Metering Pumps

A metering pump is a precision mechanical device that moves or pumps a measured amount of a fluid or liquid in a predetermined time period to create an accurate and exact volumetric flow...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in depth look at level switches and their use.

You will learn more about topics such as:

A level switch is a device—either electrical or mechanical—that helps monitor the levels of liquids, powders, or bulk materials. Its purpose is to activate an alert when the contents inside a container hit a predetermined height or depth. When the level switch senses the tank is at capacity, it signifies full or upper-level detection. On the other hand, if the substance level drops below a specific threshold, indicating a nearly empty tank, the switch sends a low-level or empty detection alert.

Level switches play a vital role in production processes, especially in challenging environments characterized by extreme temperatures, pressures, and constant vibrations. Their flexibility makes them suitable for measuring a wide array of products across different settings. The precision, dependability, and robustness of level switches are critical for ensuring the smooth operation and efficiency of industrial applications.

Level switches come in various types to suit different products and applications. They serve as measurement devices, monitoring controls, or warning alarms, such as signaling when to activate or deactivate a mechanism. Depending on their design, level switches can have either mechanical or electrical outputs and can be configured as open or closed.

Among the many types of level switches, the most commonly used include inductive, thermal, float, rotating paddle, and ultrasonic switches. These are typically employed in tanks, silos, and various storage bins. For managing fluid levels, level switches are often integrated into control valves or pumps to help regulate tank levels and prevent overflows.

Level switches are categorized into point and continuous types. Point level switches include optical, horizontal float, vertical, and ultrasonic varieties. Continuous level switches encompass submersible, ultrasonic, and capacitive models. The choice of level switch depends on the specific measurement requirements and environmental conditions.

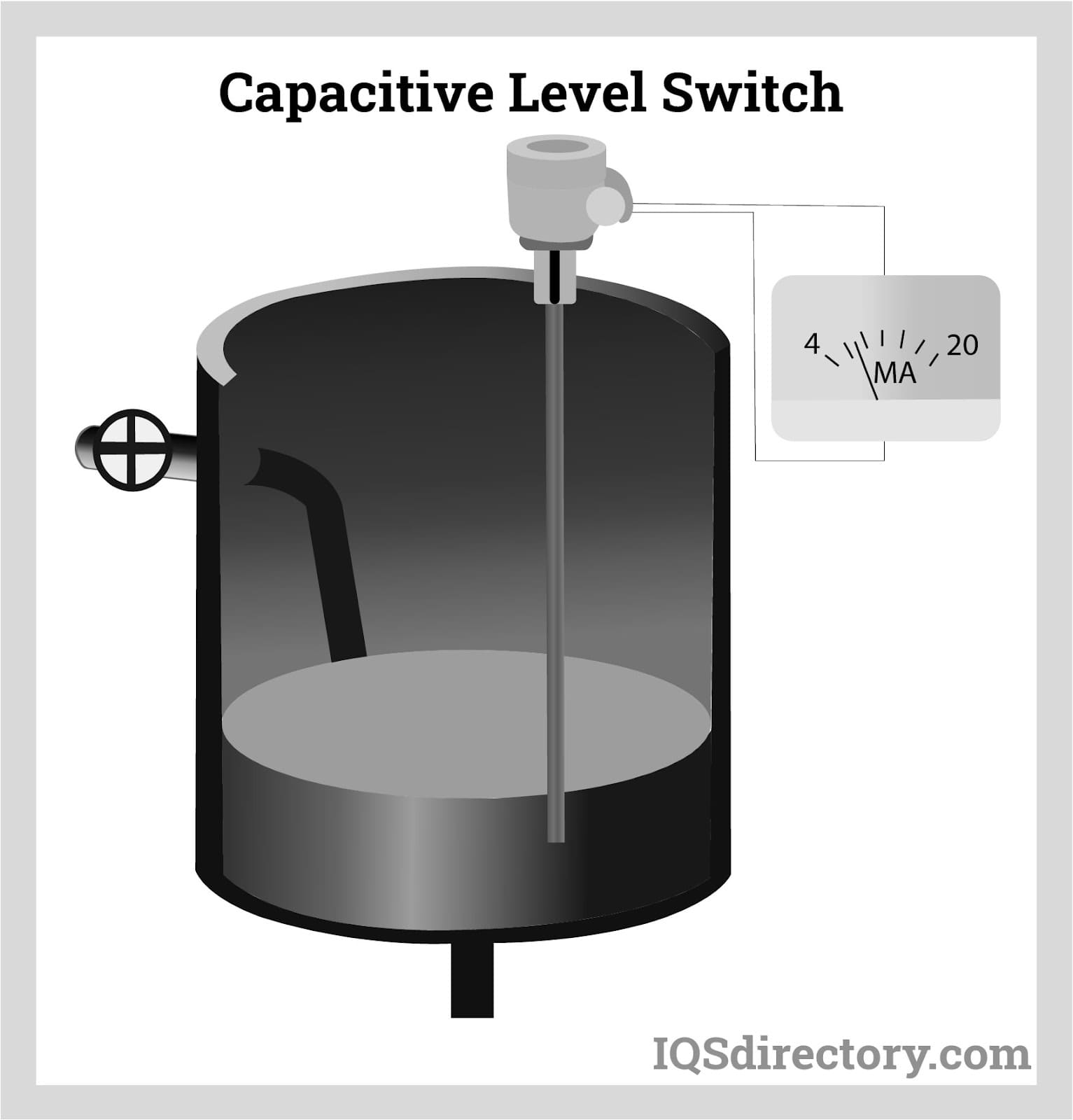

Capacitive level switches are designed to measure corrosive liquids, high temperatures, and liquid levels within sealed containers. They operate based on the principle of capacitance. These switches feature an electrode that adjusts its capacitance—its electrical charge ratio—when the level of the medium changes. This variation in capacitance is converted into a current signal, which is then sent to a secondary instrument or computer for further processing.

