Agitators

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

In this article, you will learn about high shear mixers. This comprehensive guide offers you the following:

High shear mixers, also known as high shear reactors, rotor-stator mixers, or high shear homogenizers, are highly specialized devices designed for emulsifying, homogenizing, dispersing, grinding, and dissolving immiscible mixtures. These tools function at high rotor tip speeds and shear rates, delivering concentrated energy dissipation and utilizing more energy compared to standard industrial mixers.

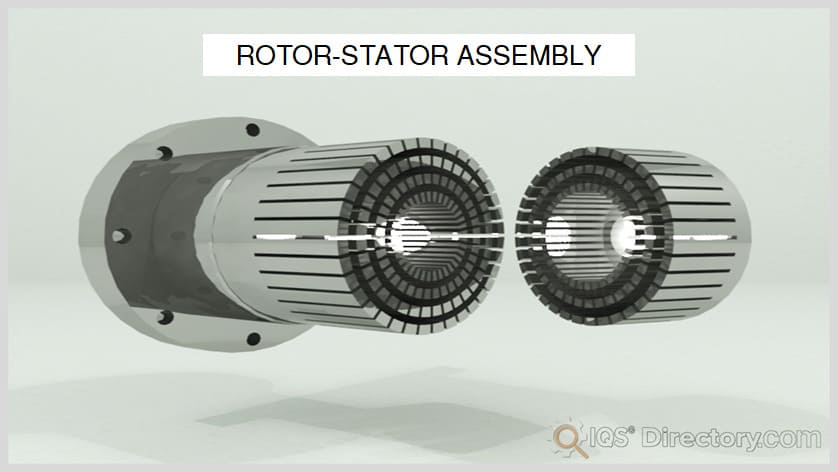

Shearing forces are the stresses exerted by mixing blades or impellers on the liquids, solids, and other materials being processed. In high-speed mixing applications, a rotating rotor forces the material against a non-moving stator, producing shear by moving various portions of the material in opposing directions on the same plane. This unique technique allows for the blending of liquids, solids, or gases that ordinary mixing methods cannot effectively achieve.

High shear mixers are indispensable for creating consumer products with immiscible components, including salad dressings, paints, cosmetics, detergents, shampoos, and various ointments. They serve a multitude of functions such as emulsifying liquids, blending liquids with varying viscosities, incorporating solids into liquids, dispersing powders into liquids, and particle size reduction. These mixers are vital in industrial operations, playing an integral role in manufacturing pharmaceuticals, chemicals, healthcare products, and cosmetics.

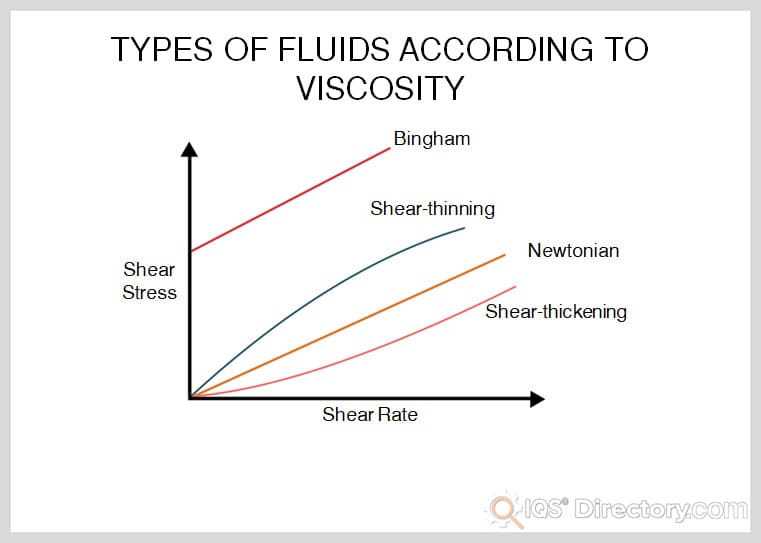

A fluid is any substance in a liquid or gaseous state that can flow freely and is not constrained by surface effects. The behavior and properties of fluids, such as their viscosity, density, and flow patterns, are studied within the field of fluid mechanics. Like solids, fluids can experience force, stress, or pressure—factors that play a critical role in industrial mixing and blending applications. When a fluid flows, it encounters shear stress, which is the fundamental principle behind the operation of high shear mixers in process engineering.

Shear stress in fluids primarily arises from friction between the fluid molecules, attributed to viscosity. Additionally, shear stress is generated by the friction between the fluid and any moving body within it, such as the fast-rotating elements found in industrial mixers. This relationship between viscosity, shear forces, and friction is essential to achieving targeted mixing results—such as homogenization, emulsification, dispersion, and particle size reduction.

The moving body and the fluid molecules in direct contact with it share the same velocity—a phenomenon known as the no-slip condition. Intermolecular forces between the fluid molecules and the body's surface, referred to as the boundary layer, create an attractive force. Once a steady state is reached, the velocity profile across these layers becomes linear. At this point, there is no further acceleration or force needed to deform or shear the fluid. Motion is transferred across each fluid layer and is opposed by its viscosity, directly impacting the mixing efficiency and energy transfer in applications like food processing, pharmaceutical manufacturing, and cosmetics production.

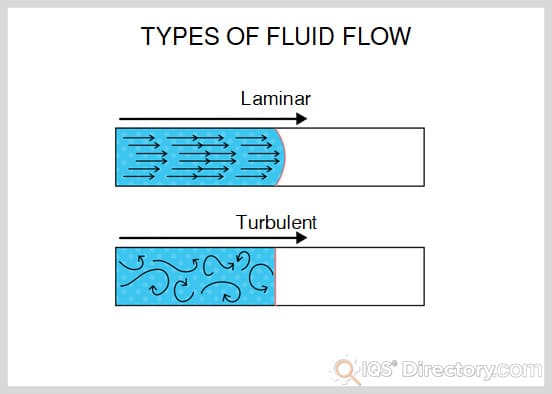

Laminar flow occurs when the fluid moves smoothly and evenly without disturbances across these layers. Introducing different bodies that create shearing forces in various directions disrupts this flow, leading to turbulent flow. Turbulent flow is characterized by random, chaotic motion that enhances mass transfer and blending across fluid layers. This accelerated and uneven flow is key for breaking up droplets or particles suspended in the mixture, resulting in emulsion, dispersion, and homogenization of the components—an essential step in the formulation of creams, suspensions, and emulsions in many industries.

