Deburring

Deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on Polishing Machine .

This article will provide detailed information on finishing machines.

The article will investigate the topics such as:

Finishing machines are used in the final stage of metal fabrication, focusing on the finishing touches of the metal surfaces. This stage aims to achieve a smooth and polished appearance. The process can involve various materials and methods, including tumbling media, plating, and loose abrasives, all of which contribute to refining the metal's surface.

Metal finishing involves a range of procedures designed to clean, polish, and enhance the surface of metals. This includes electroplating and other techniques tailored to improve the metal's appearance and functionality. The metal finishing industry employs various processes, each offering distinct advantages for surface treatment and refinement.

Different machines are employed in metal finishing, with variations in capabilities and efficiency. The performance of these finishing machines depends on their size and capacity. This article will explore the key types of finishing machines, highlighting their unique features and applications.

Surface finishing offers several benefits, including:

Different methods are employed to achieve metal finishing. These methods are outlined below.

Metal polishing is a process that smooths surfaces using abrasive materials. This technique removes imperfections from metal surfaces, resulting in a shiny, reflective finish with an improved appearance. Often, metal polishing is combined with buffing, which is gentler on the metal. Beyond its aesthetic benefits, metal polishing also helps to eliminate oxidation beneath the surface, thus preventing corrosion and extending the metal's lifespan.

Various abrasives can be used in the metal finishing process, with the choice of abrasive depending on the material being polished. When dealing with unfinished materials, several stages must be followed. Initially, a coarser abrasive is employed to eliminate imperfections from the surface. In the following stages, progressively finer abrasives are utilized to refine and enhance the finish of the material.

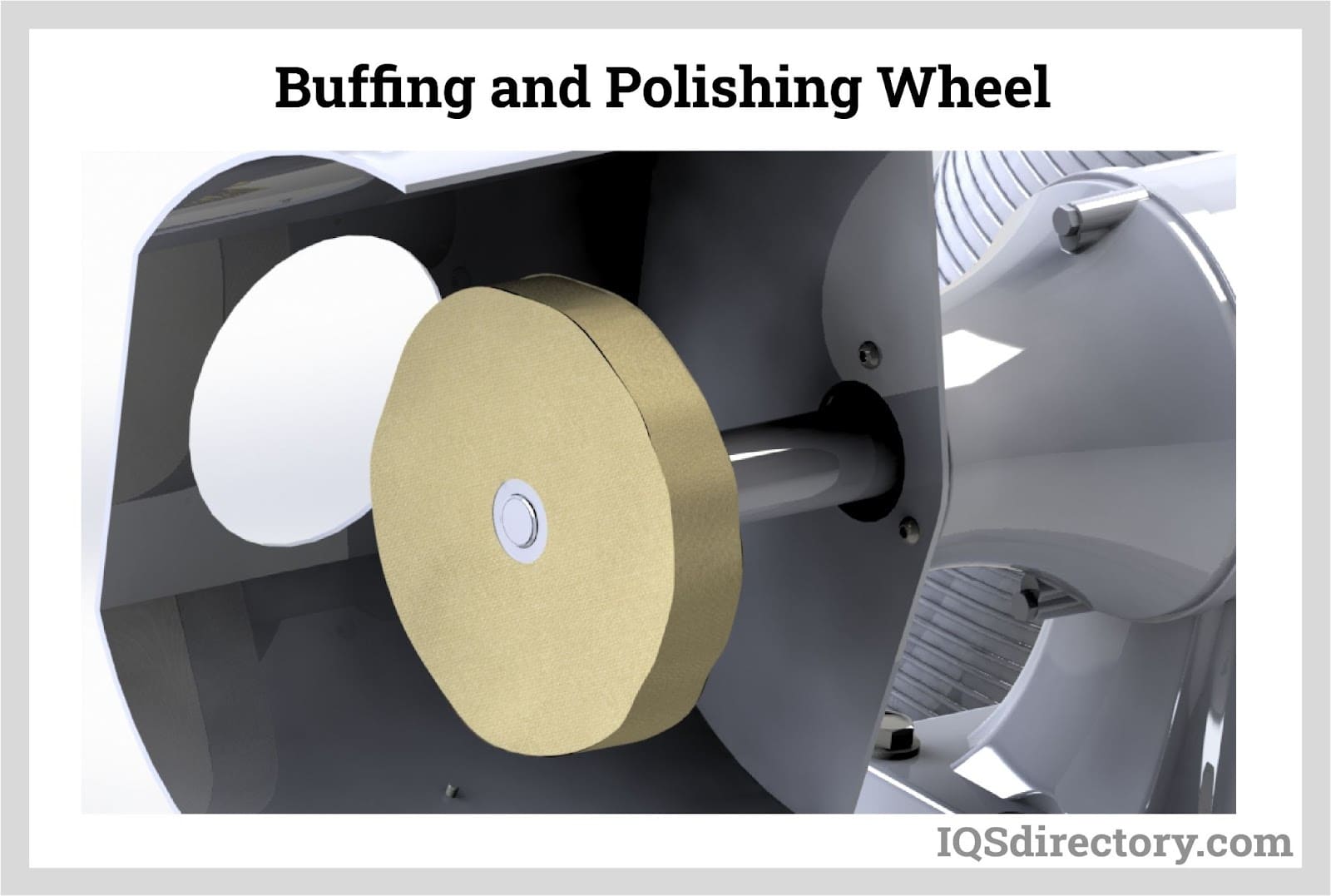

A mirror-like finish can be achieved by incorporating buffing and polishing compounds into the polishing wheels. Generally, polishing is applied as is, although lubricants such as kerosene or wax can be used in some cases. Die grinders, stationary polishers, or specialized equipment can be used to give a brighter shine during buffing.

For softer metals like brass, a very fine grit that is copper-plated can be employed to achieve a smooth surface. Buffing is performed using an airflow mop. Different tools, such as hammers, wrenches, screwdrivers, and chisels, each require specific polishing techniques due to their distinct characteristics. Initially, these tools are roughed out using a grinding wheel, followed by dry polishing materials to complete the process. In cases where additional polishing is necessary, grease may be applied.

Polishing enhances surface quality by reducing friction and wear, contributing to better performance and longevity of the tools.

Various abrasives are selected based on the metal's strength during the polishing stage.

Metals with lower tensile strength, like copper, brass, and aluminum, typically require gray silicon carbide abrasives. These abrasives are also suitable for use on cemented and gray iron carbide.

