Factory Automation

Introduction

A description of factory automation with a list of companies that provide, implement, and plan it

You will learn:

- What is Factory Automation?

- The Types of Factory Automation

- How Factory Automation is Planned and Implemented

- Equipment for Factory Automation

- And much more …

Chapter 1: What is Factory Automation?

Factory automation involves integrating advanced technology processes to boost productivity, elevate manufacturing output, and significantly improve production efficiency. Through a seamless set of operations, products are manufactured, assembled, packaged, and made ready for distribution and shipping. The core of factory automation depends on computer programming to manage each processing and production phase efficiently.

The rapid expansion of factory automation stems from rising global market competition. To retain a competitive edge, businesses are adopting factory automation to optimize operations, cut costs, and enhance productivity. Factory automation enables continuous 24-hour production with minimal errors, reduced waste, and outstanding product quality.

Factory automation includes extensive technology systems regulated by distributed control systems (DCS) or supervisory control and data acquisition (SCADA) systems. Programmable logic controllers (PLCs) and remote terminal units (RTUs) strategically placed throughout the factories take signals from the system to direct equipment in executing tasks. PLCs and RTUs are tailored to fit the specifications of products and processes. Crucial components of a factory automation system comprise PLCs, advanced solutions, cybersecurity measures, and operational technology (OT). Each element is integrated into the system to oversee and manage factory operations effectively.

Chapter 2: Types of Factory Automation

It is difficult to encapsulate what factory automation is due its many forms, which run the full gamut of industrial operations. Although it is possible to name a form of factory automation, each form is adjusted and customized to meet client demands that vary according to the product being produced and the industrial environment.

The term automation brings up visions of machines working independently and together for a single objective and purpose. In some ways, the processes and engineering of factory automation takes on a feeling of science fiction and futuristic contraptions. Although these conceptions may seem misguided and imaginary, many of the design features engineered by automation engineers represent a look into the future of industrial manufacturing.

Factory automation takes several forms from ones that include human participation to ones that are completely computer controlled. The inclusion of human participation, as with other factors, is dependent on the type of product. In many cases, robotic arms and equipment work with humans in a codependent manufacturing process.

With the rise in technological advancements and industrial modernization, the use of factory automation is rapidly increasing. It is estimated that by the year 2030 the use of factory automation will reach $400 billion. This increase has motivated companies to research automation processes as to how they can use them to produce their products.

The four general types of factory automation are fixed, programmable, flexible, and integrated. The various types are differentiated by their complexity, programming, and amount of work they perform. They are further divided by the amount of human involvement.

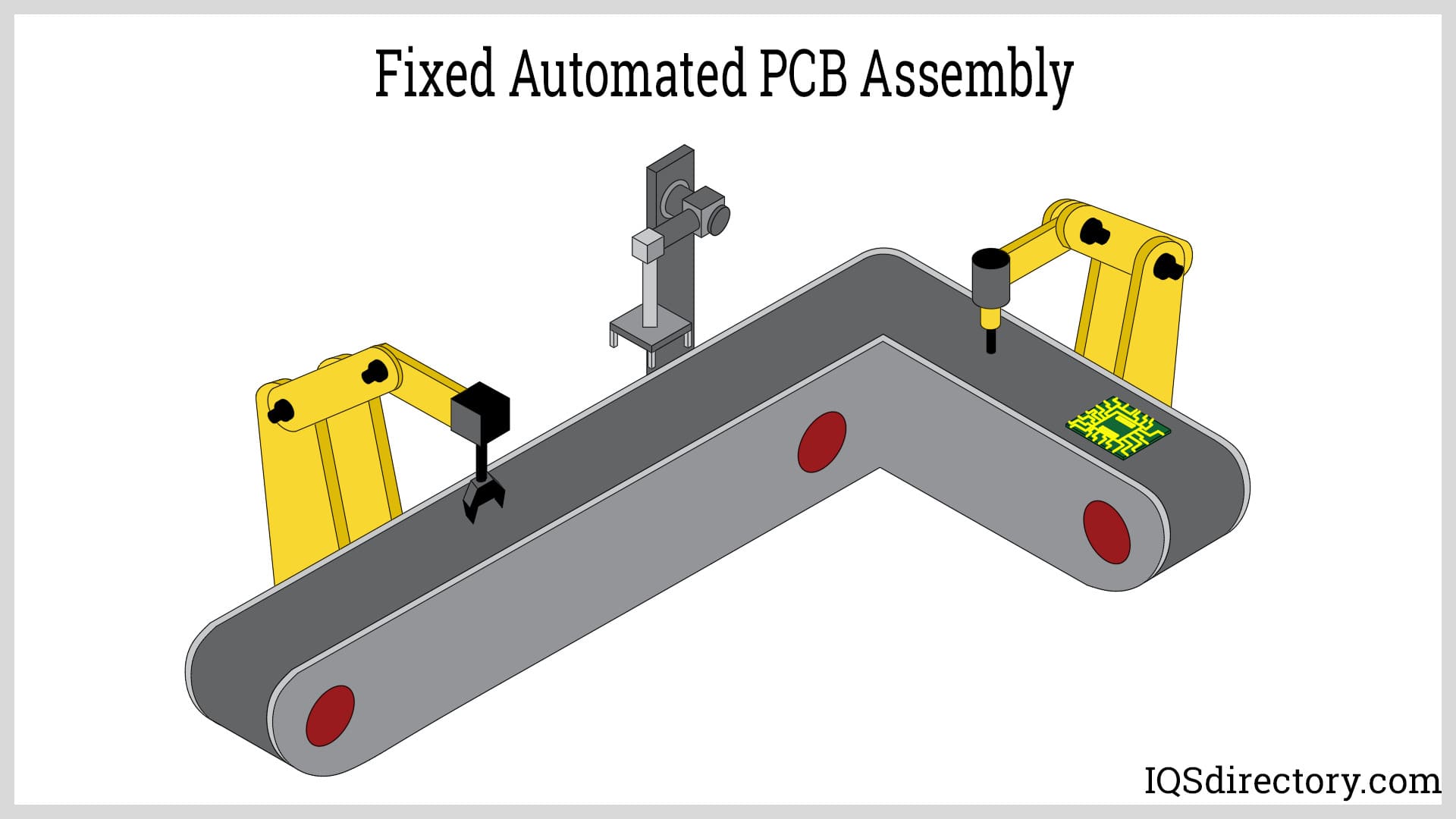

Fixed Automation

Fixed automation is the most basic type of factory automation, which has been used for many years. Referred to as hard automation or special purpose automation, fixed automation systems are assemblies designed and preset to produce one product. A set of production operations are tooled, crafted, and equipped for high volume production of a single product. Once set up and placed, fixed automation systems cannot be changed. Such systems include a set of specialized tools oriented toward one and only one task.

Regardless of being the most basic form of factory automation, fixed automation systems have the same complexity and intricacies found in more technologically advanced automation systems.

The design and engineering of fixed automation systems require specific design knowledge and substantial initial investment. The systems are inflexible and are designed for high volume production rates. As with other high-cost pieces of equipment, the cost of fixed automation systems is amortized over several years due to the stability of the systems and their long useful life.

Examples of Fixed Automation Systems

- Automated Assembly

- Web Handling

- Converting Systems

- Chemical Processes

- Conveyor Systems

- Transfer Lines

- Paint Processes

- Coating Processes

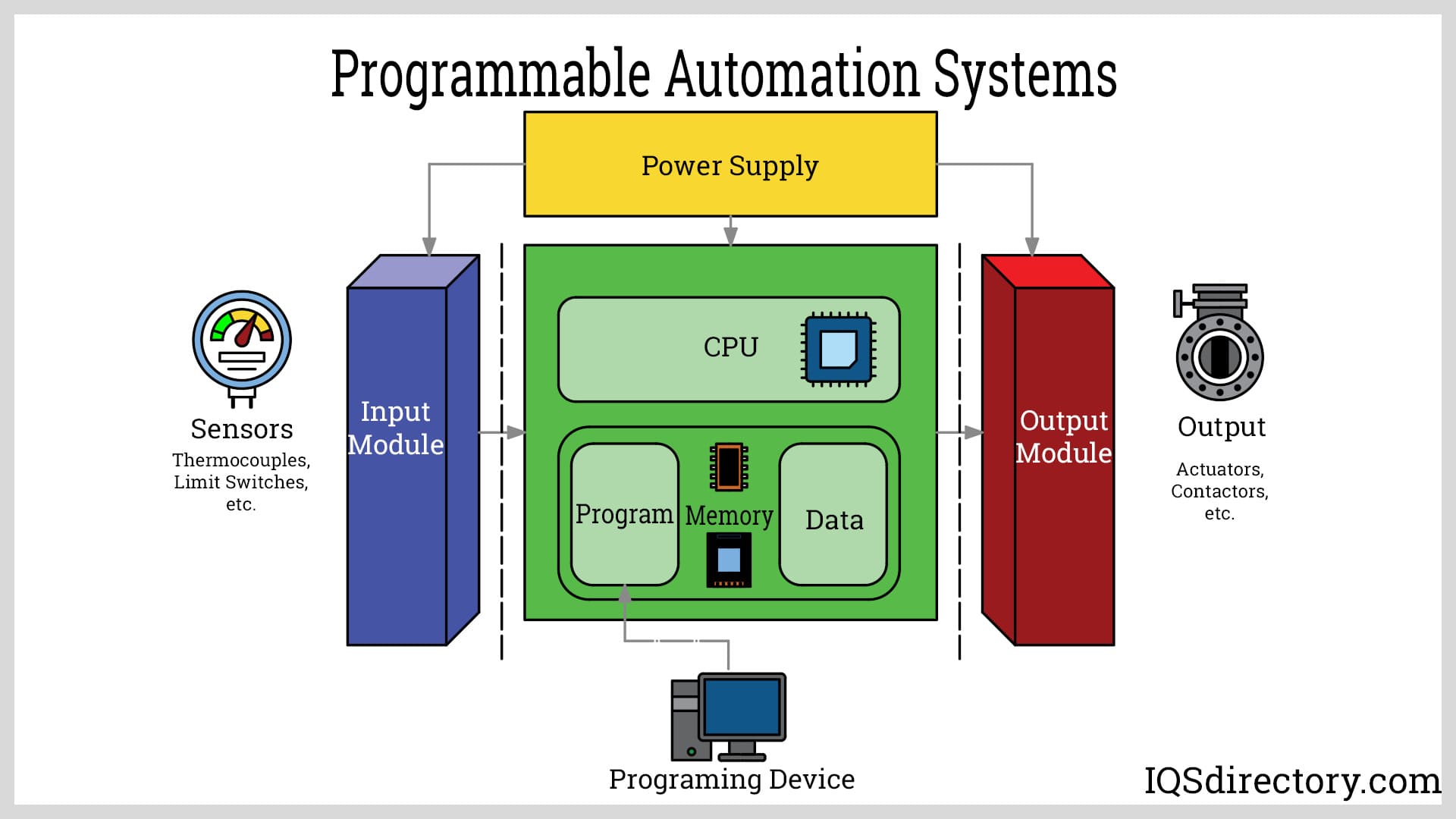

Programmable Automation Systems

Unlike fixed or hard automation, programmable automation can be changed and adjusted for the production of different products. In some ways, such systems are similar to the days when auto manufacturers shut down their factories for a change over during model year end. The key to programmable automation is their programming, which can be changed as a new set of tasks are entered into the system. Programmable automation is flexible due to its programmability, which makes the system efficient and ideal for moderate production volume.

