Metal Grating

Metal grating is a metal product produced by perforating metal sheets or joining bars of metal to form a grid. They are a metal product that is widely used in various industries as...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will give an in-depth discussion on expanded metal.

The article will discuss topics such as:

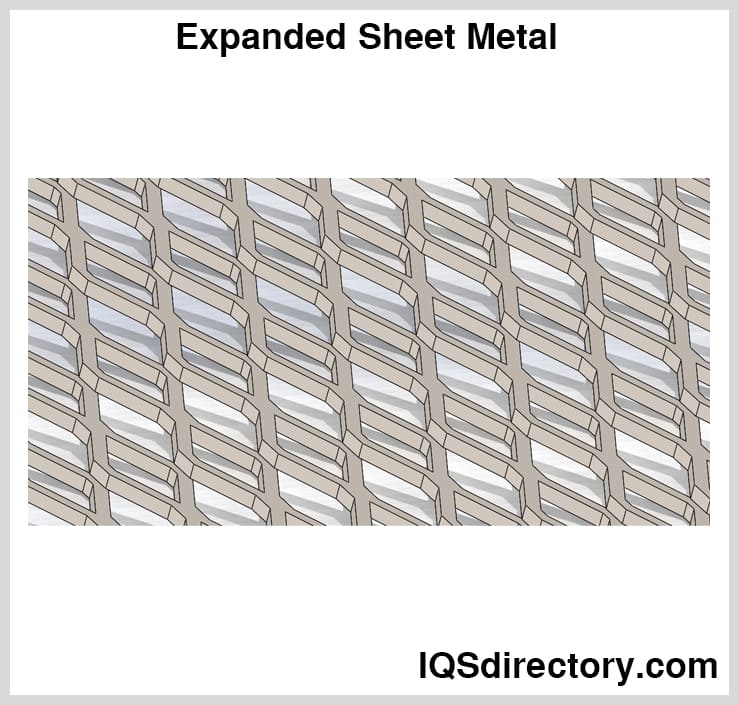

Expanded metal is a specific form of sheet metal mesh that is produced by elongating a slitted sheet of ductile metal. The slits are strategically placed perpendicular to the direction of stretching, creating a mesh composed of multiple holes from the slitted sections.

The concept behind expanded metal is grounded in the natural tendency of metals to expand and contract when exposed to varying conditions. This tendency is governed by the metal's atomic structure and inherent chemical properties, leading to the formation of expanded metal.

Expanded metal can be compared to and is often an alternative to other types, including:

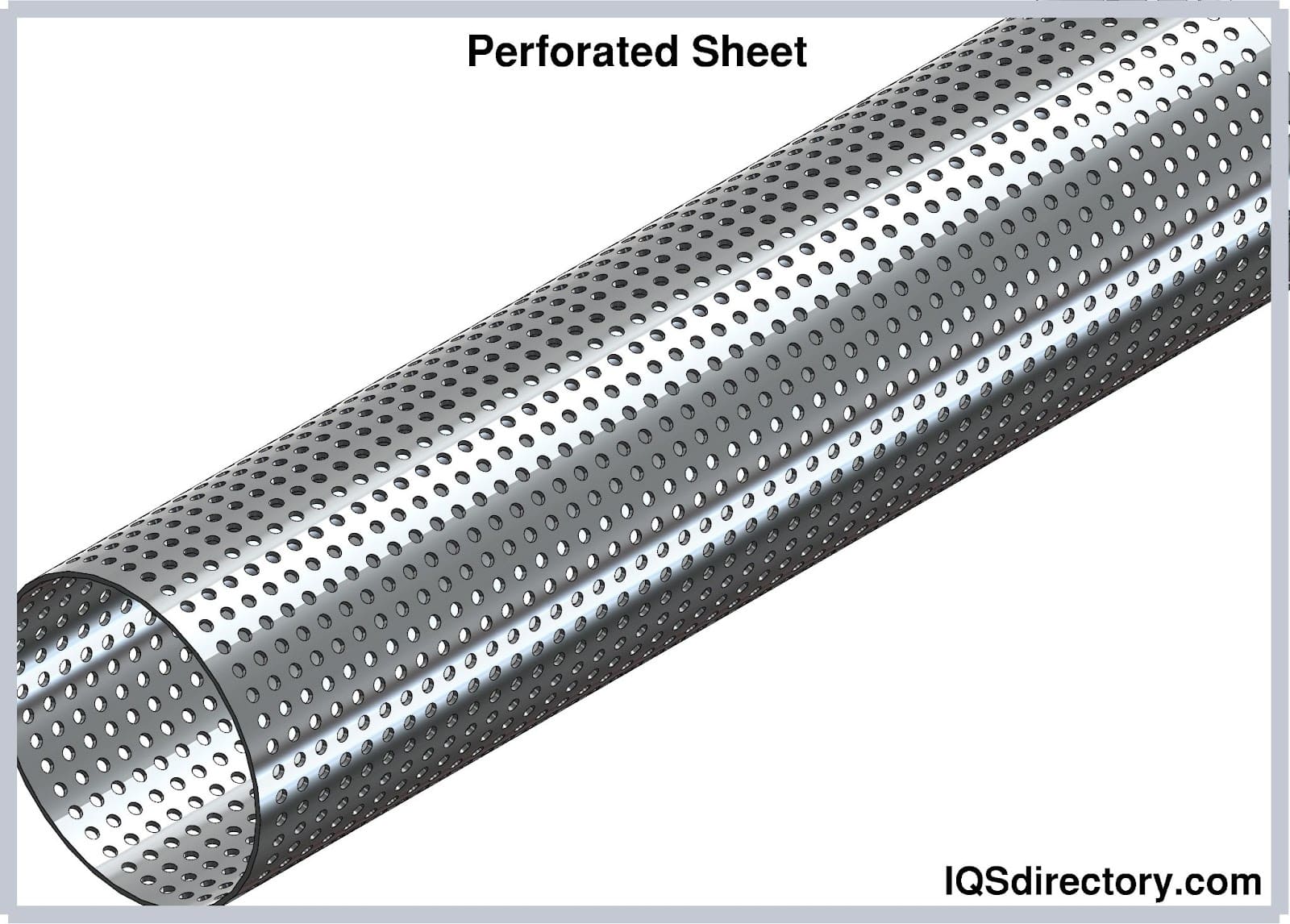

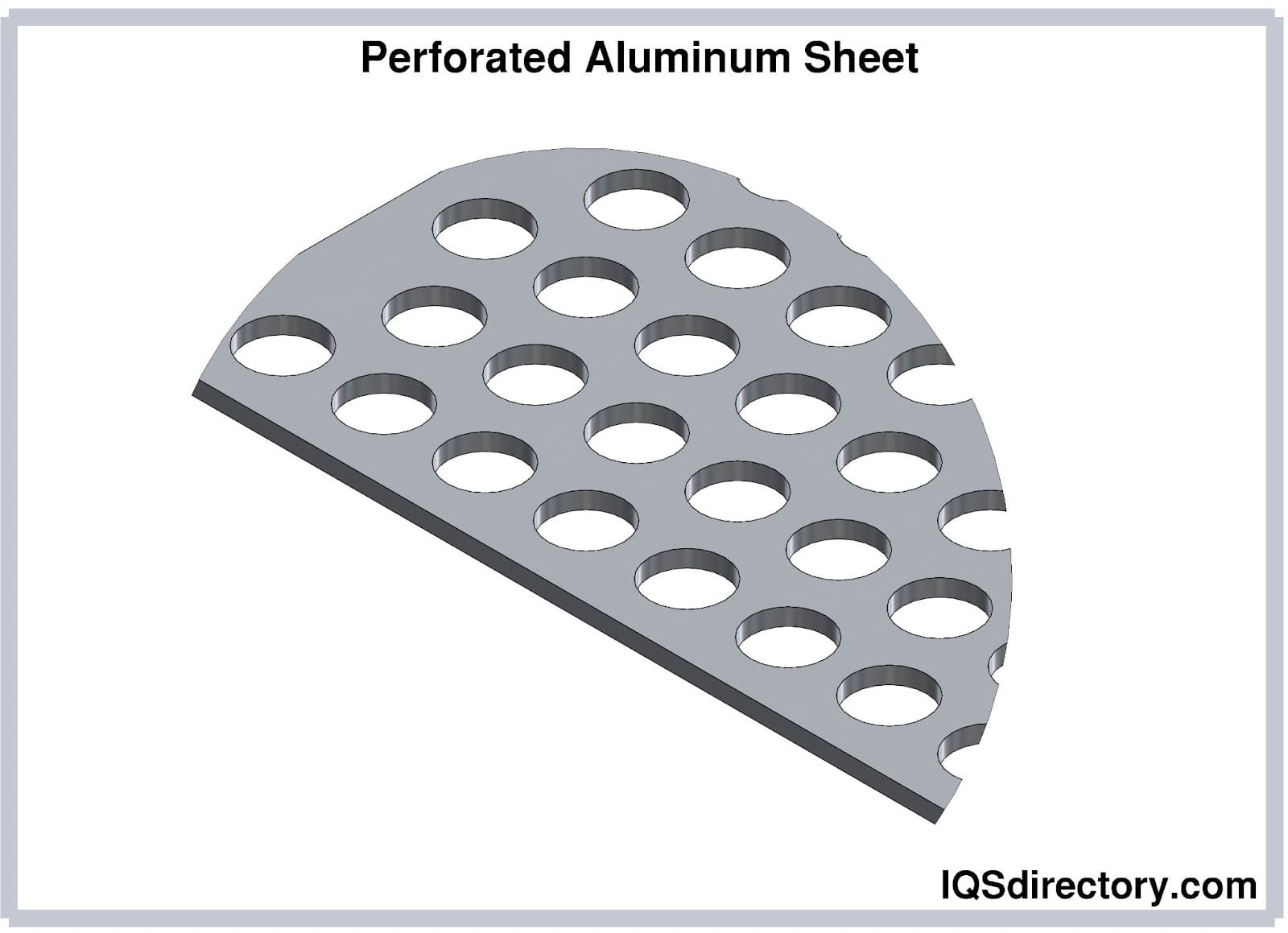

Perforation involves the creation of holes within a sheet of metal. This leads to a (metal) perforated sheet. Many of the same sheets that are capable of being perforated can also undergo expansion. Perforation is essentially a subtractive method where the formation of holes leads to material loss, often considered waste. Unlike expanded metal, perforation typically doesn't involve stretching the metal sheet. Its benefits include the ability to produce tiny openings and drainage casings for various uses. It also allows for unique shapes, especially for decorative applications.

Perforated sheets are frequently utilized in the design of computer casing enclosures.

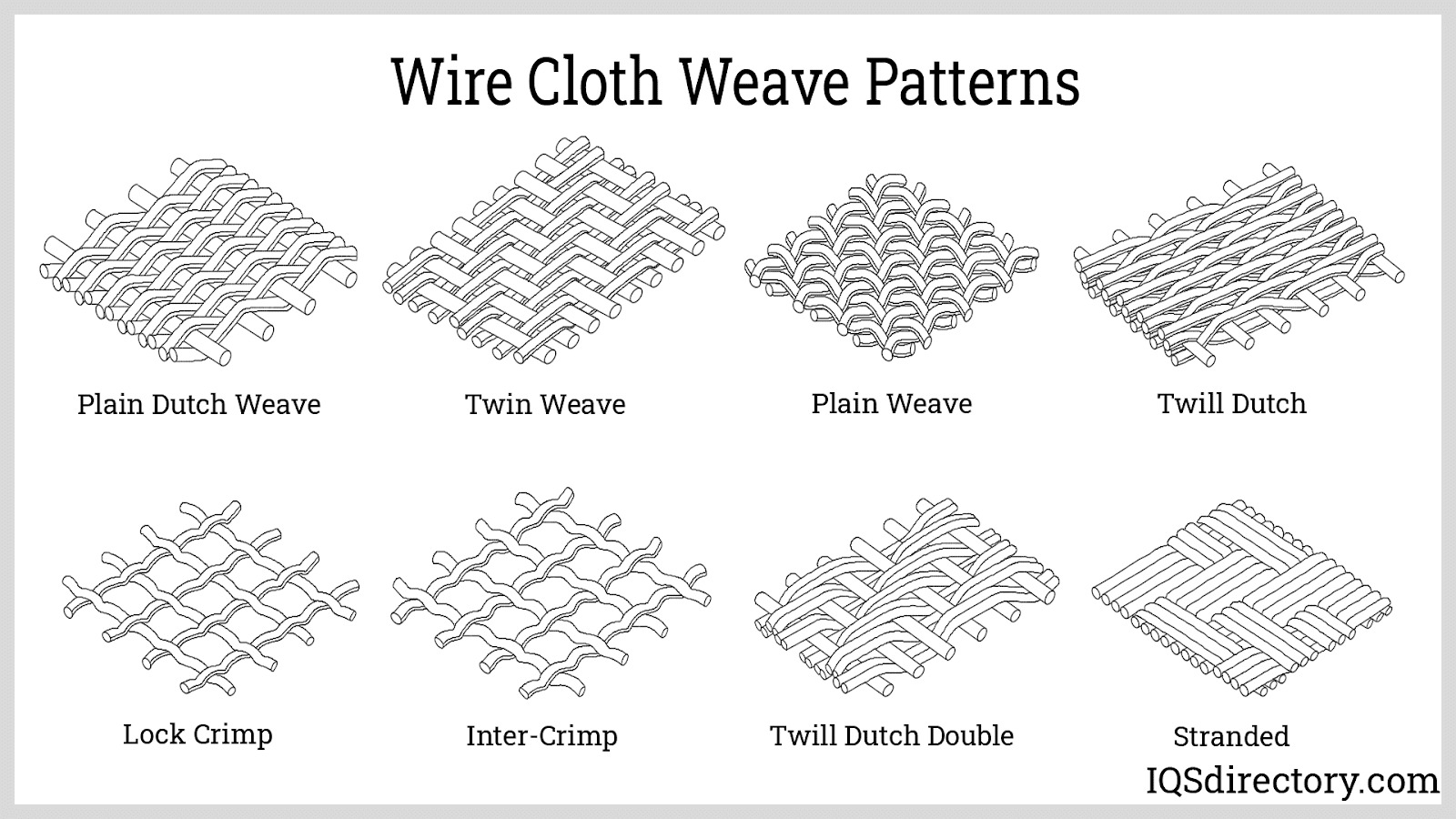

This technique involves interlacing metal wires much like weaving fabric threads. The integrity of the weave is maintained through friction and the wires' stiffness since no bonding occurs between the separate wires. Unsecured edges may unravel. Woven mesh is commonly used for sieving sand and related applications.

This mesh consists of two grids of parallel wires superimposed at 90-degree angles to one another, secured at each crossing point with welds. It is ideal for spanning large areas. Finely spaced meshes present production challenges due to the dense requirement of welds per unit area.

Welded mesh is often used to reinforce concrete structures and enhance their durability.

In principle, all metals that are malleable can be stretched or expanded. Nevertheless, not all of these metals are practical for large-scale industrial expansion. The following section will cover some of these materials.

Historically, copper isn't typically the primary choice for structural applications, particularly when only structural factors are considered. Additionally, copper is relatively expensive, especially when assessed per unit volume. Volume is crucial as it affects the final size of the expanded metal sheet. The high density of copper is a disadvantage in applications where weight is a critical factor, such as in rigging.

Copper becomes relevant when factors beyond just structural concerns are important. These considerations include:

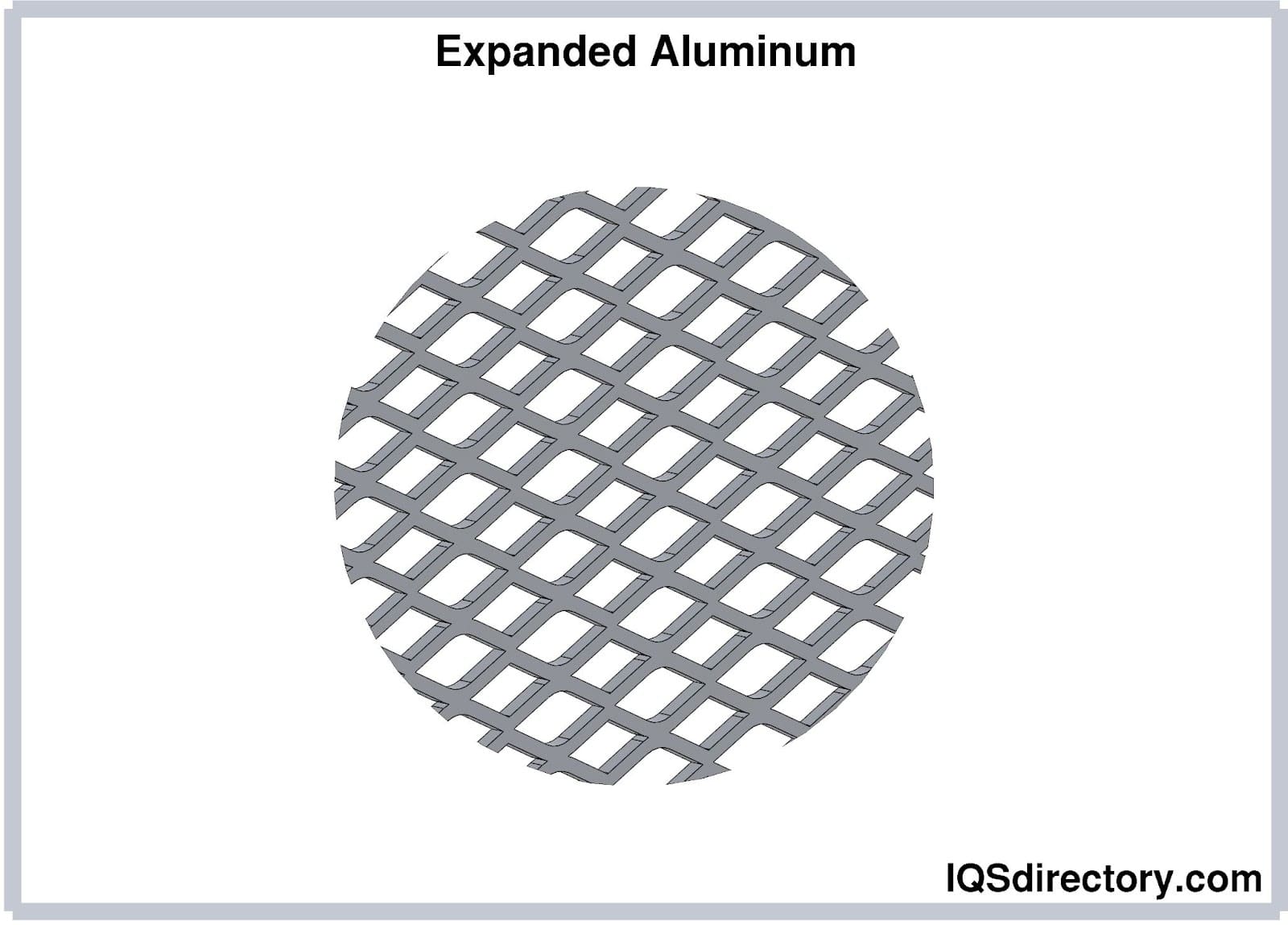

Aluminum has a wide range of structural applications due to its strength and lightweight nature. It is an effective conductor, which is why it's often used in overhead power lines.

