Agitators

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on Mixers .

This article will take an in-depth look at the types of mixers.

The article will bring more detail on topics such as:

Common scenarios in mixing involve solid-to-solid dispersion, solid-to-liquid, liquid-to-gas, and two types of liquid-to-liquid interactions: miscible and immiscible. The mix's effectiveness is influenced by the strength and nature of the eddy currents or turbulence and the opposing forces. If these opposing forces are more powerful, achieving a greater degree of mixing becomes crucial.

A mixer is a sophisticated, specialized tool designed for blending, emulsifying, homogenizing, and integrating diverse ingredients crucial to manufacturing or production processes. Mixing plays an essential role in creating commercial and industrial goods, such as pharmaceuticals, cosmetics, and food. Mixing must be precisely controlled, especially when dealing with incompatible or disparate chemicals and materials.

The performance of a mixer is gauged by its capacity to reliably replicate the mixing process while ensuring uniformity. The complexity arises from the varied properties of mixed materials, which demands careful handling. Proper mixing starts with a comprehensive analysis of the materials to ensure process success. Much like other industrial tasks, mixing often requires equipment tailored to the unique needs and circumstances of the production process.

When discussing mixers, distinguishing between blending and mixing is key, as they may appear similar but serve different functions. Blending involves a gentle process to evenly distribute materials, resulting in a distinct new substance. Conversely, mixing involves merging ingredients that might separate back to their original states. This distinction is vital when selecting a mixer since most applications aim to create a new uniform substance, typically achieved through blending.

Industrial mixers vary widely, with some designed for compact applications like combining plastic polymers, while others tackle pulverizing and blending pellets and stones. The success of mixing is characterized by efficiency, equipment quality, durability, and dependability. Industrial mixers are crucial elements in numerous industrial processes and applications.

Choosing a suitable mixer begins with evaluating the materials to be mixed, which vary across industries. Typically, these include liquids, emulsions, slurries, pastes, solids with liquids, and powders or granules. Understanding their consistency, properties, and characteristics aids in choosing an appropriate mixer for each application's requirements.

Factors like material shape, density, size, and static charge determine their interaction and influence the blending process. Each of these components is critical in choosing the best mixer for optimal mixing performance.

Manufacturers frequently customize equipment with distinctive features to meet specific functionalities. Given the variety of materials available, selecting a mixer that aligns with their properties is crucial. A significant consideration is material volume since batch sizes must match the mixer’s capacity for effective mixing. For instance, drum mixers typically have a capacity of 50 to 100 gallons (190 to 380 liters), whereas agitator mixers range from 16 to 264 gallons (60 to 1000 liters).