For metals with higher tensile strength, such as carbon and alloy steel, non-ferrous metals, and iron alloys, abrasives like white and gray aluminum oxide are preferred. Green chromium oxide abrasives are specifically used for ferrous metals, including steel.

Materials like leather and canvas are commonly used in polishing. Other options include felt, plastic, wool, and rubber. Buffing wheels or mops often use cotton or wool cloth.

In manufacturing, polishing is essential for items like kitchenware, cookware, automotive components, and architectural metals, ensuring they are market-ready. Polishing is also used to refurbish or mend metal parts when needed.

Buffing and polishing contribute to workplace safety as well. For instance, polishing can help prevent corrosion in specialized plumbing systems. In the pharmaceutical and dairy industries, polishing can eliminate mold and bacteria in pipes, reducing corrosion and improving product safety.

Mass finishing can produce exceptionally flat surfaces. High-contact metal surfaces, such as those in bearings, benefit from smoothing, which minimizes noise and abrasion. Surface peaks can be reduced to an Rpk of less than 0.1 μ while preserving valleys that serve as oil reservoirs. This smoothing process results in a surface that decreases wear and extends the lifespan of tools.

The smoothing process can achieve Ra values as low as 0.01 µ with consistent results. This technique is primarily used in:

Deburring and surface finishing machines are highly effective for mass finishing of plastic, rubber, ceramic, and metal parts. Utilizing these machines in product finishing is crucial for achieving consistent and reliable outcomes.

For optimal surface quality, it's important to pair the appropriate process media with each machine. In wet finishing, a water or compound mixture is typically used. This combination helps absorb and wash away debris, ensuring high efficiency during the entire process and preventing media clogging.

Selecting the correct process and medium is crucial in surface finishing. Dry finishing involves operations without the use of liquids. To prevent issues or accidents when working with dry abrasive granulates, a sufficiently powerful extraction unit is essential. This method is often employed in polishing, where a polishing paste or powder is applied to the medium. Friction between the medium and workpiece, caused by the finishing process, leads to material removal and produces a polished surface.

Finishing and polishing both utilize abrasives but serve different purposes. Finishing eliminates scratches or surface imperfections caused by cutting or grinding tools, while polishing adds a glossy or lustrous appearance to the material’s surface.

Polishing typically uses abrasive belts, whereas buffing employs cloth wheels treated with compounds. Polishing creates a lined or brushed finish, whereas buffing produces a bright, lustrous finish and removes any remaining lines. Buffing usually requires prior surface refinement through polishing.

Surfaces can be leveled through polishing by using abrasive discs or belts to eliminate scale, pits, and scratches. Buffing is then used to remove polishing lines. The finest abrasives are recommended for polishing to correct levels, welds, and surface imperfections before removing the scratch lines.

In the buffing process, a rotating cloth wheel with fine abrasive compounds is used to achieve a bright, lustrous finish. The buff wheel carries a greaseless compound-based matrix, with the compound performing the actual surface finishing.

Metal finishing is a crucial phase in metal production. The process typically includes several steps: grinding, buffing, sandblasting, metal plating, chemical finishing, electroplating, electroless plating, and other methods.

The process involves applying friction to the workpiece, removing imperfections and creating a textured grain for a smooth exterior finish. This method results in a non-reflective surface and is typically performed using abrasive belts or fine bristle brushes. Brushed finishes can be achieved with brush-back sander heads, stainless steel wire wheel brushes, nylon discs, and various types of abrasive cloths.

This process uses abrasive compounds to create a radiant finish on metal surfaces. The abrasive compound is applied to a buffing wheel, which then performs the finishing work. This fine polishing process produces a smooth, lined surface. However, cut buffing requires significant effort, time, and pressure, making it challenging to operate. Finish buffing, on the other hand, refines the surface by removing fine lines to achieve a more radiant finish. It is quicker and easier than cut buffing, requiring less pressure. While effective for smoothing surfaces and rounding edges, this process may not be suitable for applications involving delicate, intricate, or recessed features due to the limitations of the cloth wheel.

Centrifugal disc finishing, also known as roll flow finishing, is a recent addition to finishing processes, introduced in Great Britain in 1969 and in Germany in 1998. This method utilizes a machine with an open-top bowl, stationary side walls, and a rotary disc at the bottom.

For many years, there has been a need in manufacturing to brighten dull metals, smooth rough surfaces, and soften sharp edges. The traditional approach involves using abrasive finishing media and water.

The early mechanical methods for finishing materials included rotary tumbling and vibratory systems, which have proven to be effective. The development of the centrifugal barrel finisher (CBF) marked a significant advancement, featuring a closed barrel mounted on a rotating turret that exerted substantial force on the parts and media inside.

While the CBF was productive, it required extensive material handling and had longer cycle times compared to vibratory or rotary tumbling systems. Manufacturers sought a method that combined the advantages of centrifugal barrel finishing with faster processing speeds, precise control, and compatibility with modern automation.

This led to the creation of the centrifugal disc finisher, which features a round, rotating disc at the bottom of a stationary chamber. In this system, parts, finishing media, water, and either dry or liquid compounds are placed into the chamber.

When activated, the disc rotates at peripheral speeds up to 2000 sfpm (610 m/min), causing the mass of parts, media, and compounds to move upward and outward against the chamber walls. This mass then slows, tumbles, and falls back towards the disc, where the upward and outward motion resumes, mimicking a natural vortex.

The rapid disc rotation enhances the mass's weight and creates highly efficient, aggressive finishing energy. The rpms of the centrifugal disc finisher can be adjusted to suit different batch requirements.

Centrifugal disc finishers are capable of finishing parts eight to ten times faster than tub or vibratory systems. For instance, a process that takes two hours in a vibratory system can be completed in just 12 to 15 minutes with a CDF. A 2 cu ft centrifugal disc finisher can accomplish the work of a 20 cu ft vibratory system in less than half the time.

These processes involve various methods, such as dipping or washing metals during fabrication. They utilize highly specialized chemicals with unique properties tailored to specific metals. Occasionally, these chemicals are used to achieve dull surfaces through chemical etching.