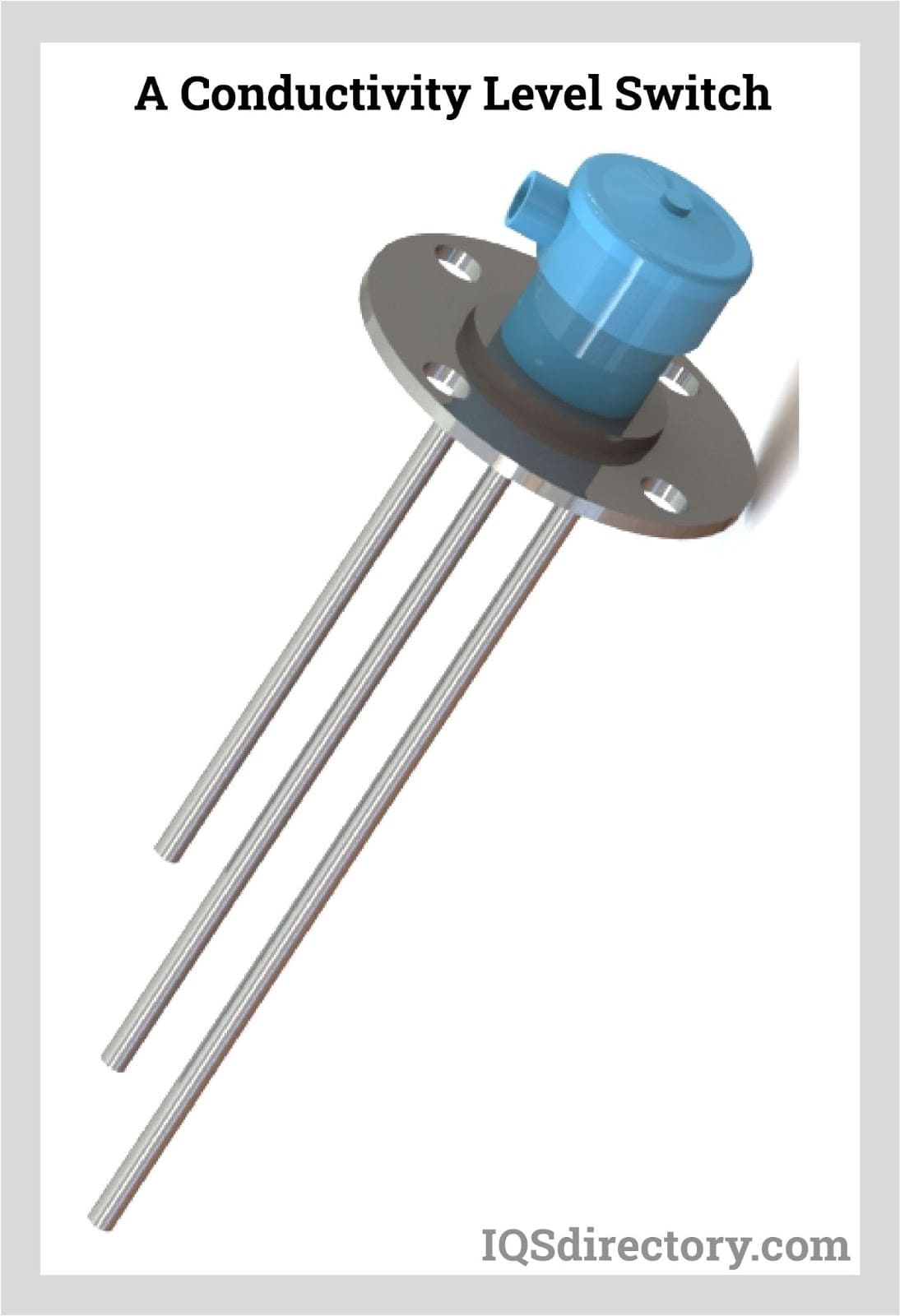

Conductivity level switches utilize advanced and highly sensitive sensors to detect even minor changes in liquid levels. These switches feature conductive probes with insulated electrodes, leaving only the tips exposed to prevent electrical bridging. The probes operate by measuring variations in electrical resistance between them, with one probe serving as the reference electrode and the other as the level control electrode.

The conductivity electrodes detect resistance levels when they come into contact with the medium. In some cases, an electrically conductive tank wall can substitute for one of the electrodes.

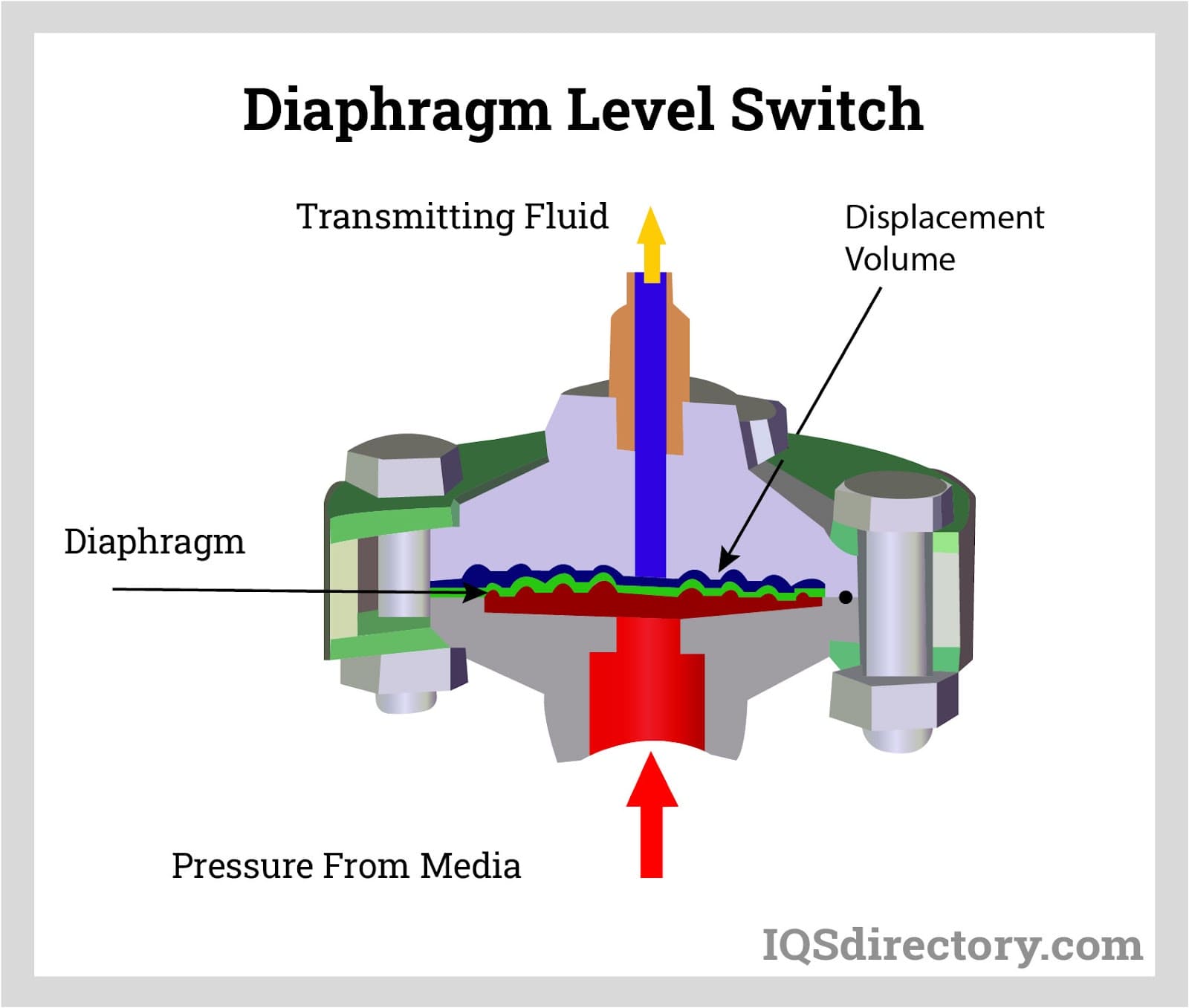

A diaphragm level switch measures pressure changes due to the rising or falling level of a material. As the level increases, the air pressure rises, causing the diaphragm's face to move under the pressure and activate a micro switch. When the pressure decreases, the diaphragm returns to its original position. Diaphragm level switches feature electrical contact outputs and are widely used in industrial applications.