Programmable automation is ideal for batch manufacturing where a company can produce one product in the morning and switch over to another product in the afternoon. The system is capable of producing similar products and be reprogrammed for a completely different product. Programmable automation is the perfect scenario for products that have a short market life, such as specialty items for holidays or once in a lifetime events.

The many positive aspects of programmable automation make it an ideal solution for short run manufacturing processes. It is versatile, efficient, cost effect, and ensures the production of high-quality products.

There are two negative aspects of programmable automation, which are its initial cost and the requirement of technical expertise. The initial cost of programmable automation is like any other technologically advanced piece of equipment that necessitates complex setup. Manufacturers that choose to use programmable automation have the resources, personnel, and environment necessary to operate such production methods.

Examples of programmable automation include computer numerical control (CNC) systems that rely on a set of codes, robotics, 3D printing that uses design files to shape a product, warehousing automation, programmable automation controller (PAC) and PLCs. Programmable automation is rapidly becoming the standard for product production. Such processes lower labor costs and produce exceptionally high-quality products.

Programmable automation is used in conditions where the manufacture of various products uses the same tools and equipment. Switching from one product to another requires changing the instructions for the use of a tool without having to change the tooling.

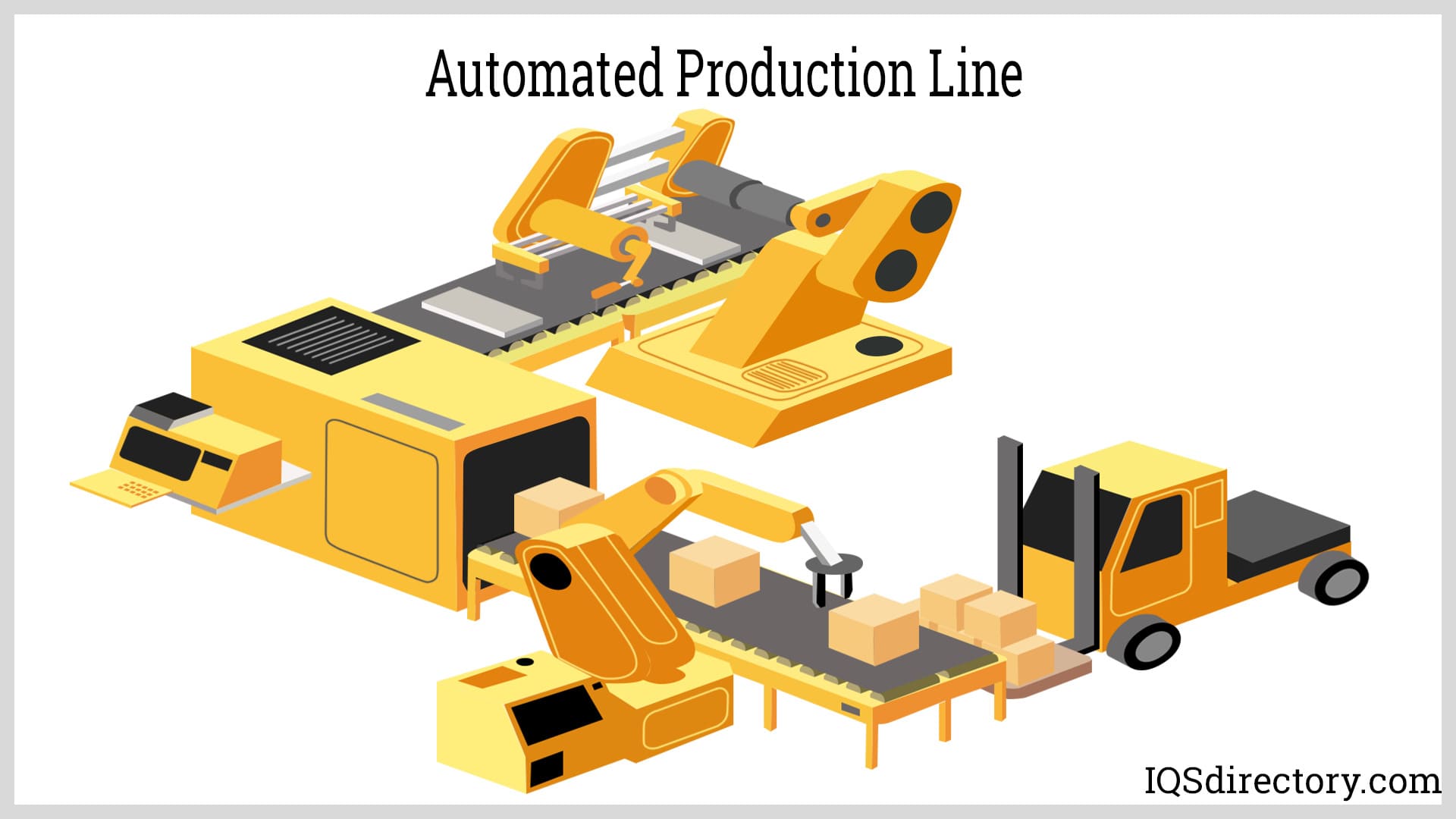

Automation Production Lines

Automation production lines are somewhat similar to the initial production lines established by Henry Ford over 100 years ago. As with any form of production line, an automated production line has a series of stations that perform a single task before a workpiece is passed on to the next station. The various stations are linked by a transfer system, which can be a conveyor belt or other form of material handling mechanism. Like programmable automation systems, automation production lines are electrically controlled and contain sensors that monitor product production.

An automated production line is programmed such that each station is timed regarding the completion of their part of assembly. It is a defined sequence that ensures an efficient progression of workpieces between work stations. Human involvement includes monitoring of the process, ensuring adherence to system design, and making necessary adjustments. The length of automation production lines varies in accordance with the product being produced with some systems being several feet while other systems can run the full breadth and width of a building.

End-to-End Automation (E2E)

End-to-end automation is an all-encompassing process that begins with raw materials and outputs completed products ready for shipment. The process involves the use of technically advanced programming for automating business flow and removes the need for workers to complete mundane, repetitive, and monotonous tasks.

Facilities that use end-to-end automation are referred to as lights out or dark manufacturing environments. End-to-end automation operations run 24 hours a day every day of the week. The only intervention by humans is in regard to checking system programming, ensuring there are sufficient raw materials, and checking for errors in the system.

The use of E2E is expected to continue to grow as new technologies and methods are interlaced with automated systems. Presently, E2E requires humans to check raw materials, repair equipment, and constantly monitor operations. Such interventions ensure that the process of E2E is functioning at its highest level. The essential part of end-to-end automation is the software and hardware that is used to create the process and ensure its efficiency.

The initial steps in end-to-end automation are working with a software company that produces programs that provide commands for equipment and investigate what steps need to be implemented. There are several types of end-to-end that manufacturers offer to revolutionize a manufacturing process.

End-to-end automation is associated with lean manufacturing, a manufacturing concept designed to reduce costs, enhance product quality, improve production efficiency, and increase profitability. Lean manufacturing has been part of industrial operations for many years as part of the Six Sigma program. End-to-end automation is the next step in the lean manufacturing philosophy, in that end-to-end automation removes many of the factors that impact production costs.

