Aluminum Forging

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

The content of this article contains everything you need to know about copper and brass forging.

You will learn:

Copper and brass forging involves molding these metals by deforming them to form complex and detailed shapes. This technique demands exact temperature management and regulation, as copper and brass have melting points ranging from 1675°F to 1981°F (913°C to 1082°C). The metals' excellent ductility and malleability make them perfect candidates for forging processes.

The remarkable properties of copper and brass make them popular choices in forging, allowing them to be shaped into various intricate and elaborate designs. Forged copper and brass products are of exceptional quality, featuring precise dimensional accuracy and a sleek, polished finish that competes with other metalworks in craftsmanship and appeal.

Various conventional forging techniques are applied to work with copper and brass alloys, both renowned for their excellent ductility, malleability, and corrosion resistance. The selection of specific copper forging or brass forging methods depends on the alloy in use, as each type of copper and brass exhibits unique physical, mechanical, and metallurgical properties that affect how it can be forged. The practice of forging these non-ferrous metals dates back thousands of years, with both copper and brass being known well before the advent of the modern calendar. Today, industries utilize advanced copper and brass forging to manufacture high-performance components for automotive, electrical, plumbing, aerospace, and industrial markets.

No matter the forging technique used, each process involves a die or forging tool specifically designed to meet the product’s requirements. Typically, the billet, ingot, or sheet of copper or brass undergoes force application, altering the metal’s internal grain structure to achieve the desired shape, strength, and surface finish. These changes enhance the mechanical strength, corrosion resistance, and thermal conductivity crucial in high-demand applications for copper and brass forged parts.

Cold forging modifies the structure of copper or brass at temperatures below their recrystallization point, which is typically near room temperature, by pressing the metal into a die. The die used can be either a closed or open type and consists of two parts: an upper die and a lower die. Cold forging is highly valued for its low energy consumption, improved surface finish, high dimensional accuracy, and the ability to preserve the inherent electrical and thermal properties of copper and brass.

The cold forging process starts with creating a die that is precisely shaped to match the desired part. To endure the forging forces, the die is constructed from pre-hardened steel, which is heat-treated to reach the required hardness. The hardening method varies based on the die's complexity; dies with intricate designs or deep cavities need additional toughness to prevent cracking or failure.

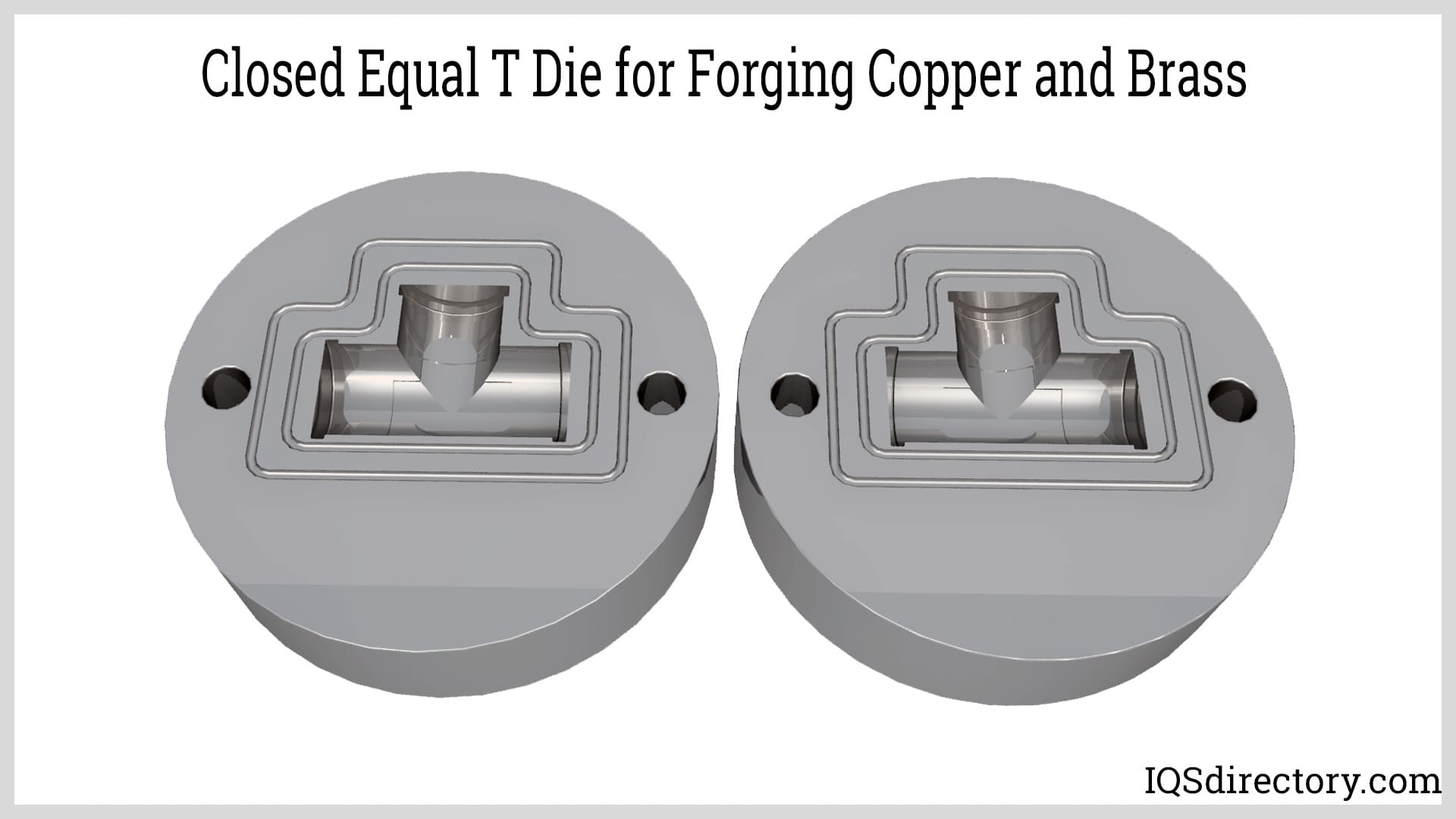

For forging copper and brass, dies are typically made from H21, H11, or H13 hot work steel, with a Rockwell hardness ranging from 48 to 52. Durability and strength are crucial for these dies, as they are employed to produce numerous parts in high volumes. Despite the ductility and malleability of copper and brass, substantial force is still needed to achieve the precise shape and complexity of the components. Modern die design ensures consistent quality in copper forged fittings, brass precision components, and other industrial products.

The selection of copper and bronze alloys for cold forging is based on their specific composition and properties. This forging method enhances the hardness and ductility of the materials, as well as improves their dimensional precision, toughness, and surface finish. Cold forging involves shaping the metals at room temperature through processes such as impact, stretching, bending, and forming, without applying additional heat to deform them.

In cold forging, a copper or brass ingot, billet, or sheet is positioned in the lower section of a die attached to the anvil of a vertical press. The upper section of the die is connected to the ram. A motor powers the ram, which descends onto the metal, exerting force that molds the metal into the die's shape. This process occurs swiftly, resulting in the rapid formation of new shapes. Choosing the right copper grade or brass alloy is critical for optimizing strength, conductivity, and machinability throughout the forging process.

