Aluminum Forging

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at open vs closed die forging.

The article will bring more detail on topics such as:

In this section, we will discuss the various methods used in open and closed die forging, delving into their applications in the manufacturing of a diverse range of items.

In this article, we spotlight key terminology related to open and closed die forging, stressing the significance of these terms for a comprehensive understanding.

Forging is a production method in which metal is shaped by exerting pressure through pressing, hammering, or rolling, resulting in varied forms and patterns.

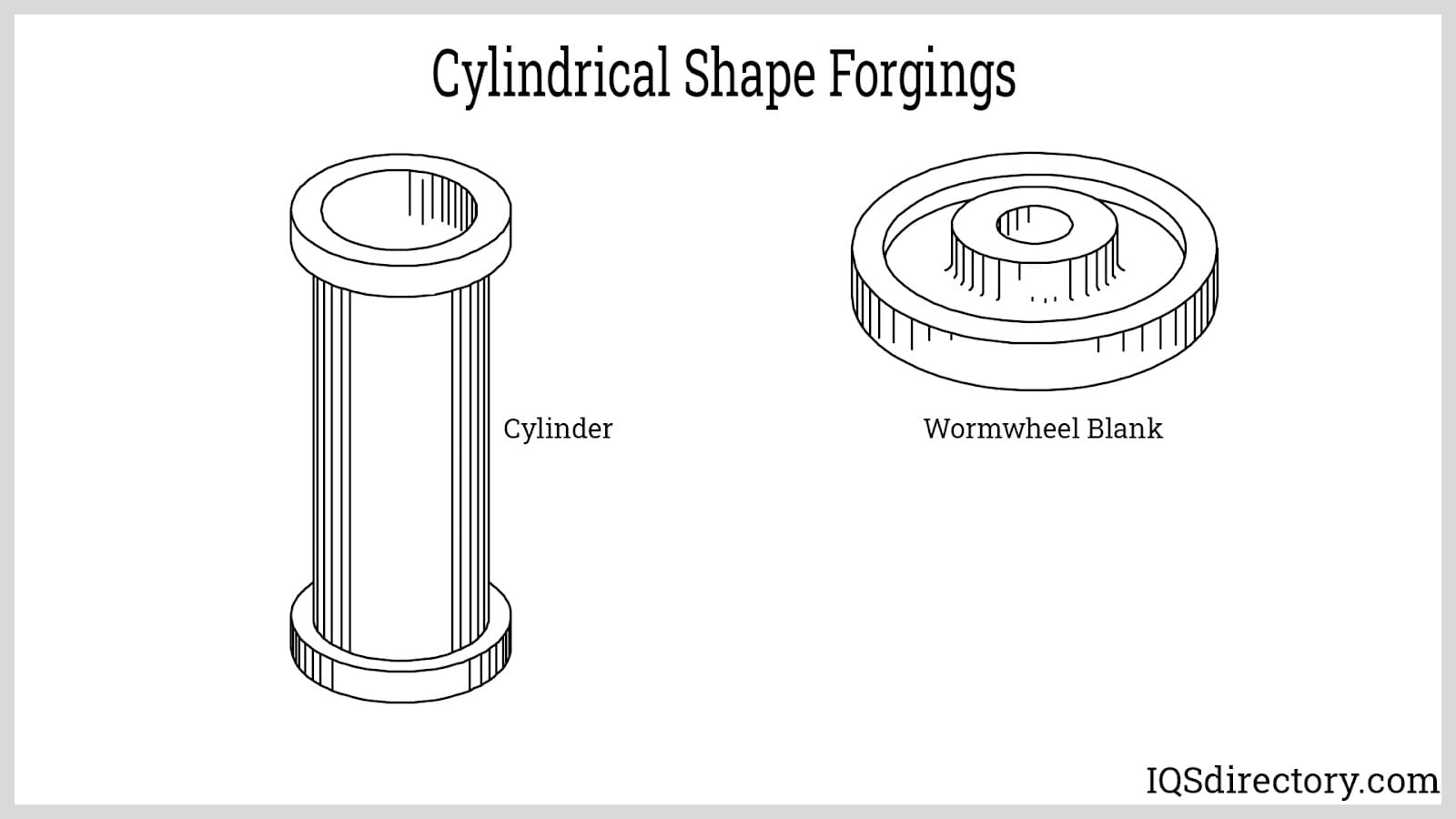

Forged parts come in a plethora of forms and dimensions, including disks, blanks, hollows, rings, bars, hubs, and shafts. Below is a schematic that details the steps in the forging process, with more thorough descriptions provided in later chapters.

The initial stage involves accurately placing the workpiece on the lower die. Proper positioning is crucial, as reversing the process once begun is complex.

In this phase, the upper die is forced down upon the heated workpiece to mold it as per the die's configuration. The elevated temperature renders the workpiece sufficiently pliable to adopt the die's form with minimal force. Force estimation is conducted through calculations and mechanical or electrical power experiments to ensure precise deformation.

After allowing the workpiece to cool, the upper die is withdrawn based on the workpiece material. The image below illustrates a forged component that can be adapted for numerous functions.

