Aluminum Forging

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at rolled ring forging.

You will learn more about topics such as:

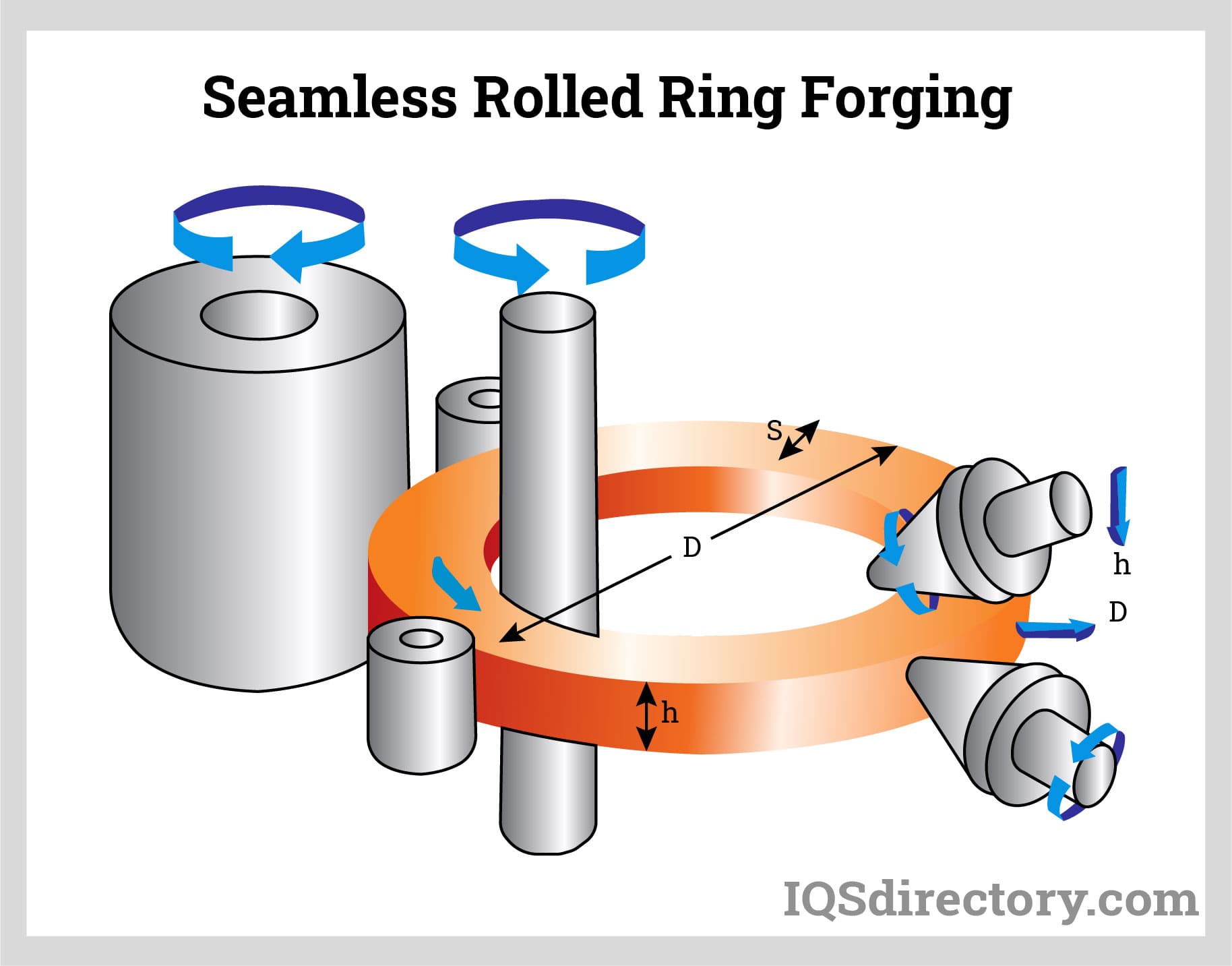

Rolled ring forging is a technique in metalworking that begins with a circular, pre-shaped metal piece. This initial piece is upset and then pierced to form a doughnut-like shape, also known as a torus. It is then heated to a temperature above its recrystallization point and positioned on a mandrel or idler.

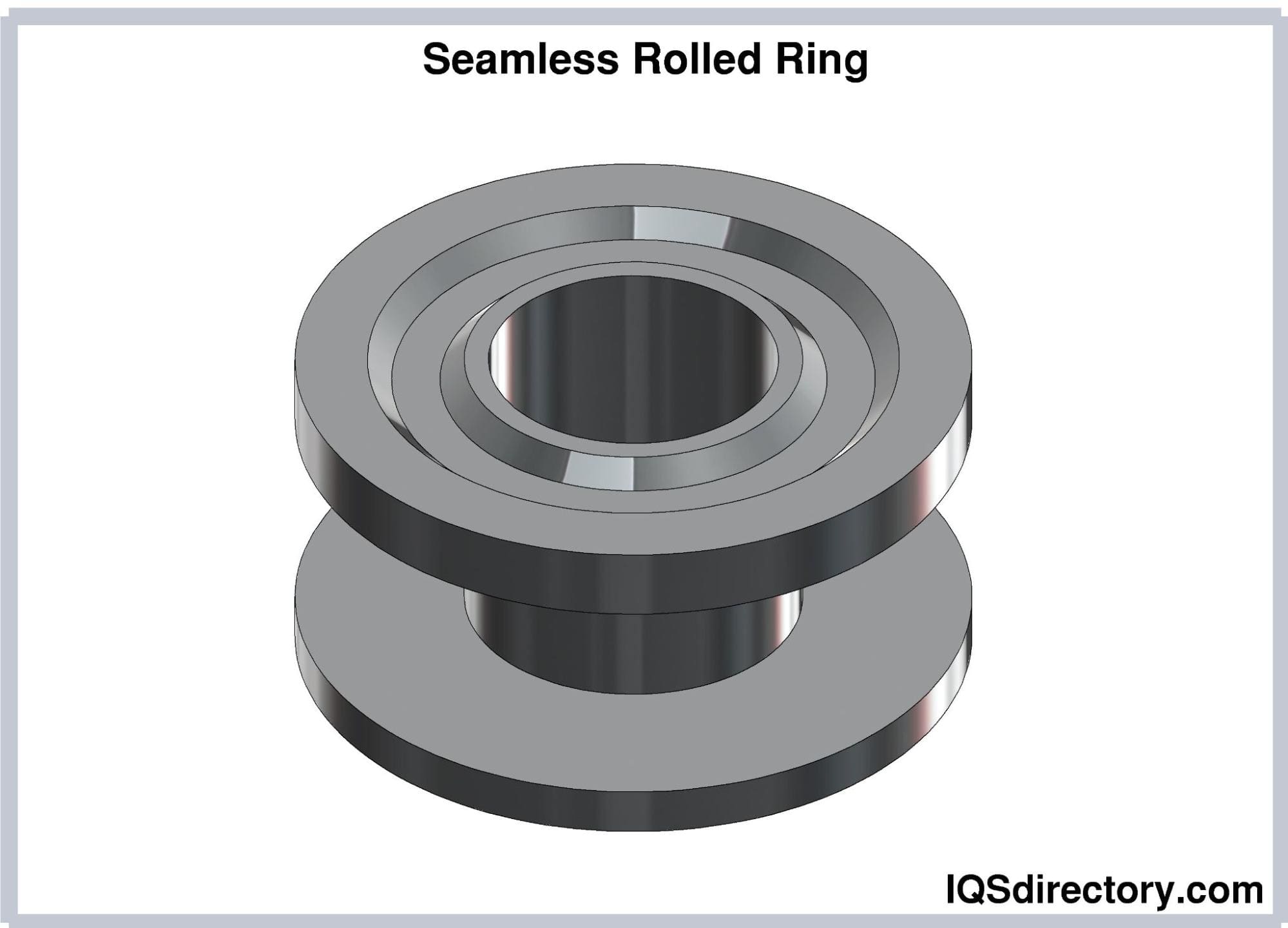

The idler guides the pierced doughnut configuration toward a drive roller, which rotates consistently to reduce the torus's wall thickness while expanding its inner and outer diameters evenly. This process ultimately results in a product known as a seamless rolled ring.