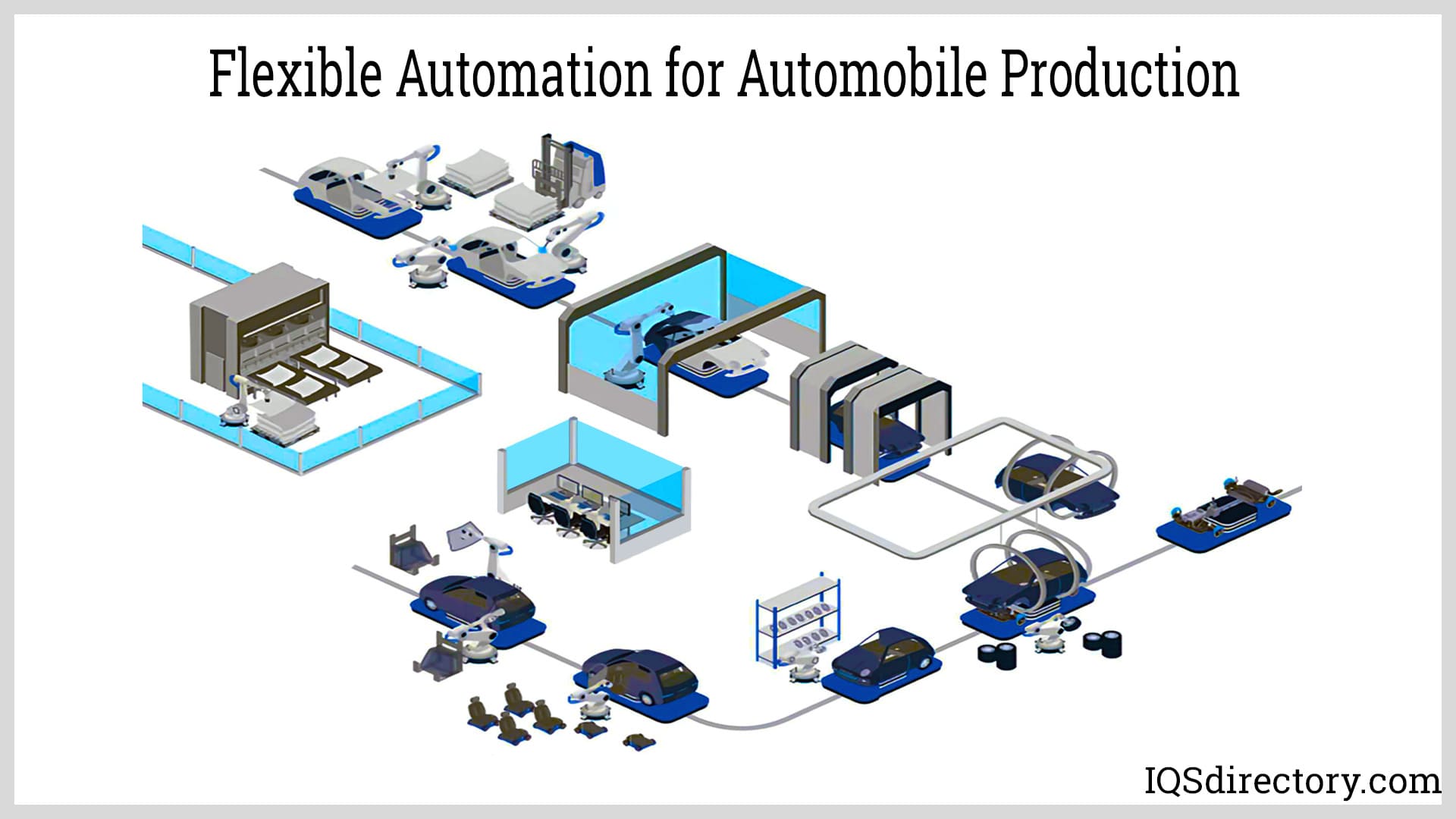

Flexible Automation (FA)

Flexible or soft automation is a batched process capable of manufacturing a wide variety of products. New codes are entered into a computer that provide instructions for pieces of equipment. Product changeovers can be initiated quickly with very little down time. The process removes the need to change tooling, reconfigure equipment, or make any upgrades.

Part of the flexibility of flexible automation is the ability of robots or equipment to perform one task. In addition, unlike fixed automation, the angles, position, and number of tasks performed at one station can be adjusted. A welder that performs the same weld over and over again in fixed automation can be programmed to perform a series of different welds depending on the product being produced in flexible automation. Each type of product may require the reorientation of a tool such that it applies a function in a different orientation or position for each type of product.

The extreme precision, accuracy, and quality of products produced by flexible automation requires a significant amount of investment, which necessitates careful planning and consideration when choosing the process. Fortunately, automation experts, providers, manufacturers, and engineers work closely with their clients to ensure the process being chosen meets the cost and needs of their clients.

The choice of equipment for flexible automation is dependent on the intricacy and complexity of the product being manufactured. In many cases, the time spent by a worker is compared to the time it takes for flexible automation to complete the same process. The implementation of flexible automation radically increases the volume of completed products compared to manual manufacturing.

Integrated Automation

Integrated automation is very much like end-to-end automation. It involves limited human intervention from the design phase of parts to the testing of designs and the completion of fabrication. Integrated automation combines all of the facets of manufacturing into a single streamlined system that is efficient, quick and reliable. Such systems operate seamlessly and flawlessly without the need for human intervention.

The essence of an integrated automation system is technologically advanced tools that include sensors, actuators, controllers, and monitors that work in unison to control different aspects of the system. Due to their dependability, integrated systems are used for production processes that require high productivity and reliability.

A component of integrated automation systems is their common manufacturing database, which is the control point that makes it possible to integrate industrial and non-industrial applications. It is a computer generated manufacturing method that is designed to enhance efficiency, increase productivity, and bring all aspects of manufacturing together. Sometimes referred to as computer integrated manufacturing (CIM), integrated automation oversees all parts of the manufacturing process to provide a streamlined operation with improved quality controls.

A CIM system coordinates every automated part ensuring that every aspect works as part of a team operation. In essence, CIM makes everything work smoother, quicker, and eliminates mistakes and errors. The combination of computers and automation provides an improved and more efficient process.

As can be engendered from the examples above, factory automation is a complex and multifaceted subject that takes several forms. When researching the subject, it is common to find multiple names and descriptions for the same system, which is due to manufacturer preferences and their types of descriptors. Other names associated with factory automation include industrial automation, robotics, artificial intelligence (AI) manufacturing, 3D printing, additive manufacturing, and process automation. Each of these terms are used by manufacturers to provide a clear and easily understandable definition of their systems.

Factory Automation Category List

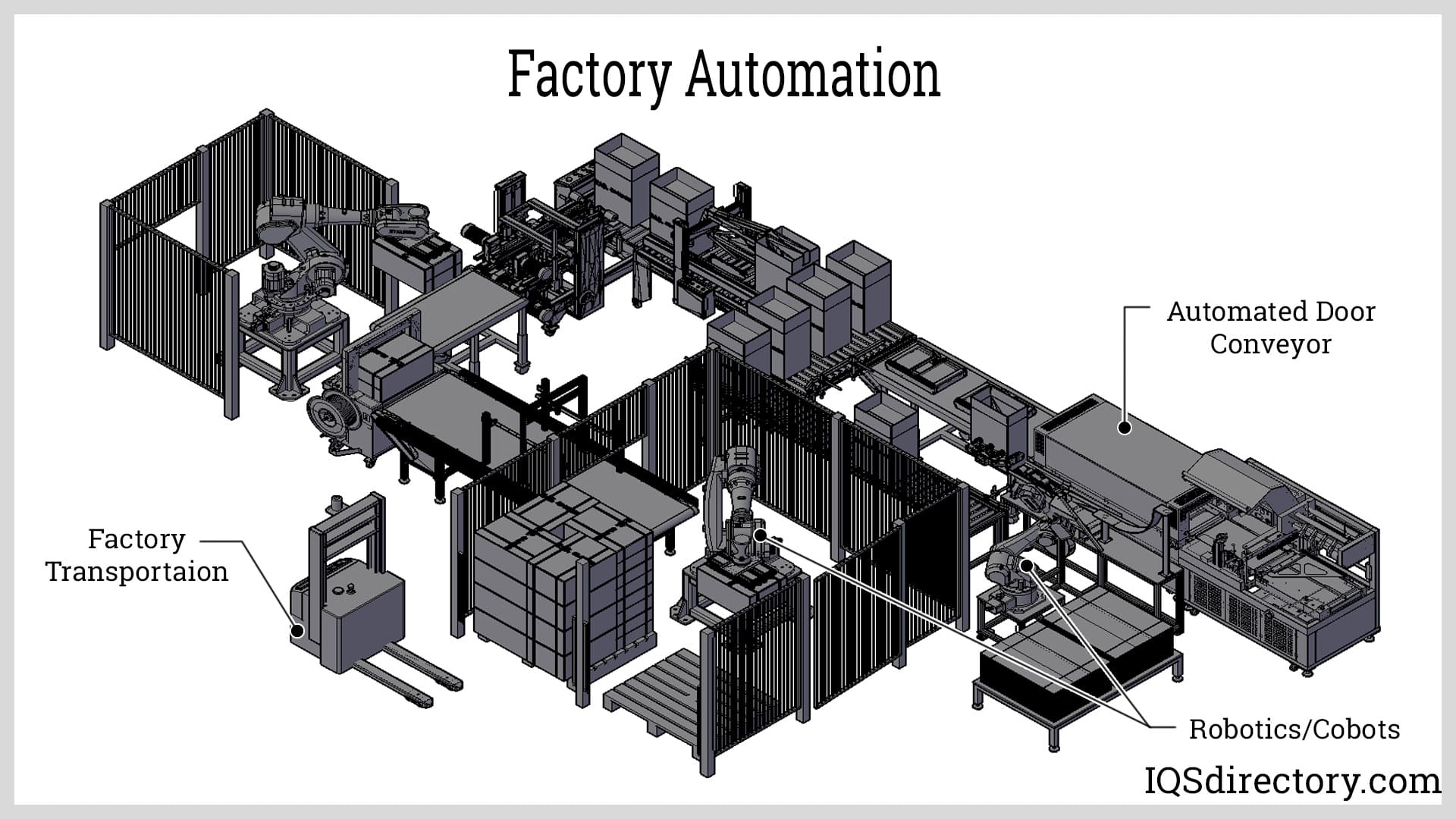

Chapter 3: Factory and Industrial Automation Tools

The tools of factory automation are the technological controls, management tools, and devices that remove any concern for human error, help decrease costs, and substantially save production time. So much of manufacturing is moving to factory automation due to its efficiency, reliability, precision, accuracy, and high tolerances. Factory automation uses digital, computer, and mechanical technologies to smooth and streamline manufacturing processes.

Industrial and factory automation companies provide clear outlines of how to custom plan automation tools that can radically change and improve profitability by lowering labor and production costs. Every automation system is custom built to meet the needs of a product and the environment.