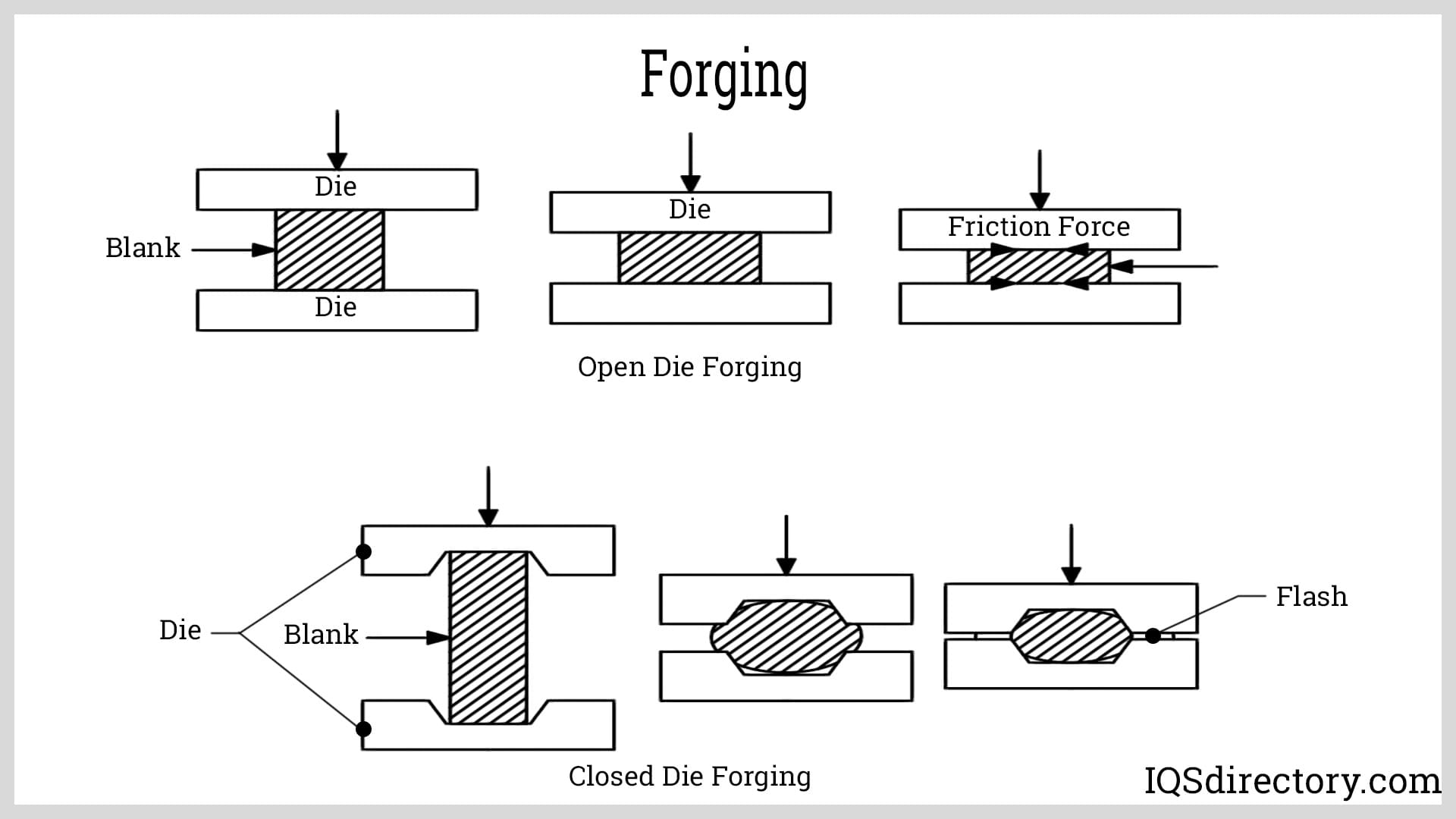

Forging processes can be either closed or open. Closed die forging involves two die halves that come together to fully enclose the workpiece. In contrast, open die forging, or smithing, compresses the workpiece between dies with simple shapes like angles or flat surfaces. Unlike closed die forging, the metal is not completely enclosed during open die forging. Closed die forging is preferred for precision copper components, electrical connectors, and intricate shapes, while open die forging often serves for larger, simpler geometries.

Copper and brass are well-suited for cold forging due to their excellent ductility and malleability. Compared to forging steel, iron, or stainless steel, these metals require less force to achieve the desired shape, allowing for the efficient production of high volumes of parts in diverse shapes and sizes. Cold forged copper and brass parts are frequently utilized in the electronics, plumbing, and automotive sectors due to their consistent quality, tight tolerances, and superior physical properties.

In hot forging, the copper or brass billet, ingot, or sheet is heated to a particular temperature so that when compressed by the ram, it fully occupies both halves of the die. This method results in parts with high density, minimal imperfections, improved mechanical strength, and consistent dimensional precision. Like cold forging, hot forged copper and brass also exhibit a smooth, shiny surface finish, making them ideal for components requiring excellent aesthetics in addition to durability.

The heating process involves cutting extruded slugs from ingots into rods of the appropriate length to fit the die cavity. These slugs are then heated to the forging temperature, which ranges from 1350°F to 1700°F (732°C to 927°C). Precise control of the heating process is crucial to ensure the slug is adequately prepared for forging. If the slug is not heated sufficiently, the resulting product may be inadequately formed and exhibit defects. Uniform temperature distribution ensures consistency in forged copper electrical parts, plumbing fixtures, and precision brass components.

Regardless of whether the forging process is cold or hot, it involves applying force to reshape the workpiece. In hot forging, the die is preheated before placing the slug in the lower section of the die to facilitate optimal metal flow. Similar to cold forging, the ram’s downward motion forces the slug to conform to the shape and dimensions of the die.

Due to the malleability and ductility of copper and brass, typically only a single stroke of the ram is needed to achieve the desired shape, unlike steel or iron, which may require multiple strokes. This efficiency in shaping complex and intricate designs eliminates the need for a series of progressive dies. Consequently, a higher volume of parts can be produced, ranging from 100 to 1200 per hour, with an average rate between 200 and 600 parts per hour. Hot forging is especially used for large production runs in copper busbars, plumbing parts, and complex fittings for the electrical and energy industries.

As the ram applies force, the grain structure of copper and brass is altered to ensure uniform density and excellent physical and mechanical properties. The intrinsic properties and lighter weight of copper and brass make them ideal choices for various applications, making parts forged from these metals highly desirable for complex, high-performance end uses.