Aluminum's malleability makes it easier to work with than steel (when cold), and its resistance to corrosion adds to its advantages. With a high melting point and excellent thermal reflectivity, aluminum is well-suited for high-temperature environments.

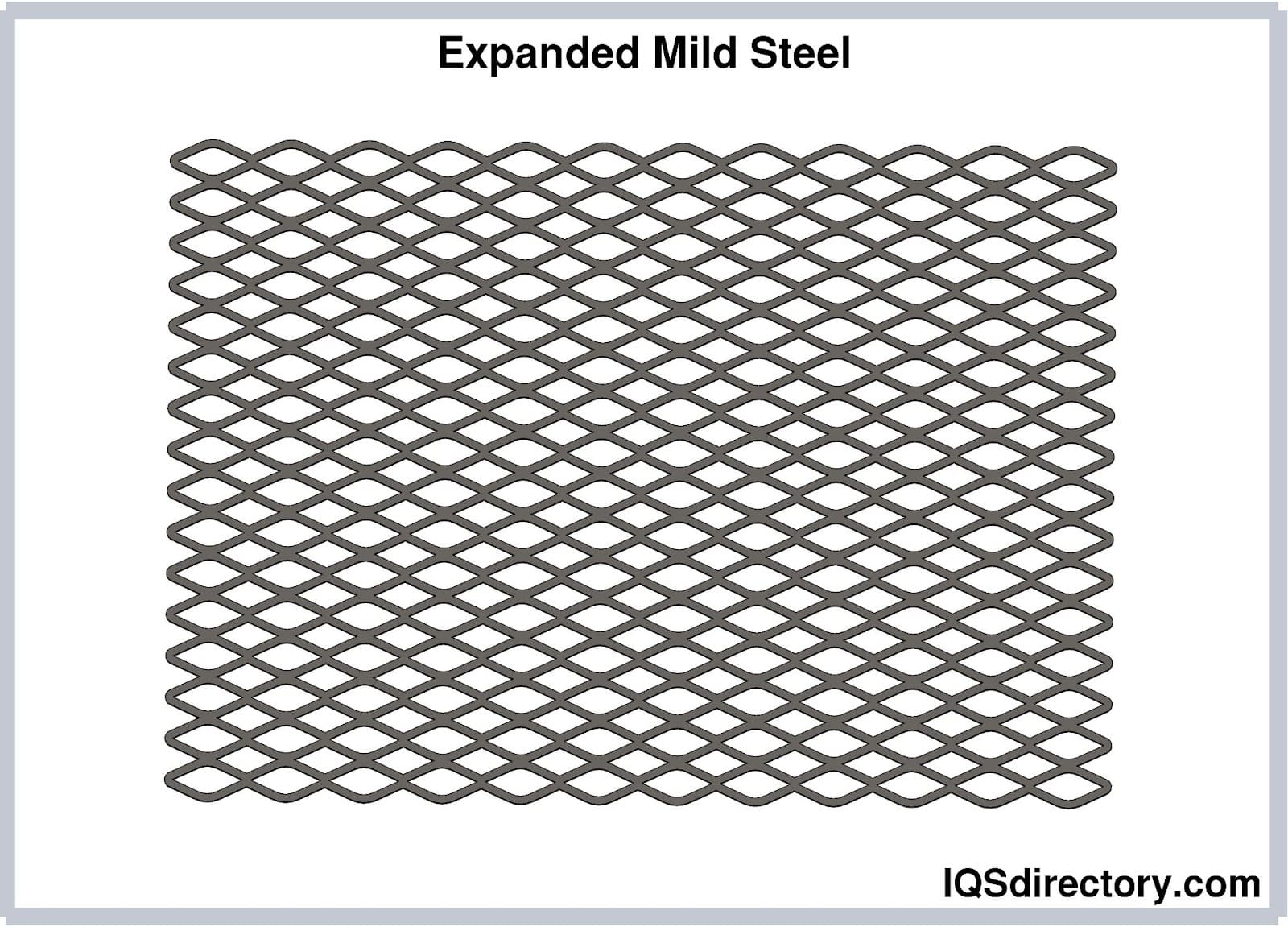

Steel is the most widely used structural metal, known for its exceptional strength compared to other metals listed here, provided it remains free from corrosion. Steel comes in various types:

This provides a robust and economical solution. It is commonly coated with molten zinc through a hot-dipping process for galvanization.

This expanded metal sheet is made from higher gauge metal sheets, typically crafted from mild steel.

Stainless steel offers greater resistance to corrosion compared to mild steel and is more effective in high-temperature environments.

The production of expanded metal encompasses several stages. These stages will be outlined in the following sections.

The initial step involves selecting the appropriate sheet metal. This choice is determined by the specific application for which the expanded metal will be used.

When selecting the metal, the following properties are taken into account:

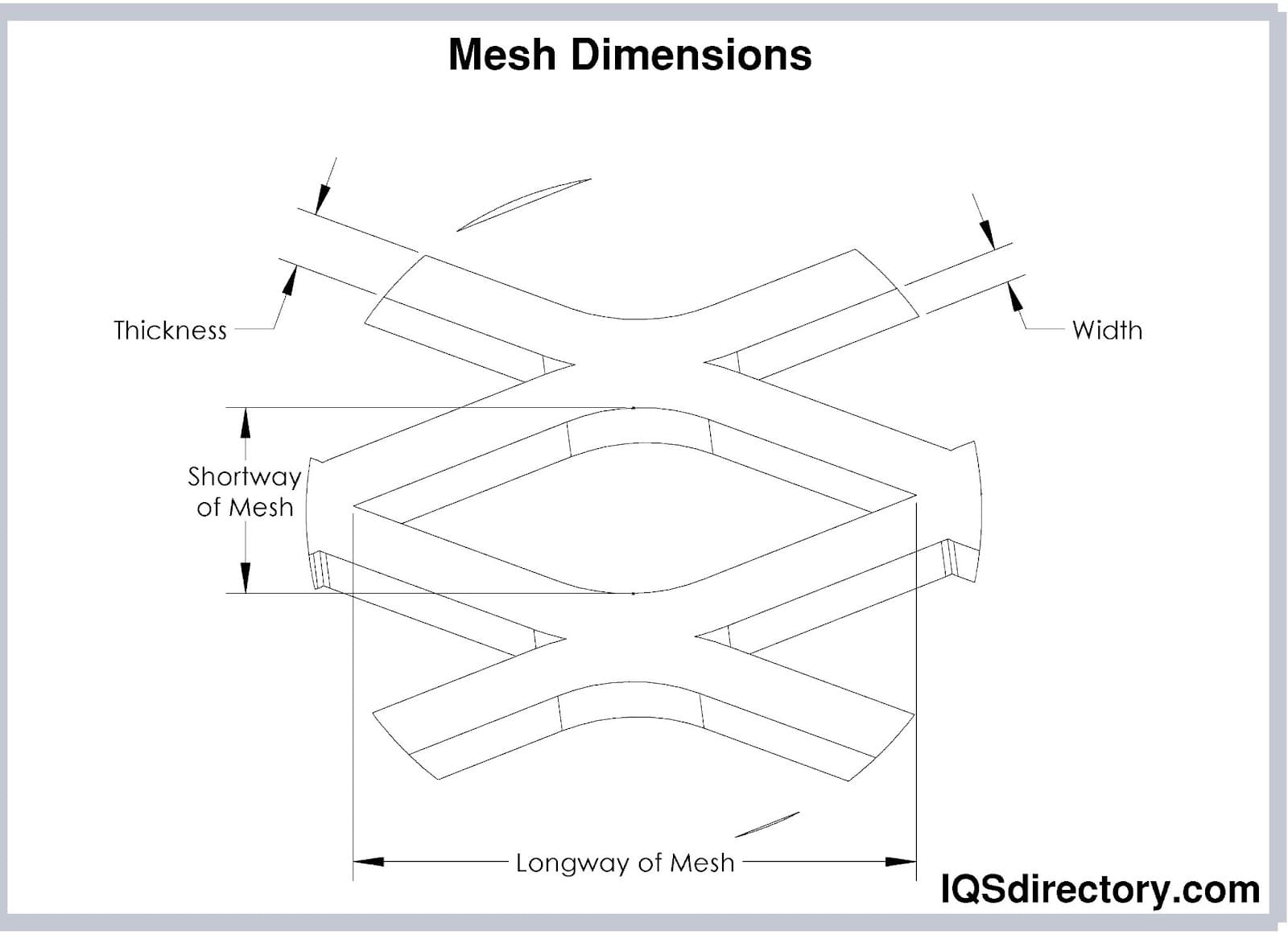

In addition to the metal's chemical and structural properties, the dimensions are also a crucial consideration.

