehicles help optimize workflows in environments such as manufacturing plants, logistics centers, and distribution warehouses. Below are the primary categories of AGVs deployed in warehouse automation solutions:

These robust, highly flexible vehicles excel in environments demanding precise navigation and adaptability. Their modular nature allows for easy system scalability and integration into existing automation infrastructures.

Automated forklifts revolutionize pallet handling by stacking and moving palletized goods at variable heights. They are ideal for both ground-level pallet transport and automated high-bay racking operations.

Automatic guided vehicles (AGVs) autonomously transport inventory—ranging from raw materials to finished goods—using computer-control systems and various sensor-based safety mechanisms. AGVs follow defined pathways, adapt movement speeds, and leverage collision-avoidance technologies to ensure workplace safety and efficiency. These vehicles are crucial in supporting robotics manufacturing lines, as well as facilitating just-in-time inventory supply for picking, staging, and replenishment processes within fulfillment centers.

Also known as automated guided carts (AGCs), these compact, flexible vehicles operate by navigating beneath carts or baskets and gently lifting them for transportation. Commonly found in hospital automation and light manufacturing, they automate repetitive delivery tasks for medical supplies, food service, and linens.

Also referred to as tagger-guided vehicles, towing AGVs efficiently pull unpowered trailers or carriers, streamlining large-scale material transfers. While they excel at high-capacity load movement and route consolidation, they are generally not used for precise load positioning within racks or storage systems.

Designed to transport palletized or containerized inventory without engaging in active lifting, unit load AGVs partner with automated conveyors, stacker cranes, and robotic arms to drive pallet flows in high-density storage environments.

These highly maneuverable, tunneling vehicles specialize in delivering parts and assemblies directly to workstations. Their precision navigation simplifies integration into sophisticated manufacturing and assembly operations.

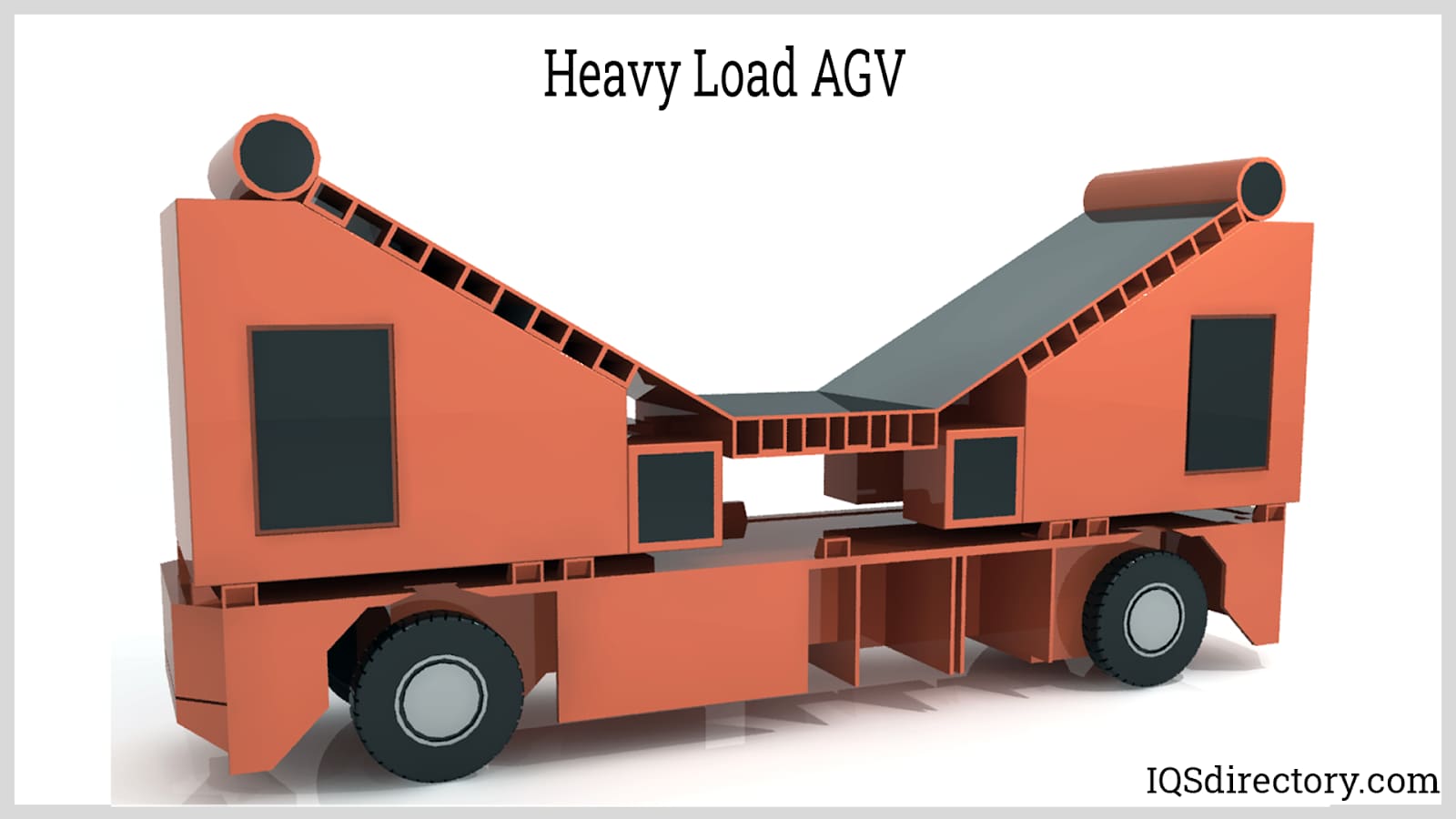

Engineered for rigorous industrial applications—including steel and paper mills—these AGVs transport massive loads with enhanced safety and durability. Their robust construction, advanced navigation, and load management features meet the requirements of demanding warehouse environments.

Also called small load carriers, mini AGVs are lightweight vehicles designed for fast, flexible movement of small parts or bins. Often deployed in automated racking systems and zone-to-zone picking scenarios, they boost productivity through high-speed travel and agile maneuverability.

