Drum Mixers

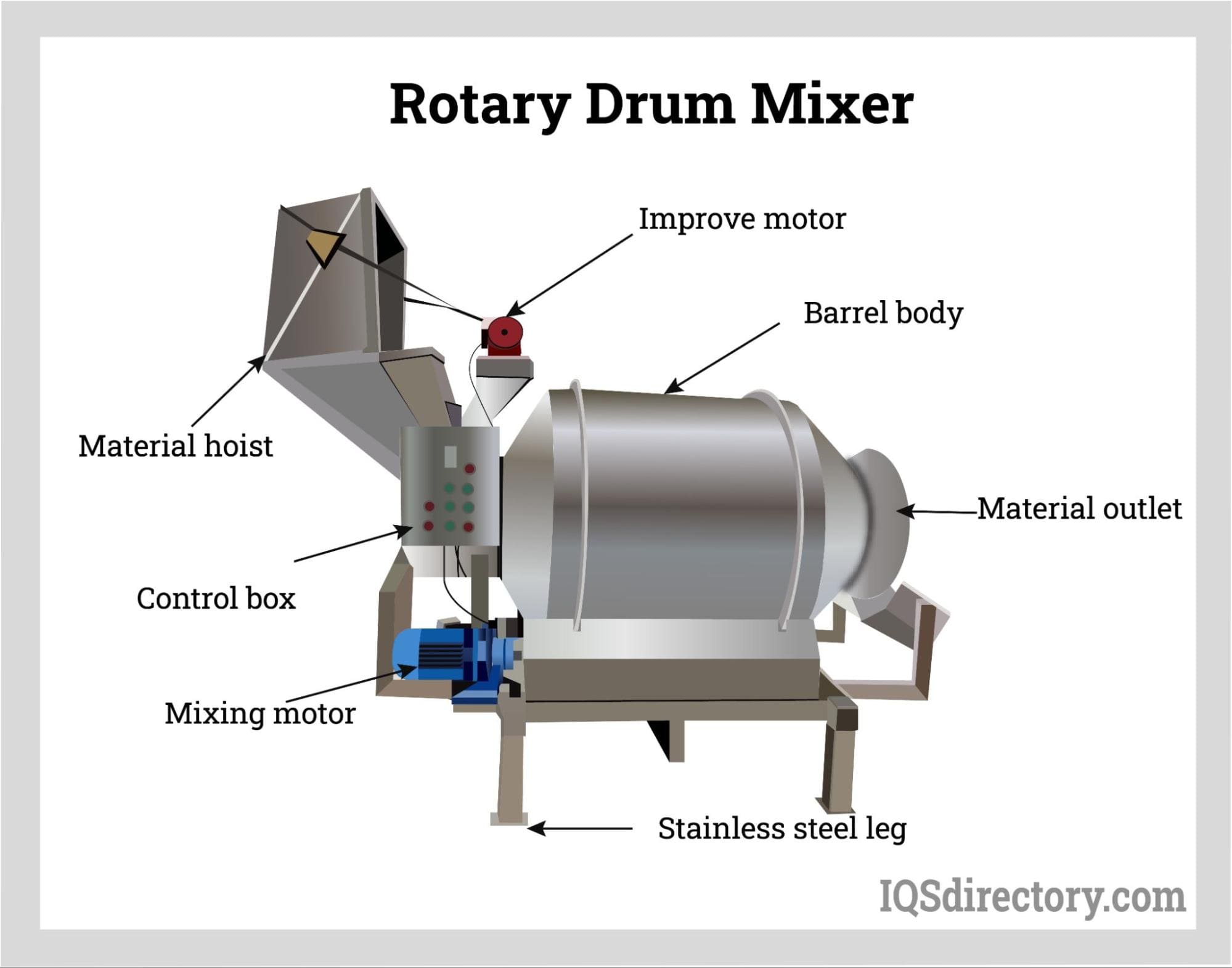

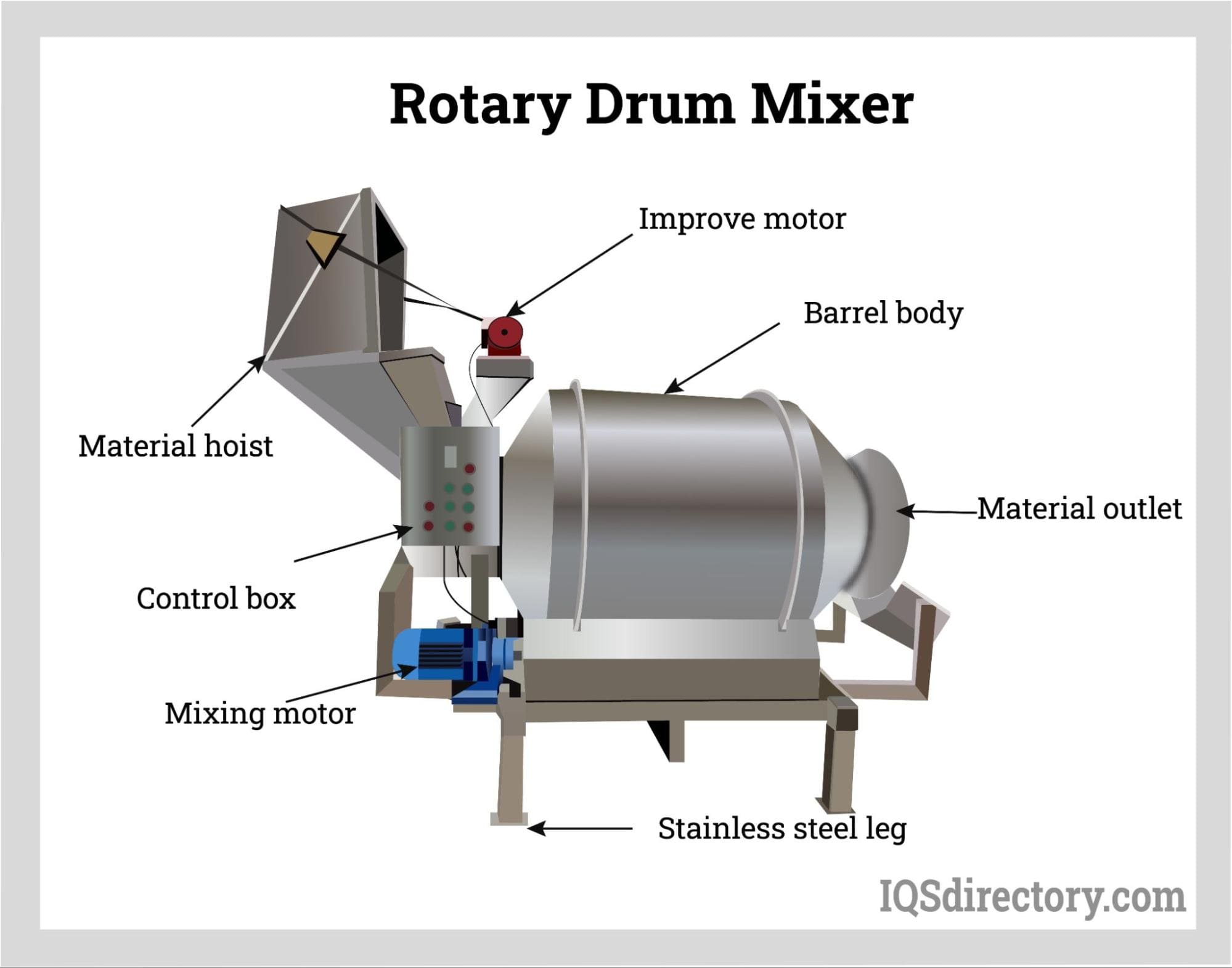

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

A description of the types of ribbon mixers and ribbon mixer manufacturers as well as the benefits of ribbon mixers.