Edge rounding can be categorized into the following types:

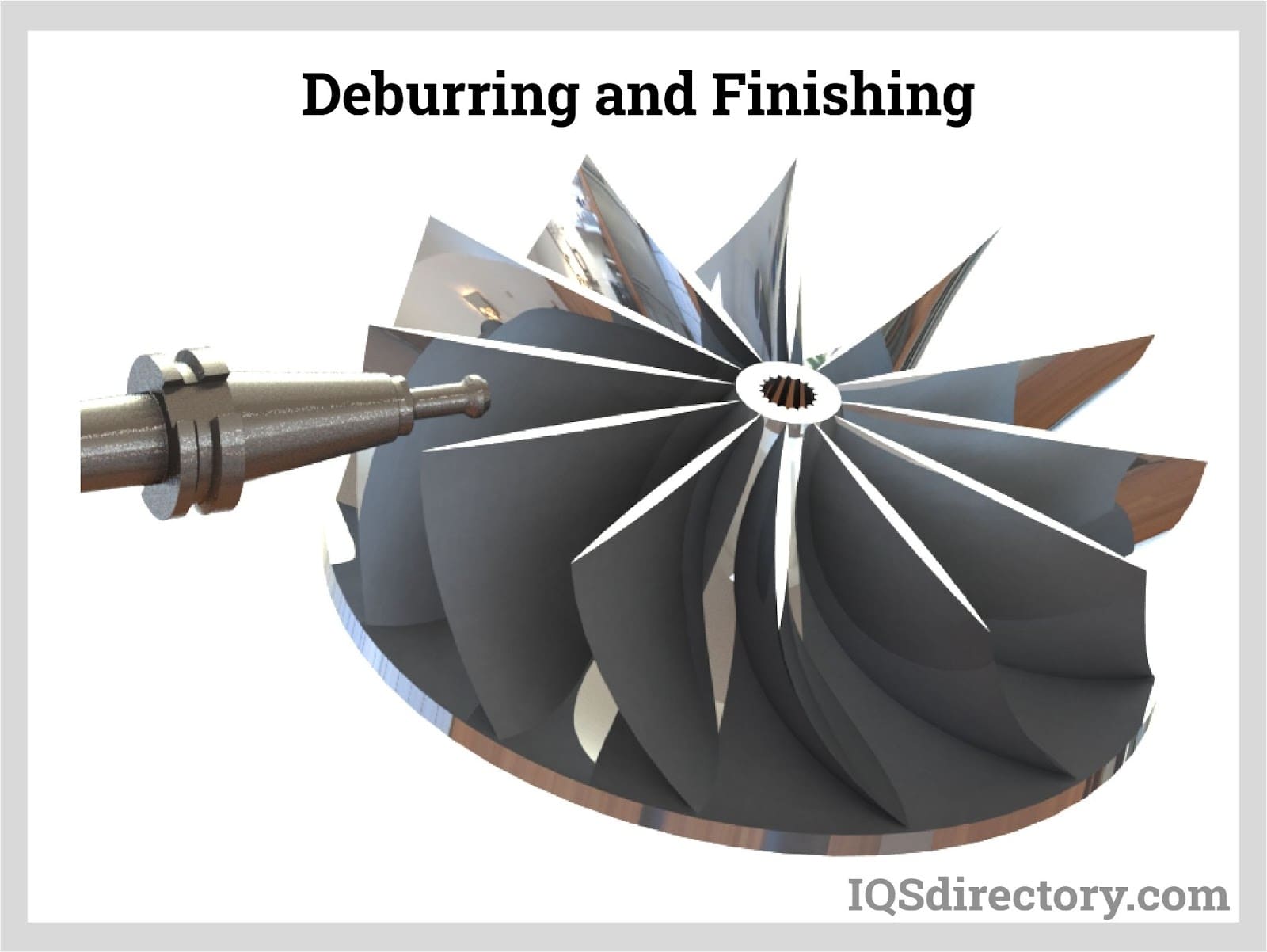

The process involves rounding edges, creating sharp edges, producing unique effects, smoothing, and deburring. Grinding machines, either stationary or handheld, are commonly used for this purpose. Metal grinding relies on attrition, compression, or friction to achieve a smooth surface. The final smoothness of the surface depends on the type of grinder used. Various grinding methods include surface, electrochemical, centerless, and cylindrical grinding, among others. The choice of method depends on the type of product and metal being processed.

This is the process of depositing a metal coating onto a surface or workpiece by giving it a negative charge when it is settled in metal salt. A thin metal coating is produced by attracting the negatively charged material to the positively charged. The process can be completed by dipping metal into a metallic solution called electroless plating or electroplating.