Displacer level switches are designed to work where there are high temperatures and pressure. They have a weight, which is its displacer, suspended on a spring that is heavier than the media. When the media makes contact with the displacer, buoyancy force is produced that changes the weight of the displacer and causes the spring to retract. As the spring retracts, it sends a magnet upward that actuates the switching element.

In certain setups, three or more displacer level switches can be employed to monitor a medium at different levels.

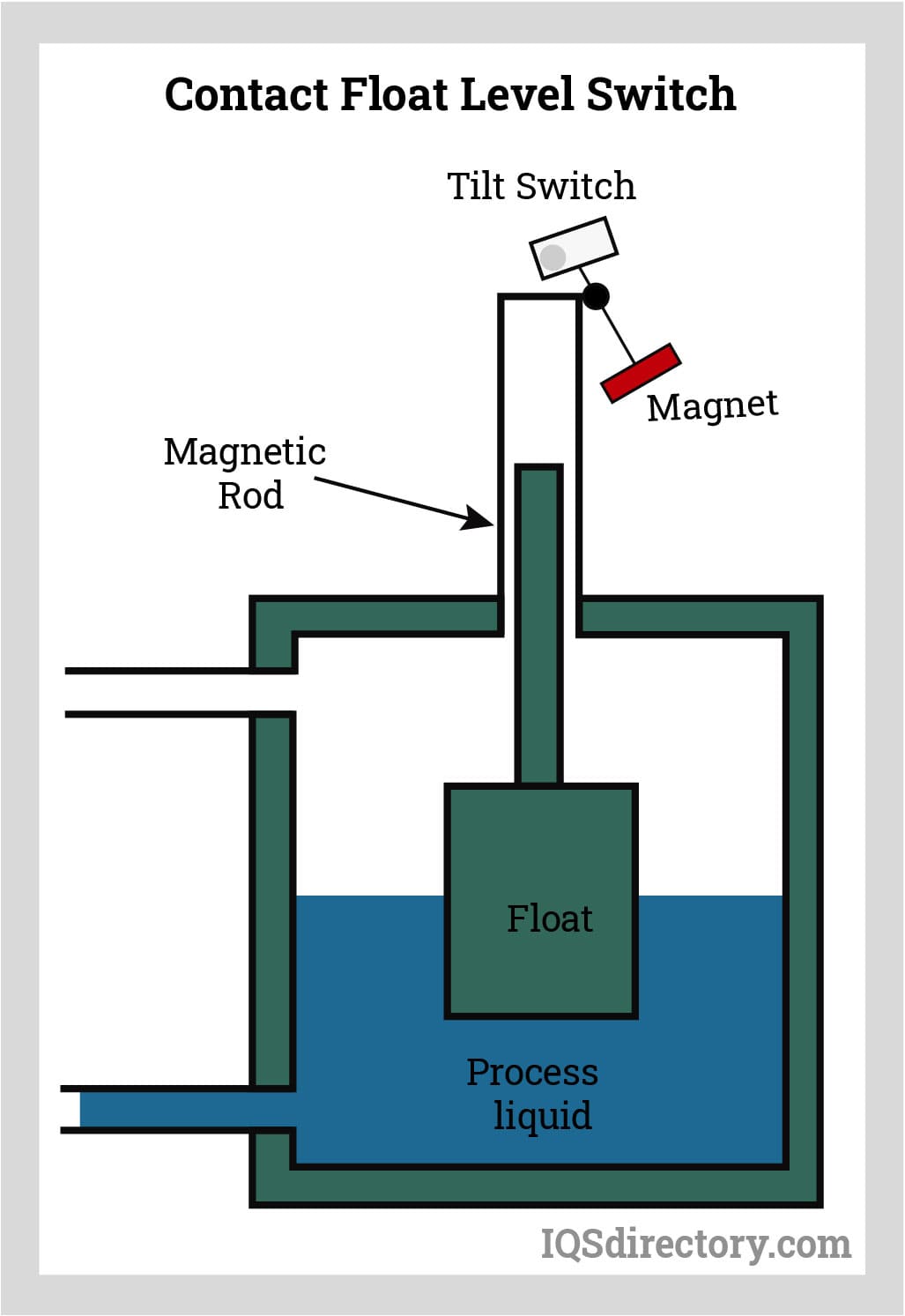

A float level switch is a mechanical switch that floats on the surface of the media and moves up or down as the media rises or falls. They are commonly used with pumps, valves, or alarms. Float switches are a cost effective and reliable level switch that can be used with a wide variety of media.

A float switch is built with a hollow body that houses a switch or sensor, typically a reed switch with an internal magnet. The switch operates by opening or closing in response to gravity and the media level. Float switches are calibrated to activate when the level exceeds predetermined limits. When triggered, the switch sends a signal to control a connected device, causing it to open or close.

Hydrostatic level switches are a threshold contact that contains a pressure switch or pressure sensor placed in a solid state NPN or PNP switch. All liquids are influenced by gravity and produce hydrostatic pressure, which is similar to the weight of a solid object. With liquids, it is possible to measure the weight of the liquid in relation to its level. The weight of the liquid at different levels is proportional to a specific level.

Hydrostatic level switches are used for continuous level measurement and are typically mounted on the side of a container. They can be attached via a flange, threaded port, or sealed clamp.

Inductive level switches operate without direct contact, detecting a material when it enters the sensing range. They use an oscillator circuit with an open core coil to generate a focused high-frequency electromagnetic field. When the material moves into this field, it creates eddy currents.

As the material is detected, the oscillation amplitude of the unit decreases, causing the oscillator's signal to weaken. This reduced amplitude triggers a change in the electronic circuit, altering the switching state of the inductive level switch.

A laser sensor is a non-contact level switch that measures levels by using the speed of light. It operates with a laser transmitter positioned at the top of the container, which emits a short pulse of light toward the surface of the process material. The light then reflects back to the detector. Similar to ultrasonic level switches, the sensor uses a timing circuit to measure the time of flight (ToF) to determine the distance.