The rolled ring forging method allows the production of seamless metal rings in a variety of sizes, ideal for applications in machine tools, turbines, pipes, and pressure vessels. This technique substantially enhances the mechanical attributes of the forged metal and maintains its grain structure.

This forging process results in pieces with improved density and remarkably aligned grain flow. The forged rings range in weight from a few pounds to many thousands of pounds, with diameters spanning from a few inches to over twenty feet. Configurations include washer-like shapes and cylindrical forms. Wall-thickness-to-height ratios can vary greatly from 1:16 to 16:1, with larger ratios achievable through specialized forging techniques.

Rolled ring forgings most commonly have a rectangular cross-section. However, specialized tooling can produce custom shapes with detailed contours on both the inner and outer diameters.

As a form of open die forging, the rolled ring method involves a precisely cut, weighed, and rounded workpiece, allowing the upsetting process to achieve optimal structural integrity and directional grain flow. This open die forging method works the metal repeatedly, enhancing its strength, boosting its fatigue resistance, and removing any voids.

Rolled ring forging is praised for its cost-effectiveness, flexibility, and the high quality of the final products. It can produce flat washers and cylinders up to two feet in height, with diameters extending to several feet and weights exceeding six tons. Additionally, the metal's grain structure is preserved since the material remains solid throughout the process.

With minimal waste and the ability to produce a wide range of sizes, rolled ring forging is an excellent choice for metal forming. This process can shape various metals, including stainless steel, aluminum, nickel alloys, and different types of steel. The primary method, seamless rolled ring forging, delivers rings with superior strength and fatigue resistance compared to welded or torch-cut rings.

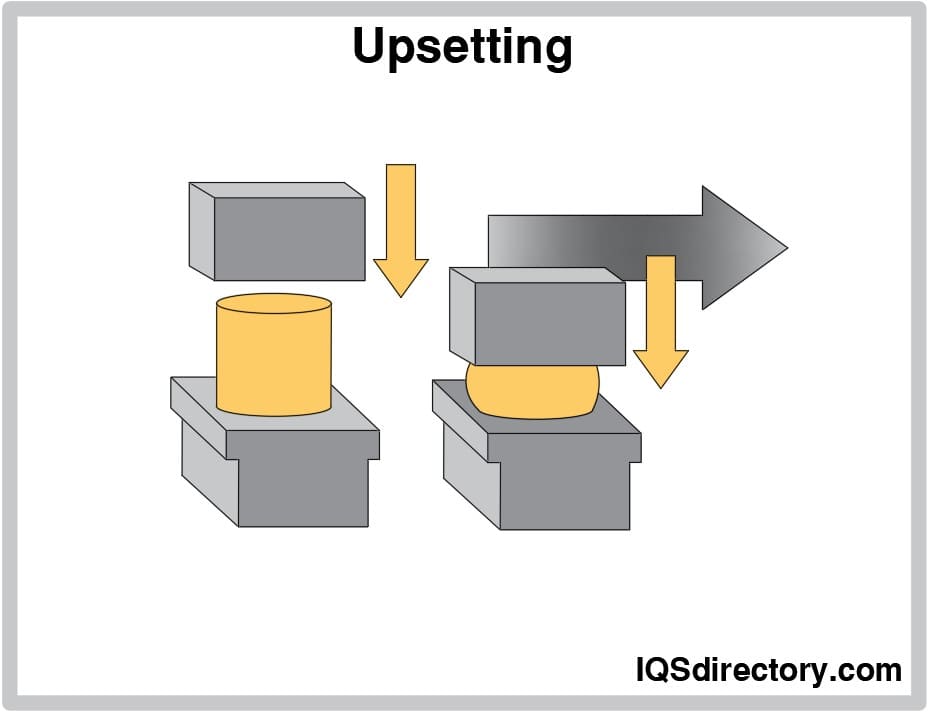

The initial stage of the rolled ring forging process involves taking a billet, usually in cylindrical form, and subjecting it to an upsetting operation. Upsetting prepares the workpiece by deforming it to the required diameter, height, and shape, which increases its cross-sectional area. This deformation is achieved by applying significant horizontal pressure through a hydraulic press, which forces the workpiece to expand along its length axis.

During upsetting, the dies compress the workpiece at its plastic deformation temperature, allowing it to extend beyond the press's confines. This open die process involves pressing the cylinder between an upper and lower die and can be performed either hot or cold.

Heating the workpiece for upsetting induces changes in the metal's grain structure, as heating affects the metal's crystalline phases. When heated past the austenite phase, the metal undergoes a transformation from a body-centered cubic lattice to a face-centered cubic lattice. In the austenite phase, metals become ductile and soft, facilitating easier shaping.

Upsetting is a common forging method that is used to shape and form multiple pieces quickly and efficiently. It is used to form the heads of bolts as part of cold forging. Upsetting machines have a ram that moves in a horizontal direction against a workpiece. The results of the horizontal strokes are an increase in the volume and shape of the workpiece.