| Material Types for a Mixer | |

|---|---|

| Industrial Mixer Type | Specifically Designed for Mixing |

| Paddle Mixer | Viscous semi-solid substances |

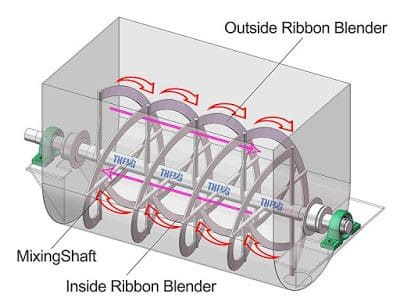

| Horizontal Ribbon Mixer | Food, chemicals, powders |

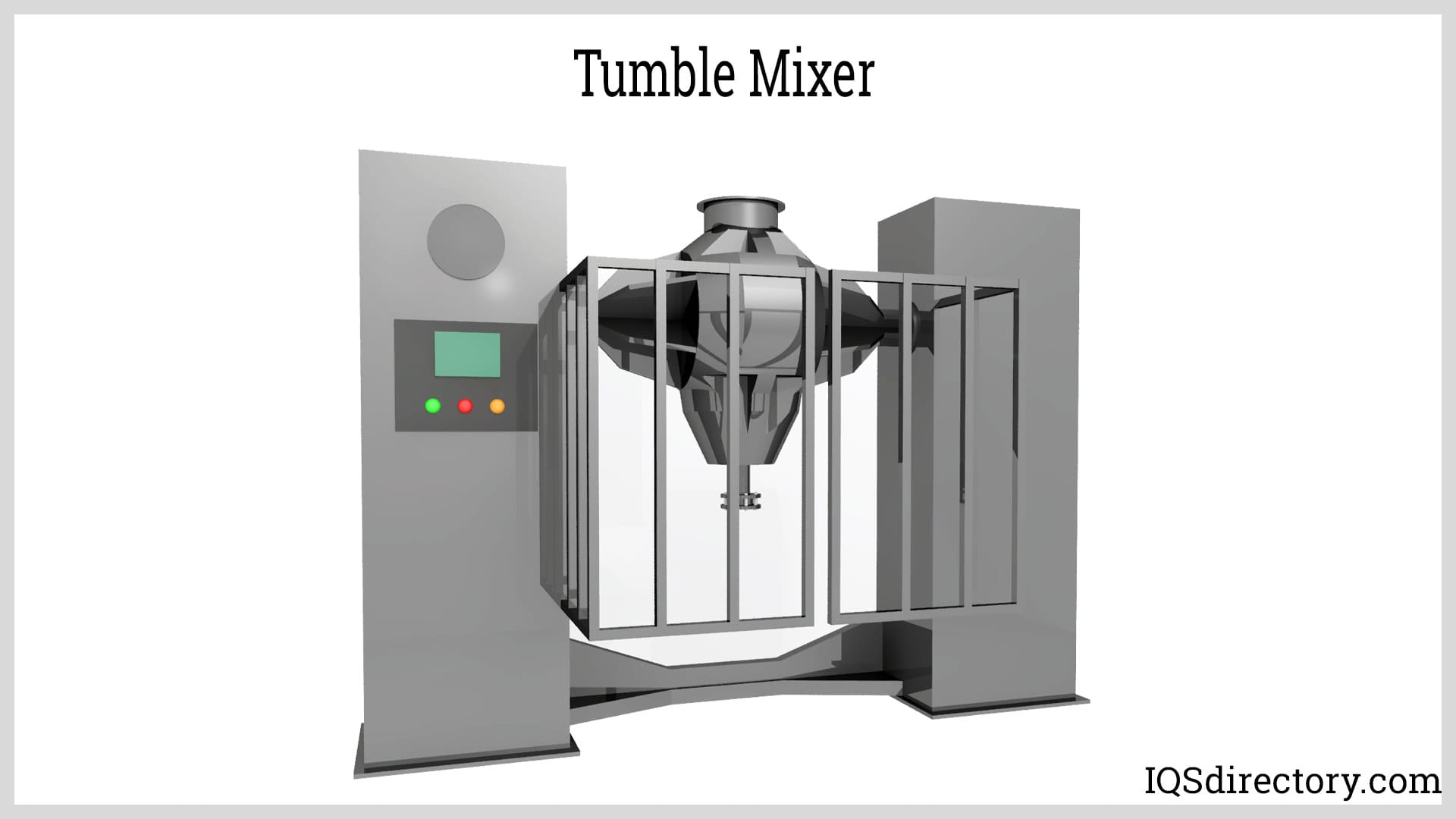

| Tumbler Mixer | Bakery ingredients |

| Drum Mixer | Low and medium viscosity materials, like slurry or cement |

| Emulsifier | Immiscible liquids, like oils |

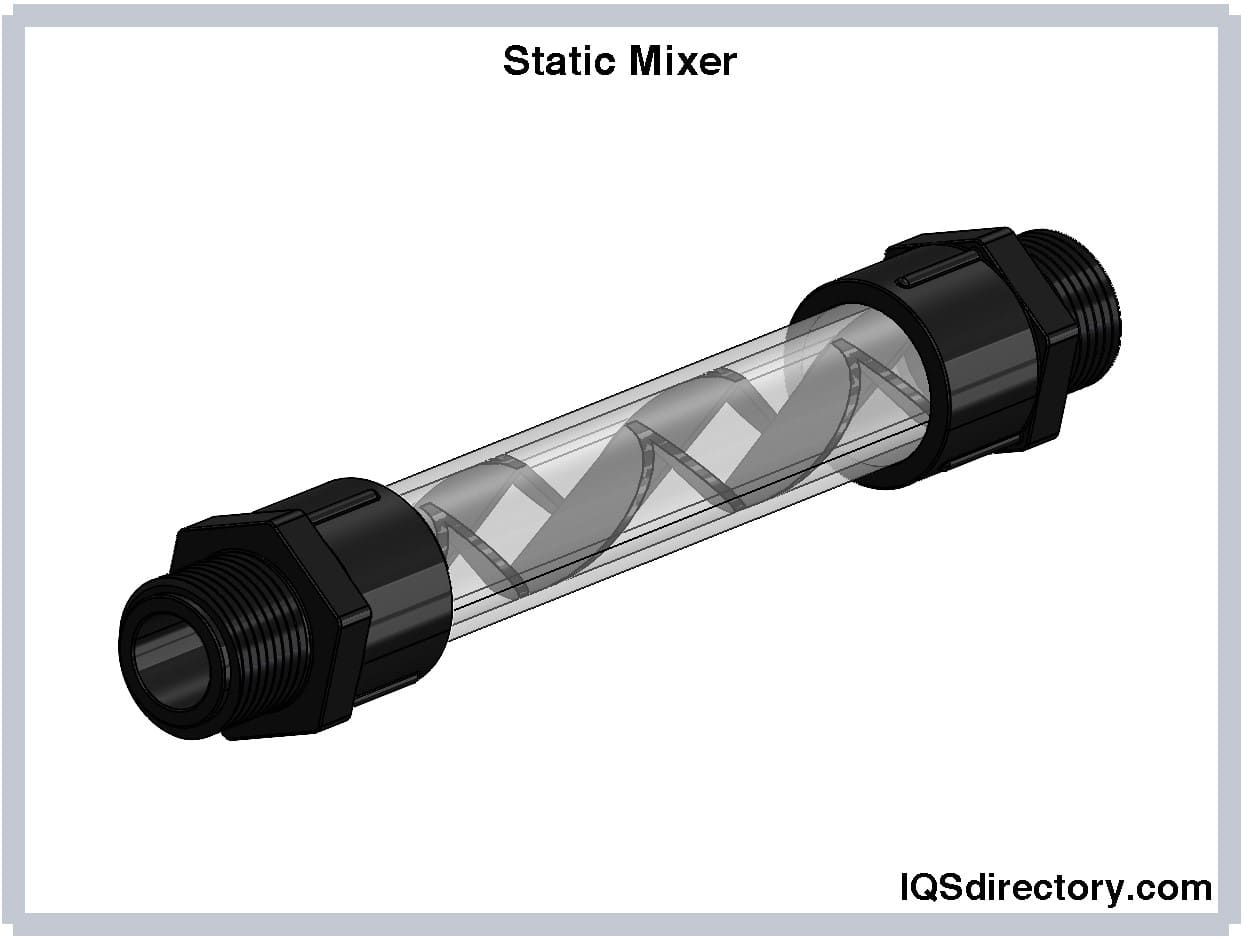

| Static Mixer | Gasses and liquids |

The viscosity of a liquid measures its resistance to flow and mixing, dictated by the movement of molecules past each other. This characteristic, referred to as viscosity, is measured in centipoise (cps), with water having a viscosity of one cps in laminar flow. Various materials exhibit a wide range of cps values.

As viscosity rises, the material flow becomes more laminar. Mixer designs must ensure sufficient agitation and uniform mixture. For high-viscosity materials, the torque and type of mixing blades or impellers are critical.

The efficiency of mixing is defined by torque, determined by dividing horsepower by RPM. Since horsepower alone isn't an indicator of efficiency, high-viscosity applications often require higher torque or lower RPMs, mandating stronger drive systems, larger mixer shafts, and broader diameter impellers. Specialized impellers are essential for controlling and propelling viscous fluids effectively.

Viscous fluids often exhibit pseudoplastic or thixotropic properties, unlike laminar fluids. Laminar fluids have high momentum diffusion and low convection, typical of less common scenarios. Pseudoplastic and thixotropic fluids thin with shear, with thixotropic fluids thinning over time when sheared, like how ketchup becomes more fluid after shaking yet remains thick normally.

For successful high-viscosity mixing, mixers with gearboxes that lower RPM and raise torque are most effective. Adequate mixer shaft diameters are necessary to accommodate larger impellers with extensive blades and aggressive pitches to enhance surface contact.

Smaller tanks provide efficient pumping and mixing, while larger tanks may require different approaches. For example, substantial 100,000-barrel oil tanks employ side-entering mixers and may take hours or even days to achieve optimal blending. Extended mixing times in large tanks necessitate multiple smaller support mixers to assist. Small vessels manufacture the product, while large tanks mostly serve storage purposes.

The blending process encompasses several stages: loading, mixing, packing, and cleaning. To accurately evaluate mixer efficiency, it's important to determine the exact time required per stage. Each mixer has a standard average mixing time, factoring the time necessary for loading and packing along with actual blending. The complete cycle, from commencement to completion, may be longer than just the blending phase.

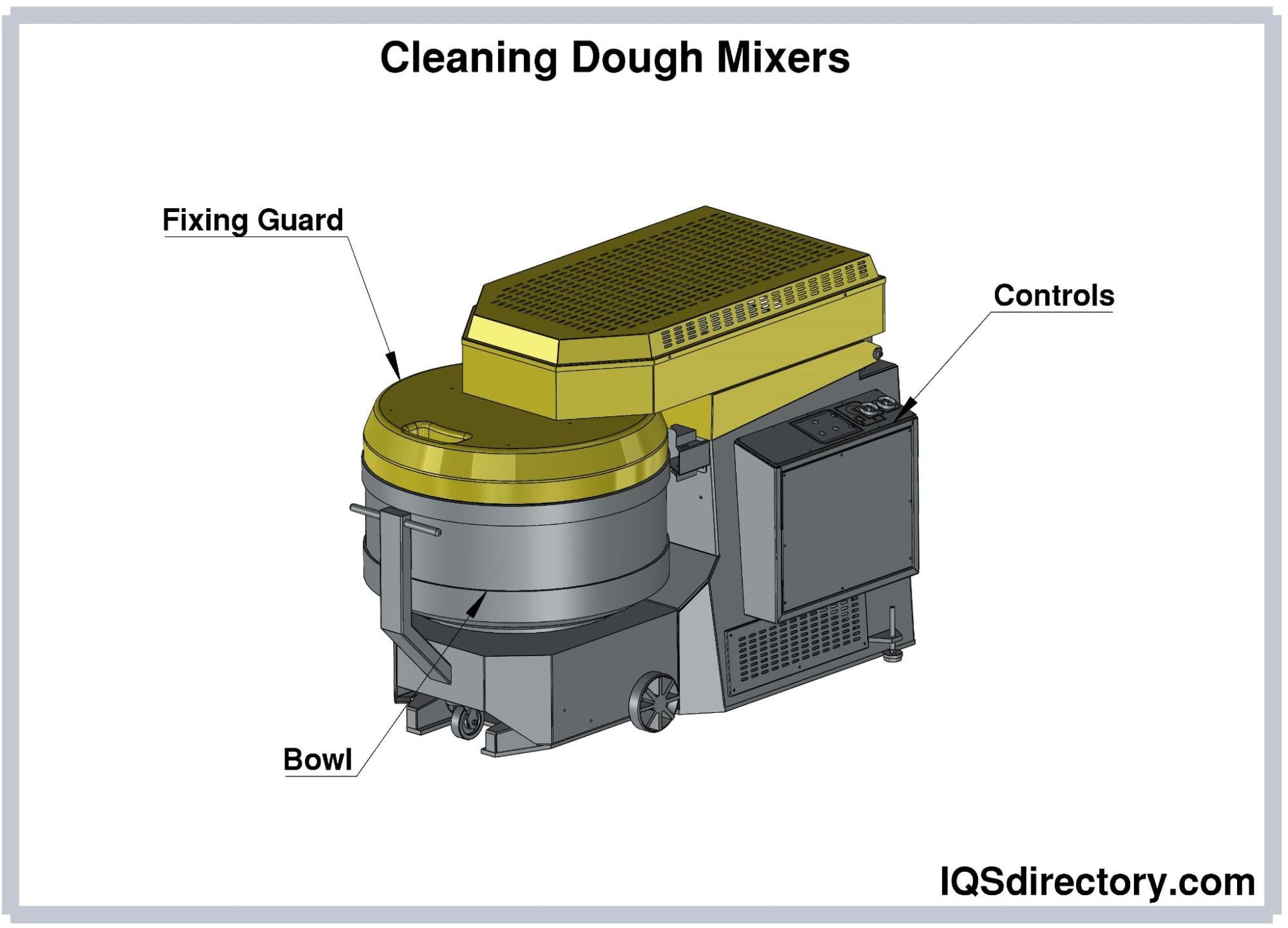

Mixers with multiple moving components can lead to product becoming dislodged and adhering to bearings, the mixer walls, and paddles. This causes both a significant product loss and poses contamination risks. Adherence of the product to these surfaces can cause contamination issues, highlighting the necessity of addressing these concerns in mixer design and upkeep.