High shear mixers typically consist of two primary components: the rotor and the stator—collectively referred to as the mixing head or generator. These are the heart of high shear mixer design. The rotor accelerates the fluid tangentially, creating intense inertia that prevents the fluid from moving at the same speed as the rotor. As a result, fluid is forced towards a narrow gap between the rotor tip and stator—the shear gap. Within this precisely engineered shear gap, high velocity differentials and turbulent flow generate intense shear rates. The resulting mechanical energy is efficiently transferred, ensuring rapid and uniform mixing of diverse materials.

The profile and configuration of the rotor and stator, along with features like holes, slots, and vane shapes, play a crucial role in shaping the fluid flow and determining the mixing intensity suitable for the specific application—whether for high-viscosity pastes, powders, or liquids. Below are some of the core mixing processes facilitated by high shear mixers, each addressing unique production challenges in industries such as chemical manufacturing, pharmaceuticals, food processing, cosmetics, and adhesives.

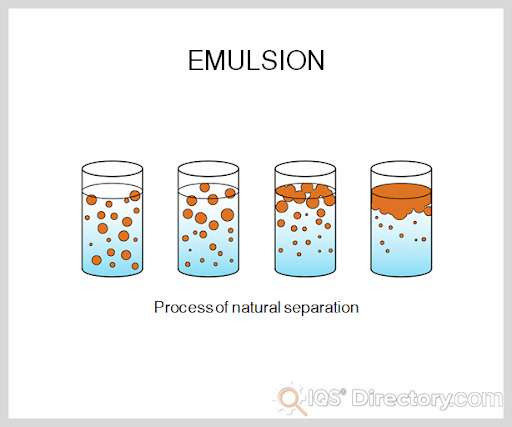

To create a uniform mixture with a single continuous phase, the liquid droplets must be evenly sized and distributed—a process fundamental to emulsion manufacturing. In this setup, the droplets represent the dispersed phase, while the liquid in which they are suspended is the continuous phase. Emulsions often experience natural separation between these phases, particularly in immiscible liquids like oil and water. Since oil is nonpolar and not attracted to water molecules, and because oil is typically less dense than water, it tends to float and separate from the water. The high shear mixer’s goal is to continually break down these droplets to prevent this natural separation by applying intense shear energy.

Another type of emulsion involves mixing miscible liquids with different viscosities. When adding low-viscosity droplets to a high-viscosity solvent, it’s essential to use more mixing time and carefully control the rates at which components are added. High shear mixers improve the emulsification process by reducing droplet size, increasing surface area, and ensuring long-term physical stability of the emulsion—a critical requirement for quality control in products like lotions, creams, sauces, and pharmaceuticals.

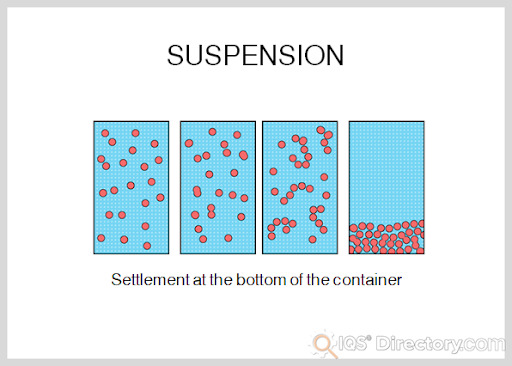

A suspension mixture contains solid particles large enough to settle out and that cannot be fully dissolved in the liquid. The goal, similar to emulsion homogenization, is to break down these large solid particles into smaller ones and evenly disperse them throughout the medium. This process achieves a stable suspension and prevents sedimentation, ensuring product consistency over time.

One challenge in this process is effectively wetting the solid particles, which often tend to float on the surface of the solvent due to the liquid’s surface tension and the hydrophobic nature of the particles. Advanced high shear mixers utilize optimized rotor-stator geometries and precise control over mixing parameters—such as tip speed and residence time—to overcome these challenges and achieve full particle dispersion. This issue will be further explored in the section on in-line high shear mixers.

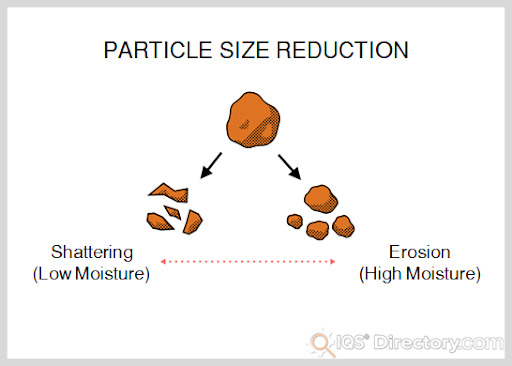

In this application, solid or semi-solid materials are ground into finer particles, either in a solution or a fine suspension. The extent of size reduction depends on the hardness and brittleness of the material, as well as the mixing energy applied. High shear mixing achieves precise particle size reduction by exposing the particles to repeated cycles of high stress, resulting in uniform particle distribution and improved product performance. This method is critical for the manufacturing of micro-emulsions, drug delivery systems, food sauces, and specialty chemicals that require consistent particle distribution.