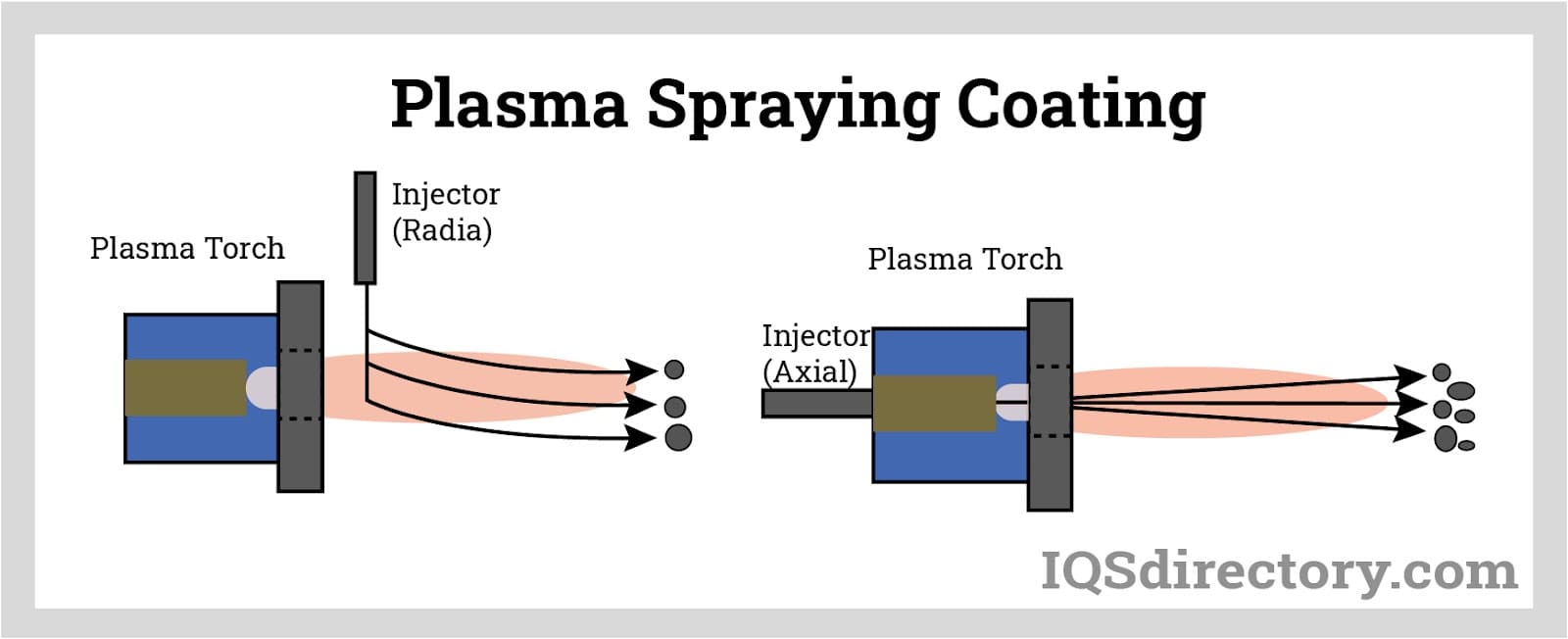

Thermal spraying is a process where a surface is coated with molten material at high temperatures. The surface is rapidly heated to a high velocity and then quickly cooled to form a hard, solid coating. This coating provides protection against wear, corrosion, erosion, and high temperatures. When applied correctly, thermal spraying can also alter the electrical and aesthetic properties of the workpiece.

This process typically complies with environmental regulations and is known for its high-quality results and efficient operation. It involves using polyurethane resin combined with leveling agents, pigments, additives, and flow modifiers. These components are melted and mixed into a powder that resembles baking flour. The powder is then applied to the metal substrate using an electrostatic spray, followed by curing in an oven. Powder coating can also be applied to non-metal surfaces such as certain types of fiberboard and plastic. Additionally, it can be used to eliminate deformities and defects.

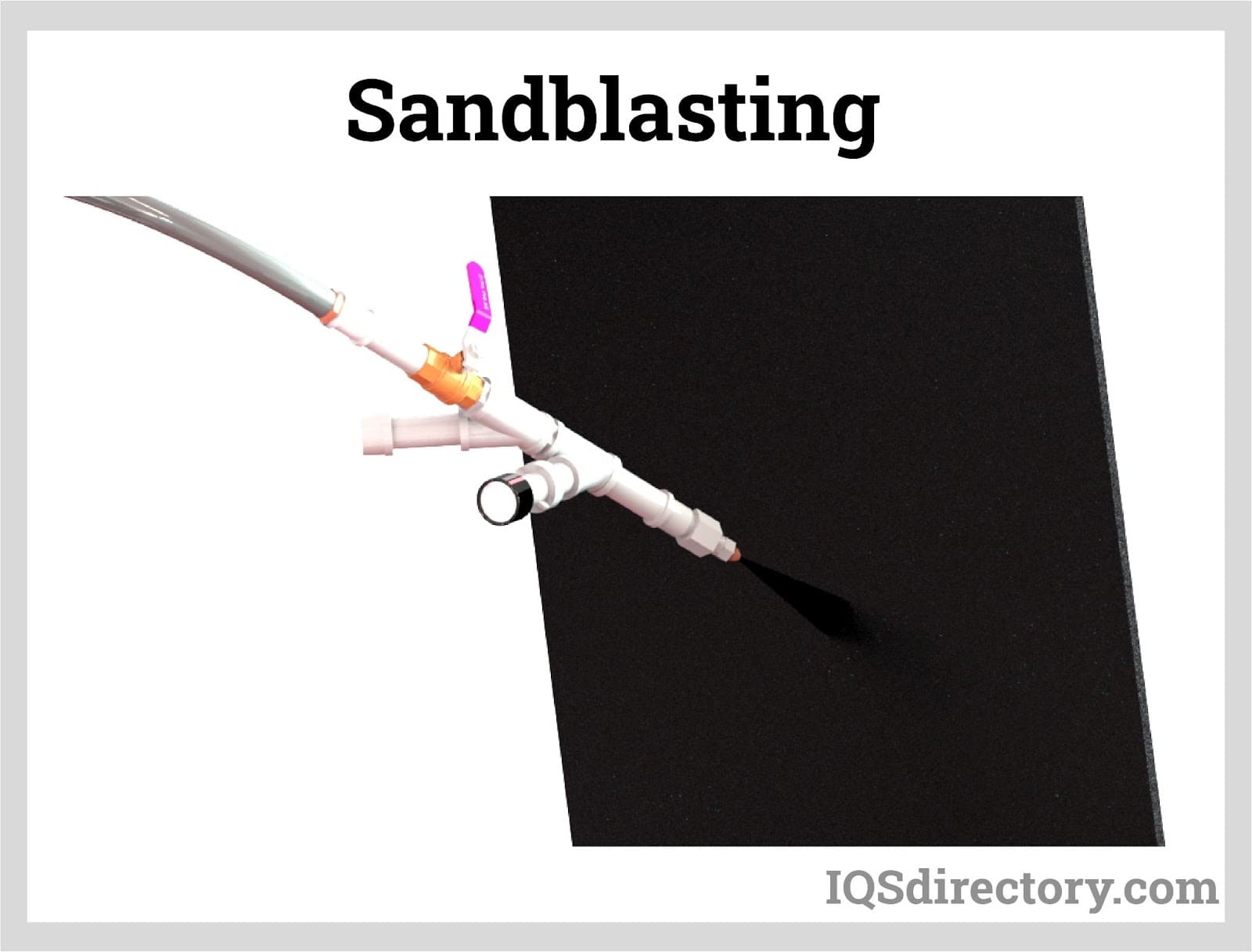

This process effectively removes debris, dirt, and particles that accumulate on surfaces during processing. By eliminating the need for post-processing cleanup, it saves time and reduces costs. It offers high efficiency and productivity, being up to 75 percent faster than other methods. The process utilizes various abrasive materials, such as silicon carbide, glass beads, plastic abrasives, aluminum oxide, and corncob grit. These materials produce a range of finishes, from textured patterns to a soft, satiny appearance.

The smoothing process provides a cost-effective, quick-cycle method for surface finishing. In the automotive industry, it is ideal for polishing and smoothing components such as gear wheels, pistons, camshafts, expansion screws, rocker arms, and valves. In metalworking, smoothing is used for high-speed spindle finishing, while in tooling, it is applied to forming and pressing surfaces for polishing and smoothing.

