Deburring

Deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at vibratory tumblers.

Read further and learn more about topics such as:

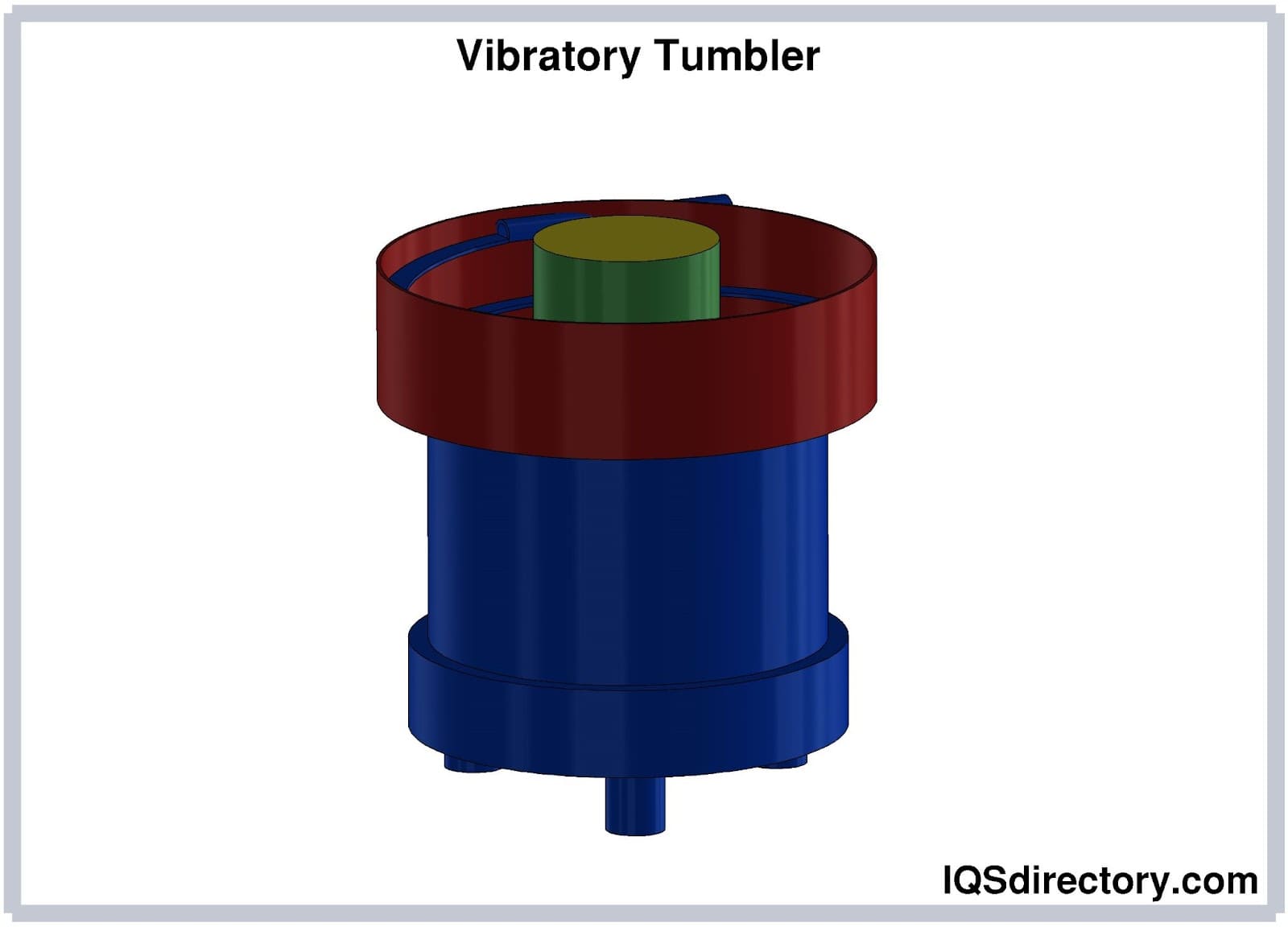

A vibratory tumbler is a type of machinery utilized in the vibratory finishing process, a prevalent technique for mass finishing applications. So, how exactly does a vibratory tumbler function?

The operation of a vibratory tumbler involves placing the workpieces and components into a container filled with specially designed media pellets. A motor produces vibrational energy that agitates the contents of the container. Strong springs underneath provide support during this motion. Additionally, a specialized finishing compound might be included in the mix to enhance the finishing results.

The movement causes the media to grind against the pieces, effectively polishing them. Although the tumbler itself vibrates, the apparatus and its contents remain in place. Vibratory tumblers are adaptable, functioning either in batch mode or continuous mode.

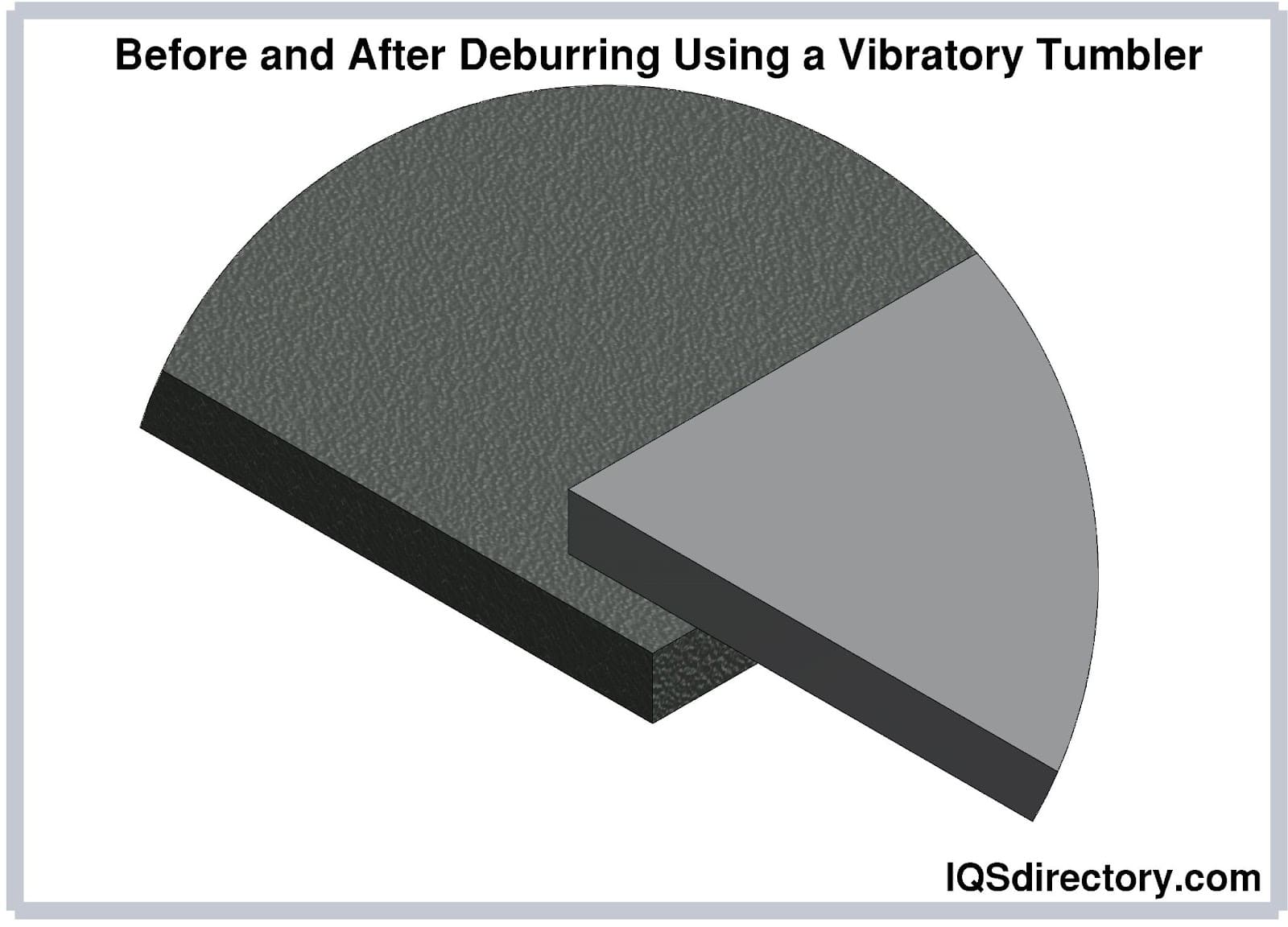

The vibratory finishing process is effective for cleaning, deburring, deflashing, descaling, and polishing various workpieces. It serves as an essential step for improving the adhesion of coatings, platings, and adhesives and is generally performed after machining. Moreover, it can slightly reduce the size or refine the edges of irregularly shaped parts, while maintaining the original form of the workpiece. This method offers a level of precision unattainable by manual polishing and deburring.