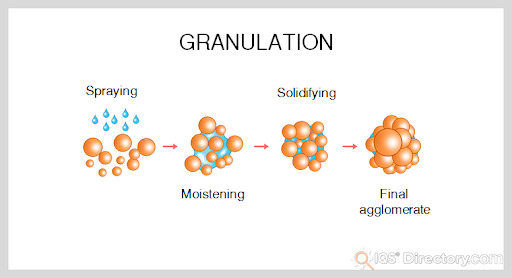

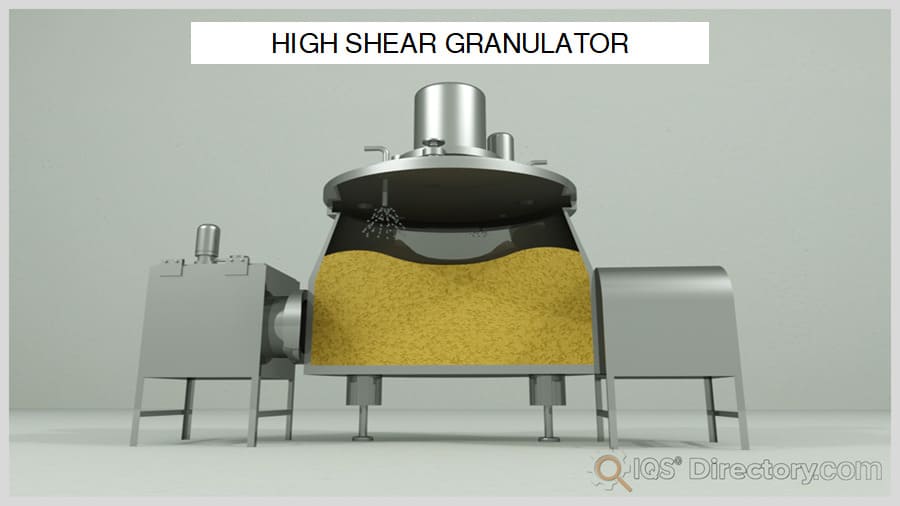

This process involves combining solid products with a binder or granulating liquid. As the powder and binder are mixed, the mixture is continuously formed into high-density granules—resulting in improved flow properties, reduced dust generation, and enhanced compressibility. High shear granulation is widely used in the pharmaceutical industry to manufacture tablets, in food processing to create instant drink powders, and in the production of catalysts and fertilizers.

Many manufacturers claim that their equipment can perform all these functions. While it is true that most mixers can handle these tasks, they often do so with lower efficiency or less consistent results. High shear mixers are specifically engineered with detailed considerations of the dispersed particle phase, fluid viscosity, required particle size, flow rate, and operational scale. To achieve reliable results, sophisticated tools like Computational Fluid Dynamics (CFD) analysis are used to simulate mixer operation and determine the optimal design for both the rotating and stationary components.

Accurately simulating real-world conditions with CFD analysis is complex and requires advanced expertise. As a result, the design of high shear mixers often relies on empirical methods, focusing on development through application-specific testing for various products and manufacturing setups. Selecting the right high shear mixer for your industry—whether for batch mixing, in-line mixing, or continuous processing—depends on understanding your application requirements, desired results, and production scale. Consulting with experienced suppliers and reviewing case studies or pilot trials can help you evaluate the most suitable options, improve process efficiency, reduce operational costs, and achieve superior product consistency.

High shear mixers are a vital category of industrial mixing equipment, classified by their configurations and application methods: batch, in-line, powder induction, high shear granulators, ultra-high shear, and bottom entry high shear types. While each mixing methodology may employ different technologies and workflows, the core shearing process—essential for reducing particle size, homogenizing viscous compounds, emulsifying immiscible liquids, and dispersing solids—remains consistent across all high shear mixing equipment. Manufacturers across the food, pharmaceutical, chemical, cosmetics, and adhesives sectors rely on high shear mixers to blend viscous materials into uniform, stable products, as well as to agglomerate materials that maintain their structural integrity without breakdown. The ability to customize the process depending on product formulation makes high shear mixers indispensable for processing stable emulsions, suspensions, gels, and creams.