The aspects considered to be dimensions of the metal sheet are:

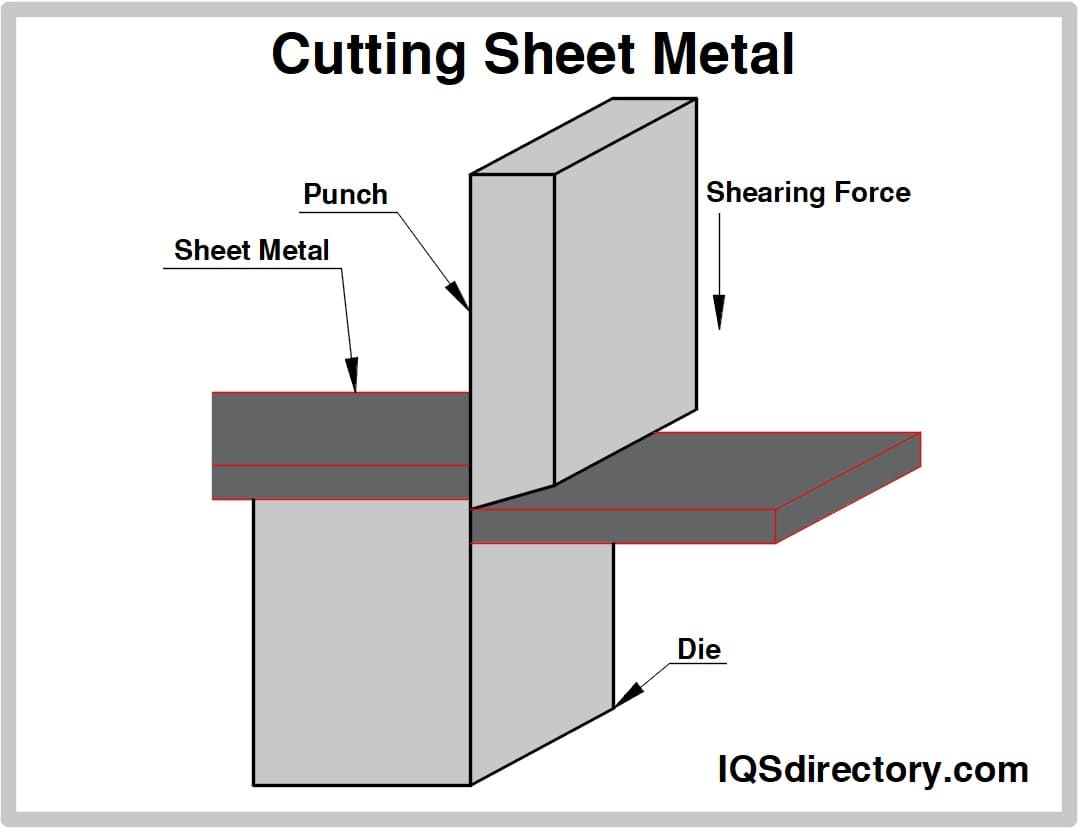

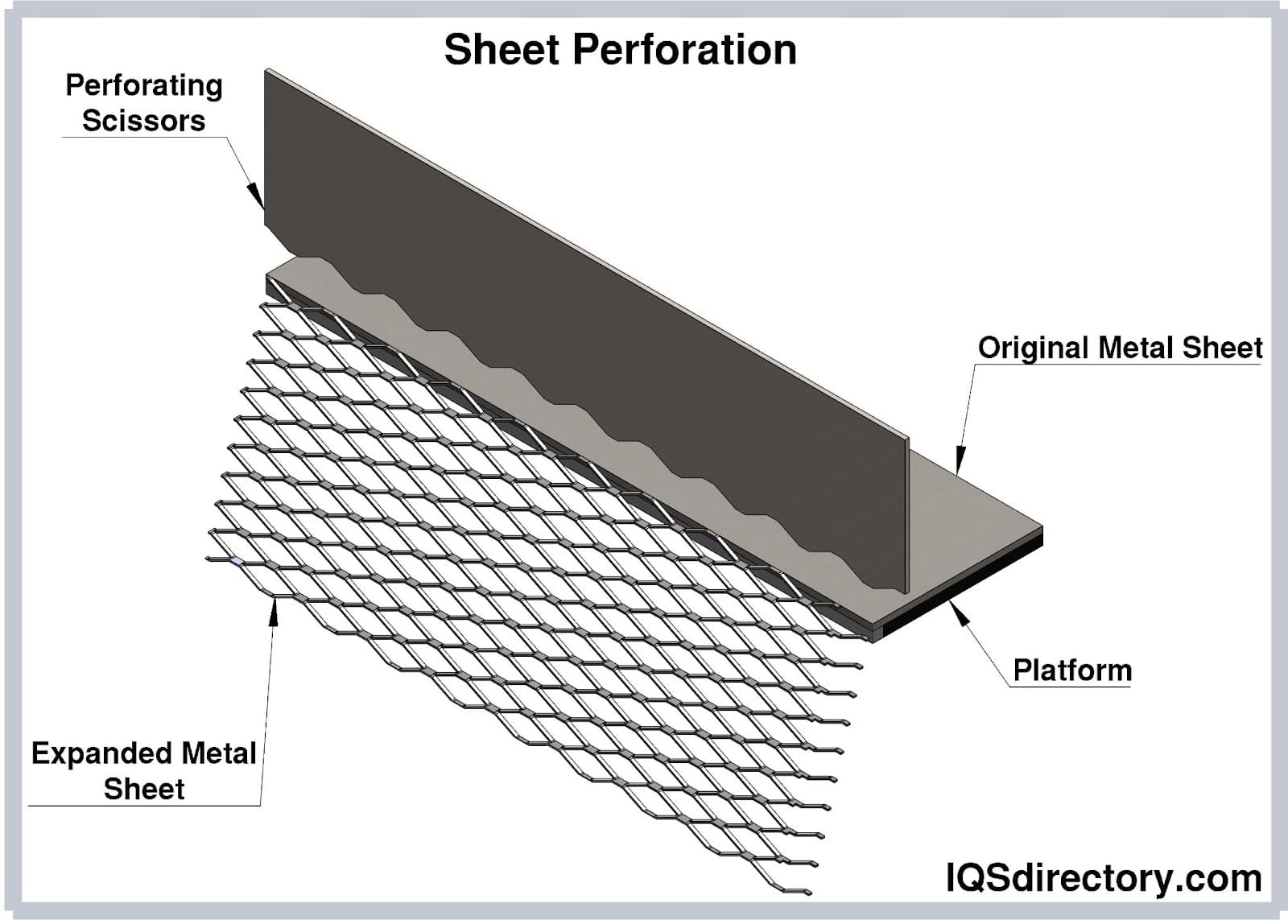

The cutting process creates the openings in the expanded metal, setting the final dimensions of these openings. This can either be done in two separate steps—cutting and stretching—or in a single combined operation, which is more frequently used.

A die is employed to define half of a row across the full width of the sheet. The metal sheet is aligned with the inner edge of the die, which also aligns with the supporting platform. The sheet is then fed under the die at a rate corresponding to the desired strand thickness. The die descends to cut and stretch the sheet in one motion (creating the first half row), and then it retracts.

If the expanded sheet metal requires uniformly sized and shaped openings, a single die will be used for the entire process. In this case:

When different sizes or shapes are required, two distinct but complementary dies are used. These dies alternate in operation to form the various shapes.