Vibratory tumblers excel at handling large quantities, offering a high throughput that makes them perfect for processing extensive batches of parts. They often produce finished components faster than rotary tumblers, though times can vary based on part size and nature. By selecting the appropriate media, vibration intensity, and finish type, these tumblers can proficiently polish plastic, metal, and ceramic workpieces.

Available in a variety of sizes, shapes, and capacities, many vibratory tumbler models are equipped with advanced automation to enhance control over the finishing process, with some even incorporating drying features.

Products finished with vibratory tumblers are frequently used in sectors such as aerospace, firearms, machinery components, and orthopedic implants.

Finishing media, also known as abrasive media or tumbling media, are essential materials used to polish, deburr, clean, and refine metal and non-metal components during the vibratory finishing process. As the finishing media moves within a vibratory bowl or tumbler, it rubs against the surfaces of parts to smooth rough edges, remove burrs, and create uniform finishes. The type, grade, shape, and size of media dramatically impact the surface quality, cycle time, and end appearance of your workpieces. Carefully selecting the right finishing media helps achieve high-quality, cost-effective surface finishing results for applications in industries such as automotive, aerospace, manufacturing, medical device production, and jewelry making.

The types of finishing media in vibratory finishing, categorized by material type, include:

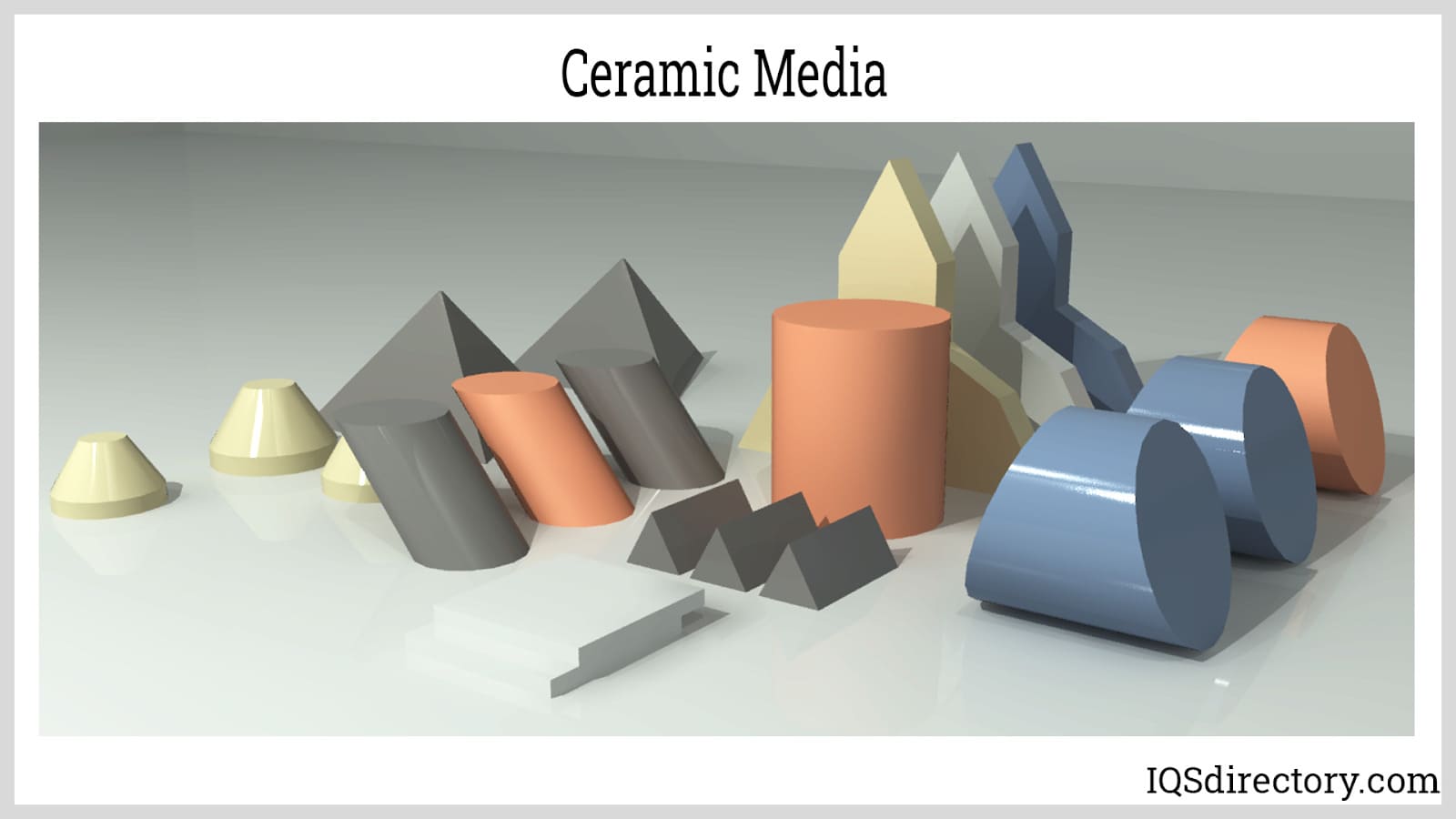

Ceramic media is the most widely used vibratory finishing media, recognized for its high density, strength, and toughness. Ceramic media is ideal for heavy-duty applications such as deburring, edge radiusing, burnishing, and polishing hard metals like steel, stainless steel, titanium, and hardened alloys. Its aggressive abrasive action makes ceramic media suitable for rust removal, surface preparation before coating or painting, and fast grinding operations. Common applications include the removal of machining marks, surface refinement, and preparation for painting or powder coating.

Ceramic media is usually composed of materials like porcelain, aluminum oxide, silicon carbide, and silica. Aluminum oxide and silicon carbide are popular choices for rapidly processing harder metals, while silica-based ceramics are designed for gentler action on softer alloys. However, users should note that ceramic media can chip, generating loose ceramic particles that may lodge in small holes or tight tolerances on complex parts. Proper media selection and screening can help minimize this risk.

Steel media, manufactured from hardened carbon steel or stainless steel, features a very high density and exceptional durability. Steel media is widely used for burnishing, ball burnishing, and polishing in vibratory finishing machines. They deliver a bright, smooth, burr-free surface, making them ideal for finishing operations where a mirror-like or highly reflective finish is required on non-ferrous and ferrous components such as aluminum, brass, copper, and steel. Steel media’s robust construction allows for extended service life and excellent wear resistance, making them cost-effective for high-volume industrial processes. Their substantial mass enables aggressive media action, suitable for removing heavy burrs or providing fine finishing after initial grinding steps. Steel tumbling media also resists corrosion when manufactured from stainless alloys, making it safe for use with both ferrous and non-ferrous metals as well as plastic parts that require high-impact finishing.