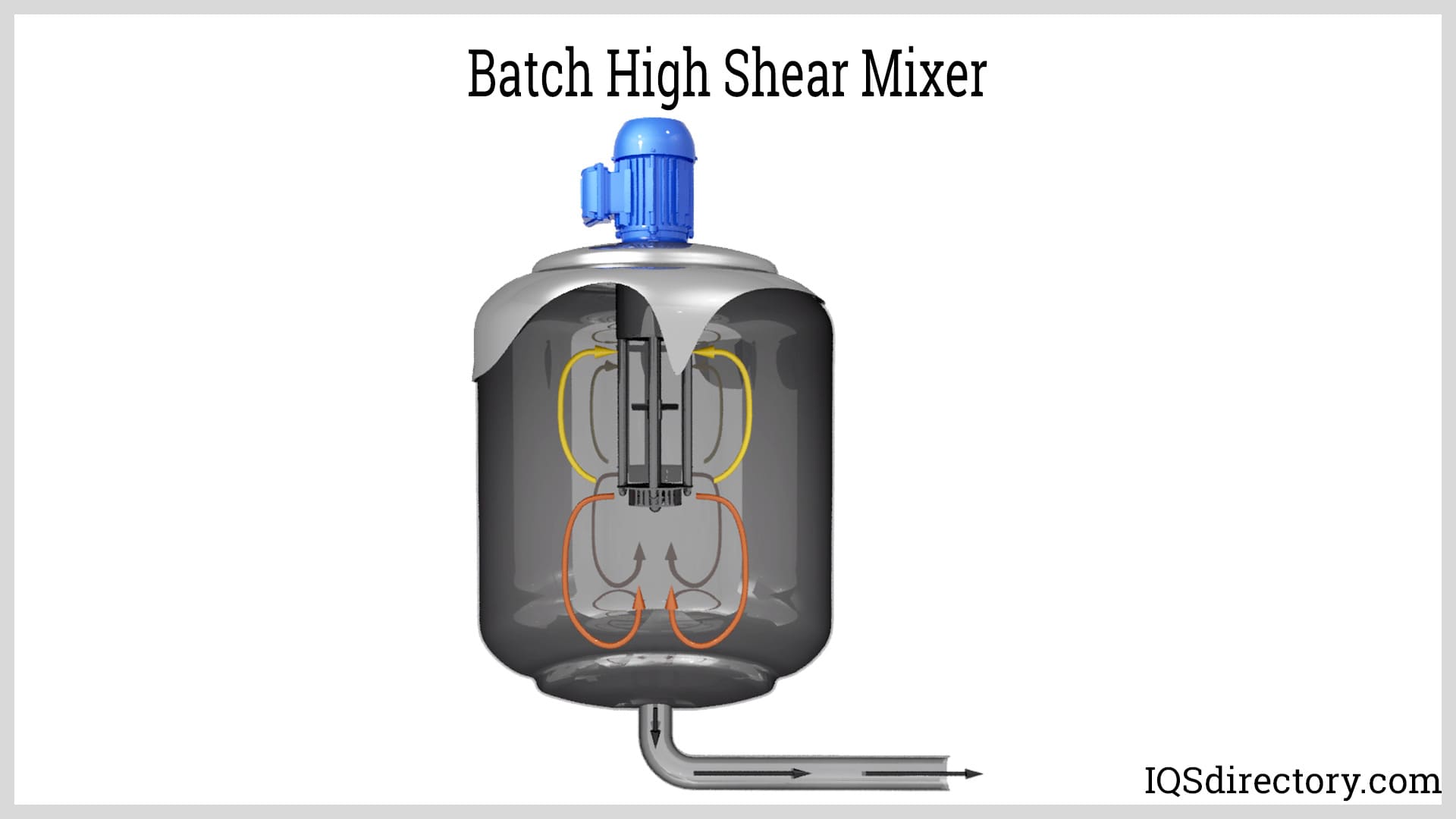

Batch high shear mixers are widely used for processing all components in large volumes within a single tank or vessel, making them suitable for high-viscosity applications and formulations requiring extended mixing times. Components are typically added from the top, and the batch mixer may use a single high shear head that can be lifted and moved across multiple vessels for flexible operation. Batch mixing is often faster than in-line high shear mixing when comparing mixers with the same power rating, offering high efficiency for specialty chemical processing, food production, adhesives, and pharmaceutical manufacturing. However, a primary challenge is cleaning between batches—especially for viscous or sticky mixtures. Residues from previous runs can lead to product contamination or cross-contamination of allergens and active ingredients. To meet sanitary processing standards, plants employ Clean-In-Place (CIP) systems or use removable parts for easier maintenance and compliance.

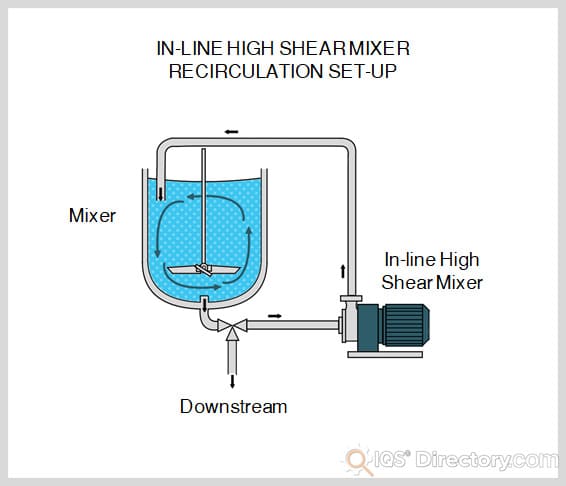

In-line high shear mixers are incorporated directly into continuous processing lines, enabling precise process control and high-efficiency mixing of liquids and solids. Their rotor-stator assembly is positioned perpendicular to ingredient flow, delivering a highly concentrated shear zone that rapidly disperses and homogenizes materials—crucial for emulsification, fine suspension, and dissolution of powders into liquids at the industrial scale. Commonly found in chemical, cosmetic, beverage, and pharmaceutical manufacturing, in-line mixers are the backbone of modern process engineering that demands consistent quality and reproducibility.

These mixers feature a tightly sealed chamber with dedicated inlet and outlet ports, where centrifugal force acts as a powerful pump to circulate the product through the rotor-stator assembly. The design prevents external contamination and supports hygienic, sanitary processing—key requirements for the production of food ingredients, medicine, and personal care products. Being part of a continuous product stream, in-line high shear mixers allow real-time adjustment of mixing parameters by operators, ensuring that viscosity, particle size, and dispersion quality precisely meet product specifications for every batch.

With an in-line high shear mixer, processors typically use a mixing pot or vessel to collect, pre-blend, and feed all raw materials into the mixing chamber. This vessel can be a dedicated tank or a batch mixer, depending on the process flow.

Materials are transferred via the static head into the in-line high shear mixer, leveraging the self-priming effect provided by the design. As the in-line mixer homogenizes, it can either send the product on to downstream equipment—such as filling stations, packaging lines, or chemical reactors—or recirculate it for intensive processing. This recirculation continues until the desired particle size distribution, viscosity, or emulsion stability is achieved, after which the product advances to the next stage of manufacturing.

Integrating an in-line high shear mixer in the processing system guarantees uninterrupted product flow, advanced product consistency, and superior automation capability. The perpendicular rotor-stator configuration enables extremely fine particle size reduction and stable emulsion or suspension formation, making this mixer type especially popular in pharmaceuticals, cosmetics, food manufacturing, and personal care goods. Operators also benefit from the compact design, easy system integration, and high energy efficiency of these industrial mixers.

Modern in-line high shear mixers support a wide range of process parameters, accommodating everything from low-viscosity liquids to semi-solids, thixotropic fluids, and shear-sensitive compounds. With robust construction, sanitary finishes, and advanced control systems, they are engineered for long-term, reliable operation in the most demanding process environments.