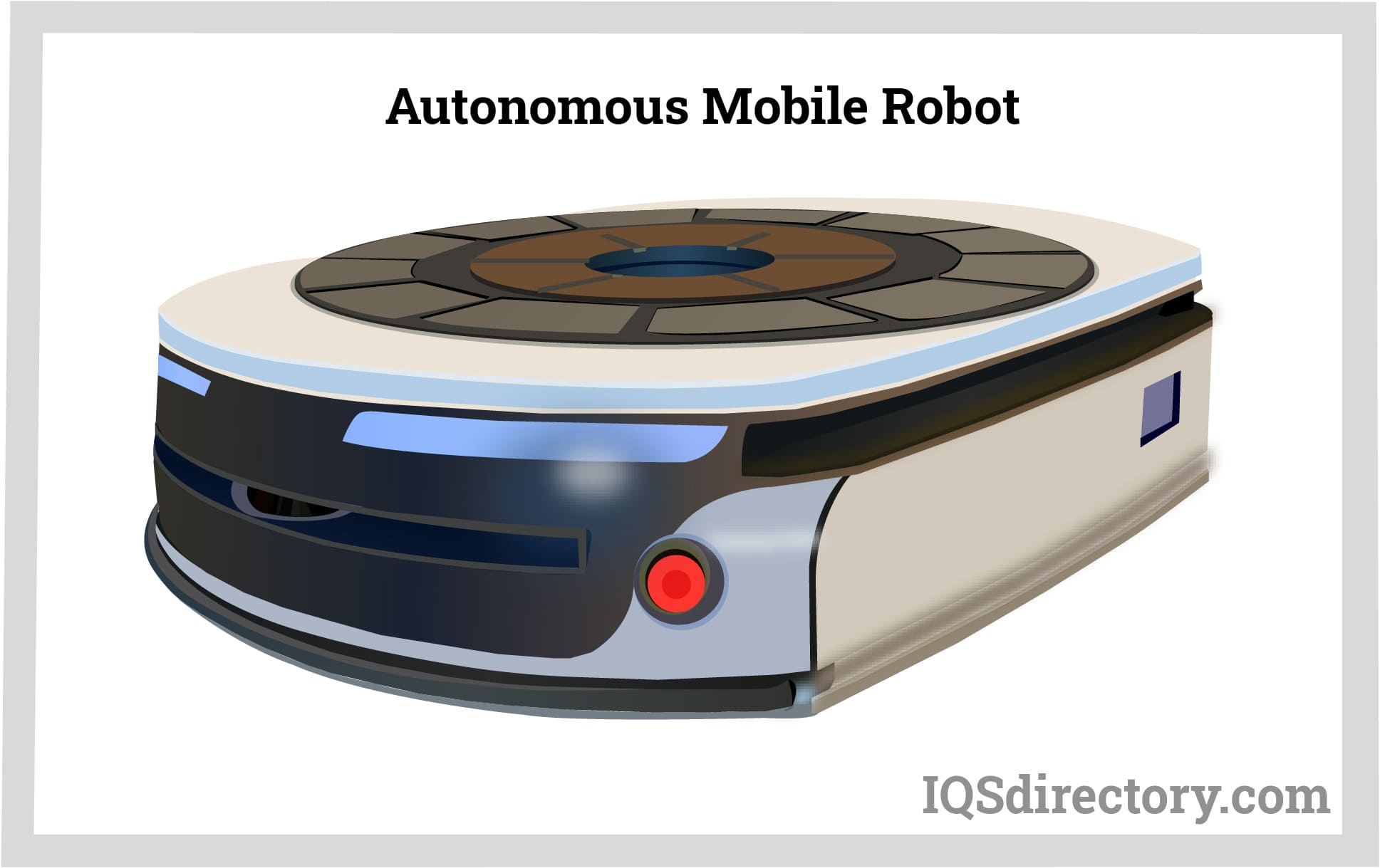

Autonomous mobile robots (AMRs) represent the next generation of smart, flexible warehouse robots. Equipped with advanced sensors, onboard processing, and real-time mapping technology (such as LiDAR and simultaneous localization and mapping – SLAM), AMRs independently navigate complex warehouse layouts without fixed guidance systems. Their main objective is to automate repetitive tasks—such as pallet movement, order picking, and item replenishment—enabling employees to focus on high-value, exception-based tasks in the warehouse.

Unlike AGVs, which follow rigid, predefined paths, AMRs can dynamically adjust routes and operate collaboratively in shared workspaces. This flexibility makes them ideal for modern distribution centers, e-commerce fulfillment operations, and environments characterized by high inventory variability and SKU proliferation.

The use of AMRs in logistics automation offers significant advantages, including:

Another important benefit of using autonomous mobile robots is improved warehouse safety through built-in safety sensors, cameras, and collision-avoidance algorithms. Additionally, AMRs support warehouse digital transformation by enabling integration with cloud-based inventory management platforms, real-time analytics, and predictive maintenance systems.