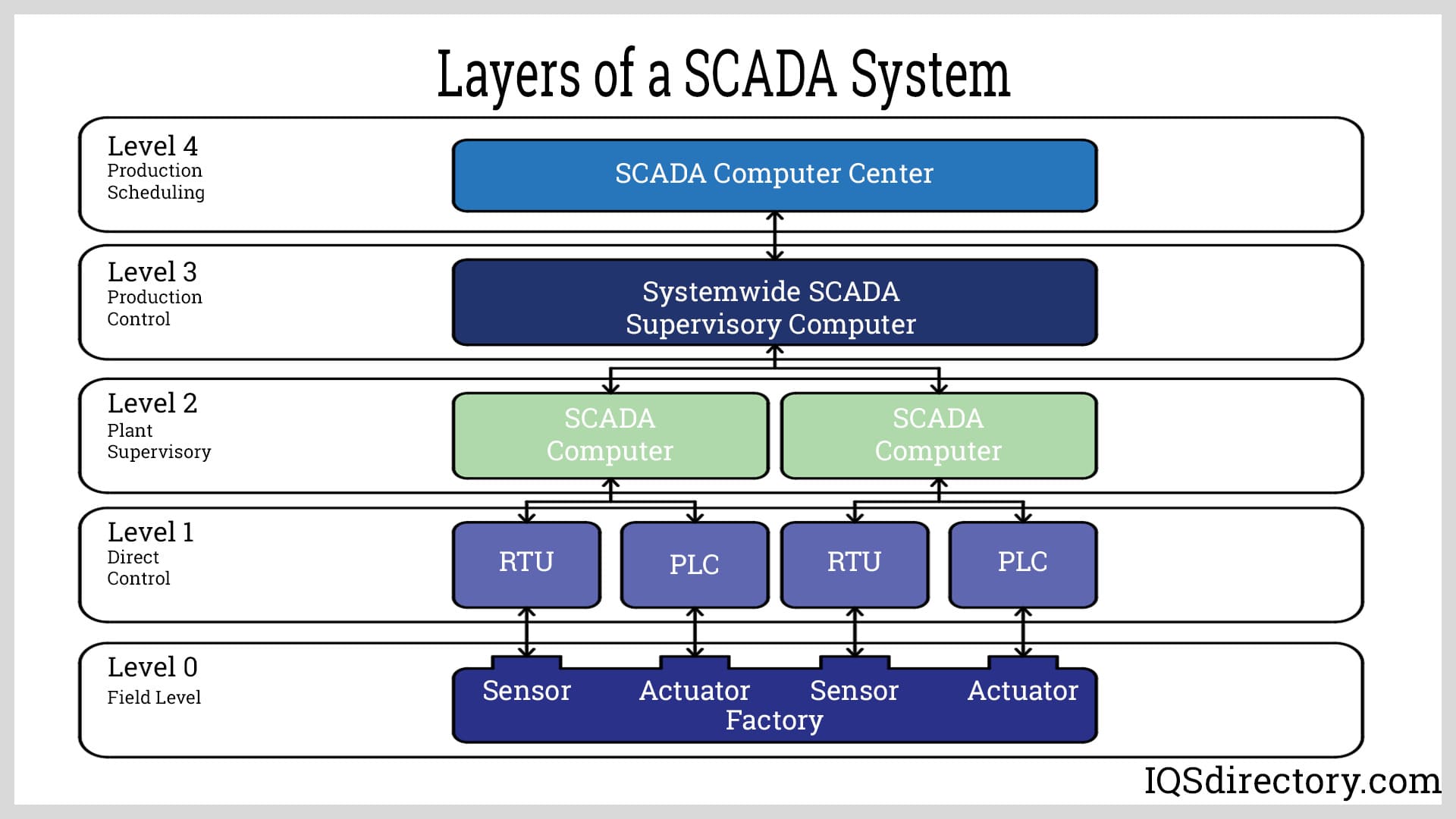

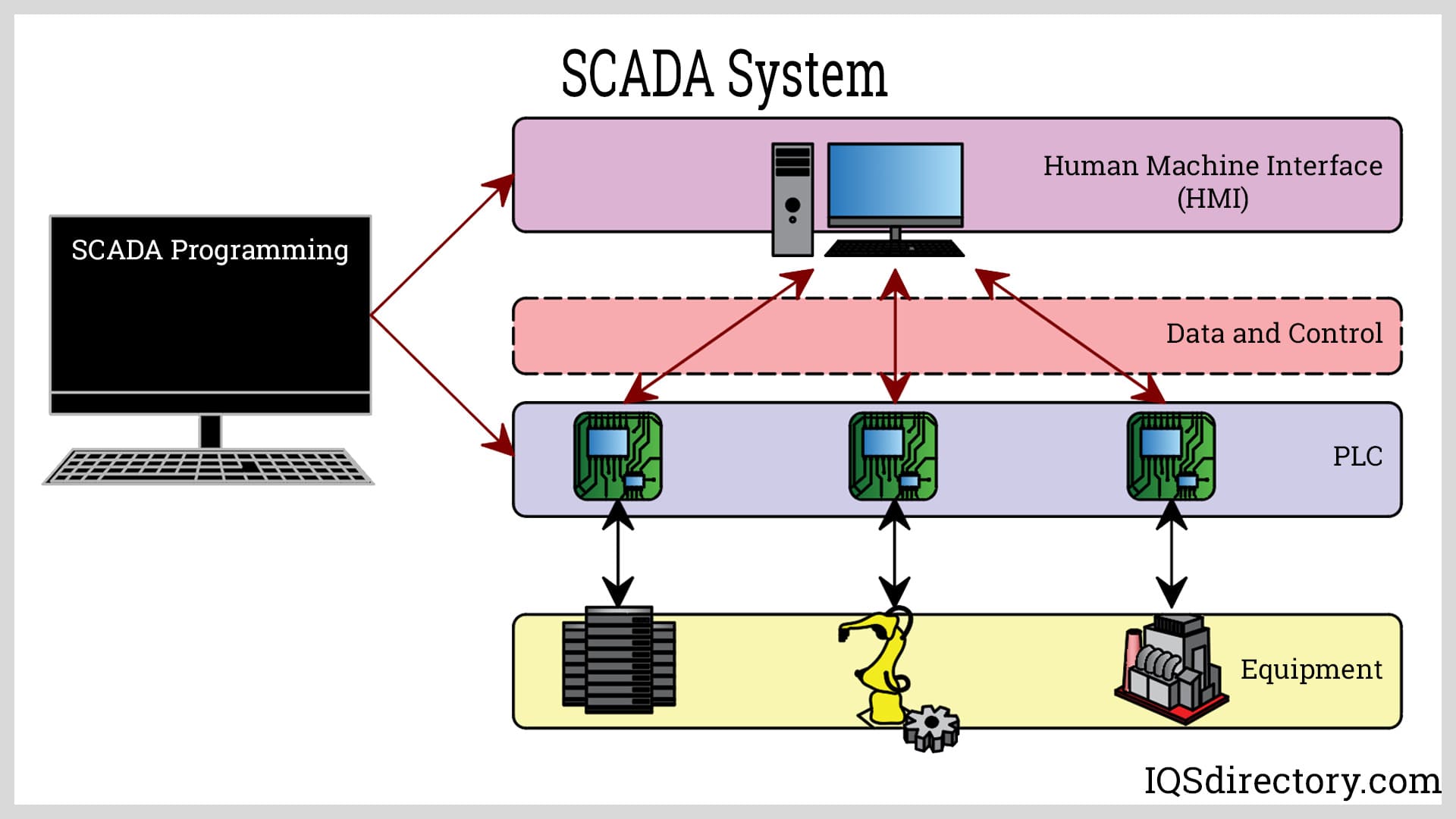

Supervisory Control and Data Acquisition (SCADA)

SCADA is a central system of software installed in a computer system to act as an interface between industrial equipment. It allows users to compile data regarding equipment, enter commands, make changes, and adjust parameters for production improvement. Data from PLCs and RTUs is fed to the SCADA system. Human machine interfaces (HMIs) are used to enter commands, make adjustments, and monitor processes.

Using a SCADA system, real time data can be accessed anywhere in the world. The collected data enables managers and supervisors to make decisions regarding various aspects of a process. SCADA interfaces with production equipment and machinery to provide data regarding manufacturing processes and their status.

The components of SCADA are programmable logic controllers (PLCs) and remote terminal units (RTUs), which are microcomputers that communicate with machines, HMIs, sensors, and other devices. SCADA systems are adaptable to any form of industrial operation from energy and food production to the biochemical industry and waste water management. The wide use of SCADA systems saves time, money, and ensures smooth and safe operations of equipment.

If a piece of equipment malfunctions, sensors on the equipment send data through the SCADA system to an end user in the form of a work order. SCADA is often compared to the industrial internet of things (IIoT), since both are used to monitor and control equipment. One of the differences between the two systems is IIoT’s ability to store data on site or in the cloud in various formats. The data is used as a diagnostic tool for predicting equipment failures.

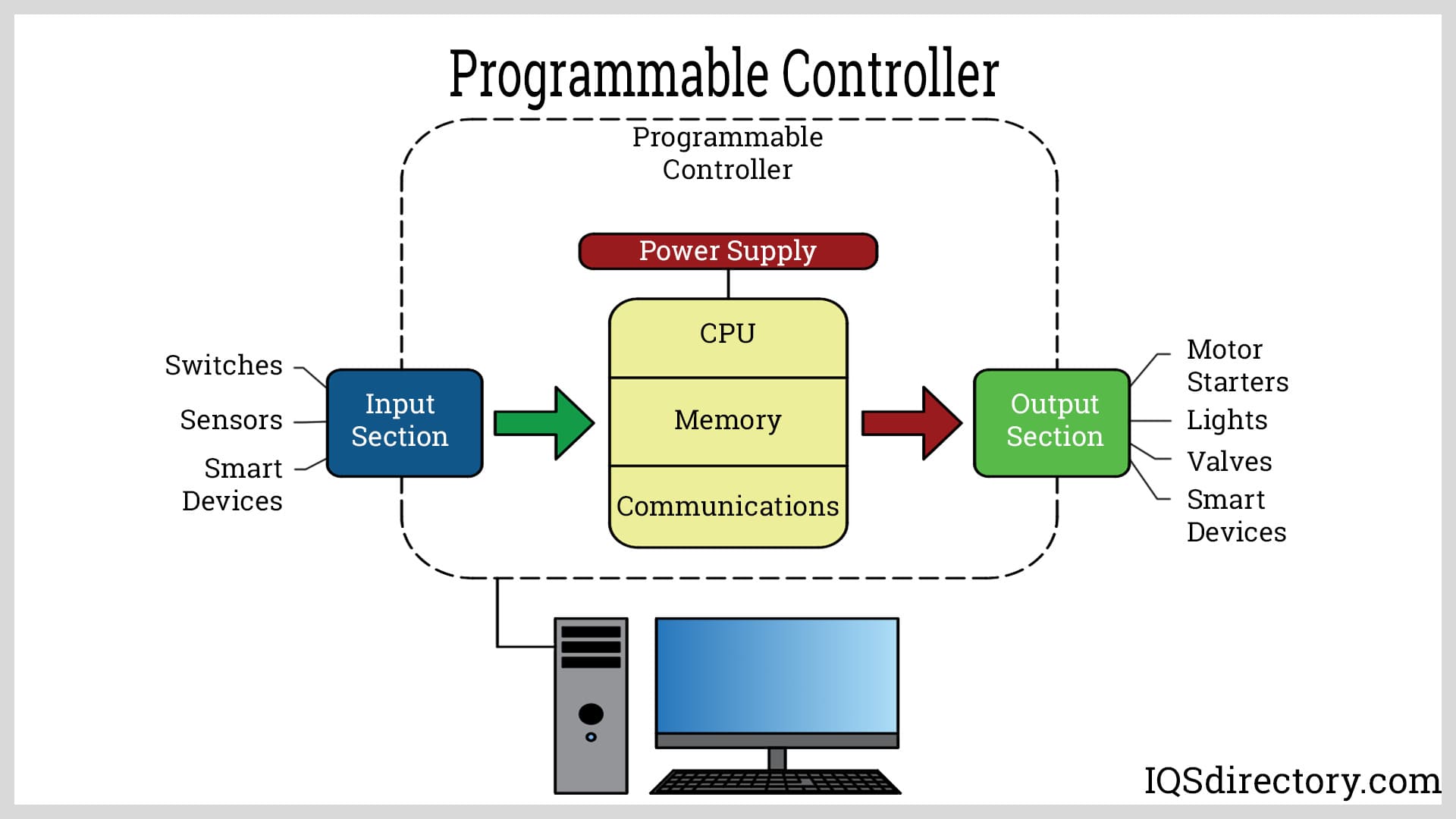

Programmable Logic Controller (PLC)

PLCs are industrial computers that have hardware and software for control functions. They monitor inputs to generate appropriate outputs to make production operations efficient and productive. The main function of PLCs is for industrial electromechanical automation of assembly lines, amusement parks, and food processing. The sections of PLCs are the central processing unit (CPU) and the input/output ((I/O) interface.

