Die Casting

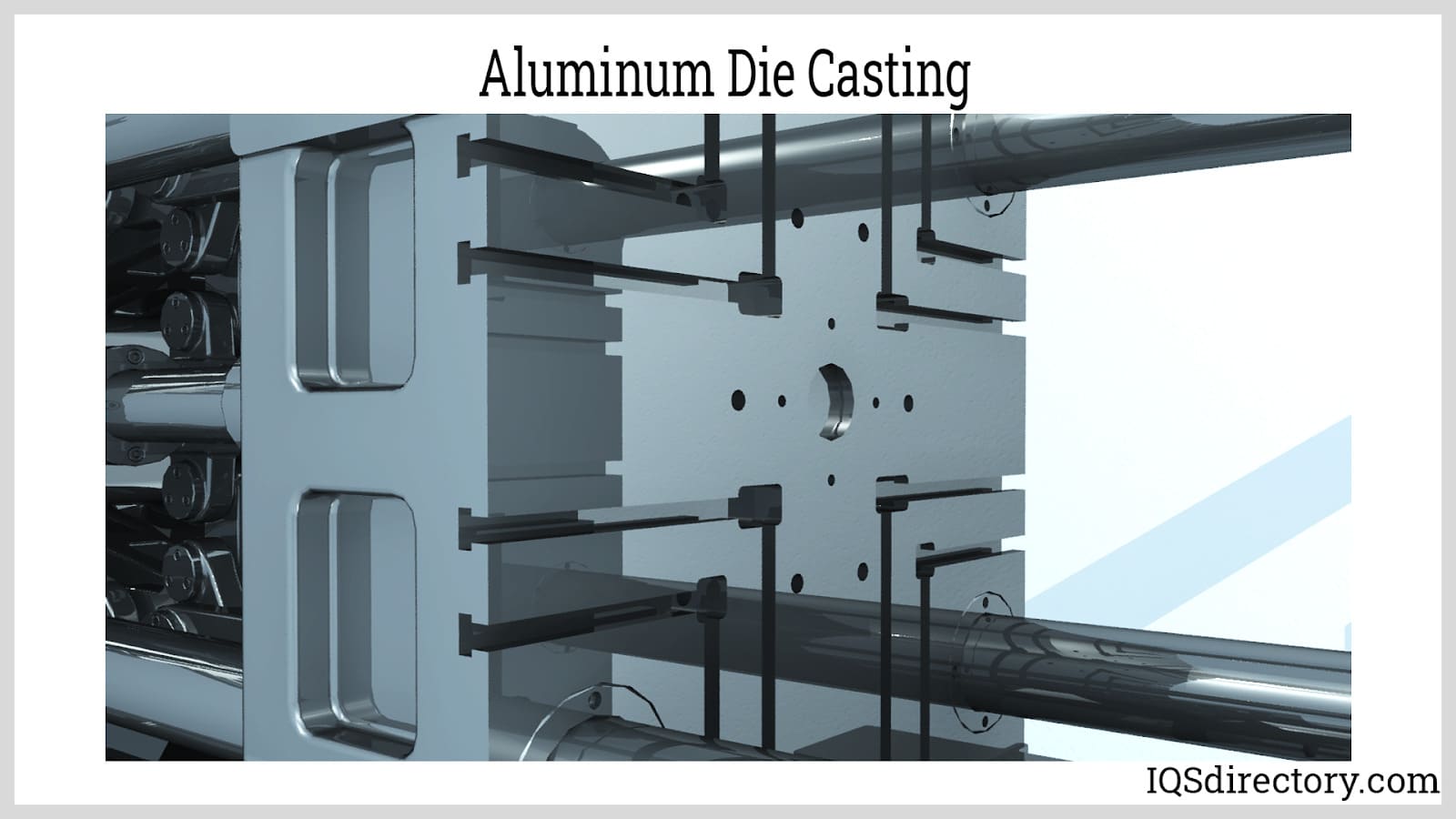

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article contains all the information you need to know about aluminum casting.

You will learn about topics such as:

Aluminum casting is the process of pouring molten aluminum into specially crafted dies, molds, or forms to manufacture parts with high precision and superior quality. This highly effective method is perfect for producing intricate, complex, and highly detailed components that accurately adhere to the design specifications originally outlined.