Powder induction high shear mixers are engineered for powder-liquid processing applications where controlled, dust-free powder addition is crucial. Employing vacuum technology, these mixers draw powdered ingredients directly and safely into the mixing head via a sealed, sanitary process. This design mitigates dust exposure, prevents powder loss, and considerably reduces the risk of cross-contamination or operator inhalation—important considerations for food, cosmetic, pharmaceutical, and specialty chemical production.

Adding powders to liquid often results in clumping or surface agglomeration, caused by rapid wetting on the liquid surface. To ensure complete dispersion and dissolution, powder induction systems generate high-velocity mixing that creates a vortex, rapidly drawing powders to the rotor-stator zone for uniform incorporation. Careful control is key; slow powder addition can compromise throughput, while rapid addition risks incomplete dispersion. Automated feeding controls and optimized mixing speeds address these industrial-scale challenges by maximizing mass transfer and contact efficiency.

Another challenge is preventing irreversible viscosity shifts and ingredient degradation due to heat buildup or excess shear—a frequent issue in non-Newtonian fluids. Shear-thinning liquids (pseudoplastic) become less viscous under high shear, while shear-thickening types increase in viscosity. Thixotropic fluids exhibit time-dependent thinning that requires accurate control of mixing duration. Incomplete or excessive mixing can adversely impact final product specifications, such as cream thickness in cosmetics or suspension quality in pharmaceuticals.

Material degradation often results from excessive temperature rise in closed-system mixers; friction between fluid molecules during high shear can activate unwanted chemical or physical changes. In batch mixing, thermal management—through jacketed vessels or external chillers—helps avoid overheating, preserving active compound stability and ensuring optimal product quality across food, cosmetic, pharmaceutical, and chemical manufacturing industries.

High shear granulators are specialized mixers that efficiently convert fine powders into compact, dense granules—ideal for controlled-release pharmaceuticals, tablets, food additives, and fertilizer production. The high shear granulation process involves the simultaneous addition of binder liquids and intense agitation by an impeller, resulting in high-density wet granules suitable for pressing or drying. This wet granulation not only boosts uniformity but also enhances flowability, compressibility, and dissolution rate in finished products.

The typical high shear granulation cycle proceeds through wetting (binder application), growth (granule coalescence), and breakage (size reduction) stages. During wetting, powder particulates absorb binder, forming primary nuclei that grow via impact and agglomeration in the high-energy shearing zone. Final granule size is regulated through sustained shearing and breaking forces, ensuring consistent, dust-free, and free-flowing end products for pharmaceutical tablets, instant drink powders, fertilizers, and more.

Although liquid binders are standard, certain high-melt index powders can serve as binders when heated by frictional or external sources, minimizing clogging concerns found in viscous binder systems. Advanced control over moisture addition, temperature, and blade speed enhances the precision of granulation, reducing variability in downstream tablet compression or encapsulation processes.

Ultra-high shear mixers are engineered to deliver the highest available tip speeds and shear rates, yielding the finest particle size distribution in challenging mixing scenarios. These specialized mixers facilitate the rapid homogenization of immiscible liquids (emulsion formation), fine comminution of solids, and efficient deagglomeration, widely used in nanotechnology, pigment dispersion, polymer emulsification, biotechnology, and advanced ceramics production. The rotor-stator is precisely contoured to generate exceptional pumping capacity and intense localized shear, driving superior results in short residence times.

Intense vortices above and below the mixing head draw even floating or settled agglomerates directly into the high shear zone, maximizing dispersion and accelerating batch processing. Applications range from high-shear emulsification of pharmaceutical suspensions to pigment grinding in specialty chemicals and high-performance coatings.