In the metalworking industry, the term refers to the process of removing sharp edges from metal parts or components after manufacturing or treatment. Stream or drag finishing machines are employed for large and heavy metal pieces that remain separate during processing. Selecting the appropriate abrasive media is crucial to ensure that burrs or sharp edges are fully removed rather than just bent over. Specialized knowledge and experience are required for individuals or teams performing this process.

Finishing machines vary in shape, size, and function. This section will provide a detailed overview of different types of finishing machines and their various functions.

One common type of finishing machine is the vibratory finishing machine. Its benefits include, but are not limited to:

This finishing process is more aggressive than the previously mentioned methods. The centrifugal barrel finishing machine uses 3 to 4 barrels mounted on a turret assembly. The rapid processing is due to the high centrifugal forces generated by the turret's high-speed rotation.

The machine operates at variable frequencies to match the required rotational speed for each process, ensuring a more consistent and uniform surface finish. It is predominantly used in industries such as bearing, compressor, automotive, jewelry, textile, and aerospace.

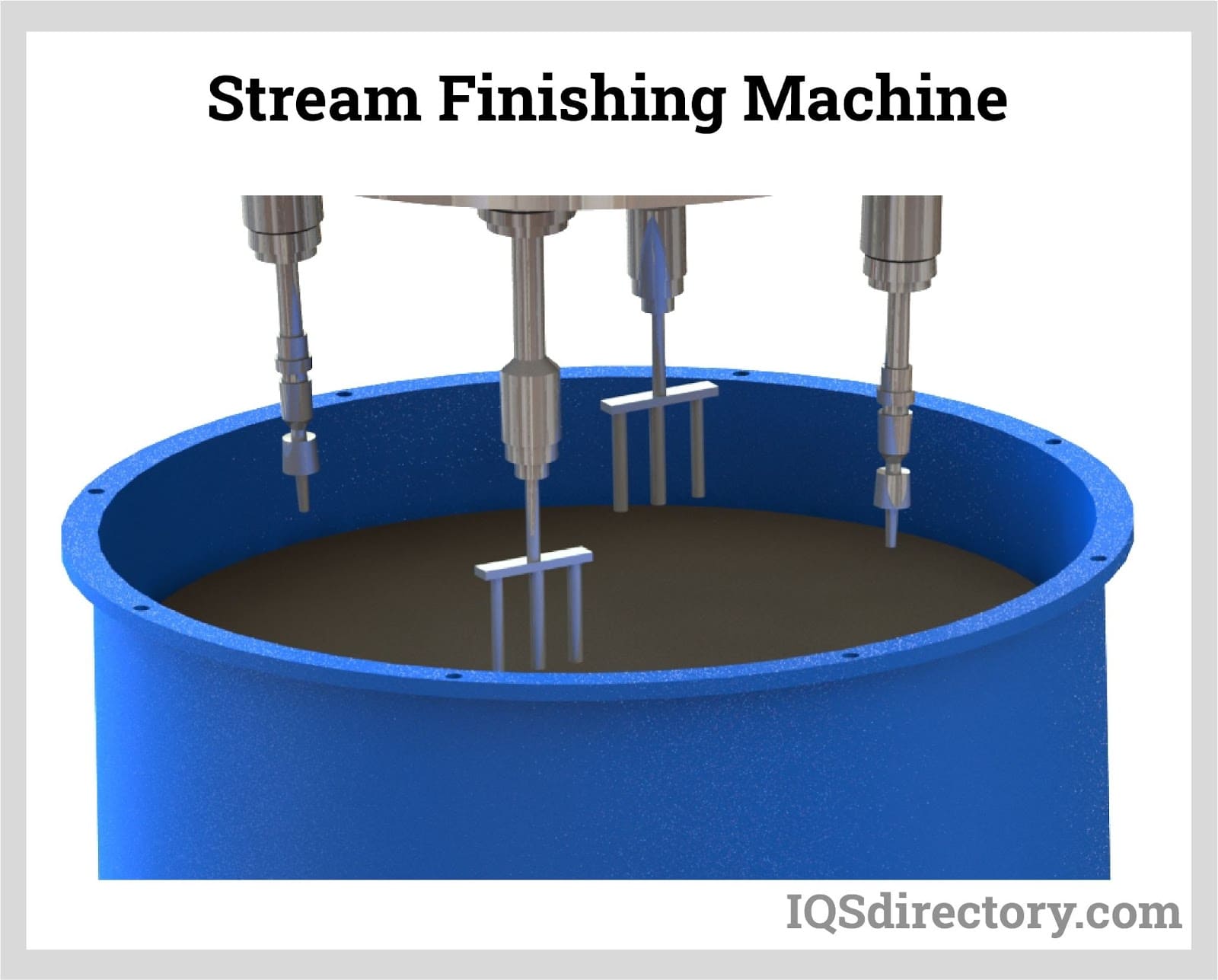

This finishing process involves securing workpieces in specially designed holders, which are then dragged in a circular motion through a drum containing polishing and grinding granules. The high-speed movement creates significant contact pressure between the media and the workpiece. This pressure results in precision smoothing and edge rounding that closely resembles manual finishing.

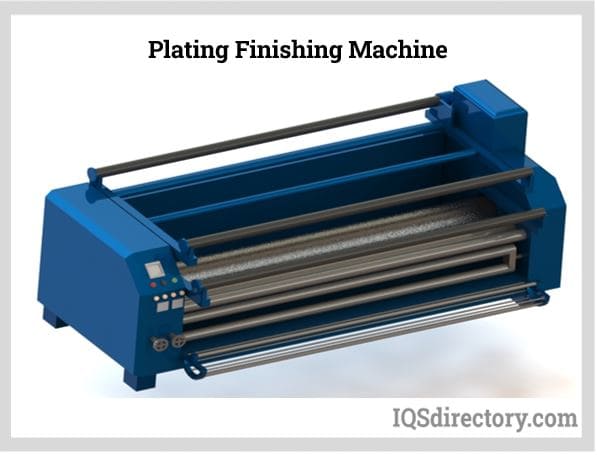

This plating technique utilizes chemical reactions in conjunction with an aqueous solution. One method involves covering a surface with a thin metal layer, which is then bonded through heat and pressure. Materials used in plating include composite, gold, chrome, alloy, cadmium, zinc nickel, zinc, rhodium, nickel, and gold. In jewelry manufacturing, plating is applied to achieve gold or silver finishes. Metallizing refers to coating metals onto non-metallic objects or workpieces.