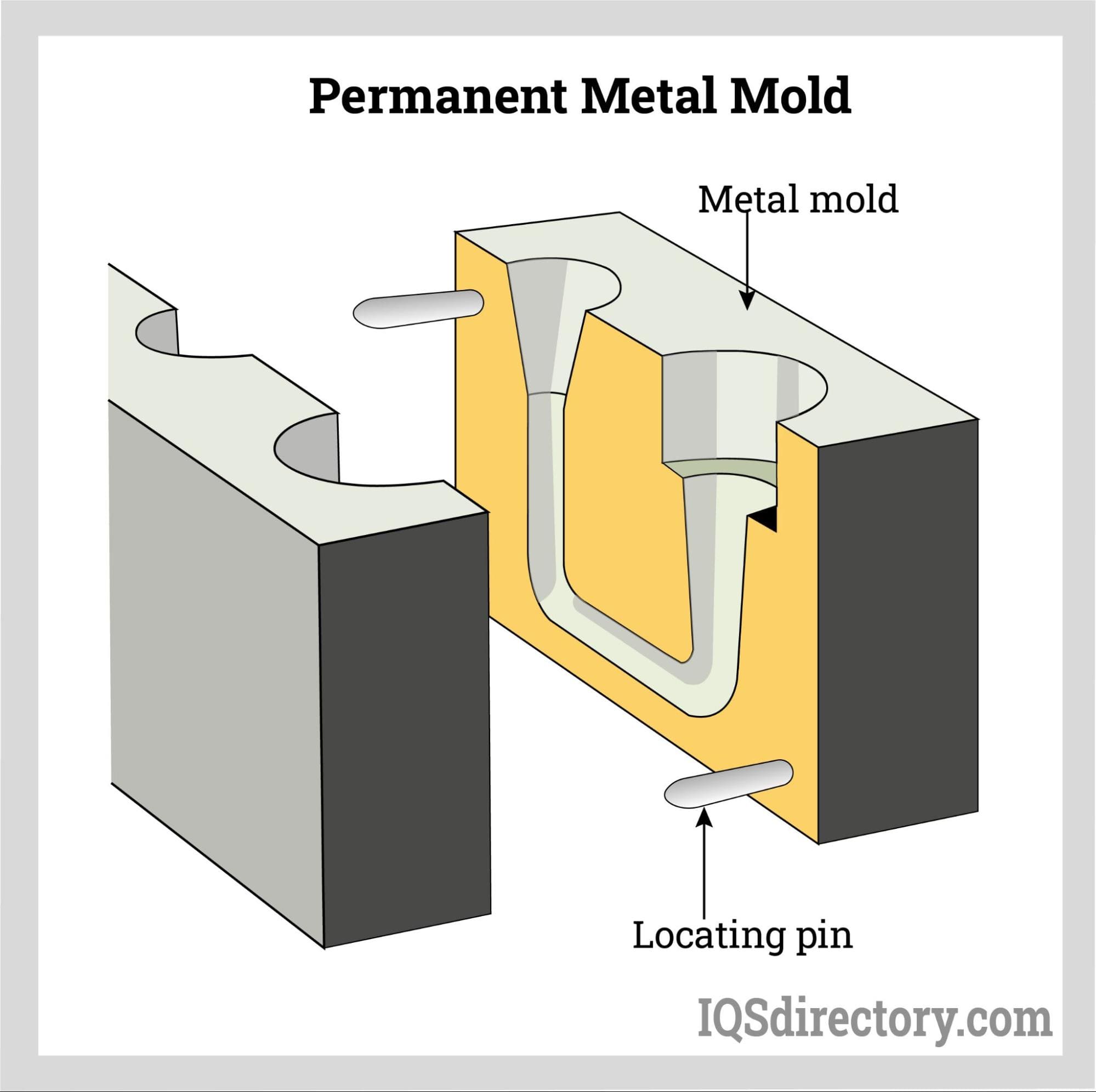

A common and highly efficient method for casting aluminum and aluminum alloys involves pouring molten aluminum into steel or iron molds that are precision-engineered to ensure exceptional dimensional accuracy, consistent part quality, and a smooth, finished surface. These reusable or permanent molds, often made from high-melting-point metals such as tool steel or gray iron, are specifically designed to withstand the rigorous temperatures of molten aluminum, making them ideal for aluminum mold casting applications.

Reusable or permanent molds are highly suitable for high-volume manufacturing production runs and mass production, as they can be used repeatedly over thousands of casting cycles. This approach, known as permanent mold casting, allows manufacturers to create complex geometries, intricate designs, and thin-wall aluminum parts with minimal labor costs and a high degree of repeatability. Additionally, this efficient metal casting process generates very little scrap waste, maximizing raw material utilization and resulting in significant cost savings for both manufacturers and their customers. The ability to recycle and re-use molds contributes to sustainable manufacturing practices as well.

However, it is worth noting that the initial creation, CNC machining, and tooling of these durable molds is labor-intensive and requires upfront investment, which should be considered when evaluating overall production costs versus other casting methods such as sand casting or low-pressure casting. Despite this, the long-term benefits—such as reduced per-unit cost, exceptional part consistency, and shorter lead times—often outweigh the initial setup expenses for mid- to large-scale aluminum casting projects.

One significant cost in aluminum permanent mold casting lies in the precision machining and thermal treatment of the mold, which is typically made from robust gray iron or tool-grade steel. The mold is meticulously engineered to match the exact geometric shape and casting tolerance required for the part—often split into two or more halves (sometimes called die halves). During metal casting, these halves are clamped tightly together to prevent the introduction of air, contaminants, or inclusions, ensuring a dense and defect-free structure. The mold is carefully preheated before the molten aluminum is poured, injected, or gravity-fed into the cavity, reducing thermal shock and improving surface finish.

Once the molten aluminum is introduced, it is allowed to cool within the mold, enabling rapid solidification and minimizing grain structure defects. After cooling, the finished casting is quickly ejected or removed to avoid the risk of sticking or distortion, followed by any necessary secondary operations such as trimming or deburring.

Although the permanent mold casting process may seem straightforward, it is, in fact, a scientifically and technically advanced manufacturing method optimized for high-volume aluminum part production. This approach is favored in industries such as automotive, aerospace, marine, and industrial equipment sectors for the strength, consistency, and reliability of the produced components.

Die casting is a high-precision manufacturing process whereby molten aluminum is forcefully injected under high pressure into a custom-designed, hardened steel mold (die). Renowned for its ability to produce aluminum parts with tight tolerances, fine details, and smooth surfaces, die casting often eliminates the need for additional finishing or machining. Its fast production rates and capability for automation make it especially cost-effective for the mass production of high-volume aluminum components, such as automotive housings, consumer electronics frames, and industrial hardware.

There are two primary types of die casting used in the aluminum casting industry: hot chamber die casting and cold chamber die casting. The primary distinction between these methods is how the molten metal is delivered to the mold. In hot chamber die casting, commonly used for lower melting point metals, the melting pot is directly connected to the machine, and a plunger forces the material through a gooseneck into the die cavity. In contrast, cold chamber die casting is more suitable for high-melting-point metals such as aluminum alloys; here, the molten aluminum is ladled into a cooled chamber before being injected into the die by a plunger. This technique prevents excessive wear on the machinery and maintains the integrity of the molten aluminum.

Understanding the difference between these processes helps manufacturers and engineers select the optimal aluminum casting technique for their projects, balancing factors like cost, speed, precision, and material requirements. In the diagram below, hot chamber die casting is shown on the left, and cold chamber die casting is depicted on the right.

Vacuum die casting is an advanced variation of standard die casting that utilizes an airtight bell housing with a sprue opening at the bottom and a vacuum outlet at the top. The process is initiated by submerging the sprue beneath the surface of the molten aluminum alloy. By creating a controlled vacuum in the receiver, a pressure differential is established between the die cavity and the molten aluminum held in the crucible.

This pressure difference causes the molten aluminum to flow upward through the sprue, precisely filling the die cavity, which then allows the alloy to solidify with minimal porosity. Once the casting is cooled and fully solidified, the mold is separated from the vacuum receiver, opened, and the part is automatically ejected, minimizing cycle time and supporting high-volume production requirements.

By fine-tuning the vacuum and managing the pressure differential, vacuum die casting offers superior control over fill rate and part quality. This results in dense, reliable castings with enhanced mechanical properties and minimal defects—making it ideal for applications requiring airtight, pressure-resistant parts, such as hydraulic components, transmission housings, and aerospace-grade aluminum castings.

Submerging the sprue below the melt surface reduces oxidation and dross formation, yielding cleaner, higher-quality aluminum castings with minimal contamination—significantly advantageous for manufacturers who prioritize quality assurance and performance in their end products.