Consequently, considering the full time needed for drying and cleansing mixer parts is critical. Dismantling and reassembling these parts is time-intensive and requires careful consideration. When selecting an appropriate mixer, efficient manufacturing processes and ease of maintenance are paramount. Thoroughness and patience ensure striking a balance between operational efficiency and effective maintenance.

Tip speed is the distance an impeller moves within a certain period. By multiplying the impeller's diameter by π (pi) to get the circumference and then multiplying this by the impeller’s RPM (revolutions per minute) or RPS (revolutions per second), you obtain the tip speed, expressed in feet per minute or meters per second.

In mixers handling dry materials, tip speed significantly influences cycle times. Higher tip speeds yield shorter cycles. For instance, low-speed mixers like ribbon blenders have a tip speed of about 1.4 meters per second, medium-speed systems such as horizontal mixers range between 6 to 10 meters per second, whereas high-speed mixers, including vertical high-speed mixers, reach speeds from 28 to 40 meters per second.

Exceeding a certain tip speed threshold results in fluidization, where dry materials mimic liquid behavior, enhancing the mixing process, much like the improvement when using a food processor over stirring by hand. Vertical and horizontal high-speed mixers facilitate fluidized mixing compared to ribbon blenders.

Elevated tip speeds demand more power. For instance, ribbon blenders necessitate 1 HP per 100 to 200 pounds (45.3 to 90.7 kg) of material, whereas vertical high-speed mixers process under 4 pounds (0.45 kg) per HP.

Tip speed further influences the dispersion of agglomerated particles. Efficient dry material blending often entails mixing larger particles with smaller, agglomerated ones. Creating a uniform blend requires separating small clumped particles like plastic powder with pigments. As pigments are micron-sized particles, breaking them apart demands considerable energy.

Vertical mixers offer enough energy to fluidize mixtures and efficiently separate small agglomerated particles. Medium-speed horizontal mixers can perform such separations, though not as efficiently as vertical high-speed mixers. Incorporating high-speed choppers in a medium-speed mixer enhances dispersion, with the chopper blades’ tip speed paralleling main mixing blades' speeds in high-speed mixers, aiding the dispersion of agglomerated ingredients.

The choice of a mixer, or industrial mixing equipment, depends primarily on its intended application and the physical properties of the materials to be mixed. In industrial process engineering, mixers are essential for blending chemicals, liquids, gases, granules, polymers, powders, and pellets. The industrial mixer market offers a diverse portfolio of commercial mixers designed to handle materials with various levels of viscosity, density, and reactivity—including those that pose mixing challenges, such as high viscosity adhesives, slurries, and immiscible compounds. Generally, mixers fall into three broad categories: diffusion (tumbling), shearing, and convection mixers. Each type features distinct construction, agitator or impeller designs, mixing speeds, and operating functions. Understanding these industrial mixer categories is crucial for selecting the best mixer for process efficiency, scalability, and product quality.

Tumbler mixers, also called tumbling mixers, are a type of diffusion mixer that use rotational motion to blend bulk materials. By tumbling the batch, these mixers also incorporate air, aiding in even distribution without the use of impellers or internal moving parts. Tumbler mixers are optimal for mixing free-flowing solids, powders, pharmaceuticals, ceramics, and fragile granular ingredients. In certain applications, they can also process some liquid or liquid-solid blends.

Gravity in tumbler mixers continually recirculates the batch to the bottom of the rotating drum, ensuring repeated and gentle mixing cycles that prevent product degradation. Tumbler mixer configurations include octagonal, conical, double-cone, and V-shape blenders—each suited to different batch sizes and mixing goals, such as achieving uniform particle distribution in powder processing.

High shear mixers, also known as high shear reactors (HSRs) or rotor-stator mixers, are specially engineered for intensive industrial processes involving the rapid emulsification, homogenization, particle size reduction, and dispersion of both solid and liquid phases. These process mixers utilize high-speed mixing blades or rotors to generate significant shear forces, breaking apart agglomerates and ensuring a fine dispersion or emulsion. Typical applications include paint manufacturing, ink production, adhesives, polymers, food processing, cosmetics, biotechnology, and pharmaceutical manufacturing.

High shear mixing technology is essential when blending immiscible liquids (such as oil and water), or dispersing solids into high-viscosity or high-density liquids, where standard paddle or ribbon mixers would fail. Dispersion blades fragment and suspend particles into the liquid medium, improving product consistency and stability. Adjustable speeds and modular rotor-stator configurations enable operators to customize shear rates for batch-to-batch reproducibility and improved throughput.

High shear mixers can combine difficult materials that resist blending—such as emulsifying oil and water or dispersing pigments and fine powders. The high shear mixers are widely used across a range of sectors, including chemical, food, beverage, pharmaceutical, cosmetics, and adhesives, further demonstrating their versatility in process industries.

High speed mixers are specialized for industrial processes requiring rapid dispersion, granulation, wetting, or cooling of ingredients. With rotational speeds significantly higher than standard mixers, they excel in operations where short processing times or high throughput are critical, such as plastic compounding, colorant manufacturing, and powder blending. High speed mixers are available as compact bench-top units for formulation labs, or as large-capacity production mixers for continuous or batch processing in sectors like paints, plastics, food, and pharmaceuticals.

Typical uses include rapid blending of resins, pigments, dry powders, wet granules, and ensuring efficient heat transfer during the mixing cycle. Designed for robust performance, high speed mixers are essential equipment for high-volume manufacturers seeking consistency and scalability in their production lines.

The term "ribbon blender" refers to the specialized helical ribbon blades that span the length of the mixer. These double and outer ribbons provide counteracting flow patterns: the outer ribbons draw material from the tank walls to the center, while the inner ribbons push from the center outward. This dual-motion convective mixing generates highly uniform blends, particularly for dry powders, granules, seasonings, nutraceuticals, pharmaceuticals, and some paste materials.

Ribbon blenders perform rapid and thorough mixing, typically finishing a batch in under 20 minutes at a tip speed of 1.4 meters per second. Despite the efficiency, their gentle agitation safeguards fragile ingredients. Ribbon blenders support industrial batch processing in food, chemical, powder coating, and construction materials industries.

While ribbon blenders deliver excellent mix quality and scalability, they can be costlier and require more maintenance versus paddle mixers, especially for abrasive or sticky materials. Proper cleaning and preventive maintenance are essential for long-term performance and hygiene.

Paddle mixers utilize overlapping paddles to gently scoop, lift, and tumble various materials within the mixing chamber. This makes them an ideal choice for blending ingredients of variable particle sizes, densities, and viscosities—such as salad mixes, rubber, specialty chemicals, and fragile solids like glass fibers or nuts. The low-impact mixing action minimizes material degradation, preserving the shape and integrity of sensitive components.

The unique three-dimensional figure-eight motion created by the pitched paddles of a paddle mixer ensures complete batch circulation and intensive micro-mixing. Dual shaft configurations further boost kneading, folding, and homogeneous distribution of binders, additives, or colorants.

Paddle mixers are used for food, chemicals, fertilizers, construction materials, and other process industries needing gentle yet effective mixing of both free-flowing and cohesive materials.

Agitator mixers are mechanical devices engineered to mix, suspend, or agitate liquids and slurries during industrial batch or continuous mixing operations. Commonly employed in chemical solutions, wastewater treatment, and liquid food or beverage production, agitators utilize a central rotating shaft and impeller to induce turbulent flow and mass transfer. Top-load washing machines and large-scale process tanks often rely on agitator mechanisms for proper blending and dissolution of ingredients, gases, or solids.

Typical agitator mixer applications include solid suspension, dissolving gases into liquids, blending miscible and immiscible liquids (by dispersing droplets), and transferring heat. Agitators are classified by impeller configuration—axial or radial flow—determined by blade angle and flow direction. These mixers are well-suited for medium to high viscosity materials, though high shear mixers may be necessary for process-intense or shear-thinning fluids.

Agitator mixer selection should consider vessel size, desired turnover rate, viscosity, power input, and efficiency goals. Proper impeller sizing and positioning are key for industrial agitation systems.

Axial flow agitators have impeller blades angled less than 90 degrees to the rotation plane, driving material flow parallel to the impeller shaft and producing efficient top-to-bottom mixing. These are valuable for solid suspension and uniform bulk blending.

Radial flow impellers have blades that release flow perpendicular to the impeller axis, generating high shear near the tank walls—suitable for gas-liquid dispersions, emulsifications, and heat transfer.

