Portable Offices

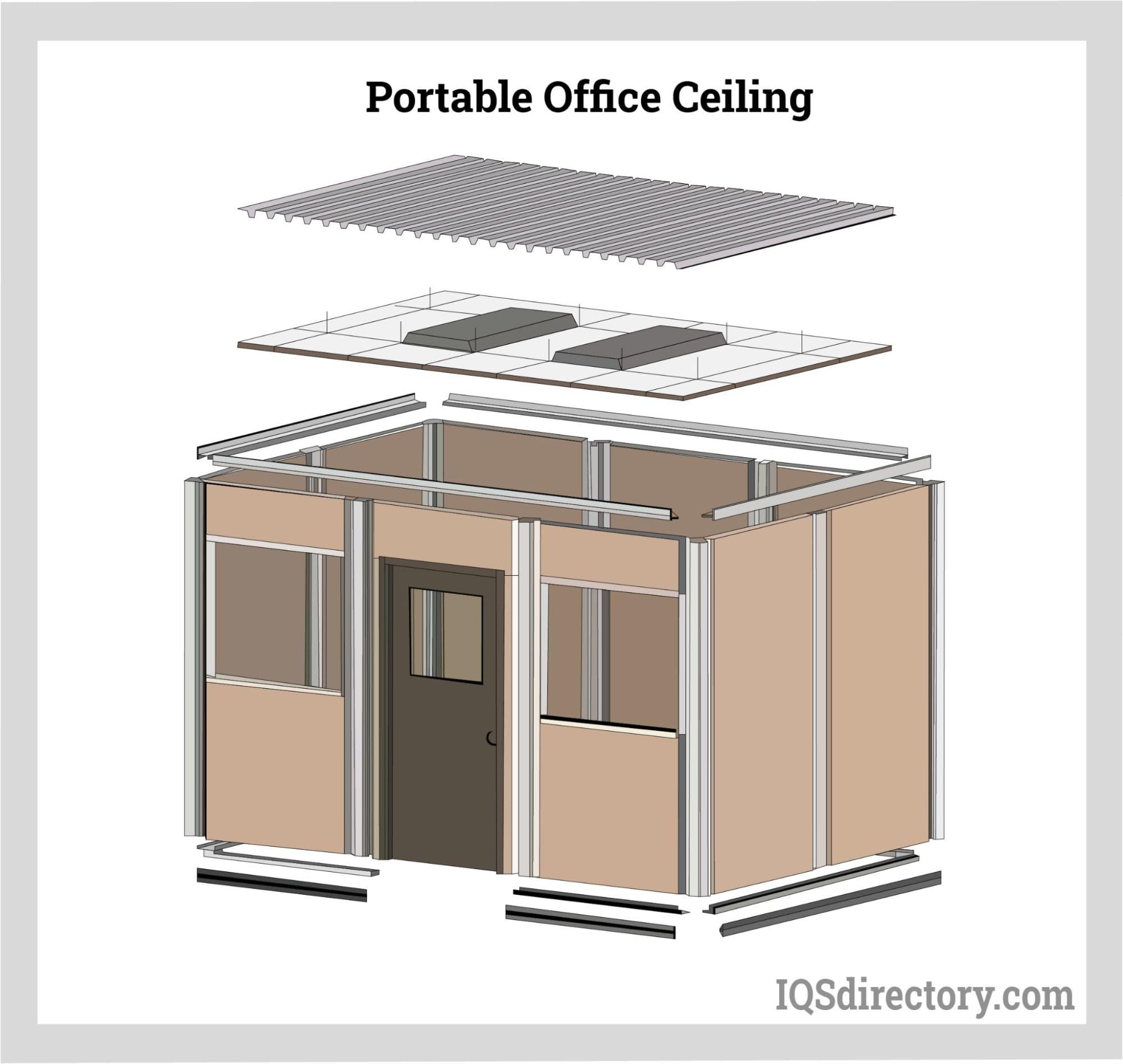

A portable office is a mobile workspace that can be easily assembled and placed to provide a quiet and convenient location for meetings, completing paperwork, or examining plans. They are built using...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at modular buildings.

Read further and learn more about:

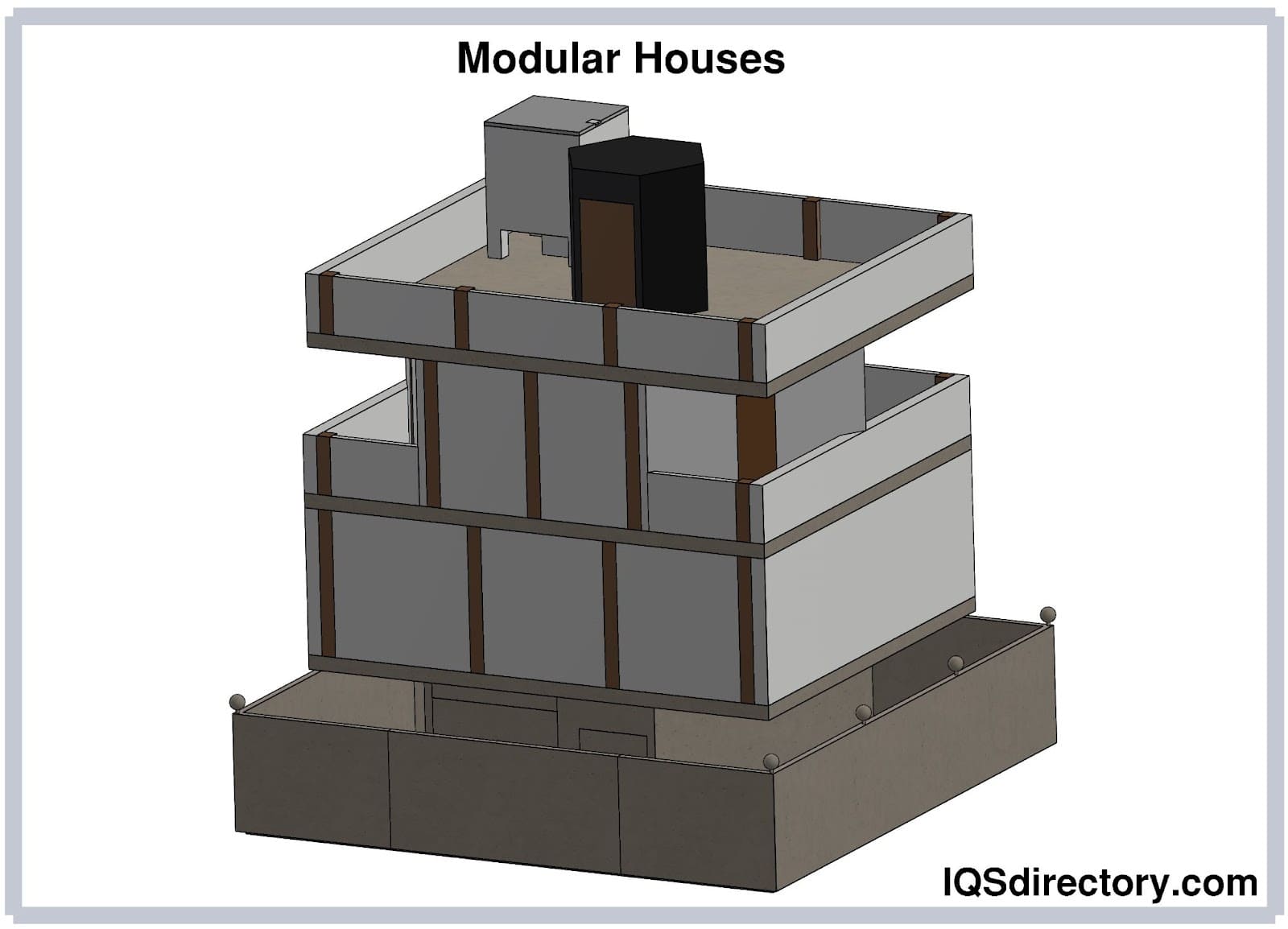

Modular buildings are created from standardized parts called "modules," which are produced in a controlled factory environment rather than on the construction site. These factory-produced modules typically incorporate components like walls, doors, ceilings, frames, and windows. They use the same materials and adhere to the same building codes and regulations as conventional buildings. Upon completion, these modular sections are transported to the construction location and assembled in line with the specific design and plan requirements.

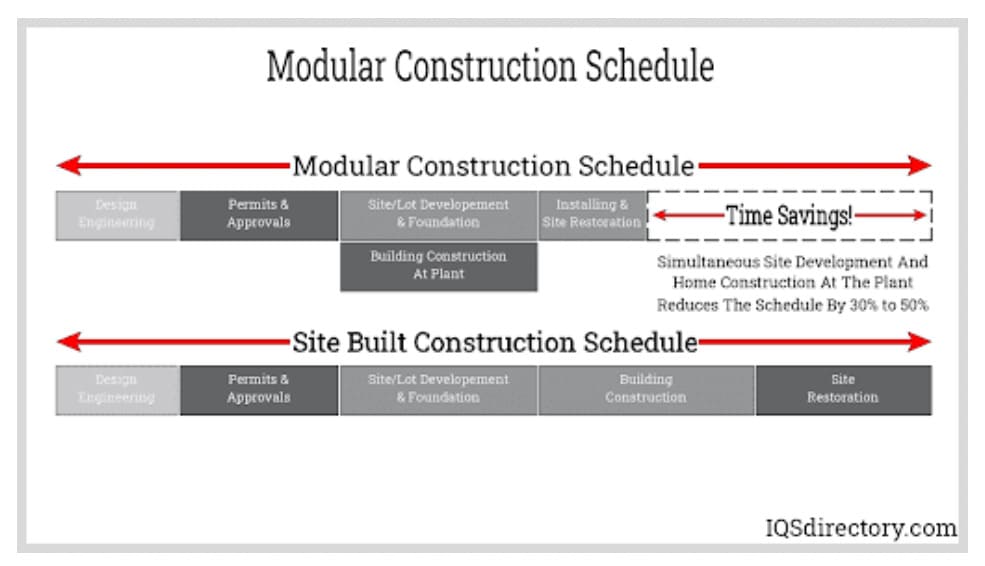

The modular construction approach is recognized for its quick building process, often allowing projects to be finished in half the time required by traditional construction methods, ultimately saving valuable time. Despite the expedited construction timeline, modular buildings are designed to be structurally sound. Manufacturers with specialization in modular buildings, whether intended to be permanent or relocatable, provide extensive knowledge to fulfill specific client demands. Their sophisticated manufacturing processes and strict quality controls ensure these buildings meet and frequently surpass industry benchmarks.