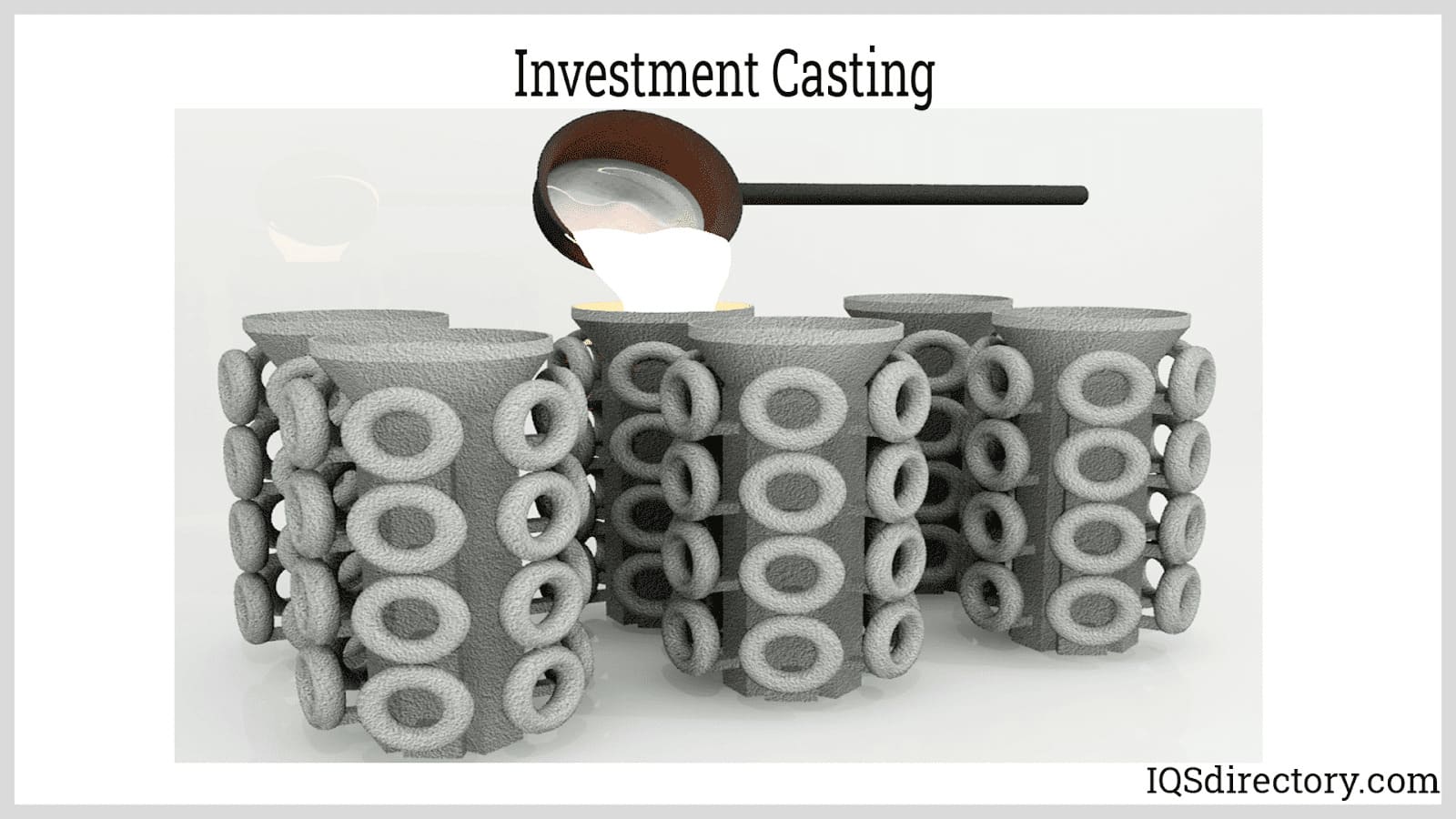

Investment casting, also referred to as the lost wax casting process, begins by precisely injecting wax into specially designed metal dies to form detailed patterns replicating the desired aluminum part. These wax patterns are mounted on a sprue system to create a "tree," enabling simultaneous production of multiple components. This assembly is repeatedly dipped into a refractory ceramic slurry, building a durable ceramic shell that will serve as the mold for molten aluminum.

After the ceramic shell has hardened, it undergoes a dewaxing stage in an autoclave to remove all traces of wax, leaving behind a cavity with exact detail and dimensional accuracy. The ceramic shell is then preheated to the target temperature to prepare for the aluminum casting process. Molten aluminum or specialty aluminum alloys are then poured through the sprue, filling every crevice in the delicate ceramic cavity. Once solidified, the ceramic shell is carefully broken away, and the individual investment cast aluminum parts are separated from the gating system and finished as needed.

Investment casting is significantly valued for its ability to deliver near-net-shape aluminum components with excellent detail, thin wall capability, and tight tolerances—suited for complex parts used in aerospace, defense, and high-performance industrial applications. This process is ideal when the production volume does not justify the expense of permanent molds, but high-quality surface finish and dimensional precision remain priorities.

The lost foam casting process is an innovative variation of investment casting that utilizes expanded polystyrene (EPS) foam patterns instead of wax. Lightweight foam patterns are molded using polystyrene beads injected into heated aluminum molds—commonly under low pressure and steam expansion to ensure uniformity and eliminate air gaps. These foam patterns are then assembled into clusters, similar to traditional investment casting runner and sprue systems, allowing manufacturers to produce multiple complex parts in one casting operation.

Next, the foam cluster is embedded in a dry, unbonded sand mold—vibrated mechanically to compact the sand tightly around the intricate pattern and eliminate all voids. When molten aluminum is poured directly into this sand mold, the foam evaporates completely, leaving a cavity that is immediately filled by the liquid metal, thus forming the aluminum casting.

Lost foam casting has gained popularity for producing near-net-shape aluminum castings with excellent dimensional accuracy, minimal finishing requirements, and high complexity. This process is commonly employed in the automotive industry for making engine blocks, intake manifolds, and other lightweight structural components. It also enables rapid prototyping for aluminum cast products, supporting agile product development and faster time-to-market.

When evaluating aluminum casting for your project, consider the specific requirements: part complexity, production volume, material properties, cost constraints, and required mechanical performance. Permanent mold and die casting processes excel in mass production and repeatability, while investment casting and lost foam casting provide flexibility for complex geometries and lower-volume runs.

Consulting with a reputable aluminum foundry or precision casting supplier can help determine the ideal process for your application. Whether your priority is aerospace-grade strength, lightweight automotive parts, intricate electronic housings, or industrial equipment components, understanding these advanced reusable aluminum casting methods empowers you to make informed decisions, optimize cost, and guarantee superior part quality—and remain competitive in today’s dynamic manufacturing environment.

Expendable aluminum casting, sometimes called disposable mold casting, refers to aluminum casting processes that utilize non-permanent molds. In these methods, the mold is intentionally destroyed or broken away in order to extract the finished aluminum casting. Common processes under the category of expendable mold casting include lost wax casting (investment casting), sand casting, lost foam casting, and investment casting. When manufacturing custom aluminum parts using expendable molds, manufacturers pour molten aluminum or aluminum alloys into the mold, which is then broken apart to release the solidified metal part. This cost-effective casting technique accommodates complex geometries and a broad range of metals, making it highly versatile for both prototyping and production runs across the automotive, aerospace, and machinery manufacturing industries.

Unlike permanent mold casting, expendable aluminum molds are typically fabricated from less expensive and more easily manipulated materials such as sand, ceramic, or polystyrene foam. This eliminates the need for intricate metal tooling or reusable dies. However, the trade-off of this lower-cost production method is a modest reduction in overall dimensional accuracy and surface finish quality, especially when compared with high-precision permanent mold processes. Still, expendable mold casting is ideal for short-run or custom part production, as it provides design flexibility, accommodates intricate internal features, and allows for rapid iteration.