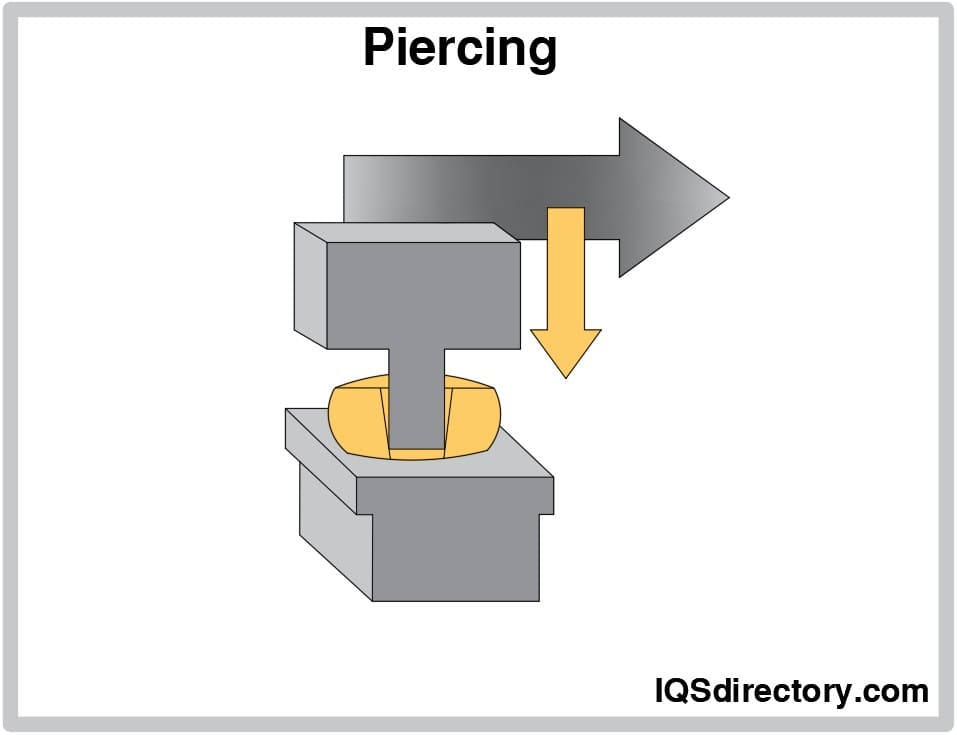

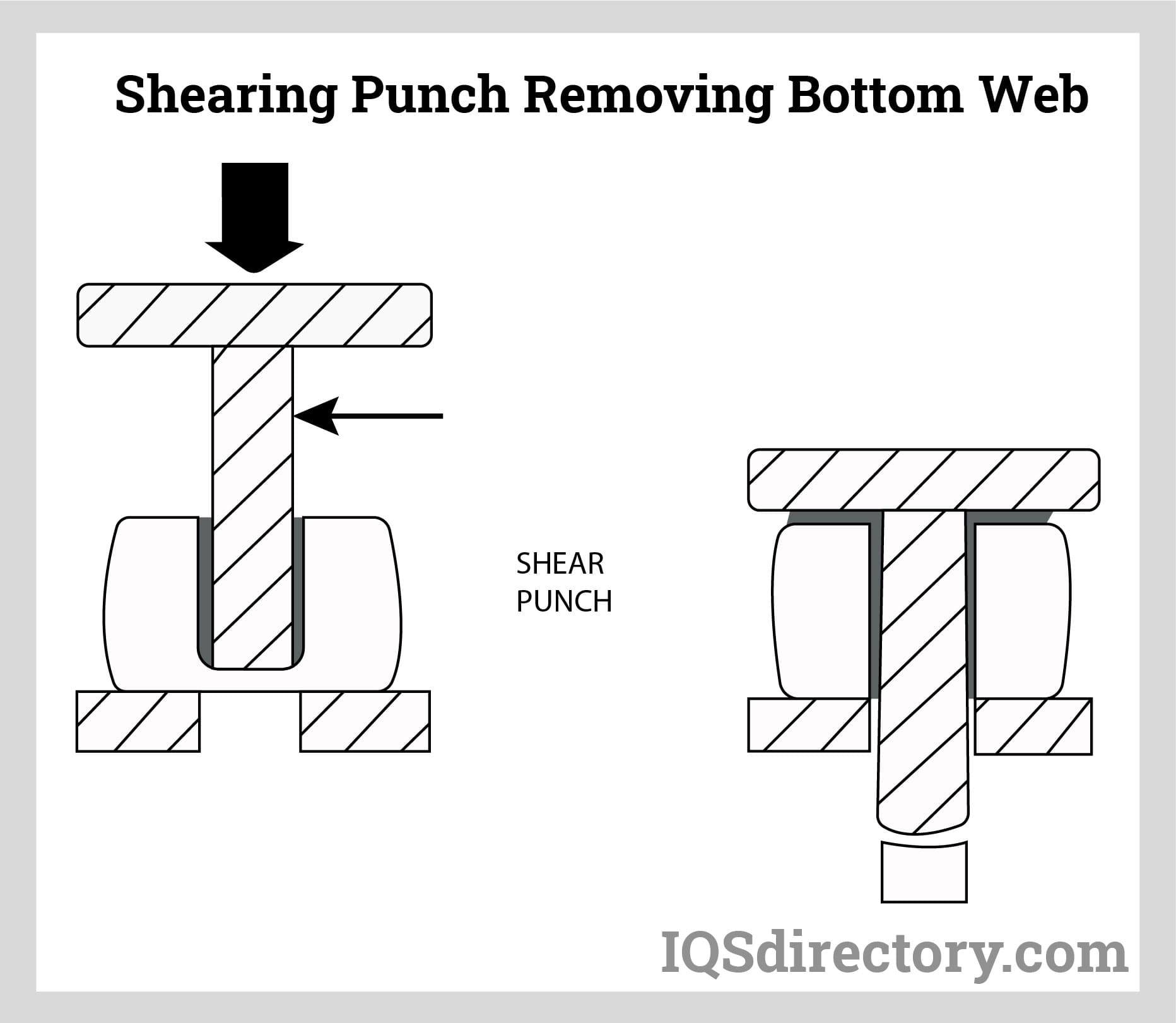

In the seamless rolled ring forging process, it is necessary to remove the center of the workpiece. This step, known by various terms such as punching or shearing, involves creating a hole in the middle of the workpiece. The spacing between the die and punch is determined by the workpiece's thickness and strength, which also influences the load or pressure applied at the tool’s cutting edge.

The piercing process results in a round doughnut-shaped piece. Unlike drilling, piercing does not cut into the workpiece but rather creates an opening by pushing a punch that radically deforms the metal, leaving a thin web at the base of the hole. This is classified as a forging technique because it involves deformation rather than drilling or grinding the surface.

Various types of piercing processes exist, including lancing, shaving, cut-off, and parting-off. For preparing a workpiece for rolled ring forging, the method used is referred to as punching, as it involves punching through the center of the billet. The removed section is considered scrap and can be repurposed to create additional billets.

Shearing, used beyond rolled ring forging, serves the purpose of trimming and removing unwanted metal sections to prepare them for additional processing. This cold working method employs various tools, and in rolled ring forging, a punch is used as the shearing tool to finalize the piercing process by removing the web at the base of the hole.

For the workpiece or doughnut shape to fit properly over the mandrel or idler, its inner surface must be smooth and free of any obstructions. The shearing tool moves along the length of the pierced hole in a single stroke, cutting out the bottom web. This results in a fully completed hole that prepares the workpiece for the rolled ring forging process.