You will learn:

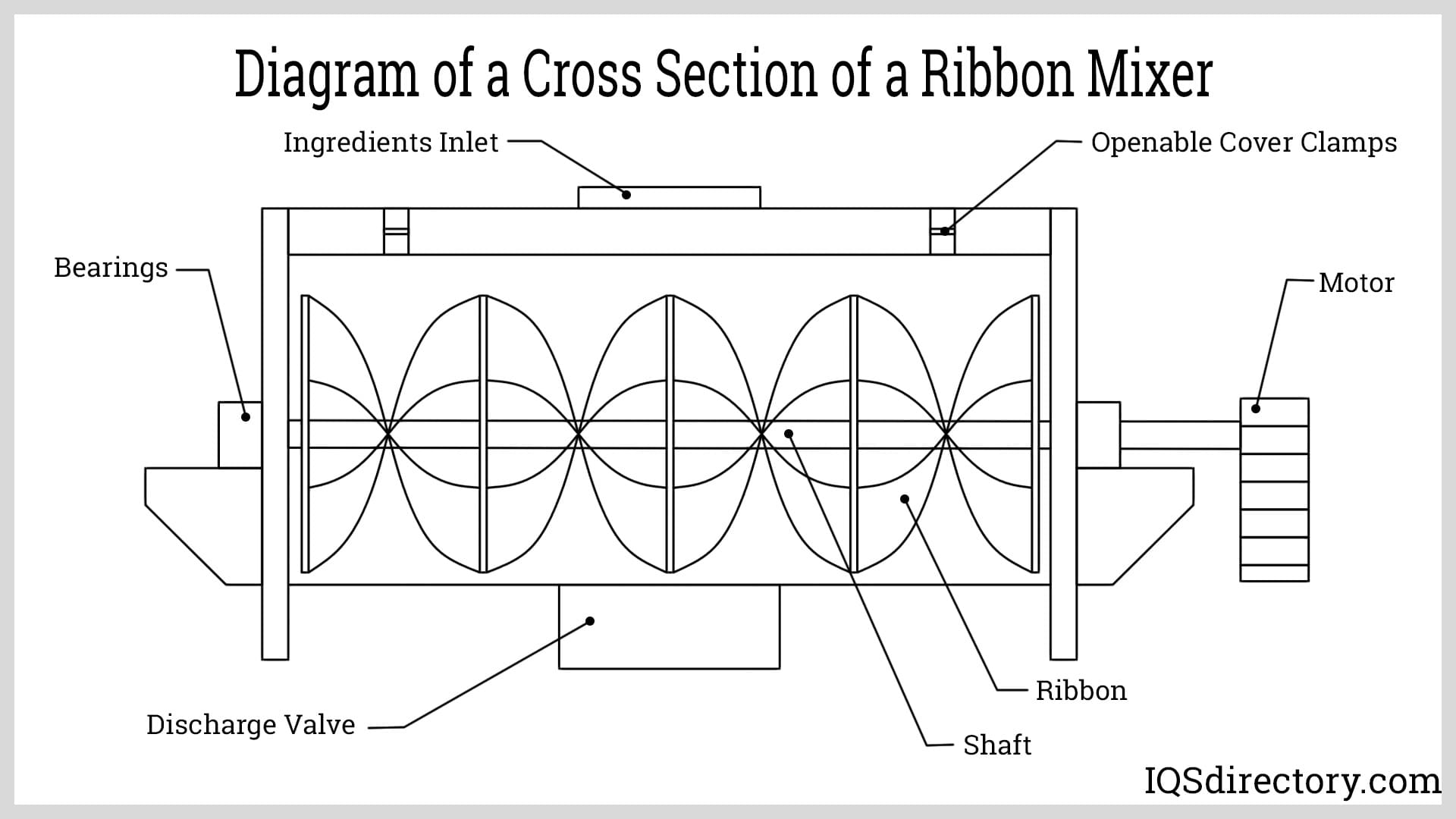

Ribbon mixers are specialized mixing devices utilizing helical ribbons to effectively blend a wide range of materials by channeling them inward, outward, forward, and backward during the mixing cycle. These mixers are particularly prevalent for the blending of slurries, dry powders, and granular substances. The design includes a single shaft with spokes that secure the helical ribbons, facilitating the merging and mixing action. In a dual ribbon mixer, external helical ribbons draw materials from the sides toward the center, while internal ribbons drive the powder product back toward the sides, creating an efficient folding and convective mixing motion.

A key feature of ribbon mixers or blenders is their distinctive U-shaped drum that houses the helical ribbons. This U-shaped trough, also referred to as a U-shaped horizontal trough mixer, sets ribbon mixers apart from other industrial mixers. The U-shape assists in several practical aspects such as the straightforward loading of ingredients, ease of cleaning, and remarkably effective mixing capabilities.

The unique U-shaped configuration allows for the installation of choppers and spray systems, useful for blending liquids, semi-solids, coatings, and low-viscosity pastes when needed. As with all types of blenders, the core of the ribbon mixer's functionality lies within its trough or drum. This component is securely sealed, welded, and polished to maximize the efficiency and effectiveness of the mixing process.

The various types of ribbon blenders are designed for the homogeneous blending of powders, slurries, and granular materials. They are used for coating dry particles using spray assemblies attached to the trough of the mixer. Shearing and kneading are completed in a ribbon mixer using the in and out movement of the blender's ribbons. The solid action of a ribbon blender ensures an even blending of ingredients such that the ingredients are balanced to create a high-quality mix. The ribbons mounted on the central shaft provide an efficient mixing process that is easy to maintain and clean.

The ribbons of ribbon blenders have a precision measured gap between the walls of the blender and the ribbons. In some instances, wipers can be added to prevent the build up of ingredients on the walls. There are different forms of drives used to power ribbon blenders and include chain drives, belt drives, and direct gearbox drives.