Modular construction companies are typically categorized into two segments based on their specialization: permanent modular constructions and temporary modular constructions.

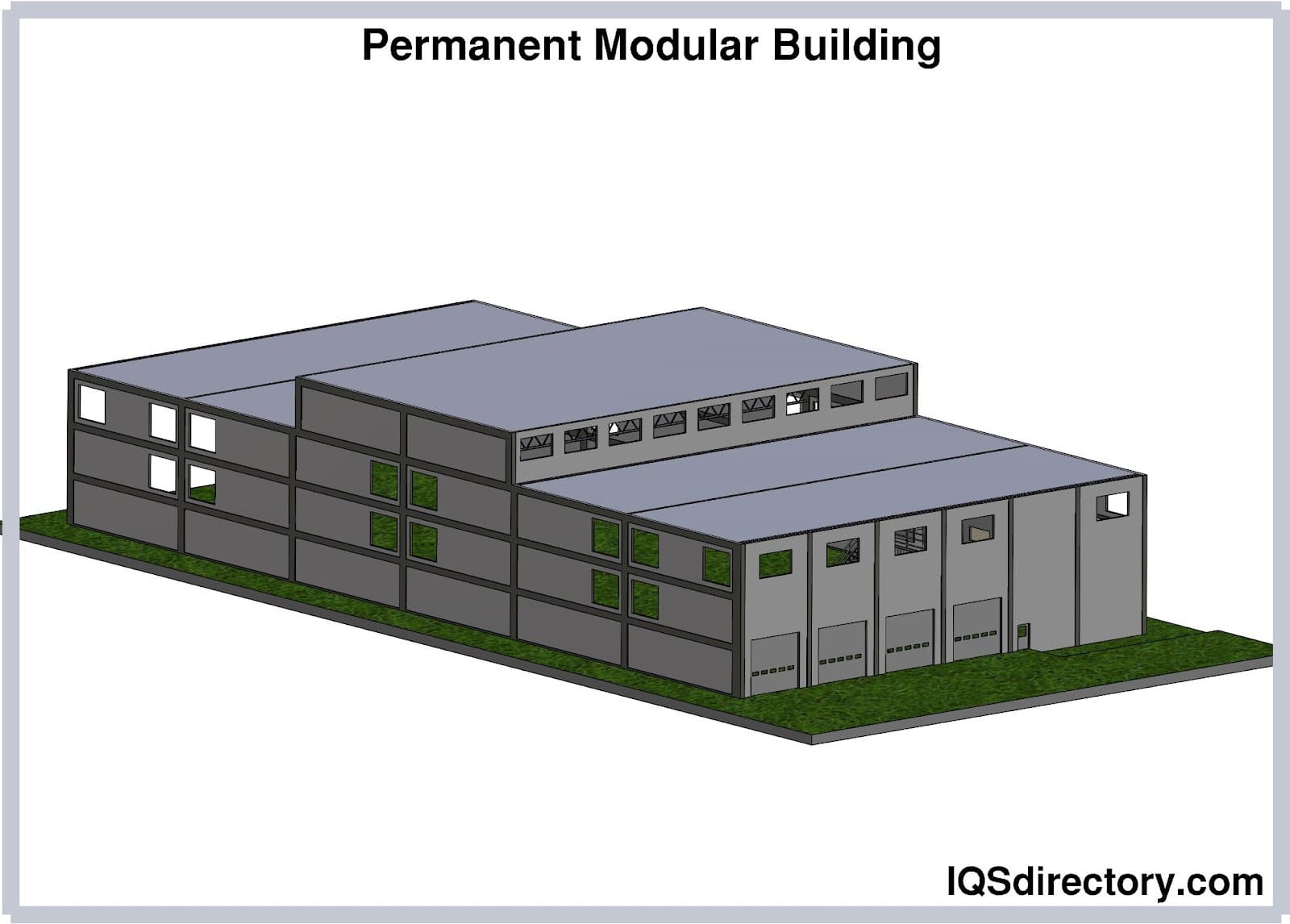

Permanent modular construction (PMC) involves building facilities intended for long-term use at their assembled location. PMC utilizes advanced offsite manufacturing techniques to prefabricate building sections. Unlike traditional real estate properties, PMC buildings are designed to remain in place and are not meant for relocation.

PMC buildings are constructed on permanent concrete foundations and can either stand alone or be integrated with existing structures. Given their intended permanence, they are made from durable materials such as steel, wood, and concrete. PMC offers excellent architectural design options and significant customization flexibility, allowing for additions like lobbies, elevators, and stairwells. This approach is suitable for multi-story buildings, schools, offices, and residential spaces. However, the assembly process for PMC buildings can be lengthier, depending on the size and complexity of the design.

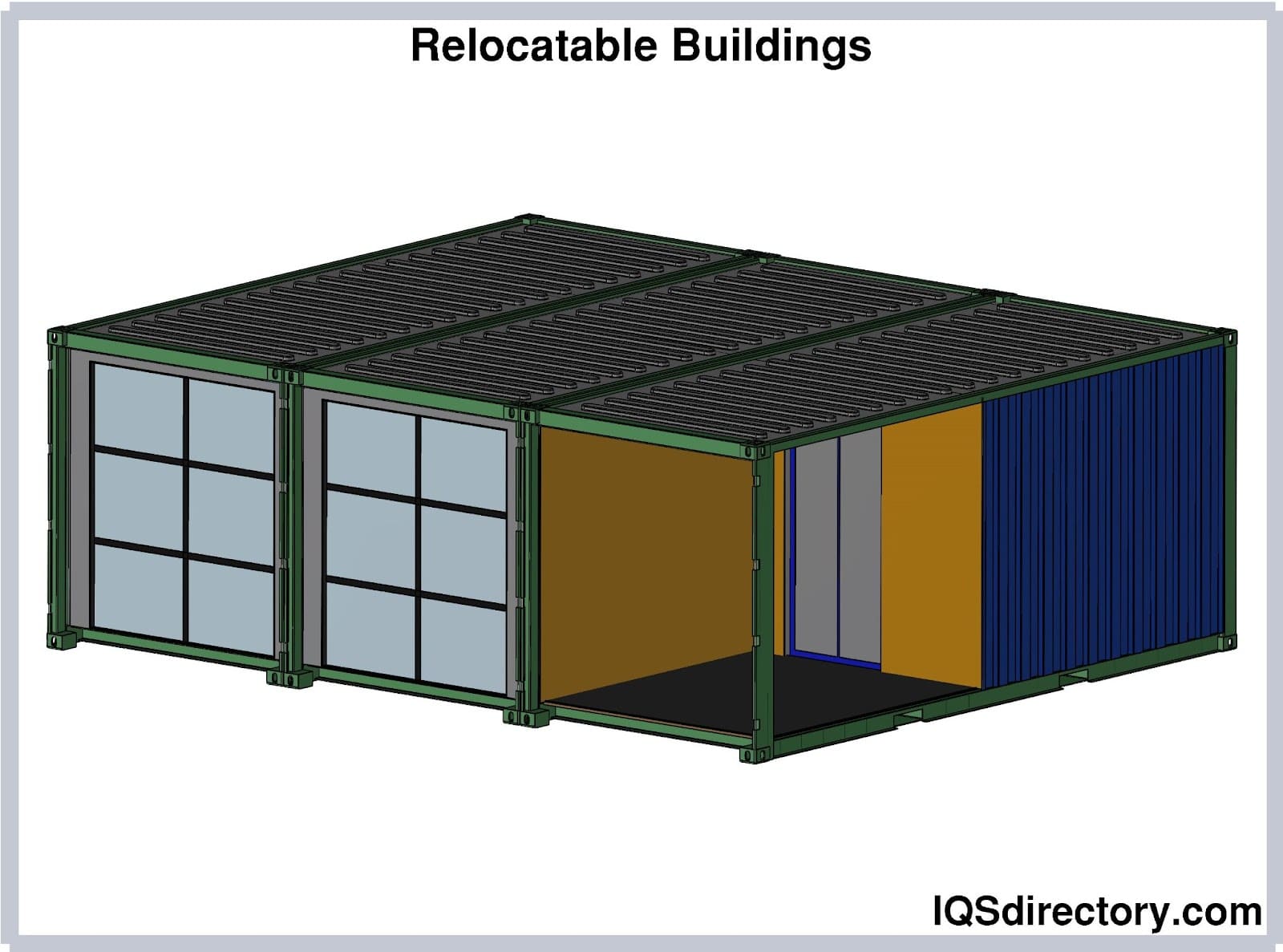

Temporary modular construction (TMC), also known as non-permanent construction, involves creating facilities—referred to as "relocatable buildings"—that are designed for mobility. These buildings can be repurposed and moved to different sites as needed. Despite their portability, relocatable buildings adhere to the same construction standards and codes as permanent modular construction (PMC) facilities. Their modular components are produced in a controlled factory environment using advanced manufacturing techniques. Relocatable buildings can be either leased for short-term use or purchased outright.

Relocatable buildings are particularly suited for situations requiring rapid construction, such as temporary housing, clinics, medical facilities, stores, and temporary commercial spaces. Constructed with lightweight materials like wood and rigid plastic, these buildings are designed to be durable and resilient to multiple relocations. However, they typically offer fewer options for layout, design, and customization compared to permanent modular constructions.