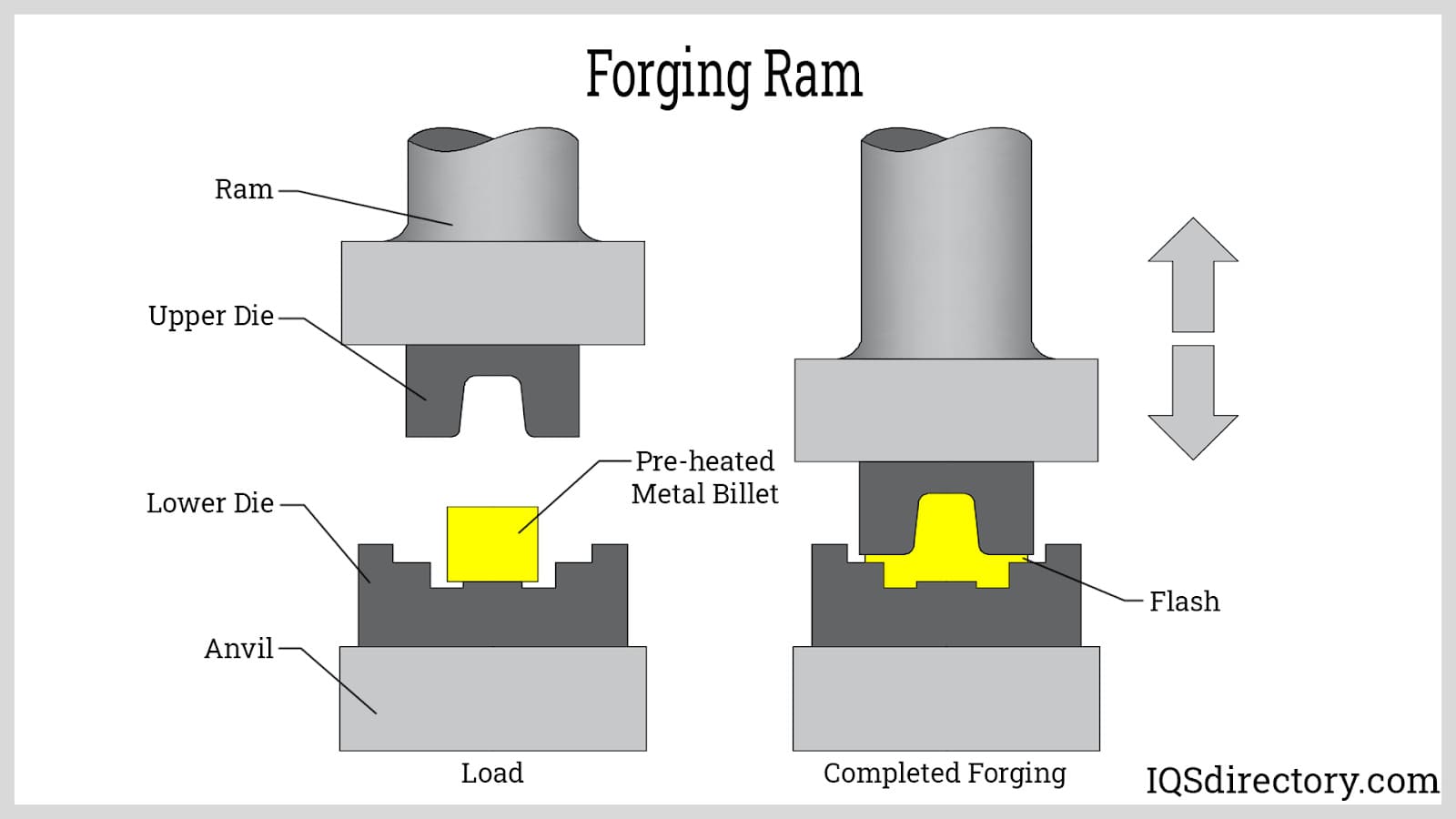

The ram is an integral part of forging machinery, mainly controlling the vertical movement of the upper die. It provides the necessary strokes and forces required for deforming the workpiece, translating power into mechanical force.

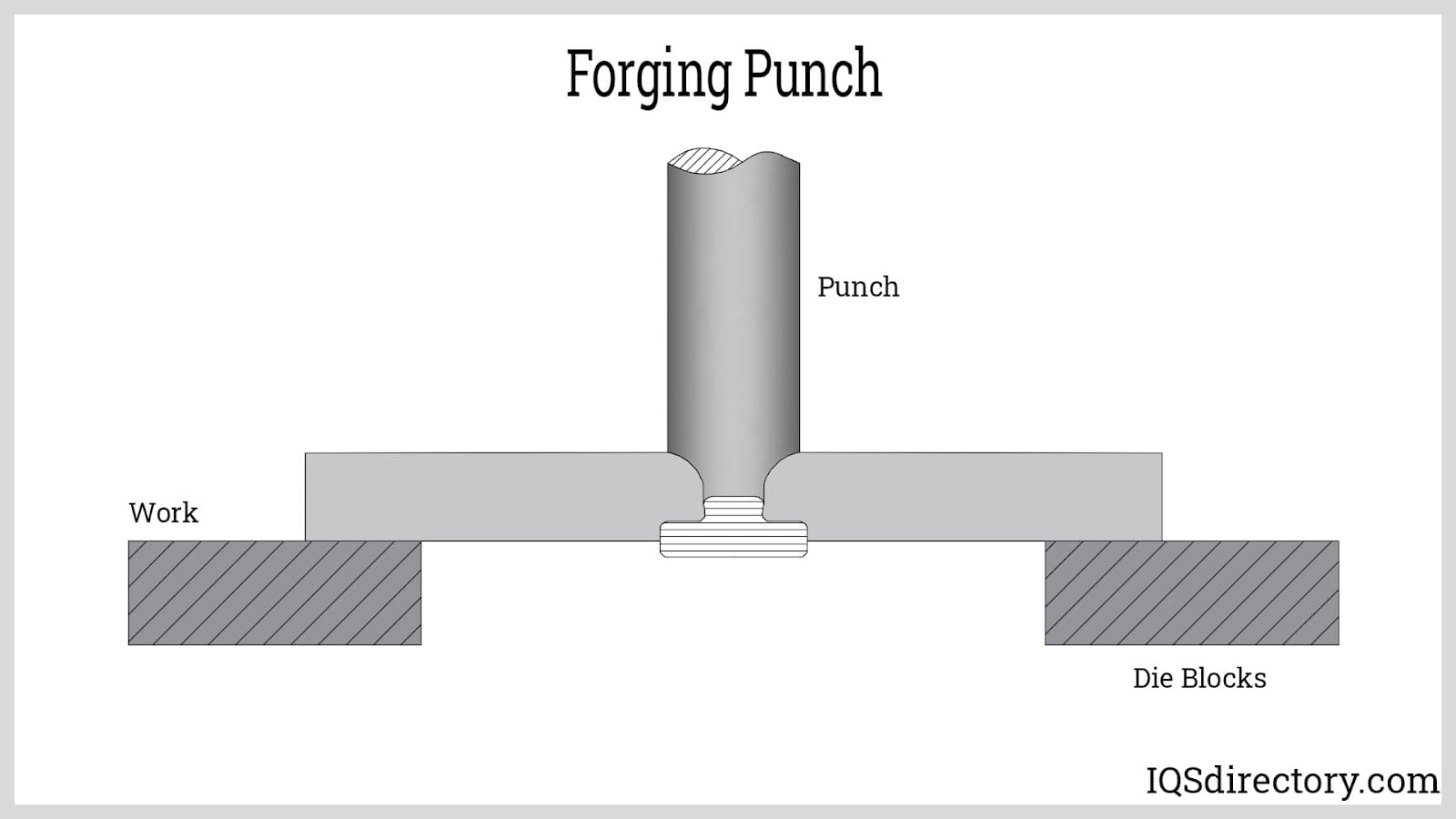

A die is a specialized tool tailored to shape materials into distinct profiles. Frequently used in manufacturing with pressing machines, it molds the workpiece between the top and bottom dies to achieve its final form. Below, a diagram demonstrates the interaction between the dies and the workpiece during force application.