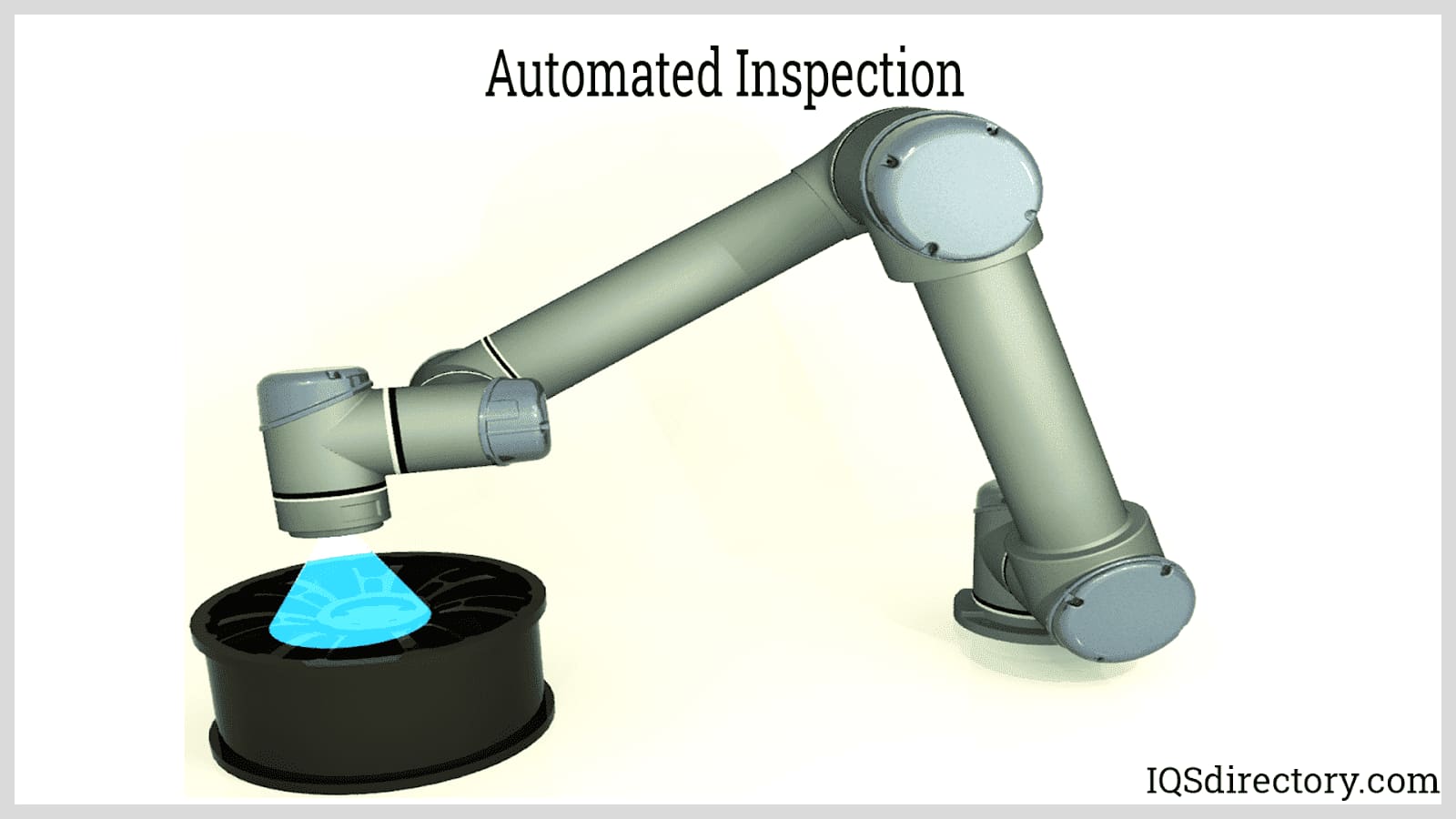

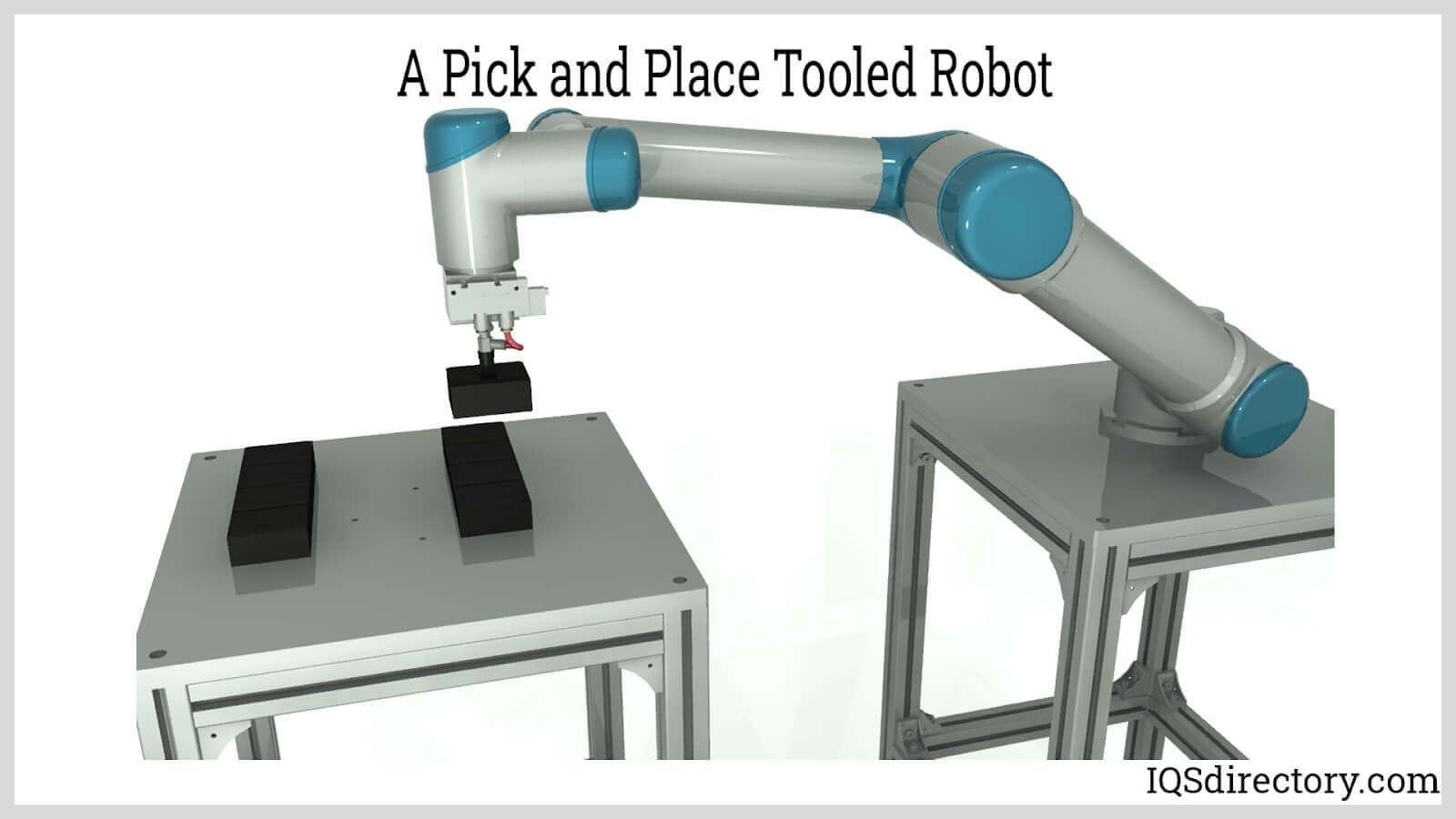

Warehouse robotic arms leverage machine learning and AI to deliver rapid, precise material handling. Automated picking robots are a key part of robotics automation in order fulfillment, as they drive efficiency in labor-constrained warehouses. Robotic arms are now used for a wide variety of applications—including automated sorting, case packing, order consolidation, bin picking, and handling diverse package types for e-commerce fulfillment.

While robotics and automation technology are not expected to completely replace human labor, advancements in computer vision, deep learning, and gripping mechanics continue to expand the available use cases. As labor shortages persist and order volumes rise, more warehouses are deploying robotic arms to keep pace with demand, improve workplace safety, and reduce repetitive strain injuries among workers.

Recent innovations—such as the "Sensitive Cobotics" LBR iisy cobot showcased by KUKA Robotics at IMTS 2022—enable rapid integration into existing warehouse systems. These collaborative robots (cobots) can perform both routine and complex tasks, adapting to hybrid environments where they work safely alongside human staff. Their versatility, coupled with advanced safety features, makes them an essential part of scalable warehouse automation solutions.

Smart robotic palletizers are engineered to automate the process of loading and unloading goods onto pallets based on custom stacking patterns, order requirements, and SKU diversity. A robotic palletizer efficiently manages multi-SKU order fulfillment, using machine vision and AI-driven algorithms to select, arrange, and stack items. Robots can be trained to handle high-velocity applications, maintain high throughput (8 to 30 cases per minute or more), and handle both case and layer picking. Robotic depalletizers help automate the unloading process and integrate with downstream packaging and shipping systems.