The following below are the types of modular buildings:

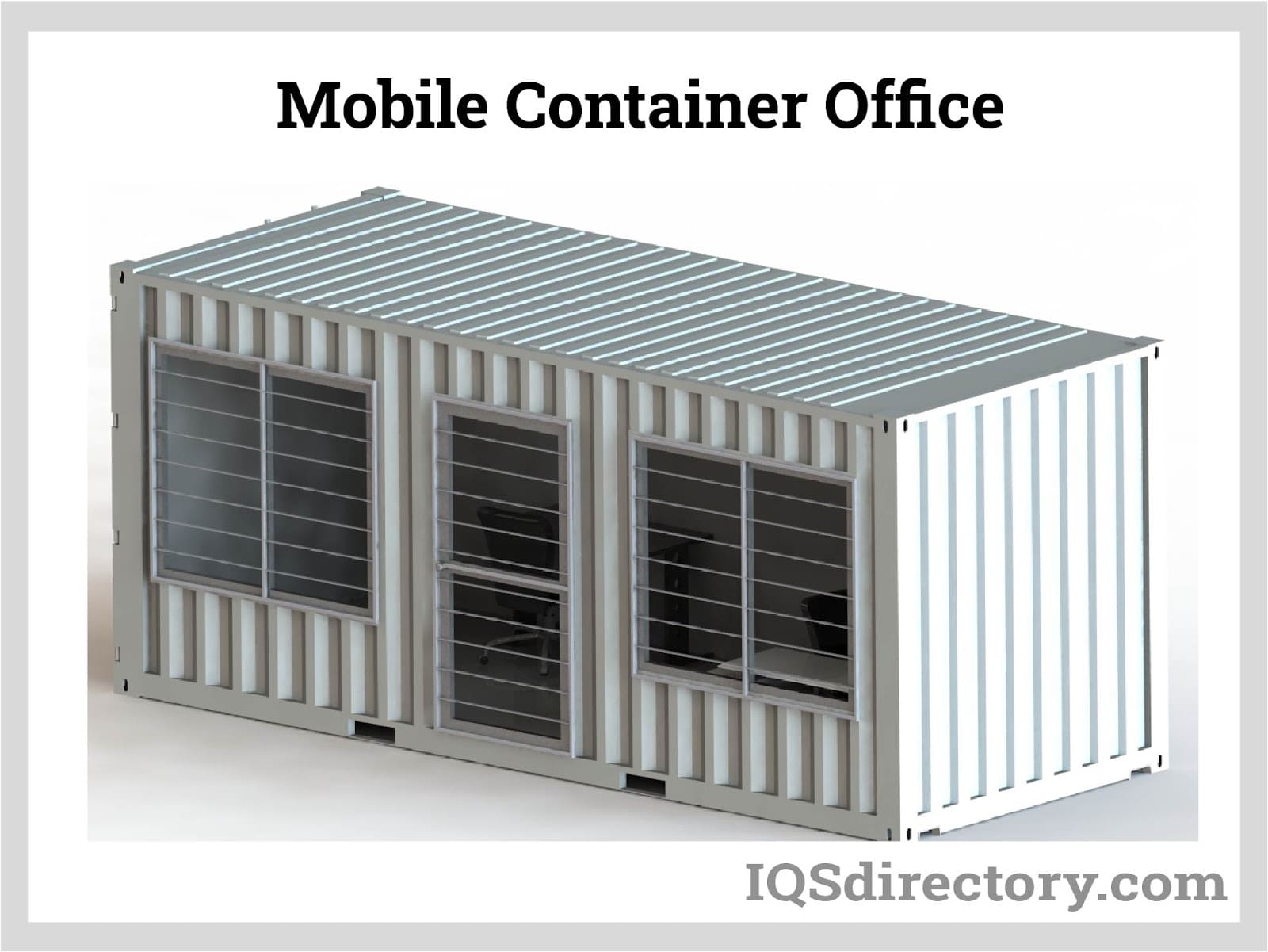

Mobile offices are offices that have mobility features that allow office workers to function as if they are in a permanent office rather than in the field. The furniture and equipment of mobile offices are similar to those found in traditional offices. Electricity and other utilities are installed on the sites temporarily. Portable computer systems, internet access, IT services, and telephone and mailing services enable the company to connect with clients and various stakeholders even without listing a permanent address.

Mobile offices, which are towable via trailer trucks or motorhomes, offer exceptional flexibility for companies with transient office needs. Their mobility allows for easy relocation, making them an economical solution for reducing overhead expenses. Mobile offices are also well-suited for contractors and freelancers who require adaptable and temporary workspaces.

Modular offices are versatile facilities that provide office spaces, including in-plant offices and modular buildings. These offices are assembled quickly within a warehouse or manufacturing facility, allowing for convenient access to in-plant services. They are ideal for accommodating the expanding needs of an organization as it grows, offering additional space for increased personnel. Additionally, modular offices can be used to oversee operations within a manufacturing plant or factory, and are often referred to as modular factory offices.

While modular offices are less mobile than mobile offices, they remain a practical solution for expanding office space. They can be easily installed, repurposed, and relocated, helping to optimize space utilization and minimize company downtime and disruptions during transitions.

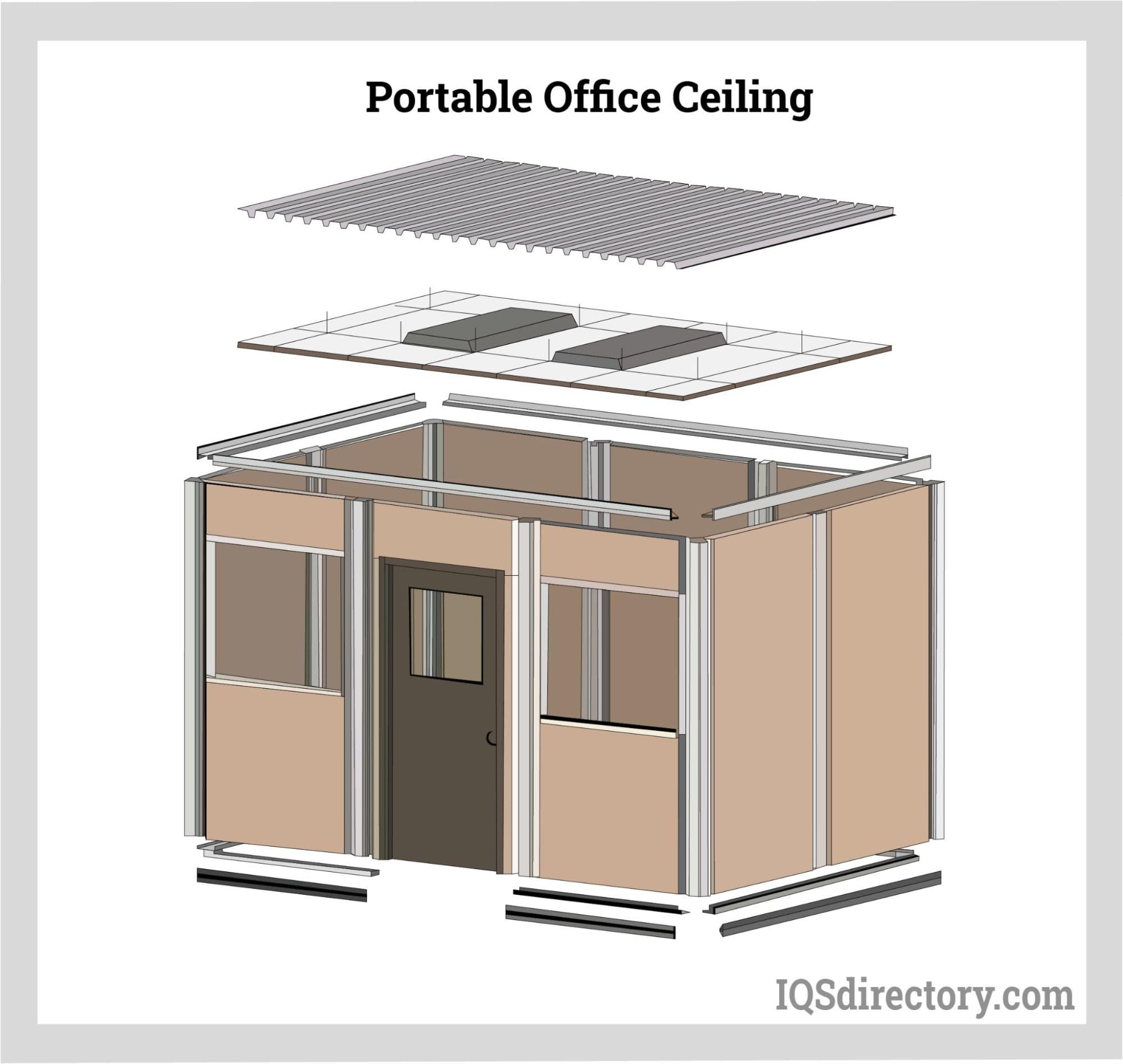

Portable offices are offices built on bases that are accessed and can be transported by a forklift or a truck. These offices can be relocated easily without performing significant dismantling of the facility. Portable offices provide temporary spaces for increasing personnel and accommodate occasional or seasonal demand for spaces (e.g., festival and carnival booths and food trucks). They can also be put up in oil drilling and construction sites.