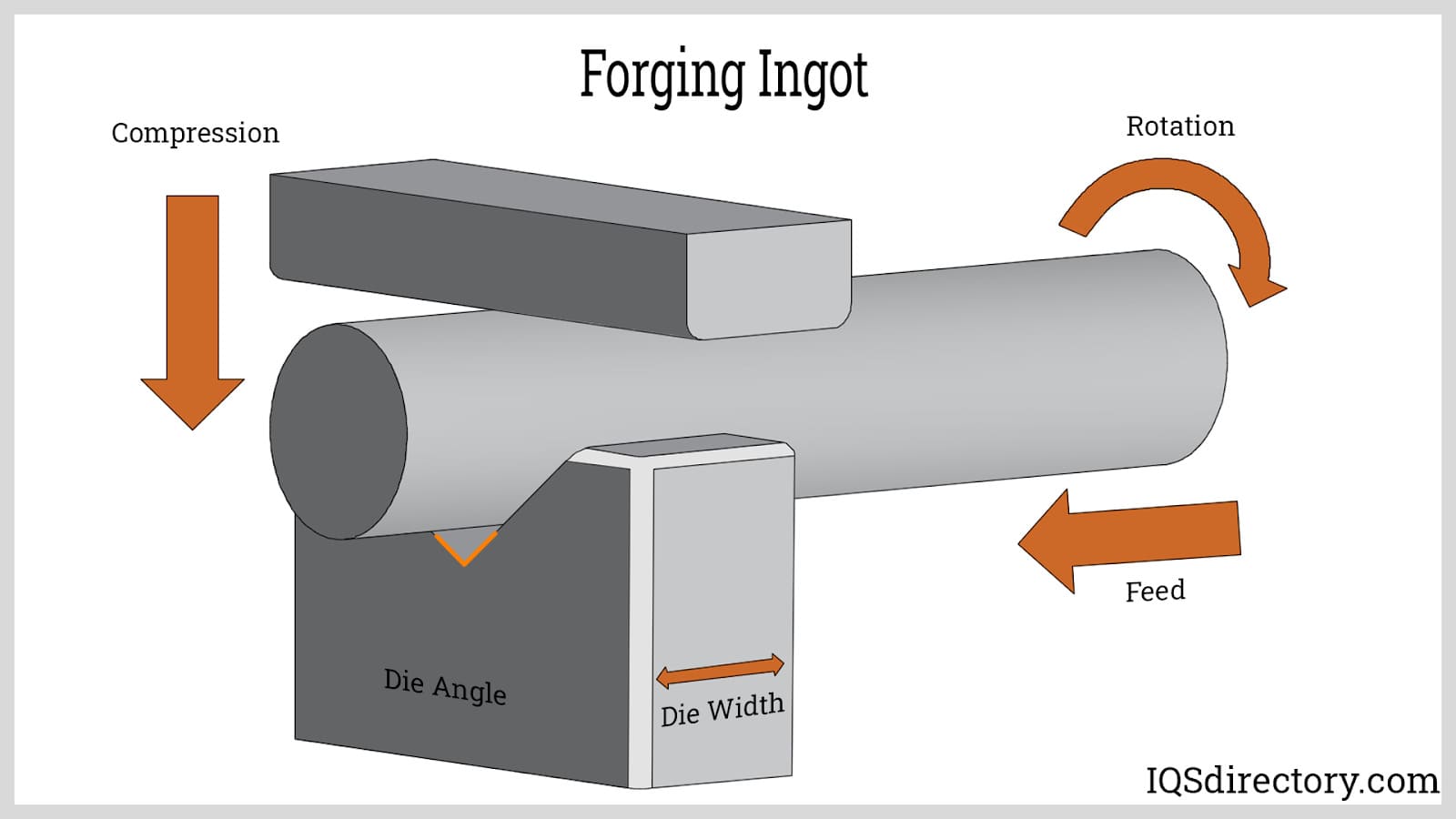

An ingot refers to a block of metal, often made of materials such as gold, silver, or steel, and is usually molded into shapes like rectangles or squares.

Grain flow, an important concept in the realms of open and closed die forging, refers to the alignment of metal grains due to distortions during forging, signifying the orientation of the grains.

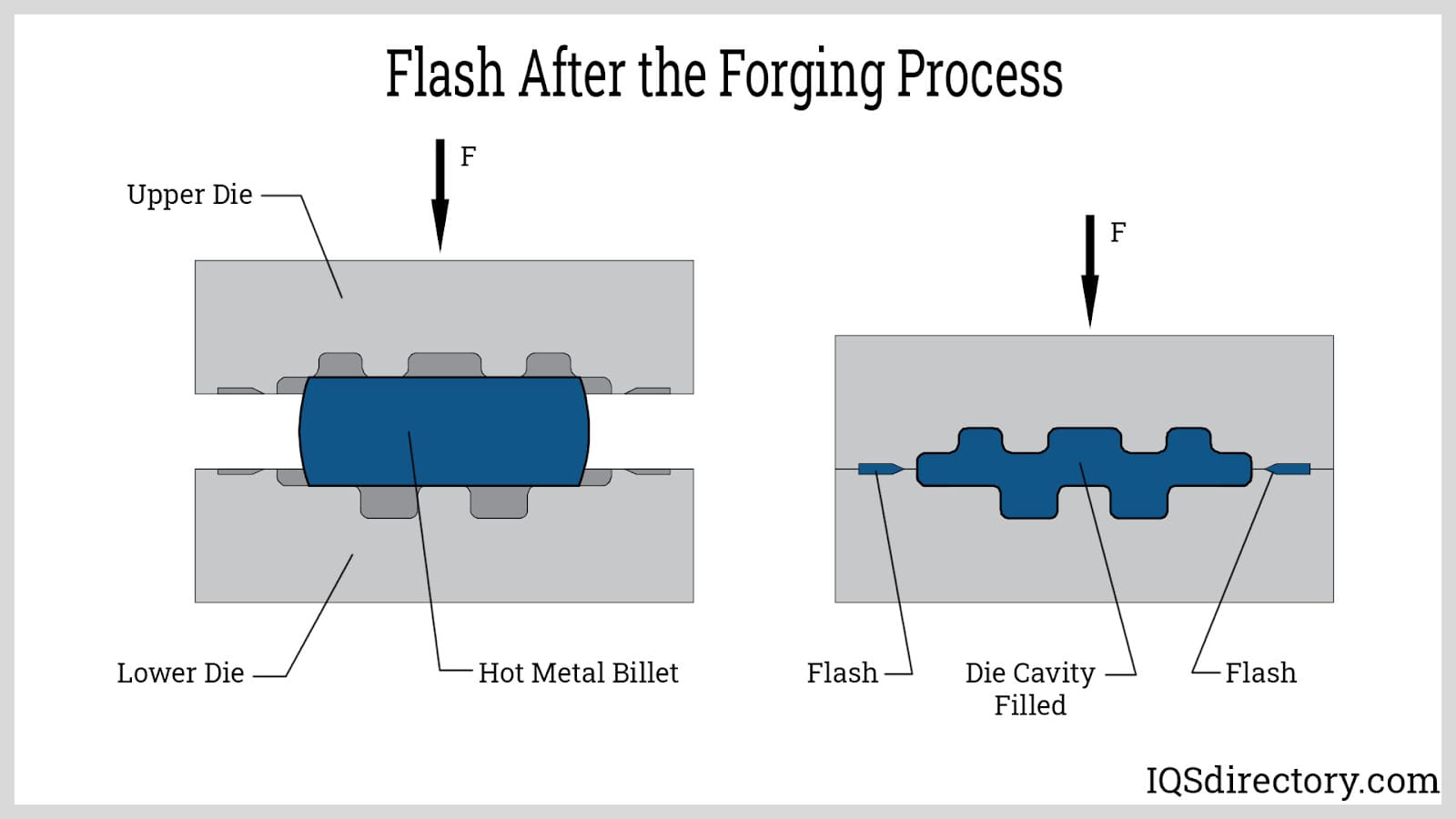

Flash is the surplus material that protrudes beyond the intended dimensions during forging. This excess, which does not constitute part of the final product, generally overlaps and is trimmed off through machining post-forging. The diagram below shows the flash created when force F is applied to a metal billet.