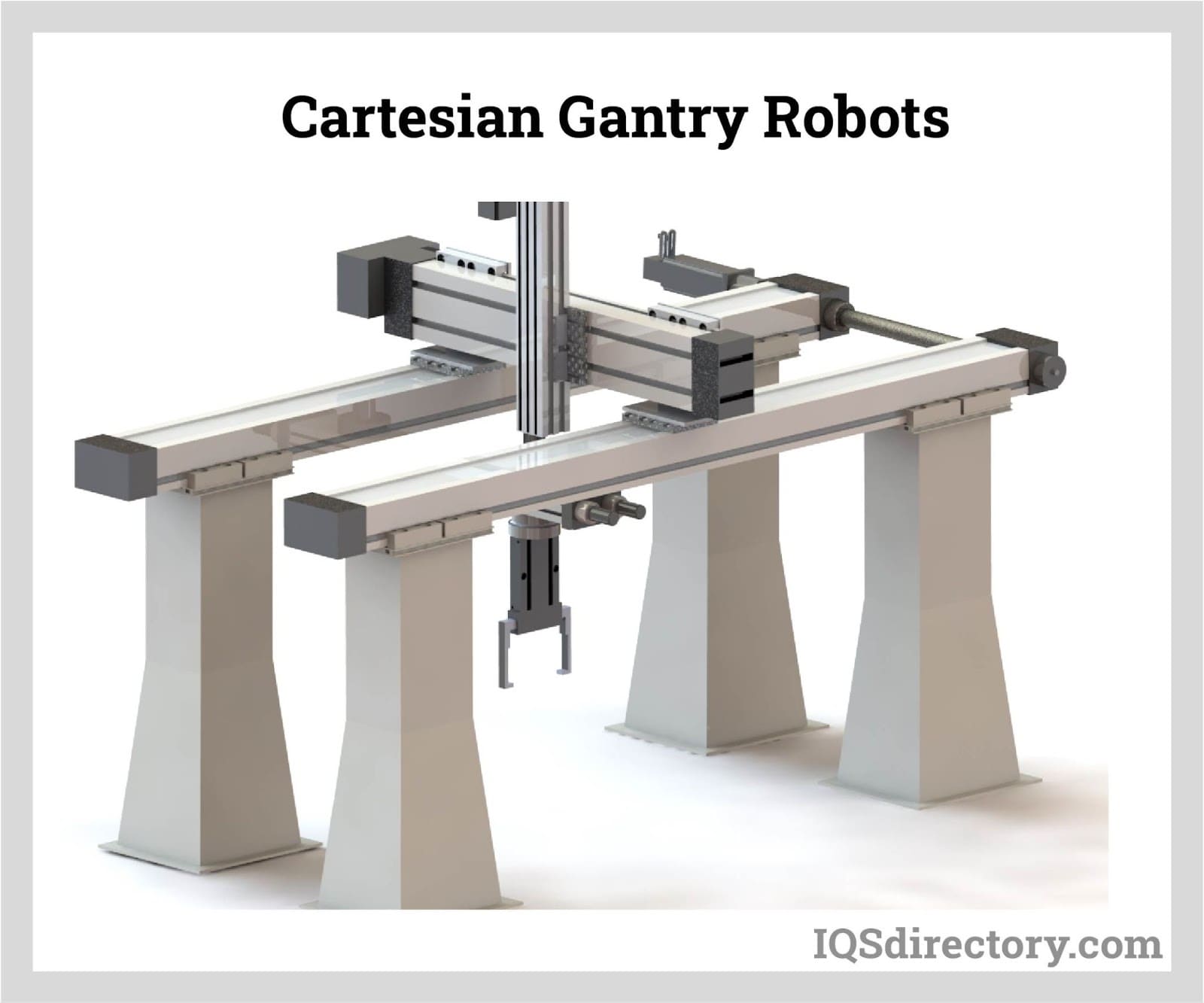

Cartesian gantry robots (sometimes simply called gantry robots) provide scalable, high-precision solutions for automated material handling, assembly, palletizing, and pick-and-place operations. Their simple construction—linear movement along X, Y, and Z axes—enables them to maximize cubic storage space utilization, making them ideal for high-bay warehouses and automated pallet storage systems.

Gantry robots are typically mounted on overhead rails or frame structures and can be tailored to warehouse size, load weight, and automation requirements. They are well-suited for large-scale handling and can interface with conveyor belts, gearboxes, and other automation components for advanced logistics solutions.

Key benefits of Cartesian gantry robots include:

Potential limitations to consider:

Automated Storage and Retrieval Systems (AS/RS) are high-density warehouse automation solutions engineered to improve product storage, inventory control, and order fulfillment accuracy. These systems use configurations such as shuttles, cranes, vertical lift modules (VLMs), and carousels to manage the storage and retrieval of goods with minimal human intervention. AS/RS solutions are vital components of sophisticated distribution centers and automated warehouses seeking to maximize space, reduce headcount, and increase workflow efficiency.

AS/RS enable just-in-time inventory management and are readily scalable to changing order profiles and SKU mixes.

Pick-to-light and put-to-light systems use illuminated visual aids and barcoding to direct operators through the picking or placement process. These light-directed picking solutions increase warehouse throughput, improve order accuracy, and shorten employee training time. With a pick-to-light system, an employee scans a barcode to access the specific order details associated with it. Lights mounted on storage racks then guide workers to the correct products and locations for order fulfillment.

Pick-to-light and put-to-light systems operate as complementary technologies—pick-to-light directs employees to items to be picked, while put-to-light assists in guiding proper placement of materials. The advantages of these light-guided picking solutions include:

These systems are highly adaptable to multi-zone picking, batch picking, and high-SKU environments often found in ecommerce order fulfillment.

Voice-directed warehouse systems utilize speech recognition and wearable headsets to communicate picking instructions and streamline task execution. Integrated with ERP systems or advanced warehouse management systems (WMS), voice-directed picking improves productivity, safety, and accuracy by guiding employees through warehouse workflows hands-free and in real time.

After receiving an order, the system automatically conveys verbal instructions for picking or inventory tasks to workers, who confirm completion using voice responses. Benefits of voice picking and voice tasking solutions include:

Automated sortation systems employ sensor-based conveyor technologies, barcoding, and scanning to automatically route items to their correct storage or shipping destination. Sortation automation eliminates manual sorting labor and accelerates order throughput, which is crucial in high-volume fulfillment centers and last-mile distribution facilities.

Collaborative mobile robots—or cobots—are designed specifically to operate safely alongside human workers, performing repetitive or physically demanding tasks such as palletizing, packing, inspection, and order picking. By automating these time-consuming warehouse processes, cobots reduce error rates, boost productivity, and allow employees to focus on activities that require decision-making and problem-solving skills. Their compact design and adaptive capabilities make cobots an ideal solution for tight warehouse spaces and dynamic fulfillment environments.

Warehouse drones, a fast-growing addition to warehouse automation, are used for airborne inventory management and cycle counting. By utilizing barcode scanning technology, drones can complete inventory checks, identify misplaced items, and prompt restocking notifications in real-time. Some warehouse automation innovators are piloting drone technology for last-mile delivery and intra-facility shuttling of goods as well. While drones currently offer more value in inventory monitoring than in transportation, their application in real-time data collection and logistics automation is rapidly expanding.

As warehouse automation technologies continue to evolve, selecting the right mix of solutions—including AGVs, AMRs, robotics, WMS integrations, and analytics-driven management tools—remains key for businesses seeking to maximize efficiency, reduce operational costs, and meet rising customer expectations in the global supply chain.

This chapter will discuss the reasons to automate a warehouse and how to automate it.

An inefficient warehouse can significantly impact customer experience. Automated warehouses, on the other hand, can handle more tasks with fewer resources and adapt well to increasing customer demands. Automation in warehouse operations offers numerous advantages, including reducing errors and enhancing overall efficiency.

Some frequently cited benefits of warehouse automation include reduced operational costs and labor, improved customer service, minimized human error, increased employee satisfaction, better resource utilization, and fewer shipping errors. Additionally, automation enhances order fulfillment through improved material handling and coordination.