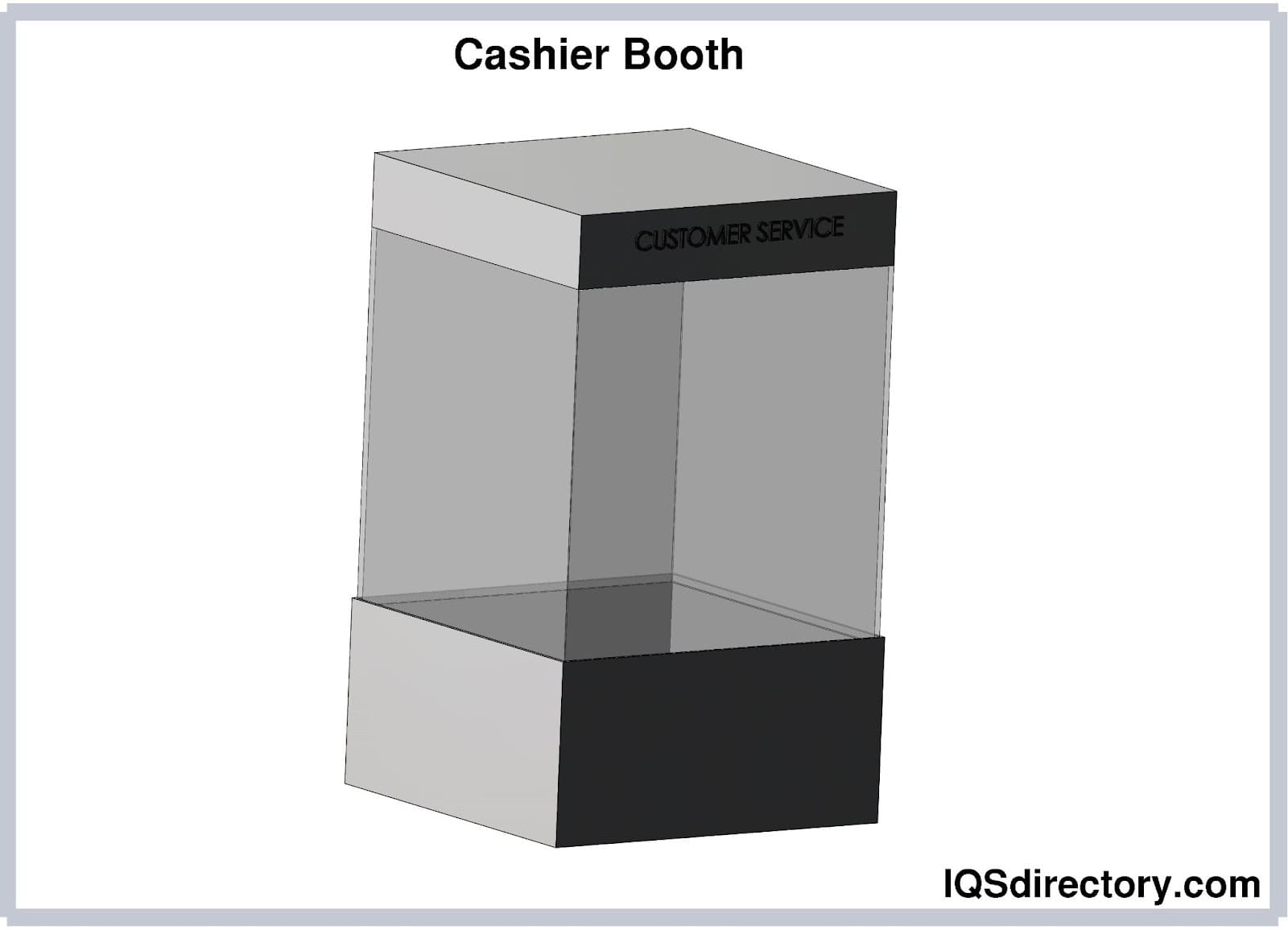

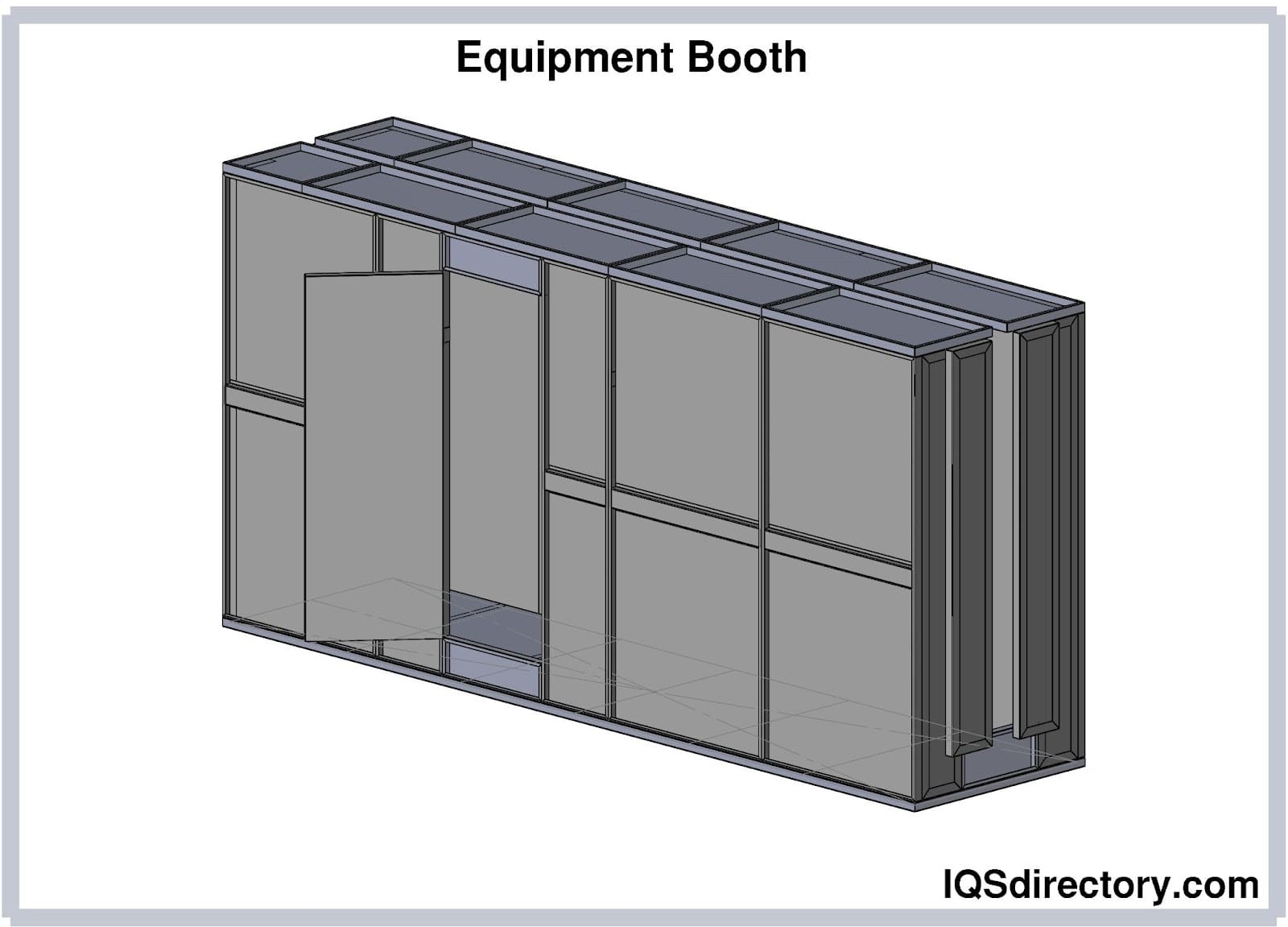

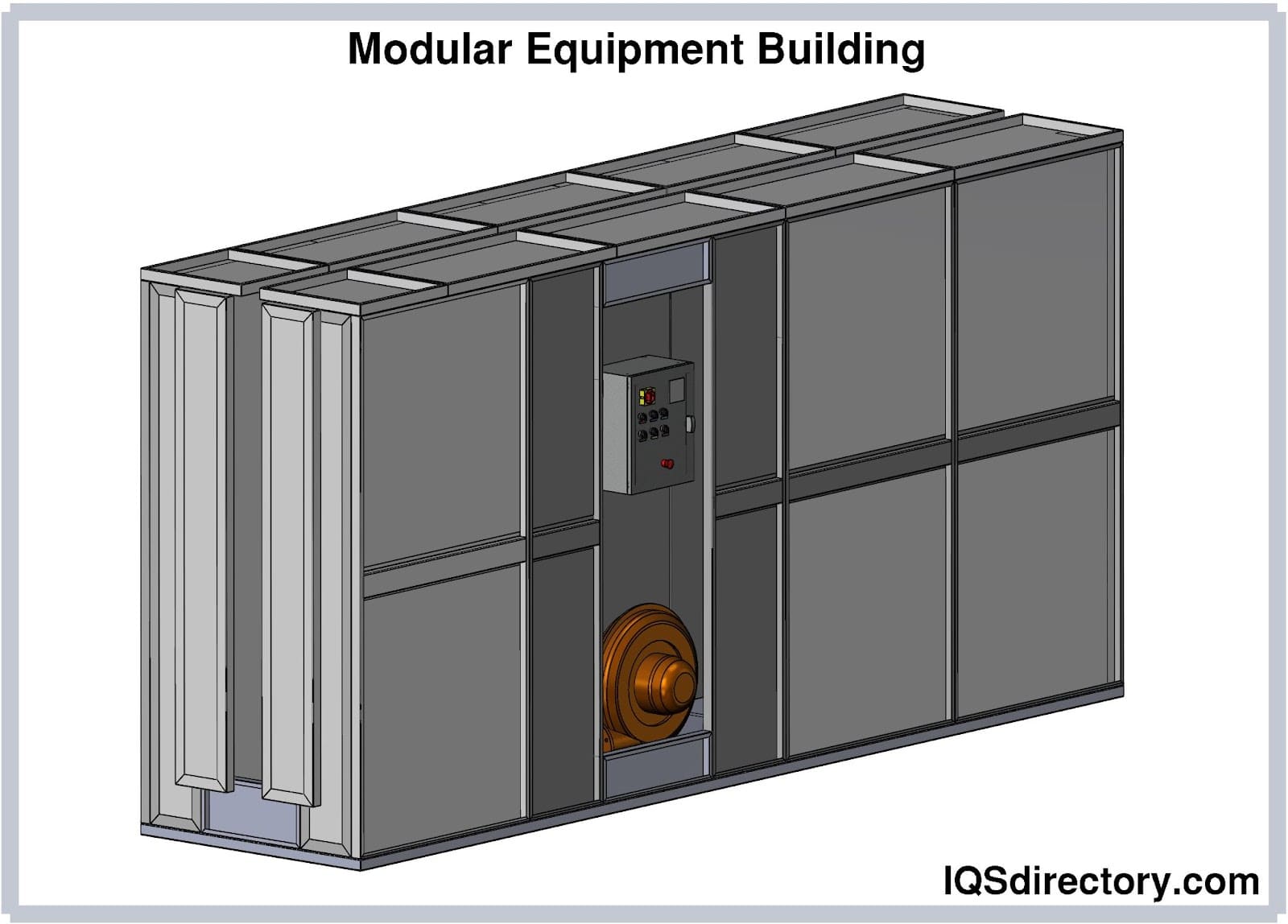

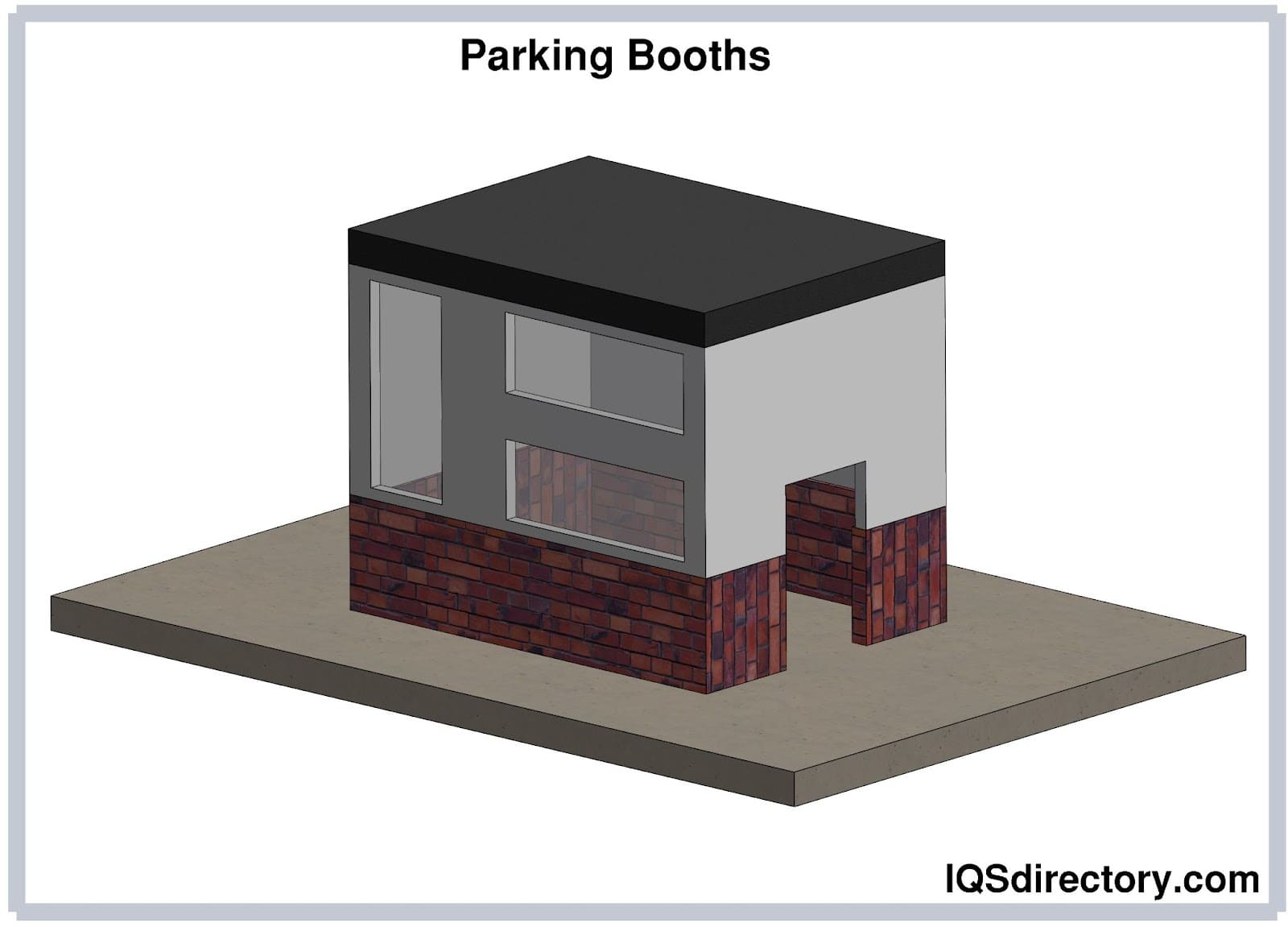

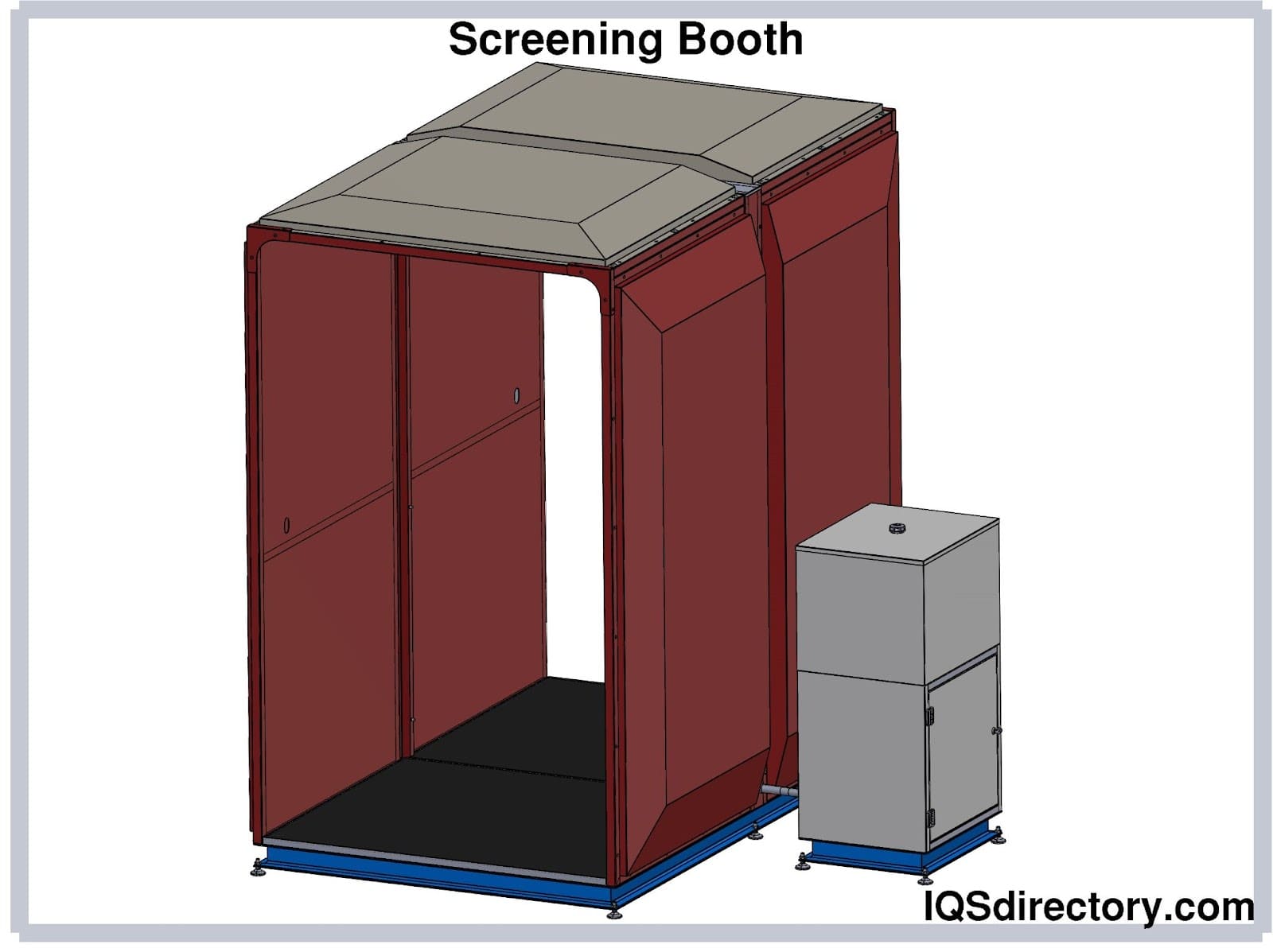

Prefabricated booths are compact, enclosed structures with components manufactured offsite in a factory and then transported and assembled at the installation site. These booths feature panelized wall systems and frames and roofs made from welded steel or aluminum. They offer flexible design and customization options, allowing for the integration of various utilities such as HVAC systems, sinks, electricity, water supply, and internet access, enhancing the convenience and comfort of the occupants.

Prefabricated booths can be installed either permanently or temporarily, depending on the duration of use. They come in various types to suit specific applications:

Cashier booths are widely used in settings such as movie theaters, amusement parks, sports facilities, resorts, restaurant drive-thrus, gasoline stations, and various other commercial establishments. They serve as designated areas where customers can purchase tickets and cashiers can process payments. These booths typically feature a sliding or pass-through transaction window to facilitate secure transactions while the staff remains inside. Additionally, cashier booths are equipped with security and anti-theft measures to protect the collected cash from theft.