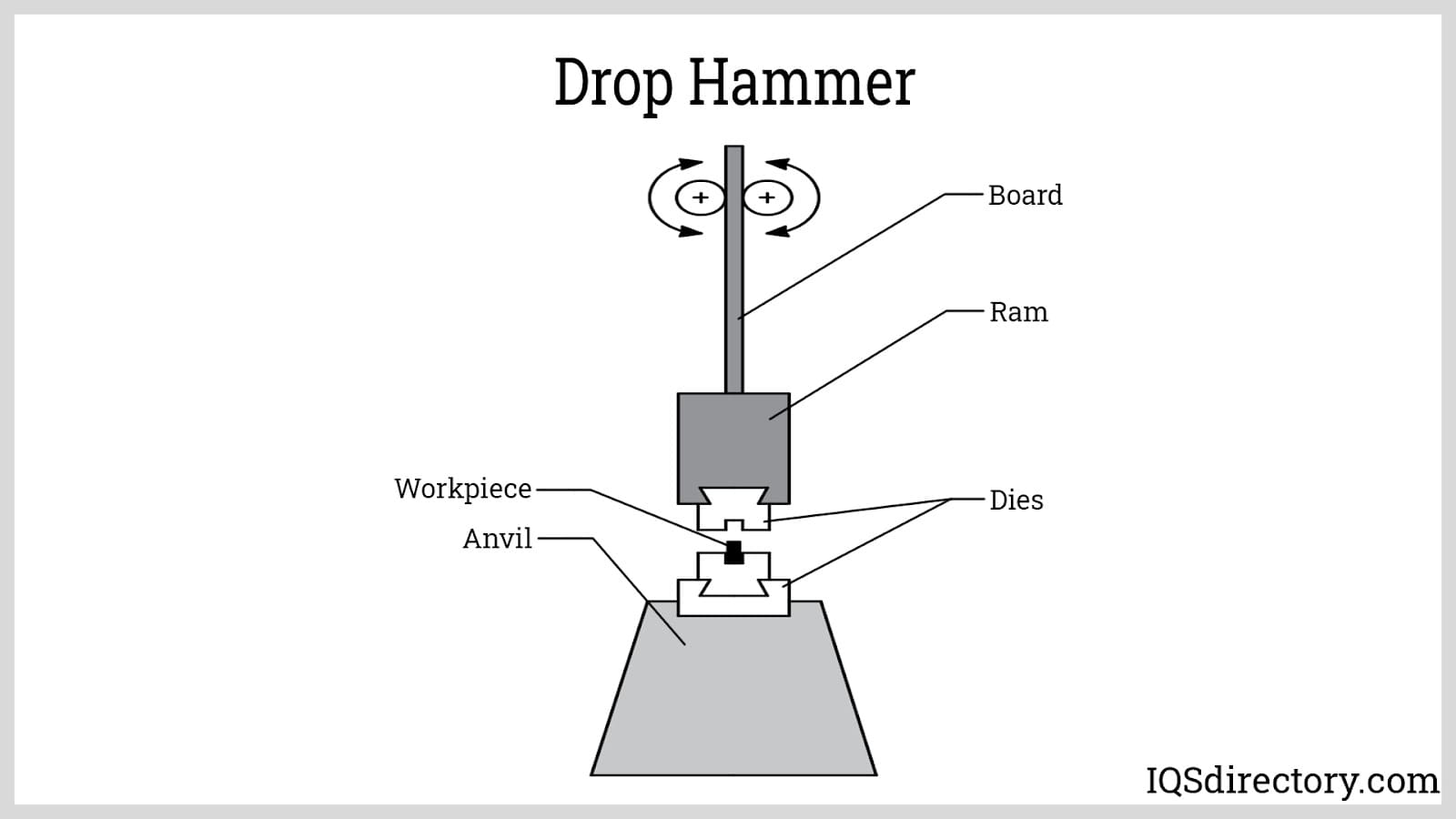

A forging hammer utilizes mechanical or electrical power to apply the required force for shaping heated metallic materials. It delivers quick, repeated strikes, engaging with the workpiece only momentarily during the entire process.

A forging press is a machine engineered to exert pressure to shape, flatten, or extract liquids such as oil or juice from various materials.

An anvil is a heavy iron block featuring a flat top used in hammering, flattening, and a multitude of metalworking processes, inclusive of forging.

A forging punch is a metal tool employed for creating or expanding holes during forging. Available in diverse shapes, sizes, and compositions, punches are selected based on the particular application requirements.

This chapter explores the essential differences between open die forging and closed die forging, examining their unique forging processes, typical applications in the manufacturing industry, and critical criteria for selecting the right forging process. Understanding these distinctions is vital for engineers, buyers, and manufacturers aiming to maximize product quality, cost-effectiveness, and material performance through metal forming techniques.

Open die forging, also referred to as free forging, flat die forging, blacksmith forging, or hand forging, is a metalworking process where heated metal, such as alloy or carbon steels, is shaped by compressive forces between flat or simple-shaped dies that do not enclose the workpiece entirely. Because the metal is not restricted laterally, the final shape largely depends on the operator’s expertise and the capabilities of the forge press or hammer, which is why this method is often associated with traditional blacksmithing.

With modern advancements, today’s open die forging presses are computer-controlled, enabling higher precision and repeatability in forging complex shapes, custom components, and larger metal parts. This process is ideal for manufacturing heavy-duty components such as shafts, disks, rings, cylinders, and bars—often those weighing several tons or more—particularly when superior mechanical properties like enhanced grain flow, strength, and impact resistance are needed. Open die forging is widely utilized in industries such as aerospace, power generation, oil and gas, mining, and shipbuilding, where custom-forged parts and large dimensions are required.

The open die forging process is a hot forming method that uses convex and concave standard dies within hydraulic or mechanical presses to manipulate the workpiece. It accommodates a wide range of workpiece sizes, from just a few kilograms to over 300 tons, providing unmatched flexibility in forging large metal components and custom shapes. Heating the metal ensures optimal plasticity and reduces the required forging force, enhancing the efficiency and accuracy of the shaping operation. The inherent flexibility of open die forging makes it especially suitable for low-volume production, prototypes, and specialty alloy forging.

During open die forging, the workpiece is alternately struck and repositioned on the stationary lower die by a manipulator, while the upper die delivers controlled strokes. This operation allows for precise directional grain flow, contributing to improved fatigue resistance and structural integrity. Force is applied primarily in the axial direction, but can be adjusted or rotated as needed for optimal material flow and grain refinement. Below are some of the most common operations involved in open die forging.