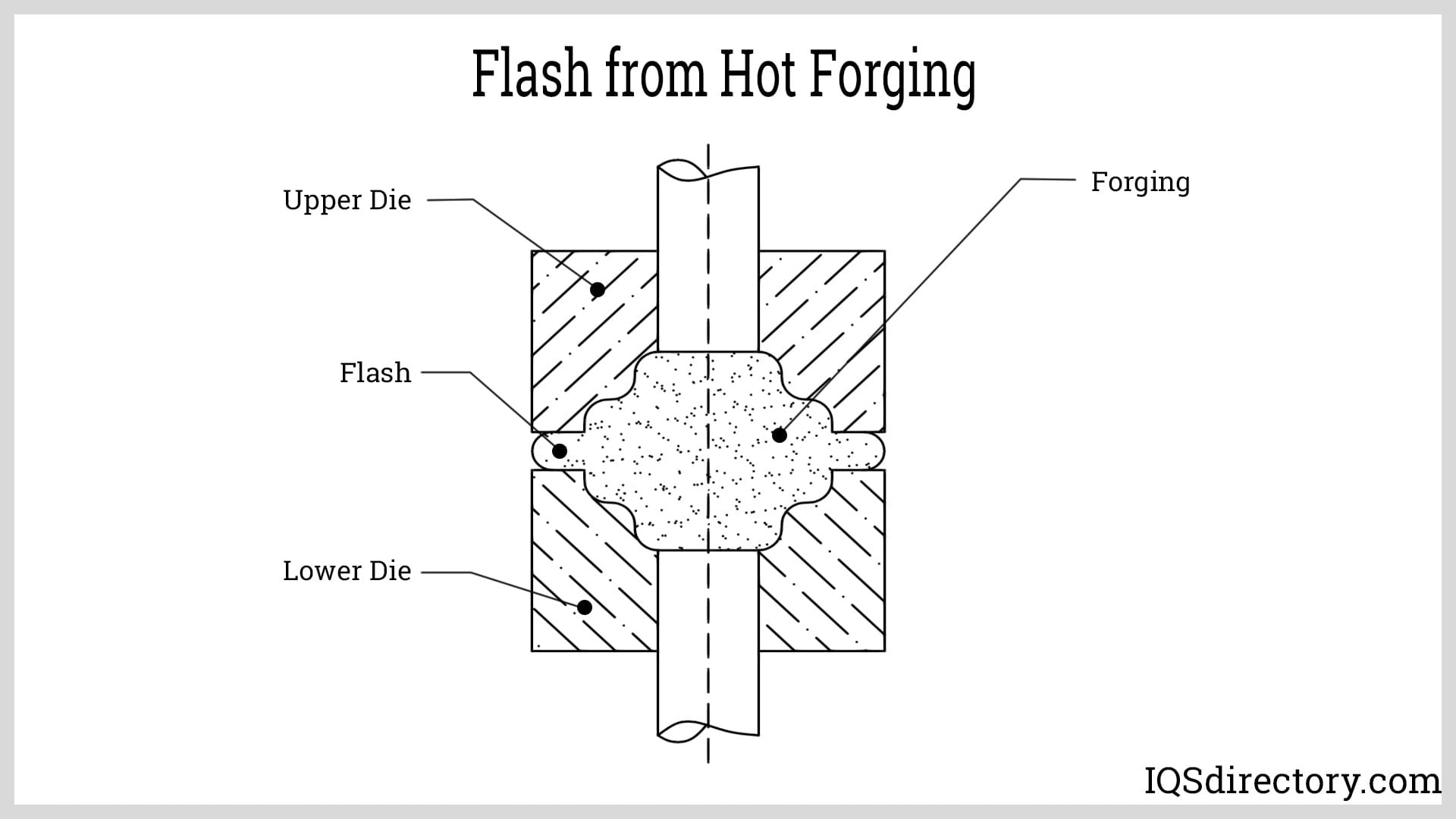

The copper or brass slug used in forging is typically slightly larger than the volume needed to fully fill the die cavity. The die halves are designed with channels, or gutters, that allow excess metal to escape as flash, which must be trimmed off during the finishing process. Dies are carefully engineered to minimize the amount of flash and prevent any damage to the forged component.

The thickness of the flash depends on factors such as the ram's pressure, the amount of excess metal, the slug's temperature, and the die's temperature. While trimming is the standard method for removing flash, parts with precise outer dimensions may require more meticulous trimming, a process known as shaving. Precise flash removal and secondary machining enable manufacturers to achieve strict dimensional tolerances in copper and brass forged parts, critical for applications such as valve components, pipe fittings, and electrical connectors.

Rolled ring forging is a specialized forging technique often used alongside cold forging. This method involves shaping rings with the help of rollers, a mandrel, and applied force. It is particularly well-suited for producing smooth and evenly symmetrical rings from copper and brass. Precision rolled ring forging is essential for manufacturing durable seals, bearings, and flanges required in petrochemical, power generation, and aerospace industries.

First, the copper or brass stock is cut to the required size and weight, then upset to decrease its height and increase its diameter to match the intended ring size. This initial shaping is done using open cold forging. To form the necessary ring shape, the round workpiece is then pierced through the center.

Proper preparation of the workpiece is crucial for achieving the desired dimensions of the final rolled ring. Just as with other forging processes, the characteristics of the copper or brass are key, as the workpiece must be sufficiently malleable to form the donut shape effectively. Selecting an optimal copper alloy or brass grade is important to balance hardness, workability, and structural integrity in the final forged ring.

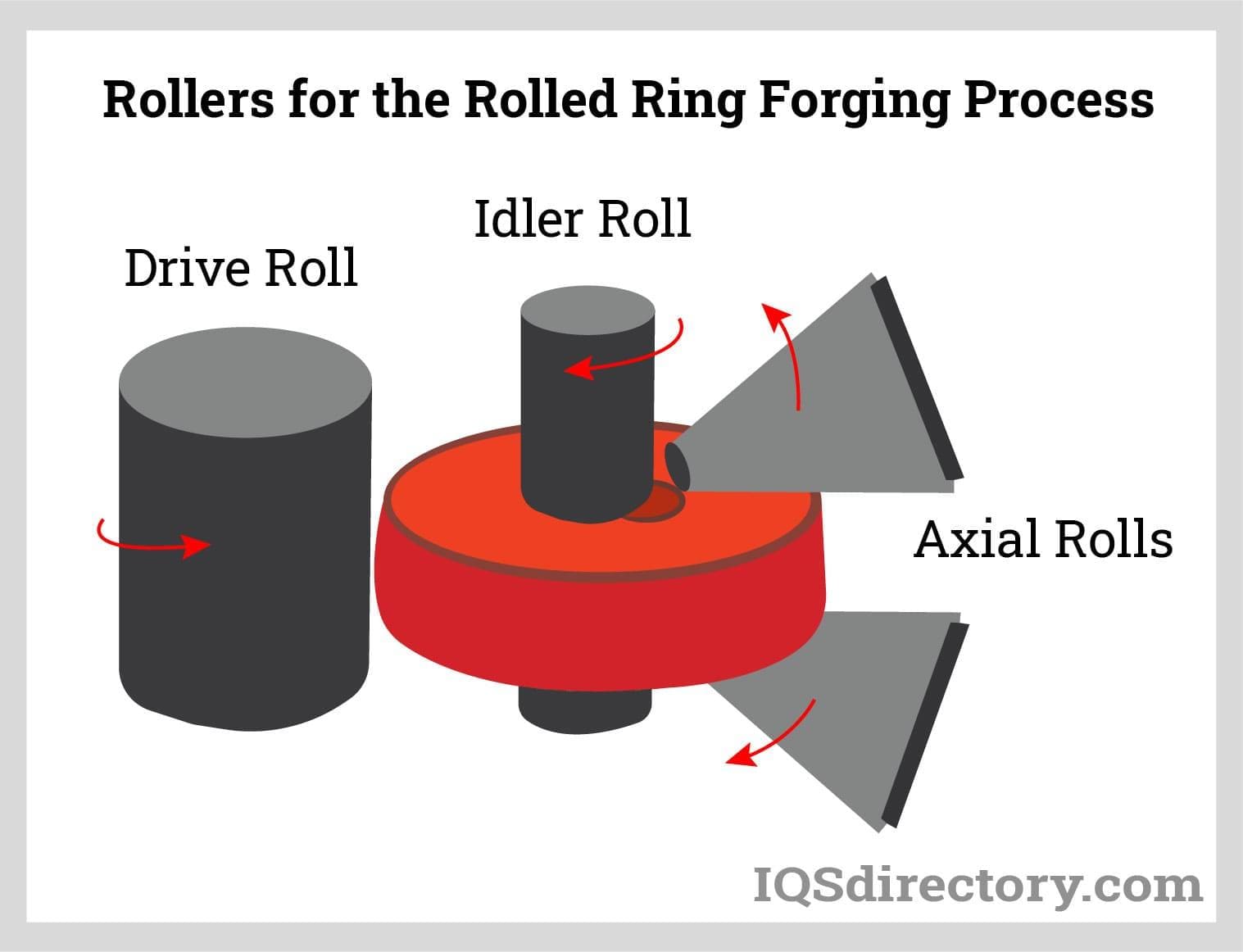

The rolled ring forging process involves a coordinated mechanism that shapes the ring to the required height and thickness. This system includes a drive roller that rotates the ring during shaping, while the pierced hole is positioned over an idler roller. The idler roller, working in conjunction with the drive roller, reduces the ring's thickness as it rotates. Additionally, two axial rollers, positioned opposite the drive roller, regulate the ring's height. Each component is precisely designed to adjust the workpiece to achieve the final ring dimensions.