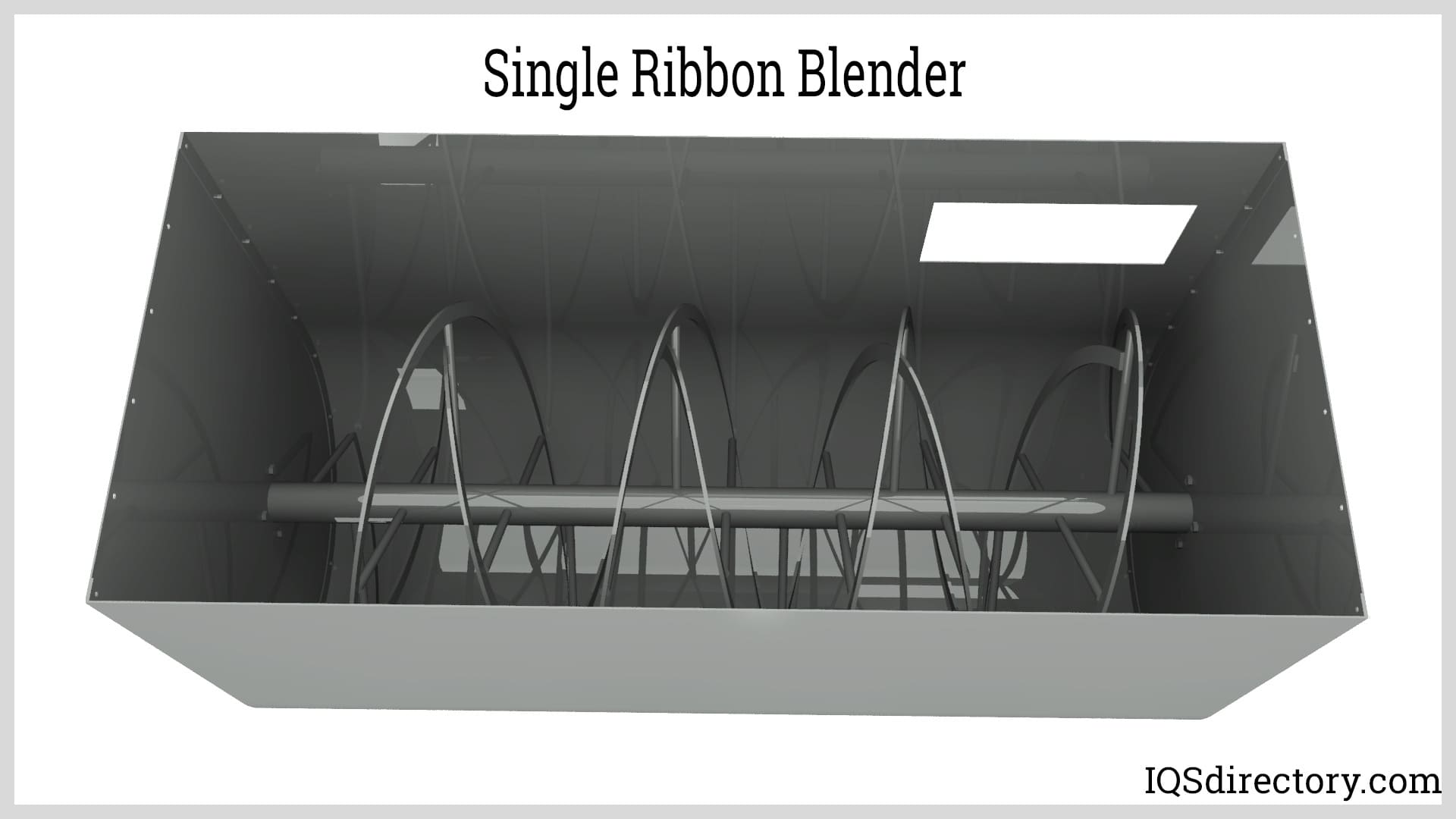

Single ribbon or single shaft blenders have a helical ribbon agitator and are used for materials that do not require a high degree of mixing. They have a very simple design with fewer parts, which makes maintenance easier. Single ribbon blenders are used for coarse materials that blend easily and do not need an intensive blending process. Single ribbon blenders can be vertical or horizontal. Vertical ribbon blenders are similar to traditional blenders that have ingredients added from the top. Horizontal single ribbon blenders can be continually fed and move ingredients from one end of the blender to the other end. Materials are moved radially and laterally to ensure thorough blending.

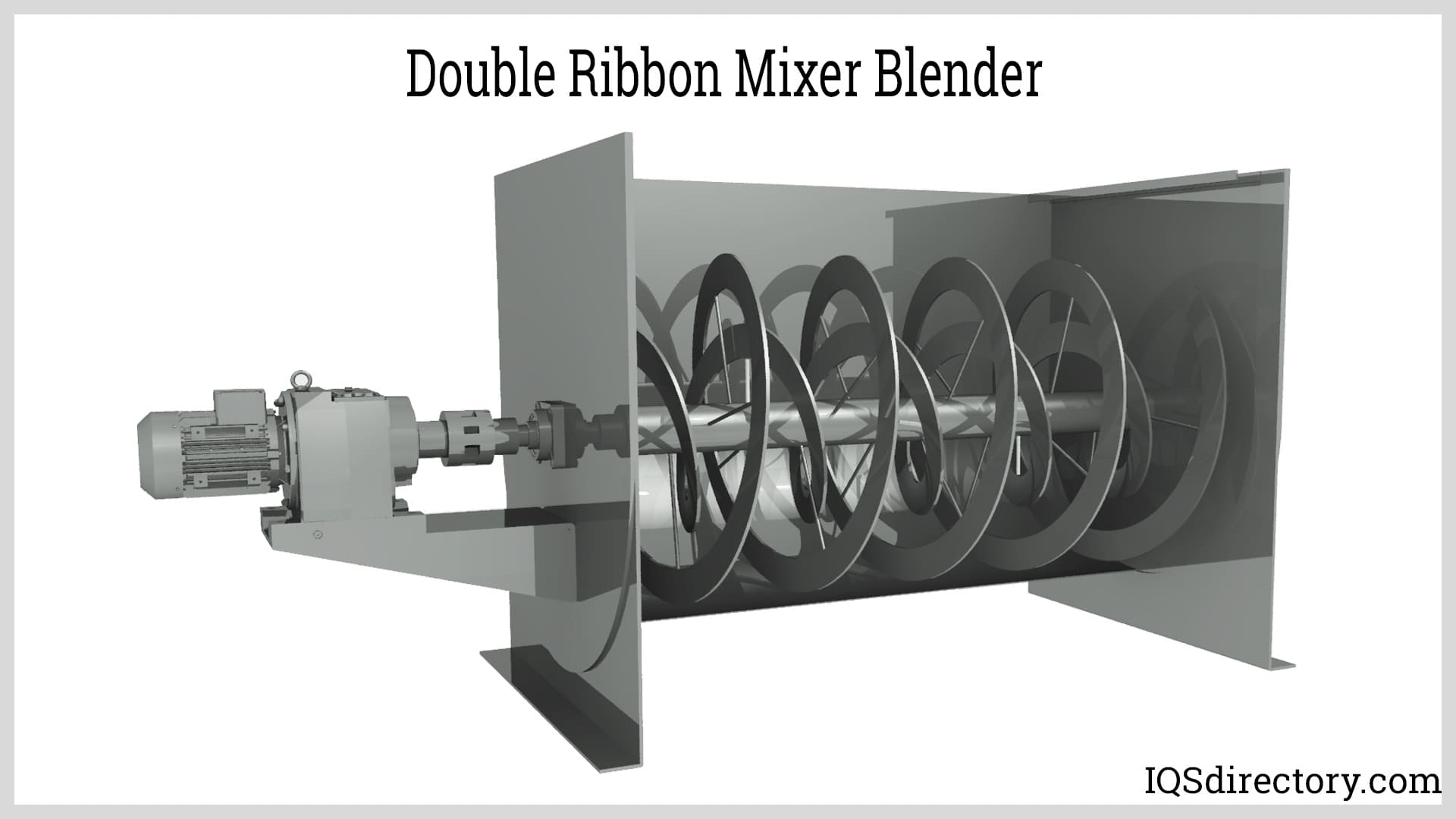

Double ribbon mixers or blenders are horizontal mixers with two helical agitators on the same shaft. The ribbons are positioned such that there is one ribbon on the outer part of the trough and another ribbon on the inner part of the trough. The design of double ribbon blenders ensures the movement of ingredients such that they are thoroughly mixed. Ingredients are moved radially and laterally providing sufficient motion such that they can intermix and blend.

With a double ribbon blender, the outer ribbon moves ingredients in the opposite direction to the direction that the inner ribbons move the ingredients. The motion and movement provide a uniform counter flow of ingredients throughout the trough. The discharge configuration for double ribbon blenders can be at center bottom or either bottom end depending on the types of material being blended and the design of the blender. The mixing time for a double ribbon blender varies in accordance with how full the trough is, with the range of times being between five and twenty minutes.

The forward and reverse rotation of a double ribbon mixer along the same horizontal axis forms a low power efficient vortex mixing process. The vortex mixing method speeds up and improves the homogeneity of a mixture.

Triple ribbon blenders have one central ribbon and two side ribbons for a more intensive mixing process. The agitator construction provides triple action for faster, quicker, and more efficient blending. For the triple ribbon blender design to work, the dimensions and configuration of the ribbons has to be carefully balanced to avoid dead spots and enable rapid product discharge.

As the agitator rotates, the ingredients are tumbled along the inside of the trough. The pitch of the portions of the outer ribbon moves the ingredients toward the discharge opening. The ribbons of the inner ribbon have an opposing pitch that moves the ingredients away from the discharge opening. The constant motion between the varying pitches moves the ingredients back and forth such that they collide, mix and blend.