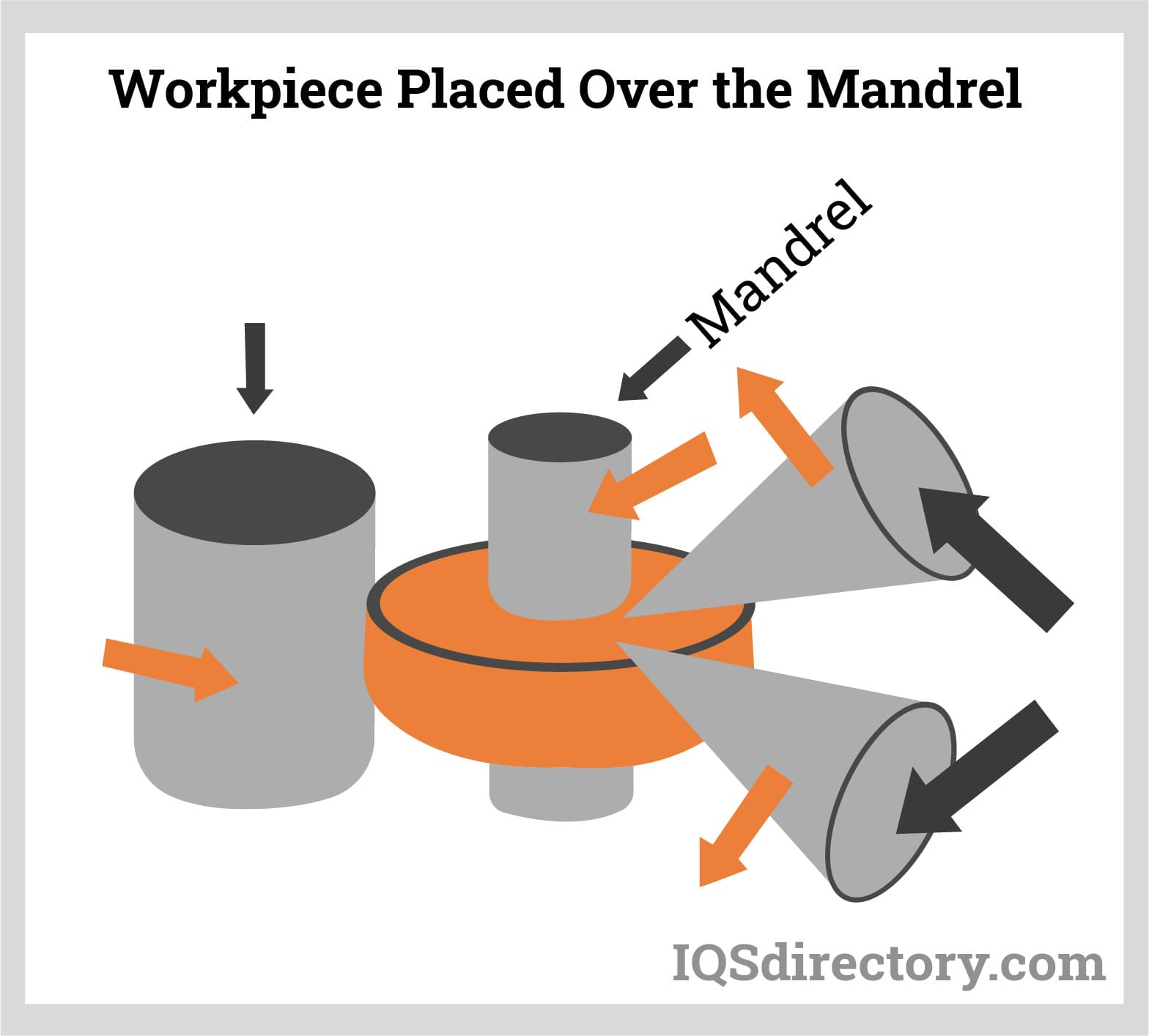

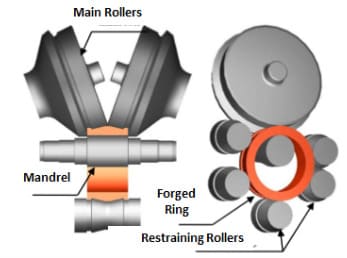

The piercing and shearing processes create a hole in the workpiece, allowing it to be positioned over the mandrel, a blunt rod used to shape the hole of the doughnut. Mandrels, also known as saddles or idlers, are typically made from steel or medium carbon steel, providing the strength and durability needed to apply the necessary force and endure the stress from pressing the workpiece.

Before being placed over the mandrel, the workpiece is heated to just below its recrystallization temperature. It is then rotated in incremental steps to forge the ring to its final dimensions and shape. The mandrel, saddle, or idler presses the doughnut-shaped workpiece against the drive roller, which increases its inner and outer diameters to achieve the desired final dimensions.

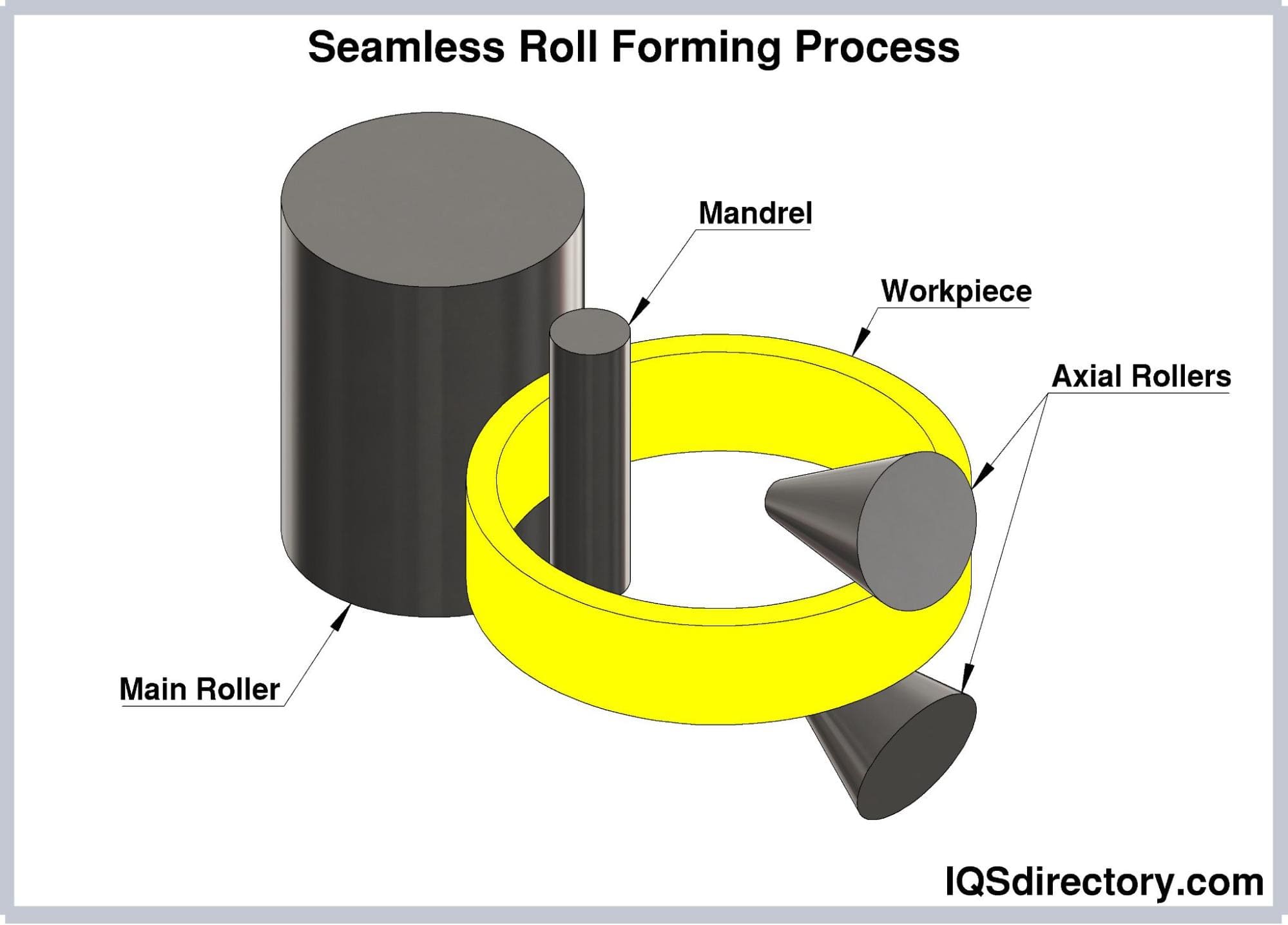

The shaping process starts with the gradual, incremental rotation of the preformed doughnut shape by the main roller. As the doughnut rotates, the mandrel presses against its interior, pushing it against the main roller. This combined rotation and pressure expand both the inner and outer diameters of the workpiece while thinning its walls.