Automating a warehouse requires a comprehensive project plan. Key elements to consider include identifying all stakeholders, conducting a risk assessment, creating a project schedule, and analyzing deliverables and goals. The process begins with forming a support team and appointing a project manager. This team will develop the project schedule, establish a timeline, and create a deliverables calendar. Additionally, implementation support plans are essential for successful execution.

Feedback from all management levels, including warehouse managers in various locations and corporate leadership, is crucial. Additionally, selecting the automation solution that best fits the business needs is essential. Thorough research and evaluation of different automation options are necessary. The process of warehouse automation can be broken down into the following steps:p>

Formation of an implementation team – This team should consist of stakeholders with deep knowledge and experience regarding the current capabilities, challenges, and performance of the warehouse. The team must be adept at identifying technology gaps that need to be addressed. Additional experts with extensive experience in supply chain and demand automation relevant to warehouse operations can be included.

Collection of critical data – Successful warehouse automation heavily relies on supply chain operations and critical business processes. Prior to implementing automation technology, it is essential to assess the current data infrastructure and collection procedures. This assessment ensures that ownership of data is assigned to skilled information technology stakeholders.

Evaluation of inventory controls – Inventory control is central to warehouse operations. Standard operating procedures must be established before implementing the warehouse automation solution. These procedures should cover shipping, purchasing, receiving, inventory loss, and customer satisfaction. To measure the success of automated procedures and processes, key performance indicators (KPIs) must be defined.

Implementation of a warehouse management system – The warehouse management system (WMS) software is designed to track and manage inventory, reduce labor costs, oversee warehouse operations, and enhance customer service. The chosen system should integrate seamlessly with existing software and support mobile devices.

Determining the best automation solution – Choosing a warehouse automation solution is crucial. It must align with the company's specific goals and meet customer demand.

Best practices for warehouse automation include:

Make sure that the warehouse automation solutions you choose can integrate with a WMS platform. Look for solutions that automate inventory control, manage inventory, track and report labor costs, and connect dashboards. Familiarize yourself with WMS features and understand the differences between warehouse management and inventory management.

Invest in scalable solutions, as technology should evolve with your company. The system should accommodate future expansions, including additional warehouses, personnel, tools, and supply chain partners such as third-party logistics providers or drop shippers.

Begin with a system that automates data collection, transport, and storage, regardless of the type or extent of automation technologies you plan to explore. Combining cloud-based technologies with portable barcode scanners offers a low-cost, low-risk approach to automation. This setup allows you to collect essential warehouse performance and inventory data, store it in a consolidated cloud database for analysis, and reduce human error.

Cycle counts are an essential part of any warehouse management system, used to compare actual inventory levels with inventory data records. With automated data collection systems, you can use mobile barcode scanning or RFID sensors to perform continuous cycle counts. This data can then be reviewed for inconsistencies using dashboards.

Since receiving is the starting point for warehouse data collection, it’s important to have a system that captures as much information as possible upfront to guide warehouse activities. Assess the dimensions, classifications, and packaging of incoming goods before establishing rules in the WMS for managing, storing, and allocating resources.

For physical automation technologies like GTP and AS/RS systems, AGVs, and sortation systems to be effective, the warehouse must have a precise layout and ample space. Consider redesigning existing warehouses and distribution centers to better accommodate these technologies. Collaborate with solution providers, architects, and contractors who understand your specific needs. Ensure that this evaluation is included in your implementation budget.

With advancements in technology, companies now have access to a broader range of warehousing technologies than ever before. From logistics automation robotics and depalletizing robots to storage and order picking systems, these 21st-century automated solutions offer cost-effective methods for handling products and supporting assembly line automation and supply chain operations.

The market for robotics integrators and logistics automation is diverse, with many companies offering varying levels of technological skills and expertise. The effectiveness of these integrators often hinges on the design of their services, the type of software they use, and their control systems. While many companies may claim to have the tools for robotic integration, they might lack the necessary expertise. Customers seeking warehouse automation systems should thoroughly evaluate different providers and choose one with the expertise to meet their specific needs.

Formic aims to simplify and make robotics integration accessible, saving time, money, and labor costs. Their robotics systems offer a range of labor-saving logistics automation solutions, utilizing advanced robotics technology. Formic provides robotics for applications such as advanced manufacturing, consumer packaging, and other industrial uses, allowing companies to enhance their manufacturing capabilities with minimal risk.

Dematic is a supplier of automated technologies and software for manufacturing, supply chain, and distribution centers. The company offers automated storage and retrieval systems for inventory management and utilizes advanced technologies in robotic mechatronics, guidance systems, and AI for automatic palletizing and depalletizing. Their fully robotic systems are designed to eliminate labor. Dematic serves companies of all sizes—small, medium, and large—providing robotic technology to enhance product flow and production efficiency.

Vanderlande has extensive experience in warehouse logistics automation and automated material handling systems, offering a wide range of solutions for parcel center logistics. Their integrated solutions provide fast, reliable, and innovative technologies to help customers improve operational processes. Recently, Vanderlande has focused on e-commerce and has become a leading choice in logistics automation systems for this sector.

Knapp is a leading provider of warehouse robot integration systems and logistics software. The company specializes in automation solutions for small item fulfillment, variability operations, and various AGV systems. Knapp's main goal is to deliver innovative robotic integration methods tailored to the specific needs of customers. With a highly trained team of experts and engineers, Knapp designs, implements, and refines warehouse solutions for a wide range of customers and operational conditions.

SSI Schaefer aims to provide comprehensive, end-to-end automated systems for large-scale integrated warehouse automation. Their wide array of warehousing and supply chain solutions includes flat pack picking, single piece picking robotics, and AGV and AMR robot integration. The company offers automated solutions for picking, conveying, shipping, storage, and material handling, utilizing customized technologies and systems.

Emerging technologies and robots have significantly improved businesses and their supply chains by enhancing the timeliness and accuracy of product information. Warehouse robotics primarily involves the implementation and ongoing use of automated systems. Historically, automation was used to reduce headcount, but now companies are struggling to maintain sufficient staff due to rising labor costs. Although industrial robots have been in use for many years, their capabilities and equipment were previously quite limited.

Emerging warehouse robots utilize artificial intelligence to navigate facilities effectively. They can work alongside humans to pick up or drop off items. Various types of warehouse robotics systems are employed, including facility management robots that can mow lawns or mop floors, autonomous drones that can access high shelves and deliver items, and static robotic systems designed for picking, pulling, dropping, and packing orders into boxes or containers. Robots play a crucial role in warehouses, performing a range of important tasks, which are listed below.

Sorting – Sorting might appear straightforward for workers, but its automation involves a complex process. Automated robots in the warehouse are equipped with sensors, cameras, conveyors, arms, and software that enable them to identify specific items and direct them to the precise location for storage, retrieval, or disposal. Artificial intelligence sorting systems are integrated with these picking robots to accurately sort batch-picked items into their required order components.

Packaging – Warehouse automation includes bagging machines and automated robots equipped with customization software to reduce packing time. These systems utilize length and weight dimensions to determine the optimal carton size for specific orders and guide associates through the correct packaging process.