Laser sensors are advantageous due to their precise beam focus and lack of false echoes, making them effective in narrow spaces. They are highly versatile, capable of measuring through vapors and foam.

A magnetostrictive level switch measures fluid levels by detecting the position of magnets within a float and transmitting this data to the control system. This method leverages buoyancy, magnetostriction, and electronic components. The float, which moves up and down with the fluid level, is mounted on the level transmitter stem and contains a magnetic element.

In operation, an electrical current pulse travels along the sensor wire to the float's location. A timing circuit measures the time taken for the pulse to return, providing the information needed to determine the float’s position and the fluid level.

Microwave level switches are non-contact devices that use a microwave beam transmitted in bursts at a frequency of 220 times per second. The beam travels from a sender to a receiver, and if the bursts are interrupted—either absorbed or reflected by the material—the relay is activated.

Microwave sensors are particularly useful in environments where contact sensors would be eroded or damaged, and they are effective in high temperature, high pressure, and with aggregate materials.

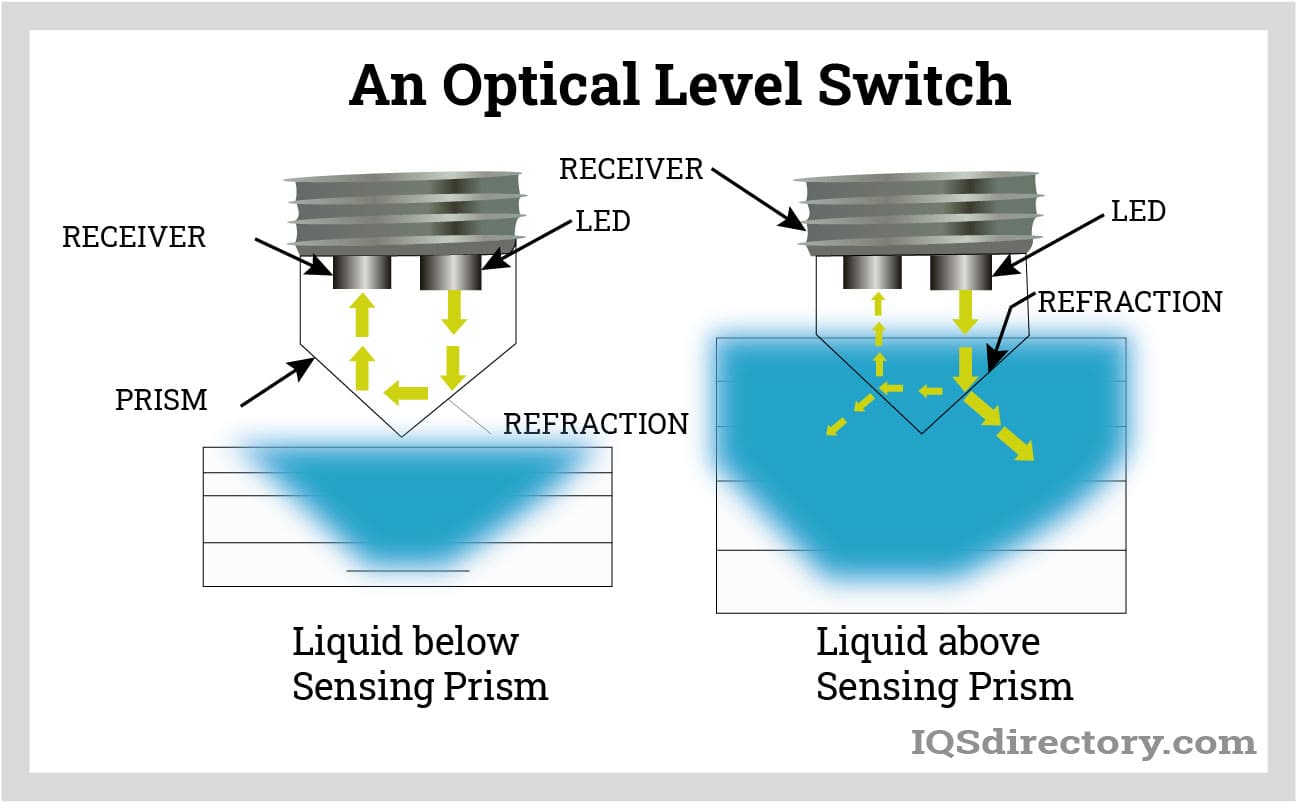

An optical level switch uses the concept of reflection in a prism and is used for high temperature and pressure applications. It can be used as a point level detector and continuous measurement level switch for solids and liquids. A reflected light is sent to the receiver of the sensor and is refracted by the liquid being monitored.

The main components of an optical level sensor are an infrared LED and a light receiver. The sensor detects level changes by emitting infrared light from a diode towards a cone-shaped prism. When the cone is above the liquid, the light is reflected back to the detector. If the cone is below the liquid level, the light is not reflected. In the absence of returned light, the detector activates an alarm or control mechanism.