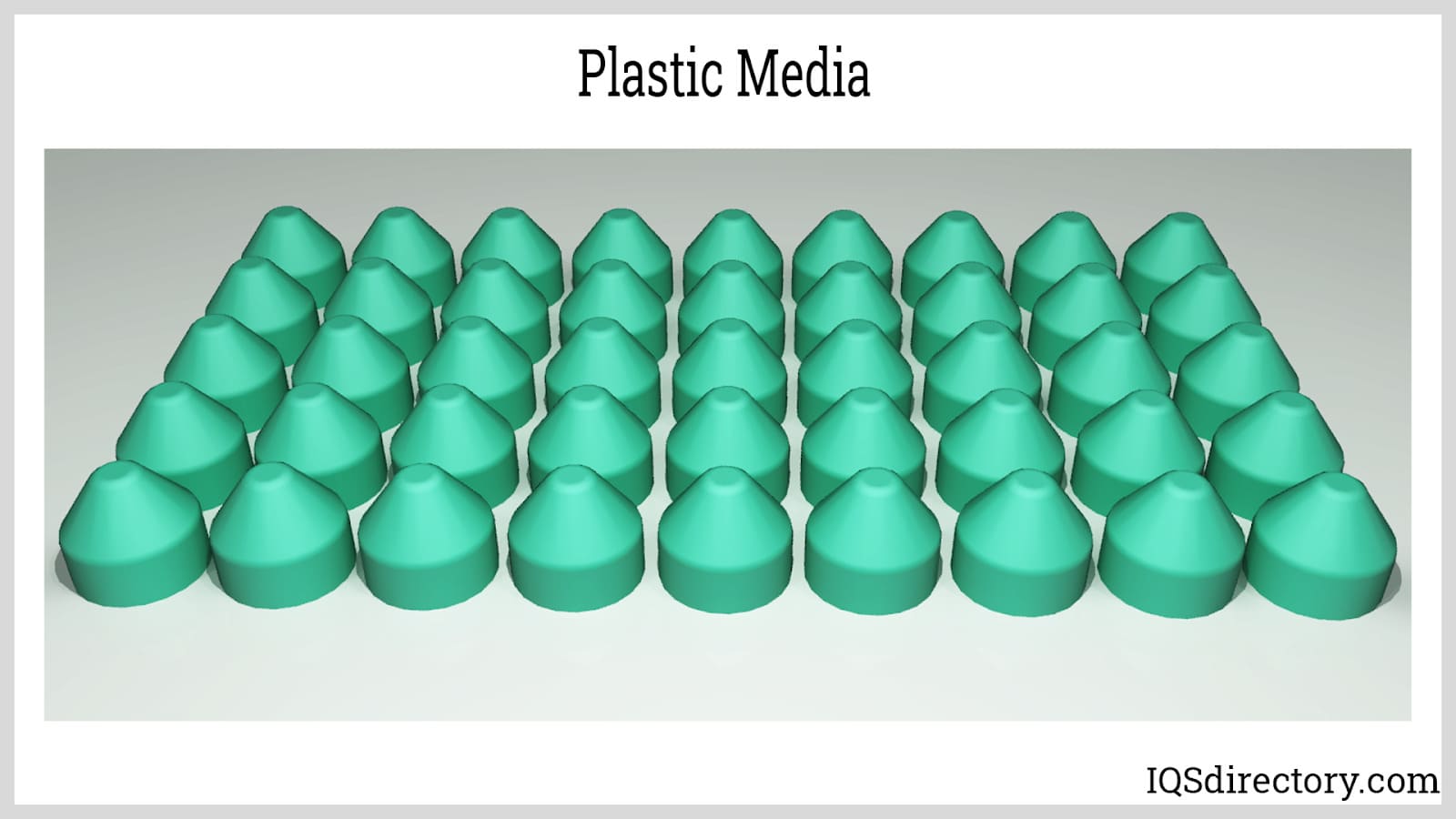

Plastic media, made from durable polymers such as polyester, urea, or formaldehyde, offers a versatile choice for finishing softer, delicate, or threaded components. Plastic vibratory media is particularly effective for deburring, cleaning, burnishing, and polishing non-ferrous metals such as aluminum, zinc, brass, copper, and specialty alloys. Its lower density reduces the risk of distorting or damaging thin-walled or intricate parts, making it a safe and dependable option for industries that require tight dimensional tolerances and gentle surface enhancement, such as electronics, medical devices, and precision engineering.

Plastic media formulations are engineered to deliver specific results and are often selected based on part geometry, material, and the level of abrasion required:

Plastic tumbling media is also available in a variety of shapes and sizes to optimize media-to-part contact, flow, and finishing action.

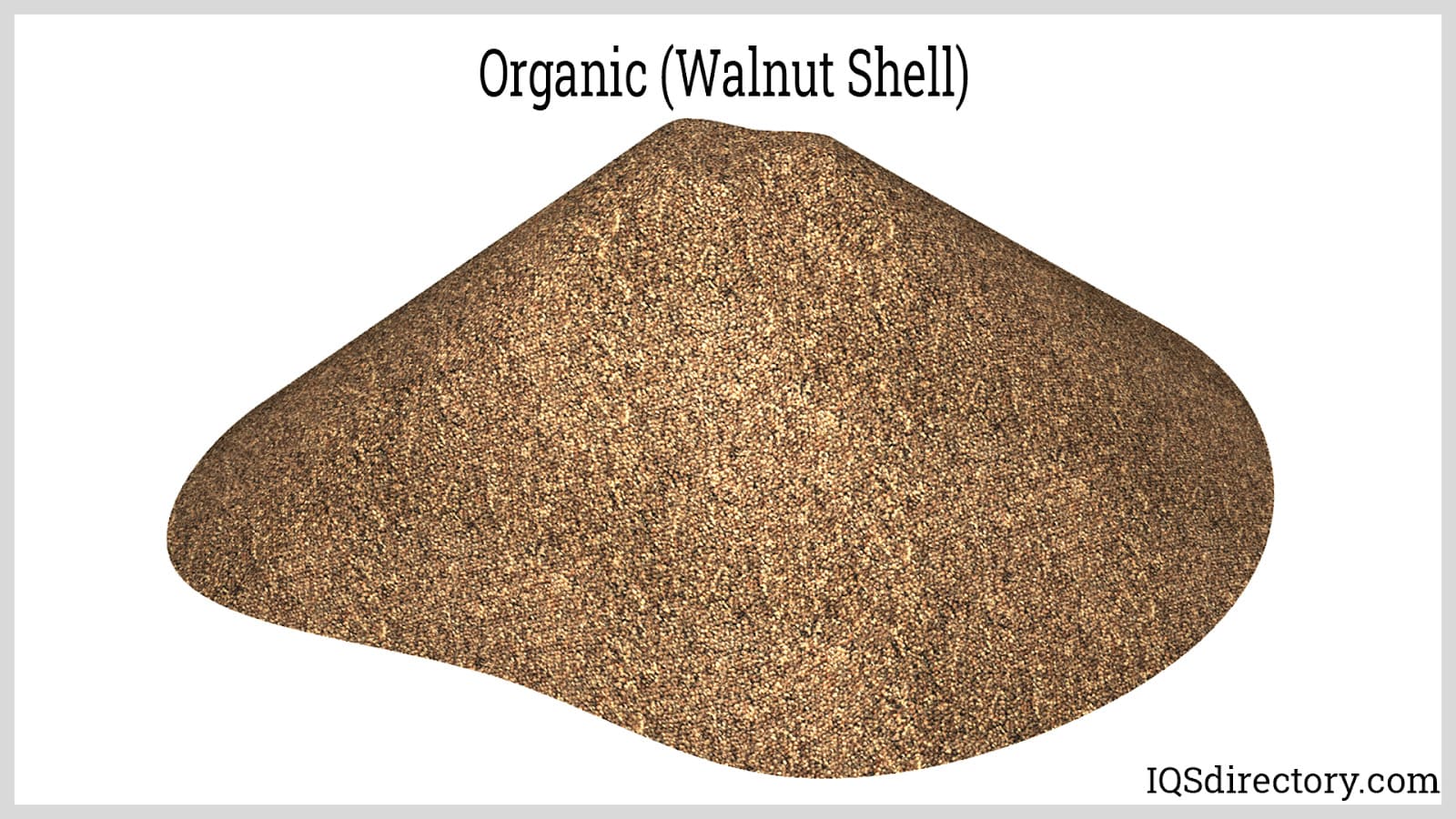

Organic media, typically made from natural materials such as ground walnut shells and crushed corn cobs, is preferred for environmentally friendly, non-toxic, and biodegradable finishing. Organic media is especially suitable for light deburring, fine polishing, and cleaning sensitive metals (including jewelry, brass, and bronze) without damaging the underlying surface. Organic media can also be used as a drying media after a wet vibratory process, absorbing moisture and residual oils to enhance corrosion resistance and surface cleanliness. Polishing with organic media and appropriate compounds produces a bright, glossy, and professional finish on components. Overall, organic finishing media is ideal for applications requiring a gentle touch, low environmental impact, and media reusability.

The grades of vibratory finishing media are as follows:

Light cutting media offer gentle abrasive action, making them a popular choice for deburring, deflashing, and burnishing delicate or thin-walled parts. These media produce refined, smooth, and bright surfaces, ideal for final finishing prior to plating, anodizing, or coating.

Non-abrasive or polishing media are formulated to create a lustrous, smooth, and flawless finish without removing significant material. These media are common in final surface refinement and are used for high-gloss polishing of precious metals, plated parts, and optical components.