Rotor mixers (including rotor-stator and high-speed blenders) use spinning blades at the container’s base to create vortex action for blending, emulsification, and size reduction. Detachable attachments accommodate various batch sizes or materials, providing flexibility for pilot-scale or production-scale mixing.

The rotor mixers are used in sectors such as food processing, adhesives, pharmaceuticals, fine chemical manufacturing, and laboratory research.

Static mixers feature a fixed mixing element, like a twisted ribbon or helical baffle, inside a stationary tube. These inline industrial mixers have no moving parts and are designed to continuously mix and homogenize liquid or gas streams as they flow through the unit. The static mixer disrupts laminar flow, creating turbulence to blend components and achieve uniformity without mechanical agitation.

Static mixers are highly effective for dispersing gases into immiscible liquids, continuous dosing of chemicals, water treatment, wastewater neutralization, polymer blending, and low-viscosity applications where consistent, precision mixing is required.

Industries such as chemical processing, oil & gas, utility water treatment, food & beverage, pharmaceuticals, and cosmetics use static mixers for inline blending, dilution, and fluid conditioning in pipeline infrastructure. Static mixers excel where automated, maintenance-free mixing, energy efficiency, and product consistency are desired.

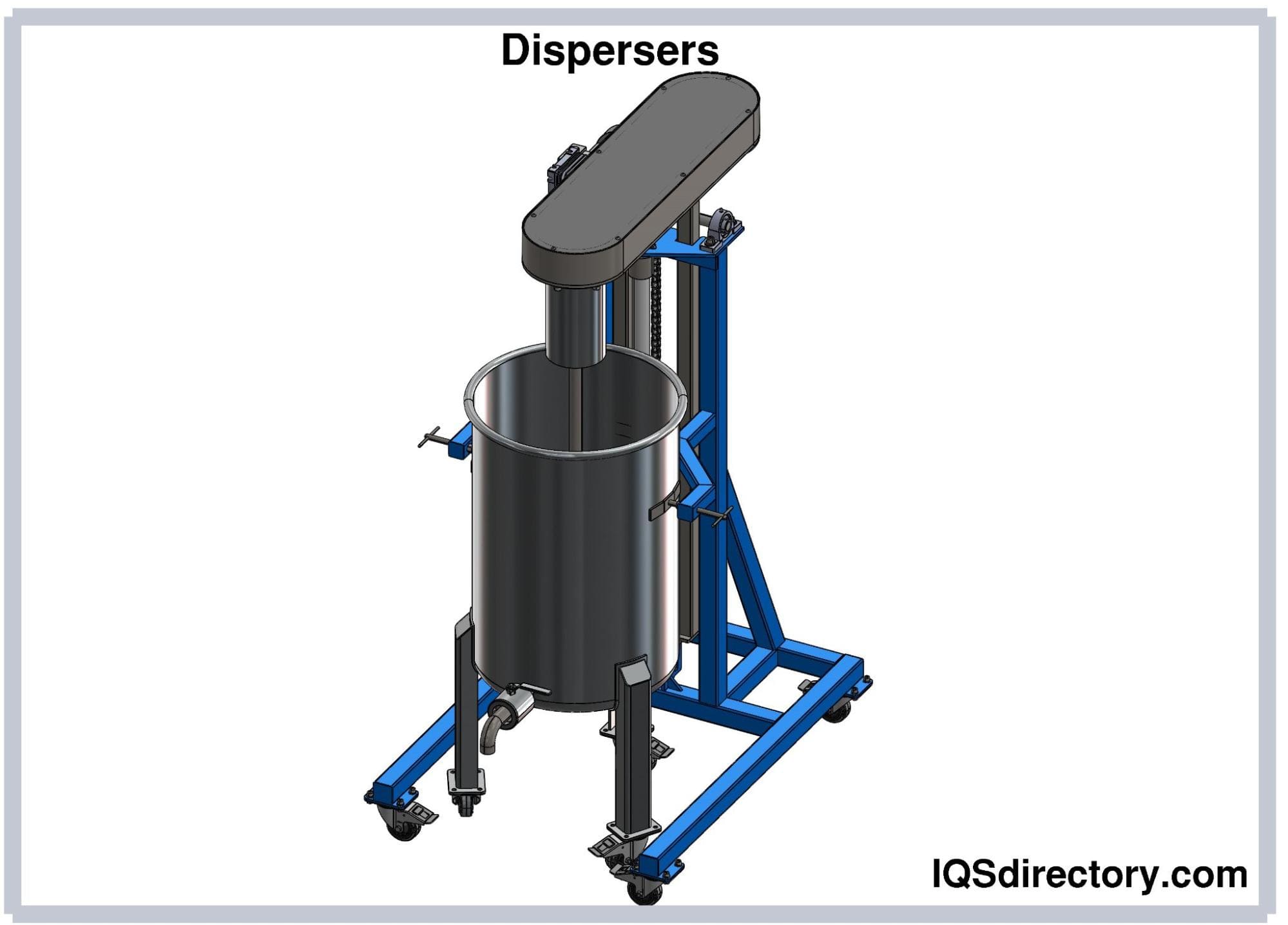

A disperser mixer delivers localized, high-speed energy to break down, dissolve, and evenly disperse solids in powders or liquids. These industrial dispersers use disc-shaped blades or saw-tooth impellers rotating at high velocity to generate intense shear for colloidal and suspension mixing.

Dispersers are utilized in food manufacturing (for dissolving powders or pre-mixes), adhesives, paint and coatings, inks, cosmetics, and pharmaceutical formulations. They are particularly effective for wetting, particle deagglomeration, and incorporation of insoluble ingredients that require additional force for stable blending. Proper disperser selection is vital for optimizing viscosity reduction, color development, and stability of the final product.

Emulsifier mixers are engineered for the consistent blending of immiscible liquids such as oil and water, often crucial in cosmetic, pharmaceutical, and food applications. These machines create oil-in-water or water-in-oil emulsions using high shear, vacuum, and controlled pressure, vital for achieving creamy and stable products like lotions, mayonnaise, salad dressings, and ointments.

Vacuum emulsifier homogenizers combine centrifugal force and high-speed work heads to disintegrate fat droplets or particulate matter, ensuring micro-level uniformity. Emulsifier mixers are widely used for the production of dairy products, beverages, pharmaceuticals, and cosmetic creams—ensuring reliable scale-up and repeatability.

Homogenizer mixers apply intense force, pressure, and turbulence to thoroughly integrate liquid-liquid, gas-liquid, or solid-liquid mixtures at the microscopic level. This ensures that all mixture components are evenly dispersed—eliminating lumps or layering. These mixers are indispensable in food technology, dairy processing, biotechnology, cosmetics, and chemical production, where texture, product stability, and shelf-life are critical outcomes.

Heavy duty mixers are purpose-built for very high-viscosity and dense materials such as pastes, mastics, silicones, rubber, polymer melts, slurries, and wax compounds. Standard industrial mixers may fail under such loads, but heavy-duty systems—like planetary mixers and multi-shaft mixers—are designed to handle viscosities beyond 750,000 centipoises. They ensure robust mixing, kneading, and homogenization even under high torque conditions.