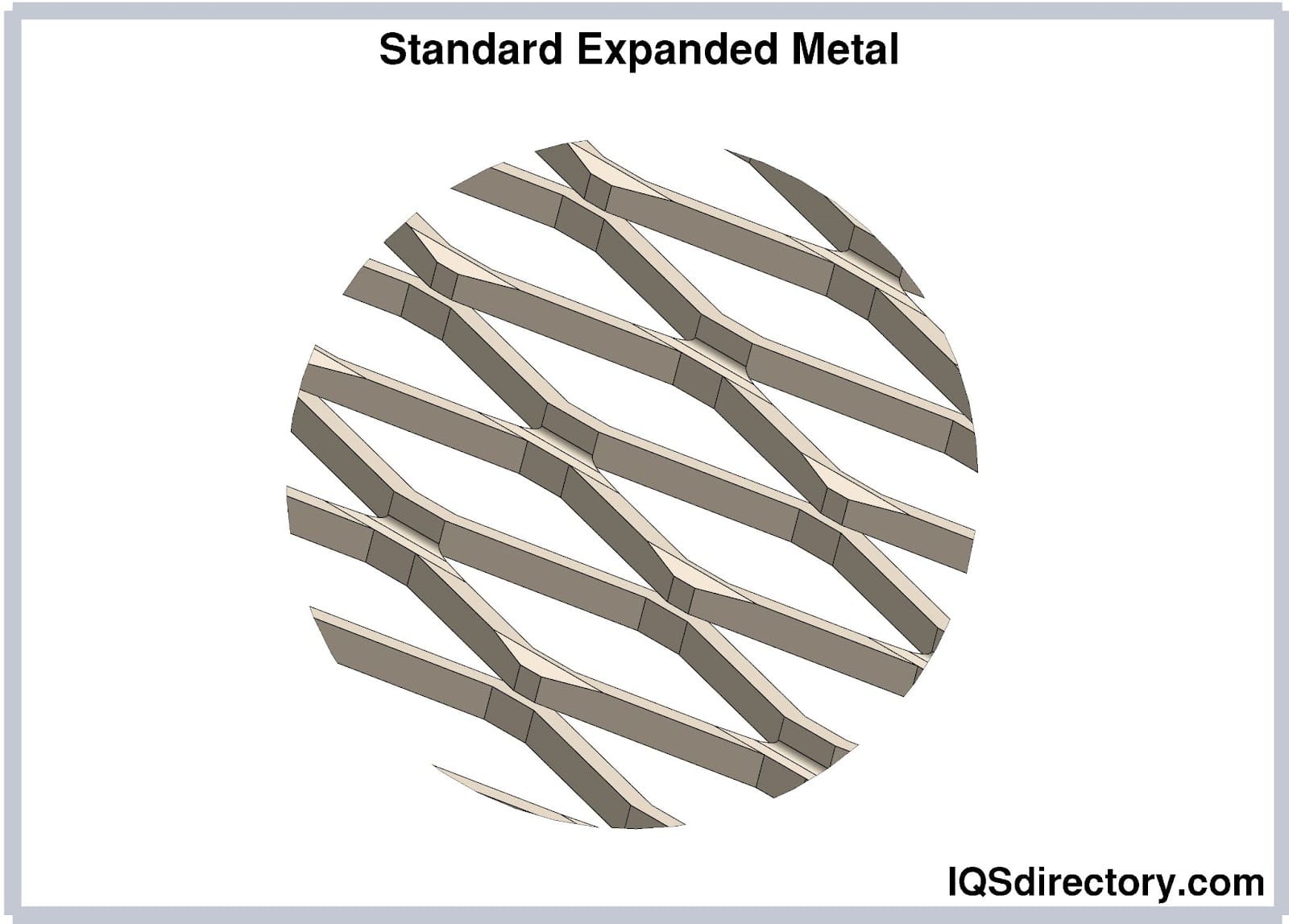

This method of cutting and feeding results in an expanded metal sheet with a textured, raised surface, often referred to as standard expanded metal.

During the expansion process, coolants and lubricants used by the presses often remain on the surface of the expanded metal. These residues may be left in place, particularly if no further finishing is planned after expansion (and flattening). Interestingly, these substances can sometimes help the metal resist corrosion.

However, if additional finishing or appearance considerations are important, these chemicals can be problematic. In such cases, they can be removed, typically through chemical methods like using detergents.

Diamond shape – This is the most commonly used pattern for expanded metal sheets.

Square shape – This is a variation of the diamond pattern where the diagonals are of equal length.

Louvered – The metal is pressed to create a louvered appearance. This pattern typically results in minimal expansion, meaning there is a smaller increase in the overall dimensions of the metal sheet.

Decorative – Custom shapes can be designed to meet specific aesthetic and architectural needs.

The thickness of the strands affects the overall percentage of open areas in an expanded metal sheet for any given die shape and opening size. It also influences the ratio of the total area of the expanded sheet to that of the original solid sheet from which it was produced.

Strand thickness is influenced by the feed rate during the stretching process. A higher feed rate results in expanded metal sheets with a lower percentage of open space.

It is possible to have varying strand thicknesses within a single sheet by adjusting the feed rate as needed during production.