Medium cutting media provide a balance between material removal and surface quality, enabling efficient deburring of machined or stamped components while maintaining surface integrity and brightness. Medium-cut media are ideal for general-purpose vibratory finishing applications across metal fabrication, casting, and industrial manufacturing sectors.

Fast cutting media deliver aggressive abrasive action, designed for rapid removal of heavy burrs, scale, or oxidation from tough or heavily worked parts. These high-performance media are the preferred choice for pre-finishing, where cycle time and throughput are critical, such as in high-volume manufacturing or foundry applications.

The shape and size of media are vital factors in vibratory finishing efficiency, media flow, and access to intricate part geometries. The most commonly available media shapes and their best-use applications include:

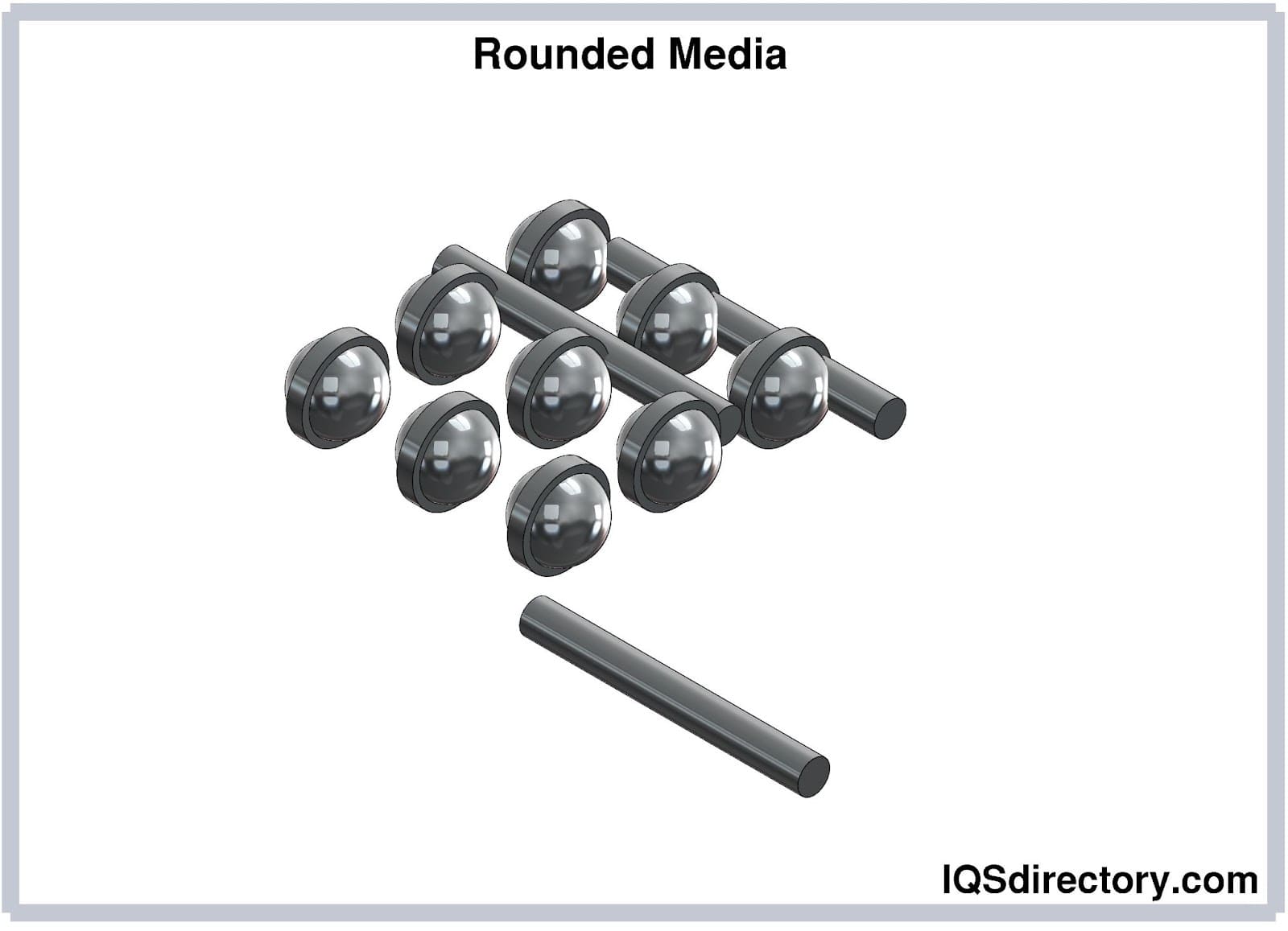

Rounded Media (spheres, oval, and cylinders) function ideally for light deburring, contaminant removal, and the finishing of smooth, contoured surfaces. Their smooth edges minimize the risk of part lodging, jamming, and media chipping, making them well-suited for parts with minimal recesses or undercuts.

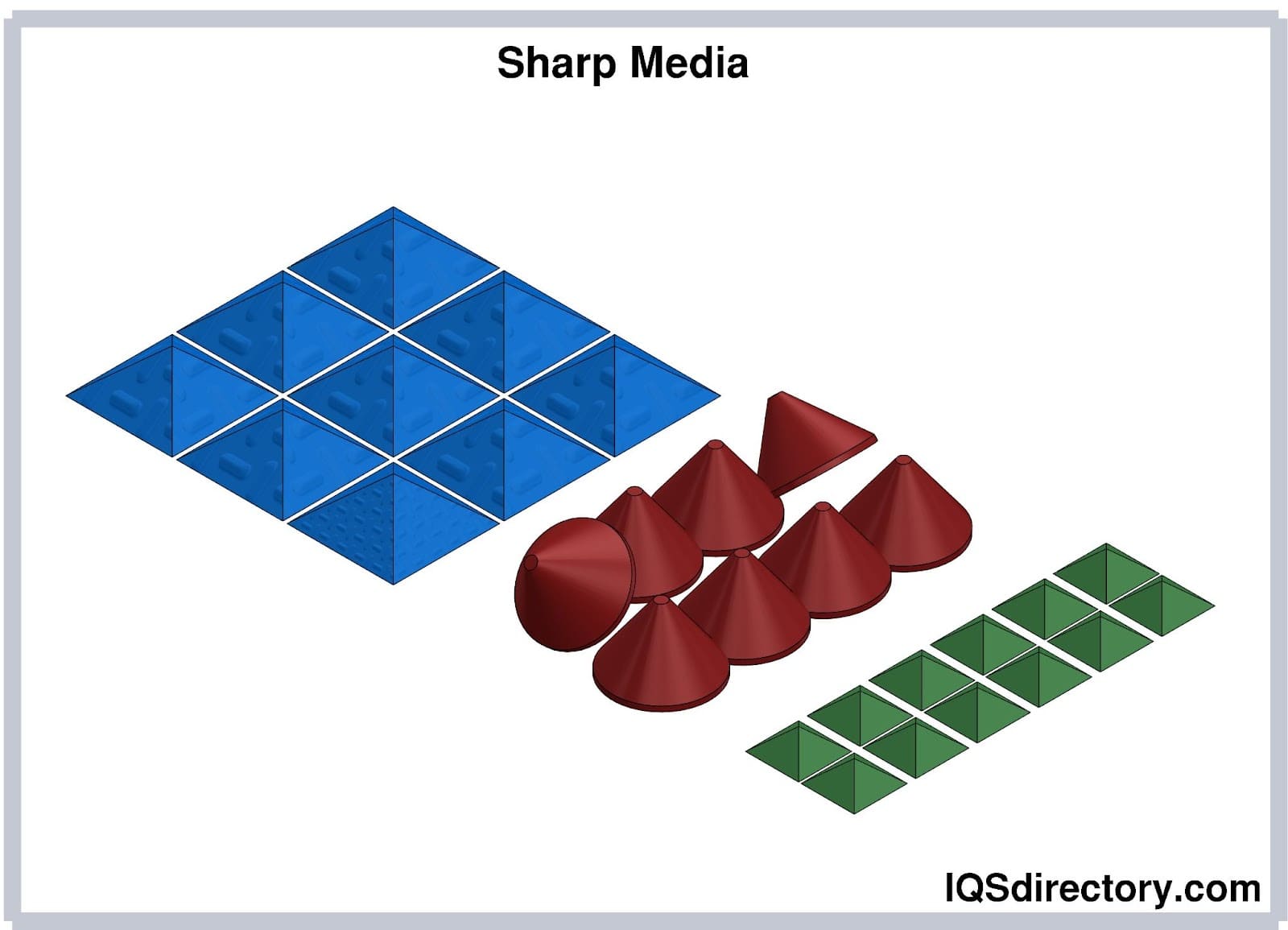

Sharp Media (triangles, wedges, and arrowheads) are specifically designed for deburring, edge radiusing, and cleaning hard-to-reach recesses such as holes, grooves, and sharp internal corners. Their flat faces and sharp angles efficiently finish areas where rounded media may fail to contact effectively. While these shapes are more prone to chipping, they excel at accessing intricate part details and providing maximum abrasive action on edges.