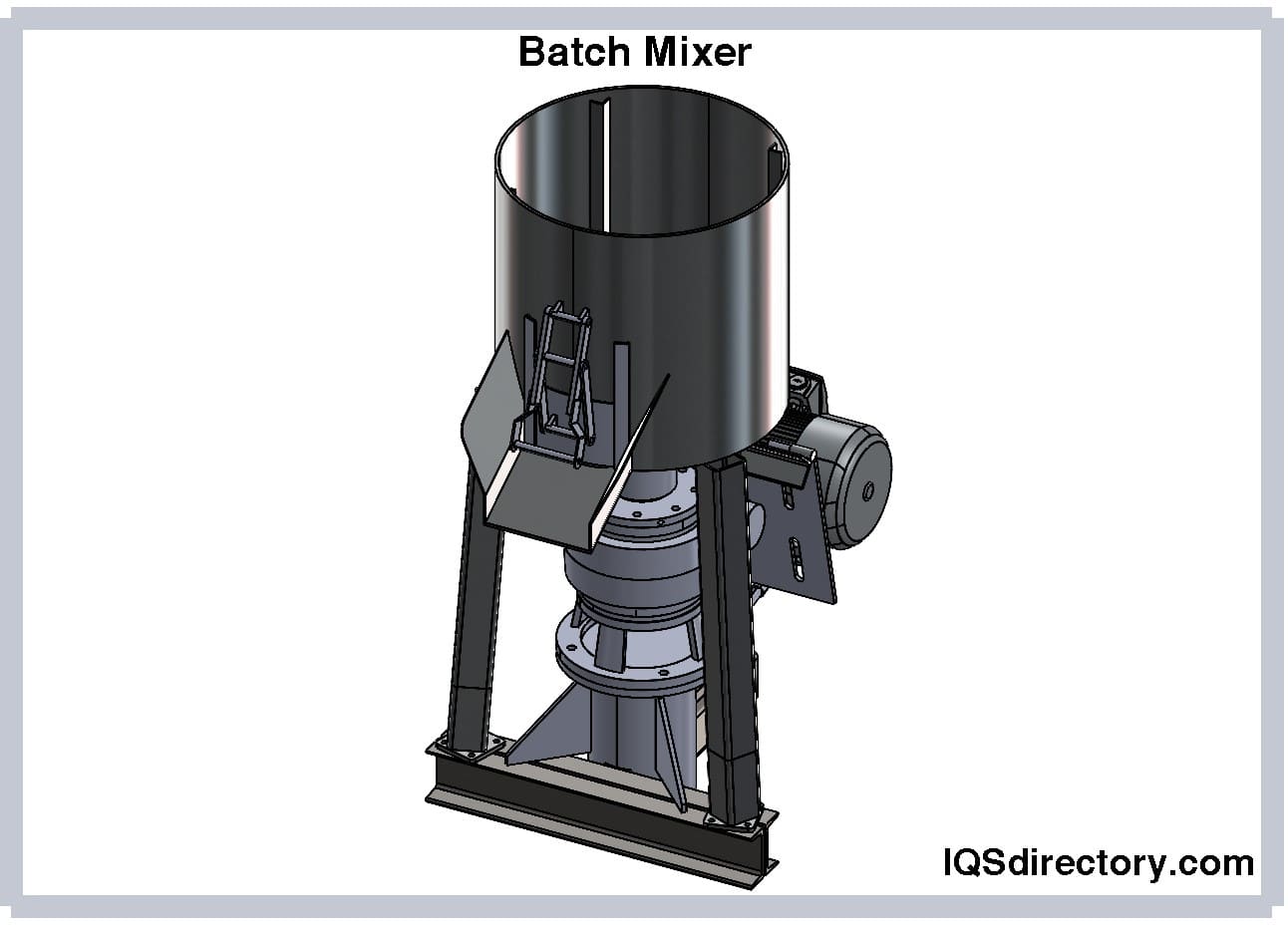

Batch mixers are flexible and efficient industrial mixing systems capable of processing discrete volumes of raw materials. With cylindrical or horizontal twin-shaft designs, batch mixers allow precise dosing, blending, and quality control for each lot—ideal for chemicals, pharmaceuticals, cement, powder blending, and specialty food production. Batch mixers include ribbon blenders, paddle mixers, planetary mixers, and top-entering agitators, among others.

Typical batch sizes vary from small laboratory batches to thousands of gallons or liters. The batch approach enables quality testing before downstream processing and supports products that are sensitive to environmental changes over time. Batches are often transferred to storage or to continuous production lines for further blending or packaging.

Features such as rapid discharge doors, automated ingredient addition, and programmable batch cycles enhance productivity, traceability, and process control for powder mixers, pastes, or specialized industrial compounds.

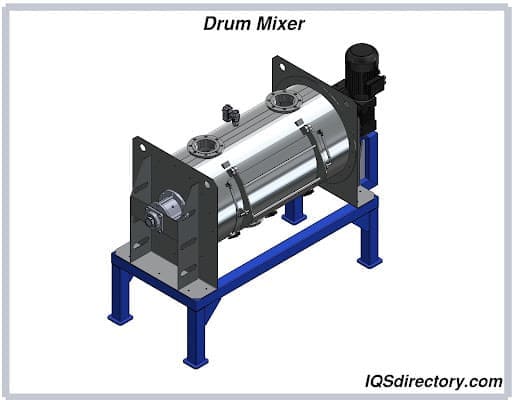

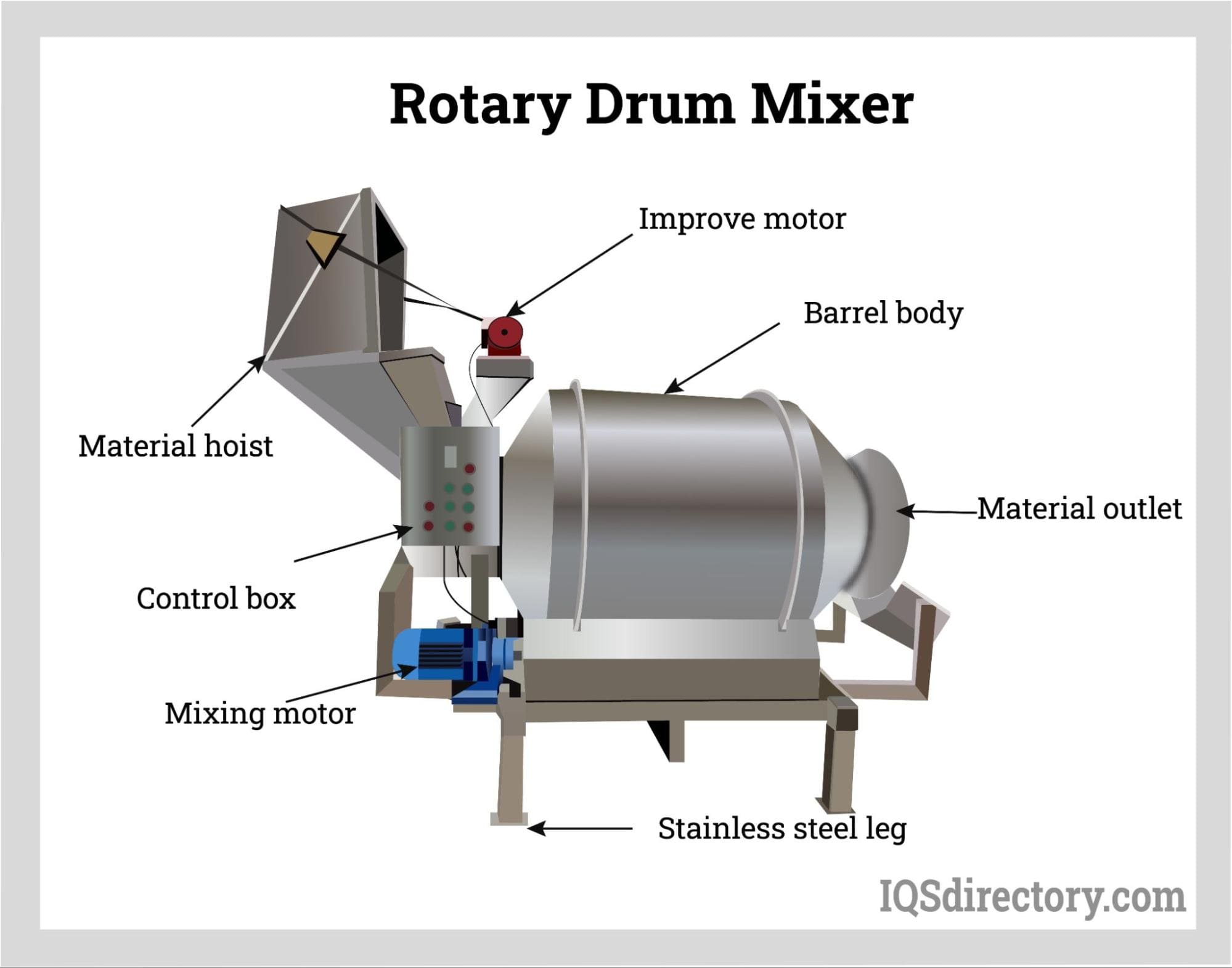

Drum mixers utilize rotating drums with interior blades or vanes that tumble and combine ingredients. With models available in portable, stationary, and high-volume designs, drum mixers are ideal for mixing materials ranging from concrete and adhesives to slurries and granular chemicals.

They provide modularity, dosing control, and tight enclosure—minimizing contamination and supporting industries with stringent quality or safety requirements, such as paints and coatings, construction, and specialty chemicals.

Continuous mixers are designed for uninterrupted production environments, delivering steady material inflow, blending, and discharge. Using automated feeders and screw conveyors, these systems excel in large-scale manufacturing, such as concrete production, mineral processing, and food extrusion operations. They are ideal for applications where consistent mix ratios and high throughput are necessary, and downtime is not an option.