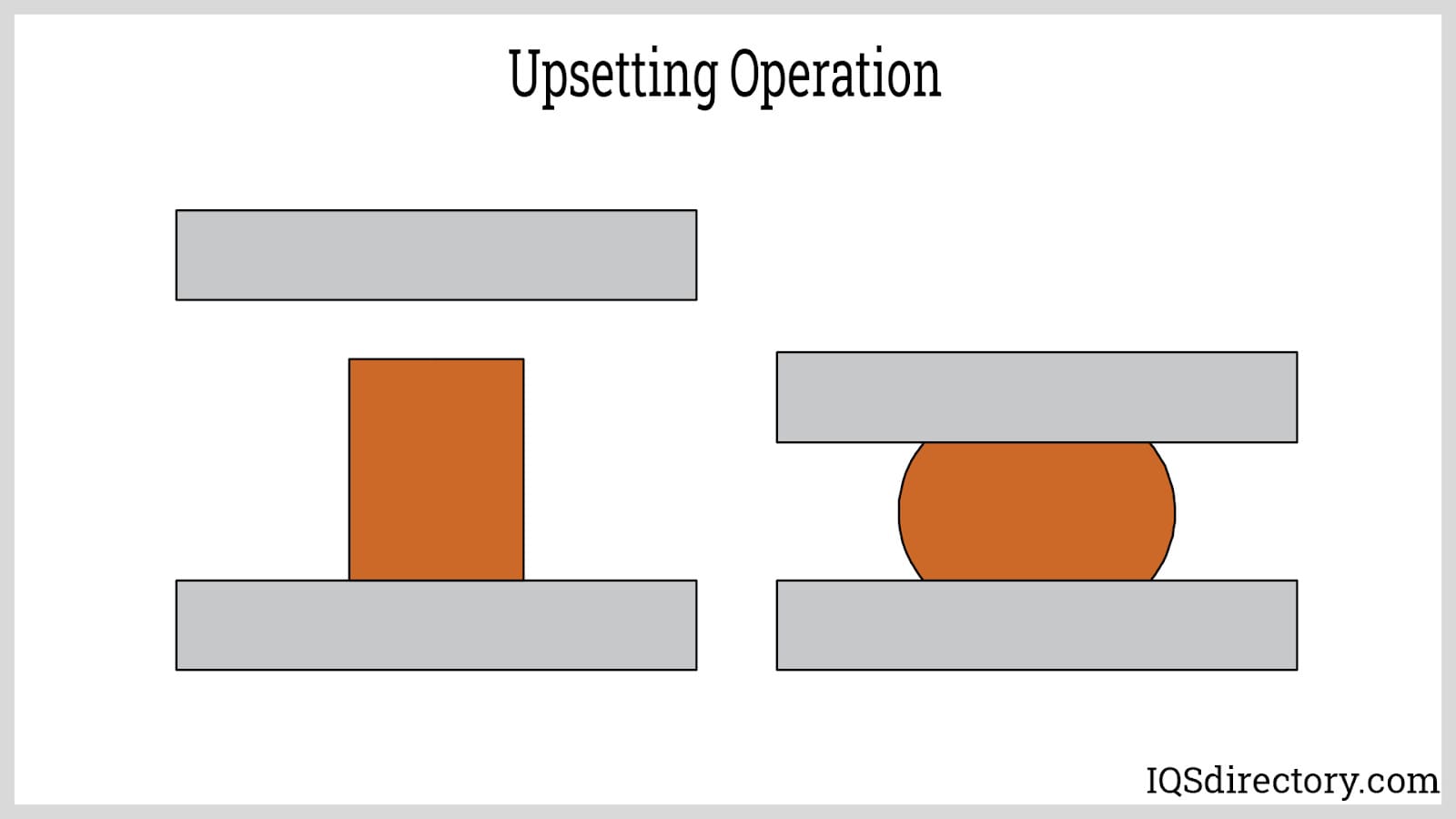

The upsetting operation positions the workpiece vertically under the hammer of the forging press, increasing its cross-sectional area and reducing its axial length. This improves material soundness and refines the internal structure. Flat dies with broad surfaces are commonly used in upsetting to accommodate the expansion of the workpiece—especially in shaft and flange forging.

Cogging utilizes narrow dies—shaped flat, V-patterned, convex, or concave—to incrementally elongate and reduce the ingot’s size, often with rotational movement. This process efficiently breaks down cast macrostructures, refines grain, eliminates porosity, and prepares billets for further metalworking processes like rolling or precision forging.

Drawing in open die forging is used to produce components where the length far exceeds the cross-sectional dimension, such as rods and axles. This is accomplished by repeatedly elongating and reducing the cross-section of blooms or ingots, thereby aligning the metal’s grain structure parallel to the length of the part—a critical property for parts subjected to heavy loading.

These operations focus on creating cavities within the forged metal. Piecing forms blind holes by deforming the heated metal without material removal, while punching creates a complete through-hole by pressing a solid punch and removing slugs. Trepanning, a type of hollow punching, removes central material to create large-diameter holes, often required for tube and pipe forging applications.

Hollow forging shapes metal around a mandrel to form tubular or hollow sections. The diameter increases and wall thickness decreases as the material is worked, making this process highly valuable for manufacturing forged cylinders, rings, and seamless pipe components.

Closing in operations focus on reducing the cross-section of hollow or tubular workpieces. This is achieved by heating the metal and using shaped dies—V-shaped, curved, or custom-formed—to compact targeted areas, enhancing dimensional control where required.

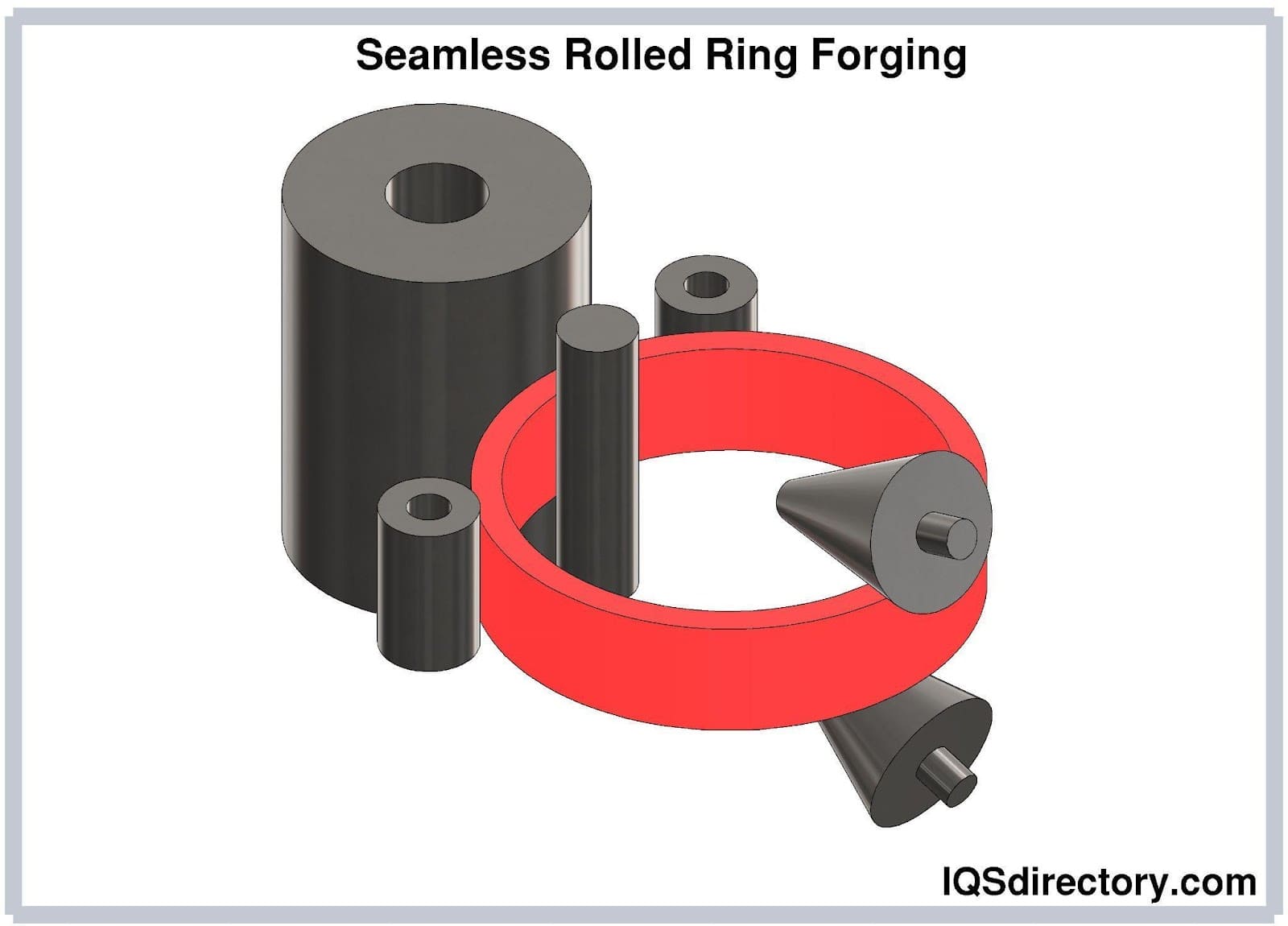

Ring forging produces seamless rolled rings from pieced blanks over a mandrel, crucial for applications requiring high strength, fatigue resistance, and durability—such as in aerospace, bearings, and oilfield equipment. As the ring rotates, pressing strokes reduce wall thickness and expand both inside and outside diameters, ensuring a uniform ring profile and optimal grain orientation.

Often, open die forging techniques are combined to create highly customized components, including complex geometries and specialty parts in various sizes. By adapting multiple forging operations within a single process, forgers can better control grain flow, mechanical properties, and material integrity—benefits valued in industries where component reliability is critical.