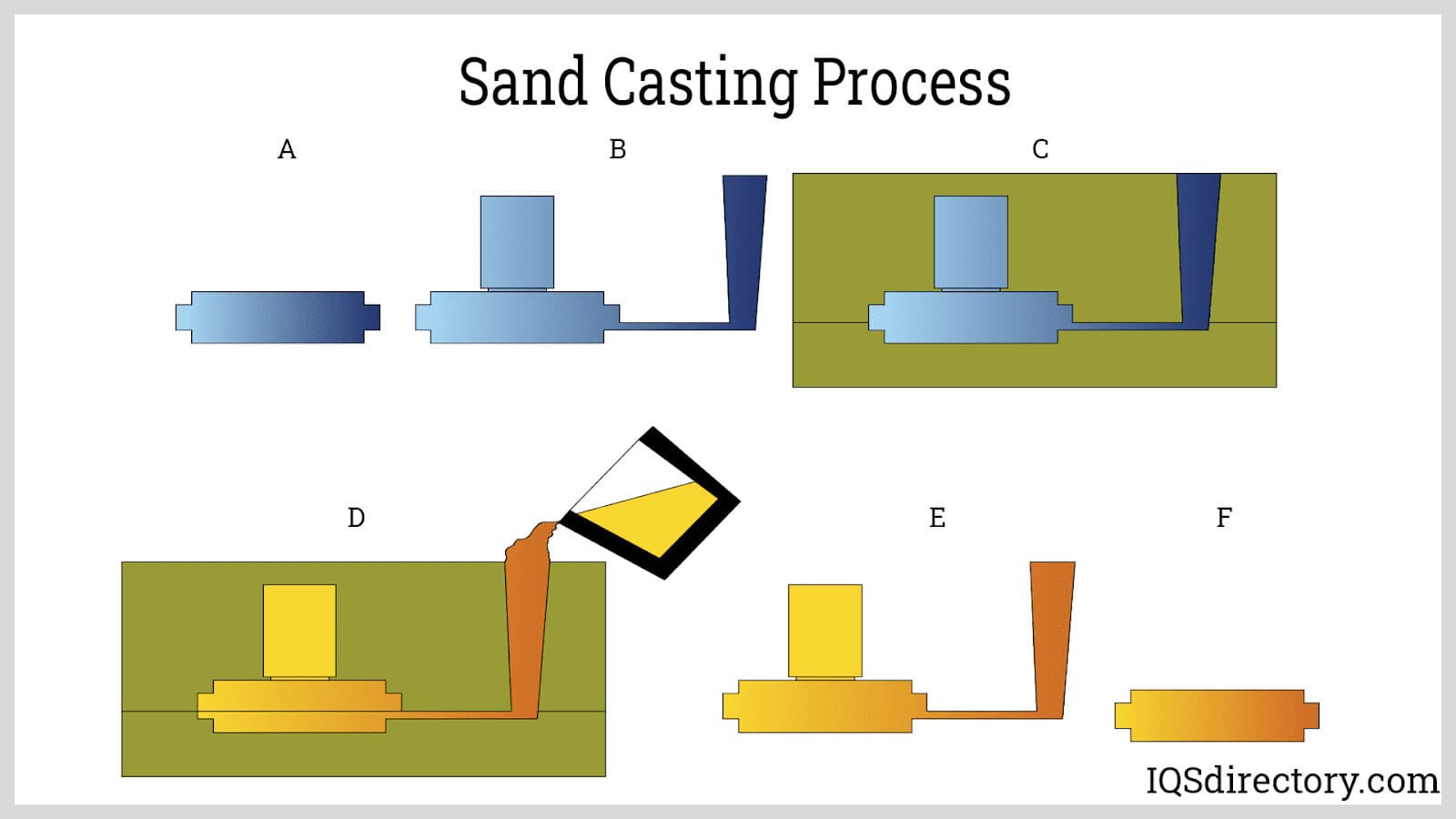

The sand casting process is one of the oldest and most widely used forms of aluminum casting. It involves compacting specialty foundry sand, often reinforced with clay or resin, around a precisely crafted reusable pattern that determines the shape and internal details of the finished aluminum product. The pattern system incorporates risers and vents to manage the flow of molten metal and to prevent casting defects such as shrinkage porosity. This traditional technique enables the manufacture of both small and very large aluminum components at an economical price.

A critical component of sand mold design is the sprue, which channels molten aluminum alloy into the cavity. Patterns are designed slightly oversized to anticipate metal contraction during cooling. The foundry-grade sand must be robust and thermally stable to withstand pouring temperatures and prevent chemical reactions with the aluminum. Modern sand casting applications range from automotive engine blocks and transmission housings to architectural hardware and industrial machinery parts, making it an essential process in aluminum manufacturing.

Investment casting, often referred to as lost wax aluminum casting, is a precision casting method prized for its ability to reproduce exceptionally fine details and complex part geometries. The process begins by injecting molten wax into a die to create a highly accurate and detailed wax pattern, mirroring the final part. These patterns are assembled onto a central wax sprue, forming what is known as a “tree.” The assembly is methodically coated with refractory ceramic slurries to build a rigid, heat-resistant shell.

After the ceramic shell hardens, the wax inside is melted out—typically using autoclave or high-pressure steam—leaving a hollow ceramic mold. This mold is then preheated prior to the pouring of molten aluminum or aluminum alloy. As the metal fills the shell, it captures the intricate details and fine surface finish of the mold. Once cooled, the ceramic is mechanically or chemically broken away, allowing for the removal and separation of individual cast parts. Investment casting is widely used in aerospace and medical components, as well as high-end industrial castings, due to its dimensional accuracy and ability to produce thin-walled, net-shape aluminum castings with minimal post-processing.

Lost foam casting is an innovative derivative of investment casting that utilizes expendable polystyrene foam patterns instead of traditional wax. Foam patterns are meticulously molded from polystyrene beads using low-pressure injection into heated precision molds. During this step, steam is introduced to fully expand the beads, ensuring a perfectly formed pattern with a seamless surface that accurately replicates the target component's shape and dimensions.

Once the foam patterns are completed, they are arranged into cluster assemblies analogous to the runners and sprues in conventional investment casting. These foam patterns are embedded in dry foundry sand, which is compacted—usually by vibration—to ensure full support and eliminate voids. As molten aluminum is poured into the sand mold, the high temperature causes the foam to vaporize instantly, allowing the aluminum alloy to take its place and occupy the exact volume, resulting in a highly accurate final casting. Lost foam casting is valued for its ability to produce complex aluminum parts in a single operation with minimal tooling and reduced need for post-casting machining.

Choosing the Right Expendable Aluminum Casting Process

When evaluating which expendable mold casting process to use for your aluminum parts, consider factors such as required part complexity, dimensional tolerances, production volume, and desired material properties. Each method—sand casting, investment casting, and lost foam casting—offers unique advantages. Sand casting is ideal for large, simple to moderately complex components and lower tooling costs. Investment casting is preferred for high-precision, intricate parts with excellent surface finish, while lost foam casting allows for economical mass production of complex shapes with minimal assembly. Consult with an experienced aluminum foundry or casting supplier to determine the most suitable process based on your application's needs, lead time, and cost constraints. By understanding the strengths and limitations of each expendable casting method, you can optimize both the quality and efficiency of your aluminum component manufacturing.