This type of vibratory finishing machine is suited for processes requiring less than 10 minutes of operation. Elliptical machines are effective for removing light burrs and finishing small parts such as bearing cages and ceramic insulation tiles.

The plating finishing machine applies a plating layer to the surface of materials to enhance adhesion, strength, friction reduction, decoration, solderability, and other properties. Despite its long history, it remains crucial in contemporary technology. This process often imparts qualities to the material that are not present in the base material, such as an attractive surface, corrosion resistance, and magnetic properties.

Recent advancements have led to the use of liquids for plating workpieces.

Barrel finishing machines, also known as polishing barrel tumblers, feature 6 or 8-sided rotating drums that can be used for deburring, rounding, or surface treatment. These machines utilize lubricating agents, abrasives, and tumbler media to create friction in the barrel drum, enhancing the effectiveness of the abrasive material. There are two main types of polishing tumblers: wet and dry. Wet tumblers, with their slower cutting rate, produce a finer finish and are more effective at removing excess stock. Dry tumblers, on the other hand, operate vertically and handle materials throughout all stages of finishing.

Barrel finishing machines, sometimes referred to as barrel tumblers, have 6 or 8-sided rotating drums designed for deburring, rounding, or surface treatment. They use lubricating agents, abrasives, and tumbler media to generate friction within the barrel drum, which boosts the effectiveness of the abrasives. The two primary types of barrel finishing machines are wet and dry tumblers. Wet tumblers offer a slower cutting rate, resulting in a finer finish and greater efficiency in removing excess stock. Dry tumblers operate vertically and manage materials through all finishing stages.

Bowl round machines are horizontal units lined with urethane, featuring a donut-shaped container with an open top. The container includes a vertical eccentric shaft drive centered in the column. Media mass spins around this column in a forward rolling motion. These machines are widely used in the manufacturing industry and help keep parts aligned to prevent damage.

The bowl can be divided into large parts, and the greatest advantage of using the machine is that gates, screens, and ramps can be loaded into the bowl. This will also enable the self-unloading of parts from the finishing machine and media. They are used mostly to finish small parts like screws and rivets, including bigger ones like turbine blades.

This type of finishing machine is renowned for its capability to both clean and smooth metal surfaces simultaneously. The machine works by introducing abrasive agents, such as metal pellets or sand particles, into the system at high speeds. The level of finishing is influenced by the speed of the abrasive particles, the duration of the cleaning stage, and the angle of the applied force.

This is an enhanced version of Round Vibratory Finishing Machines, designed for thorough and efficient separation of parts in just 8-10 minutes. The bowl’s spiral shape improves process efficiency compared to round vibratory machines. Spiral vibratory finishing machines are commonly used in the bearing industry, furniture industry, and for finishing valve bodies.

Stream finishing machines, also known as SF technology, represent a modern advancement in mass finishing equipment. The process involves clamping the workpiece and lowering it into a spinning container filled with polishing or grinding media. The combined rotation of the workpiece and the flowing medium generates the finishing motion. This method provides reliable and consistent results in a short amount of time while allowing for selective material removal.

This type of vibratory finishing machine is used for degreasing, polishing, and deburring mid-sized parts, including rods, marble and granite tiles, turbine blades, shafts, axles, and aerospace components, among others. Its capacity allows for maximum channel width and facilitates easy separation of parts with removable compartment dividers.

The tub finishers’ structural design is stronger and firmly joined together, giving a U-shaped trough encrusted with a premium polyurethane lining than is fixed on coil-coated springs. The drive has a premium effectiveness motor that controls an offset drive shaft with weights that can be easily adjusted. The increase or reduction of machine combativeness weights is made by adjusting the weights. The system is mostly fueled by a shaft that has an eccentric hook on the tub, a sheave, motor drive, and V-belt are used to rotate or spin the shaft. Eccentric weights may be loaded or unloaded around the shaft to reduce or add vibration.

Various unique machines employ different techniques. Examples of such machinery include:

These machines are commonly used in larger applications to remove scale, rust, or paint from metals at a much faster rate. Abrasive blasting equipment can include chain-fed conveyors or sandblasting systems, capable of processing up to 1000 pounds (454 kg) of steel per hour.