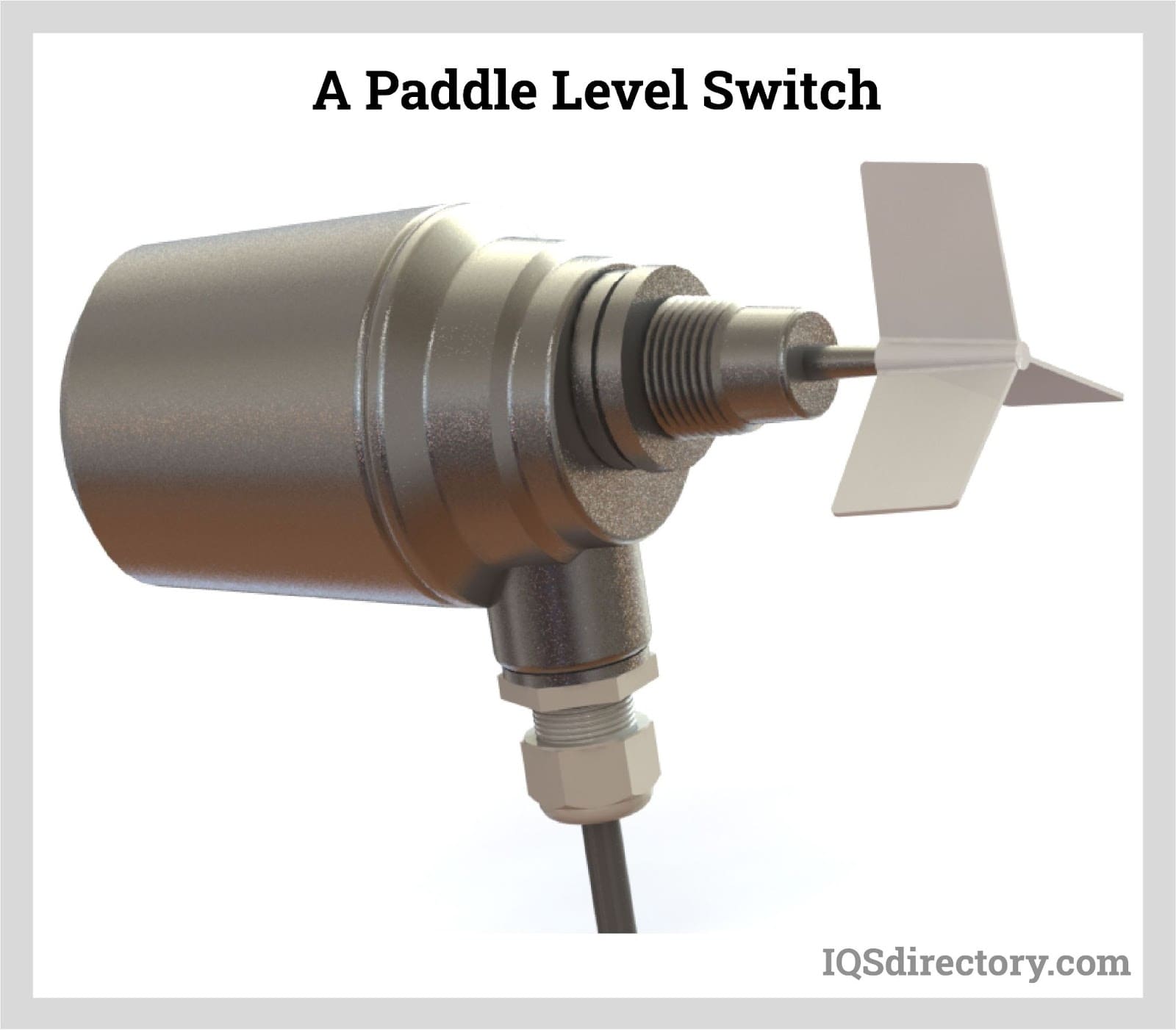

A paddle level switch features an electric motor that rotates a metal paddle slowly. When the material in the container reaches the paddle, it exerts a load on it. A torque switch, attached to the motor, activates when the paddle experiences sufficient torsional stress.

Paddle level switches are designed for point level detection in dry bulk materials. The paddle is driven by a one RPM magnet-driven motor. As material accumulates in the container, it blocks the movement of the paddle, triggering an alarm.

Potentiometric level switches are continuous level switches used in metal containers. They involve a low resistance measuring tube immersed in a conductive liquid, such as an adhesive or paste. A high-frequency current is sent through the tube, and a voltage reading is taken from the space between the probe and the tank wall. This reading is sent to an amplifier and is proportional to the liquid level in the tank.

Rod level switches consist of a stainless steel rod that vibrates or oscillates at a specific frequency, driven by an electronic circuit. When the material reaches the rod, it disrupts the vibrations, signaling the control system. These switches are commonly used for detecting high and low levels or identifying clogged chutes. They are engineered to minimize material accumulation, which helps in reducing false alarms.

Thermal level switches detect variations in temperature between the vapor space and the liquid or changes in thermal conductivity when a probe is submerged in a liquid. These switches use a heated thermal resistor or thermistor that maintains a constant temperature. The switch is triggered when the temperature of the thermistor decreases significantly due to immersion in the liquid.

Various types of thermal level sensors include those with two resistance temperature detectors (RTDs).

Because heat disperses more rapidly in liquids compared to gases or air, the resistance of the thermistor probe experiences a notable change when immersed in a liquid. Thermal level switches are capable of measuring temperatures up to 1000°C accurately.

Tilt level switches are high level indicators that are suspended on a cable above the material. As the media rises and contacts the switch, the switch tilts to the side. Tilt level switches are designed to prevent bin overflow and control levels in open pipes. They are also used for over or under loads for conveyor systems.

The sensor triggers when tilted at an angle of 17° within a full 360° range. It features a threaded bore for actuator attachment, enhancing sensing accuracy and safeguarding the switch from direct contact with the media.

Tuning fork level switches detect changes in liquid levels through variations in frequency. These switches contain two tuning forks that oscillate within a circuit, initially vibrating at the frequency of air. When immersed in a medium denser than air, such as a liquid, the forks' vibration frequency decreases.

The tuning forks protrude from the switch housing and come into contact with the medium. As the medium contacts the forks, the resonant frequency feedback alters, signaling a change in the level of the medium.

A level switch is engineered to perform a specific function: to alert controllers when there is an issue with the level or presence of a product. It triggers an alert when the detected level deviates from the set parameters. Upon receiving this alert, the system might activate equipment such as a pump or open a valve to take corrective measures.

Essentially, a level switch adds an additional layer of protection and control, enhancing system efficiency and safeguarding sensitive components. Despite the precision of a system, errors in readings can happen. Level switches are crucial in preventing overfills, minimizing waste, and addressing other potential issues.