Aluminum casting is carried out using specialized equipment known as aluminum casting machines or systems. Below are five brands of these machines available in the United States and Canada, each with specific models and their distinct capabilities, features, or characteristics:

The Bühler Carat is a high-pressure die casting machine designed for aluminum castings. It offers a modular design with flexible configurations to meet specific casting requirements. The Carat features advanced control systems for precise process management, including automatic ladling, real-time quality control, and energy-efficient operation.

The Toshiba Machine DC-J Series includes die casting machines suitable for aluminum. Known for their robust construction and high injection performance, these machines ensure efficient and accurate casting. They feature advanced hydraulic and control systems for consistent quality, along with real-time monitoring, automatic lubrication, and user-friendly programming interfaces.

The Italpresse AL by Italpresse Gauss is designed for high productivity and flexibility in aluminum casting. This series includes both cold and hot chamber machines, equipped with advanced control systems and process optimization tools. Features include automatic die spraying, data logging, and energy-saving technologies.

LK Machinery's Evolution Series offers robust and reliable die casting machines for aluminum applications. These machines are known for their high-performance hydraulic systems and advanced control tools for process optimization. Features include automatic ladling, real-time production data monitoring, and remote diagnostics capabilities.

The Frech DAK Series consists of die casting machines specifically tailored for aluminum casting. These machines are modular and customizable to suit various casting needs. They incorporate advanced control systems and sensor technology for precise monitoring and process control, including automatic spraying, integrated process visualization, and energy-efficient operation.

Keep in mind that availability and specific models may change, so consulting manufacturers or authorized distributors is recommended for the most current information on models and features.

Aluminum is the third most abundant element on Earth, following oxygen and silicon, and is the most prevalent metal. Extracting aluminum from the Earth's crust is more challenging compared to extracting iron or other metals due to the complex and intricate processes required.

Bauxite, a sedimentary rock containing 45% to 60% aluminum, is the primary ore from which aluminum is extracted. Historically, processing aluminum was difficult and costly, making it a rare and expensive metal. It wasn't until the end of the first industrial revolution that more efficient refining methods were developed, making aluminum more accessible.

While aluminum can be used in its pure form, it is often alloyed with other metals to enhance its properties or the properties of the other metals. These alloys offer improved performance for various applications.

Aluminum alloys are categorized into eight series, numbered from one to eight. The first digit(s) of the number indicate the primary alloying element combined with aluminum. For casting alloys, a decimal is placed between the third and fourth digits, with the fourth digit specifying the form of the product. Each alloy is also rated from one to five in categories such as crack resistance, corrosion resistance, finish quality, and joinability, with one being the best and five being the worst. For example, 1000 series alloys receive a rating of one across all categories, while 8000 series alloys receive a rating of five.

The following descriptions pertain to wrought aluminum alloys, which use a different grading system than casting alloys. Unlike casting alloys, wrought alloys do not include a decimal in their designation, which helps distinguish between the two grading methods.

The 1000 series consists of nearly pure aluminum, with a composition of 99% aluminum. This series is characterized by its softness and ductility, offering excellent workability. The 1000 series alloys can undergo extreme forming processes due to their slow hardening rate, and they are easily weldable and processable.

The 2000 series alloys are alloyed primarily with copper, containing between 2% and 10% copper along with small amounts of other elements. This alloying improves the strength and hardness of aluminum but decreases its ductility and corrosion resistance. The 2000 series alloys are challenging to weld but can be heat treated to enhance their properties.

The 3000 series alloys are primarily alloyed with manganese. This combination enhances corrosion resistance while providing moderate strength. Known for its heat treatability, the 3000 series offers low density, good plasticity, and excellent weldability. Additionally, it features high ductility and a very smooth finished surface.

The 4000 series alloys are alloyed with silicon, which lowers the melting point and improves fluidity. This makes it a popular choice for casting, as it is easy to form in its molten state. The 4000 series is also commonly used as a filler for welding and brazing applications.