Before being fed into the rolled ring forging setup, the donut-shaped workpiece is heated to just below its recrystallization temperature to enhance its ductility and malleability. As the donut rotates driven by the drive roller, the drive roller and idler roller work together to reduce its thickness while expanding its diameter. The dimensions of the finished ring are programmed into the forming mechanism to ensure that the deformation remains within specified design limits.

Given the properties of copper and brass, the rolled ring forging process is carried out in slow, controlled stages to ensure precise and accurate deformation. Rolled ring forging is the preferred method for producing seamless copper and brass rings, offering exceptional strength, homogeneity, and resistance to fatigue or stress fractures—particularly vital for critical industrial and mechanical assemblies.

Warm forging is often employed for working with alloyed steel as an alternative to cold forging. It is also used for forging copper and brass, providing a middle ground between cold and hot forging. In warm forging, the metal is heated to a temperature slightly above room temperature but lower than that used in hot forging. Copper and brass alloys show enhanced plasticity at warm forging temperatures, which enables the creation of complex components with fine details and excellent surface quality.

This technique enhances tool longevity, accommodates a broad range of part tolerances, and can improve surface finishes. By precisely controlling the temperature, warm forging achieves tight tolerances and reduces issues like shrinkage that are common in hot forging. This precision reduces the need for secondary finishing processes, such as flash removal. Additionally, warm forging increases the ductility of copper and brass, allowing for greater deformation without sacrificing quality. Components produced via warm forging deliver an ideal balance of mechanical strength and manufacturability, making them suitable for high-specification electrical, automotive, and fluid handling systems.

Warm forging is often termed precision forging due to its ability to produce high-quality parts. It requires less forming force compared to cold forging and can create intricate and complex shapes. The success of warm forging relies on meticulous control of the deformation temperature and the heating equipment used. With demand growing for precision copper forged parts and intricate brass mechanisms, warm forging is increasingly leveraged to meet stringent industry specifications and reduce energy consumption in modern manufacturing plants.

When selecting a forging method for copper and brass, manufacturers must consider critical criteria such as alloy composition, desired mechanical properties, application environment, production volume, dimensional tolerances, and cost-effectiveness. For example, closed die forging is frequently used for copper electrical contacts and high-strength brass fittings needing consistent tolerances, while open die forging is chosen for custom or large-sized copper busbars and heavy-duty mechanical components.

In addition, variables such as forging temperature, die material, and surface treatment impact the achievable grain structure, hardness, and corrosion resistance of the finished copper or brass component. Precision forging processes, including cold, hot, and warm forging, enable the production of seamless brass rings, copper valves, electrical busbars, heat exchanger parts, and custom machined copper fittings optimized for specific end uses.

By understanding the spectrum of available copper and brass forging processes—as well as the performance requirements of your finished component—you can select the ideal method and material to ensure optimal product performance, cost efficiency, and long-term durability in demanding applications.

Brass is widely recognized in metalworking and manufacturing industries as a highly versatile alloy, primarily composed of copper and zinc. However, many people are unaware that brass is not a single formula—it encompasses a diverse group of alloys, each engineered for specific mechanical and physical properties. Different types of brass alloys incorporate varying ratios of copper and zinc, and often include other metals like lead, tin, aluminum, or iron. This flexibility makes brass a top choice for forging a broad spectrum of products, from plumbing fittings to door hardware, precision machined components, decorative elements, and marine fixtures.

Throughout its long history—dating from ancient Mesopotamia to modern industrial manufacturing—brass has been modified and optimized for different environments and performance needs. Due to its exceptional malleability, corrosion resistance, and thermal conductivity, brass forging continues to be essential in industries such as plumbing, electronics, automotive, and architecture. Brass is not only one of the oldest forged metals but also among the most adaptable, able to be hot forged or cold worked into precise shapes by skilled fabricators today.

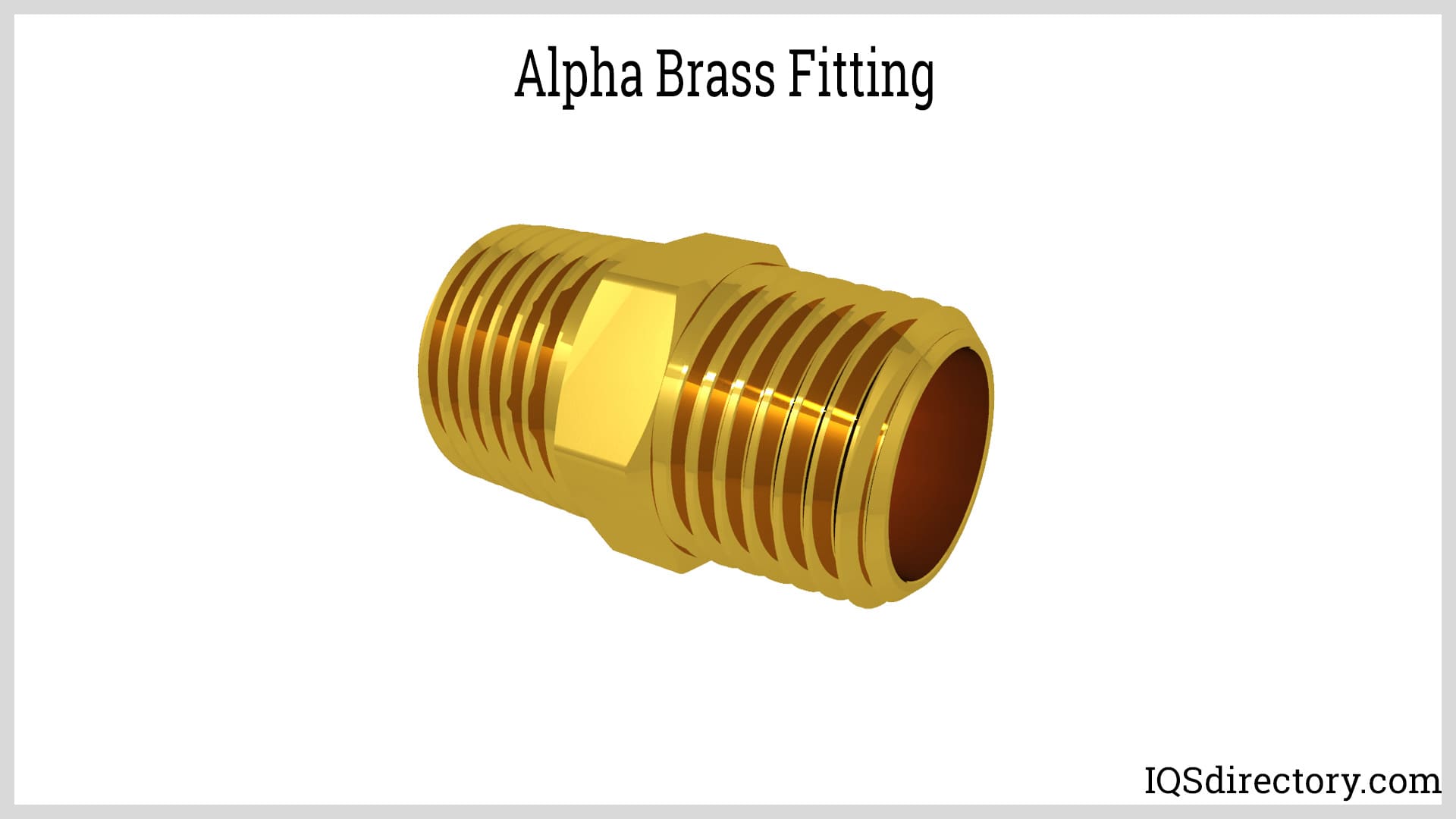

Alpha brass is a single-phase copper-zinc alloy, typically composed of 55% to 65% copper and 35% to 45% zinc. This category of brass is highly valued for its excellent ductility and ease of fabrication, which enables it to be extensively cold worked without risk of cracking. Alpha brass demonstrates outstanding corrosion resistance, making it a preferred material for architectural features, decorative hardware, electrical connectors, shell casings, and seamless tubes. Manufacturers and metalworkers often enhance alpha brass by introducing minor elements such as iron, aluminum, or silicon, further boosting its mechanical strength and forming properties. Its striking golden sheen and ability to take a high polish have made it a go-to for visible, aesthetic applications in both historical and modern contexts.