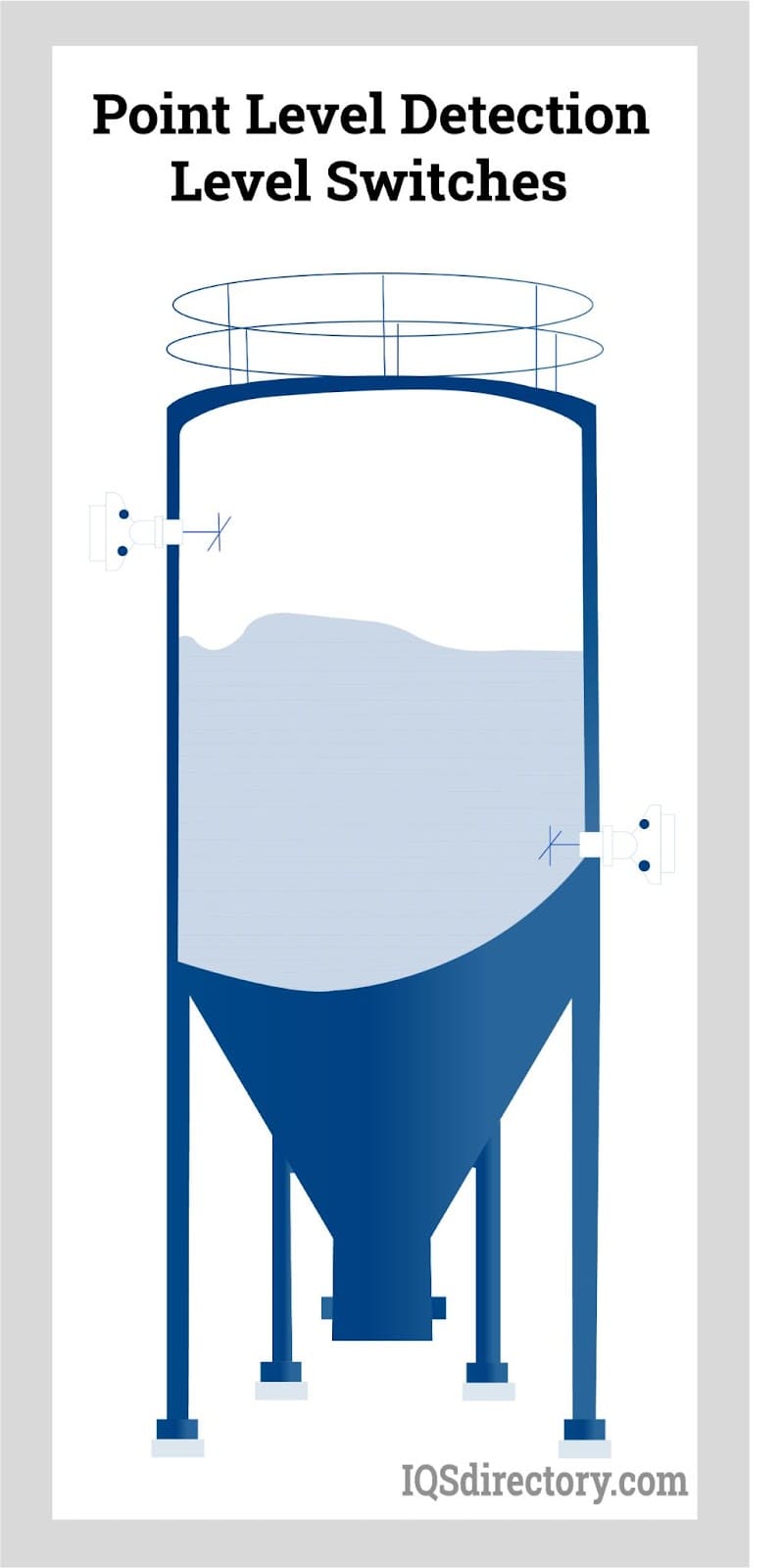

A point level detection switch is set to activate when a specific predetermined level is reached. Common types of point level switches include capacitance, ultrasonic, rotary paddle, and tuning fork or rod vibration sensors. Typically, a point level detection system includes two switches: one for monitoring the high level and another for the low level.

The high-level switch prevents the container from overflowing by signaling when it reaches its maximum capacity, while the low-level switch triggers an alert to indicate that the container is running low and needs to be refilled.

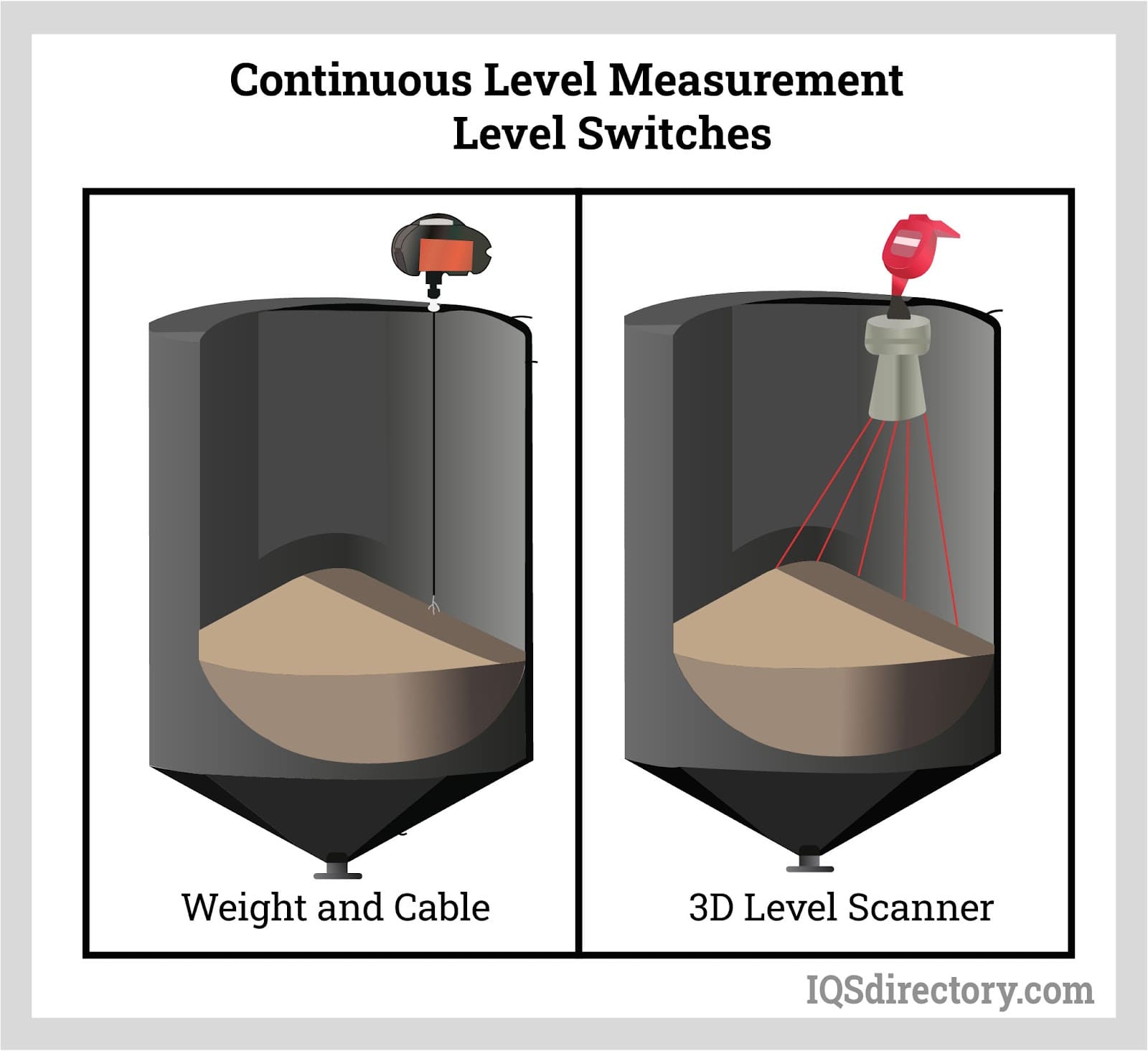

Continuous level measurement switches track and report the levels of materials within a container, offering ongoing data about the level of the media. These include technologies such as microwave, ultrasonic, capacitive, and float switches. Unlike point level detectors, continuous level measurement switches provide a comprehensive overview of the entire system by monitoring various levels to generate an analog representation of the container's fill status.

Continuous level switches can be installed in either horizontal or vertical orientations. They are designed to oversee and manage materials in confined or restricted spaces, ensuring precise and continuous monitoring. This capability is crucial for processes where maintaining accurate and ongoing level data is essential for operational efficiency.