- Central Processing Unit (CPU) – The CPU controls system activity using its processor and memory system. It consists of a microprocessor, memory chip, and integrated logic control circuits, monitoring, and communications. The different operating modes of a CPU are programming mode and run mode. The programming mode accepts changes to the downloaded logic while the run mode executes the program and operates processes. Data from field devices, such as switches and sensors, are processed, and the CPU performs the commands of the control program. The cycles of the program happen very quickly at about 1/1000th of a second. A CPU’s memory stores the program, holds the status of the I/O, and offers a method for storing data.

-

Input/Output (I/O) Interface – The input output system is directly connected to equipment and provides an interface with the CPU’s information providers (inputs) and controllable devices (output). The CPU processes input and makes required output changes executing user programming. PLCs are constantly performing three processing steps, which are:

- Input Scan – Detects the status of devices

- Program Scan – Implements programmed logic

- Output Scan – Changes the status of connected devices

The processes of PLCs differ in accordance with the industries they serve. As with all forms of factory automation, PLCs are customized to meet the requirements of the products being produced. Software and data handling methods are adjusted to fit the needs of a platform.

The most popular programming languages for PLCs are structured text, sequential function charts, ladder logic diagram, function block diagram, and instruction list, which are recognized by the IEC. PLC programming languages can be selected for their appropriateness for the applications they control. As with all forms of industrial tools, programming languages have their advantages, disadvantages and weaknesses.

In order to establish some form of controls for PLCs, the International Electrotechnical Commission (IEC) created a standard for the appearance of PLCs that includes types of equipment, software, communications, safety measures, and many other aspects of programmable controllers. Since 1982, when the first five part standard was introduced, the IEC standard has changed and developed with the present version having 9 parts with a 10th part being developed.

Remote Terminal Units (RTU)

RTUs collect data from field devices and relay the data wirelessly or by fixed communications to the SCADA platform. The other functions include controlling equipment, providing alarm notifications, and integrating with other automation systems. Traditionally, RTUs were less advanced than PLCs. With technological advances and innovations, modern RTUs have the same or similar capabilities to that of PLCs.

Remote terminal units, also known as remote telemetry units or remote telecontrollers, collect and process data from sensors, various devices, and actuators. Like PLCs, RTUs are used to monitor industrial operations and send commands. They can operate like a computer, which is unlike PLCs and are less expensive.

RTUs can be programmed using a simple web interface or using their setup software to configure input and output streams. The languages that can be used with RTUs are Basic, Visual Basic, and C#, which require special skills to set up. The durability of RTUs makes it possible to use them in extremely remote locations that can be hundreds of miles away from the SCADA system.

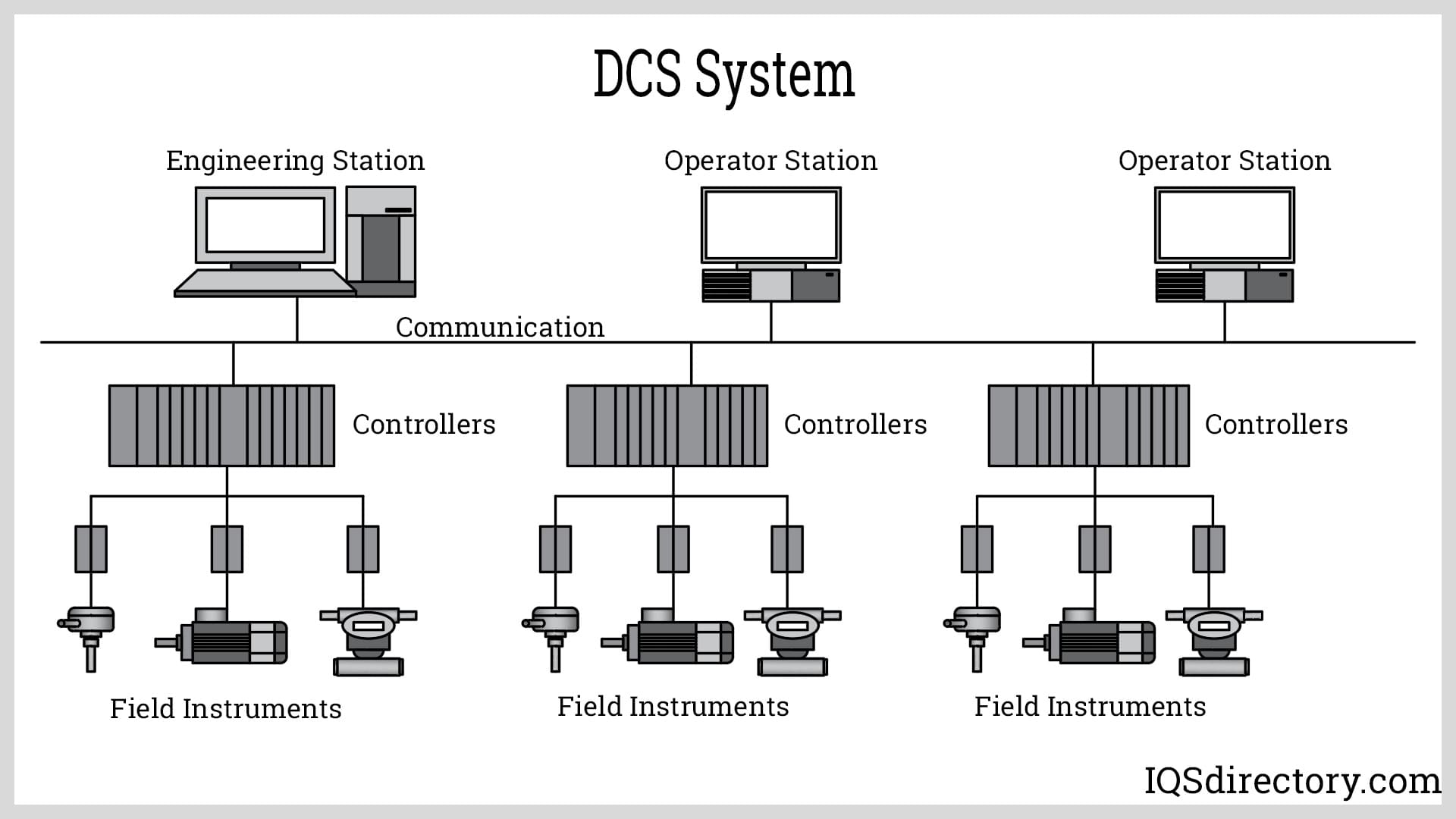

Distributed Control Systems (DCS)

A DCS system is a central brain that coordinates and controls process subsystems of industrial operations. The system controls complex and intricate processes for large manufacturing factories. The subsystems of DCS, such as sensors and data collection devices, communicate with the DCS, which interprets production trends and sends instructions to controllers, actuators, equipment, and PLCs located in the factory. Unlike PLCs that oversee a few production processes, DCSs send instructions, commands, and output to thousands of PLCs that are monitored, supervised, and controlled by a DCS. Thousands of applications, including production schedules, maintenance scheduling, and information exchange are controlled by a DCS system.

The distribution of control of DCS systems across several nodes minimizes single point failures, which helps improve efficiency.

The components of a DCS system include:

- Control Nodes – Execute control functions

- Human Machine Interface (HMI) – How operators interact with the system

- Data Communication Network – Transfers data between nodes and HMI

- Field Instruments – Sensors, actuators, and data collection devices that execute commands

A key part of DCS functions is data integration, which allows for the smooth flow of information from sources, controllers, and equipment. To function properly DCS systems have to be integrated with other business data systems to have a complete overview of manufacturing operations. The capabilities of DCS include predictive maintenance, process optimization, supply management, energy management, quality control, safety monitoring, batch processing, remote monitoring and control, data reporting, and IIoT integration.

Robotics

An essential element of factory automation is robotics, processes that are used in multiple ways to enhance efficiency and increase the speed of production. The use of robotics has been associated with replacing manual labor for repetitive processes. As essential as robotics may be, they are only one part of the larger factory automation process. Three or six axis robotic arms do material handling, pick and place, and complete mundane tasks faster than workers.

The use of robotics for repetitive processes improves production volume. Engineers program robots for lifting, placing, and orienting workpieces using technology that allows them to determine the motions of a robot due to program choices and the flexibility and adaptability of robots for different applications.

Although robots are valuable tools, they do not fit into every type of factory automated system. An initial definition of the production problem helps to determine if robotics are applicable to the conditions. Robotics are commonly used for low volume and sensitive production processes.

Chapter 4: Software for Factory Automation

The complexity of factory automation requires innovative and technologically advanced computer software in order to oversee the thousands of actions and tasks performed by equipment. The discussion of software for industrial and factory automation covers a wide swath of technological solutions. Each type of software has aspects that are specifically honed for a particular product or industry.

As every person, manager, and business owner knows, the term computer software covers a long list of solutions. Although this is true, the types of software used for SCADA and DCS is complex, intuitive, and exceptionally technical due to the processes it is designed to oversee. Automation software is designed for business record keeping, customer orders, shipping, the operation of equipment, and production scheduling. Fortunately, industrial automation designers and solution providers have the tools and technology to assist their clients in choosing the perfect software.