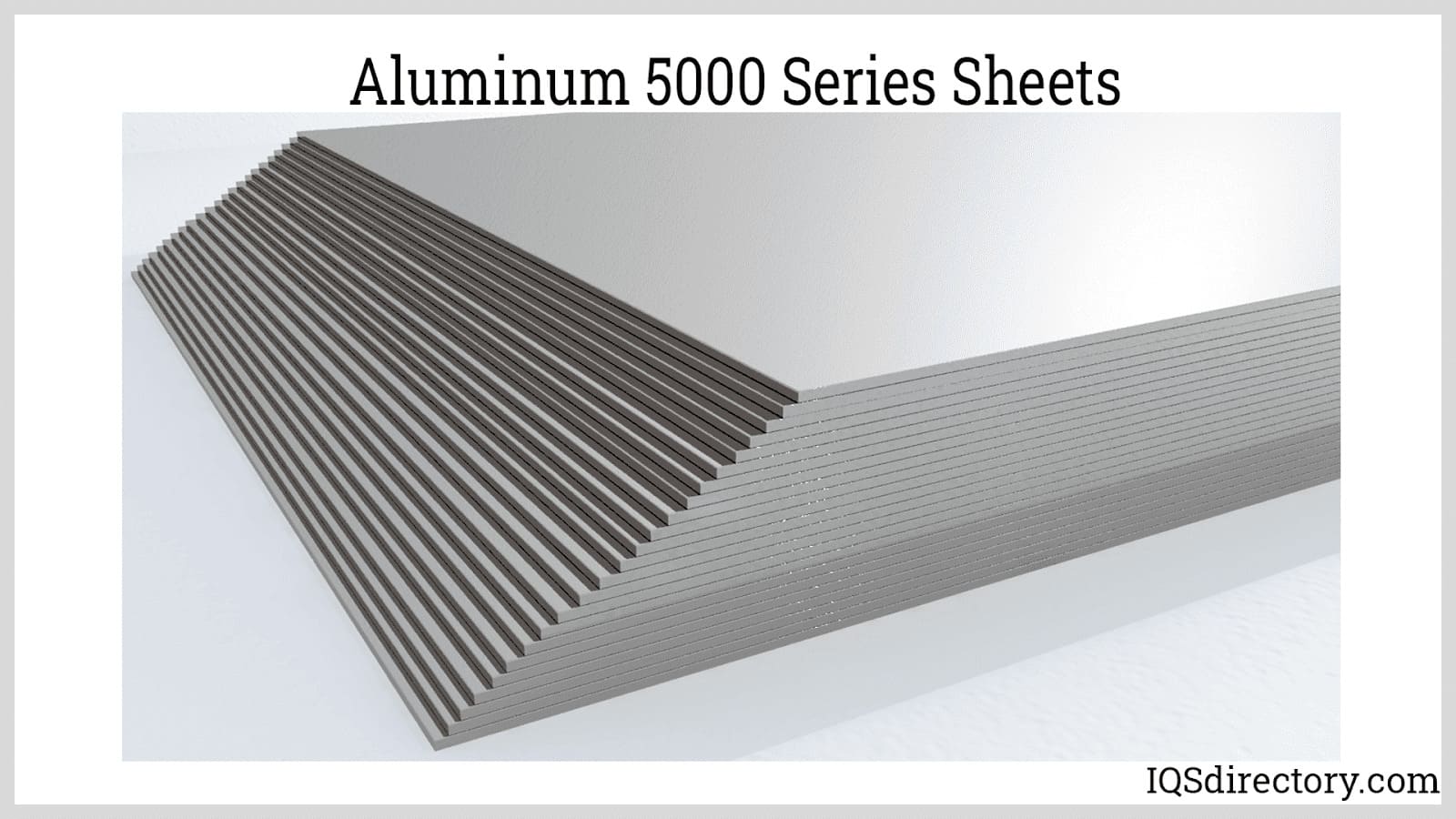

The 5000 series alloys are alloyed with magnesium, which imparts exceptional tensile strength and formability. This series is classified as a high-strength alloy, particularly suited for sheet and plate applications due to its excellent weldability. Its resistance to corrosion from acids and alkalis makes it ideal for use in harsh and hostile environments.

The 6000 series alloys are alloyed with both magnesium and silicon, providing a balance of strength, mechanical properties, and corrosion resistance. Some variations of the 6000 series are combined with elements from the 4000 and 5000 series to further enhance their properties. Processing the 6000 series requires specialized and advanced equipment, which can be complex and costly. However, this series is known for its excellent corrosion and oxidation resistance, as well as its ease of coating, treatment, and workability.

The 7000 series aluminum alloys are the strongest and most durable among aluminum types, with strength comparable to about two-thirds of industrial-grade A3 steel. These alloys are known for their high hardness, excellent wear resistance, and good mechanical properties, making them ideal for high-stress applications such as aircraft components. Zinc is the primary alloying element in the 7000 series, enhancing the hardness of the aluminum, even though zinc's hardness is similar to that of aluminum on the Mohs scale.

The 8000 series aluminum alloys are primarily alloyed with tin, along with small amounts of copper and nickel. While these alloys offer lower strength compared to other series, they excel in machinability and wear resistance. The specific composition of the 8000 series can vary depending on the intended application of the product. This variation affects the metal’s temperature performance, density, and stiffness.

One of the key advantages of using aluminum for casting is the ability to tailor its properties to meet specific requirements. For virtually any project, there is an aluminum alloy available that matches the necessary application criteria. It’s simply a matter of identifying the required characteristics.

When selecting the appropriate alloy for a particular application, the following list can serve as a useful guide for determining the necessary properties and characteristics.

The two charts below illustrate the differences between cast alloys and wrought alloys. Please note that series 600.X is not included in the cast alloy chart.

| Cast Aluminum Grades | ||||||

|---|---|---|---|---|---|---|

| Grade | Alloys | Strength | Cracking | Corrosion Resistance | Finishing Capabilities | Weldability |

| 100.X | Unalloyed | Work Hardening | 1 | 3 | 5 | |

| 200.X | Cu | Heat Treatment | 4 | 4 | 1 To 3 | 2 To 4 |

| 300.X | Mg, Si, Cu | Work Harding | 1 | 1 | 1 | 3 |

| 400.X | Si | Undetermined | 4 | 1 | 1 | 3 |

| 500.X | Mg | Work Hardening | 1 | 1 | 1 | 2 |

| 700.X | Zn | Heat Treatment | 1 | 4 | 3 | 1 |

| 800.X | Sn/ Tin, Cu, Ni | Heat Treatment | 5 | 5 | 5 | 5 |

| Wrought Alloys Cast Aluminum Grades | ||||||

|---|---|---|---|---|---|---|

| Grade | Alloys | Strength | Cracking | Corrosion Resistance | Finishing Capabilities | Weldability |

| 1000 | Unalloyed | Work Hardening | 1 | 1 | 3 | 5 |

| 2000 | Cu | Heat Treatment | 4 | 4 | 5 | 1 |

| 3000 | Mn | Work Hardening | 2 | 1 | 1 | 3 |

| 4000 | Si | Undetermined | 4 | 1 | 1 | 3 |

| 5000 | Mg | Work Hardening | 1 | 1 | 1 | 2 |

| 6000 | Mg And Si | Heat Treatment | 3 | 2 | 2 | 2 |

| 7000 | Zn | Heat Treatment | 1 | 4 | 3 | 1 |

| 8000 | Sn/ Tin, Cu, Ni | Limited | - | - | - | - |

Since the introduction of the Bayer and Hall-Héroult processes for refining aluminum, the metal has become essential in the production of a wide range of commercial and industrial products. Advances in these methods have enabled engineers and designers to rapidly incorporate aluminum into their designs due to its practicality and cost-effectiveness.

From aerospace applications to kitchen appliances, aluminum's diverse properties make it a reliable and durable material with a long service life. Its versatility allows it to be shaped and formed to meet various design requirements. Additionally, aluminum can be alloyed with over 270 different elements to further enhance its performance and benefits.

Since the end of World War II, the aerospace industry has depended heavily on aluminum, with the metal constituting approximately 80% of an aircraft's structure. Cast aluminum parts possess the essential properties and characteristics required by the industry. Aircraft manufacturers have achieved significant cost savings by utilizing cast aluminum components.

With the growing emphasis on improving vehicle fuel efficiency, auto manufacturers are increasingly incorporating high-strength aluminum castings into their designs. In response, aluminum casting producers have been enhancing their methods and refining their techniques to streamline production and boost output while maintaining cost-effectiveness.

Automotive aluminum castings include components such as oil pumps, water pump housings, connectors, transmission parts, and various brackets. The durability and dependability of these cast parts make them essential for advancing vehicle design and performance.