Transportation - Carting items from one side of the factory to the other is often a significant task. Warehouse automation systems reduce the time workers spend on this chore, allowing them to focus on more critical tasks. Robotics, such as automated guided vehicles (AGVs), help reduce the stress and human labor associated with manual transportation. These robots can move order items from their designated zones to sorting areas. They serve various functions, including acting as conveyors to transport bins, boxes, and other items, or as monorails to move pallets and similar goods.

Replenishment – Warehouse robots can enhance workflows by minimizing backorders and stockouts through automated reordering processes. They monitor inventory levels and issue notifications when stock drops below a predetermined threshold.

As a result, the following developments in robotics and automation are transforming the modern warehouse:

In the first quarter of 2020, investments in warehouse robotics companies surged by 57%, exceeding $380 million. In a post-pandemic economy and in regions like Japan, where there is a shortage of workers, the adoption of warehouse robotics is expected to continue growing.

Cobotics refers to the collaboration between humans and robots, combining robotics with cooperative efforts. Cobots, designed to work alongside people, do not replace human workers. In warehouse automation, AMRs (Autonomous Mobile Robots) are a type of cobot that can scan their environment. With a 360-degree range of view, these cobot AMRs detect changes to avoid accidents with people and human-operated equipment, and can safely reverse when necessary.

To address the need for flexible warehouse management and automated technologies such as autonomous robots, service-based warehouse marketplaces are growing. Companies offering subscription-based, fully automated warehouse solutions are challenging traditional producers and service providers of automated equipment and systems.

Intelligent drone fleets, powered by advanced algorithms and integrated with cloud-based warehouse management systems, can effectively manage inventories within warehouses. These drones often come equipped with vision sensors or barcode scanners to handle inventory management tasks and automate processes such as cycle counting.

Blockchain technology is a secure, automated network that uses cryptography to record data transfers in blocks on a public digital ledger. Though still in its early stages, blockchain offers sophisticated data authentication, validation, and transparency that can significantly impact warehouse operations and inventory management. With shared data storage accessible to all participants within the secure network, blockchain databases could allow every entity in complex supply chains to connect and exchange permanent, automated records for each transaction.

Amazon is a prominent example of a company adopting GTP systems driven by AGVs and AGRs. Their fleets of autonomous robots can replenish mobile shelving units with stock and transport them to designated locations. This setup allows employees to pick orders with minimal walking or physical activity required.

Automated distribution centers and warehouses are increasingly using autonomous robotic forklifts. It is also expected that automated delivery trucks will extend their reach further up the supply chain, transporting merchandise between warehouses, manufacturers, and retail outlets.

The high demand for rapid online delivery, driven by the "Amazon effect" of one- or two-day shipping, has created a significant need for same-day shipment. This demand continues to drive warehouse automation, which improves the accuracy and efficiency of automated packing and shipping processes and accelerates order fulfillment operations, including picking.

Industrial automation now includes robotic floor cleaners capable of navigating complex warehouse layouts. A new generation of autonomous mobile cleaning robots is emerging, designed to safely clean and disinfect high-touch areas in distribution centers and warehouses using sanitizing chemicals and UV rays.

This capability is made possible by advancements in sensor technologies, cloud databases, and Internet of Things (IoT) applications. Telemetry from onboard computers provides your system with comprehensive information on equipment location, scheduled maintenance, and accident alerts.

Machine learning (ML) and API technologies are facilitating the integration of automation solutions with ERP suites, creating comprehensive end-to-end automated business platforms. Further advancements in automation and ERP software will allow back-office workers to focus on tasks that are more value-added, creative, and customer-oriented.

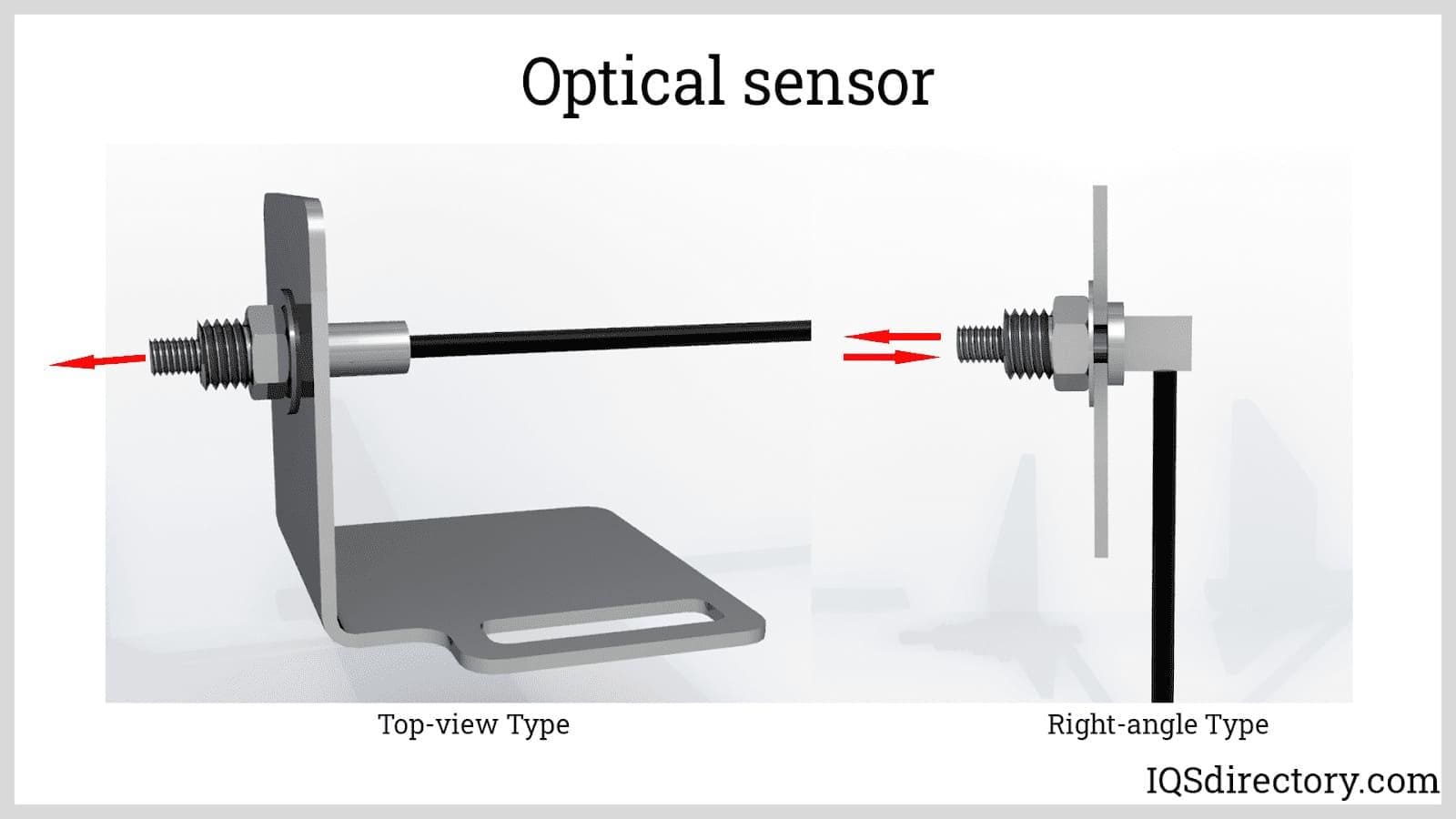

RFID sensors, while not new, remain a crucial element in advancing IoT applications that optimize supply chains and warehouse operations. IoT technology enhances warehouse visibility by providing real-time location information for inventory and equipment. The portability, cost-effectiveness, and real-time tracking capabilities of RFID sensors significantly improve data collection and integration across systems.