In contrast to other prefabricated booths, equipment booths are designed to house equipment rather than accommodate people. They provide temperature control and environmental protection for sensitive equipment, shielding it from harsh conditions. Equipment booths are commonly installed within plants or manufacturing facilities.

Modular equipment buildings are larger than equipment booths and offer greater flexibility and customization. They are designed to house industrial equipment, including motors, generators, pumps, process control devices, and electrical machinery. These buildings can be equipped with sound-proofing materials to mitigate noise from the equipment. Additional features such as fire retardation, and blast- and bullet-resistant glass and walls can also be incorporated for enhanced safety and protection.

Parking booths are located at the entrances or exits of parking lots, buildings, and parking decks. Similar to guardhouses, they serve as the workspace for parking attendants who manage incoming vehicles and handle transactions. Equipped with sliding windows, these booths facilitate interaction and transactions between the attendant and customers. Additionally, parking booths can include RFID systems or ticket generators to enhance operational efficiency.

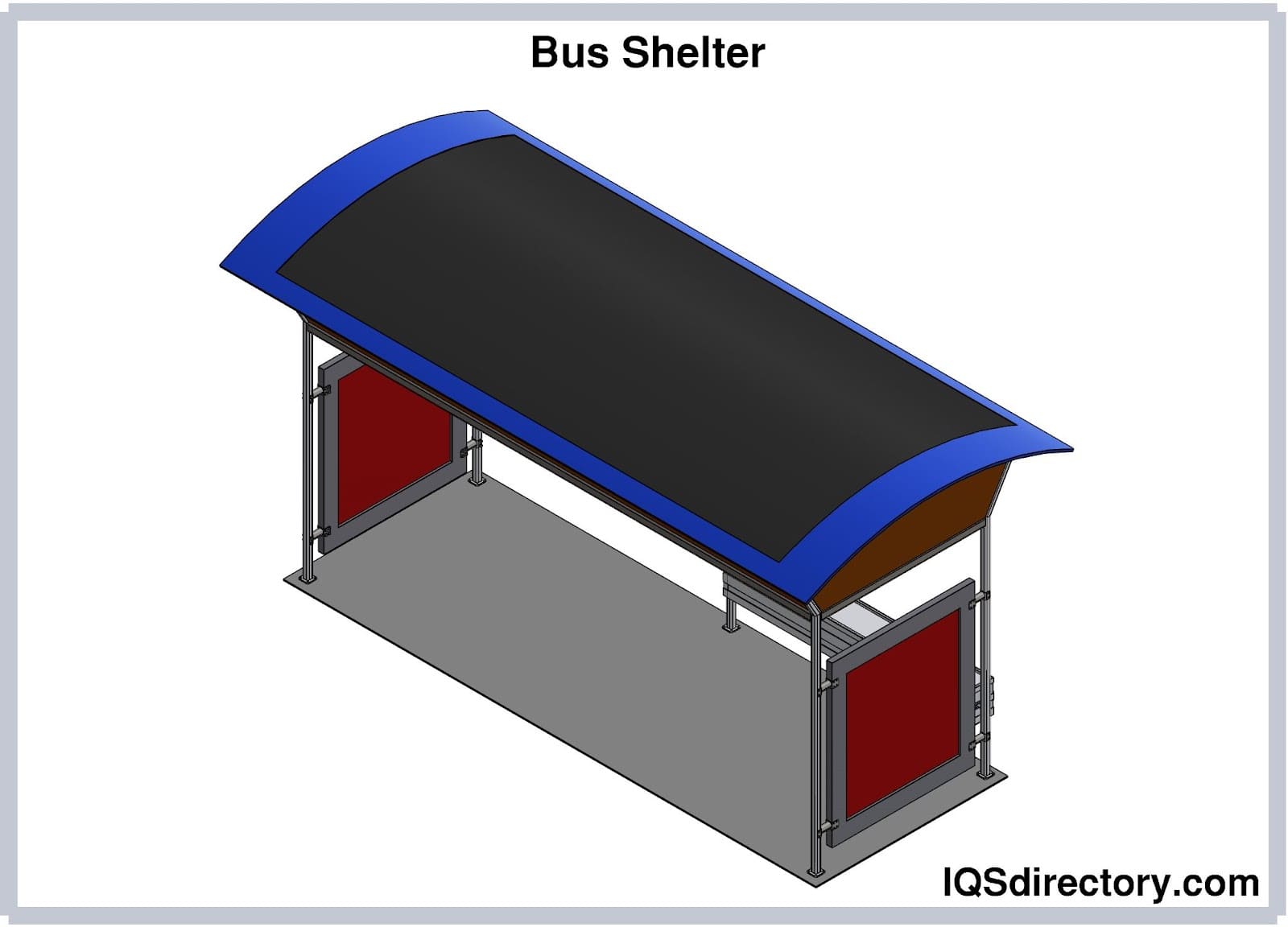

Prefabricated shelters provide safe and comfortable outdoor spaces for customers, employees, passengers, and equipment that protect them from extreme weather, pollution, debris, and rain. They are popular in urbanized areas. Like booths, prefabricated shelters are also highly customizable. Some of the prefabricated shelter types are the following:

Screening booths gained prominence during the COVID-19 pandemic as they provide protection for screening personnel while checking for symptoms at facility entrances. These booths are equipped with contactless temperature scanning stations to screen guests, occupants, or workers. They feature plexiglass windows and glove ports to facilitate specimen collection for testing. Designed for high mobility and temporary use, screening booths can be easily relocated as needed.

Bus shelters are prefabricated structures designed for commuters waiting at bus stops and terminals. Typically featuring a roof for protection, these shelters offer ventilation and may include amenities such as seating and Wi-Fi. They provide shelter from heat, rain, dust, and smoke, enhancing comfort for passengers while they wait for their bus.

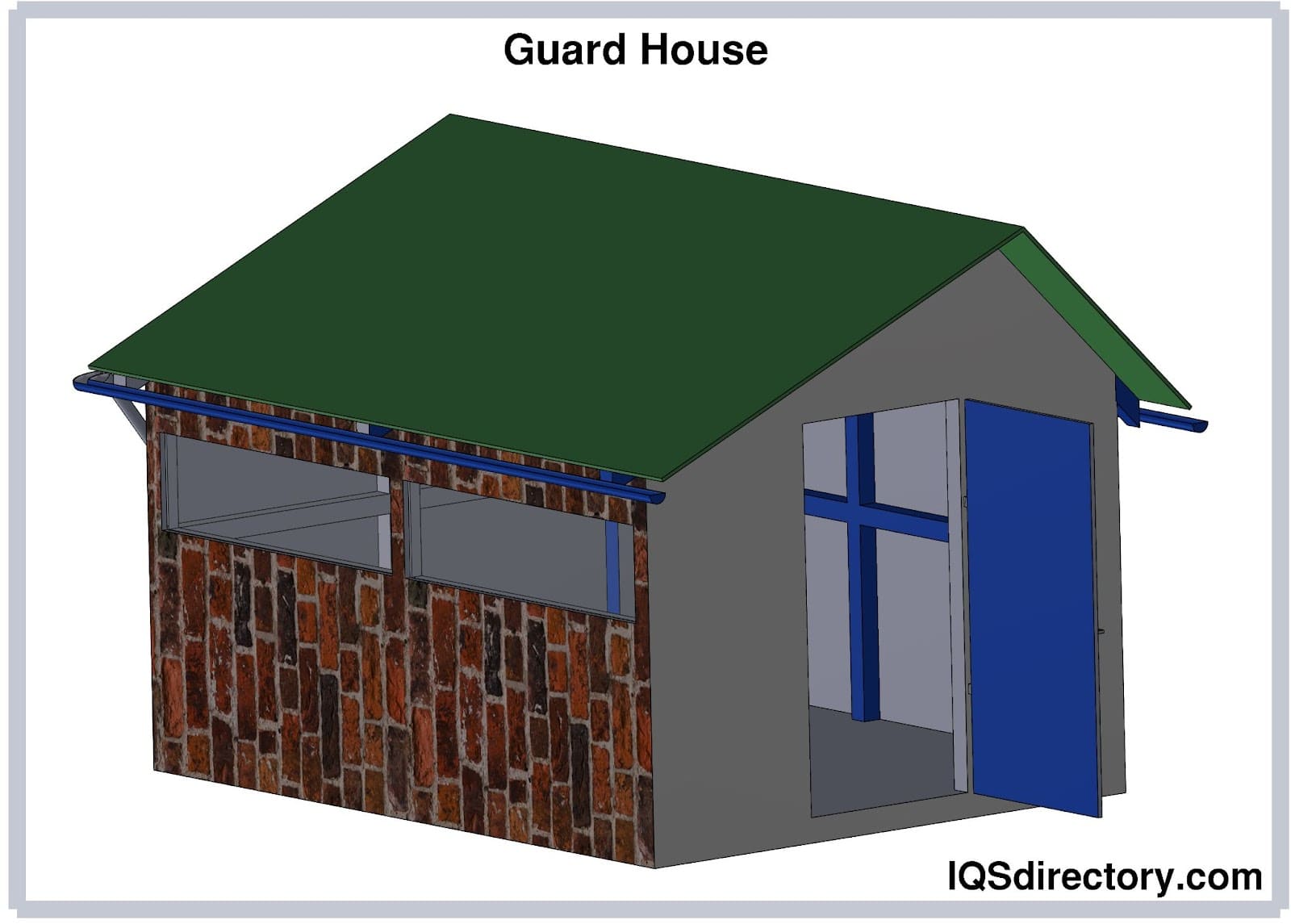

Guard houses or security guard booths are located in strategic private communities or compounds (usually at the entrance). They can also be installed in security checkpoints. They improve the efficiency of security personnel in their jobs. They act as a holding and working area for security guards in monitoring the security of the region through surveillance monitors. Windows are installed in the walls for the security personnel to authenticate the passing residents and incoming guests or visitors.

An observation tower is a specialized guardhouse designed to provide security personnel with a 360° view of the surrounding area.

Portable buildings are designed to be movable rather than permanently fixed in one location. Manufactured and assembled in a factory, these buildings are constructed as complete, stand-alone units that can be transported by crane, forklift, or truck. Upon arrival at the site, they are ready for immediate installation. Portable buildings can be adapted for various uses, including cabins, barns, storage warehouses, sheds, classrooms, medical facilities, remote housing, and more.

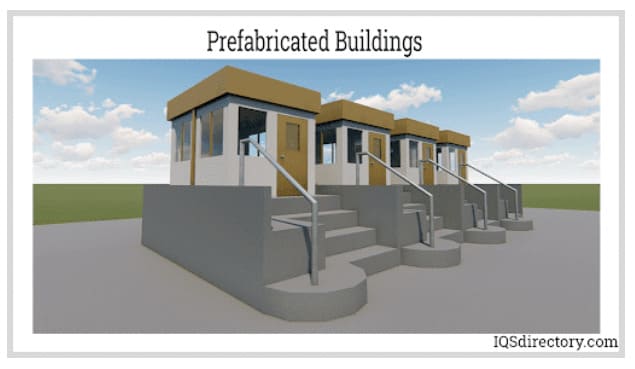

Prefabricated buildings are modular structures whose sections such as roofs, walls, ceilings, and furniture are highly customized, depending on the customer's request, and built offsite. The term "prefabricated buildings " refers to sections transported to the desired location and then fully or partially assembled. "Prefabricated buildings" are often used interchangeably with "modular buildings." Manufacturers of prefabricated buildings allow more flexibility. Meanwhile, modular buildings consist of standardized, uniform sections that can be sold as a mere product. The customer is responsible for the enhancement and installation of certain features.

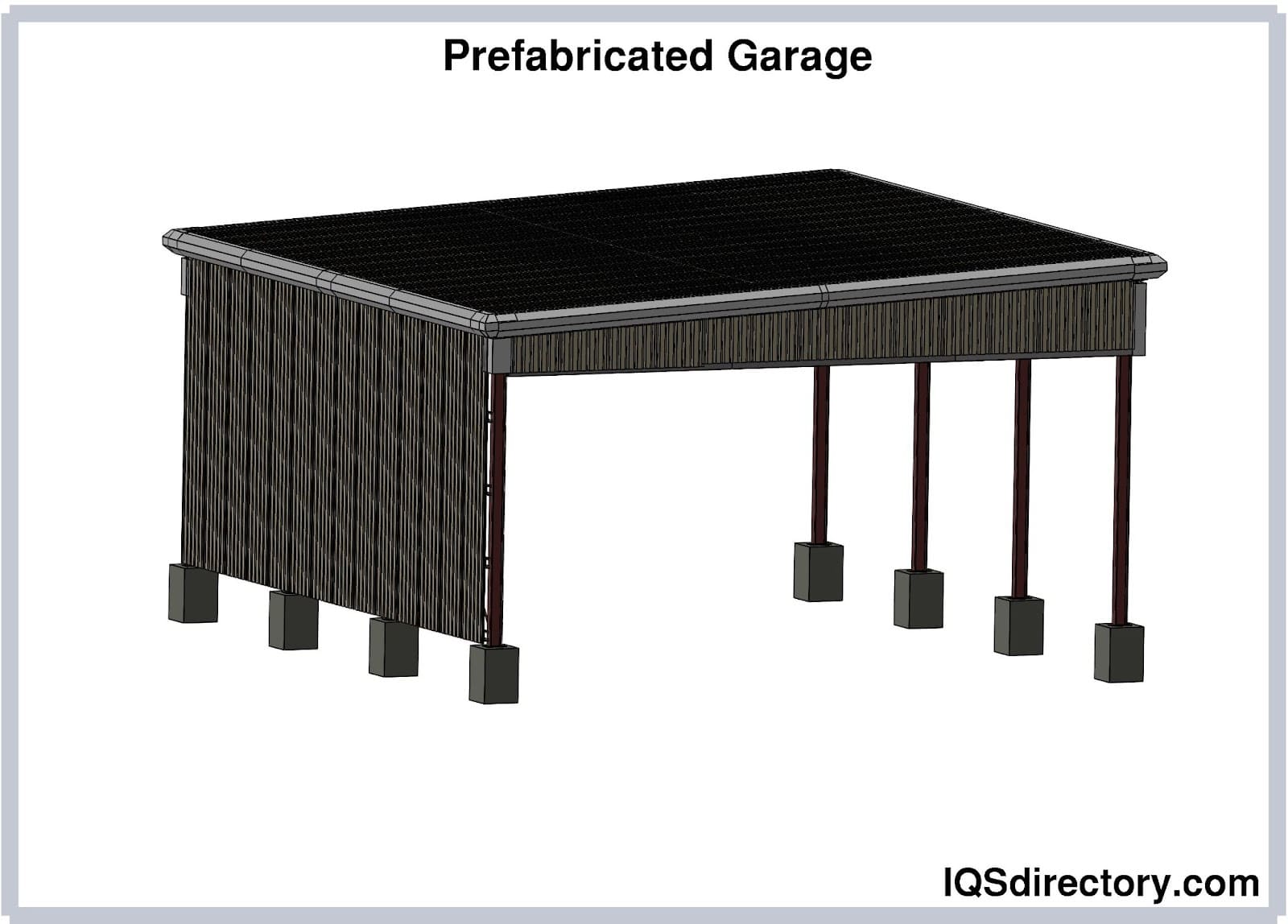

Prefabricated garages are modular structures designed to shelter vehicles and protect them from the elements and theft. These garages can feature multiple rooms under a single roof to accommodate several cars and often come with automatic garage doors. Additional security features can be installed to enhance protection. Choosing prefabricated garages is a cost-effective and time-saving alternative to constructing a permanent garage.