Siemens

Siemens, a German company, provides a full spectrum of automation solution software from PLCs to all encompassing factory wide software systems. Part of their software includes virtual simulations that allow the testing of automation processes before implementing them.

Advanced Integration Technology (AIT)

AIT offers custom solutions for the complete integration of automated systems. They program and tailor their software to the type of product and includes material handling and quality control inspection devices. A feature of AIT systems is their Scorpion Vision Machine that performs high speed inspection of production lines.

Rockwell Automation

Rockwell specializes in PLCs, HMIs, and complete solution industrial software. The company is well known for its integration of specialized forms of equipment, which is a necessity in modern manufacturing. Rockwell’s Allen-Bradley ControlLogix can be scaled for small machines and factory wide complex production.

ABB

ABB, a Swiss automation control company, offers robots, PLCs, drives, motors, and software for specialized applications. The main focus of ABB is robots for manufacturing and logistics. An important part of the services that ABB offers is their collaborative robots.

Honeywell

Honeywell specializes in factory wide solutions by offering hardware and software. A key to Honeywell’s software package is their advanced security solutions to safeguard control systems.

Emerson

Emerson provides sensors, valves, actuators, and software for process control. The company’s DeltaV is a DCS system known for its flexibility and scalability for process industries.

The few software solutions listed above are a sampling of the many worldwide solutions that are available from France, Japan, the United States, and Germany. The types and sizes of companies that provide industrial automation solutions come in many sizes. The girth of industrial automation companies is due to the rapid and ever growing use of factory automation systems. As every automation solution company will say, it is essential to work closely with an expert when making the choice of factory automation solution.

Leading Manufacturers and Suppliers

Chapter 5: Factory Automation Equipment

As can be interpreted by the plethora of information regarding factory automation, there are several types of equipment that are used to complete tasks commanded by factory automation control systems. Although specialized types of equipment are common for factory automation, there are certain forms that are applicable for all systems.

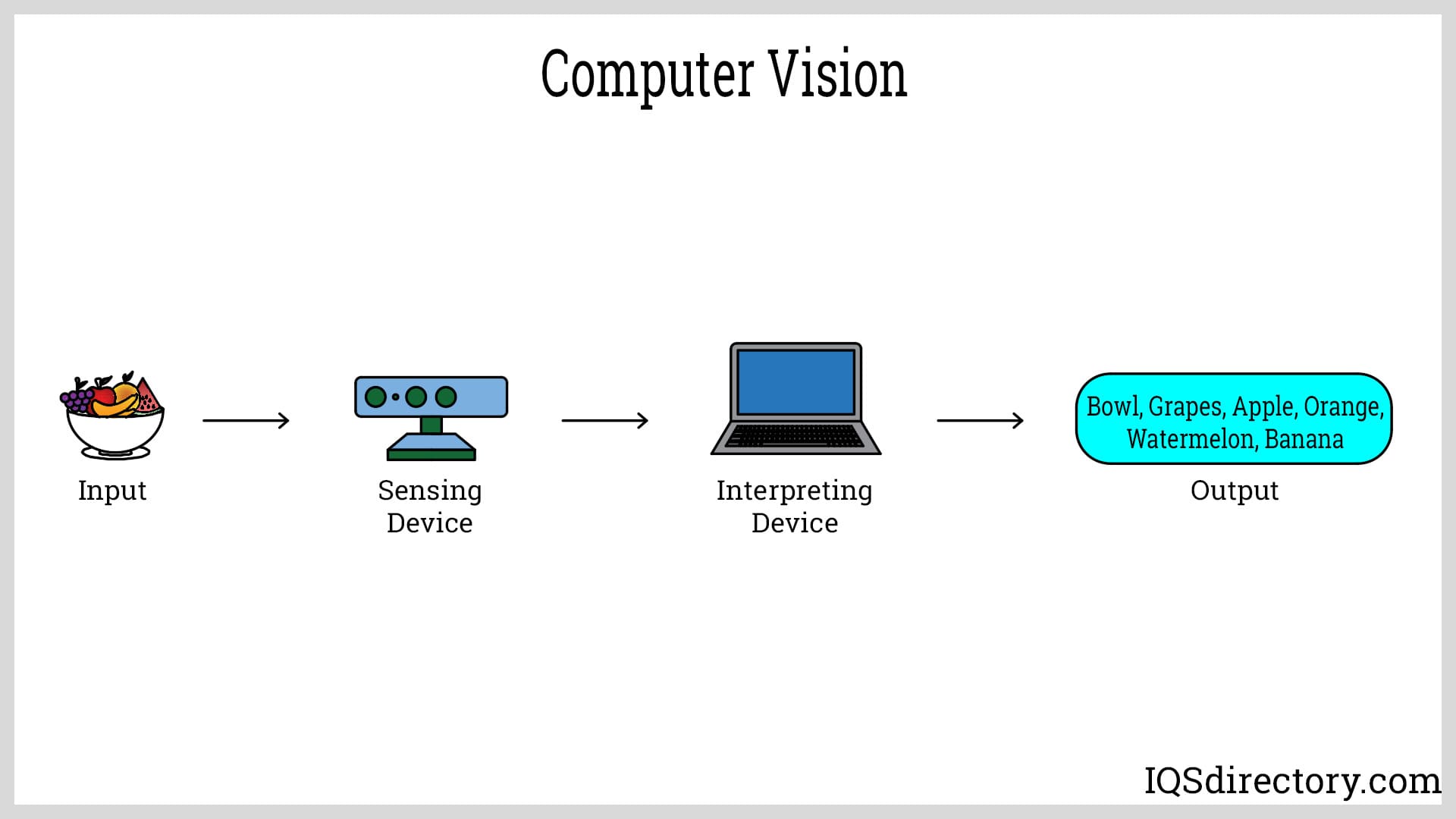

Computer Vision

Computer vision is an artificial intelligence (AI) tool that gets information from images, videos, and objects, identifies them, and stores the data or sends it to a HMI. They use input to learn. Computer vision runs on algorithms that have data or images saved in the cloud. When computer vision recognizes a pattern, it uses the pattern to decide the content of other images.

Images captured by sensing devices, such as cameras, imaging methods, or other devices, are analyzed by the system. During analysis, the image is broken down and compared to patterns in the computer vision’s library. Users receive information about an image by requesting it.

Collaborative Robotics

Collaborative robotics is a blending of manual labor with automated devices. Often referred to as cobots, collaborative robots are designed to work safely with humans. They complete repetitive, menial tasks as their human partner works on more complex, thought provoking, and intricate activities. The basic design of collaborative robots is to complement and support the work of their human partner.

The work of collaborative robots and humans expands the number of applications that can be performed, resulting in increased productivity and efficiency. Part of the safety aspects of collaborative robots is their ability to lift and move workpieces too heavy or difficult for humans. Collaborative robots can position such a workpiece and adjust it in different positions for easy access.

Industrial Robotics

A rapidly growing part of product production is industrial robotics, which are a key part of end-to-end automation. Industrial robots are a step up from collaborative robots and are able to complete mundane repetitive tasks thousands of times a day. The use of industrial robots is beginning to find a footing in product production. The full capabilities of these technological wonders are constantly expanding and being examined.

Industrial robotics consists of multiple machines with robotic arms that operate on three or more axes. They are commonly used in warehousing and assembly lines due to their ability to repeat repetitive tasks quickly, efficiently, and accurately with exceptionally high precision. The number of industrial robots presently in use in the world is close to four million and rising. Tasks normally completed by industrial robots include assembly, material handling, spot welding, and applications requiring extreme precision.

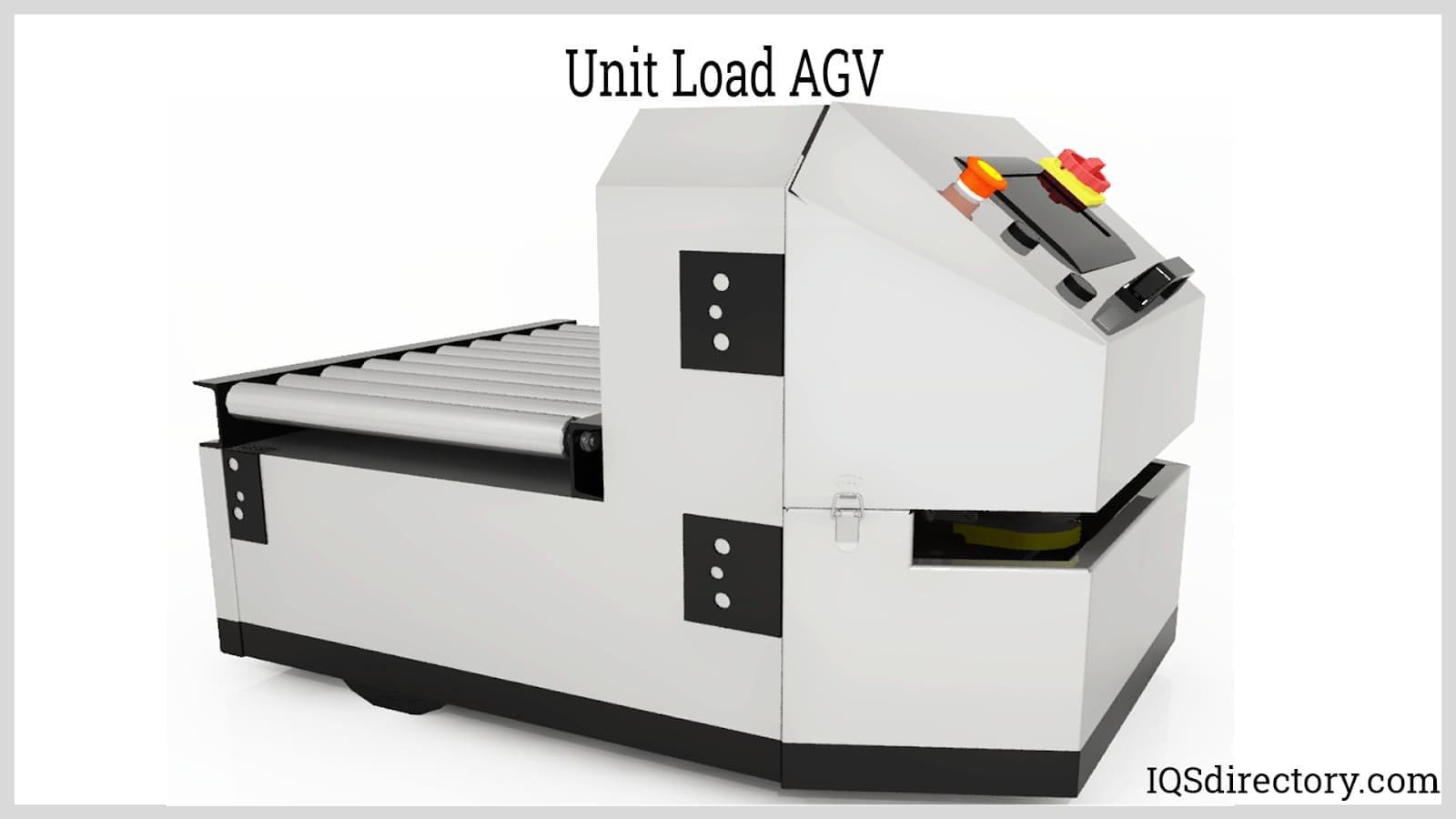

Autonomous Guided Vehicles (AGV)

AGVs, also known as Autonomous Mobile Robots (AMRs) or Intelligent Autonomous Vehicles (AIVs), are material transport vehicles that use a guidance system to move about an industrial facility. The main uses for AGVs are in warehouses for moving goods, on assembly lines for supplying raw materials, and at the end of assembly operations for moving completed products to storage.