How to Choose the Best Vibratory Finishing Media for Your Needs

Selecting the right vibratory finishing media depends on several key considerations, including the material of your workpiece (aluminum, steel, brass, plastic, etc.), part geometry, required surface finish, cycle time, and post-processing requirements such as cleaning, plating, or painting. Factors such as media composition, size, shape, cut rate, and reusability all play a role in achieving optimal results and minimizing part damage or media impingement. Consult your vibratory finishing equipment supplier or media manufacturer for guidance and sample testing to determine the perfect match for your application.

Additional aspects such as media-to-part ratio, media wear rate, and compatibility with finishing compounds or lubricants should also be evaluated. Understanding these principles will ensure consistent, cost-effective, and high-quality vibratory finishing outcomes across a wide range of industrial, automotive, aerospace, and precision engineering uses.

Before discussing the specific types of vibratory tumblers, it is important to understand the two primary vibratory finishing processes: dry vibratory finishing and wet vibratory finishing. Each method utilizes distinct vibratory equipment and media, which affect surface treatment results, material removal rates, and overall efficiency for diverse finishing applications.

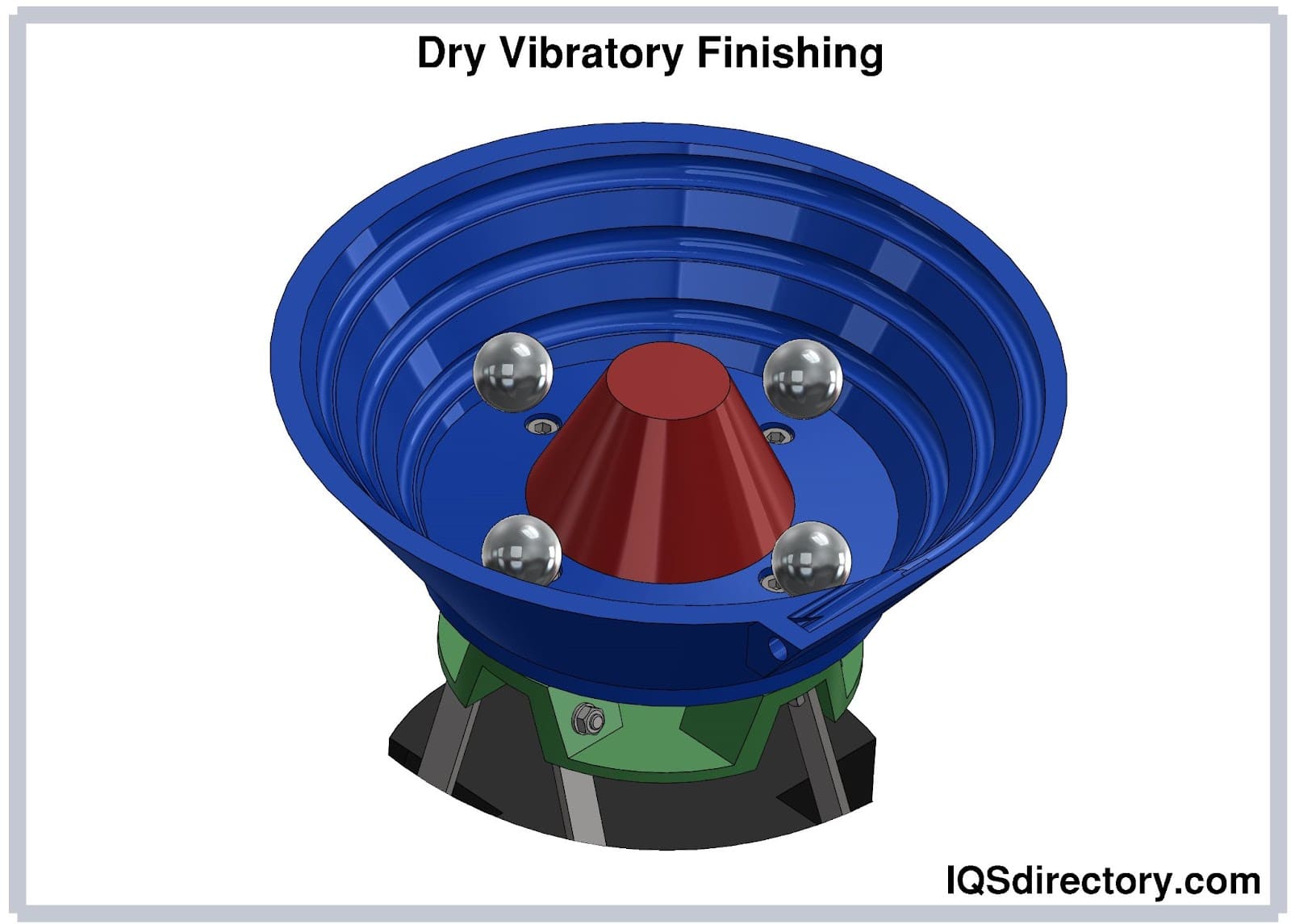

In a dry vibratory finishing process, finishing is accomplished solely by the tumbling media, without the use of specialty chemicals or water. Typically, non-abrasive media, such as corn cob grit, walnut shell media, or other organic materials, are used for surface treatment. This process is effective for deburring, light cleaning, and especially for drying and polishing parts, resulting in a bright and lustrous surface finish on the workpiece.

Dry vibratory finishing is generally less expensive than wet vibratory finishing, making it attractive for cost-sensitive operations. However, dry media can become contaminated with dirt, oils, and metal oxides after several cycles, reducing polishing performance and risking contamination of sensitive machined parts. Harder, denser media types, such as ceramic vibratory tumbling media, may also scratch soft workpieces or delicate components. Additionally, dry compounds wear down over multiple processing cycles, necessitating the use of an effective dust or particulate collector system to maintain workplace safety and product cleanliness. Dry finishing operations may also generate significant noise, requiring noise-reduction enclosures or ear protection for operators.

Wet vibratory finishing is a surface finishing process that uses a liquid solution—typically water combined with specialty finishing compounds—to assist in the tumbling process. The addition of fluids acts as a lubricant and coolant, reducing the heat generated from the rubbing of the abrasive media and workpiece. The processing liquid also helps remove oxides, grease, machining oil, and surface contamination, resulting in a cleaner and more highly polished part. The finishing media absorbs some of the solution, which minimizes workpiece distortion and reduces overall debris generation and redeposition on the media itself.

This versatile method can be performed using virtually all types of vibratory media—ranging from ceramic, plastic, and stainless steel to synthetic and abrasive compounds—with the exception of organic media, which are typically reserved for dry finishing. Wet vibratory finishing offers a broader range of customizable surface treatments, including aggressive deburring, descaling, radiusing, precision smoothing, and mirror polishing. The wet process is generally more popular for mass finishing applications in industries like aerospace, automotive, and metal fabrication, thanks to its wide range of surface finish capabilities. However, the process is generally more expensive due to the requirement for chemical compound replenishment and wastewater treatment/disposal of spent process fluids.