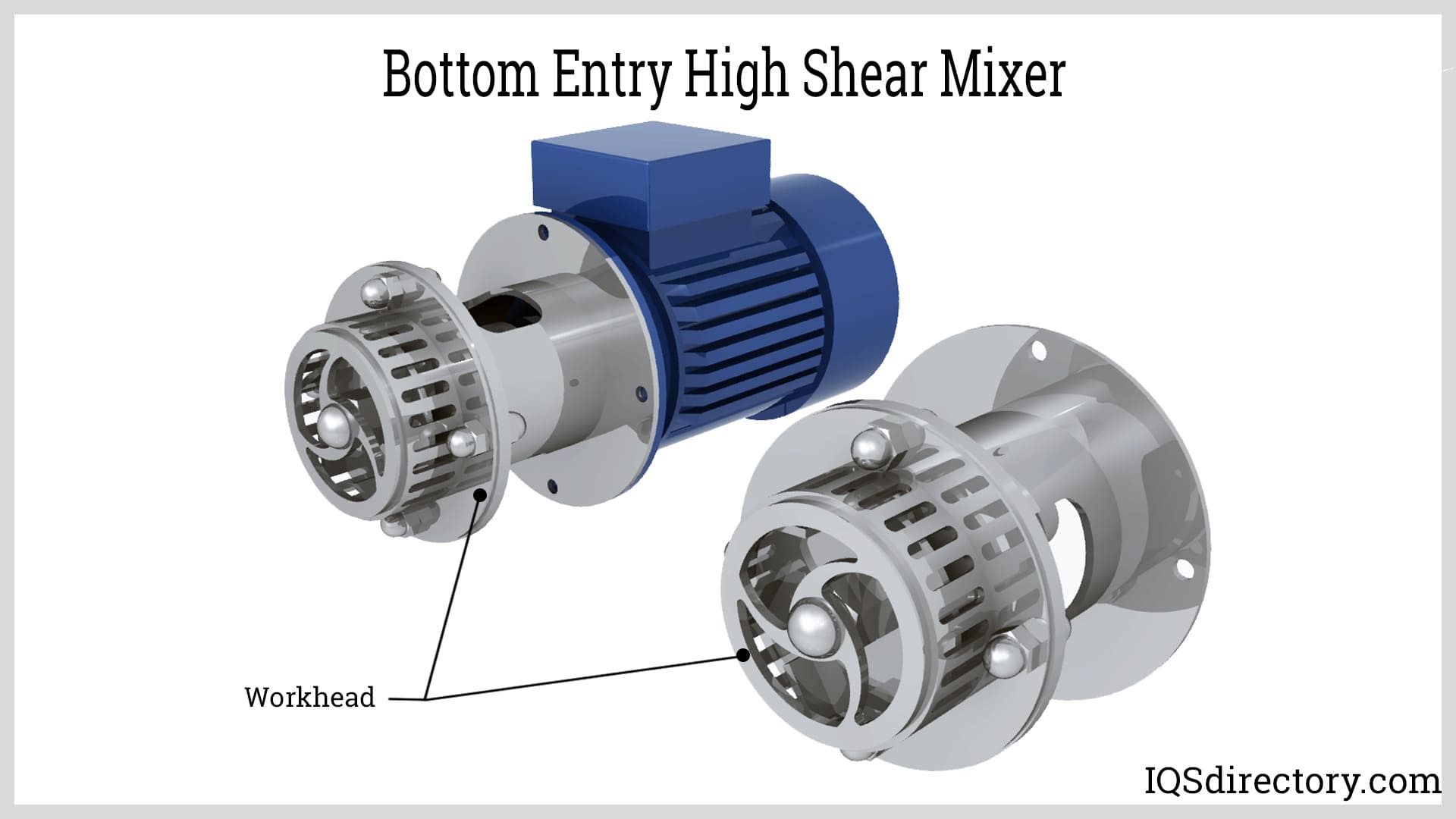

Bottom entry high shear mixers are installed at the base or side of tanks and are designed for joining high-shear homogenization with gentle, uniform distribution from a slow-moving anchor stirrer or scraper unit. This configuration is especially beneficial for heat-sensitive products, viscous pastes, or high-solid formulations prone to fouling tank walls. The direct shaft-driven rotor-stator assembly enables intense mixing right at the vessel bottom, preventing sedimentation and ensuring there are no “dead zones” common in top-entry designs.

During operation, the high-speed rotor creates powerful suction, pulling both liquid and solid materials downward into the workhead. Centrifugal force expels materials across the stator, where they are milled at extremely high velocity, generating substantial hydraulic shear. This cycle maintains continuous incorporation of all product zones for optimal batch homogeneity. Industries such as pharmaceuticals, cosmetics, and food manufacturing rely on bottom entry high shear mixers for consistent results in processing creams, sauces, gels, and viscous emulsions.

Equilibrium mixing in high shear mixing is used to determine the characteristics of the finished mixture. It represents the point at which further mixing is unnecessary, as additional processing will not alter the product’s properties. Achieving equilibrium is the primary objective of high shear mixing and signals when mixing can be stopped.

High shear mixers are designed to blend ingredients that are naturally immiscible. When mixing two or more types of liquids, the result is known as an emulsion. Combining a solid with a liquid produces a suspension, while dispersing a gas in a liquid forms a lyosol, which includes micellar solutions and aqueous biopolymer solutions. The energy required for mixing determines whether the combination of solids, gases, and liquids is adequately homogenized.

To achieve a consistent mixture with a high shear mixer, equilibrium mixing helps identify when the reactants will no longer change. For dispersions, equilibrium is defined by particle size, while for emulsions, it is defined by droplet size. The amount of mixing required to reach equilibrium depends on the number of times materials pass through the high shear zone.

Determining whether a mixture has reached equilibrium involves assessing whether the mixture has achieved its target characteristics, such as viscosity, particle size, and granule density. Once equilibrium is achieved, additional mixing will not improve the mixture and may be counterproductive.

The concept of equilibrium is crucial for scaling up the volume of a rotor-stator mixing head. Smaller mixing heads reach equilibrium faster than larger, full-production units. Thus, the design of the mixing head affects how quickly equilibrium is achieved.

In high shear mixing, equilibrium is typically reached within 5 to 10 passes through the rotor-stator. Exceeding this number of passes is inefficient, may damage the mixer, waste energy, and increase equipment wear and tear.

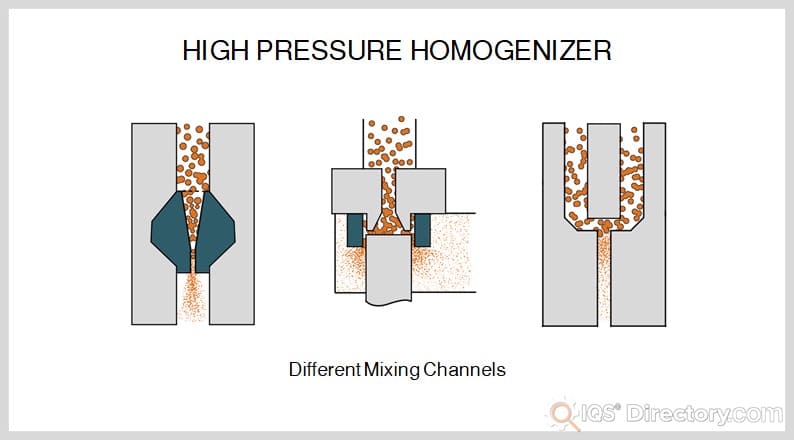

High pressure homogenizers or mixers apply high pressure to a liquid to force it through a membrane or valve that has narrow slits. The process causes high shear, large pressure drop, and cavitation that homogenizes the sample. A high pressure homogenizer uses a combination of shearing, impact, and cavitation. The term high pressure homogenizer refers to any homogenizer that forces a liquid in order to reduce particle sizes.

A high-pressure homogenizer consists of high-pressure tanks that hold the materials to be mixed, with pressures ranging from 15 to 40 bars. As the materials are forced through a valve or channel with narrow slits, high shear stress, pressure drop, and cavitation occur, collectively contributing to the homogenization of the mixture.

Adjusting the pressure and power input changes the size of the droplets or particles in the mixture.

Being a closed system, high-pressure homogenizers are shielded from microbes and external contaminants. Component charging is done in separate containers, further reducing the risk of contamination.