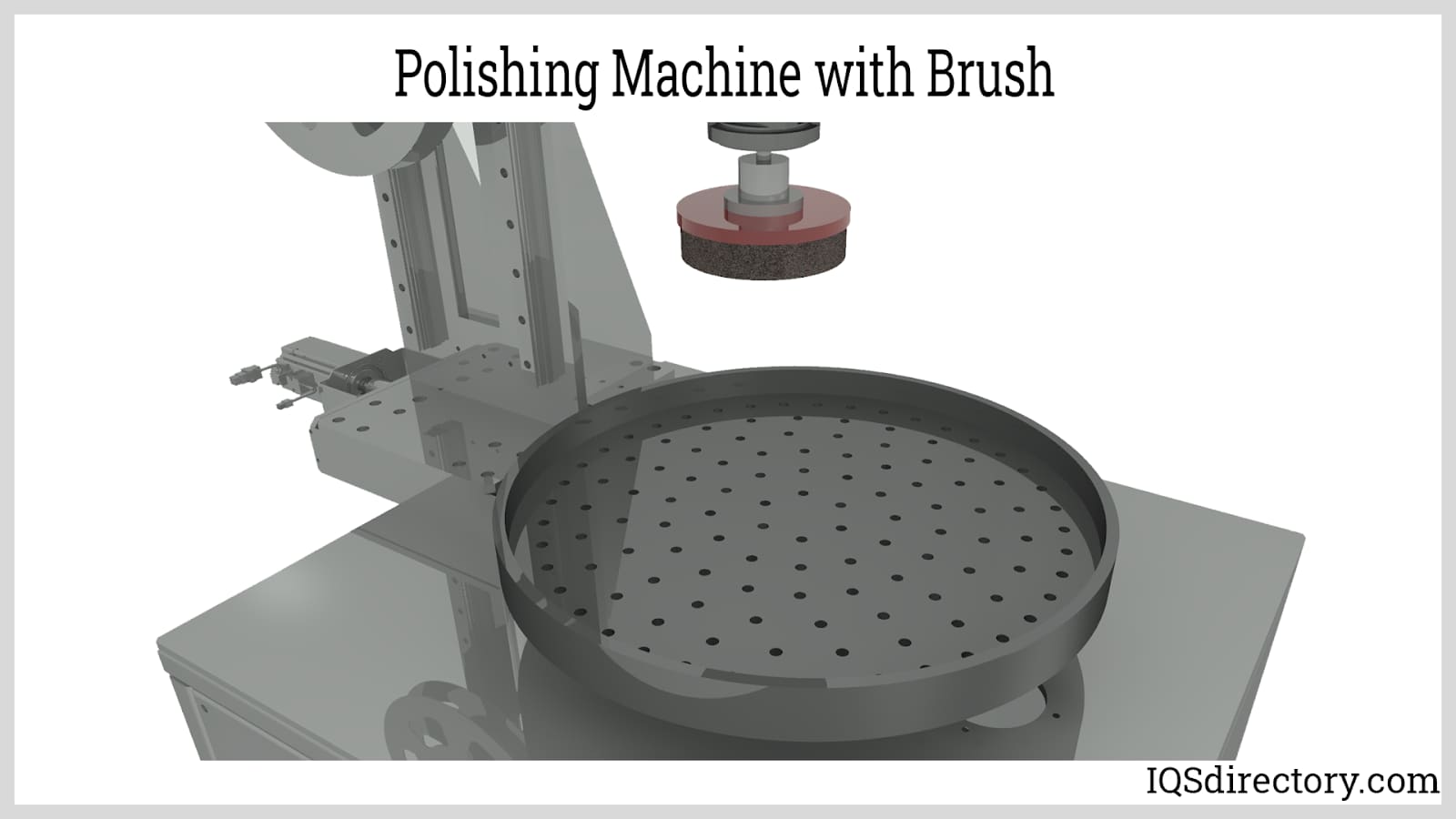

This method combines belt sanding with either a drum-style rotating abrasive brush or a cup-style rotating brush. The brushes, made from durable materials and coated with abrasives such as garnet, enhance their effectiveness in surface finishing and material removal. The primary goal of this system is to round sharp edges and deburr the material surface, ensuring safe handling of parts for subsequent use.

The finishing technique described here is well-suited for metal components with small, hard-to-reach areas such as pockets, chambers, and deep holes. This method involves placing the parts in a container filled with magnetized abrasive particles. These particles work to polish the inner surfaces of the difficult-to-access regions, resulting in a smooth and polished finish. The magnetic polishing method enhances the durability of intricate parts while providing a soft sheen that protects against air and liquid exposure. Not only does this process achieve a high-quality surface finish, but it is also economical and effective in rounding and deburring components to a high degree.

This finishing technique involves applying a black oxide coating to the material’s surface, aiming to improve its appearance and increase resistance to abrasion.

This method facilitates the removal of minor burrs, metal projections, and surface imperfections. The process involves placing components in a container with abrasive media and then using vibration to mix everything thoroughly. This vibratory action helps to eliminate burrs and creates a texture that can be either directly used or easily coated with paints, powder coatings, clear lacquers, or other materials that provide a more resilient finish resistant to scratches and chips.

This finishing technique is designed to clean and refine smooth and curved surfaces by creating irregular, non-linear textures. Various abrasive media can be used in this process, with higher grit numbers and finer particles yielding a more refined finish. Finer grits produce a mirror-like polish similar to that on stainless steel, while coarser grits remove material more quickly. The process can be carried out using automated belt systems or manually operated belt sanders, where materials are fed through a rotating belt or other mechanisms to achieve the desired finish.

Finishing machines are selected based on the specific requirements of each project. Below is a list of some finishing machinery options that were not covered previously.

These machines feature a polyurethane-lined bowl mounted on springs and equipped with a vibratory motor and imbalance weights to create gyroscopic motion. They are utilized for a range of processes including descaling, polishing, smoothing, degreasing, mirror finishing, and edge refinement. Commonly used for deburring and finishing molded, forged, sheet metal, machined, and cast components, they are versatile tools in various manufacturing applications.

This type of equipment can handle a broad array of components, such as those used in aerospace, consumer goods, automotive, and defense industries. Water may be added to provide a dampening effect, which helps reduce the cutting rate and is especially useful for operations like burnishing that require minimal material removal. The vibratory finishing machine operates at high frequencies, delivering up to 1800 vibrations per second to enclose the metal in intense motion.

This section will outline the benefits and drawbacks of various types of finishing machines.

The benefits of utilizing barrel finishing machines include:

This chapter will explore the factors to consider when selecting the appropriate finishing process and machine.

The finishing process represents the final stage in achieving the ideal texture and appearance of a product. It enhances the design of the workpiece while providing protection against rust, tarnishing, and corrosion, and also adds strength, thickness, durability, and hardness to the finished item.

Cost is a primary factor in the production process. Considerations include the type of coating, energy consumption, various consumables, waste generated, cleanup, and labor expenses.

The choice of finishing process and machine should be based on the type of metal being processed. With various metals, from aluminum to stainless steel, understanding the specific requirements for each type is essential to achieve the best results economically.

Understanding the processing times for different methods is crucial to selecting one that fits the project's timeline. Proper time management helps meet deadlines and enhances efficiency, while also supporting a stable supply chain and avoiding the costs and errors associated with last-minute work.

The ability to fabricate and manipulate metal depends on its strength, durability, and endurance. Metal strength is categorized into ultimate, yield, and breakable strength. Yield indicates the deformation stage, while ultimate strength represents the maximum stress the material can handle. Choosing the right finishing process is critical to success and can save on labor, cost, and time.

Selecting the appropriate deburring and finishing machine requires considering several factors, including:

It is important to choose a machine that matches the requirements of the finishing process. Dry machines are ideal for industries with consistent material types being processed.

In industries dealing with various material types, wet deburring and finishing machines are more suitable. Evaluating the workpiece's characteristics and the type of abrasive used is vital for optimal machine performance.

The characteristics of the labor force, including the number of workers and their technical skills, should be considered. A larger workforce may accommodate high-maintenance machines, while a skilled labor force can efficiently operate automated machinery.

Longer project durations increase costs and may disrupt the supply chain if deadlines are missed. Therefore, selecting a machine that aligns with the project's timeframe is essential.

When choosing finishing machinery, staying within the budget is crucial. This includes not only the initial cost but also ongoing operational expenses and the need for technical expertise to operate and maintain the equipment. Failure to account for these factors may impact the quality and quantity of the finished products.

Choosing the right deburring or finishing machine can be complex, so seeking advice from professionals is recommended. Consulting with metal fabrication experts can be beneficial. Key factors to consider when selecting an expert include their relevant industry experience, manufacturing partnerships, and references from previous clients.