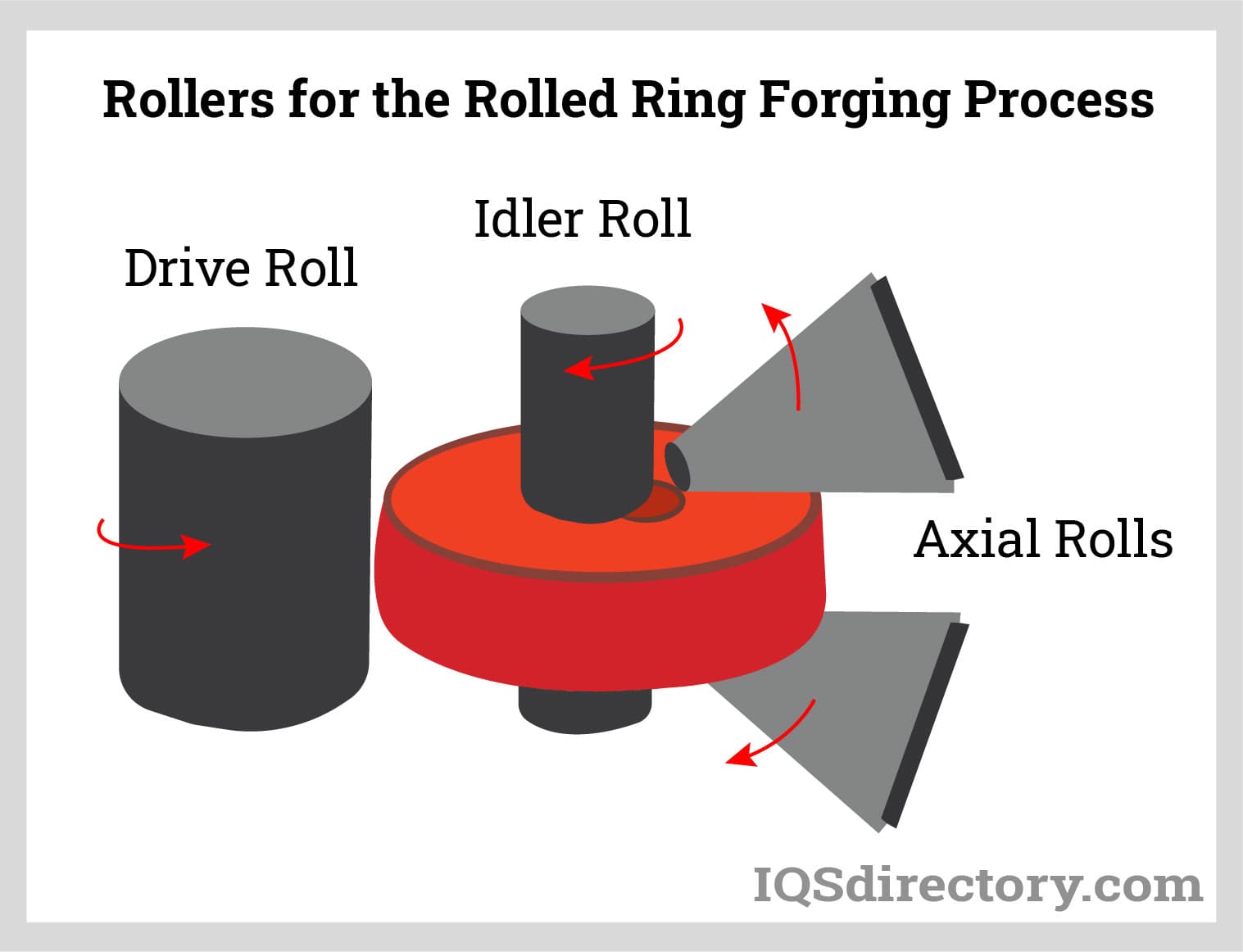

In the diagram below, you can see the main roller positioned to the left of the yellow workpiece, with the mandrel situated inside the workpiece to the right of the main roller. The mandrel presses the ring of the workpiece against the main roller. This process is conducted slowly and with high precision to achieve the correct dimensions and shape.

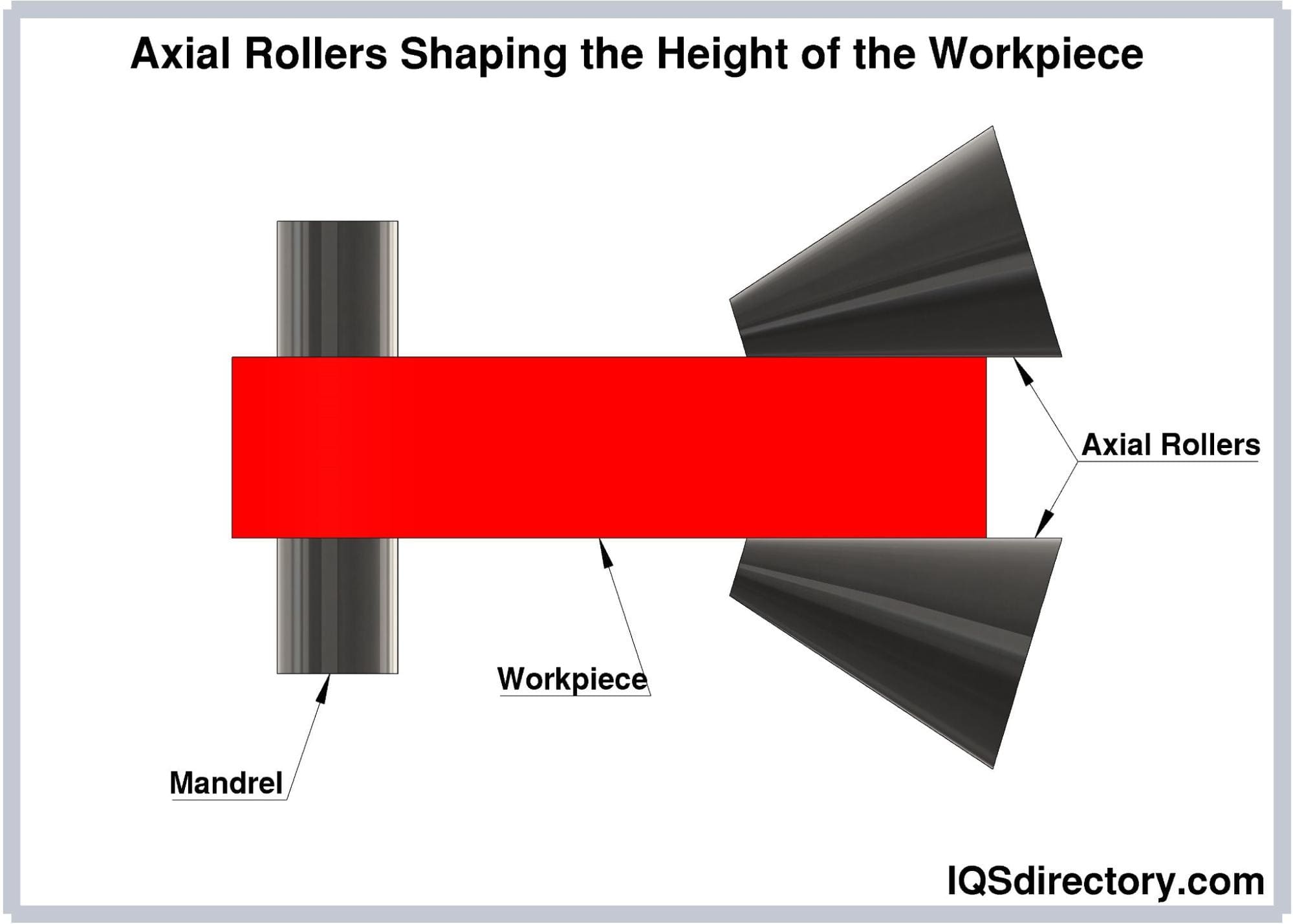

As the mandrel and main roller work to increase the diameter and thin the walls of the workpiece, the axial rollers focus on reducing the height of the workpiece's cross-section. The continuous and gradual rotation of the workpiece by the main roller and mandrel, combined with the axial rollers' motion, ensures that the workpiece maintains its grain structure.