The main types of vibratory tumblers used in industrial finishing processes are detailed below:

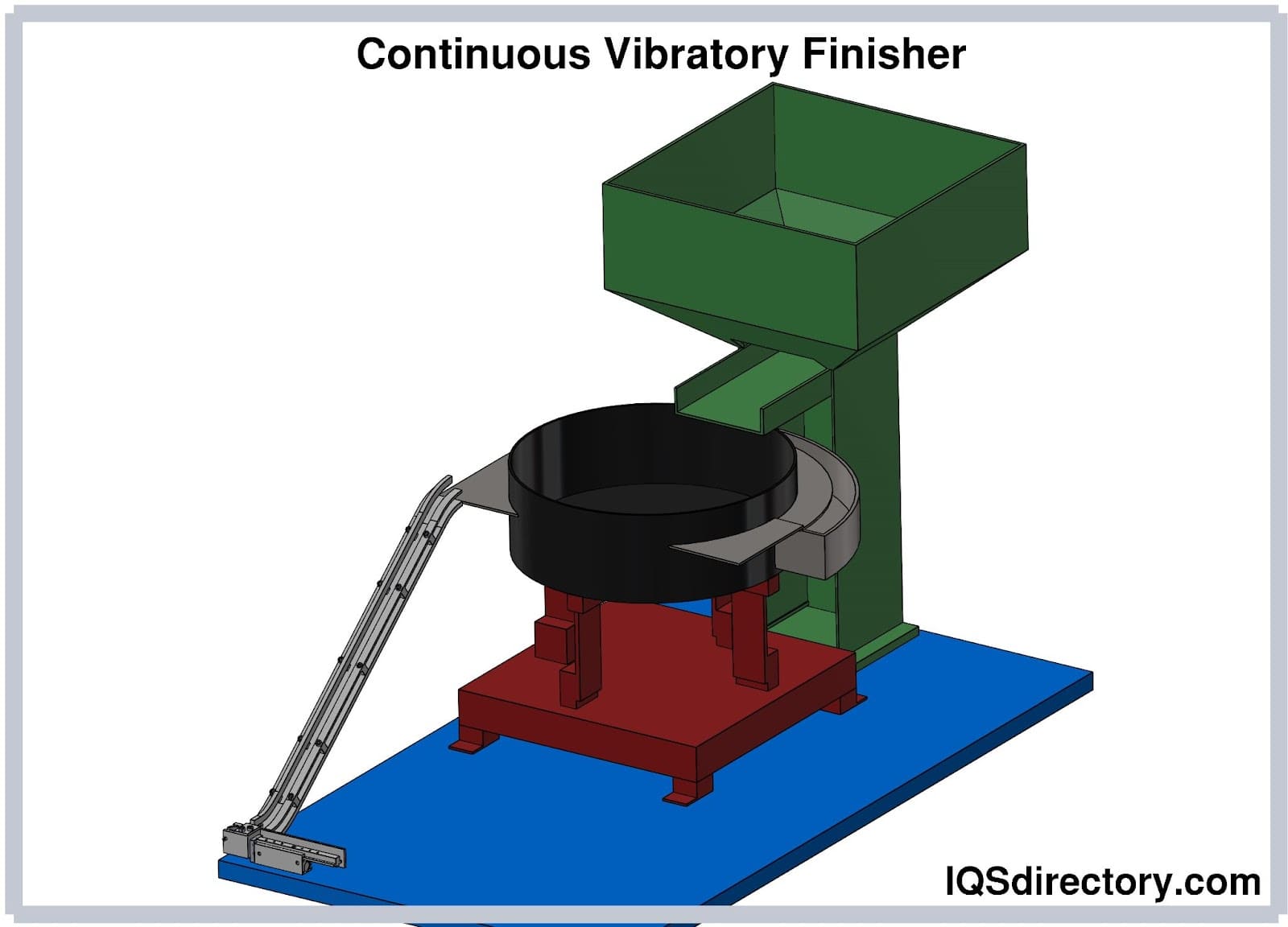

A continuous vibratory finisher is a high-efficiency vibratory finishing machine in which unfinished parts are introduced at one end, processed as they travel the length of the working chamber along with the tumbling media, and discharged automatically at the opposite end. This process is ideal for high-volume operations, such as mass finishing, because it combines simultaneous finishing and part conveyance—effectively reducing processing cycle time and streamlining part flow for bulk production environments.

Continuous vibratory finishers provide excellent process control, consistency, and automation potential, making them ideal for applications such as deburring, edge rounding, surface smoothing, and cleaning of parts prior to coating or assembly. They can also be integrated with automated part-handling and separation systems for seamless in-line manufacturing.

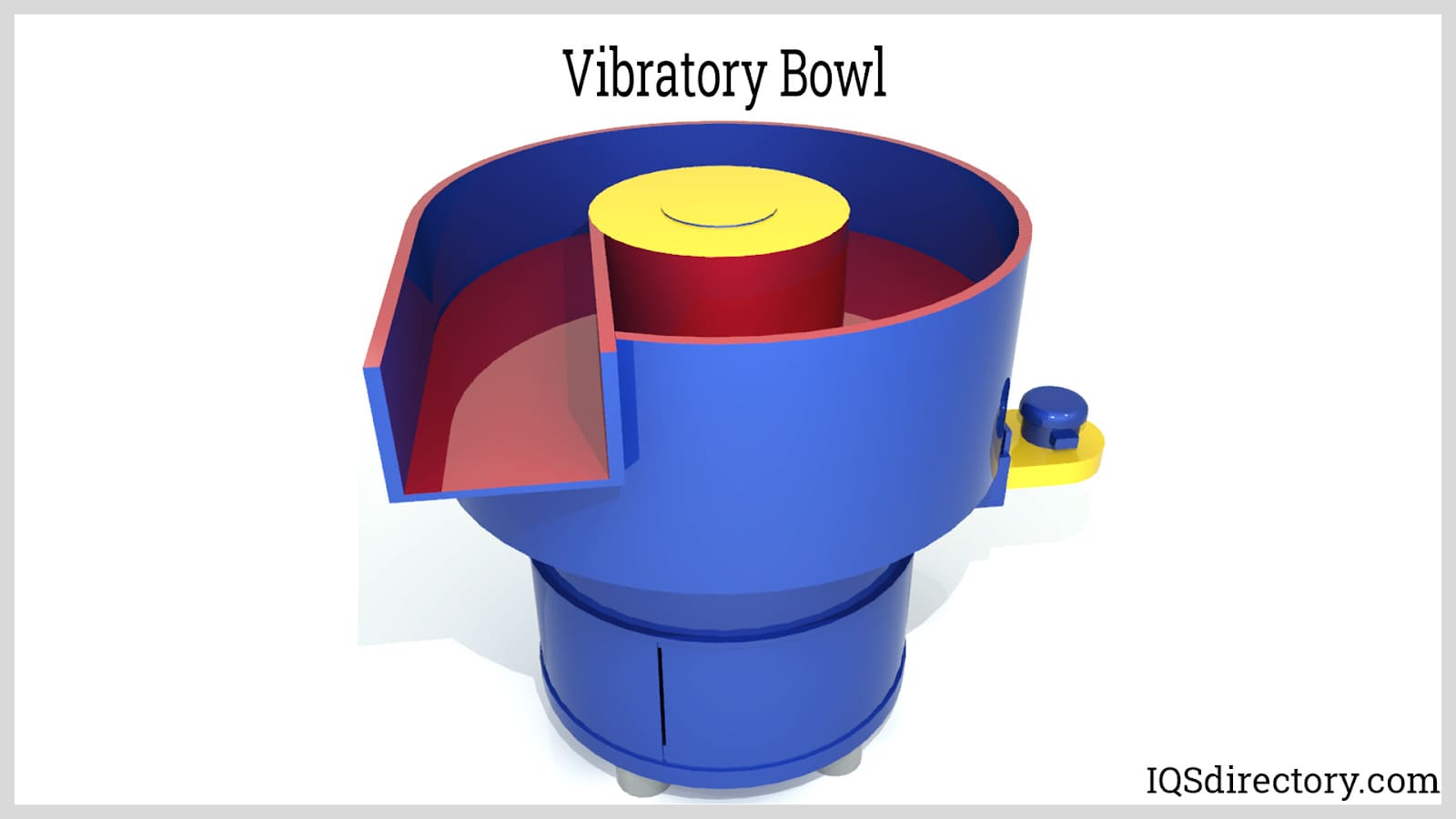

The vibratory bowl is the most common and simplest configuration of vibratory finishing equipment. It features a work chamber in the shape of a bowl—typically lined with polyurethane or rubber. The lining reduces the coefficient of friction between the bowl and tumbling media, thus protecting both the machine and the parts from excessive wear during the finishing process. Adjustable or removable dividers can be installed to process small, sensitive, or precision-machined components in separate compartments, preventing part-to-part impingement and surface damage.

Vibratory bowls are available in a wide range of shapes and sizes, including round, rectangular, or bowl-shaped tubs. Some models are designed with narrow central channels to accommodate larger or unusually shaped products. The variety of bowl geometries allows manufacturers to select equipment best suited to their part dimensions, material, and desired finishing result.