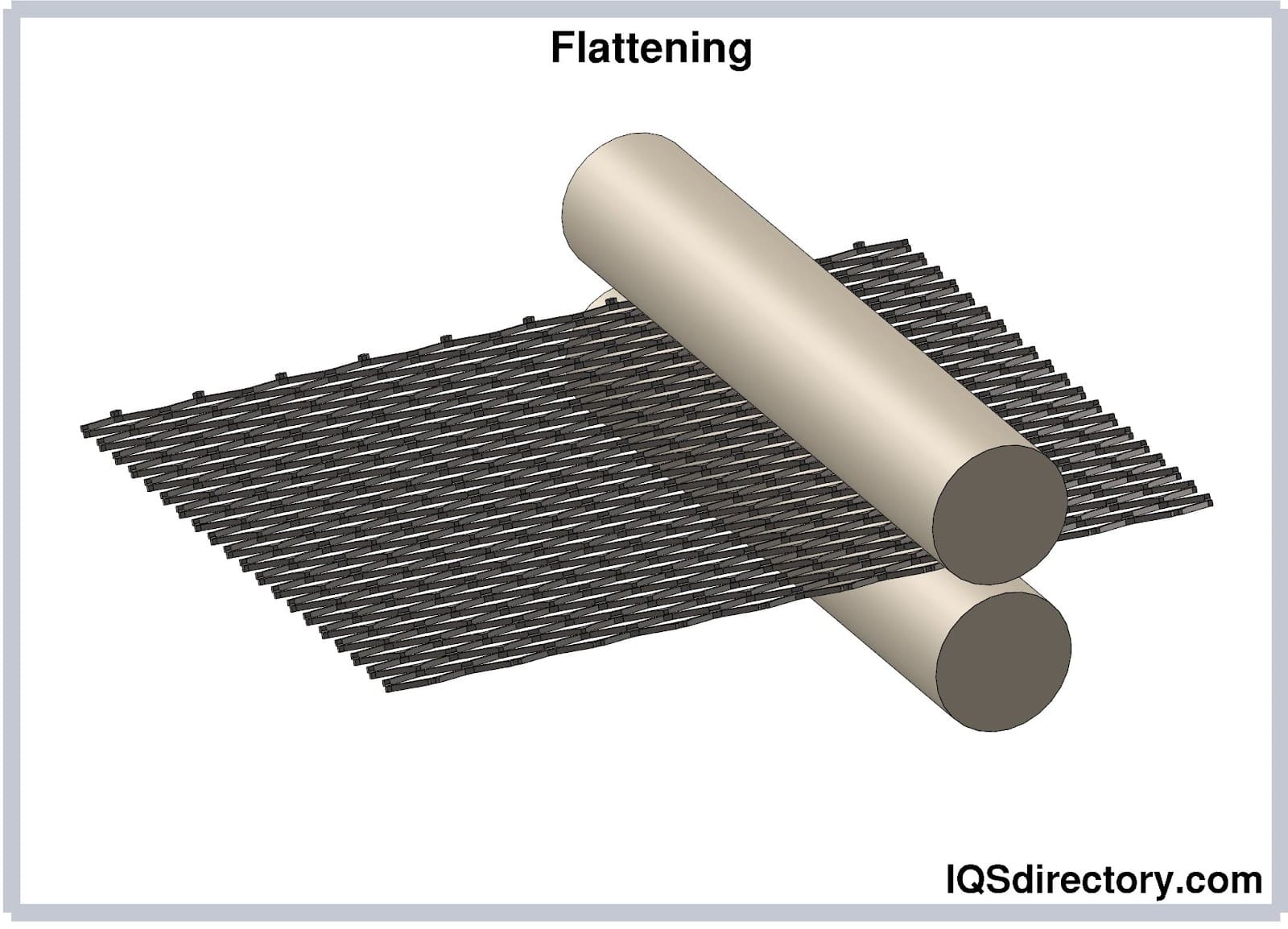

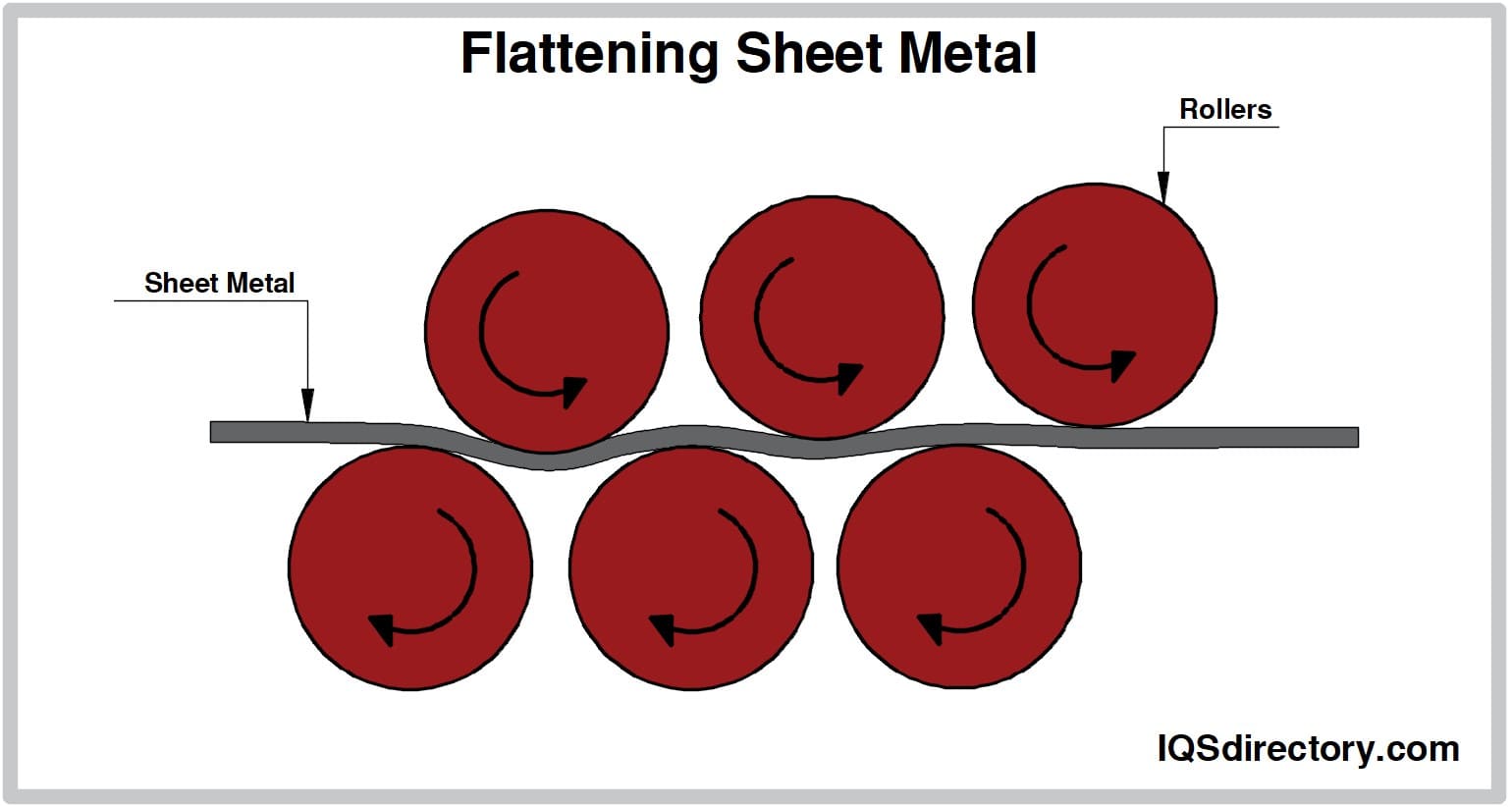

This process results in a flat surface finish on the expanded metal when such a finish is desired. Typically, the cutting and stretching processes leave the metal with a ridged or rippled texture, often referred to as a raised surface. While a raised finish may be preferable in some applications, it is not always desirable. In cases where a smooth finish is needed, flattening is applied.

Expanded metal that has not been flattened is commonly known as standard expanded metal, as it emerges directly from the expanding machine. Flattening is accomplished through cold rolling, which compresses the metal to make it thinner and more even. As the metal is cold rolled, it becomes thinner and elongates in the direction of movement through the rollers.

The lengthening of the expanded metal sheet results in the stretching of the openings in the same direction. Consequently, the openings may appear elongated or wider compared to those in the standard expanded metal sheet.

This process should not be confused with flattening. Flattening removes the ridged texture from the surface of the expanded metal, while leveling ensures that the sheet lies flat on a level surface. Flattening addresses the surface texture, whereas leveling concerns the overall flatness of the sheet. Leveling pertains to the sheet's three-dimensional geometry and measures how well different points align within the same plane.

An expanded metal sheet is considered level when it is free from waves and buckles. Since completely eliminating these imperfections is difficult, acceptable tolerances are established to define what is considered acceptable.

This chapter will cover the topics of surface finishing and shearing for expanded metal.

In many cases, expanded metal sheets are utilized directly as they come from the roller or stretching machine, with no further modifications.

However, for certain applications, additional surface finishing is necessary. These include:

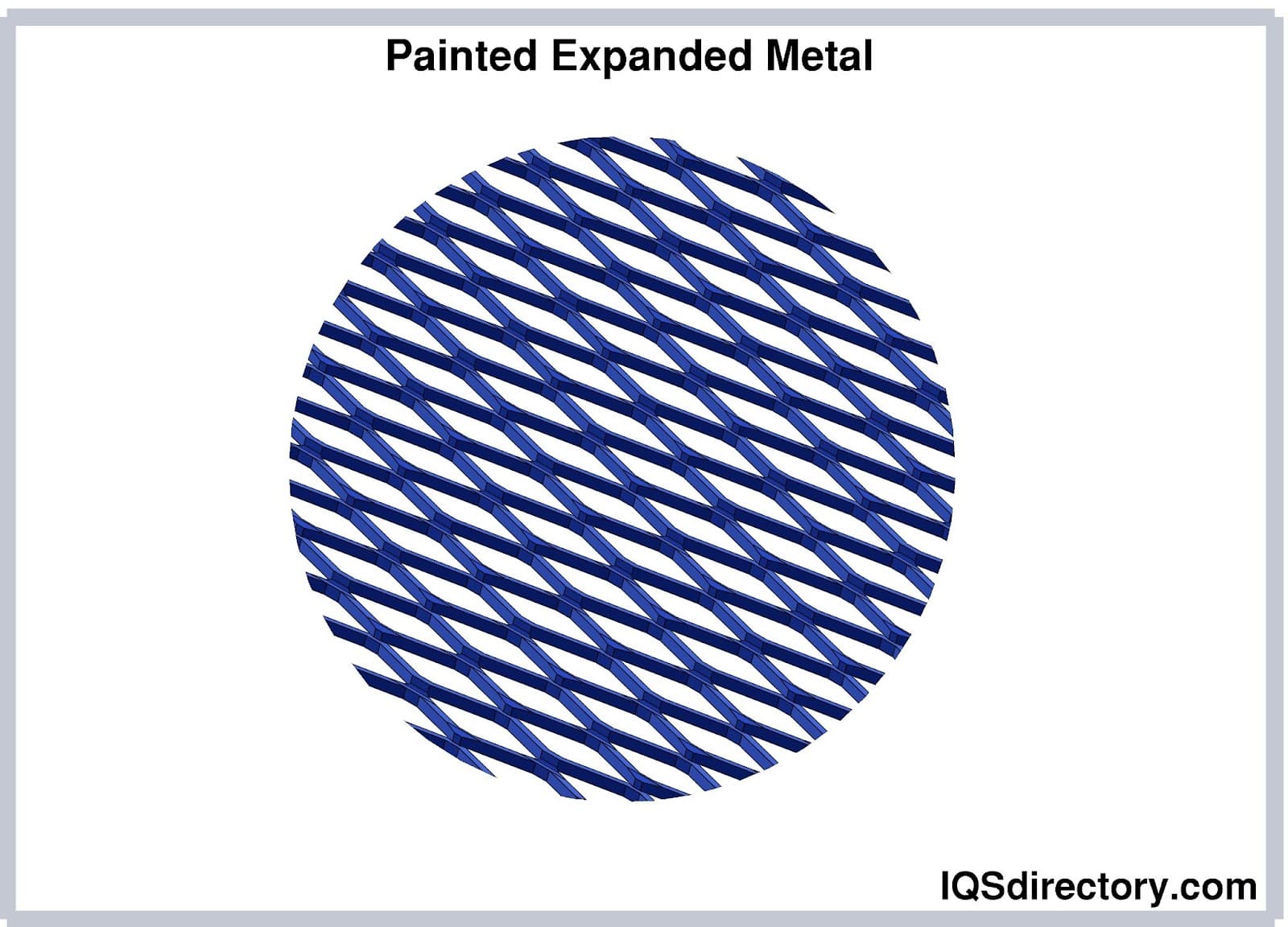

Painting is often the most economical method for finishing expanded metal sheets. Paint can be used for aesthetic purposes or to provide corrosion protection. However, for effective corrosion resistance, the paint must be fully intact; any small gaps can allow corrosion to develop underneath the coating. Of the coatings mentioned, painting is the least expensive, offers the least corrosion protection, and requires the most frequent maintenance.

This method often provides results similar to painting, but uses plastic instead. It tends to be more durable than painting. Typically, a spray gun is used to apply the plastic powder, which is often electrostatically charged. The coated sheet is then heated to bond the plastic with the metal surface.

In the galvanizing process, the expanded metal sheet is immersed in molten zinc, which forms a protective zinc coating. This coating helps safeguard the mesh from corrosion. However, due to the high temperatures involved, this method has limitations on the dimensions of the expanded metal that can be galvanized. Very fine meshes are generally not suitable for galvanizing due to these constraints.

Anodizing is an electroplating technique where the expanded metal sheet is coated while being electrically charged. This process provides a more granular coating compared to other methods and ensures a stronger bond with the metal. Despite its effectiveness, anodizing is relatively expensive, both in terms of the plating material and the process itself. Its higher cost is a primary reason for its less frequent use.