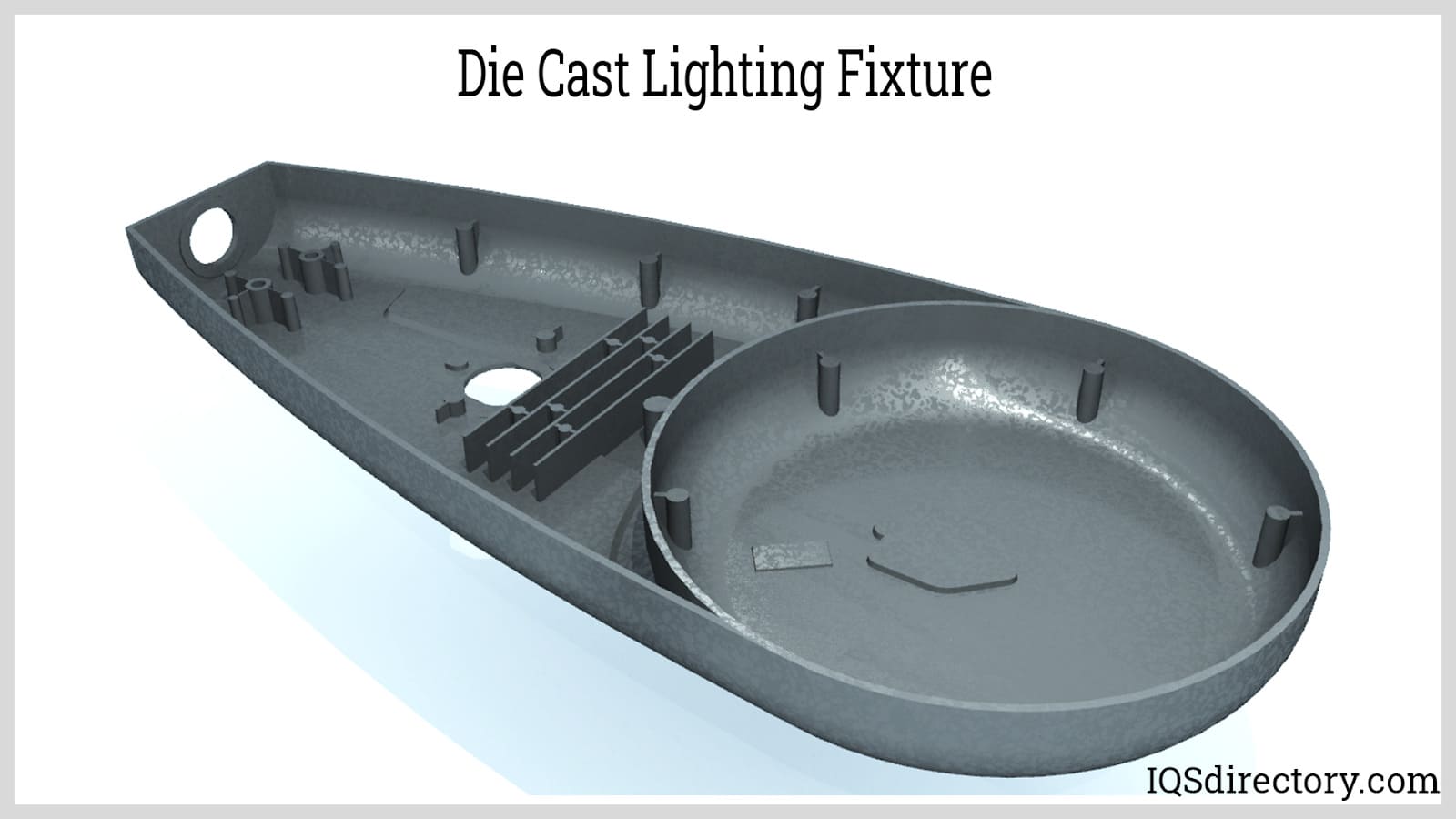

Aluminum cast lighting fixtures offer several advantages, including being non-toxic and lightweight. Their corrosion resistance makes them particularly well-suited for outdoor applications. Popular manufacturing processes for these fixtures include permanent mold and gravity casting, which facilitate working with lighter forms of aluminum and streamline production. Much like automotive components, casting aluminum for lighting fixtures is both cost-effective and efficient.

The versatility of aluminum casting processes allows for easy adaptation to various designs, providing the stability and characteristics needed for each application. The combination of ease of production, reduced weight, and exceptional durability contributes to the widespread popularity of aluminum cast lighting.

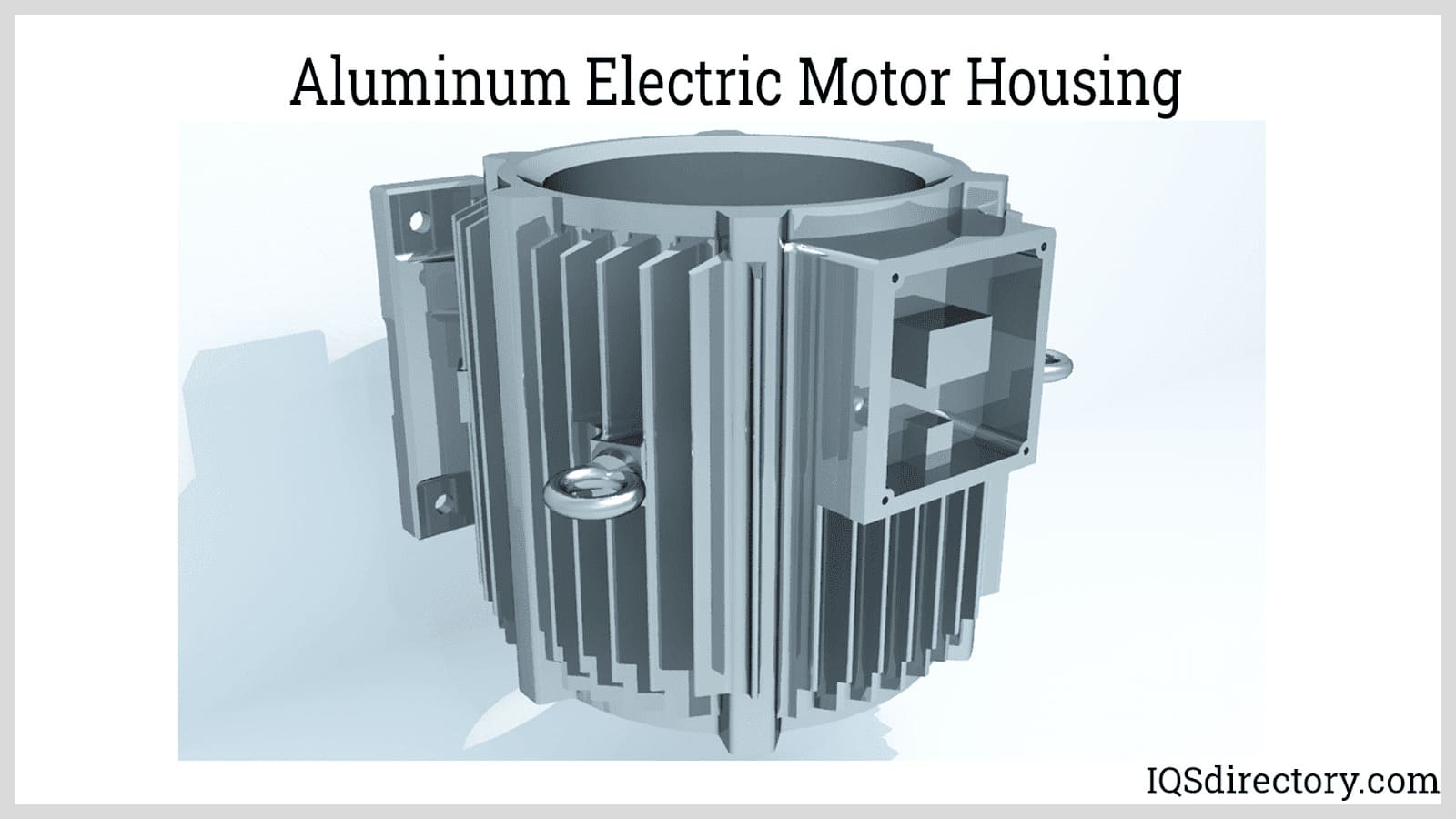

Aluminum cast parts used in agriculture share many requirements and specifications with those in the automotive industry, but they often demand greater strength and durability due to the harsh conditions and constant use encountered in agricultural machinery. Cost is also a significant consideration in agricultural production. Consequently, aluminum castings are commonly utilized for critical components such as crankcase housings, gearbox housings, and motor housings, offering both the necessary strength and cost efficiency.