Initially powered by wires buried in the floor of a facility, modern AGVs use different navigation methods. They are a time saving device that removes the need for workers to transport materials and supplies.

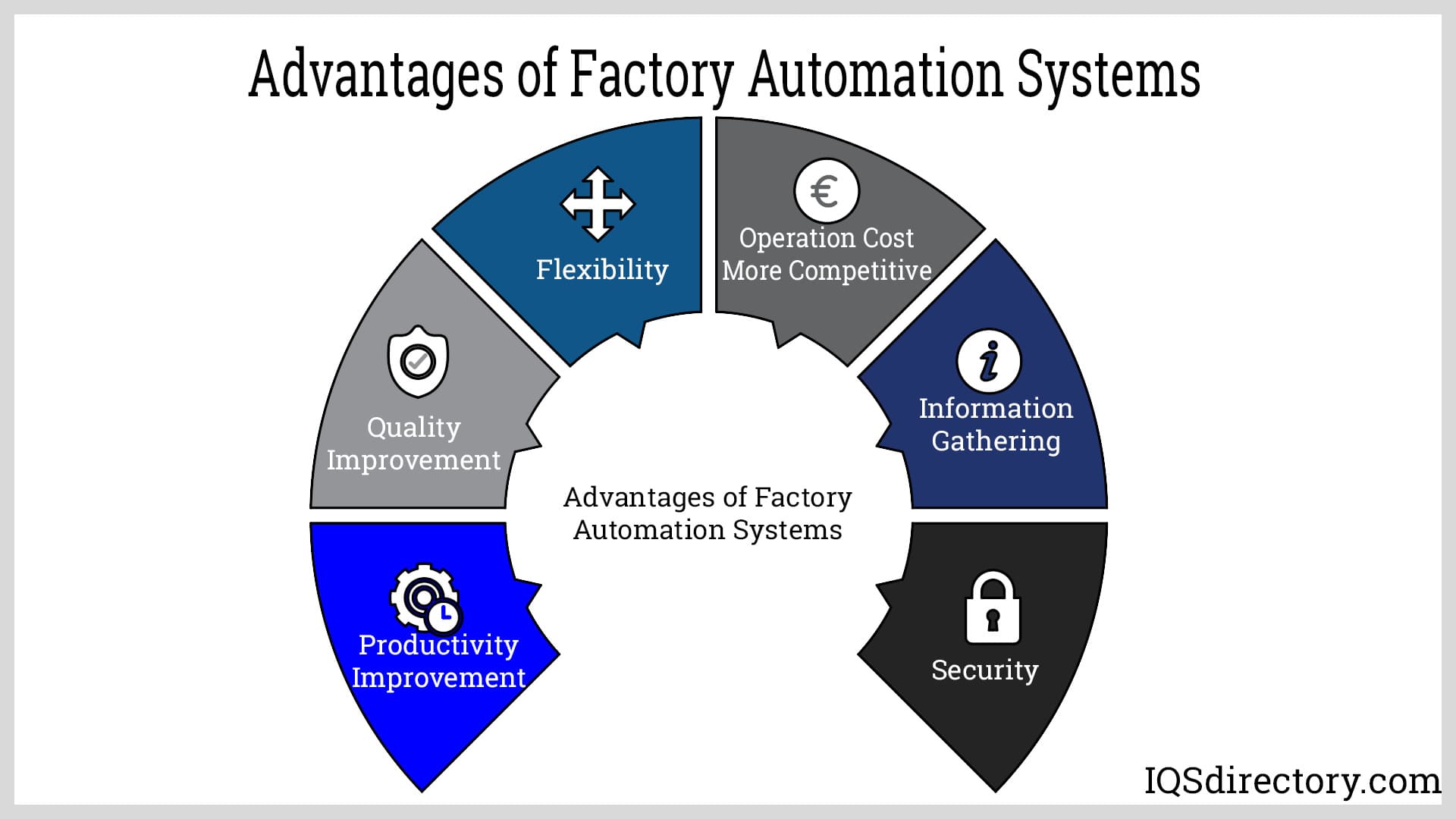

Chapter 6: The Advantages of Factory Automation

Factory automation is an advantageous method for economically and efficiently producing high quality products. In essence, it takes mundane, boring, repetitive, necessary tasks, and bundles them together under a precision control system that oversees every aspect of an operation from raw materials to final product. The choice of using factory automation is dependent on several factors that have to be carefully researched and examined.

Planning

The data provided by SCADA and DCS systems assists management in making production and delivery decisions. Production volumes are easily controlled and manipulated in relation to customer requirements. In process decisions are made according to system data. Each step of a production process is visible, adjustable, adaptable, and accessible providing real time information.

Operating Costs

There are multiple cost benefits when using factory automation, which can perform the work of several people, depending on the task, quickly and efficiently. The removal of the human factor from assembly operations eliminates the need for heat to keep workers warm. In addition, labor costs are radically reduced.

Safety

A consideration that is often overlooked when assisting the benefits of factory automation is safety. All forms of automated devices are programmed with limitations that prevent them from harming workers. Most of the restrictions are in regard to sensing people in a workspace and stopping in such circumstances. The use of factory automation enhances worker safety and nearly eliminates any adverse effects to workers.

Quality

The use of automation in place of manual labor radically reduces the number of defective, imperfect, or poor quality products. The different methods that factory automation uses to check the quality and performance of processes and the compliance of final products with design specifications nearly eliminates low quality products.

In normal manual operations, each assembly line has a quality checker who randomly removes parts and products to examine them for adherence to quality standards. The process is inefficient and frequently misses errors and flaws. Such circumstances are not possible with factory automation, since every product and part is electronically examined.

Productivity

Factory automation systems can work 24 hours a day every day of the week without tiring or needing a break. The continuous operation of equipment increases productivity and ensures the fulfillment of orders. Every element of a factory automation system from the SCADA to the PLCs and RTUs works continuously to produce high quality products.

Waste Reduction

One of the calculations that is intermixed with production operations is a determination of waste that is produced by a process, which is due to several factors. The efficiency and control factors of factory automation nearly eliminates waste concerns since quantities, amounts, and materials are carefully monitored.

Footprint

With the removal of waste, the use of streamlined equipment, and the use of less energy, factory automation reduces a company’s environmental footprint. Since stored materials are timed and used efficiently, restocking is more coordinated removing the need for warehousing and assembly line storage space.

Reduces Outsourcing

Since cells have limitless capacity, parts can easily be produced in house to meet production requirements without the need for additional equipment, which is another factor that reduces costs.

System Integration

Every aspect of manufacturing is contained in one combined system that provides easy access. Hardware, software, and controls are housed in a single system that can be adjusted and changed using a set of commands. System integration and the ease of use are one of the main reasons that companies switch to factory automation.

As production needs change, the system can be retooled and repositioned. Robots, bar feeders, and APLs are repositioned and deployed to meet the needs of an application or part. In addition, the volume of production can be adjusted and switched between products without having to rebuild production lines. Adjustments to grippers and vision tools can be changed over in accordance with part sizes and shapes.

The central factor to system integration is the ability of robots to learn and adapt to new processes. This reduces changeover time and makes it easy to adjust to changing demand requirements.