Continuous mixers stabilize process parameters with steady state steady flow (SSSF), delivering reproducible product qualities and minimizing labor. Many manufacturers use continuous systems to homogenize materials from multiple batch lines, enabling larger product runs and operational efficiencies.

Automated ingredient dosing, real-time process monitoring, and low manual intervention drive scalability and cost savings for enterprises producing construction materials, plastics, food ingredients, and specialty metals on a continuous basis.

Acoustic mixers harness vibrational energy instead of mechanical agitation, using acoustic resonance to blend materials up to 100 times faster than traditional mechanical mixers. Their low heat generation makes them essential for temperature-sensitive processes—such as pharmaceutical compounding, biotechnology, and specialty food manufacturing—where gentle yet rapid batch homogenization is required.

Acoustic mixers are equipped with clean-in-place (CIP) systems and do not require internal moving parts, reducing maintenance and contamination risk. Their flexibility covers both commercial batch and continuous process requirements in sectors striving for high purity and reproducibility.

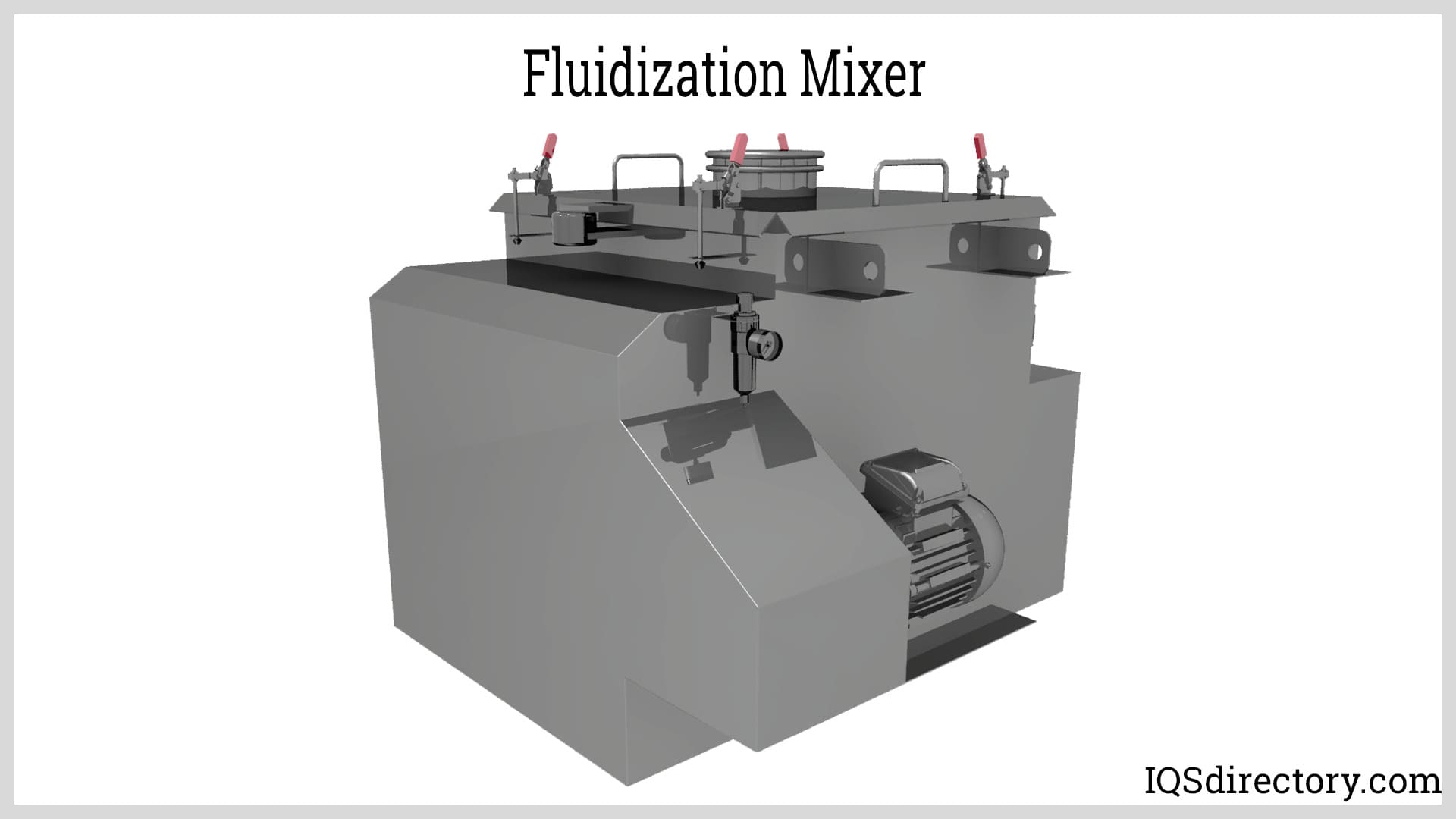

Mechanical fluidization mixers use high velocity impingement and turbulence to rapidly agitate powder or granular solids, fluidizing the particles to behave like liquids. Double paddle and plow mixers are common fluidization equipment for blending chemicals, detergents, nutrition powders, and agricultural feeds requiring extremely uniform particle-to-particle distribution in short cycle times.

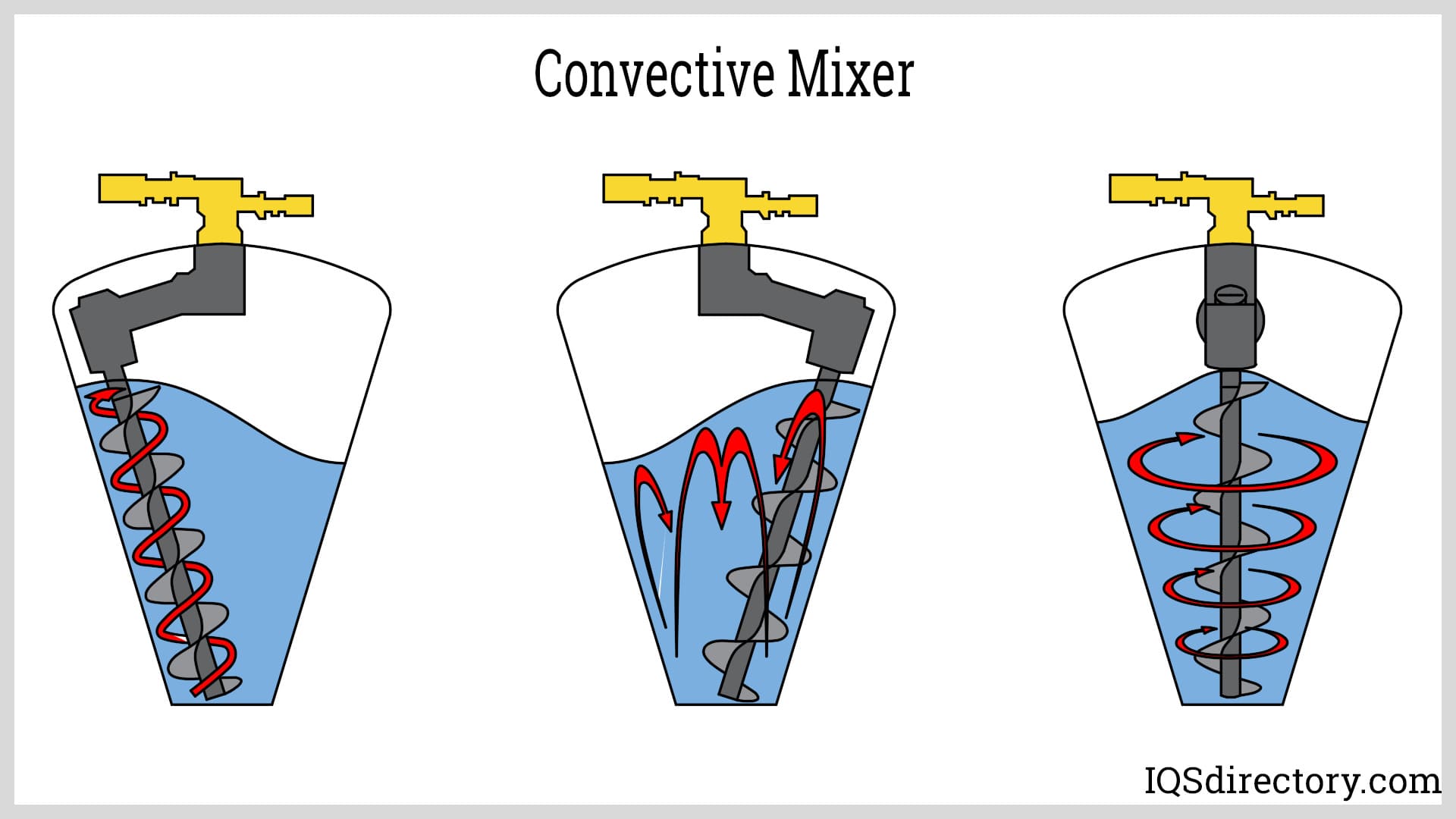

Convective mixers rely on forced movement, such as impellers or paddles, to directly propel materials within the tank. Their robust construction and rapid mixing make them favorable for industries needing short cycle times—like food processing, pharmaceuticals, cement blending, and fertilizer production. Convective mixers include ribbon blenders, vertical screw blenders, paddle blenders, and more—each optimized for high-volume batch processing of powders, granular materials, or low-viscosity liquids.