High-pressure homogenizers offer precise control for flexibility and repeatability, real-time response to parameter changes, and component charging through individual pumps. They efficiently process large volumes of materials, making them well-suited for the dairy industry. Their powerful processing capability and ability to recycle material streams enable the achievement of very small, submicron particle sizes.

Due to their high cost—units typically exceeding $10,000—and the need for multiple pumping units for efficient operation, high-pressure homogenizers are suitable only for high-volume processing. They are heavy and require a significant amount of space. Additionally, to prevent cross-contamination, thorough cleaning is necessary after each cycle.

High shear mixers are essential in many industrial processes due to their capability to execute a range of mixing functions, including reduction, dispersion, homogenization, deagglomeration, and wet milling. These processes enhance product quality and improve production efficiency. As technology advances, high shear mixers are increasingly replacing traditional mixers that use propellers and turbines.

There is a wide range of high shear mixer applications under this category. High shear mixers used in the food industry can create emulsions, suspensions, powders, and granules. A popular application is the manufacture of sauces, dressings, and pastes. Most of the ingredients are composed of solid particles, and immiscible liquids such as oil and water.

Certain ingredients, like ketchup, mayonnaise, and dough, are challenging to process due to their viscoelastic properties, which require a minimum force to initiate flow. These materials demand specialized rotor-stator mixing heads to handle their unique characteristics effectively.

In the pharmaceutical industry, various types of mixtures are processed, similar to the food industry. Inline high shear mixers are preferred for their closed system, which prevents contamination. Pharmaceutical products, including tablets, syrups, suspensions, injection solutions, ointments, gels, and creams, all undergo high shear mixing. These products have diverse viscosities and particle sizes, making high shear mixers essential for ensuring consistency and quality.

Paints, such as latex, are non-Newtonian and thixotropic liquids, which can make them challenging to process. These paints thin out when sheared, whether during processing or in use. Therefore, mixing times for these fluids must be carefully controlled to avoid over-shearing and ensure the desired consistency.

Inks used in printers exhibit the opposite behavior of paints; they are rheopectic. Rheopectic fluids thicken as they are sheared, making the mixing process highly time-dependent.

Applications in this category include combining resins and solvents for casting or injection molding, modifying oil viscosity, emulsifying waxes, and producing asphalt, among others.

The mixing process is central to many industrial applications, making high shear mixers crucial for producing high-quality products efficiently. Selecting the right high shear mixer for a specific application requires thorough study and research. Mixer manufacturers provide extensive literature to guide the purchasing process and offer sales assistance through highly trained and knowledgeable personnel.

The first consideration when purchasing a high shear mixer is the type of product being processed. High shear mixers handle products with viscosities ranging from 1 centipoise (CPS) to 10,000 CPS, where 1 CPS is equivalent to the viscosity of water. Products with viscosities above 10,000 CPS are more resistant to flow and present greater mixing challenges.

High shear mixers are versatile and can perform various mixing applications, such as particle size reduction, blending, gelling, dispersion, and emulsification. Before selecting a high shear mixer, it is crucial to understand the specific results required for the product and its consistency. Modern high shear mixers are highly adaptable and can be tailored to meet the needs of different products effectively.

Sizing refers to the daily production rate, which can range from several hundred to several hundred thousand units. The efficiency of a high shear mixer is influenced by factors such as downtime, mixing duration, material supply, and transport of raw materials. For high-volume operations, multiple mixers may be necessary to achieve production goals, as large-scale production often requires several units to maintain efficiency.

Upfront costs and long-term amortization are key considerations for manufacturers. While purchasing a highly efficient and reliable high shear mixer may involve significant initial investment, it can offer substantial benefits, including reduced downtime, efficient production, and high-quality output. The cost of high shear mixers varies, and while some equipment can be quite expensive, the focus should be on the value it provides in terms of product quality and operational efficiency.

Customization is increasingly important in modern manufacturing, as many industries develop innovative and unique products requiring specialized equipment. While custom solutions can be costly, they can significantly enhance productivity and performance. To develop equipment tailored to specific needs, it is essential to collaborate with experts in the mixer industry for planning, engineering, and designing a mixer that meets the exact requirements of the product.