Level switches that operate through direct contact with the substance being measured include types such as floats, conductive sensors, and vibrating or tuning fork devices. These switches offer a simple and economical solution for level measurement. Unlike their non-contact counterparts, contact level switches tend to have a more basic design and fewer features. When selecting contact level switches, it is crucial to consider the properties of the material being measured, including its corrosiveness, acidity, or reactivity. Despite their lower cost, careful selection is necessary to ensure compatibility with the medium.

These contact level switches function based on various mechanical principles and can be used to monitor both bulk solids and liquids. They operate using principles like buoyancy, employing floats, displacers, springs, or magnets to perform their measurements.

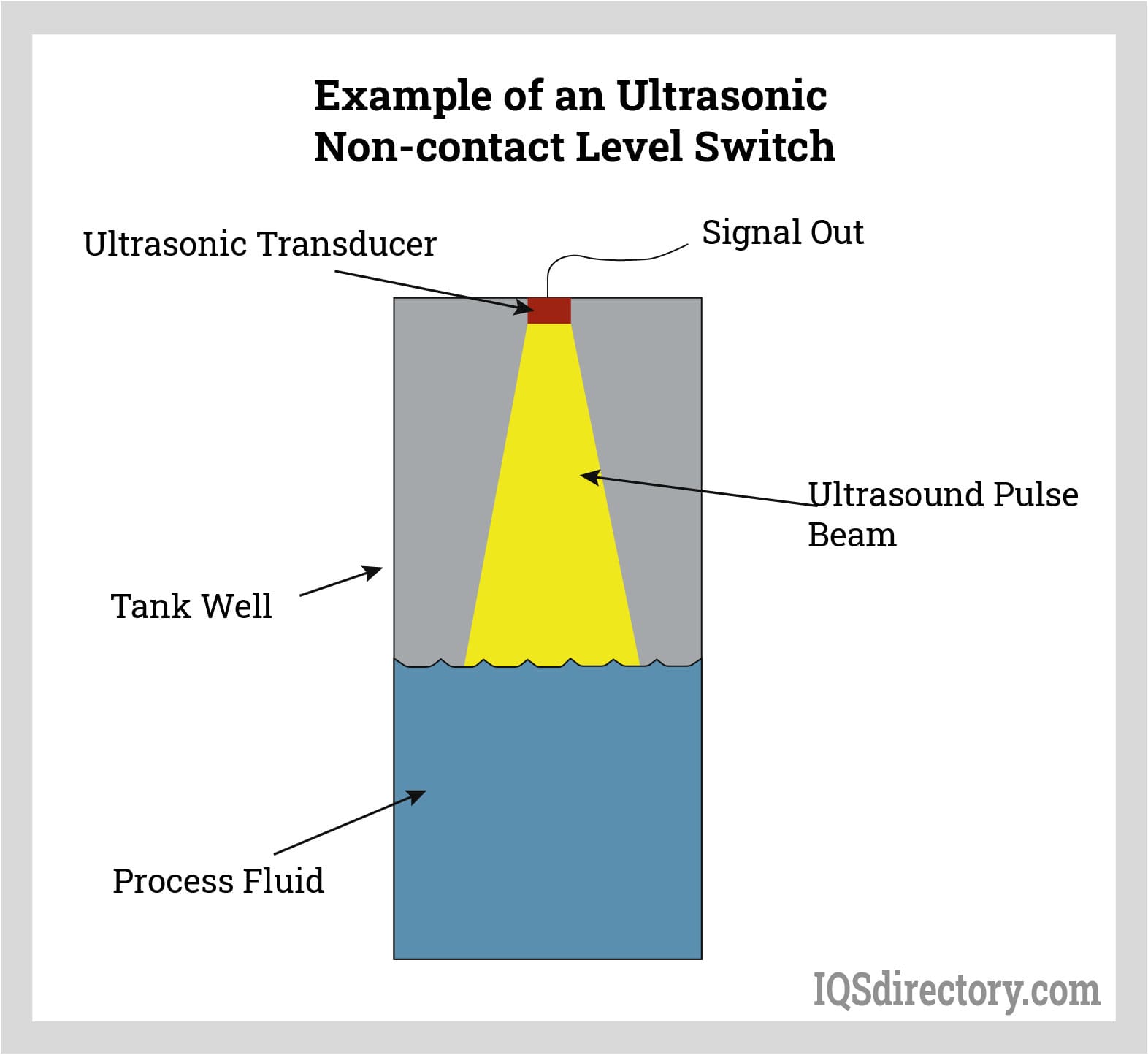

In some scenarios, it's essential to avoid direct contact with the medium due to its corrosive nature or properties that could affect the level switch's performance or accuracy. Non-contact level switches, which utilize the time of flight (ToF) method, offer a solution for continuous level measurement without physical contact with the material.

ToF technology calculates the distance by measuring the time it takes for waves to travel from the transmitter to the target and back. These devices emit either mechanical or electromagnetic waves that reflect off the surface of the material. By analyzing the time it takes for these waves to return, the distance between the sensor and the surface of the contents can be determined, indicating the level of the material in the container. For accurate readings, the medium being measured should have a low dielectric constant to minimize interference with the sensor's measurements.

While the operation of a level switch is relatively straightforward, it plays a crucial role in systems aimed at safeguarding both resources and equipment. For any operation involving bulk materials or liquids, managing and regulating the quantities and volume is essential. Although sophisticated software solutions exist for this purpose, level switches often serve as the primary tool for data collection and monitoring within these systems.

Level switches are vital for ensuring smooth operations and managing inventories by offering crucial data and measurements. They help identify discrepancies in volume and trigger alarms to alert users of potential issues.

The core element of a level switch is its sensor, which can be categorized into point level detection or continuous level measurement. Point level sensors include types such as capacitance, optical, conductivity, vibrating or tuning fork, and float switches. For continuous level measurement, the sensors used are typically ultrasonic, microwave, and radar.

Point level sensors are generally compact, cost-effective, and feature a simple design with no moving parts. They come into direct contact with the material and offer high accuracy. To maintain their precision, these sensors are calibrated according to the specific level and nature of the material being measured.

On the other hand, continuous level measurement sensors are characterized by their compact size, reliability, and the absence of moving parts. They do not come into contact with the material and remain unaffected by its properties, while also being self-cleaning. Despite their complexity and higher cost, these sensors are designed to handle various environmental factors, though they can be susceptible to issues like static electricity.

Level switches can transmit output signals using either serial or parallel communication methods, depending on their design and functionality. Serial output involves sending data in a sequential stream from a level switch to a computer or peripheral device, with clear start and end points for the transmission.