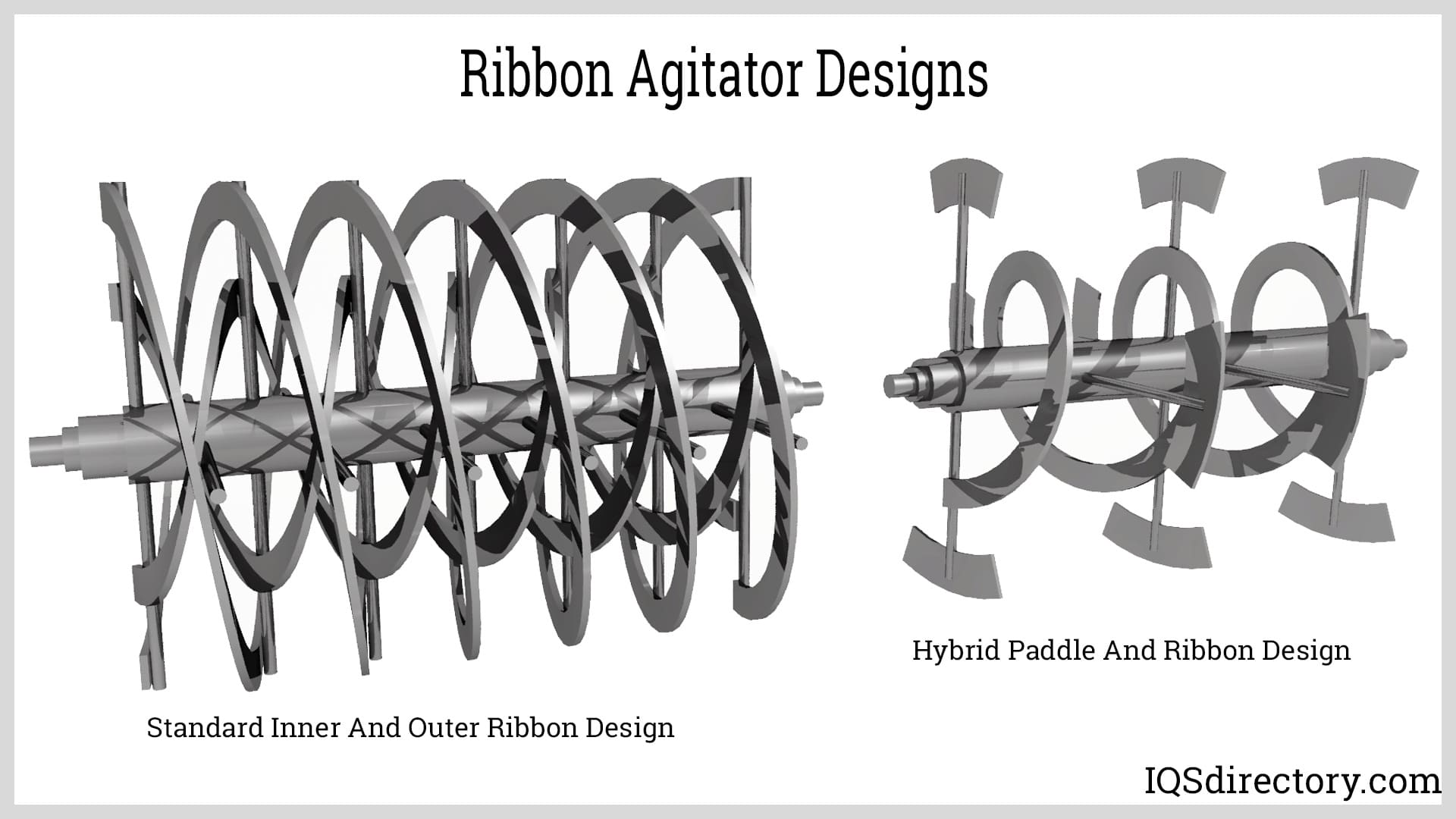

Ribbon paddle mixer blenders are referred to as hybrid agitators since they combine the tumbling action of paddles with the rolling pattern of ribbons that creates a double reversing effect. The interior design of ribbon paddle blenders can have the ribbons and paddles placed on the inside or outside depending on the application with ribbons on the inside and paddles on the outside or paddles on the inside and ribbons on the outside.

Agitators on hybrid agitators have the same function on ribbon paddle mixers as they do on all forms of ribbon mixers. The outer ribbons or paddles move the ingredients toward the discharge opening while the inner paddles or ribbons move the ingredients away from the discharge opening. Ribbon paddle mixer blenders are commonly used for mixing ingredients that contain shortening or soft agglomerates or lumps.

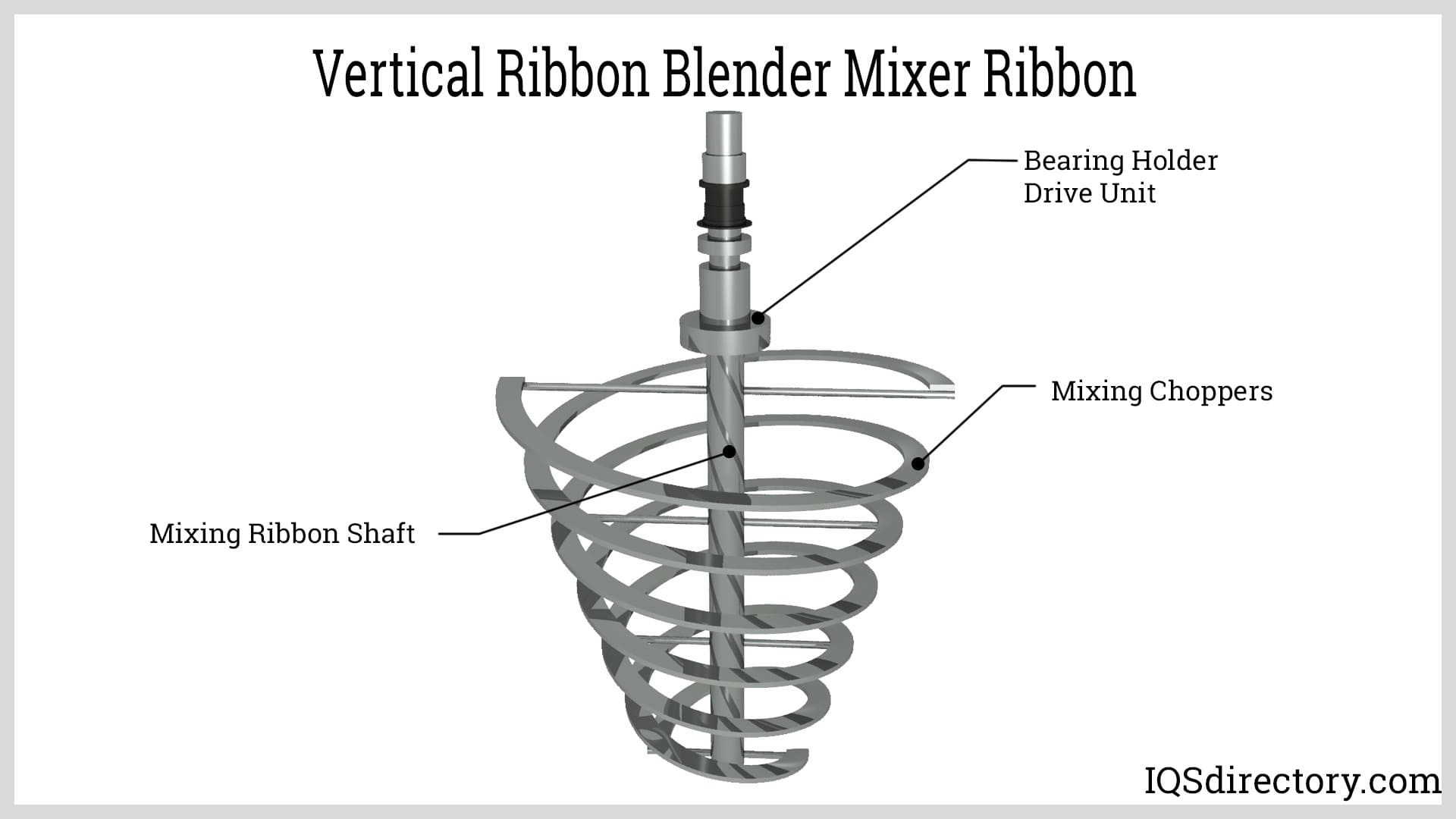

Vertical ribbon mixers take several different forms with the one common factor being their upside-down cone shape. The ribbon in a vertical ribbon mixer is a vertical spiral that rotates at moderate speed to create an upward flow of the perimeter ingredients while the central flow is downward. This creates the same type mixing that is found with a double ribbon blender using one ribbon.