Dough mixers are critical mixing machines in the commercial bakery and food processing industries, tasked with combining, kneading, and aerating dough or batter. Equipped with powerful variable-speed motors and specialized attachments, they process large dough volumes, greater than 240 kg (530 lb), for industrial bread, pastry, pizza, dumpling wrappers, and noodle production. Planetary and spiral mixers are the two main types—each offering different mixing actions and advantages for high-gluten or specialty doughs.

Spiral mixers feature separate motors for the mixing arm and bowl rotation, eliminating gears and facilitating silent, efficient operation. Spiral mixers excel at hydrating and kneading bread doughs—with an absorption rate (AR) of up to 90%. Their bi-directional mixing and variable size options provide flexibility for artisan bakeries to industrial-scale operations, supporting batch sizes from 180 lbs to 440 lbs.

Industrial mixing technology continues to evolve to meet the growing and specialized demands of modern production lines. In addition to the mixers detailed above, many manufacturers offer customized mixing equipment tailored for highly specific requirements—such as sanitary mixers for food and pharmaceutical applications, hazardous duty mixers for chemical processing, and hybrid mixing systems for multi-stage blending and compounding.

The table below introduces unique and innovative mixer designs that further enhance process flexibility, energy efficiency, and product quality across industries:

| Mixer Type | |

|---|---|

| Mixer Type | Description |

| Double Cone Mixers | Double Cone mixers and blenders create particle mobility without baffles. They have a low profile, less headroom, and a cover for easy cleaning and inspection. Double cone mixers have automatic loading and discharge ports that are in line. The shape of double cone mixers allows for the processing of larger batches. |

| Slant Cone Mixers | The asymmetrical shape of slant cone mixer provides faster blend times with a blend time reduction of up to 33 percent less than other designs. Slant cone mixers have a low profile, high efficiency, and a large mixing zone. |

| V-Shape Blenders | V-Shape Blenders have short blending times and high efficiency. Blending is achieved by the constant dividing and intermeshing of particles provided by inclined cylinders. This precision mixing action results in blend variations of 1% to 2%. The cylindrical shells have access covers for loading and cleaning. The efficiency and cost effectiveness of V-shaped blenders is enhanced by their low maintenance cost and power usage. |

A mixer extruder is a hybrid piece of processing equipment that combines high shear mixing and low or medium pressure extrusion to knead, mix, and extrude material into a continuous form. Operating as either a stand-alone processor or integrated with upstream/downstream equipment, mixer extruders efficiently blend solids and liquids into cohesive pastes or composites for plastics, chemicals, pharmaceuticals, food, and waste treatment industries.

Modern mixer extruders feature a horizontal screw shaft, automated ingredient feeding, interchangeable dies, and air or water cooling jackets for process control. High-pressure extruders target dense, high-viscosity compounds, while twin-screw or low-pressure versions accommodate continuous mixing and high powder content. They dramatically accelerate processing times and enhance material characteristics such as texture, uniformity, and mechanical strength.

Kettle mixers are large-capacity, high-throughput mixing solutions equipped with steam jackets, temperature controls, and variable speed agitators—designed for the production of soups, sauces, confectionery, prepared foods, and viscous liquids. Dual-agitator systems deliver both scraping and central mixing, preventing burning and improving batch consistency. These mixers can be gas, electric, or steam powered, and operate as fixed or tilting models for easy discharge and cleaning.

Industrial kettle mixers are essential for commercial food preparation, chemical reaction processes, and ingredient cooking operations that demand uniform heating, thermal control, and robust agitator design to manage thick or sticky substances.

Vacuum mixers operate at pressures below atmospheric, integrating mixing, dispersion, and degassing in a single processing environment. They are essential for applications where void-free mixtures, improved particle dispersion, and low-temperature drying are necessary—such as in medical device manufacturing, aerospace composites, advanced ceramics, and specialty adhesives. By reducing entrapped gases and oxygen, vacuum mixers help prevent foaming, material weakening, microbial growth, and unwanted chemical reactions.

Vacuum mixers may incorporate single or double shaft impellers or high-shear rotor-stator designs. Choosing the appropriate vacuum mixer involves evaluating mixing speed, attainable vacuum level, batch size, particle size requirements, and heat or cooling needs. Many batch mixers are now available with vacuum integration to enhance process control, material quality, and manufacturing efficiency.

The diverse range of industrial mixers reflects the specialized needs of various industries that rely on mixing equipment for efficient processing, blending, homogenization, and treatment of materials. Each type of industrial mixer—from high-shear mixers and ribbon blenders to agitators and planetary mixers—is engineered to meet unique material handling requirements, delivering exceptional performance, consistency, and product quality. By adapting to the specific characteristics and workflow demands of the industries they serve, mixers play a crucial role in optimizing process efficiency, improving throughput, and ensuring high-quality results across numerous applications.

The adhesives and sealants industry relies heavily on effective mixing and blending technologies to ensure proper homogenization of miscible fluids and uniform dispersion of high-viscosity, often dissimilar, materials. Key mixing processes include dispersing adhesive emulsions, the dissolution of polymers into volatile and non-volatile solvents, and the mastication of rubber for optimal elasticity. The selection of suitable mixing equipment—such as double planetary mixers, dual-shaft mixers, or static mixers—is critical, as it directly influences mixing efficiency, batch consistency, production scale, and the quality and physical properties of the final adhesives and sealants. Addressing challenges such as air entrainment, viscosity management, and complete wet-out of powders further underscores the complexity and importance of proper mixer selection within this sector.

In the battery and electronics manufacturing sector, mixers play a vital role in producing advanced materials such as aluminum oxide suspensions, silicone gels, conductive pastes, battery slurries, and highly viscous inks. Each material exhibits unique rheological properties, often requiring specialized high-intensity mixers, vacuum mixers, or recirculation batch mixers to ensure optimal particle dispersion, uniformity, and stability. Consistent, repeatable mixing is especially vital in battery cell production and the fabrication of electronic components, as it directly impacts product performance, energy storage capacity, electrical conductivity, and overall product reliability. Quality control protocols and process optimization are integral, ensuring traceability and the high purity required for modern electronics applications.

In medical cannabis production, industrial mixers are essential for emulsifying, dispersing, and blending cannabinoid extracts such as CBD oil, THC distillates, hash oil, and other bioactive components. High-shear dispersers are frequently used for cannabinoid extraction, nanoemulsification, and rapid homogenization, ensuring efficient breakdown and thorough mixing of cannabis concentrates with carrier oils. Multi-shaft mixers provide enhanced batching capabilities for tinctures, edibles, and topical formulations, maintaining product uniformity and potency. Additionally, ribbon mixers and planetary mixers facilitate consistent ingredient blending during bulk material preparation. Compliance with industry standards, including GMP and automated clean-in-place (CIP) protocols, is crucial for product safety and batch repeatability in this fast-growing industry.

The cosmetics and personal care industry depends on precision mixing solutions to produce sensitive, high-quality products such as lotions, creams, serums, gels, and hair care products. Industrial mixers—including shearing mixers, vacuum homogenizers, and multi-shaft mixers—ensure uniform emulsification, efficient powder wetting, and controlled particle size reduction. Advanced mixer technology allows compounders to manage viscosity, achieve stable emulsions, and reduce air incorporation—key factors for ensuring a premium sensory experience and consistent product texture. Cosmetic product developers increasingly rely on automated mixing systems and in-line mixing technologies to streamline production, guarantee product safety, and meet stringent quality control standards.

The food and beverage industry relies extensively on hygienic mixers for all stages of production, as precise mixing is fundamental to achieving desirable taste, mouthfeel, nutritional value, and product safety in food products. Mixers designed for food processing must comply with stringent Food and Drug Administration (FDA) and Hazard Analysis Critical Control Point (HACCP) standards to ensure all products meet strict food safety and quality regulations for human consumption.