Axial rollers are taper rollers mounted horizontally across from the mandrel and main roller, and they are vertically displaced. Their purpose is to compress and regulate the height of the workpiece as it rotates slowly between the idler and main roller. The combined movement of the idler and axial rollers shapes the workpiece's cross-section to the desired form.

The rotation and shaping of the workpiece persist until the final dimensions are reached. This process, known as seamless rolled ring forging, involves shaping the metal without cutting, welding, or further forging. The piece remains a solid, uninterrupted metal component throughout the entire process.

Finished products from seamless rolled ring forging are utilized in various applications, including components and parts for power plants, chemical plants, cargo ships, freighters, and windmills.

Rolled ring forging techniques are categorized based on the orientation of the rolling process, which can be radial, radial-axial, horizontal, or vertical. Each rolling method deforms the workpiece in a specific manner to create distinct shapes and grain structures. Additionally, these methods are suited for producing various ring profiles, including flanges, sheaves, and anti-friction rings.

Radial axial ring rolling is the classic form of rolled ring forming and involves the main roll rotating as the mandrel squeezes the workpiece and runs idle due to the friction on the contact surface. The axial rollers rotate at an inverse rate and withdraw as the diameter of the ring increases. As the diameter increases, the upper conical axial roller slides toward the lower axial lower, which causes height reduction in the ring. Guide rollers touch the outer diameter of the ring to keep it circular.

The radial-axial rolled ring forging process demands precise control of all three sets of rollers to ensure the final product's quality and performance. This control is achieved through a closed-loop system, which utilizes a single-point laser distance measuring tool for accurate monitoring and adjustment.

Radial rolled ring forging, also known as hot radial rolled ring (HRRR) forging, is a method used to manufacture medium-scale bearing rings. In this process, the HRRR mill’s main roller provides both rotation and linear feed, while the mandrel facilitates passive rotation. Guide rollers are positioned at the exit side of the main roller, with a signal roller placed on the opposite side. The process concludes when the outer diameter of the ring makes contact with the guide roller.

Throughout the rolling process, the ring's wall is compressed radially, causing the metal to expand tangentially. The axial direction of the metal is not constrained by a roller. This method is particularly effective for producing rectangular cross-sections, grooved shapes, and ten-shaped rings.

The traditional method for rolled ring forming is typically carried out on a horizontal rolled ring forging machine equipped with both radial and axial ring rolling mills. In the vertical variant of this machine, there are two main rollers, a mandrel, and several restraining rollers. The axles of the main rollers are inclined at an angle of 20 to 30 degrees from the horizontal and are driven by motors. The mandrel is driven idly by the ring being formed and is mounted on a lifting frame, which is raised by hydraulic controls to press the ring. The restraining rollers are strategically positioned to conform to the ring's diameter and to ensure its roundness.

Horizontal rolled ring forming is the most traditional and widely used method. In this process, the workpiece is moved radially, with a mandrel placed on the inner side of the ring to press against the ring wall. Axial rollers, located on the upper and lower or top and bottom of the ring, control its height. Centering rollers help maintain the ring’s smoothness and roundness, operating as idle rollers driven by the movement of the forged ring.

Numerous machines are available for rolled ring forging, playing a crucial role in modern industry. Rolled ring forging enables the efficient production of high-strength, seamless, and near-net-shape rings essential for critical applications in aerospace, energy, and automotive sectors. Below, we explore several prominent brands of machines utilized for rolled ring forging:

The RAW series from SMS Group is renowned for its sophisticated automation and precise control systems, delivering high throughput and accuracy in the production of rolled rings.

Siempelkamp’s RingRoller machines are engineered for rolled ring forging, featuring cutting-edge hydraulic systems, CNC controls, and versatile handling for various ring sizes and materials.

Ajax-CECO’s RRG (Rolled Ring Generator) is a versatile machine designed for rolled ring forging, boasting advanced control systems, high forming force, and customizable options to accommodate different ring sizes and materials.

Forging Equipment Solutions provides ring rolling machines for rolled ring forging, offering advanced controls, robust construction, and the ability to produce high-quality rings with precision and efficiency.

Scot Forge’s ring rolling mills are designed for rolled ring forging, providing precise control, effective material use, and the capability to create seamless, symmetrical rings with excellent mechanical properties.

Note that specific models, features, or components may have evolved since this information was provided. For the most current details on the latest models and capabilities, consult the manufacturers or industry resources.

The seamless rolled ring forging process accommodates a variety of materials, such as carbon steel, stainless steel, alloyed steel, Waspaloy, Inconel, and Hastelloy X. This method is known for its speed and cost-effectiveness in producing products with superior ductility, impact resistance, and fatigue strength.

The selection of metals for a project is determined by its intended use. Different metals offer distinct characteristics and properties, making them suitable for specific applications based on the required strength and durability.

Carbon steel is used for applications that do not require the strength and cost of stainless steel. The rolled ring forging process enhances the strength of the steel, which makes it more durable. The results of rolled ring forging of carbon steel forces porosity from the metal and creates a consistent grain flow. Unlike other ring manufacturing processes, the rolled ring process forms carbon steel to meet exacting tolerances to provide high quality performance.