For production flexibility, vibratory bowls are offered in bench-top, portable, and table-mounted versions for low- to medium-capacity finishing, as well as large industrial units for high-volume batch processing. Typical applications include deburring, polishing, surface smoothing, burnishing, and cleaning metal and plastic workpieces.

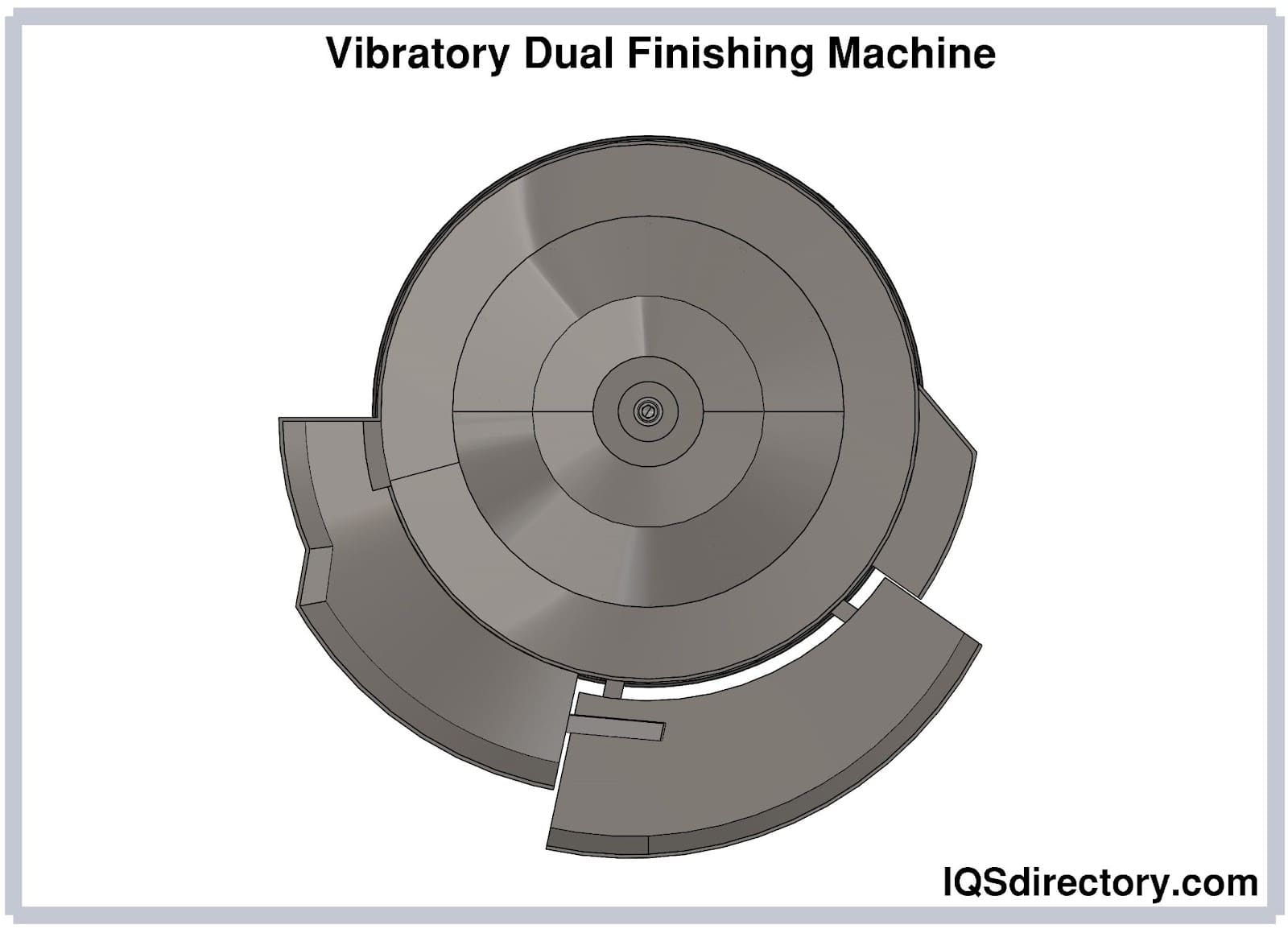

The vibratory dual finishing machine incorporates both wet and dry finishing capabilities within a single machine, utilizing an inner chamber and outer chamber design. The inner work chamber, which is usually lined with durable polyurethane, performs wet finishing processes—such as abrasive deburring, radiusing, polishing, or burnishing—with the assistance of finishing compounds. Once the primary surface treatment is complete, parts are separated from the media and transferred to the heated outer chamber, where drying media perform the drying and cleaning stages. A stable, leak-proof partition separates both chambers to avoid cross-contamination of liquids and dry materials.

This two-in-one finishing solution is highly cost-effective, especially for shops or facilities needing both wet and dry process steps within one compact system. It streamlines the workflow by eliminating the need for separate tumblers or dryers and minimizes labor cost. Vibratory dual finishing machines are commonly used for manufacturing processes requiring sequential surface finishing and drying, such as components destined for plating, painting, or further value-added operations.

Vibratory dryers use elliptically shaped tubs filled with heated drying media—commonly treated corn cob grit or synthetic granules—to effectively dry parts following a wet vibratory finishing process. In addition to removing residual moisture from the surfaces of finished parts, vibratory dryers can round out the finishing sequence by providing additional polishing and removal of fine surface particles.

Vibratory drying machines can accommodate both small and large production volumes, with options for batch or continuous operation to match the demands of automated manufacturing or flexible job-shop environments. They are frequently integrated into in-line production setups, allowing wet-finished parts to be automatically conveyed to the dryer for immediate, efficient post-process drying, ultimately improving workflow and turnaround times for mass finishing processes.