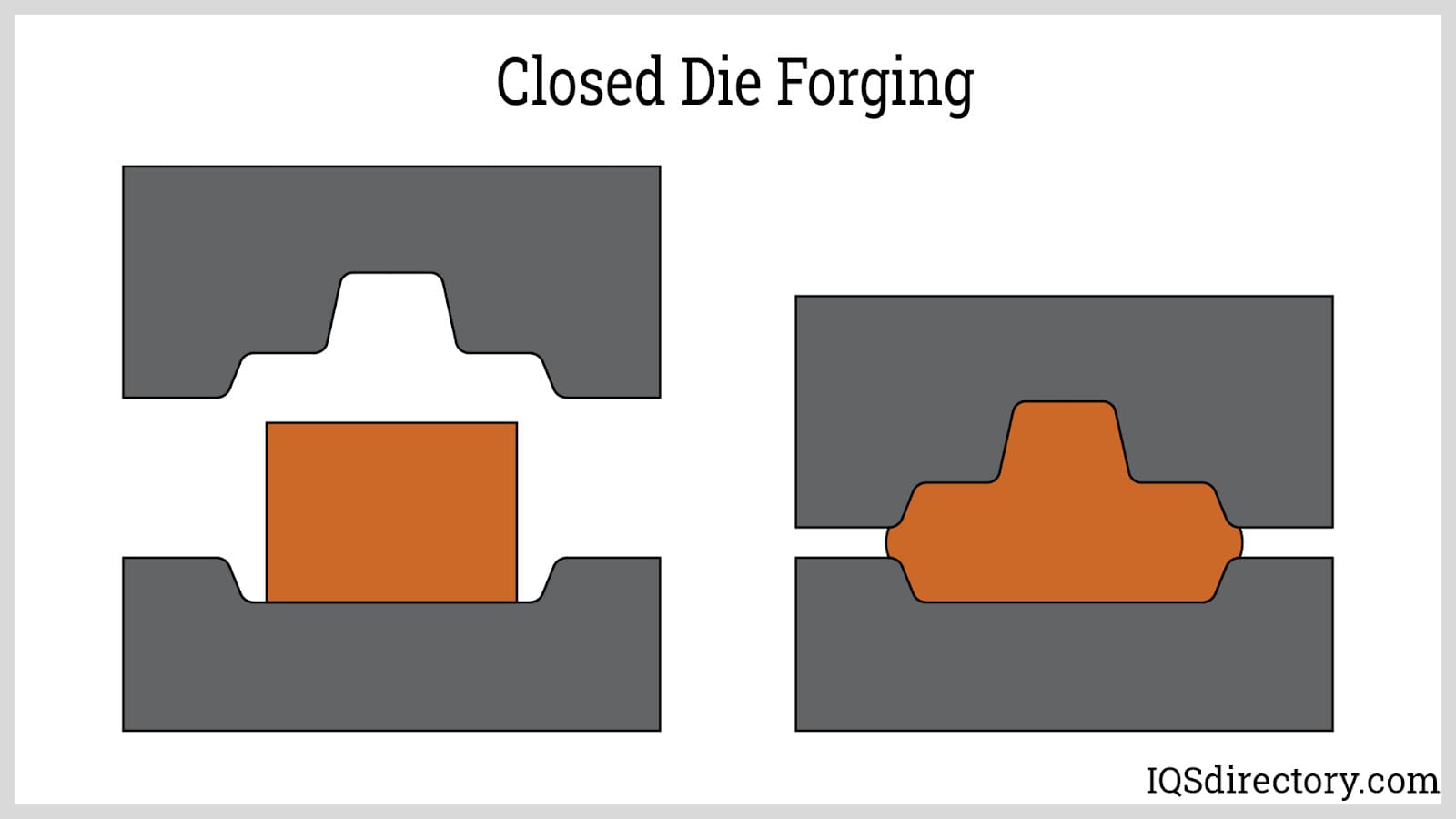

Closed die forging—also known as impression die forging—is a high-precision forming process whereby metal blanks are compressed within two or more accurately machined dies that contain the negative impression of the desired final shape. This method uses tremendous compressive forces, delivered via drop hammers or hydraulic presses, to force the heated material to fully conform to the intricate die cavities, resulting in near net-shaped or finished parts with minimal machining requirements.

During the closed die forging process, the hammer or press drives the workpiece into the dies across several strokes or rapid successive impacts, each lasting mere milliseconds. The metal fills the die space, and excess material, termed "flash," is forced out along the die parting line, where it cools quickly and is subsequently removed during a secondary trimming or finishing operation. Common materials forged by this method include carbon steel, alloy steel, stainless steel, aluminum, copper, and titanium alloys.

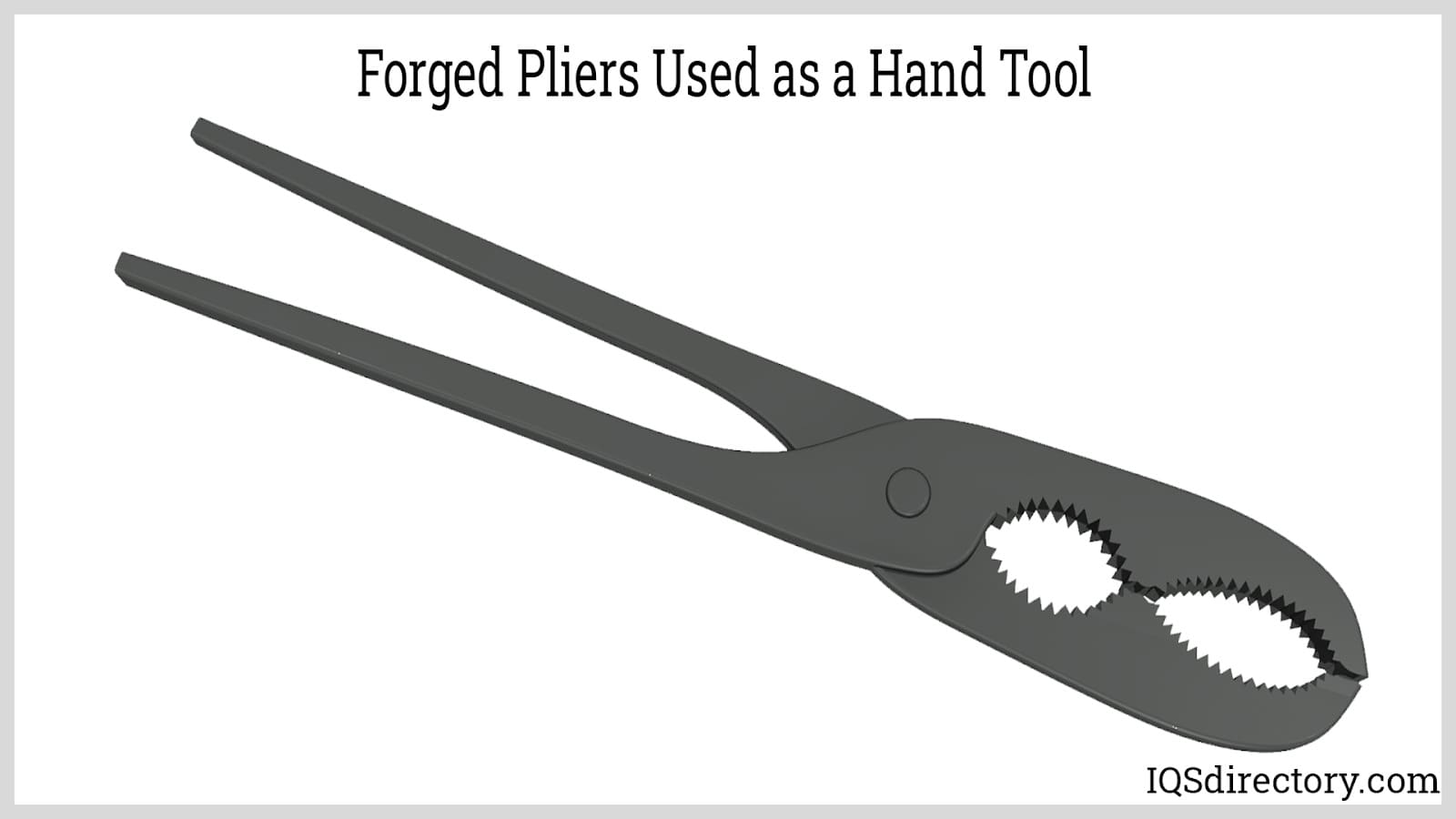

Closed die forging delivers excellent repeatability, high part-to-part consistency, tight tolerances, and fine surface finishes, making it highly suitable for mass production of complex forgings such as connecting rods, crankshafts, hardware, hand tools, automotive components, and aerospace-grade parts. The process can also exploit microalloyed and engineered materials for optimized mechanical properties and cost efficiency.