Alpha-beta brass, often referred to as duplex brass, typically contains 37% to 45% zinc and consists of both alpha and beta grains. This microstructure delivers a powerful balance between hardness and strength, albeit at the expense of some ductility compared to pure alpha brasses. Thanks to its increased zinc content, alpha-beta brass is more economical and can be hot forged or extruded into a variety of complex shapes—a key factor in the production of valves, gears, and pump components. Alloying this type of brass with tin or iron further improves its wear resistance and mechanical durability, while lead or arsenic can be included to enhance its machinability for precision parts. Due to beta phase presence, this alloy is best processed at high temperatures where it becomes more workable. Careful control of cooling rates is essential following forging to avoid unwanted grain phases and to ensure optimal properties.

Commonly used in plumbing and mechanical engineering, alpha-beta brass provides an excellent balance of cost, strength, and versatility. However, it's worth noting that the increased susceptibility to dezincification in some environments may necessitate the use of specialty variants for certain applications.

Beta brass—comprising roughly 50% copper and 50% zinc—belongs to the class of high-zinc brasses known for exceptional hardness and tensile strength. Its superior mechanical characteristics make beta brass the material of choice for high-stress components such as threaded fasteners, lock parts, springs, and heavy-duty connectors. While its high zinc content reduces ductility and makes it more challenging to cold work, beta brass is ideally suited to casting and hot forging processes, where the alloy can be shaped into robust and intricate parts. Its bright, silver-like color also differentiates it from other brasses that have warmer, golden hues.

In industrial settings, beta brass is particularly valued for parts that require significant resistance to deformation and wear under load, though care must be taken to avoid corrosion in aggressive or acidic media. As a result, beta brass is often selected for specialized fittings and construction hardware.

Leaded brass alloys are specifically engineered for high machinability, with the addition of 1% to 3% lead acting as an internal lubricant and chip-breaker. This unique structure enables faster cutting speeds and longer tool life, making leaded brasses indispensable for parts produced on Swiss screw machines and CNC lathes. Common uses include precision plumbing fittings, manifold components, and gear blanks. Leaded brass offers good corrosion resistance for non-potable water systems and moderate-strength applications.

The range of lead in such alloys can vary, providing flexibility in balancing machinability and mechanical performance. While the presence of lead at the grain boundaries visually distinguishes this class of alloy, compliance with modern environmental regulations is crucial, as some use-cases require lead-free alternatives for drinking water valves and food-contact applications.

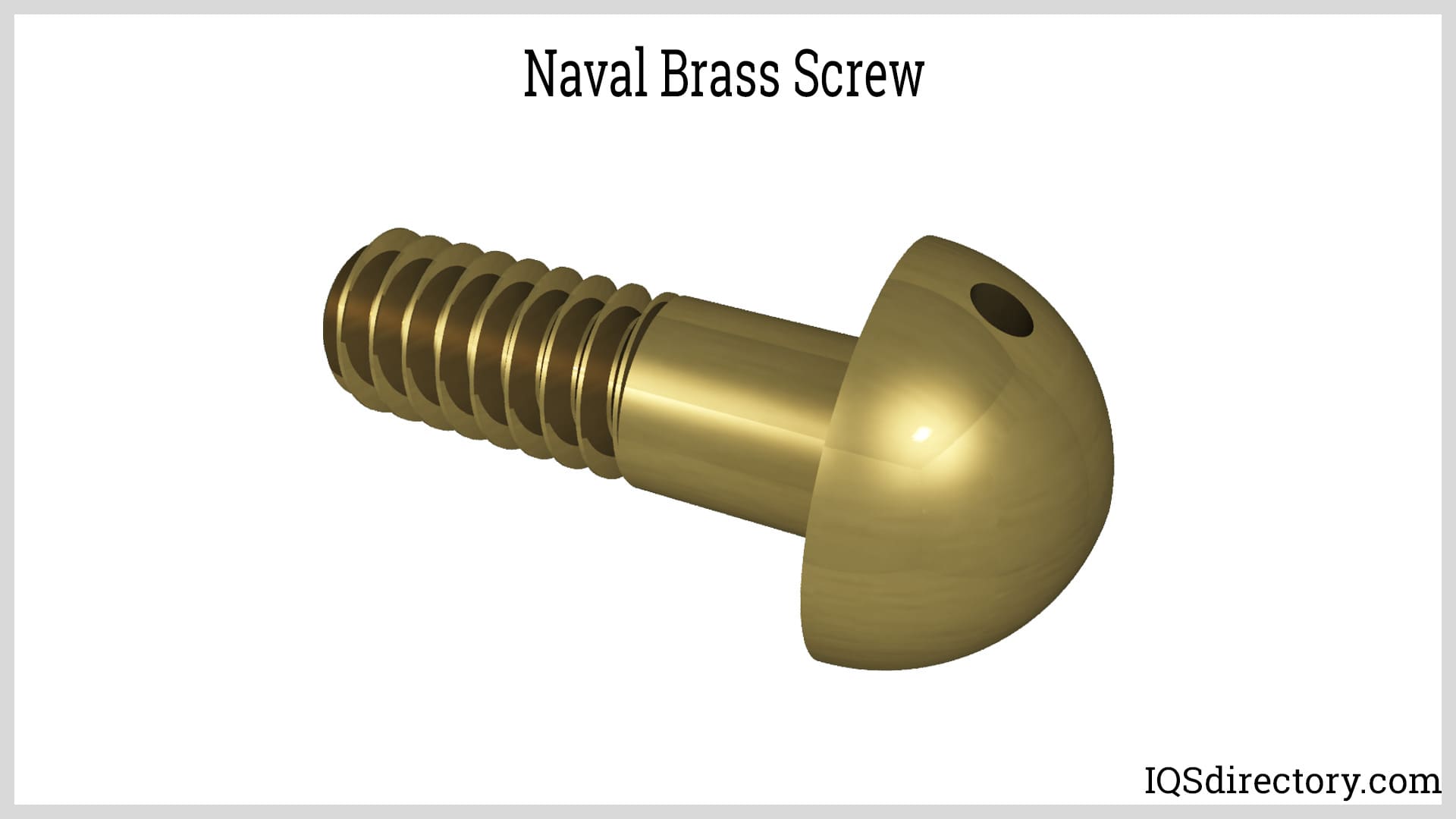

Naval brass is a specialized copper-zinc-tin alloy (typically 60% copper, 39% zinc, 1% tin) designed for exceptional corrosion resistance in marine environments. The tin addition addresses the issue of dezincification that plagues standard brass types in saltwater. This resilience makes naval brass the standard choice for shipbuilding components, propeller shafts, turnbuckles, marine hardware, seawater valves, and condenser plates. As an alpha-beta or duplex brass, naval brass boasts superior mechanical strength, wear resistance, and a longer service life compared to standard brasses in harsh, corrosive atmospheres.

Naval brass is also frequently employed in environments exposed to brine, steam, and other highly corrosive fluids, such as in offshore oil platforms and desalination plants. Its success has resulted in a range of derivatives that tailor specific performance needs within the marine industry, ensuring the reliability and longevity of critical infrastructure.