A heatsink's primary function is to dissipate heat from electronic components and devices. Aluminum cast heatsinks benefit from reduced machining requirements, which helps lower production costs and speeds up manufacturing. Additionally, features such as cooling fins can be integrated during the casting process, further enhancing production efficiency.

Aluminum cast heatsinks are electrically conductive, allowing them to be grounded effectively. They are often cast with integrated features that minimize the need for secondary operations, such as additional machining or assembly, leading to further cost savings.

Aluminum casting is frequently used to manufacture brackets for both heavy-duty industrial equipment and household appliances. The process allows for near net shape production, eliminating the need for welding or additional assembly. The single-piece construction of aluminum brackets enhances their strength and durability, reducing the likelihood of failure. If holes are required, they can be included directly in the casting mold, minimizing the need for post-production finishing.

Manufacturers have increasingly adopted aluminum casting for golf equipment due to its durability, stability, and versatility in shaping. The aim is to provide players with high-quality equipment at a more affordable price. Golf products produced using this method include golf ball warmers, clubs, handles, and brackets.

Aluminum cast enclosures are ideal for protecting sensitive electronics in various environments. The natural shielding properties of aluminum against radio frequency interference (RFI) and electromagnetic interference (EMI) enhance their effectiveness. Additionally, the seamless construction of aluminum casting ensures a watertight seal, making the enclosures durable and resistant to diverse conditions.

The National Electrical Manufacturers Association (NEMA) sets the standards and specifications for cast aluminum enclosures. Producers must adhere to these requirements to ensure their products meet industry benchmarks and are market-ready.

Aluminum casting is widely used to produce various parts and components for the military, all of which must meet stringent government specifications. The production and processing of these military parts are governed by detailed guidelines that outline the required material characteristics and properties. The specialized nature of military components presents a challenge to manufacturers, as each part demands precise engineering and meticulous attention to detail.

Below are descriptions of two unique military components.

A fire suppression housing is designed to extinguish fires in armored vehicles, ensuring that the vehicle can withstand direct hits without compromising the safety of its occupants.

A missile nose piece, which is mounted at the tip of a missile, must be precisely cast to endure the G-forces generated during launch. The casting process is carefully monitored to ensure the nose piece is both pressure-tight and accurately engineered to meet strict specifications.

Aluminum casting is favored by manufacturers for its numerous advantages. The exceptional surface finish, durability, and stability of cast aluminum parts make it a top choice for engineers designing new products. These qualities, along with the versatility of aluminum alloys, contribute to its widespread use in various applications.

Advancements in aluminum casting technology are continually evolving. Ongoing technical innovations are expanding the possibilities for manufacturing and design, offering new opportunities and improvements in the field.

Aluminum casting can create parts of any size, shape, or configuration, from tiny electrical components to large transmission casings and clutch housings for automobiles. Each part is produced with high precision according to design specifications, requiring minimal finishing.

With aluminum casting, engineers can design components with confidence, knowing that the parts will meet performance expectations and maintain their integrity throughout assembly, disassembly, repair, and reprocessing.

The extensive range of design possibilities offered by aluminum casting allows engineers to leverage its exceptional properties. This versatility enables the creation of custom and unique designs, turning imaginative concepts into reality.

Manufacturers are continually seeking faster and more efficient production methods. Advances in computerization have heightened the demand for timely deliveries. Aluminum die casting has proven to meet and exceed these demands with its high-speed production capabilities, outperforming other alloys.

Aluminum cast parts are notable for their impressive strength-to-weight ratio, surpassing other metals and alloys. While lightweight, aluminum components possess the strength of steel, contributing to their durability and longevity—essential qualities for modern products.

Despite their strength and lightweight nature, aluminum castings also offer an attractive appearance. In applications where visual appeal is important, aluminum castings maintain their aesthetic value without the need for additional adjustments or re-engineering.

Industries strive to reduce costs while maintaining high quality. Aluminum casting is a cost-effective choice due to its rapid production and minimal finishing requirements. The lower material costs and efficient production processes lead to savings that benefit both companies and consumers.

When exposed to air, aluminum castings form an oxidized surface that enhances their longevity and reliability. This natural oxidation process extends the lifespan of aluminum components, offering greater value to users.

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish...

Zinc die casting is a casting process where molten zinc is injected into a die cavity made of steel that has the shape, size, and dimensions of the part or component being produced. The finished cast zinc product has...

The casting process is an ancient art that goes back several thousand years to the beginning of written history. The archeological record has finds that document the use of the casting process over 6000 years ago around 3000 BC or BCE...

Investment casting is a metal working process that uses a ceramic shell built over a wax pattern to produce parts with extraordinarily uniform and smooth surfaces. The wax pattern is produced from an aluminum die.The final products of investment casting are without parting lines, mold half marks, or other deformities...

An iron casting is a hard product obtained from combining iron with carbon. This can be readily cast in a mold, and it contains a higher proportion of carbon compared to steel. The proportion typically ranges from 2 to 4.3...

Lost wax casting is a casting process that uses a wax pattern to create a ceramic mold for creating a part or product design. It has been known over the years as lost wax or precision casting due to its accuracy in recreating parts with precise tolerances...

Permanent molding casting is a casting process that uses strong durable reusable molds to produce parts and components using molten metals. The molds for permanent mold casting are made from steel or...

Sand casting is a manufacturing process in which liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then allowed to solidify. Casting is a manufacturing process in which...

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Cold forging is a metal shaping & manufacturing process in which bar stock is inserted into a die and squeezed into a second closed die. The process, completed is at room temperature or below the...

Copper and brass forging is the deformation of copper and brass for the purpose of manufacturing complex and intricate shapes. The temperature at which copper and brass are forged is precision controlled and...

Forging is a metal working process that manipulates, shapes, deforms, and compresses metal to achieve a desired form, configuration, or appearance outlined by a metal processing design or diagram...

In this article, there are key terms that are typically used with open and closed die forging and it is necessary to understand their meaning. Forging is a process in manufacturing that involves pressing, hammering, or...

Rolled ring forging is a metal working process that involves punching a hole in a thick, solid, round metal piece to create a donut shape and then squeezing and pressuring the donut shape into a thin ring...

Forging steel is a manufacturing process used to shape steel by using localized compressive forces, which include hammering, pressing, and rolling. It is a widely used method for producing high quality steel products...

The ancient art of forging falls into two distinct categories – hot and cold where hot forging has been around for centuries while cold did not begin until the industrial revolution of the 19th Century. Though they are quite different ...