Serial output communication can be asynchronous, where the data stream is marked by start and stop signals to define its boundaries. Alternatively, synchronous serial communication uses timing to synchronize the data transfer, reducing the need for additional bits. Serial communication is advantageous for long-distance transmission and simpler wiring setups.

In contrast, parallel communication transmits data simultaneously across multiple wires, allowing the entire dataset to be received at once. This method enables rapid and reliable data transfer, though it requires that all bits arrive simultaneously, which can lead to longer processing times due to the bulk of data being handled at once.

Level switches can come with different types of displays, each offering varying levels of precision and accuracy. The three most prevalent display types used in industrial settings are analog, digital, and video displays. Typically, computers are employed to manage and interpret the data provided by these displays.

Some level switches feature integrated unit displays, allowing users to adjust settings directly on the switch itself.

Level switches offer a cost-effective solution for overseeing and managing the levels of bulk substances and liquids. Effective control of raw materials is crucial for minimizing waste and enhancing efficiency in manufacturing processes. In today’s competitive environment, even minor discrepancies can significantly impact production and product development.

The seemingly modest size of level switches might lead some to underestimate their importance. However, investing in these devices can greatly improve the efficient use of raw materials.

Managing the storage of bulk and liquid materials helps to prevent waste from spills and overflows. A well-configured level switch can trigger valves or pumps to manage overflow and prevent losses. Continuous level measurement switches maintain the right amount of raw materials consistently, while point level sensors can alert users if a container is either too full or too empty.

In the modern business world, cost-saving measures are crucial for boosting profits. Protecting, monitoring, and controlling inventory and raw materials is essential to minimize losses. Despite advances in inventory management software, financial officers are aware that discrepancies often occur during official inventory counts.

The frequent occurrence of inventory losses requires ongoing asset monitoring. Tracking bulk materials and fluids can be particularly challenging due to their nature. Level switch manufacturers understand these challenges and offer a range of solutions designed to provide accurate data on raw material volumes and quantities.

Level switches, unlike traditional methods like floats or yardsticks, automatically deliver precise data to a computer without the need for manual intervention. If not connected to a controller, the data can still be accessed easily via digital or analog displays.

Historically, monitoring large storage containers required frequent manual checks, often leading to inaccurate or incomplete readings. Modern automatic reporting level switches have replaced these labor-intensive methods, streamlining the process.

Modern level switches are engineered to deliver reliable performance and accurate data. The durable casings and materials used ensure long-lasting precision. With minimal moving parts, level switches require little maintenance and are unlikely to fail. Routine calibrations might be necessary to maintain accuracy, but the likelihood of malfunction is very low.

Installing level switches, whether for continuous measurement or point detection, is straightforward and can be completed in one to two hours depending on the type. Their easy installation facilitates repositioning when storage configurations change.

Level switches are compact and portable, making them suitable for a variety of container sizes and shapes. Their small size allows them to fit easily into containers without obstructing the measurement process, ensuring accurate data collection.

Investing in level switches is justified by their high sensitivity and precision in data collection. Accurate and up-to-date information is essential for effective decision-making. Ensuring the correct quantity of material is transferred during production is critical, making level switches vital for inventory management and production efficiency.

There is a level switch available for virtually any type of material, including viscous slurries, tar, petroleum, grain, flour, and molten metals. This versatility allows level switches to meet a wide range of monitoring needs, proving their importance in production and processing operations.

A level switch is a device, either mechanical or electrical, designed to monitor and assess the levels within containers such as bins, silos, storage tanks, and other receptacles. These instruments help in maintaining materials within designated levels, ensuring they do not drop below or exceed predetermined points.

When selecting the appropriate level switch for your needs, several factors must be taken into account. These include electrical specifications, wire types, the positioning of the switch, the nature of the material being measured, and the method of mounting the switch.

Level switches are made from every type of material conceivable. When determining what level switch to buy, it is important that the level switch be compatible with the material it will be monitoring. Manufacturers make level switches from brass, stainless steel, and various forms of plastic. All of these materials can be used with wet materials that are non corrosive.

The chemical properties of the measured media can affect the performance of a level switch. This factor also plays a role in determining whether the switch should be an immersion type, such as a displacer or float level switch.

For a level switch to work properly, its electrical connection must match its power supply. Insufficient power supply or over supply can lead to poor performance of the level switch or non-activation.

Although it may appear straightforward, the way a level switch is mounted significantly affects its performance and functionality. Essentially, level switches can be mounted either horizontally or vertically, which represents the basic mounting options.

Mounting configurations also involve several considerations, including the size of the mounting hole, the location on the container (such as the side, top, or bottom), whether the attachment is threaded or unthreaded, and whether the switch is to be hung or wall-mounted. Each of these factors needs to be determined before purchasing a level switch.

Determining the reason for purchasing a level switch involves deciding in advance what type of data is needed and the method of measurement. All level switches are designed to provide accurate readings. The specific types of readings are influenced by how the level switch will be utilized. Typically, applications require two level switches: one to monitor the empty level and another to detect overfill.

It is essential to define the lowest acceptable level and how close the contents can come to the top of the container. These considerations are often determined by the container's dimensions and capacity.

Materials exert pressure due to their weight. When selecting a level switch, it's important to assess whether the materials being measured will apply pressure to the switch. In such cases, level switches made from materials capable of handling high pressure are available.

Level switches vary in their ability to withstand temperature extremes. The materials used and the type of wiring will dictate how much heat the switch can tolerate. While many level switches can handle a range of applications, only those specifically designed for high temperatures can endure conditions of 1000°C or above.

Different level switches provide various output types, such as relay, analog, or digital signals. The output type must be compatible with the controller receiving the data. Additionally, the choice of output may involve considering time delays, affecting whether to use parallel or serial output.

Level switches are compact and portable, which allows for easy handling. Although this is a common feature, some types of switches fit more easily into certain container sizes than others. This aspect, though seemingly straightforward, is often overlooked. The initial step in selecting a level switch is to measure the container size and determine the number of switches needed.

Some applications require progressive readings as the level of contents rises. This can be achieved using continuous level measurement switches or accurately positioned point level detectors.

A metering pump is a precision mechanical device that moves or pumps a measured amount of a fluid or liquid in a predetermined time period to create an accurate and exact volumetric flow...

A pressure gauge is a method of measuring fluid, gas, water, or steam intensity in a pressure powered machine to ensure there are no leaks or pressure changes that would affect the performance of the system. Pressure systems are designed to operate within a specific pressure range...

A pressure switch is a mechanical or electronic device activated by the pressure of the process fluid upon reaching a certain threshold or setpoint. A pressure switch can have a bourdon tube, piston, diaphragm, or membrane that moves or deforms according to the amount of pressure exerted by the system...

Battery powered sump pumps are very similar to any of the other types of sump pumps. When the water level reaches a preset level, the pump is activated by the float and water is pumped out. The main difference between a regular sump pump and...