Red brass, often described as gunmetal or 85-5-5-5 brass, typically consists of 85% copper, 5% tin, 5% lead, and 5% zinc. It stands out for its distinctive reddish-gold color, which comes from its high copper concentration. Red brass is the preferred choice in plumbing and fluid handling systems, where its remarkable resistance to dezincification, corrosion, and stress corrosion cracking is crucial for potable water pipes, well pump components, and meter housings. It is also commonly used for pressure valves, sprinkler heads, ornamental castings, coins, and musical instruments.

Excellent castability, combined with good strength and machinability, makes red brass the material of choice for a wide range of industrial and decorative products. Its superior performance and reliability have led to widespread adoption in municipal water systems, fire protection, and specialty hardware.

White brass includes copper, zinc, and small additions of aluminum, manganese, and lead, resulting in a distinctive silvery appearance and enhanced resistance to wear and tarnishing. Known as Dutch metal or German silver, white brass is not a true silver alloy but is highly valued in the jewelry, musical instrument, and decorative hardware markets for its visual appeal and formability. Due to its low melting point and high fluidity, white brass is well-suited for casting complex shapes or intricate details in artisanal or high-value applications.

White brass's cost efficiency and ease of processing have made it an attractive alternative to more expensive precious alloys. It is frequently chosen for components requiring a blend of aesthetics, corrosion resistance, and moderate strength, such as costume jewelry, door handles, and specialty fastenings.

Yellow brass, also known as cartridge brass, is comprised of 67% copper and 33% zinc. This alloy is renowned for its bright golden-yellow color, high workability, and good strength, factors that make it particularly suitable for cold heading, deep drawing, and stamping. Yellow brass is most famously used in the manufacture of ammunition casings, as well as musical instruments, lamp fixtures, and plumbing hardware. Its ease of soldering, brazing, and welding further increases its utility in precision fabrication and assembly.

In addition to these applications, yellow brass’s corrosion-resistant properties and attractive finish make it popular for decorative objects and marine hardware. The ability to recycle and reload spent brass casings also highlights its value in resource-efficient manufacturing and environmentally conscious production.

The diverse world of brass forging encompasses a wide variety of specialized alloys—each engineered to deliver specific performance characteristics for critical industrial, commercial, and consumer applications. Understanding these different types of brass for forging enables manufacturers, engineers, and buyers to select the optimal material based on strength, corrosion resistance, machinability, aesthetics, and compliance with safety or environmental standards. As industries continue to evolve, ongoing research and innovation in copper-based alloys fuel the development of even more advanced brass materials to meet demanding new challenges in global engineering and manufacturing.

Copper, along with brass and bronze, is one of the earliest metals utilized by humans for various purposes. Its inherent ductility and malleability make it highly versatile, allowing it to be shaped and formed for a wide range of applications. Initially, copper was used to create tools, with ancient methods such as anvils and hammers being employed for shaping. These traditional forging techniques have continued to be relevant throughout the centuries.

Forging is preferred for manufacturing copper components due to its ability to produce high-precision parts through controlled deformation. The process requires relatively little force, which minimizes distortion and warping, resulting in outstanding dimensional accuracy and tight tolerances.

High copper alloys consist of more than 94% copper, with small amounts of silver and tin. This alloy is renowned for its exceptional strength and durability. The high copper content provides excellent corrosion resistance, which contributes to its widespread use. Like other copper alloys, high copper exhibits superb conductivity and is easily forged. Additional elements such as zinc, nickel, iron, and aluminum can be incorporated to enhance its properties, yet the alloy's high conductivity remains a key characteristic.

Leaded copper primarily consists of copper alloyed with lead, along with small amounts of zinc, aluminum, tin, and nickel. The inclusion of lead enhances the alloy's strength and improves its forging characteristics. The excellent machinability of leaded copper makes it particularly suitable for producing precise and accurate shapes. However, due to its lead content, leaded copper is not suitable for applications involving food.

Leaded coppers are categorized into low lead alloys, also known as machining alloys, and high lead alloys. The process of alloying lead with copper is straightforward due to lead's compatibility with various metals. Like copper, lead is malleable and possesses electrical conductivity, which contributes to the alloy's useful properties.

Copper-nickel alloys are primarily forged for use in saltwater environments due to their exceptional corrosion resistance. With nickel content ranging from 10% to 30%, these alloys are ideal for marine applications. A common application is seawater piping, as copper-nickel resists the accumulation of barnacles. Additionally, copper-nickel alloys are used in seawater desalination systems, water treatment facilities, and firefighting equipment. Their reliability, strength, and dependability contribute to their broad usage.

Copper-nickel alloys maintain their shape and durability even at temperatures up to 750°F (400°C). One of the key advantages of copper-nickel is its lightweight nature, which is particularly valuable in applications where both strength and weight are crucial considerations.

Nickel silver is an alloy of copper, nickel, and zinc that is often used for making coins, jewelry, and decorative items. Despite its resemblance to sterling silver, it is commonly known as German silver because it does not contain any actual silver. Nickel silver boasts moderate to high strength and good corrosion resistance, making it suitable for applications such as food handling equipment, optical and photographic devices, and musical instruments.

Nickel silver typically contains 7% to 20% nickel and 14% to 46% zinc. Alloys with higher zinc content resemble high zinc brass alloys. Nickel dissolves easily in copper, while zinc's solubility is more limited. Alloys with around 32% zinc exhibit both alpha and beta phases and solidify across a broad temperature range. Despite its silver-like appearance, nickel silver is known for its exceptional resistance to tarnishing and corrosion, earning it the nickname "anti-tarnish alloy."