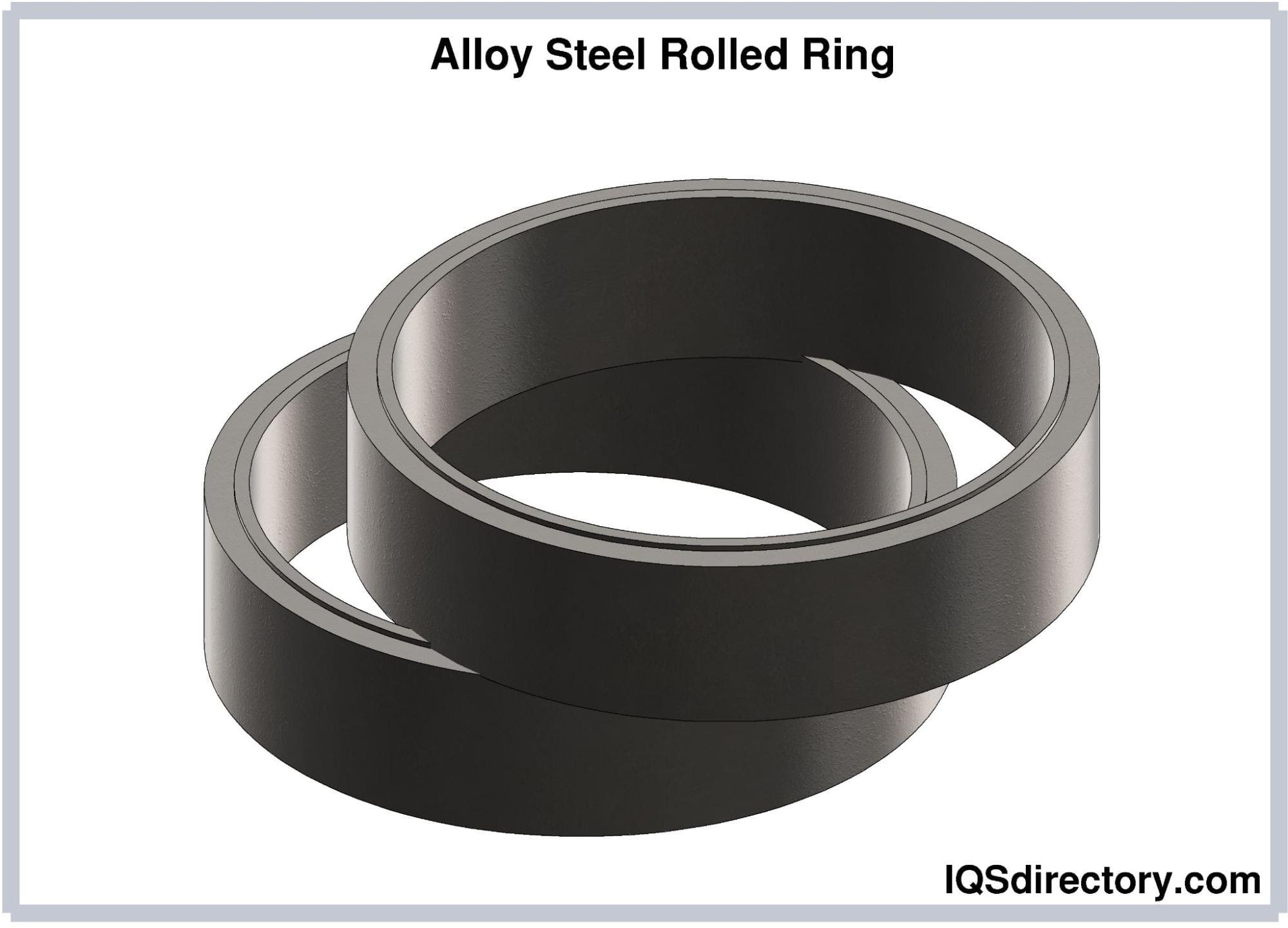

Alloy steels are created by blending various metals to produce a highly durable form of steel. The properties such as quality, strength, and resilience of alloy steel are influenced by the specific combinations of these metals. Carbon is frequently added to enhance the steel’s strength, with higher carbon levels resulting in increased hardness and reduced workability. It is primarily added when higher tensile strength is required.

Common metals combined with steel include:

The alloy steel grades commonly utilized in rolled ring forming include:

Rolled rings made from alloy steel can weigh anywhere from ten pounds to several thousand pounds, with variations depending on diameter and ring thickness. Various post-processing treatments can be applied to alloy steel to improve its durability and extend its lifespan.

Stainless steel is an obvious choice for use in rolled ring forging due to its exceptional strength, corrosion resistance, ability to be recycled, and long lifespan. Of the many selections of metals, stainless steel is the most popular and widely used.

Stainless steel is an iron-based alloy containing at least 10% chromium. Its distinctive properties are attributed to the chromium-rich oxide layer that forms on its surface. The term "stainless steel" refers to a broad range of metal grades, each with its own specific alloy composition.

Common grades of stainless steel used in rolled ring forging include A 182 and several grades from the 300 and 400 series. In addition to its strength and durability, stainless steel contributes to an attractive finish in the final rolled ring products.

Aluminum alloys offer several advantageous properties that make them well-suited for seamless rolled ring forging. Their notable tensile strength, toughness, and fatigue resistance facilitate the shaping of aluminum with an internal structure and circumferential grain flow. Additionally, aluminum’s superior surface finish is notably smooth.

Pure aluminum is seldom used in production unless corrosion resistance is prioritized over strength. To enhance the hardness and durability of aluminum, various alloys are incorporated into the rolled ring forging process.

Grades of aluminum alloys used in rolled ring forging include:

Titanium is lighter than steel but has an exceptional strength-to-weight ratio with corrosion resistance. It is a silvery-white metal protected by an oxide covering, enabling it to withstand acids and chemicals. In addition, the strength of titanium makes it capable of resisting erosion and metal fatigue. Though titanium has an excellent strength-to-weight ratio, it is much lighter and less dense than alloy steel.

Rolled ring forging enhances the formability of titanium, minimizing its tendency to spring back and reducing the likelihood of structural defects.

Hastelloy X is an austenitic nickel-based alloy composed of nickel, chromium, and iron, with a small amount of cobalt. It is renowned for its exceptional strength at high temperatures and resistance to corrosion. Hastelloy X’s properties include excellent resistance to heat, oxidation, chloride corrosion, and both reducing and carburizing environments.

This alloy is favored for rolled ring forging due to its ductility and suitability for cold working, as well as its ease of machining when in its annealed state.

Inconel is an austenitic nickel-chromium alloy known for its resistance to oxidation and its ability to maintain structural integrity under extreme temperatures and harsh environments. It also offers exceptional wear and corrosion resistance. With its high tolerances, Inconel is well-suited for specialized industries that demand precision and accuracy.

Seamless rolled forged rings are integral components in various industries, forming the backbone of critical machinery and equipment. Unlike other metal-forming processes that can weaken metals, seamless rolled rings are robust and durable since they originate from a solid metal piece. They are engineered to endure corrosion, high temperatures, and harsh environments.

The meticulous manufacturing process for seamless rolled rings ensures products with high tolerances that meet precise specifications. Each finished component is designed to fit its intended application exactly.

In oil extraction, transporting the oil through pipelines presents challenges, particularly regarding pipe connections. Concerns about leaks at these connections are addressed by using seamless rolled forged rings. These rings, produced to stringent specifications, ensure robust, leak-proof connections.

The hydraulic fracturing (fracking) process imposes significant stress on its components and connectors. Seamless rolled rings are ideal for this application due to their ability to withstand extreme stress without cracking, corroding, or failing at high temperatures. Their durability ensures dependable performance throughout the fracking process.