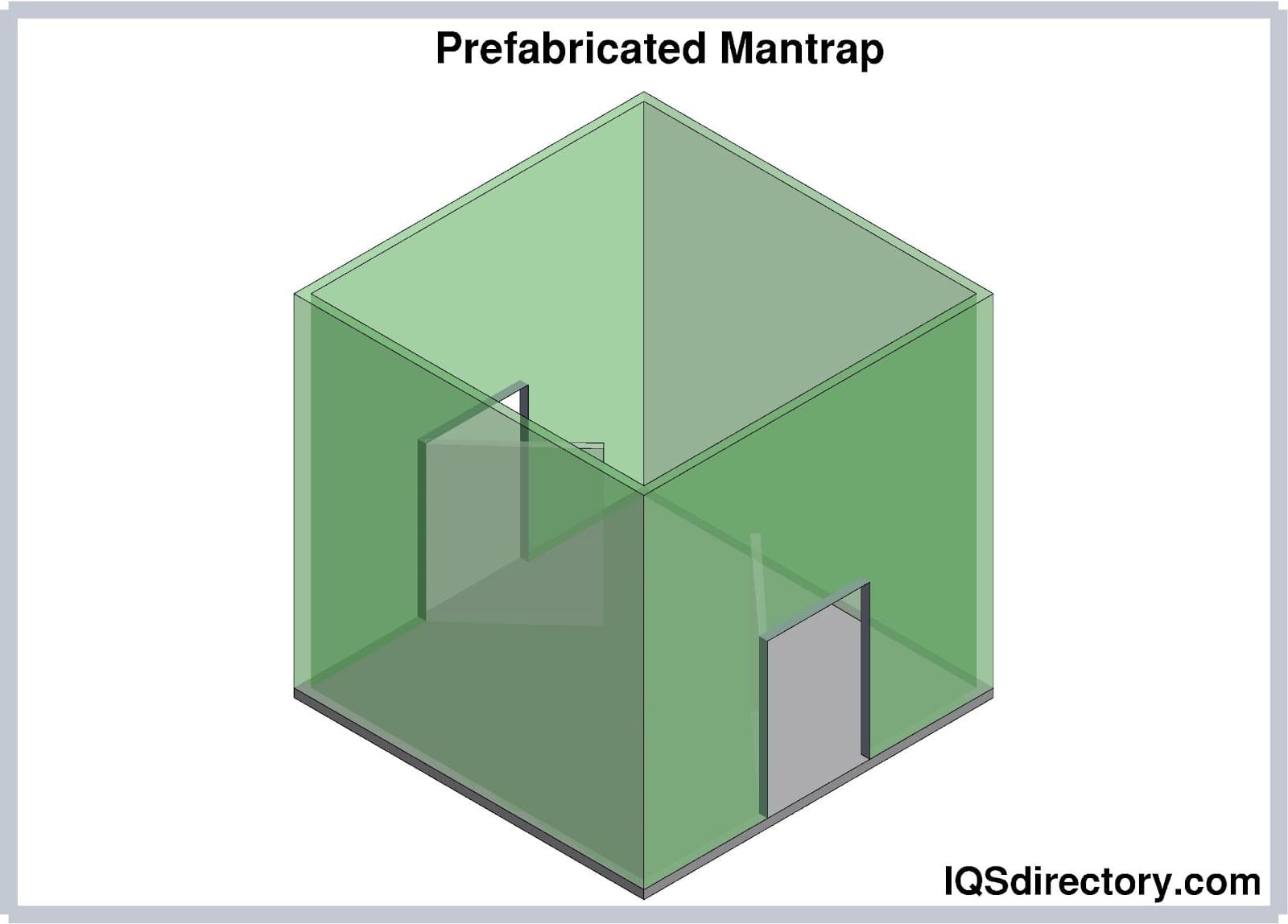

Prefabricated mantraps are modular rooms equipped with entrance and exit doors on opposite walls. They serve as a security buffer to prevent unauthorized access to restricted areas within a facility.

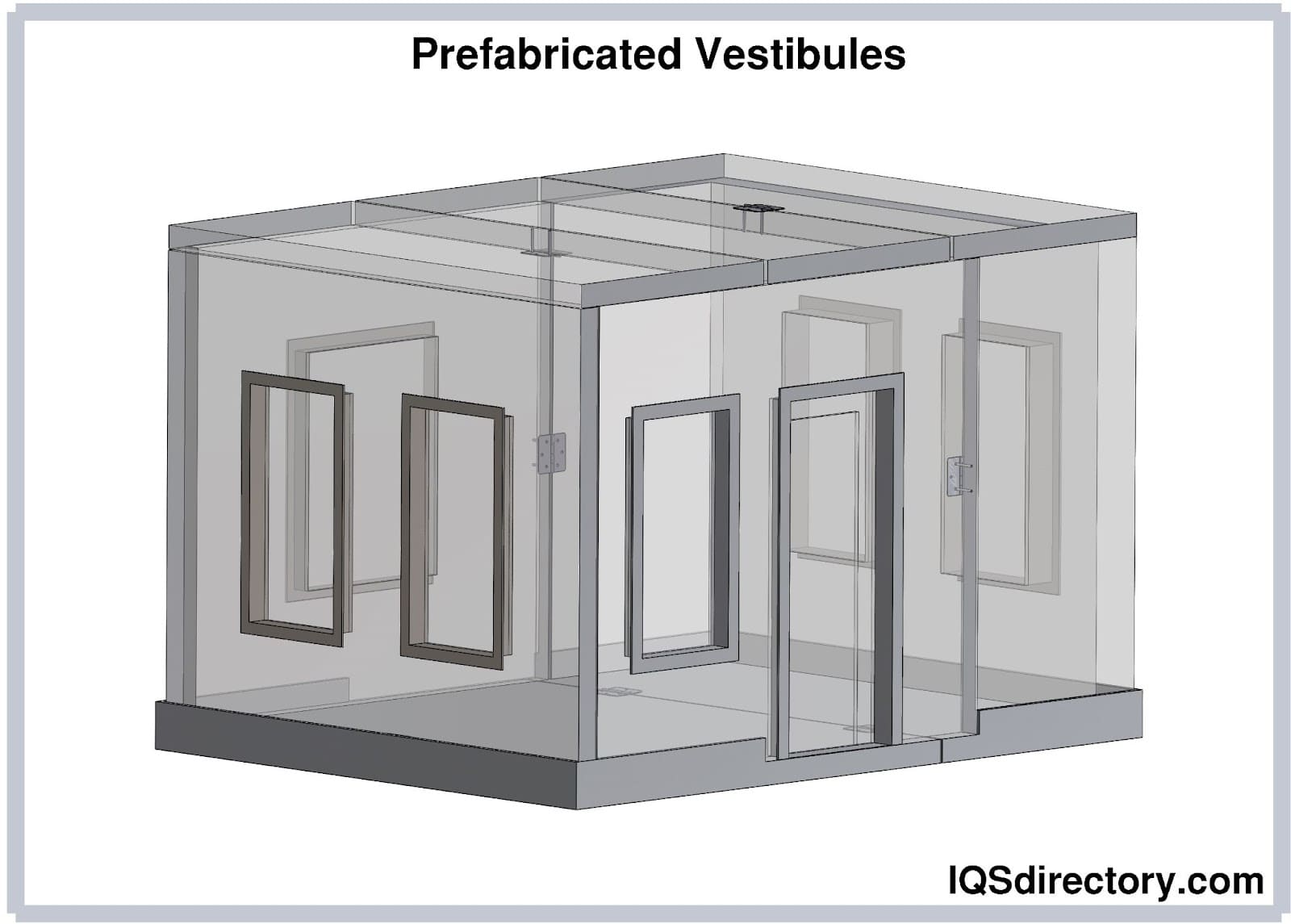

Prefabricated vestibules are modular spaces added to the exterior of buildings and homes to enhance security. These additional rooms allow personnel to screen tenants and visitors before they enter the main building. Vestibules also provide a space for storing umbrellas and coats, and for removing dust before entering the building. Additionally, they contribute to energy savings by minimizing heat transfer and reducing energy loss through the front door.