Anodizing is usually common with iron-based metals (which are prone to corrosion). This process circumvents some of the dimension limits that arise from the galvanizing process since it can be carried out at much lower temperatures.

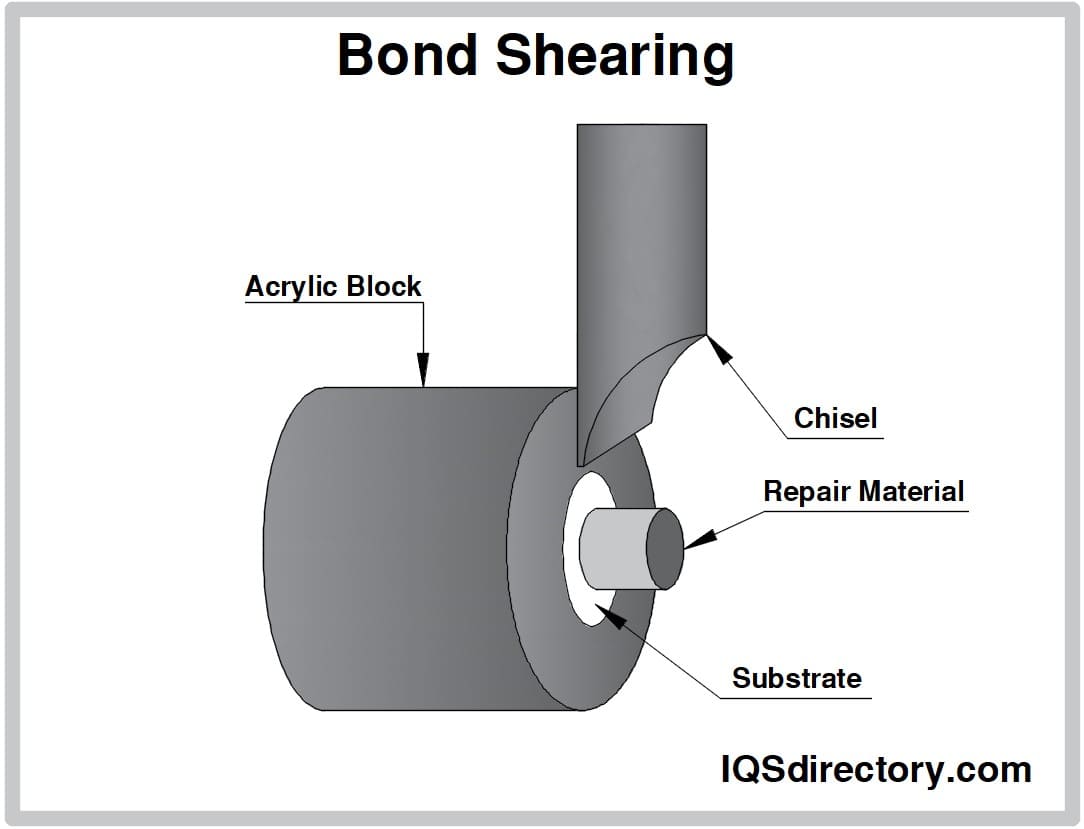

Shearing is the process used to cut expanded metal sheets to size. It involves trimming a larger sheet into smaller sections or altering its shape. Shearing is performed with shears, which are metal blades or mechanisms that operate similarly to scissors. Shears can be either manual or mechanized. When the blades come together on the expanded metal, they apply sufficient shear force to cut through the material.

Various types of shearing methods exist, which will be discussed in the following sections:

This involves shearing along the longer axis of the diamond pattern.

Bond shearing cuts the sheet precisely along the edge, resulting in closed shapes only on either side of the cut. This method aligns with the shapes of the pattern.

For raised expanded metal, bond shearing should be performed along the bonds between the rows.

Random shearing does not follow the shape edges, resulting in open shapes and irregular patterns at the edges. This method can leave sharp, spiked strands. To improve handling, expanded metal that has been randomly sheared should be U-edged or framed as an alternative.

U-edging involves applying a U-shaped metal strip to cover the edges of an expanded metal sheet.

This involves shearing with a line of symmetry on the expanded metal sheet.

This technique creates a matching section, ensuring the mesh pattern appears continuous.

This method shears along the shorter axis of the diamond shape.

This involves cutting across strands at locations other than the bonds.

Among expanded metal shapes, the diamond (hexagonal) pattern is the most common. Typically, the same shape and size of openings are used consistently throughout a sheet. The diamond shape features four-sided openings with strands meeting at the corners.

As the difference between the diagonals of the diamond shape decreases, it begins to approximate a square (geometrically, a square is a special type of diamond where the diagonals are equal). In such instances, the mesh is referred to as a square mesh.

The hexagon does not need to be regular, but the side length determines the dimensions and strength of the bonds.

Tolerances for expanded metals need to be adhered to for:

Typically, expanded metal should be free from:

Expanded metal can be produced with different tolerances, which will be described below.

This refers to the bow or curve in the sheet. It may not matter if the expanded metal sheets are to be rolled for packaging, but it can be problematic for applications needing a flatter material. This is particularly true for materials requiring higher rigidity, which could result in residual stresses in the structure.

Producing expanded sheet metal with no camper is quite rare. Therefore, tolerances are established for specific applications. If the camper falls outside the required tolerance, corrective measures are necessary; otherwise, the material can be used effectively.

The curve typically forms along the edge in the direction of the feed during the cutting and stretching phase of the expanding process. Flattening, which often involves rolling, also addresses campers by removing or reducing them, along with waves and buckles, resulting in a more even product.

This refers to the property of having a rectangular or square shape, characterized by 90° angles and straight edges. In such geometry, the diagonals are equal.

Squareness is a planar characteristic, applicable to a single plane—the view from above when the sheet is laid flat. An expanded sheet can be square without meeting all other spatial and geometric requirements, such as being level. Conversely, issues like camper and buckles can affect the squareness of an expanded metal sheet.

Deviations from squareness often stem from the initial metal sheet, which is rarely perfectly square despite tight production tolerances, or from defects in the die used.

If the application permits, re-squaring can be achieved by random shearing the expanded metal sheet along specific lines. Border shearing generally does not correct squareness, and stretching the shorter diagonal often results in non-straight edges.

This feature is often crucial, especially when the expanded metal sheet has parallel opposite sides. Sheets that are perfectly square will always have parallel sides, but sheets with parallel sides are not always square (e.g., a parallelogram). Additionally, sheets without parallel sides can never be square. Deviations from parallelism may be caused by factors such as camper.

In certain applications, expanded metal may be intentionally made with non-parallel sides. For example, a die with varying "tooth" sizes across the sheet's width can create this effect from a square solid sheet. However, such applications are quite rare.

This refers to the deviation from having parallel sides, which becomes particularly noticeable when it is undesirable. A sheet with tapered sides cannot be considered square.