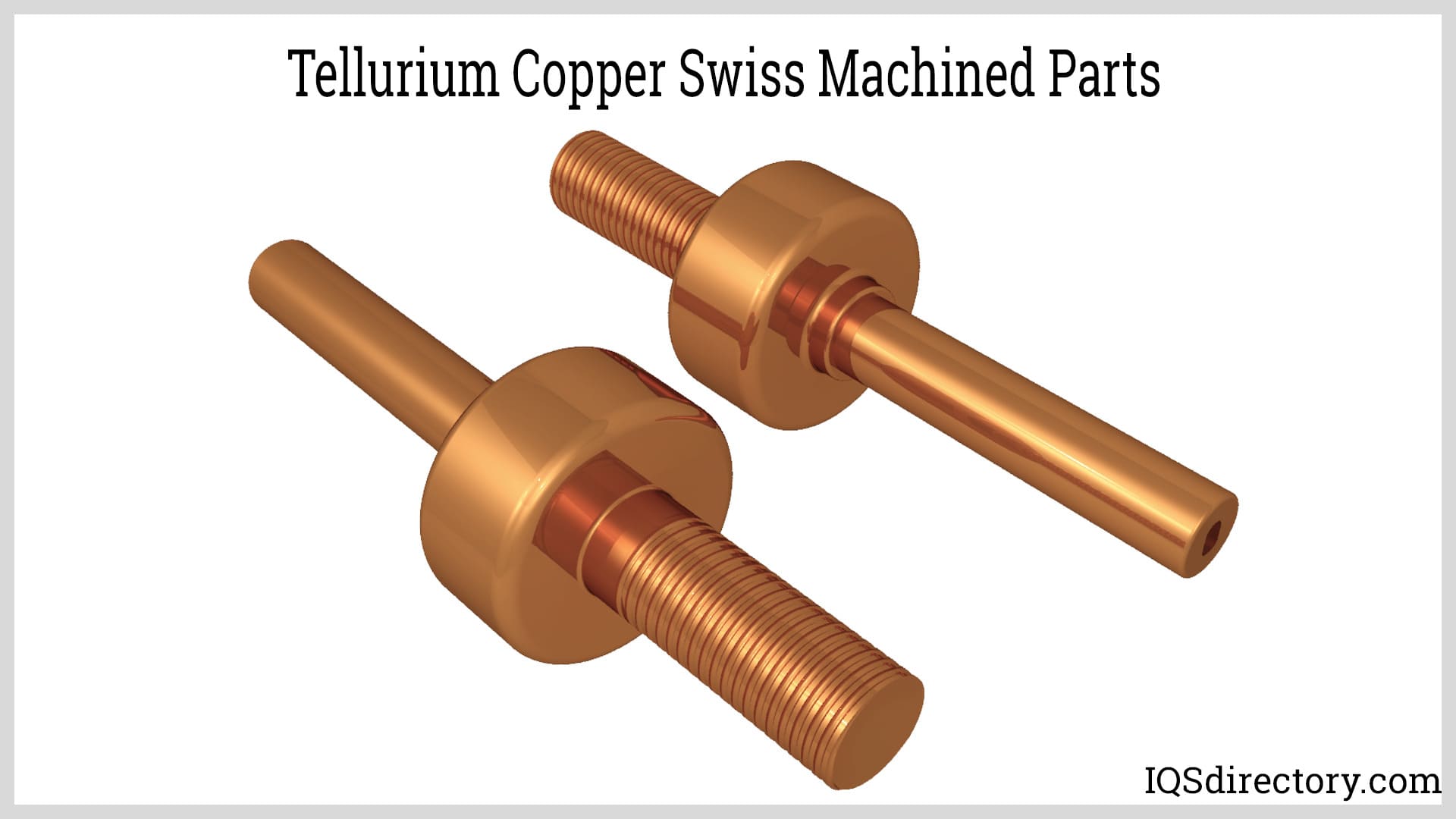

Tellurium copper is a type of tellurium bronze known for its excellent conductivity and superior machinability. The addition of tellurium, typically ranging from 0.5% to 0.75%, significantly enhances the material's machinability, often referred to as free cutting. While tellurium improves the ease with which the copper can be machined, it does not compromise its conductivity or hot working capabilities. The machinability of tellurium copper is comparable to that of brass.

Tellurium copper is widely utilized in various fields including welding, plumbing, and electrical applications. Its ease of forging, combined with good electrical and thermal conductivity, and exceptional machinability, makes it highly versatile. These attributes contribute to its suitability for a broad range of industrial and commercial uses.

The forging process produces robust and durable products by ensuring complete density through deformation. Copper and brass forged components are widely used because of their excellent thermal and electrical conductivity, as well as their capacity to accept plating effectively.

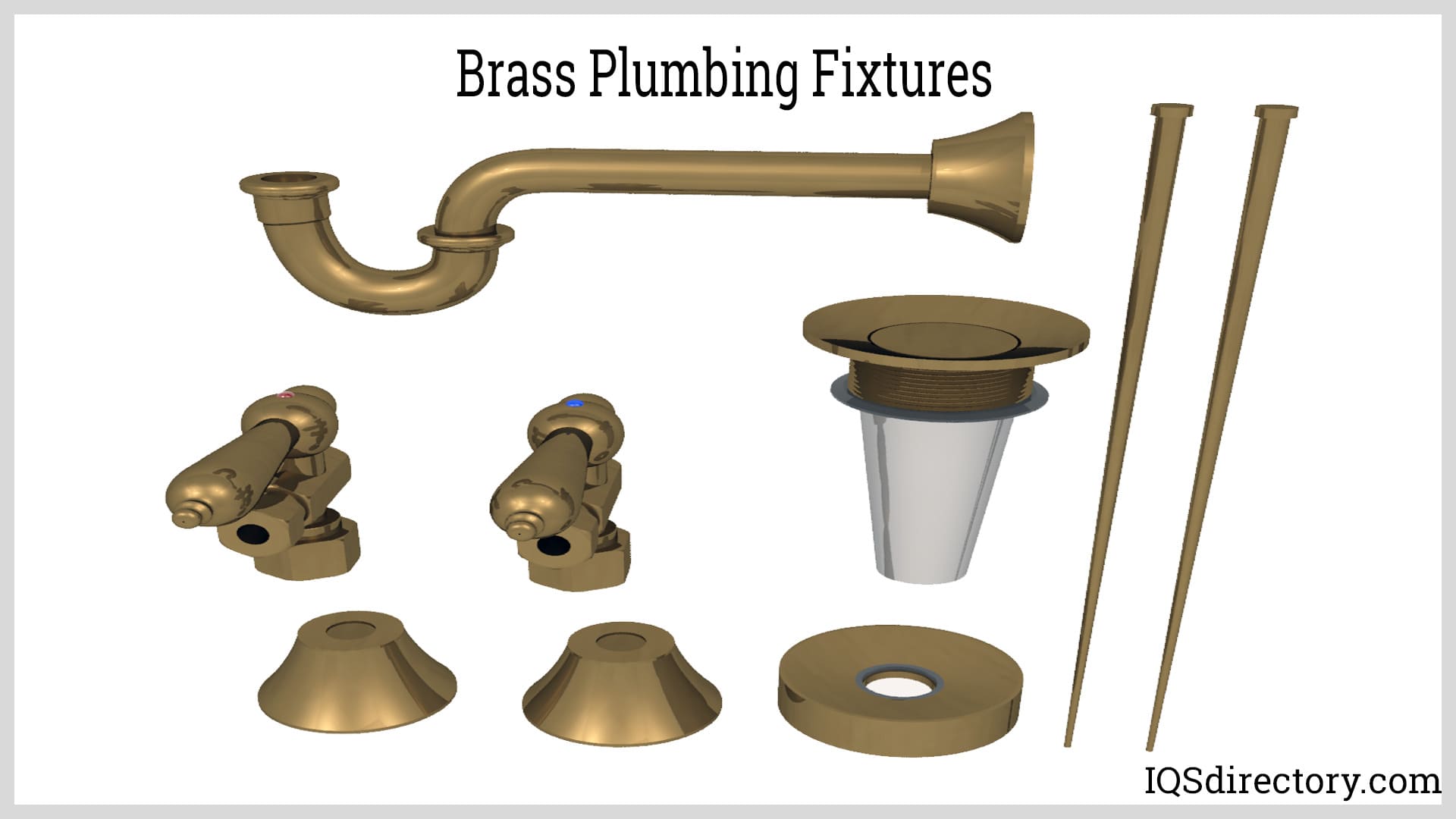

Brass is a staple material in plumbing, used in everything from pipes and fittings to faucets and handles. It has long been the preferred choice for creating secure, leak-proof, and stable plumbing systems. The durability and reliability of brass have made it the standard alloy for high-quality plumbing applications over the years.

The durability and aesthetic qualities of copper and brass make them excellent choices for manufacturing doorknobs and handles. Their natural antibacterial properties add an extra benefit, helping to maintain a healthier environment in both homes and offices.

Due to their moldability and flexibility, copper and brass are excellent materials for producing bushings. They do not adhere to steel and can accommodate various wall thicknesses, flanges, sinters, or cylinders. Copper and brass bushings are commonly utilized in applications such as water pumps and electric motors.