The following table summarizes the primary differences between open die and closed die forging in terms of process characteristics, application suitability, material utilization, and production scale:

| Open Die Forging | Closed Die Forging |

|---|---|

| Compresses the workpiece between two flat dies, allowing free lateral metal flow | Compresses the workpiece between dies with detailed impressions, restricting material flow |

| Lower die and tooling costs, suitable for prototyping and large, custom parts | Higher die and tooling costs due to precise impression dies, offsets with mass production |

| Simpler process for forging basic shapes and low-volume runs | Complex process enables production of intricate or precision components in high volumes |

| Poorer raw material utilization and more post-forge machining required | Greater material conservation, near net shape parts, minimizes machining |

| Finished products may have dimensional irregularities and looser tolerances | Produces parts with exact dimensions, closer tolerances, and superior surface finish |

| Best for simple product geometries and one-off or small batch production | Ideal for complex part geometries and large-volume manufacturing |

Selecting the optimal forging process for your application depends on a range of strategic considerations—from metal properties to production requirements and cost constraints. Below are key factors to consider, whether you are procuring industrial forgings or planning custom forging projects:

For applications demanding close tolerances and high dimensional accuracy, such as automotive engine components or aerospace fasteners, closed die forging is typically preferred due to its repeatability and tight control over final product dimensions. Evaluate the intended application's tolerance requirements by visually inspecting and measuring dimensions with tools like electronic calipers. While open die forging can deliver strong mechanical properties, its looseness in tolerances makes it less ideal for precision parts.

The type of material used in forging—such as carbon steel, alloy steel, stainless steel, aluminum alloys, nickel-based alloys, or titanium—greatly influences both process choice and outcome. High-temperature alloys, superalloys, and specialty steels may require open die forging for their optimal grain flow and mechanical performance, while softer, more ductile metals are often well-suited for closed die forging to achieve intricate shapes. Always consider the chemical and physical properties of the forging material to ensure the chosen process aligns with performance and durability needs.

Forging relies on carefully controlled heating to achieve the desired plasticity without compromising metal integrity. Certain metals may emit gases, such as carbon monoxide or volatile organic compounds, during heating—raising environmental and workplace safety concerns, and possibly requiring emissions treatment or compliance with regulatory standards. Opt for forging processes and safety protocols that address these risks, especially when forging reactive or hazardous alloys.

Forging process cost is influenced by factors like die and tooling expenses, production volume, raw material utilization, and required finishing operations. Open die forging offers flexibility and lower upfront costs for small runs or custom, oversized parts, but may require more post-forging machining. Closed die forging, while commanding higher initial die costs, is generally more cost-effective for high-volume production of precision parts, thanks to improved material yield, faster cycle times, and minimal secondary operations. Consider your project’s production schedule and lead time expectations when selecting a forging technique.

Both open and closed die forging are valued for improving the strength, grain structure, and fatigue resistance of metal parts compared to casting or machining. However, for components where customized grain flow, toughness, or impact resistance is essential—such as power generation shafts or oilfield equipment—open die forging may provide superior results. For applications demanding intricate features, high repeatability, and closer tolerances—such as automotive or aerospace components—closed die forging is optimal. Assess end-use demands, expected service conditions, and performance criteria to guide your process selection.

By carefully weighing these technical and business factors, manufacturers and engineers can choose the most appropriate forging technique, achieving optimal part performance, best total cost of ownership, and greater competitiveness in their industry.

Open and closed die forging are essential metal forming processes in the manufacturing sector, producing high-strength, durable components for industries such as automotive, aerospace, oil & gas, agricultural equipment, heavy machinery, and defense. Both forging techniques require specialized, high-precision equipment engineered for material consistency, dimensional accuracy, and efficiency. Below, we highlight some of the top industrial forging machines and prominent manufacturers, illustrating the technologies shaping the modern forging landscape and their relevance to diverse forging applications.

The Ajax-CECO Bulldog 600 is a versatile industrial forging hammer, capable of both open die forging and closed die forging processes. Its robust mechanical structure, powerful forging capacity, and flexible programmable control systems make it an industry benchmark for producing forged parts. This machine accommodates various metals, including carbon steel, alloy steel, and stainless steel, while ensuring repeatable accuracy and high throughput for shafts, gears, rings, and other forged components.

SMS Group’s FRÖHLING hydraulic forging presses deliver precise force control for heavy-duty open die and closed die forging operations. Equipped with advanced hydraulic technology, these forging presses offer customizable stroke lengths, programmable automation, and integrated quality monitoring. This ensures consistent grain structure and superior material properties in finished forged products, meeting stringent requirements in aerospace, energy, and high-performance manufacturing sectors.

Erie Press Systems' MultiForge™ series provides cutting-edge solutions for multi-station forging, supporting a wide spectrum of forging techniques, from conventional open and closed die forging to precision upset forging and ring rolling. The MultiForge™ machines feature high forge force capability, advanced PLC controls, and rapid tool change systems. These attributes are critical for custom forging shops aiming for shorter lead times and flexible production runs, optimizing productivity and reducing manufacturing costs.

National Machinery's FORMAX Plus stands out in the closed die (impression die) and open die forging space for its high-speed, high-efficiency operation. Packed with state-of-the-art servo-driven mechanisms and rapid-change tooling, FORMAX Plus automates forging production, boosts part consistency, and substantially lowers energy consumption. Common applications include automotive fasteners, precision aerospace parts, and other high-volume forged components.

LASCO’s FK series closed die forging presses are engineered for both open and closed die forging tasks. Featuring servo-hydraulic systems, advanced HMI interfaces, and high axial force output, these presses deliver impeccable repeatability and process control. Ideal for precision forgings used in automotive, agricultural, and industrial equipment, the FK presses optimize metallurgical properties and minimize waste, supporting lean manufacturing initiatives.

The choice of open die or closed die forging equipment depends on several key factors, including workpiece size, complexity, material requirements, and production volume. Leading forging machines like those listed above are trusted worldwide for producing components such as crankshafts, connecting rods, discs, rings, and flanges, each adhering to strict industry specifications and quality standards. For in-depth machine comparisons, purchasing advice, or up-to-date specifications—including innovations in heating systems, die design, and process automation—consult directly with manufacturers or refer to specialized industry resources.

Note that machine models, features, or individual specifications may change over time. For the most current selection criteria and availability of leading open and closed die forging machines in North America and globally, inquire with manufacturers or authoritative industry guides to ensure you procure equipment optimized for your forging applications.

This chapter will explore the applications and advantages of both open and closed die forging.

Open die forging has numerous applications, typically classified by the shapes of the products, as outlined below.

Cylindrical products forged through open die processes are valued for their durability and strength, making them ideal for industries like aerospace. Applications include components such as rotors, propeller parts, flat bars, and landing gears. Additionally, the military and automotive sectors benefit from forged parts due to their reliability and cost-effectiveness. Examples include wheel spindles, axle beams, kingpins, shafts, torsion bars, idler arms, ball studs, steering arms, pitman arms, connecting rods, and transmission gears and shafts.

Forgings with a pancake-like shape, resembling disks, are commonly used in aerospace, industrial, and military sectors due to their reliability and safety features. They are essential for components in helicopters, commercial jets, piston-engine planes, spacecraft, and military aircraft. Examples include hubs, flats, discs, hexes, plates, and rounds. Additionally, upset forging can produce elongated parts like screws, shafts, and piston rods, serving public works, aerospace, and automotive applications.