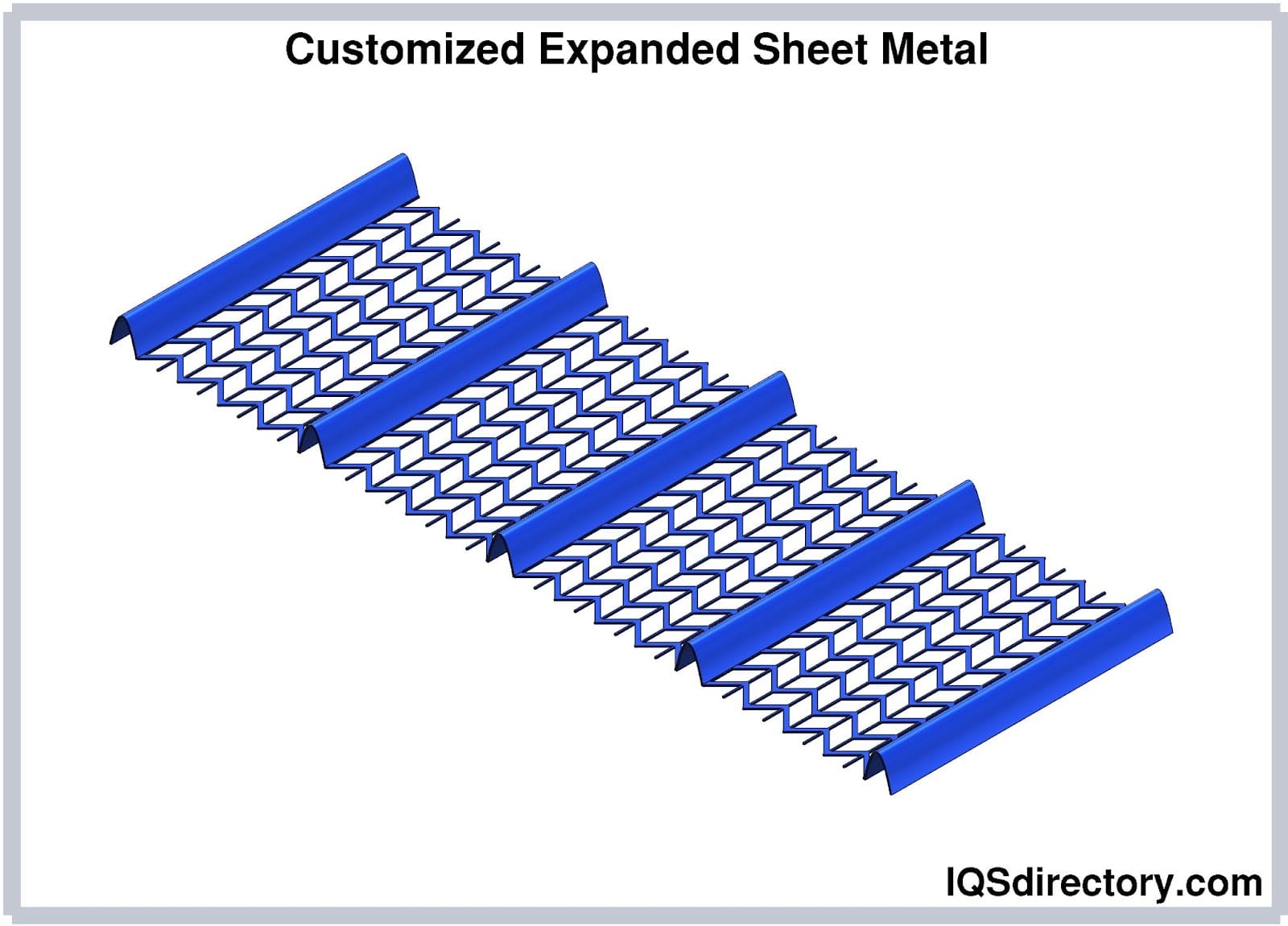

Often, expanded metal sheets require additional processing after they come out of the expanding machine. This may include cutting, bending, welding, bracing, and other modifications. Customization work is not usually part of the standard production process due to the unique requirements of each project. Additionally, some applications may need different gauges of expanded metal to work together effectively.

Customization involves modifications performed on the expanded metal sheet, typically based on specific customer requirements. These tasks may include:

This chapter will explore the uses and benefits of expanded metal.

Expanded metal is versatile and used in various applications, including:

Platforms designed for use at significant heights often incorporate expanded metal mesh to take advantage of its lightweight nature. Common applications include rigging in industries such as transportation, oil, telecommunications, and more.

Expanded metal can cover rotating shafts and machinery parts. It is lighter than solid guards but equally effective in safeguarding machine operators.

Expanded metal is used in structures to facilitate drainage and ventilation. It is commonly placed over drainage trenches along roadsides, walkways, factory floors, and similar areas.

Expanded metal mesh serves as protective screens for building and vehicle windows, including cash-in-transit vehicles.

Some bridges and suspended walkways use expanded metal for pedestrian areas to reduce the weight of the deck while maintaining structural integrity.

Expanded metal mesh is ideal for creating barriers where light, air, and sometimes water need to pass through. Such barriers are used in aquariums, buildings, tunnels, and other structures.

Expanded metal is used for protective fences, yard demarcation, animal cages, and other enclosures.

Expanded metal is suitable for making gabion walls, especially when finer aggregates are used, offering an alternative to welded mesh.

Expanded metal mesh can be utilized as a covering for equipment, offering a suitable solution when neither a solid sheet nor an uncovered area is appropriate.

Examples of equipment that might use expanded metal in their coverings include generators, tractor engines, earth-moving machinery engines, and both air and water pumps.

In architectural applications, expanded metal mesh is used in gardens, building openings, walls, roofs, guard rails, and demarcation walls. Fine meshes are also used in jewelry making.

Expanded metal mesh can be fashioned into trays used in agriculture, such as for harvesting and transporting green tea from fields.

Some recreational parks use expanded mesh on steep cliffs to provide thrill and entertainment.

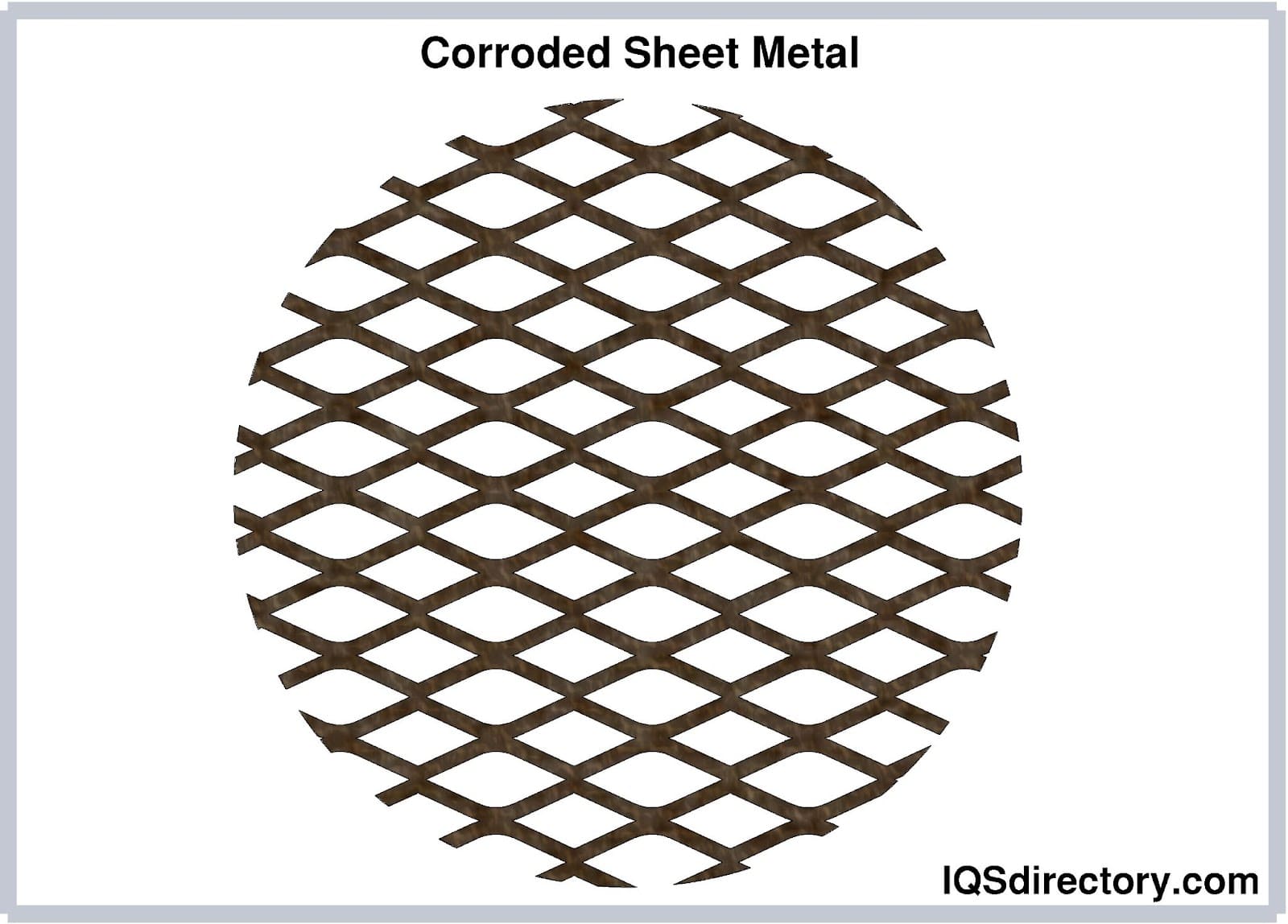

While expanded metal has some drawbacks, such as increased surface area that can lead to corrosion and chemical damage, its benefits often outweigh these issues. Some advantages of expanded metal include:

It can be reasonably inferred that the need for expanded metal products will persist into the distant future. The combination of (relatively) light weight, high strength, and moderate cost will continue to place a distinct attractiveness on expanded metal products. The general trends of structural and industrial development also seem to agree – amongst other things, the requirement for civil structures to become increasingly taller will persist, with it the need for platforms, barriers and ornamentation.

Metal grating is a metal product produced by perforating metal sheets or joining bars of metal to form a grid. They are a metal product that is widely used in various industries as...

Perforated aluminum consists of an aluminum sheet which has been manually or mechanically pierced or punched using CNC (computerized numerical control) technology in order to produce shapes and patterns of various sizes...

Perforated metals are sheets of metal that have had decorative shapes, and holes punched or stamped into their surface for practical or aesthetic purposes. The perforation of metal sheets takes several forms and includes a variety of geometrical patterns and designs...

A perforated metal is a piece of sheet metal that has been stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes. A wide range of metals are used in the perforating metal process, which include steel, aluminum, stainless steel, copper, and titanium...

Perforated stainless steel is cut, punched, or stamped to produce a precise pattern of holes or apertures. It is used for functional reasons, such as filtration or ventilation, and aesthetic ones, such as architectural accents...

Perforated metals are sheets of metal that have had decorative shapes, and holes punched or stamped into their surface for practical or aesthetic purposes. The perforation of metal sheets takes several forms and includes a variety of geometrical patterns and designs...

Wire cloth is a woven (or nonwoven) sheet or web material with a series of openings across the surface. Wire cloth is also known as: Metal Fabric or Metal Cloth; Wire Mesh, Metal Mesh, or Alloy Mesh...