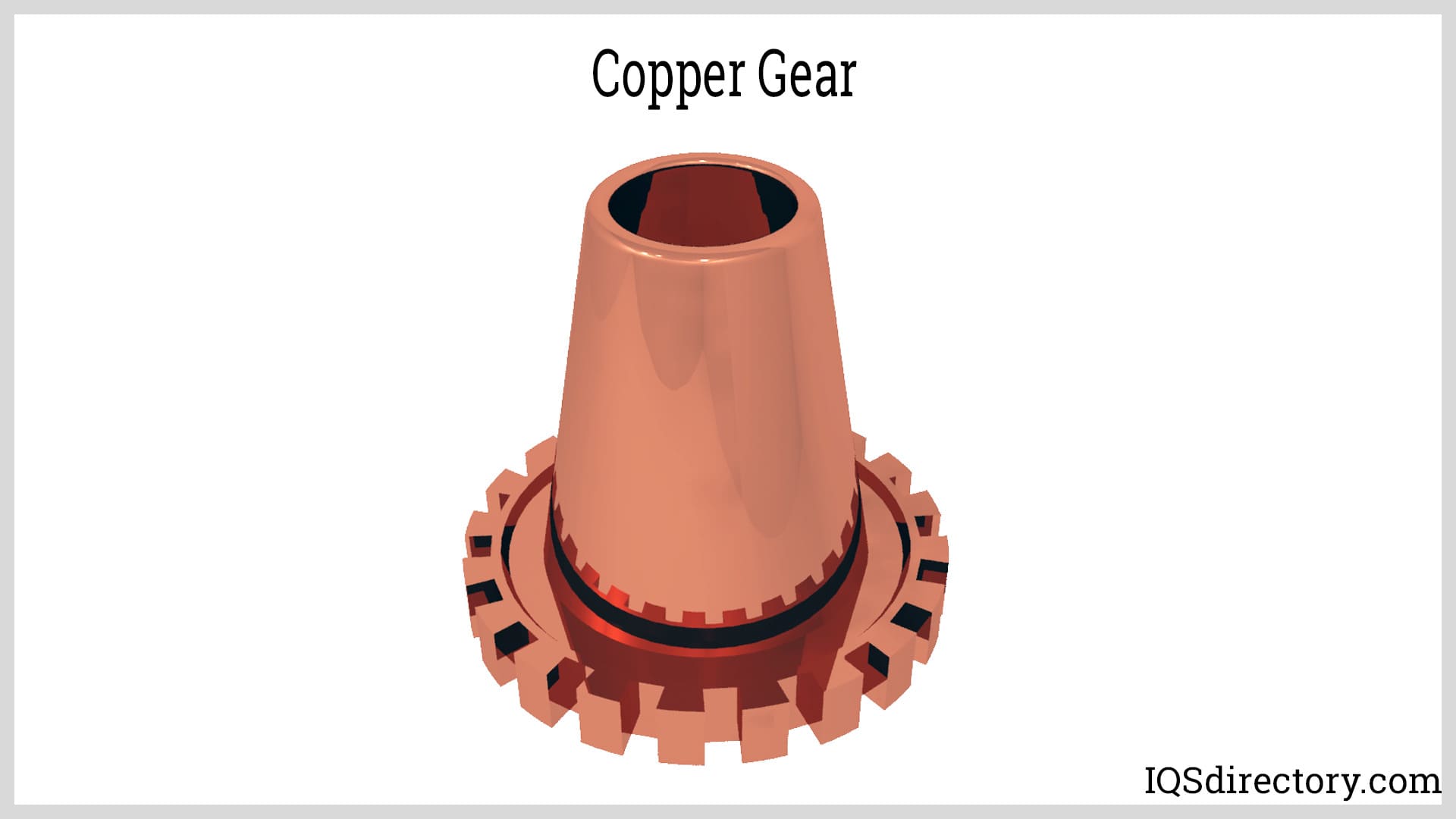

Brass gears are typically forged from yellow brass due to its excellent machinability. While other brass alloys are also used for their strength, they may be harder to machine. Copper and brass are favored for gear manufacturing because of their corrosion resistance and non-magnetic properties. The copper content not only facilitates the forging process but also imparts antimicrobial qualities to the gears. Forged copper and brass gears, such as spur gears and gear racks, are commonly used in low-load applications like instrument drive systems.

The examples of copper and brass products mentioned above represent just a fraction of the numerous parts and components that benefit from the strength and durability of forged copper and brass. The ductility, formability, and versatility of these metals make forged copper and brass crucial to a wide range of applications.

Casting and forging are distinct metalworking techniques used to create high-quality parts and components, each with unique characteristics and properties. The key difference between the two lies in their methods: forging involves applying force to shape the metal, while casting does not rely on such force.

Forging involves shaping a workpiece using a die, applying pressure and force, and manipulating temperatures. In this process, a billet, ingot, or metal sheet is pressed into a die by a ram. Forging can be categorized based on temperature, processing methods, and materials used. Throughout the forging process, thermal and mechanical energy are applied to the metal, whether it's an ingot, billet, or sheet. Importantly, the metal remains solid throughout the entire shaping and forming process.

In casting, metal is heated in a furnace until it reaches a molten state. The specific melting process depends on the type of metal being used. For metals like copper and brass, which have relatively low melting points, the energy required for heating is less intensive. Once molten, the metal is poured into a hollow mold where it cools and solidifies to form the desired component or part.

The primary and crucial difference between casting and forging copper and brass lies in the grain flow. During forging, pressure and force are applied to copper and brass billets, shaping them into the desired form. This process may require multiple applications of force, but throughout, the grain structures of the metals remain continuous and unbroken. This preservation of the grain structure contributes to the strength and durability of the forged components.

In contrast, casting disrupts the grain structure of copper and brass, which can lead to reduced strength once the metal solidifies. This factor must be carefully considered when designing and planning the manufacture of copper and brass parts.

Forging alters the microstructure of copper and brass, redistributing alloy concentrations and increasing density by eliminating voids. Unlike casting, forging enhances the mechanical properties of the metals, allowing them to withstand higher stress levels and minimizing potential failure. Although forging typically produces less complex shapes compared to casting, it can still create a variety of forms that offer the durability, reliability, and strength required for industrial applications.

| Metal Forging vs. Metal Casting | ||

|---|---|---|

| Metal Forging | Metal Casting | |

| Structural Integrity | Far superior in strength. Material predictability. | Products are porous and susceptible to breakage. |

| Tolerance | Less complex geometries. | High level of detail for tight tolerances. |

| Product Size | Limited in terms of the size and thickness of the metal. | Compatible with a wide range of sizes. |

| Material Selection | Limited alloy selection. | Any type of metal can be used |

| Secondary Operations | Secondary operations to refine and finish product to exact specifications. | Few secondary operations |

| Cost | Cost effective for medium to large production runs. | Cost is dependent on the type of casting |

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Cold forging is a metal shaping & manufacturing process in which bar stock is inserted into a die and squeezed into a second closed die. The process, completed is at room temperature or below the...

Forging is a metal working process that manipulates, shapes, deforms, and compresses metal to achieve a desired form, configuration, or appearance outlined by a metal processing design or diagram...

In this article, there are key terms that are typically used with open and closed die forging and it is necessary to understand their meaning. Forging is a process in manufacturing that involves pressing, hammering, or...

Rolled ring forging is a metal working process that involves punching a hole in a thick, solid, round metal piece to create a donut shape and then squeezing and pressuring the donut shape into a thin ring...

Forging steel is a manufacturing process used to shape steel by using localized compressive forces, which include hammering, pressing, and rolling. It is a widely used method for producing high quality steel products...

The ancient art of forging falls into two distinct categories – hot and cold where hot forging has been around for centuries while cold did not begin until the industrial revolution of the 19th Century. Though they are quite different ...

Aluminum casting is a method for producing high tolerance and high quality parts by inserting molten aluminum into a precisely designed and precision engineered die, mold, or form. It is an efficient process for the production of complex, intricate, detailed parts that exactly match the specifications of the original design...

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish...

Sand casting is a manufacturing process in which liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then allowed to solidify. Casting is a manufacturing process in which...

Zinc die casting is a casting process where molten zinc is injected into a die cavity made of steel that has the shape, size, and dimensions of the part or component being produced. The finished cast zinc product has...

The casting process is an ancient art that goes back several thousand years to the beginning of written history. The archeological record has finds that document the use of the casting process over 6000 years ago around 3000 BC or BCE...