A vertical mixer has a drive and vertical shape with a ribbon agitator that has a cone shape. The design of vertical ribbon mixers is for applications that involve ingredients that are shear sensitive. The simple construction is capable of fitting in any available space, a factor that makes vertical mixers flexible and adaptable.

Ingredients placed in a vertical mixer are lifted up by the high speed of the ribbon agitator from the bottom of the mixer up to the top from which they fall, by the force of gravity, back to the bottom of the mixer. The gentle mixing process prevents breakage of ingredients and provides good mixing. The mixing motion assists in avoiding agglomerations.

One of the popular features of vertical ribbon mixers is their ability to accommodate any type of batch sizes down to ones as small as 10% capacity. This particular aspect of vertical mixers makes them applicable for small companies that have varying demands placed on their mixing systems.

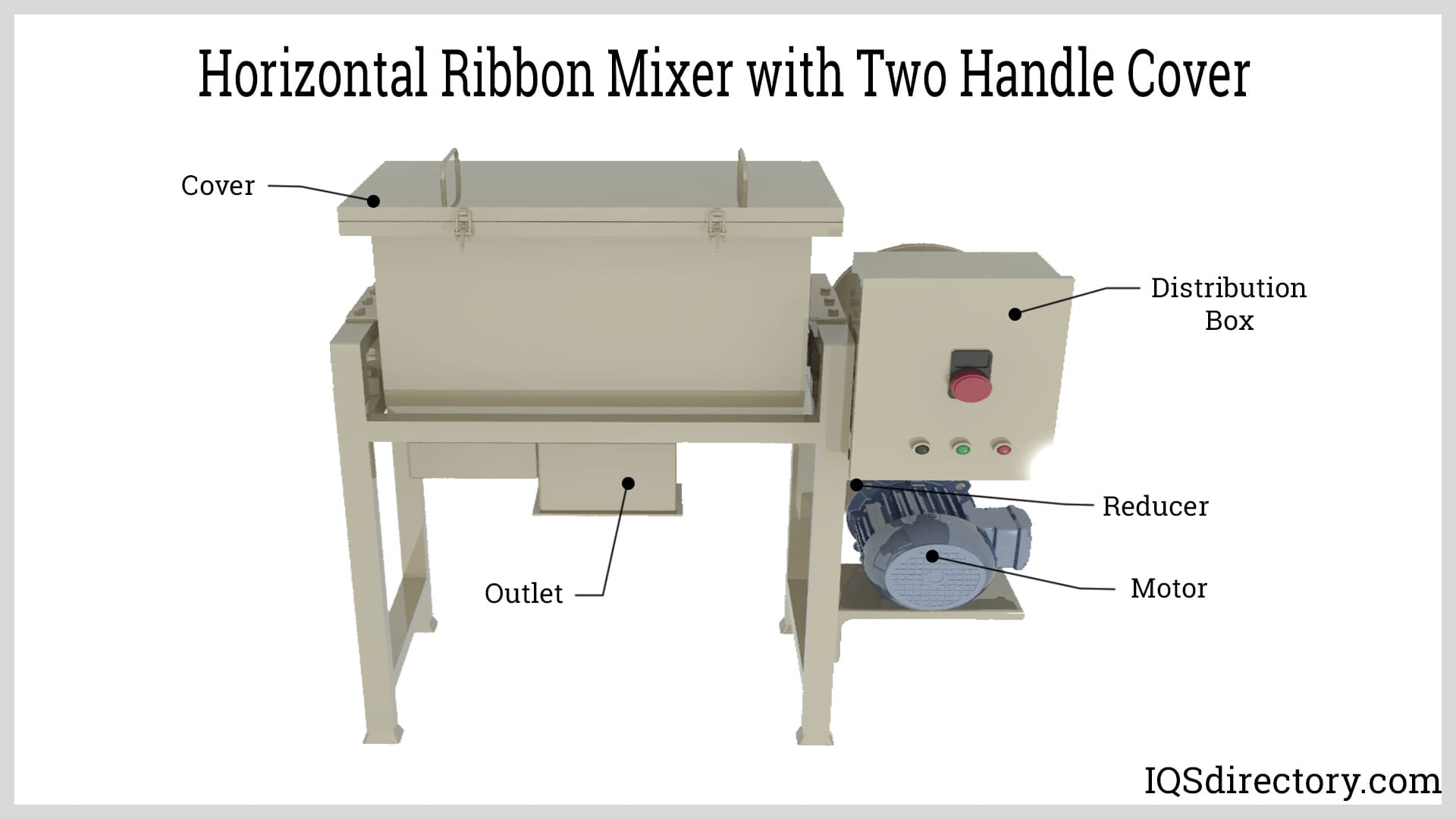

Horizontal ribbon mixers and blenders are the most common form of ribbon mixer. They have the standard shape, alignment, and configuration of ribbon mixers with agitators that rotate and spin inside a trough or cylinder. The motions of the ribbons of a horizontal ribbon mixer generate force that moves particles and materials back and forth along the trough so that ingredients collide and mix in the mixing chamber or trough.