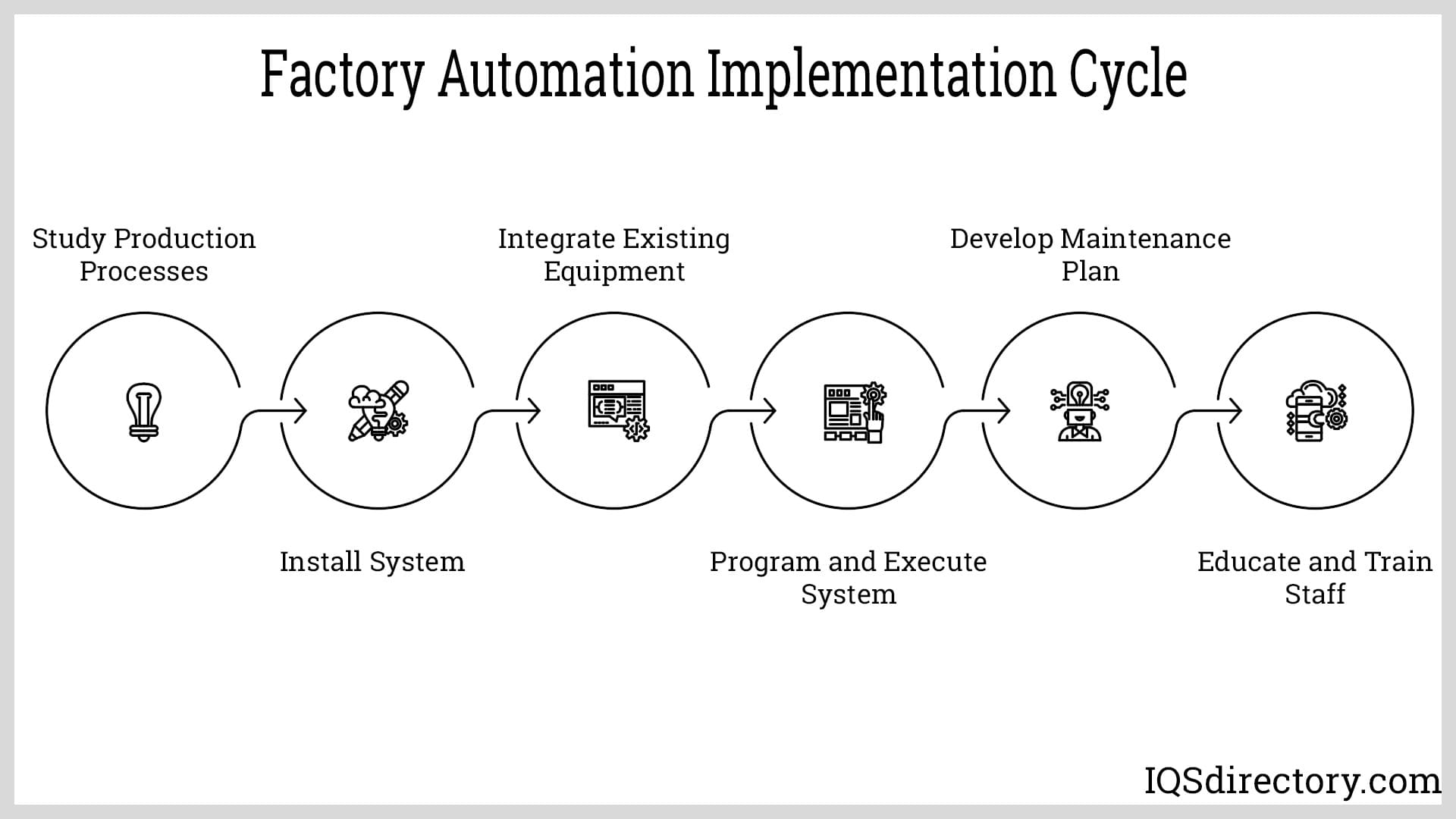

Chapter 7: Factory Automation Implementation

When companies begin the process of investigating factory automation, they have researched, studied, and examined a variety of alternatives that meet their production needs. In most cases, they have assessed the objectives of the use of a system as regards product outcomes. Their diligent and meticulous research leads them to meeting with an industrial automation provider in order to plan factory automation implementation.

In many cases, automation experts recommend automating a small portion of production to get the feel of a system. Such a plan makes it possible to examine a system and become familiar with a system’s various aspects. Starting small and building helps reduce costs, which can be financially beneficial.

Knowledge

A complete and total understanding of every step of the production process is a necessity. Each step of production should be studied, examined, and monitored down to the smallest detail. Included in this learning process are suppliers, a time table for implementation, and an inventory of available resources.

Installation

Since the implementation of a factory automation system is a major time consuming process, in order to avoid production shutdowns, implementation schedules should include a reference to slow production times or production dark periods.

Integration

Elements that are part of existing operations have to be included in the change over to a factory automated system. This necessitates communication between the system and the existing elements. Adapting these components helps in saving time and streamlines the transition process.

Execution

As excited as people are about the installation of something new, it is important to be aware of adjustments that have to be made to conform to product requirements. Every factory automation system requires programming that meets the demands of a product. This includes tweaks and minor changes that increase efficiency.

Maintenance

Regardless of being a technological wonder, factory automation systems are huge pieces of equipment that are monitored for potential failures and problems. As part of installation, a maintenance and upkeep plan is developed to ensure peak performance and limited stoppages.

Training

One of the defining concepts of every factory automation system manufacturer is their dedication to providing the necessary knowledge to be able to operate the system. The objectives of such training vary depending on the technical sophistication of personnel, since some companies already have technical processes while others are taking steps in a new direction. The successful operation of a factory automation system is directly related to the capabilities and knowledge of the personnel that run it.

Chapter 8: Industries that Use Factory Automation

The use of factory automation is rapidly increasing as companies discover the profitability of its use and its efficiency. Although not all manufacturing can use factory automation, certain industrial processes are ideally suited for its use. Factory automation companies work closely with all forms of manufacturers to assist them in choosing a system that best fits their needs and requirements.

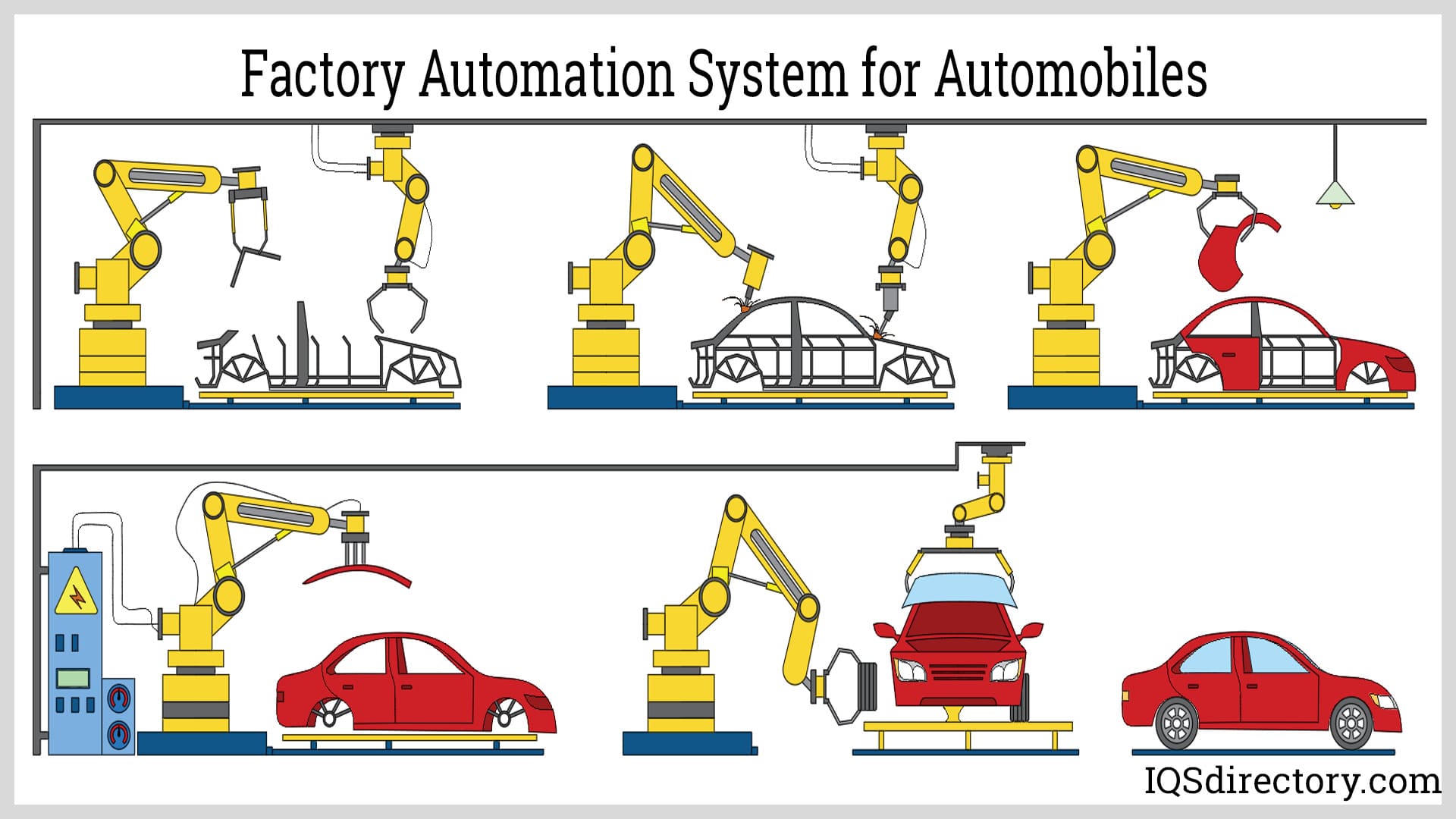

Automotive Systems

Henry Ford introduced the assembly line that increased the number of cars that could be produced per day. Each of the components for his cars were produced in small factories located in the Detroit area and shipped to an assembly plant. Ford’s invention has progressed over the years to today’s technologically advanced factory automation systems that have taken Henry’s ideas and brought them into the 21st century.

The range of parts, components, and assemblies produced for the auto industry using factory automation include engine blocks, transmissions, seats, dashboards, and bodies. Systems consist of a central controller that links all equipment to the system. Each machine is capable of producing different types of parts by simply changing the programming, removing Ford’s many little factories. Changes can be made quickly by adjusting the parameters of the system.

The process for producing a part begins with a design that is uploaded into the system that generates instructions for machines to produce the part. The central control system oversees the process and monitors production.

Aerospace

Factory automation is ideal for the aerospace industry, which requires exacting tolerances, exceptional dimensional accuracy, and high-quality parts. Engines, landing gear, and avionics systems are produced using the factory automation process. The complexity of aerospace parts demands precision programming and close attention to details. A key factor that makes factory automation ideal for aerospace is its ability to adapt to changes and quickly respond.

Electronics

A component that is produced for electronics using factory automation is printed circuit boards (PCBs) that necessitate proper positioning of minute components. The development of factory automation has made the production of PCBs easier, less time consuming and far more accurate. Like automobile components, the design of a PCB is downloaded into the central system that programs equipment and tools for producing the PCB.

Medical Instruments

As with aerospace parts, medical instruments require precision and accuracy that cannot be achieved by manual workers. The implementation of factory automation makes it possible to manufacture the most delicate and sensitive forms of medical tools, such as surgical tools, implants, diagnostic equipment, and artificial limbs. The necessity for hygienic conditions increases the desirability of factory automation for the production of medical instruments.

Food Production

The use of factory automation for food production is due to the processes ability to change from one food product to another with minimal adjustments. Unlike other industries, food producers manufacture a wide assortment of products using the same equipment. Similar to the medical instrument industry, food production requires antiseptically clean conditions to meet Food and Drug Administration standards, which makes factory automation an ideal process.

Conclusion

- Factory automation involves an array of tools, processes, and technologies that are combined and integrated to produce a product or perform an application.

- The key to factory or industrial automation is its programming that is designed to take in data and output instructions.

- The many benefits of factory automation include cost savings, improved product quality, high volume production, and on time deliveries.

- In most cases, factory automation is customized to fit the needs and requirements of the products being produced and the environment of production.

- Factory automation and industrial automation specialists work with their clients to design systems that match a client’s needs. The collaboration of supplier and client has led to years of success and profitability.