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

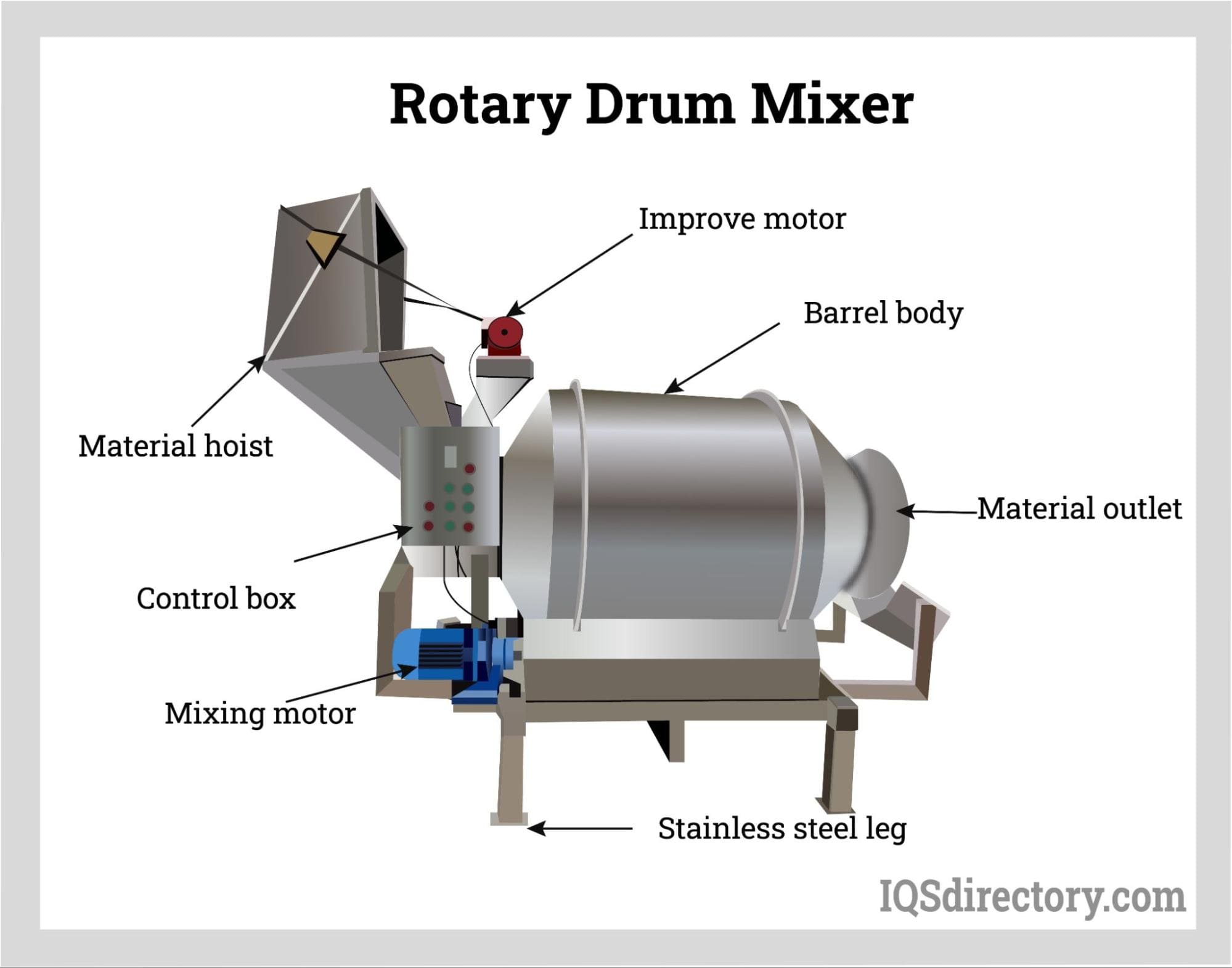

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

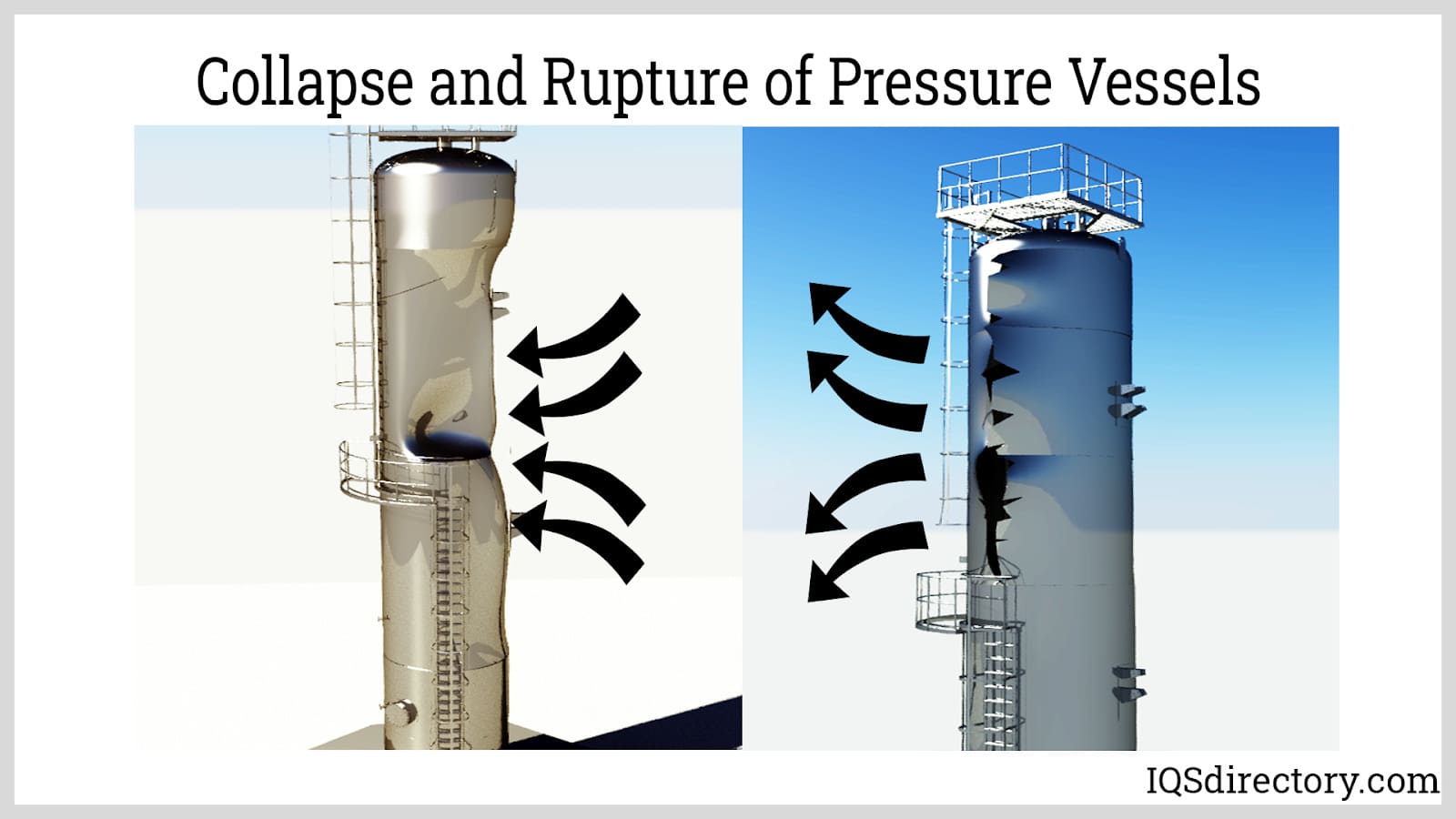

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...