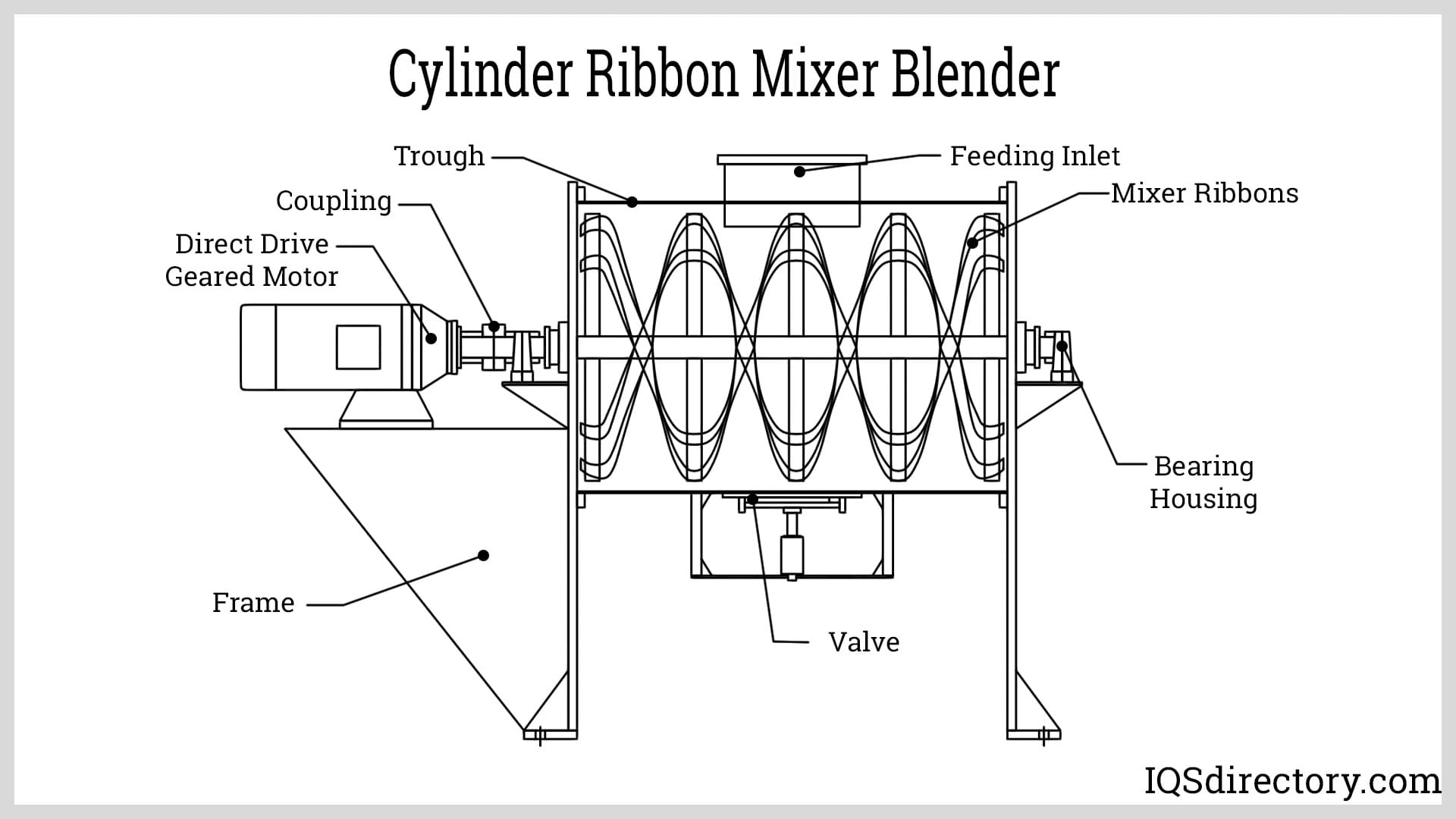

The different types of agitators that are used in ribbon mixers include trowel, paddle, double ribbon multi-pitch, and standard double ribbon. The most used of the various types is the multi-pitch double ribbon or helical cone agitator, which are ideal for batches with multiple ingredients and provide high quality mixing in a short amount of time. The components of horizontal ribbon mixers include a feed inlet, ribbon agitators, central shaft, motor, and discharge port.

Horizontal ribbon mixers are capable of mixing a variety of materials using the rotation of an agitator that has ribbon blades. The main characteristics of horizontal ribbon mixers are their stable dependable operation and good mixing. They fully mix different materials but maintain the initial physical properties of the materials. The wide use of horizontal ribbon blenders is due to their high capacity and exceptional blending efficiency.

The standard type of ribbon blender is horizontal with helical ribbons for the mixing process. Horizontal ribbon blenders have sturdy and durable components that are designed to withstand the constant forward and backward motion of the ingredients. A ribbon blender has a central shaft with helical blades attached to the shaft by spokes with the blades slanted in different directions. The configuration of the slanted helical blades is what gives a ribbon blender its name since the configuration resembles a ribbon.

The trough of ribbon blenders contains the shaft and ribbons and is the largest part of a ribbon blender. In the trough is where the blending and mixing process takes place. Troughs are made from stainless steel with welded interior walls that are polished and sealed. The shapes of troughs take different forms depending on the design of a ribbon blender.

U-shaped troughs are open at the top and are used for low pressure vacuum mixing. The top of the U-shape has a flat cover that seals the mixer during the mixing process. The cover can have inlet nozzles, if needed, which can allow the addition of dry powders. The U-shape design allows for easy access to the agitator for cleaning and maintenance.

The U-shape trough design is the most common form of trough for ribbon blenders. There are other types of troughs including cylindrical, fully cylindrical, and semi-cylindrical, which are used in accordance with the requirements of the mixing application. Troughs can be installed with choppers and spray systems for blending liquids, semi-solids, and low viscosity pastes.

The ribbon agitator is the heart of a ribbon mixer and consists of a rotating shaft that holds helical blades referred to as ribbons due their appearance. The ribbons of a ribbon mixer move ingredients from the center of the trough to the ends of the trough and back to the center to perform the mixing process. The two types of ribbons are the inner ribbons and outer ribbons. The inner ribbons move ingredients from the center of the trough to the end of the trough while the outer ribbons move the ingredients back to the center. The coordination of the ribbons ensures the completion of a uniform mixture. The axial and radial movement produces a homogeneous blend.

The helical blades are attached to the shaft by spokes that are welded to the shaft. When the shaft rotates, the ribbons move the materials to be mixed in a radial and axial flow pattern, which thoroughly mixes the materials. For the integrity of the mixture, the shaft is sealed at both ends to prevent leakage. The types of ribbon designs are single, double, triple, and hybrid with double ribbon designs being the most common.

Other forms of agitators that do not have the ribbon design are enhanced paddle designs and plow agitators. Both forms have a flat piece of metal on the end of their spokes. Enhanced paddle agitators have the same rotational motion as a ribbon agitator but move material in smaller zones over shorter distances and have cutting action that is unlike a ribbon agitator. Plow agitators have an action that folds ingredients in short zones and moves the ingredients away from the walls of the trough. It is a gentle form of mixing that is similar to hand folding of batter in a bowl.

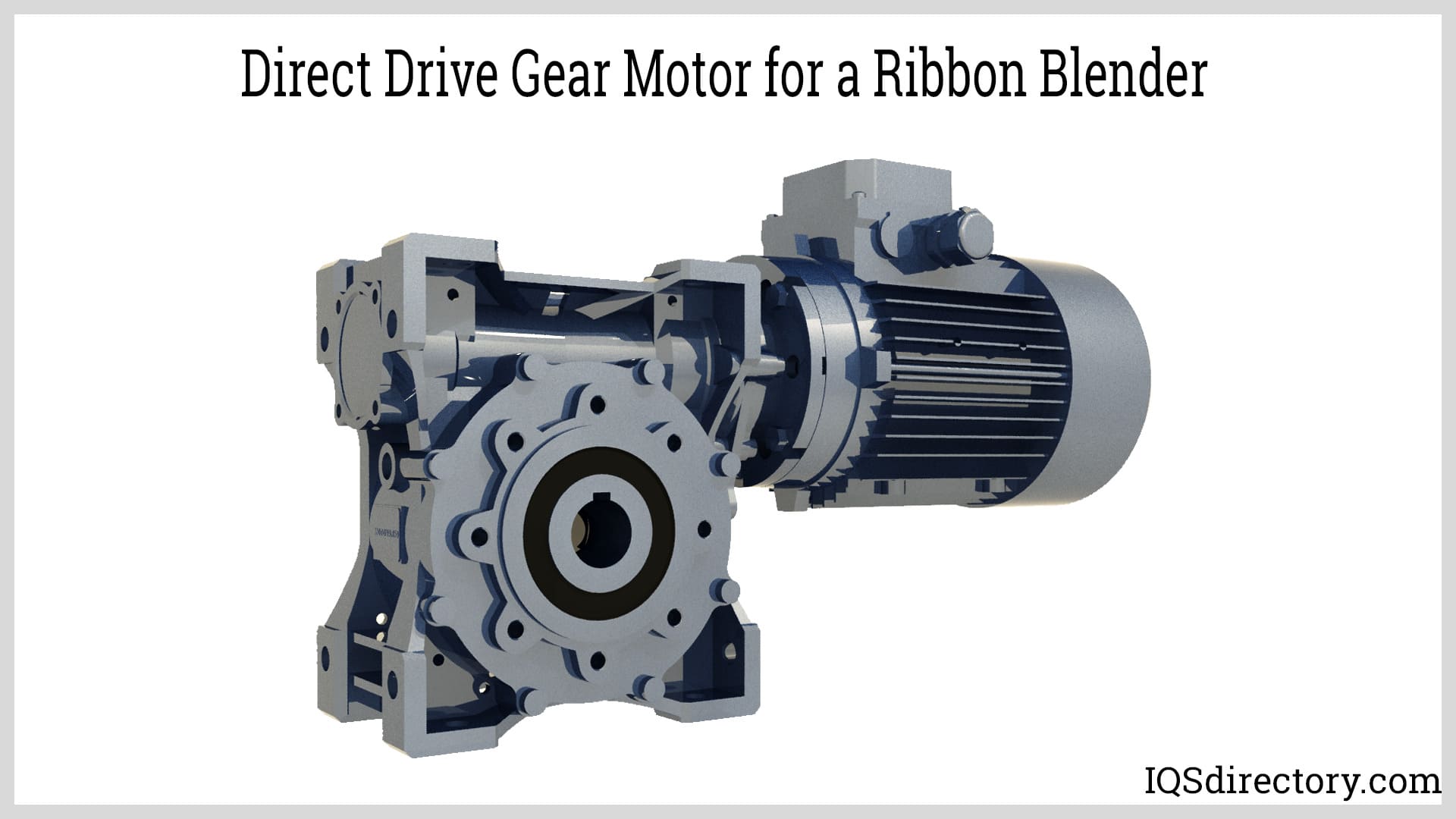

The drive systems for ribbon blenders vary from manufacturer to manufacturer with the different drive methods being belt drive, chain drive, and direct gear drive with the most reliable version being the direct gear drive motor version, which is more efficient and compact than the other drive methods. The oldest traditional drive method for ribbon mixers and blenders has been a belt drive that provides power to the motor that rotates the shaft of the blender. This form of drive system includes a flexible belt and pulleys to achieve the desired speed and torque. A variation of the belt drive is a chain drive that performs the same function as the flexible belt using chains.