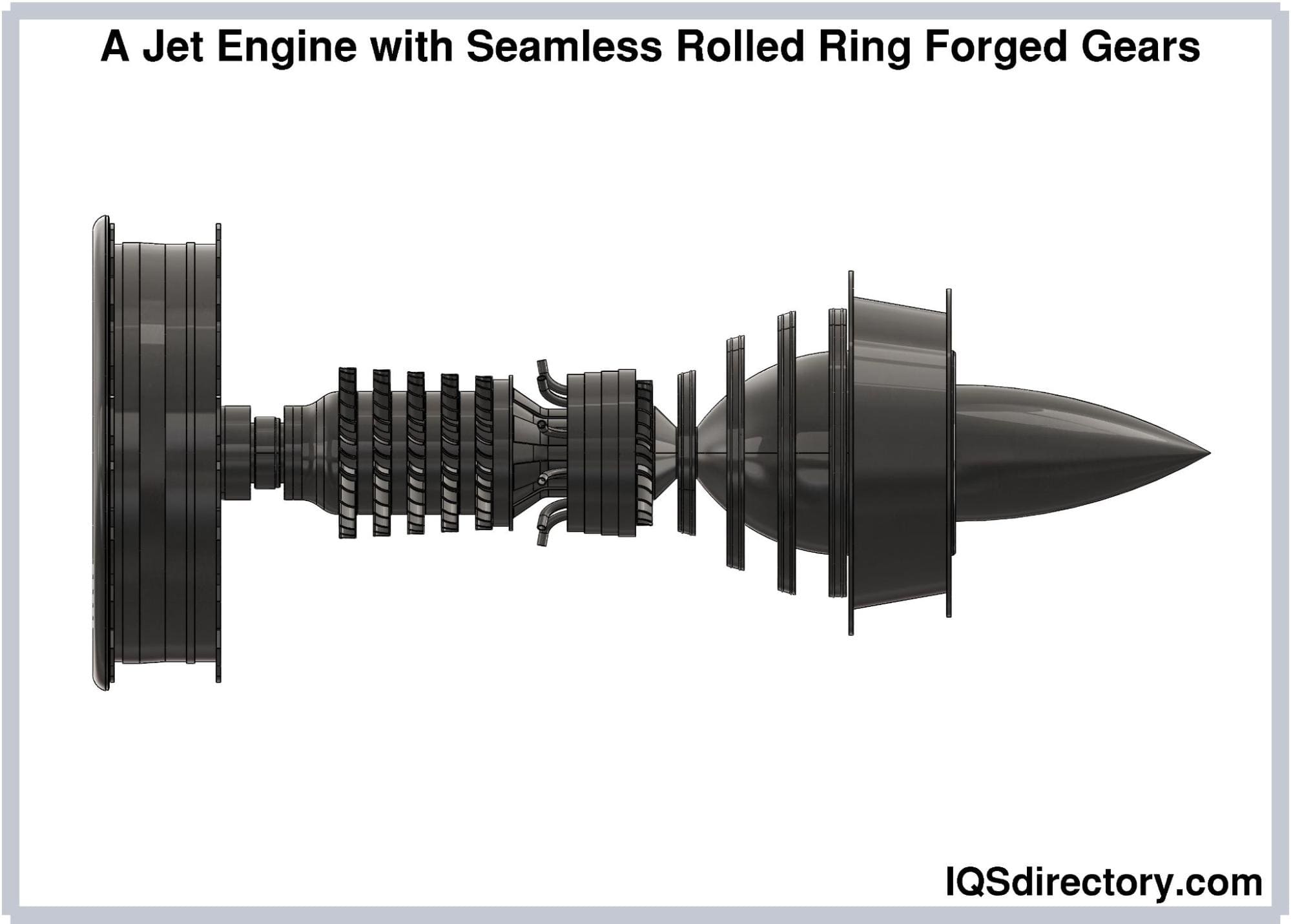

Gearboxes play a crucial role in aircraft operations, affecting both passenger and pilot safety. Constructed from highly durable metals and alloys, gearboxes are produced using the seamless rolled ring forging process to achieve high functionality and longevity.

In flight operations, the reliability of gearboxes is paramount to avoid mechanical failures. Seamless rolled ring forging creates lightweight yet strong gears and bearings essential for jet engines and helicopters, ensuring they meet rigorous aircraft standards while maintaining resilience and dependability.

Seamless rolled ring forged components are integral to every part of a wind turbine, making them crucial for turbine construction. Their precision, durability, and strength make seamless rolled rings the preferred choice for ensuring that wind turbines operate efficiently and reliably.

The main shaft of a wind turbine is engineered to endure constant fluctuations in both axial and radial loads. Seamless rolled rings function as bearings to help the shaft manage these varying forces effectively.

Wind turbines experience continuous wear and tear, which is why seamless rolled ring bearings are essential. These bearings are designed to handle the stress, preventing potential breakdowns and energy losses.

Additional components of wind turbines made with seamless rolled ring forging include flanges for connecting tower sections, gears, and couplings that manage the torque between the gearbox and the generator.

Vehicle components must withstand substantial loads and stress, requiring parts that can endure these conditions to ensure proper functioning. Seamless rolled ring forged components are integral to various vehicle systems, including trucks and cars. Parts such as crankshafts, camshafts, clutches, braking systems, gears, and couplings are manufactured using this process. These high-quality components are designed to handle frequent wear, pressure, and stress encountered during daily use. They offer a combination of lightness, versatility, and resistance to continuous torque.

The types of rolled ring forging are categorized by the metals used, including stainless steel, alloy steel, and carbon steel. These general categories represent a broader range of metals that can be forged using the rolled ring process. Strength and toughness are essential qualities for metals shaped through rolled ring forging due to the significant stress applied to the workpiece.

Modern manufacturing demands the production of strong, durable products with extended lifespans. Seamless rolled ring forging is a process that meets these requirements, producing robust components and parts designed to endure various conditions.

Seamless rolled ring forging is versatile and can produce a wide range of bearings, gears, couplings, and connectors from various durable metals. The seamless nature of the process contributes significantly to the strength and longevity of the components.

The popularity of rolled ring forging stems from the exceptional strength of its forged parts. In extreme conditions where other components might fail, rolled ring forged parts maintain their durability and performance, even at very high temperatures. This resilience makes them ideal for use in jet engines, windmills, paper mills, and oil refineries.

The high temperatures involved in rolled ring forging result in grain patterns that impart extraordinary strength and resistance to the final products.

Despite the complexity of the rolled ring forging process, the final products are surprisingly cost-effective. In fact, rolled ring forging is often more economical compared to other forging and fabrication methods. Unlike seamless rolled ring forging, alternative processes typically involve extensive handling and machining, which can drive up costs.

Additionally, low tooling costs and quick setup times contribute to reduced production expenses. The use of a single piece of metal for workpieces minimizes waste, enhancing production efficiency.

Seamless rolled ring forged parts can be made from a wide range of metals, including high-tensile stainless steel and various copper alloys. This versatility allows customers and producers to select the exact material needed for their specific application, ensuring optimal performance and suitability.

The manufacturing process of seamless rolled ring forging involves processing metals near or at their recrystallization point during shaping and formation. This approach ensures that the final product can withstand and endure high-temperature environments, thanks to the careful handling and treatment of the metals throughout the process.

Aluminum forging is a method for processing aluminum alloys using pressure and heat to form high strength, durable products. The process of aluminum forging involves pressing, pounding, and...

Cold forging is a metal shaping & manufacturing process in which bar stock is inserted into a die and squeezed into a second closed die. The process, completed is at room temperature or below the...

Copper and brass forging is the deformation of copper and brass for the purpose of manufacturing complex and intricate shapes. The temperature at which copper and brass are forged is precision controlled and...

Forging is a metal working process that manipulates, shapes, deforms, and compresses metal to achieve a desired form, configuration, or appearance outlined by a metal processing design or diagram...

In this article, there are key terms that are typically used with open and closed die forging and it is necessary to understand their meaning. Forging is a process in manufacturing that involves pressing, hammering, or...

Forging steel is a manufacturing process used to shape steel by using localized compressive forces, which include hammering, pressing, and rolling. It is a widely used method for producing high quality steel products...

The ancient art of forging falls into two distinct categories – hot and cold where hot forging has been around for centuries while cold did not begin until the industrial revolution of the 19th Century. Though they are quite different ...

Aluminum casting is a method for producing high tolerance and high quality parts by inserting molten aluminum into a precisely designed and precision engineered die, mold, or form. It is an efficient process for the production of complex, intricate, detailed parts that exactly match the specifications of the original design...

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish...

Sand casting is a manufacturing process in which liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then allowed to solidify. Casting is a manufacturing process in which...

Zinc die casting is a casting process where molten zinc is injected into a die cavity made of steel that has the shape, size, and dimensions of the part or component being produced. The finished cast zinc product has...

The casting process is an ancient art that goes back several thousand years to the beginning of written history. The archeological record has finds that document the use of the casting process over 6000 years ago around 3000 BC or BCE...