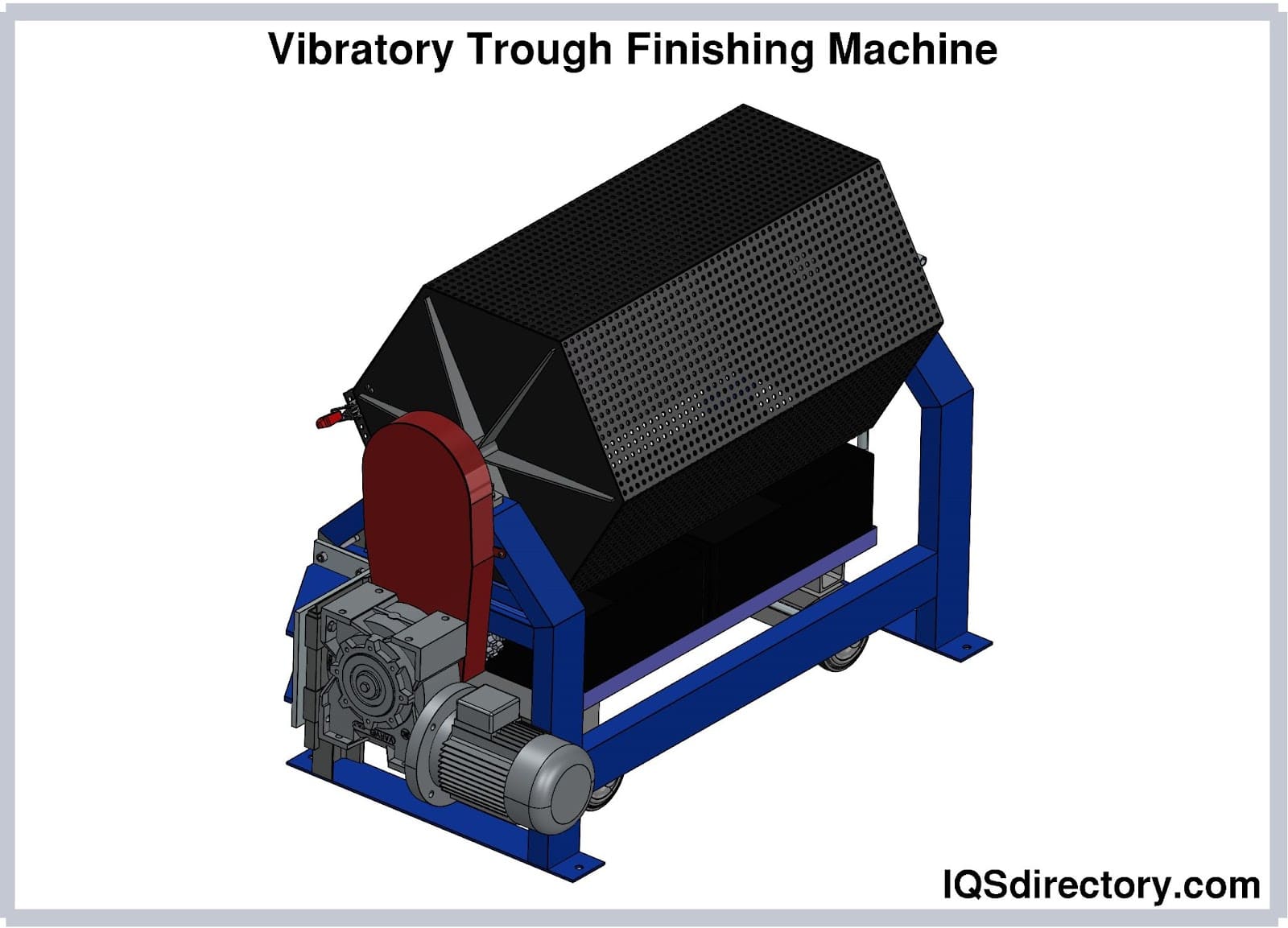

A vibratory trough finishing machine features a long, enclosed U-shaped tub lined with polyurethane, with manually adjustable divider plates inside the tub. This type of tumbler is ideal for vibratory finishing of long, large, or irregularly shaped parts, as well as delicate workpieces that could be damaged by contact with each other. The divider plates create custom chambers within the tub, isolating each part to prevent unwanted part-to-part contact and surface marring during the finishing cycle.

Vibratory trough finishing machines offer exceptional versatility, performing nearly all types of vibratory finishing operations—such as deburring, polishing, descaling, and surface smoothing—across a wide range of part sizes and shapes. Standard and custom configurations are available, with variable tub lengths, widths, and capacities to suit a variety of batch or continuous finishing requirements. Their adaptability makes them a popular choice in the automotive, aerospace, casting, and fabrication industries for both prototype work and high-volume manufacturing.

Choosing the Right Vibratory Tumbler: When evaluating vibratory finishing equipment, it is essential to consider important factors such as part size, shape, desired surface finish, production volume, media type, and overall process requirements. Understanding the differences between batch vs. continuous operation, as well as specific machine features—such as automated separation, noise control, and compound dispensing—will help manufacturers select the best vibratory tumbler for their unique application. Investing in the right finishing equipment optimizes productivity, improves part quality, and contributes to efficient, cost-effective operations in highly competitive manufacturing environments.

Here are additional considerations for selecting and operating vibratory tumblers:

The media-to-parts ratio refers to the volume of finishing media relative to the total volume of the parts. For sensitive or soft parts, a higher media-to-parts ratio is preferred to minimize scratching caused by part-to-part contact. When working with delicate products, using a divider plate is recommended. This ratio helps determine the appropriate volume for your application, with the total part and media volume ideally occupying 90% of the tub's capacity. The characteristics of the parts will influence the media-to-parts ratio. The table below outlines various media-to-parts ratios and their specific applications:

| Media-to-Parts Ratio | Application |

|---|---|

| 0:1 | Part-to-part finishing. No media is present. |

| 1:1 | Equal volumes of media and parts. Produces rough surface finish on forgings, castings, and stampings. |

| 2:1 | Still produces rough surface finish on forgings, castings, and stampings. Finishing of very small parts. |

| 3:1 | Ideal ratio for moderate deburring and surface finishing |

| 4:1 | Good ratio for ferrous metals. Sufficient ratio for non-ferrous parts. |

| 5:1 | Minimal part-to-part interaction. Suitable for soft and non-ferrous parts. |

| 6:1 | Finishing non-ferrous and fragile parts for pre-plate and decorative finish. |

| 8:1 | Bright burnished finish and high quality pre-plate finish. |

| 10:1 | Finishing fragile, sensitive, and irregularly shaped parts. |

Frequency and amplitude are key properties that define the intensity of vibration. Frequency refers to the number of vibration cycles per minute (CPM), while amplitude measures the maximum distance the vibrating object moves from its stationary position, typically in millimeters. Vibratory tumblers can operate with frequencies ranging from 900 to 3600 CPM and amplitudes from 1 to 8 mm. Amplitude can be adjusted using the motor's controls.

The surface finishing of delicate and fragile parts is best achieved using high frequency with low amplitude vibration. Conversely, processes such as burnishing, deburring, and radiusing require larger amplitudes.

A Barrel tumbler is another type of tumble mass finishing equipment. It works by rotating the parts, the media, and the finishing chemical inside a barrel. The rotational movement causes the parts and the workpiece to rub against each other. Like vibratory tumblers, barrel tumblers also perform a variety of finishing processes, from heavy cutting actions like burnishing, deburring, radiusing, and deflashing to surface improvement such as polishing, cleaning, and drying. Barrel tumblers typically operate in a batch production mode, though continuous or in-line configurations are less commonly found.

We will now compare vibratory tumblers and barrel tumblers across various aspects.

Vibratory tumblers are effective for finishing nearly all types of parts, including delicate, soft, and fragile ones. They are particularly recommended for such parts because divider plates can be used to prevent part-to-part contact. Vibratory tumblers help maintain the original shape of the parts as the tub remains stationary during operation and can also handle long parts. In contrast, rotary tumblers are better suited for smaller, harder parts.

The media used in rotary tumblers wear out more slowly compared to vibratory tumbler media, lasting about twice as long. However, rotary tumblers require more time to achieve the same finishing results as vibratory tumblers. Additionally, rotary tumblers typically consume more media.

Vibratory tumblers produce finished parts more quickly than rotary tumblers.

Rotary tumblers are well-suited for heavy deburring, radiusing, and size reduction, as they can deform parts to some extent and shape rough, irregularly shaped parts into smooth, rounded forms. On the other hand, vibratory tumblers are ideal for polishing, cleaning, and drying, though they are also capable of handling heavy finishing tasks.

Vibratory tumblers are generally more expensive than rotary tumblers because of their robust construction, versatility, and additional features. They also require more floor space. In contrast, rotary tumblers have a lower initial cost.

Vibratory tumblers can be quite noisy during operation due to the strong vibration force causing the contents to oscillate against the tub. However, advanced models offer noise control features. In contrast, rotary tumblers produce less noise.

Deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial...

Finishing machines are machines used for metal finishing, which is the last stage of the metal fabrication process; the stage encompasses the use of machines in finishing the metal surface...

A tumbling machine is a durable deburring and metal-polishing machine designed for finishing large parts or batches of smaller parts. A tumbling machine is also known as a barreling machine or a mass-finishing...

Industries worldwide utilize abrasive blasting for various purposes, including cleaning rust and oil, removing surface coatings like paint and pollutants, preparing surfaces for paint and coatings, reinforcing metal surfaces and...

An aqueous part washer is an automated or semi-automated machine manufactured to clean, remove tough grease, and dry large or small parts before distribution or surface treatment. The washing is necessary since...

Automated parts washers are mechanical devices designed to efficiently remove grit, oil, grime, dirt, paint and other contaminating substances from parts with minimum manual supervision. These substances are removed...

A parts cleaner is a cleaning device that uses various types of solvents, cleaning agents, and processes to remove grease, grime, and contaminating materials from manufactured parts prior to shipment or movement for further processing...

A parts washer is a mechanical device designed to remove grit, grime, oil, miscellaneous debris, dirt, paint, and other contaminating substances from parts in preparation for their use in assembly operations, packaging, or coating...

Sandblast cabinets include systems or machinery and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel...

Sandblasting equipment includes systems or machinery, and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel...

Shot peening equipment includes systems or machinery and components for projecting shot peening media against a part‘s surface to modify the surface or surface engineer the part...

An ultrasonic cleaner is a type of sonic cleaner or sonic cleaning machine that uses cavitation to remove unwanted material. The cleaning effect is created by the compression and refraction of a cleaning medium. Miniscule vibrations propagate throughout the...

Ultrasonic cleaning is a type of cleaning process which uses cavitation induced by alternating compression and rarefaction cycles at ultrasonic frequencies. Ultrasonic frequencies are sound waves vibrating at 20 kHz or higher...

A wastewater evaporator is a method of removing water from water-based waste by converting the water in the waste to a vapor and leaving contaminants. The function of a wastewater evaporator is to reduce the volume of waste materials...

Parts washers are designed for cleaning, degreasing of equipment, and drying of mass quantities of small or large parts in preparation for surface treatment, assembly, inspection, or shipment...