For many years, ribbon blenders had a gear reducer with an input shaft that was belt driven or chain driven for applications with a higher load and lower speed. Chain and belt drives were and are powered by an electric motor. The main problems with chain and belt drives have been tensioning on the belt or chain and the need for constant maintenance. With the development of variable speed drives (VSDs) or variable frequency drives (VFDs) for electric motors, manufacturers have been able to switch to direct drive gear motors, which are more compact and efficient.

Direct drives have become increasingly popular due to their one-piece motor reducer with a low inertia rotor that is matched to the gear unit of the motor. The advantage of gear motors is the exceptional speed control, overload protection, and the ability to adjust starting torque. Gear motors provide higher efficiency due to the elimination of overhung loads and reducer shaft bearings. Direct drive gear motors have a compact design that require less space due to the smaller mounting platform of the motor.

The feed inlet is an opening in the top of a ribbon mixer through which the ingredients to be mixed are placed in the mixer. Many versions of horizontal ribbon mixers do not have a feed inlet. Ingredients are added to the mixer by opening the cover or top of the mixer. For units with a feed inlet, it is typically placed in the top cover of U-shaped horizontal ribbon blenders and is an opening with a cover. The feed inlet can be used as a method to access the mixer for maintenance and cleaning of the trough.

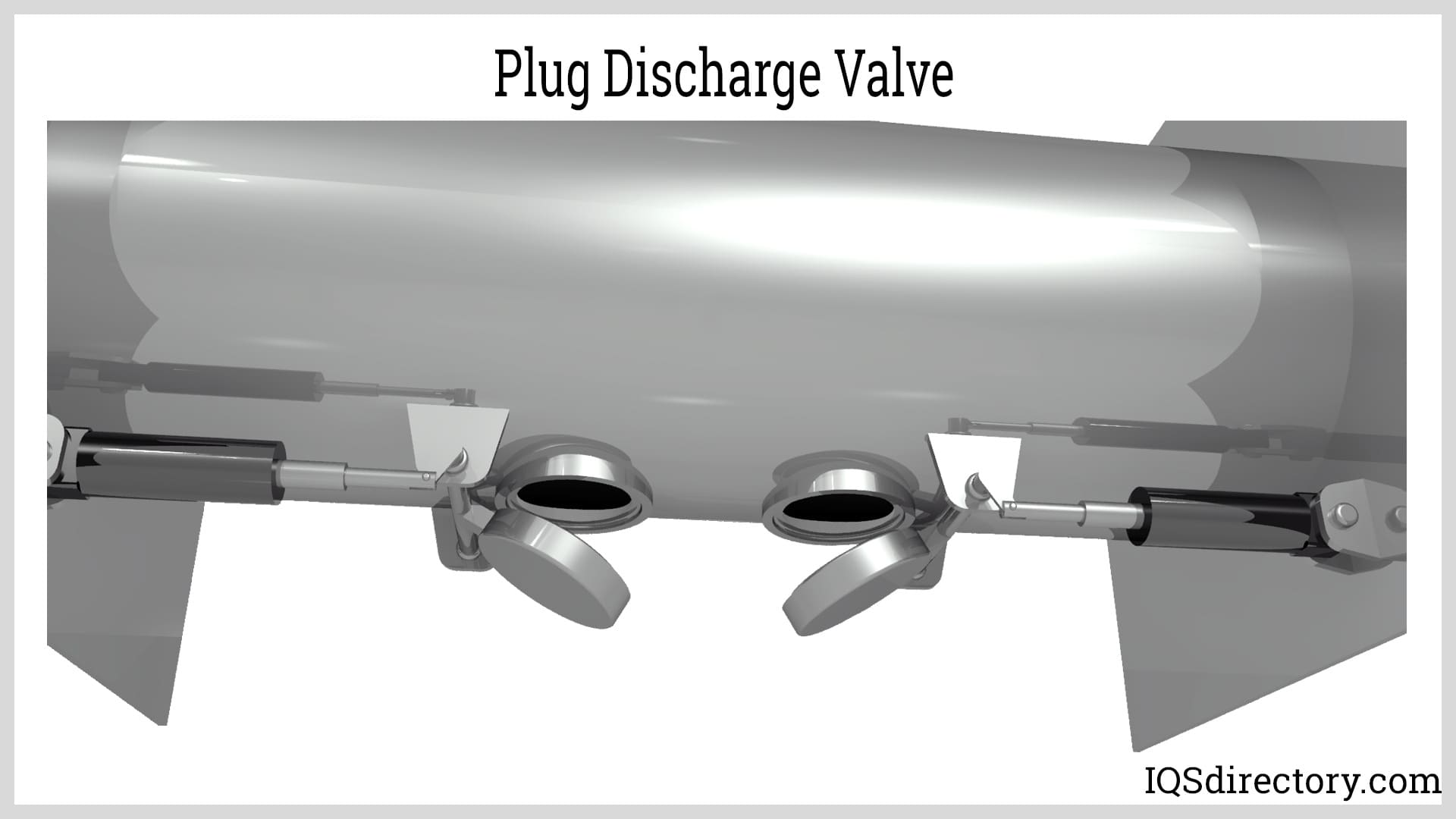

The discharge valve of a ribbon blender is the part of the blender through which the blended and mixed contents of the blender are removed. The process for emptying a ribbon blender involves running the mixer at low speed such that the mixture is pushed back and forth until the contents has been fully ejected through the discharge valve.

There are several forms of discharge valves or ports with plug valves being the most popular type. Discharge valves can be opened manually or pneumatically depending on the design of the mixer. Regardless of the type of discharge valve, they must be carefully managed to ensure the total contents of the mixture is removed such that any residue is not left to contaminate the next mixture.

The wide use of plug valves is due to their design that places them flush with the internal surface of the trough when closed and precisely matching the interior of the trough, which prevents material build up around the valve during mixing. Plug valves have a tight seal to prevent ingredients from leaking out of the trough.

The main forms of discharge valves include butterfly valves, side gate valves, knife gate valves, and spherical valves, which are also referred to as discharge gates. Each of the different discharge gates or valves are unlike plug valves in that they do not provide a sufficient seal and may allow the contents of the mixer to leak.

A special form of discharge method is bomb bay doors that are designed to prevent product loss and residue problems. Bomb bay doors are unlike any of the other discharge methods, which involve the use of some form of round valve. In essence, bomb bay doors for ribbon mixer discharge are larger, wider, and longer than typical discharge valves.

The term bomb bay is in regard to a feature that is common on airplane bombers, which have two hinged doors at the bottom of the aircraft that open to drop bombs. With ribbon mixers, bomb bay doors extend the length of the bottom of the trough or drum, have the same curved form of bomber bomb bay doors, and open to discharge the mixed ingredients. Their use reduces batch mixing times to increase production and ensures that all aspects of a mixture are removed during the discharge process.

A common feature of ribbon mixers is a control panel that allows an operator to set the speed of the agitator and ensures that the blended product is discharged at the proper rate. The control panel has components that send signals to regulate the operation of the mixer. Prior to the initiation of the blending and mixing process, operators are able to set the parameters for the process using the control panel. Buttons on the panel include a start and stop switch, discharge control button, an emergency stop, and timer for batch mixing.