The development of cloud-based databases and applications capable of collecting, analyzing, and storing large datasets will advance data analytics for warehouse operations. These technologies make data readily accessible, enhancing insights and decision-making processes.

This chapter will explore the applications and advantages of warehouse automation.

Warehouse automation has a wide range of applications across various industries. It is employed in robotics for manufacturing in sectors such as aerospace, automotive, and agriculture, as well as in medical facilities.

Some practical applications of warehouse automation across different industries include:

The advantages and benefits of an automated warehouse system are numerous. Modern warehouse technologies are more scalable and user-friendly compared to older automation solutions such as conveyors.

Conveyors are fixed and bulky, whereas operators can rent additional robots to handle increased demand during peak periods and return them when demand decreases. Collaborative mobile robots require no infrastructure changes. Other benefits of warehouse automation include increased productivity and reduced worker strain and fatigue.

Automated warehouses also lead to fewer injuries. Additional advantages include reduced operating costs, increased accuracy, and fewer shipping mistakes. Automation optimizes space by making use of vertical storage locations that are difficult for humans to access.

The use of drones and certain retrieval systems facilitates access to higher storage locations. Investing in an automated warehouse proves to be a sound financial decision due to significant cost savings from reduced errors, fewer injuries, and increased productivity.

Warehouse automation is the process of using automated technology to take the place of repetitive operations. The major objective is to eliminate time-consuming and labor-intensive tasks. As a result, employees are better able to concentrate on crucial jobs like quality control. However, warehouse automation refers to the use of software to replace tasks that are now done manually and does not always entail the employment of robots or other devices. Over time, the use of automated warehouses has immensely benefited civilization. Robotics manufacturing is used by the automotive industry and retail, which are some of the sectors that use this emerging technology. They have seen significant changes with the advent of artificial intelligence that has dramatically increased worker productivity and efficiency.

An automatic screwdriver is a piece of equipment that automatically inserts screws into a product during assembly and production. Since every production operation is unique and requires a...

An automation system is an integration of sensors, controls, and actuators designed to perform a function with minimal or no human intervention. The field concerned in this subject is called Mechatronics which is an...

Collaborative robots, also abbreviated as Cobots, are the newest technology in robotics. They have changed the automation world significantly. These robots can work safely together with workers, hence are...

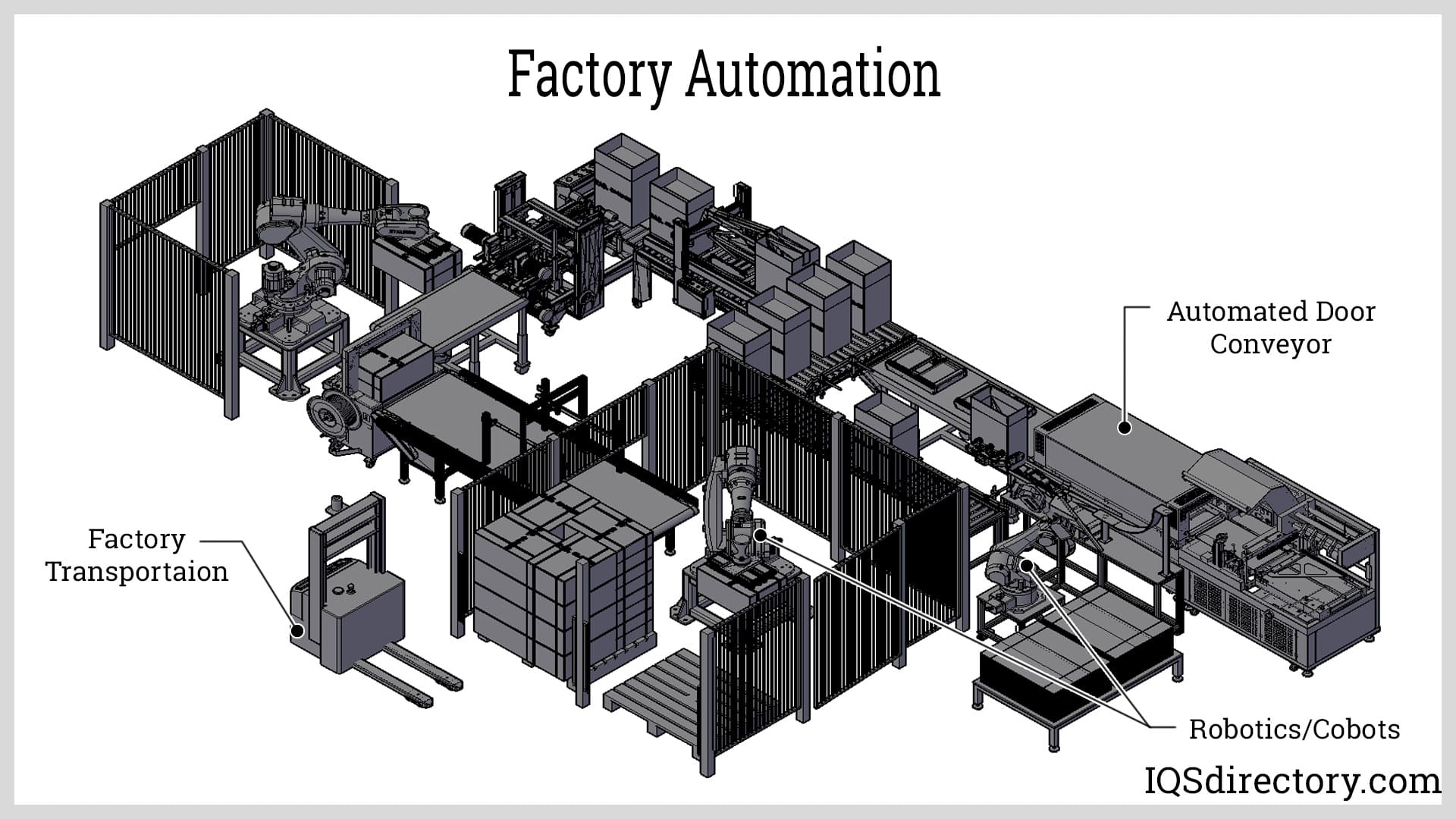

Factory automation involves integrating advanced technology processes to boost productivity, elevate manufacturing output, and significantly improve production efficiency. Through a seamless set of operations, products are...

An industrial robot is an autonomous system of sensors, controllers, and actuators that executes specific functions and operations in a manufacturing or processing line. They operate continuously through repetitive...