Hollow forgings are used to produce big parts like hollow tubes. They can be tapered hollow shapes, hollow cylinders, or straight cylinders. Hollow forgings can be used to produce rings, tubes, shafts, seamless rolled rings, or bearings. These are mainly used in the aerospace, military, automotive, and alternative energy industry.

Contour type forgings are essential for ring rolling applications, providing necessary contours with strength and cost-effectiveness. Rolled rings are widely used in demanding environments, including windmills, jet turbines, paper mills, jet engines, helicopter gearboxes, and other high-stress equipment.

Advantages of open die forging include:

Open die forging provides ample space for working on the workpiece, significantly reducing the likelihood of voids.

Fatigue is the weakening of a material due to repeated stress or loading, leading to issues like bending and cracking. Products from open die forging typically exhibit enhanced strength and resistance to fatigue, addressing these challenges effectively.

Shapes produced through open die forging generally have superior microstructures due to their larger size and longer-lasting durability.

Grain flow refers to the alignment of metal grains and inclusions resulting from forging. This technique is prevalent in crankshaft forging, where continuous grain flow forging is used due to the specific deformation processes involved.

Cost-saving involves reducing expenses that directly affect a company's profitability. Compared to closed die forging, open die forging typically offers lower costs, leading to greater expense reduction.

Open die forging primarily involves simple processes such as hammering and pressing, minimizing material waste as most of the material is utilized. In contrast, closed die forging generates waste in the form of flashing, as some material is removed during the process.

Shapes produced through open die forging benefit from strong bonds formed during compression processes like pressing and hammering. This makes them resilient to high temperatures and other stresses, enhancing their durability and longevity.

Disadvantages of open die forging include:

Open die forging often leaves ample space, allowing molten or heated metal to spread unevenly and fill the die cavities. This lack of confinement can result in irregular shapes, making it less suitable for precision manufacturing or parts.

Open die forging often results in irregular shapes, necessitating post-machining to achieve the desired part. This can increase costs, as the process may not utilize all the material efficiently.

Open die forging involves dies that remain open during the process, allowing for the creation of irregular shapes. This makes it suitable for producing parts that do not require high precision, such as supporting beams.

Due to the potential for increased irregularities, open die forging is not ideal for mass production and may result in higher losses. It is more effective for producing small quantities.

Closed die forging is widely used to produce metal components for various industrial applications, including aerospace, electronics, agriculture, automotive, commercial, manufacturing, construction, hardware, semiconductor, and food processing industries.

In the automotive and trucking industries, closed die forging is used for components such as steering arms, pitman arms, shafts, axle beams, torsion bars, idler arms, and ball studs. These components are known for their flame resistance and lower susceptibility to corrosion.

Closed die forging produces strong, tough, and cost-effective components essential for agricultural machinery and equipment. These parts must withstand harsh conditions, such as rocky terrains, making their durability crucial for reliable performance.

The components are mainly used as engine and transmission components. Examples of such components include gears, shafts, spindles, tie rod ends, levers, cultivator shafts, and harrow teeth.

Most surgical and dental instruments are made through closed die forging. Common examples include pliers, sleds, hammers, garden tools, wrenches, sockets, wire rope clips, hooks, sockets, turnbuckles, and eye bolts. For electrical transmission and distribution lines, examples include suspension clamps, caps, brackets, and sockets are mainly forged to enhance strength, resistance to corrosion, and dependability.

In the valve and fitting industry, closed die forging is essential due to the high pressure and extreme forces used, which impart extra strength and toughness to components. Common parts include heat and corrosion-resistant items like flanges, stems, elbow reducers, tees, valve bodies, saddlers, and other fittings.

Benefits of using closed die forging encompass the following:

Closed die forging results in products with superior mechanical properties due to the specific process involved. This method involves pressing and hammering, which refines the internal grain structure, enhancing characteristics such as high strength and corrosion resistance. Consequently, items produced through this forging technique are well-suited for demanding applications, such as precision instruments, owing to their durability and robustness.

Die forging processes create components with precise tolerances and achieve near-net shapes. A near-net shape means the final product's dimensions are very close to the intended specifications. This precision is due to the workpiece being enclosed in dies, leaving minimal space for excess material, which eliminates the need for additional machining. For smaller items, tolerances of approximately +/- 0.3 mm can be achieved, reducing the need for further machining or finishing and thereby cutting costs.

Forging produces near-net or net shapes, meaning the resulting forms are very close to the desired dimensions, often requiring no additional processing. The dies are designed to closely match the final shape of the workpiece, and this design is accurately reproduced through the closed die forging process.

Closed die forging accommodates a diverse array of materials, including steel, brass, aluminum, iron, and various metal alloys. This versatility makes it suitable for numerous industries where specific materials are required for different components. Unlike some forging methods that might exclude certain materials due to issues such as deformation, melting points, cooling rates, costs, or other mechanical properties, closed die forging can handle these materials with minimal adjustments to the system.

Closed die forging processes do not generate excess material that needs to be trimmed or removed afterward, making them more environmentally friendly compared to methods like open die forging or casting, which often require additional machining. Besides their ecological benefits, closed die forging also supports efficient material use, which is why some manufacturers favor this method.

Closed die forging achieves a high-quality surface finish thanks to its precise machining capabilities. This precision reduces the need for additional machining, thereby saving costs. The confined space within the dies ensures there is no excess material, which contributes to the clean surface finish.

Closed die forging utilizes intricate tools that demand sophisticated design, leading to higher tool costs. As a result, this method can be more expensive compared to other forging techniques.

Closed die forging is not ideal for producing irregular shapes, as it is best suited for precise, dimensional manufacturing. For items with complex or unconventional shapes, the open die forging method is more appropriate.

Closed die forging is not ideal for large-scale products and is better suited for smaller components.

Products created through closed die forging are generally smaller than those produced by open die forging. Due to their smaller size, there is a higher risk of accidents, as hot workpieces can be easily displaced. Operating closed die forging equipment requires heightened caution and care to ensure safety.

Both the open and closed die forging method uses heat for most of their operations. There are significant differences between the two, but there seems to be a balance on which method is the best because of what the other method can do and the other cannot do. From the outlined facts, it is evident that these forging methods complement each other and are best used depending on the type of application.

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Cold forging is a metal shaping & manufacturing process in which bar stock is inserted into a die and squeezed into a second closed die. The process, completed is at room temperature or below the...

Copper and brass forging is the deformation of copper and brass for the purpose of manufacturing complex and intricate shapes. The temperature at which copper and brass are forged is precision controlled and...

Forging is a metal working process that manipulates, shapes, deforms, and compresses metal to achieve a desired form, configuration, or appearance outlined by a metal processing design or diagram...

Rolled ring forging is a metal working process that involves punching a hole in a thick, solid, round metal piece to create a donut shape and then squeezing and pressuring the donut shape into a thin ring...

Forging steel is a manufacturing process used to shape steel by using localized compressive forces, which include hammering, pressing, and rolling. It is a widely used method for producing high quality steel products...

The ancient art of forging falls into two distinct categories – hot and cold where hot forging has been around for centuries while cold did not begin until the industrial revolution of the 19th Century. Though they are quite different ...

Aluminum casting is a method for producing high tolerance and high quality parts by inserting molten aluminum into a precisely designed and precision engineered die, mold, or form. It is an efficient process for the production of complex, intricate, detailed parts that exactly match the specifications of the original design...

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish...

Sand casting is a manufacturing process in which liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then allowed to solidify. Casting is a manufacturing process in which...

Zinc die casting is a casting process where molten zinc is injected into a die cavity made of steel that has the shape, size, and dimensions of the part or component being produced. The finished cast zinc product has...

The casting process is an ancient art that goes back several thousand years to the beginning of written history. The archeological record has finds that document the use of the casting process over 6000 years ago around 3000 BC or BCE...