It has been proven that metal finishing is as important in the production process as any other stage. To produce resilient, strong, and well-presented products, it is essential to pay much attention to what finishing suits a specific item. Workpiece characteristics have a lot to play on the choice of finishing process and machinery selected.

Deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial...

A tumbling machine is a durable deburring and metal-polishing machine designed for finishing large parts or batches of smaller parts. A tumbling machine is also known as a barreling machine or a mass-finishing...

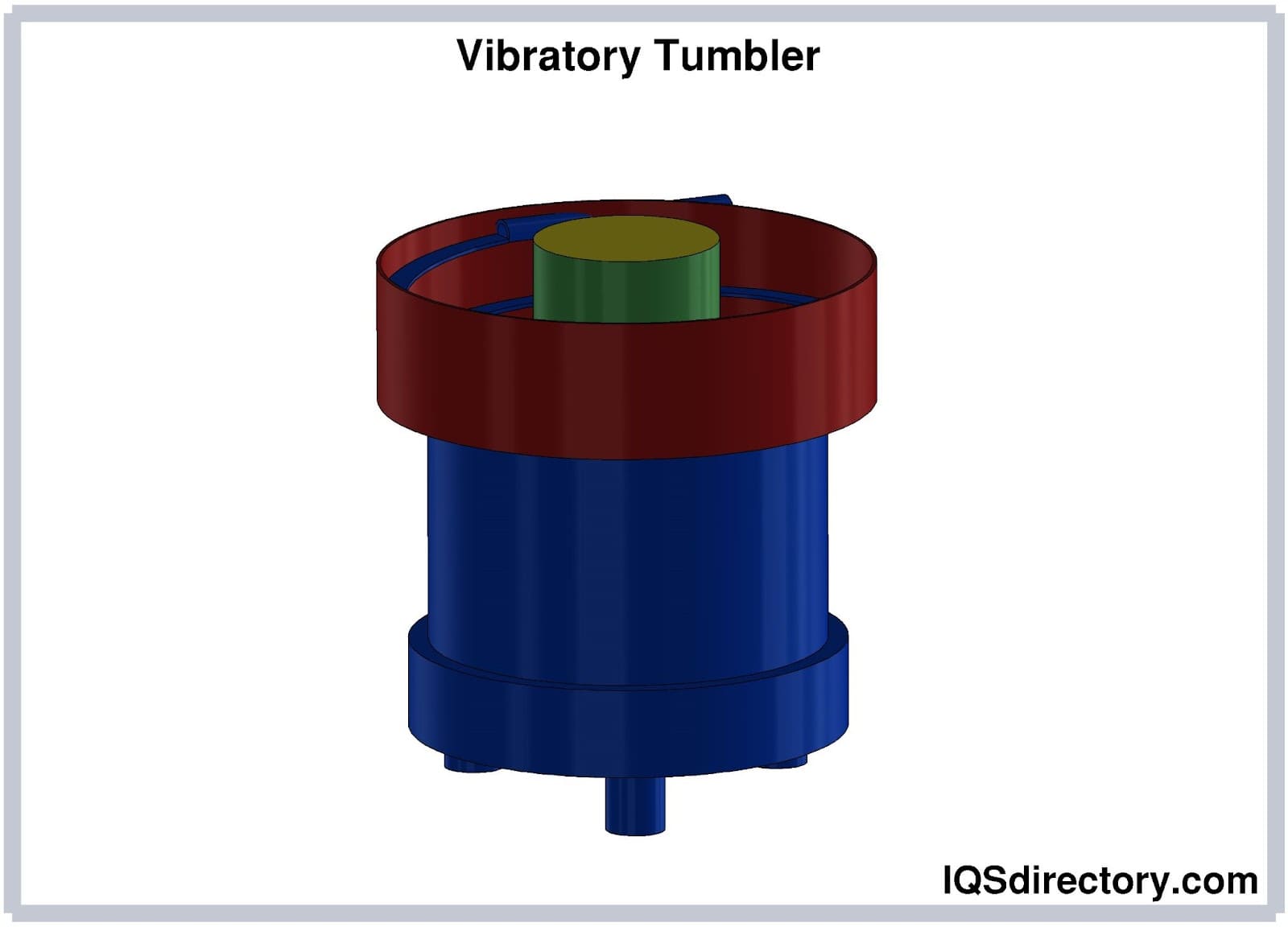

Vibratory tumbler is the equipment used in a vibratory finishing process, one of the most common methods in mass finishing. But how does a vibratory tumbler work...

Industries worldwide utilize abrasive blasting for various purposes, including cleaning rust and oil, removing surface coatings like paint and pollutants, preparing surfaces for paint and coatings, reinforcing metal surfaces and...

An aqueous part washer is an automated or semi-automated machine manufactured to clean, remove tough grease, and dry large or small parts before distribution or surface treatment. The washing is necessary since...

Automated parts washers are mechanical devices designed to efficiently remove grit, oil, grime, dirt, paint and other contaminating substances from parts with minimum manual supervision. These substances are removed...

A parts cleaner is a cleaning device that uses various types of solvents, cleaning agents, and processes to remove grease, grime, and contaminating materials from manufactured parts prior to shipment or movement for further processing...

A parts washer is a mechanical device designed to remove grit, grime, oil, miscellaneous debris, dirt, paint, and other contaminating substances from parts in preparation for their use in assembly operations, packaging, or coating...

Sandblast cabinets include systems or machinery and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel...

Sandblasting equipment includes systems or machinery, and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel...

Shot peening equipment includes systems or machinery and components for projecting shot peening media against a part‘s surface to modify the surface or surface engineer the part...

An ultrasonic cleaner is a type of sonic cleaner or sonic cleaning machine that uses cavitation to remove unwanted material. The cleaning effect is created by the compression and refraction of a cleaning medium. Miniscule vibrations propagate throughout the...

Ultrasonic cleaning is a type of cleaning process which uses cavitation induced by alternating compression and rarefaction cycles at ultrasonic frequencies. Ultrasonic frequencies are sound waves vibrating at 20 kHz or higher...

A wastewater evaporator is a method of removing water from water-based waste by converting the water in the waste to a vapor and leaving contaminants. The function of a wastewater evaporator is to reduce the volume of waste materials...

Parts washers are designed for cleaning, degreasing of equipment, and drying of mass quantities of small or large parts in preparation for surface treatment, assembly, inspection, or shipment...