Robotic system integrators are companies that provide assistance in automating a wide range of applications. They help design robotic technologies that best suit the needs of an operation for a company and solutions as...

An AGV forklift is a driverless self-operating robotic device that has the ability to carry, lift, retrieve, and place loads for easy transfer from one location to another. An automatic guided vehicle (AGV) forklift is a computer controlled mechanism that...

Automated guided vehicles (AGV) or mobile robots are types of guided robotic systems that are not bounded by a fixed range of motion. Rather, it is self-contained and can move along a line, surface, or space...

An autonomous mobile robot (AMR) is a self-propelled self-powered mechanism designed to perform repetitive tasks or organizational functions using an internal guidance system. They are able to navigate their...

A belt conveyor is a system designed to transport or move physical items like materials, goods, even people from one point to another. Unlike other conveying means that employ chains, spirals, hydraulics, etc...

A bowl feeder is a mechanism for supplying small parts and components to a production line or for sorting bulk items for rapid use. A self contained bowl feeder system has a bowl that sets on a spring loaded base that moves vertically...

A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation. The different types of conveying systems include pneumatic, screw, belt, and roller. The construction of individual systems depends on the materials...

Palletizing is the process of putting items on a pallet. The process of emptying the loaded objects in the reverse pattern is known as depalletizing. A pallet is a flat, square-shaped platform used to transport and...

A pallet stacker is a machine designed to assist the user in lifting, moving and handling palletized materials with ease. A pallet itself is a flat and horizontal structure used to support goods in a sturdy fashion...

A palletizer is an automated material handling machine used to stack and orient several individual products into a single load for a more convenient and economical method of handling, storage, and shipment. Palletizers are usually part of a bigger packaging process...

Pneumatic conveying is a method for transferring bulk materials, like powders and granules, using compressed gas or air, from one processing center to another. Material is moved through an enclosed conveying line or tube using a combination of pressure differential and airflow from a blower or fan...

A robotic palletizer is a type of palletizer that employs a robotic arm to pick, orient, and place individual products and arrange them into a single stack of load. They are the next generation of palletizers, and they will supersede conventional palletizers...

Roller conveyors are a type of conveyor belt that allows objects to skate on its surface by using rollers, which are equally spaced revolving cylinders. They transport stuff from one location to another...

Screw conveyors, or auger conveyors, are industrial equipment used in transporting bulk quantities of granular solids (e.g., powder, grains, granules), semi-solids, liquids, and even non-flowing materials from one point to another...

Vibratory conveyors are material-handling equipment used to transport fine to coarse-grained bulk materials. These vibratory conveyors are strong conveying equipment utilized for bulk commodities with fine to coarse graininess...

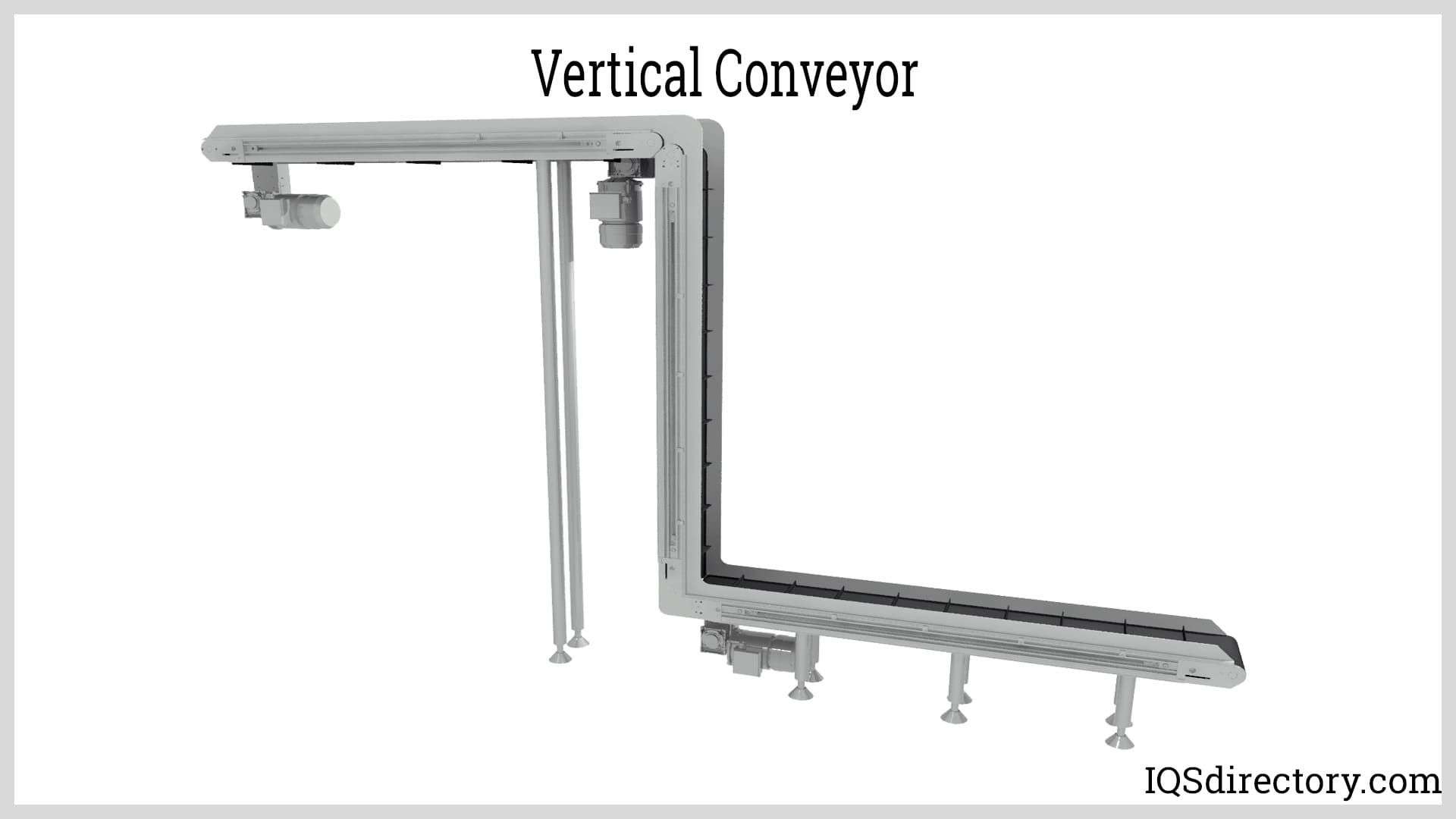

A vertical conveyor is an engineered mechanical method for moving goods, products, supplies, parts, and components from a lower level to a higher level or from a higher level to a lower level. They are...

Vibratory feeders are short conveyors used to transport bulk materials utilizing a controlled vibratory force system and gravity. The vibrations impart a combination of horizontal and vertical acceleration through tossing, hopping, or sliding-type of action to the materials being handled...

In 1954, when Arthur "Mac" Barrett, of Barrett Electronics Corporation, unveiled the first AGV, he named it Guide-o-Matic and described it as a driverless vehicle...