Food production involves a broad spectrum of mixing applications, including dry powder blending, dough kneading, emulsification of fats and oils, high-speed powder induction, dissolution of sweeteners, dispersion of thickeners, and high-viscosity mixing for confectionery, sauces, and batters. High-shear mixers and planetary mixers play vital roles in producing beverages, dairy products, ready meals, vegetable blends, protein bars, and chopped meats, highlighting the essential role of advanced mixing technology in delivering consistent, safe, and high-quality food and beverage products across diverse segments. Innovations in clean-in-place (CIP) cleaning, energy-efficient designs, and flexible batch-to-continuous mixing systems have further improved food processing productivity, supporting rapid consumer demand changes.

The plastics and composites industry depends on high-performance mixing solutions for compounding, blending, and dispersing polymers, additives, fibers, and colorants. The production of engineering plastics, polyamides, resins, plastisols, thermosets, thermoplastics, and composite injection molding formulations requires precise melting, dispersing, and homogenization of raw materials. As the sector continues to innovate with advanced materials—including bioplastics and carbon fiber composites—industrial mixers ensure the consistent quality, mechanical properties, color, and performance of extruded, injection-molded, or thermoformed products. Scalability, temperature control, and compatibility with automated extrusion lines are critical features sought by leading plastic and composite manufacturers.

The production of inks, paints, and coatings is among the most technically demanding mixing and dispersing applications across all industries. Achieving the correct pigment dispersion, viscosity, and color uniformity requires precision mixing using equipment such as high-speed dispersers, shear mixers, sand mills, bead mills, and multi-shaft mixers. Proper mixing technology ensures optimal adhesion, durability, rheological properties, gloss, and leveling characteristics—each essential for delivering high-performance printing inks, architectural paints, and specialty coatings. Advanced mixer designs also support requirements for rapid color changes, reduced energy consumption, and minimization of agglomerates, ensuring that end products meet stringent industry standards and customer specifications.

The chemical industry relies on a broad range of industrial mixing solutions for production processes involving high to low viscosity mixing, dry blending, particle size reduction, emulsification, homogenization, and powder dispersion. Industrial mixers, including static mixers, agitators, and dispersers, are employed for combining raw materials such as abrasives for shaping and finishing, coal suspensions for synfuel processing, flotation reagents, lubricants and oils, pigments, catalysts, and propellants. The flexibility of industrial mixing equipment supports both batch and continuous processing, enabling chemical manufacturers to achieve desired reaction rates, yield, mixture stability, and precise particle control. Mixer selection is also influenced by factors such as chemical compatibility, corrosion resistance, pressure and temperature requirements, as well as process automation needs.

The eight industries above represent just a fraction of the many sectors powered by industrial mixing technology. Virtually any industry involving the combination, blending, or processing of raw materials depends on some form of mixing to achieve desired product outcomes. The industrial mixer sector remains dynamic and innovation-driven, continually evolving with advancements in mixer design, automation, process integration, and materials science to offer high-quality, custom-engineered solutions that meet the unique challenges and objectives of modern manufacturing.

The goal of any industrial operation is to produce high-quality products efficiently and cost-effectively. Industrial mixers are engineered to meet specific requirements and operational demands. Manufacturers evaluate the types of materials being blended, the desired homogeneity, and overall efficiency to choose mixers that are best suited for each application. This ensures that the mixers deliver optimal performance, consistency, and cost savings.

Mixers are engineered to meet customer needs through efficient and streamlined production processes. This increased efficiency translates to savings in energy, materials, and labor costs. Additionally, mixers are built to be durable and long-lasting, requiring minimal regular maintenance and repair, which further enhances their cost-effectiveness and reliability in industrial settings.

Every manufacturer aims for improved efficiency, and highly engineered mixers play a crucial role in achieving this. By producing higher quality products in less time, these mixers are tailored to meet the precise demands of specific applications. This enhanced efficiency not only accelerates production but also reduces the time and energy required, aligning seamlessly with lean manufacturing principles.

Manufacturers choose mixers based on their specific needs, offering them greater control over the mixing process. Each customer has unique specifications, standards, and requirements that must be met for product success. The right mixer provides the precision needed for blending materials to exact standards. Mixers can be customized and designed to meet individual requirements, ensuring that end products align perfectly with the user's needs and specifications.

Users can modify and fine-tune the design and performance of a mixer to suit their specific needs. Mixers can be adapted for various materials and processes, ensuring flexibility and precision. Mixer manufacturers understand that a single mixer model cannot address every customer's needs. Therefore, they offer customization options and adaptations to ensure the chosen mixer seamlessly integrates into the production process.

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

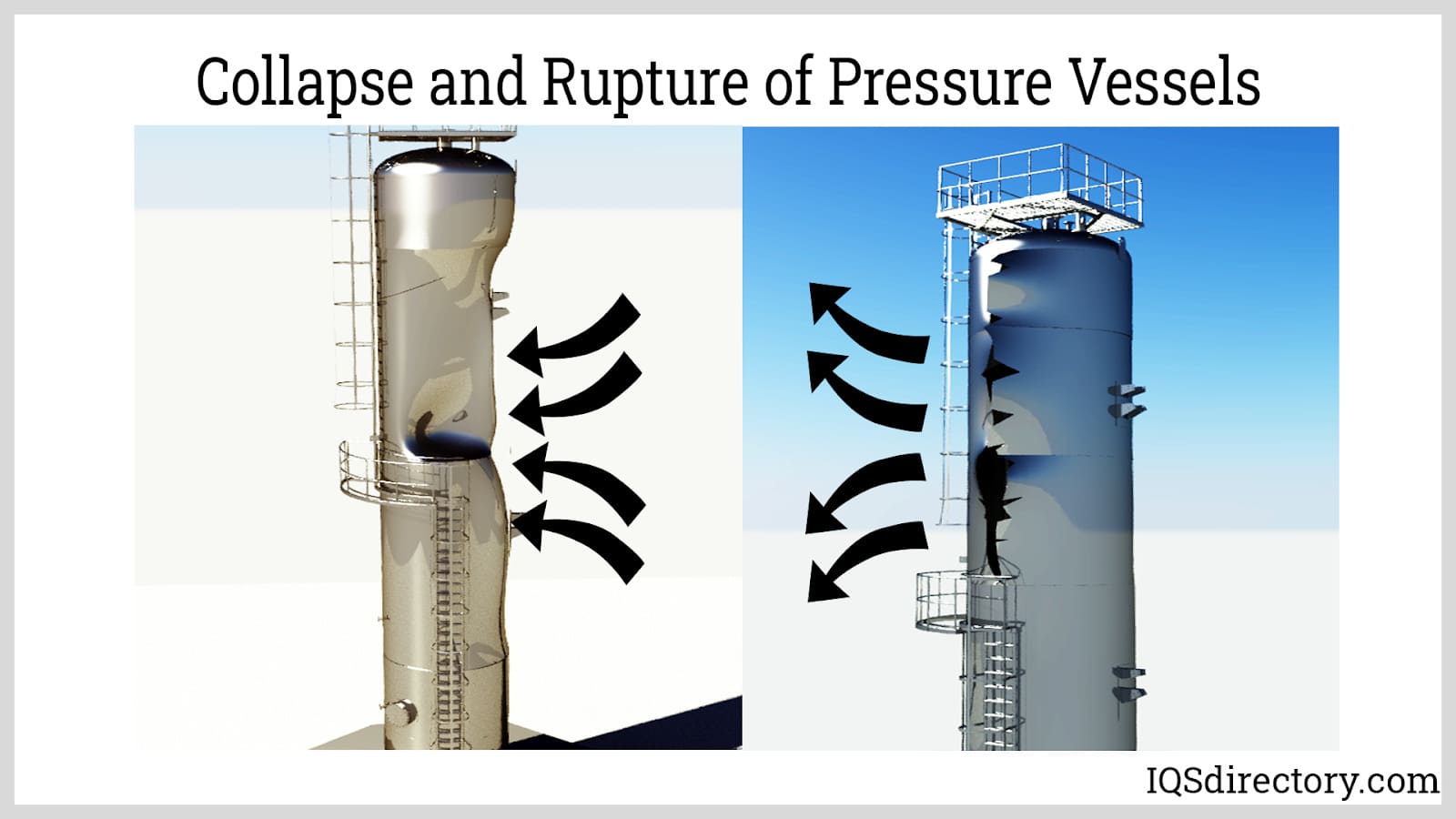

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...