Most ribbon mixers and blenders have covers that come in various sizes with smaller covers for semi-cylinder ribbon blenders and larger covers for U-shaped horizontal ribbon blenders and vertical ribbon blenders. The cover of a ribbon blender seals the blender such that the blending process is uninhibited. Ribbon blender covers are hinged and removable with safety locks. They can have inlet ports, vents, safety grates, dust hoods, and filter socks. All covers are reinforced and clamped for high- or low-pressure blending.

As with all forms of industrial equipment, ribbon mixers are required to meet certain safety standards for the protection of operators. One of the main safety concerns is the drum where the ribbons rotate and ingredients are loaded to be formed into a homogeneous mixture. Ribbon mixers are equipped with two safety features regarding the mixing drum that include a limit switch that prevents the mixer from operating if any cover is open. An additional feature that can be added is safety grating that is installed underneath the cover.

The use of ribbon blenders covers a wide array of powders, slurries, and granular materials. The breadth of substances necessitates safety features regarding the handling and transporting of mixtures. It is essential that materials to be blended should be adequately contained such that they will not contaminate the environment. In order to ensure this aspect of the process, there is a set of considerations that should be adhered to for worker protection.

The efficiency and durability of ribbon mixers make them an ideal solution for mixing slurries, powders, and other dry materials. As with any form of industrial equipment, ribbon blenders have to be treated in accordance with the processes they perform. By doing so, a ribbon blender becomes a safe and reliable mixing solution.

The choice of a blender or mixer for a process plays an important part in regard to how fast, efficient, and well the process is completed. When selecting a ribbon mixer or blender, it is possible to add different options that can increase the quality of the process. To ensure the proper selection for an application, it is important to examine the primary factors related to the application for which a ribbon blender is purchased.

The volume of a ribbon mixer is determined by the amount of material to be mixed and the speed at which it should be mixed. The many sizes of ribbon mixers make it possible to choose the ideal size for the requirements of a mixing process. One of the variations in the configuration of the blending process is whether to choose one large high capacity, high volume ribbon blender or several smaller ribbon blenders to avoid relying on a single blender.

In order to get the best results from a ribbon mixer, it is best to select a ribbon mixer that can be filled to its swept volume capacity, the volume of the area that contains the agitator. The length, width, height, volume, and agitator size are major factors to consider when choosing a ribbon blender.

The common forms of ribbon agitators are single, double, triple, and hybrid. The general process for a ribbon mixer is to move the ingredients back and forth along the length of the trough. If shearing is required, the mixing speed can be increased or accessories added, such as choppers. Hybrid ribbon blenders have a unique form of agitator that includes ribbons and paddles that perform mixing processes to increase the speed of the mixing.

The factors that can help identify the type of agitator are:

The choice of a ribbon blender can be significantly impacted by the materials from which the ribbon blender is made, since certain industries have to adhere to codes that dictate the types of equipment they use. The construction materials depend on the materials that will be mixed. For the food industry, which has regulations stipulated by the Food and Drug Administration (FDA), the construction of ribbon mixers are of the highest quality of stainless steel that has a special finish to enhance cleanliness and hygiene.

Although stainless steel is the main material for the manufacture of ribbon mixers, mild steels can be used for certain types of material. For non-food related applications, the interior of the trough may be made of stainless steel while the non-contact side of the mixer can be made of mild steel. Various types of coatings may be added to the interior surface of stainless steel that enhances the mixing process, which is needed when abrasive materials are blended.

Ribbon mixers operate at 20 RPMs but require more power for dual agitators and wider ribbons. Manufacturers work with their customers to select a ribbon mixer with sufficient horsepower to fit the needs of the application for which the ribbon mixer will be used. Motors that are too powerful can increase the expense of a ribbon mixer while low powered mixers will be unable to start due to the load.

The type of discharge gate is influenced by downstream processes, which determine the best time to discharge the mixture with some processes requiring immediate discharge while others need a gradual and slower discharge. Although there are several styles of discharge gates, the three most common are drop bottom, pneumatic slide gate, and multiple slide gate.

Every set of materials that is processed by a ribbon mixer has a set of stipulated characteristics that require examination in regard to the selection of a ribbon mixer. Different types of ingredients necessitate different procedures in order to mix properly. Attempting to process ingredients in the wrong type of mixer can damage the mixer and the ingredients and separate ingredients faster. Manufacturers use the list of ingredients that will be processed to assist clients in the purchase of the correct mixer for their mixing process.

Density, adhesion, melting and freezing point, particle size, friability, shear sensitivity, and explosiveness are characteristics that assist in selecting the right ribbon mixer for an application. Although choosing a less expensive one may seem to be an option, the cost of a mixer may be irrelevant when examining the characteristics of the ingredients.

One of the first steps in the assessment by a ribbon mixer manufacturer is to examine the facility where a ribbon mixer will be used. When space is limited and the ingredients are appropriate, a vertical ribbon mixer may be used since they require less space and have a similar mixing motion to that of a double ribbon mixer. There is a wide variety of horizontal mixers with ones of a few cubic feet up to ones with thousands of cubic feet. This factor makes it possible to select a ribbon mixer that is the right size and configuration.

In addition to an examination of the space for a ribbon mixer, it is important to determine how a ribbon mixer will fit into production requirements. Again, manufacturers will provide advice, guidance, and data regarding proper placement such that a ribbon mixer fits smoothly into a production process. Such information can also be used to determine how many mixers will be required and are necessary.

Ribbon mixers require a clean, dry, well lit, and well-ventilated space with a flat stable surface. The power supply for a ribbon mixer must function properly and be grounded. Prior to operation, the seals on the mixing trough and stirring blades should be cleaned and tested for unrestricted rotation. Bearing temperatures must be below 60o C (140o F) when the machine is operating.

A ribbon mixer is an investment that requires careful consideration and the assistance of experienced professionals, which is provided by ribbon mixer manufacturers who work closely with their clients to select the right machine for an application. A ribbon blender should be suited for the process for which it was purchased and the characteristics of the materials to be mixed, information that is available from ribbon mixer manufacturers.

Several industries rely on ribbon mixer blenders for the blending of ingredients for various applications. The adaptability and flexibility of ribbon mixers makes them ideal since ribbon blenders can be used for mixing food ingredients and chemicals, industries that have highly restrictive regulations and requirements.

In the fertilizer industry, ribbon mixers are used for their power and mixing capabilities. The two axes motion helps in the manufacture of large production runs of natural fertilizers. The types of fertilizers that are produced using ribbon mixers include ureas, organic manure, and roughage.

The manufacture of chemicals requires vigorous mixing, blending, heating, and cooling for complex product production. Ribbon mixers are chosen for use in the chemical industry due to their safety and ability to adapt to hygienic conditions. Since several chemical products involve granules, dry powders, low viscosity materials, and seasonings, ribbon blenders are ideal due to their function and design.

The types of materials blended by the mineral industry require a mixer that can mix substances of varying densities. Ribbon mixers provide a reliable, efficient, adaptable, and flexible mixing solution for blending dry materials of different densities and semi-wet materials.

Many of the products for cosmetics involve the use of some form of powder that needs to be blended and homogenized into a single mixture. For many years, the cosmetics industry has relied on ribbon mixers to blend and mix the various powders and ingredients that require gentle but thorough processing. Lotions, shampoos, hair gels, sanitizers, toothpaste, lipstick, and make up powders depend on the mixing power of ribbon blenders and mixers.

The industry that makes the most use of ribbon blender mixers is the food and beverage industry that rely on ribbon mixers for sanitary and hygienic construction. The FDA places highly restrictive standards and regulations on equipment used to produce food products for the protection of the public. Ribbon mixers are made of series 300 stainless steels that are ultra-hygienic, resistant to bacteria, and resistant to corrosion such that items produced are protected from contaminants.

Another reason for the wide use of ribbon mixers in the food industry is their flexibility and adaptability. The controls on ribbon mixers make it possible to set the exact rotational speed of the shaft in order to gently blend ingredients. In addition, ribbon blenders can blend semi-dense and semi-wet materials, which are common to the food industry. Ribbon blenders are used for preparing bread, cookies, chocolates, brownies, cakes, and other baked goods.

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...