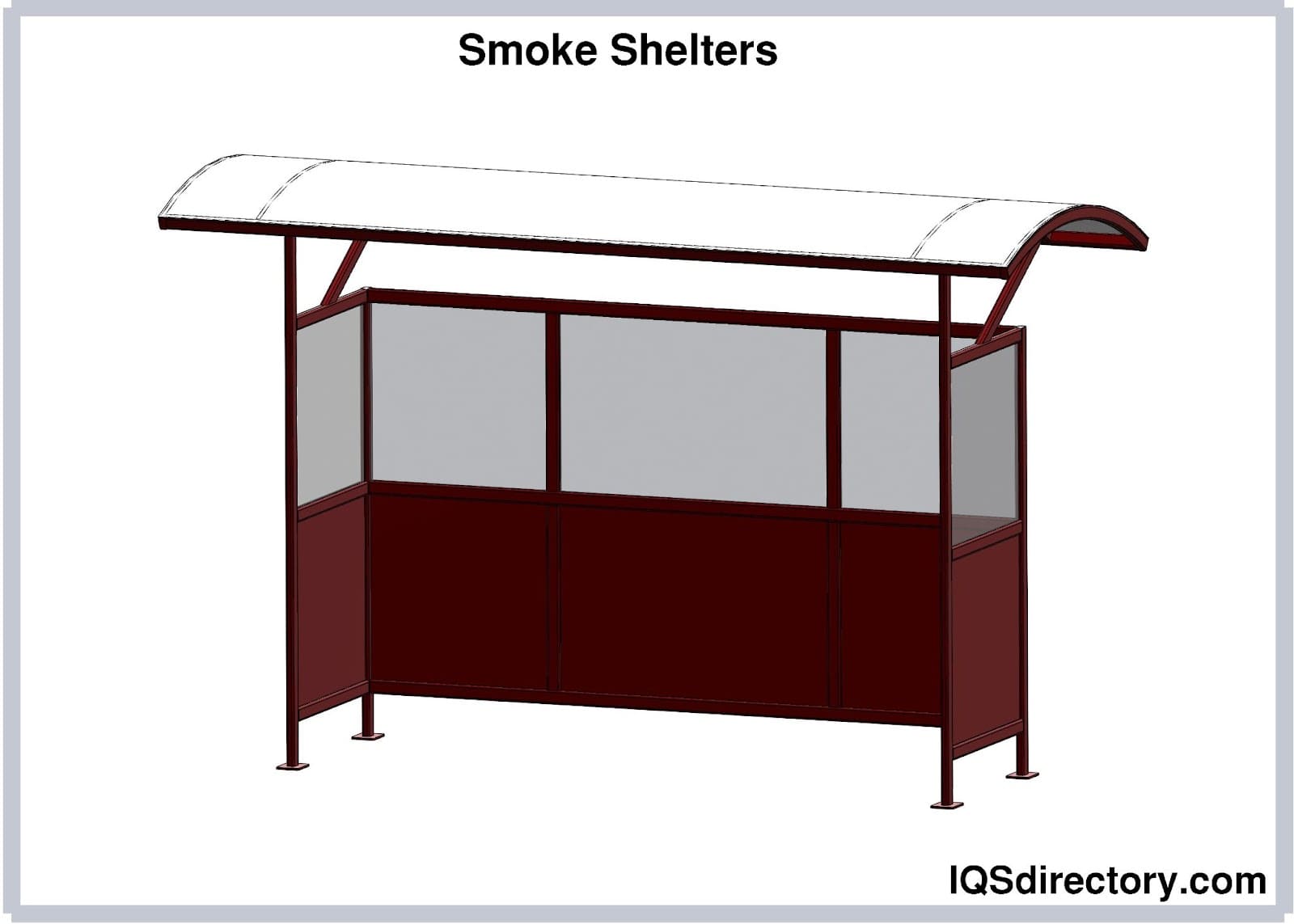

Smoke shelters are modular structures designed to serve as designated outdoor smoking areas for offices, residential spaces, and commercial facilities. Typically featuring a semi-enclosed space with a roof or ceiling, they provide a designated area for smoking in locations where smoking is restricted in public areas. Smoke shelters also help protect non-smokers from exposure to secondhand smoke.

As previously noted, modular construction can significantly shorten project turnaround times, often completing in half the time of traditional construction methods. This efficiency arises from the simultaneous execution of foundation work on-site and the production of prefabricated sections in the factory. This parallel process accelerates construction and minimizes delays caused by adverse weather, which can impact construction quality and worker safety. Once on-site, the prefabricated sections are typically ready for immediate installation, further reducing both time and effort.

Modular sections are produced in a controlled environment, safeguarding them from moisture, heat, and weather conditions. Manufacturers leverage technical expertise, advanced methods, and rigorous quality control procedures. Each section undergoes inspection, testing, and certification before delivery. As a result, modular buildings are durable and are likely to comply with all relevant building codes and standards.

Modular buildings offer flexibility in relocation and refurbishment, reducing the need for new materials and energy for constructing new buildings. They can also be added to existing structures. This makes them particularly suitable for remote locations or areas affected by disasters, where traditional construction is challenging and costly.

With modular sections manufactured offsite, there are fewer disruptions such as traffic and noise pollution at the construction site. This minimizes the impact on the client's business operations, which is especially advantageous in busy urban areas where such disturbances can affect productivity.

Modular construction is environmentally sustainable as the factory manages and properly disposes of air emissions, solid waste, and wastewater. This controlled handling reduces the environmental footprint of the construction process.

Manufacturers of modular buildings use lean production techniques to minimize waste while maintaining high quality and efficiency. Strict inventory control and proper material storage further reduce material consumption and waste.

Modular building manufacturers benefit from economies of scale, which lower production costs as output increases. These reduced fixed costs, including skilled labor, are spread across multiple projects, allowing manufacturers to offer modular buildings at lower prices, which is advantageous for customers.

Transportation costs can be high depending on the distance between the factory and the site, as well as the size of the modular parts. Larger modules may require oversized vehicles, and there is always a risk of damage during transport and handling due to mishandling or accidents.

Modular buildings may be limited to standard designs and styles due to mass production constraints. This can result in a lack of aesthetic appeal and features that might be desirable to the customer. While they are designed to meet general needs, customization is necessary to tailor the building to specific requirements and enhance occupant comfort.

In addition to the corporate, manufacturing, and trade industries, modular buildings are commonly acquired and utilized by the following sectors:

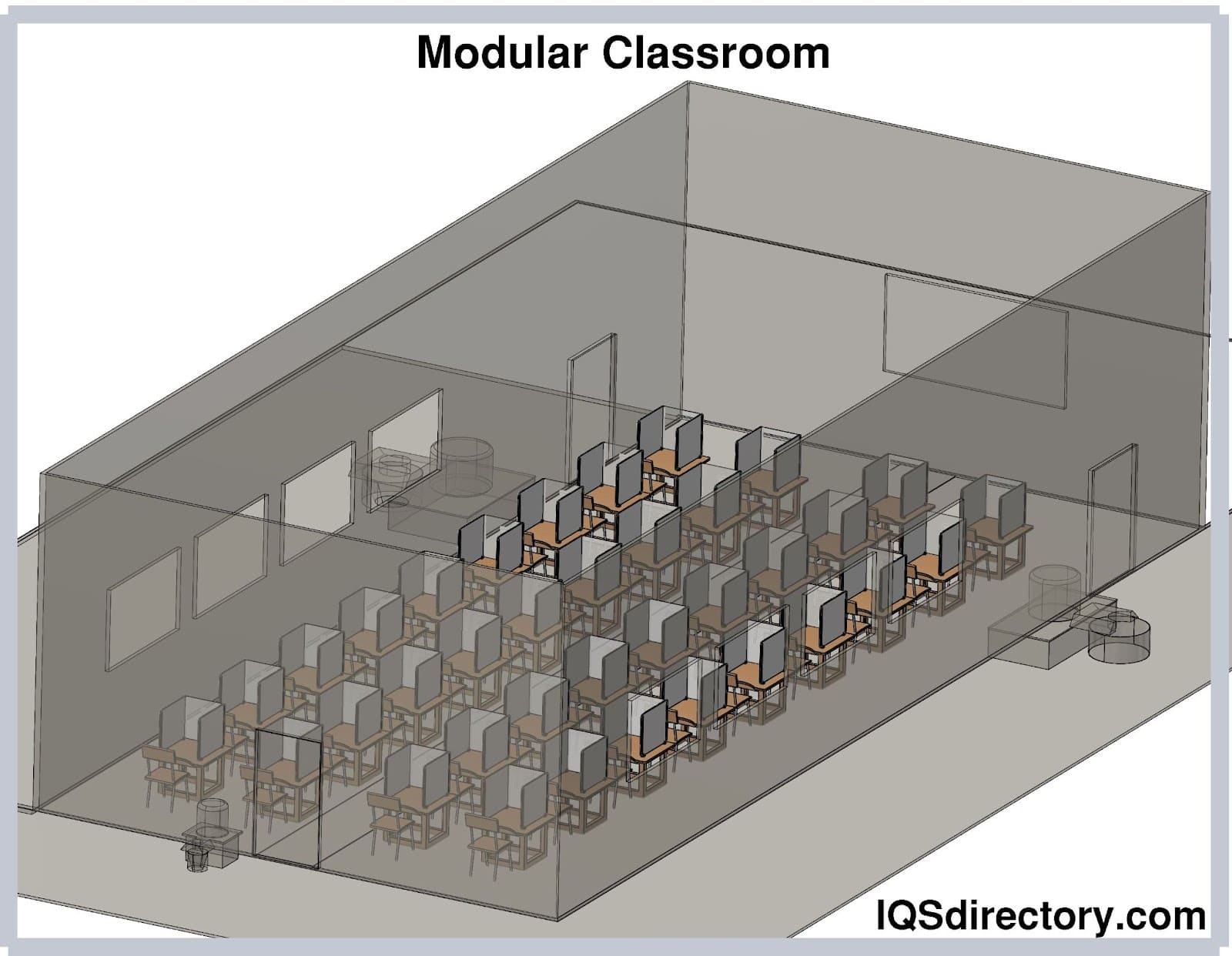

Modular buildings can serve as modular classrooms, equipped to accommodate chairs, tables, blackboards, and computers, and even labs. These buildings can house single or multiple classrooms, making them a flexible solution for schools facing maximum capacity issues. Modular classrooms are particularly useful as they can be adjusted to meet the varying number of students each school year.

Satellite government offices can be set up in various locations to address growing populations, seasonal demands, or increases in staff. These modular offices can be adapted for diverse functions, including administrative and management tasks, training facilities, and as headquarters for firefighters and police, among other uses.

Modular buildings play a crucial role in disaster response due to their ability to be rapidly deployed in emergencies. They can serve as temporary shelters for disaster victims and as operational bases for response teams, providing essential support in the aftermath of calamities.

Modular buildings can serve as temporary extensions for clinics, wards, and laboratories when the main hospital's patient capacity is exceeded. Additionally, relocatable medical facilities are used to provide care in remote areas, expanding access to healthcare services where needed.

Companies operating in remote or hard-to-access areas may purchase modular, prefabricated houses to provide housing for their workers. These modular units can also be used as student dormitories, offering flexible and efficient accommodation solutions.

A portable office is a mobile workspace that can be easily assembled and placed to provide a quiet and convenient location for meetings, completing paperwork, or examining plans. They are built using...

Prefabricated buildings, or prefabs, are buildings with components (walls, roof, and floor) that are manufactured in a factory or manufacturing plant. These components can be fully or partially assembled in a factory which is then transferred at the construction site...

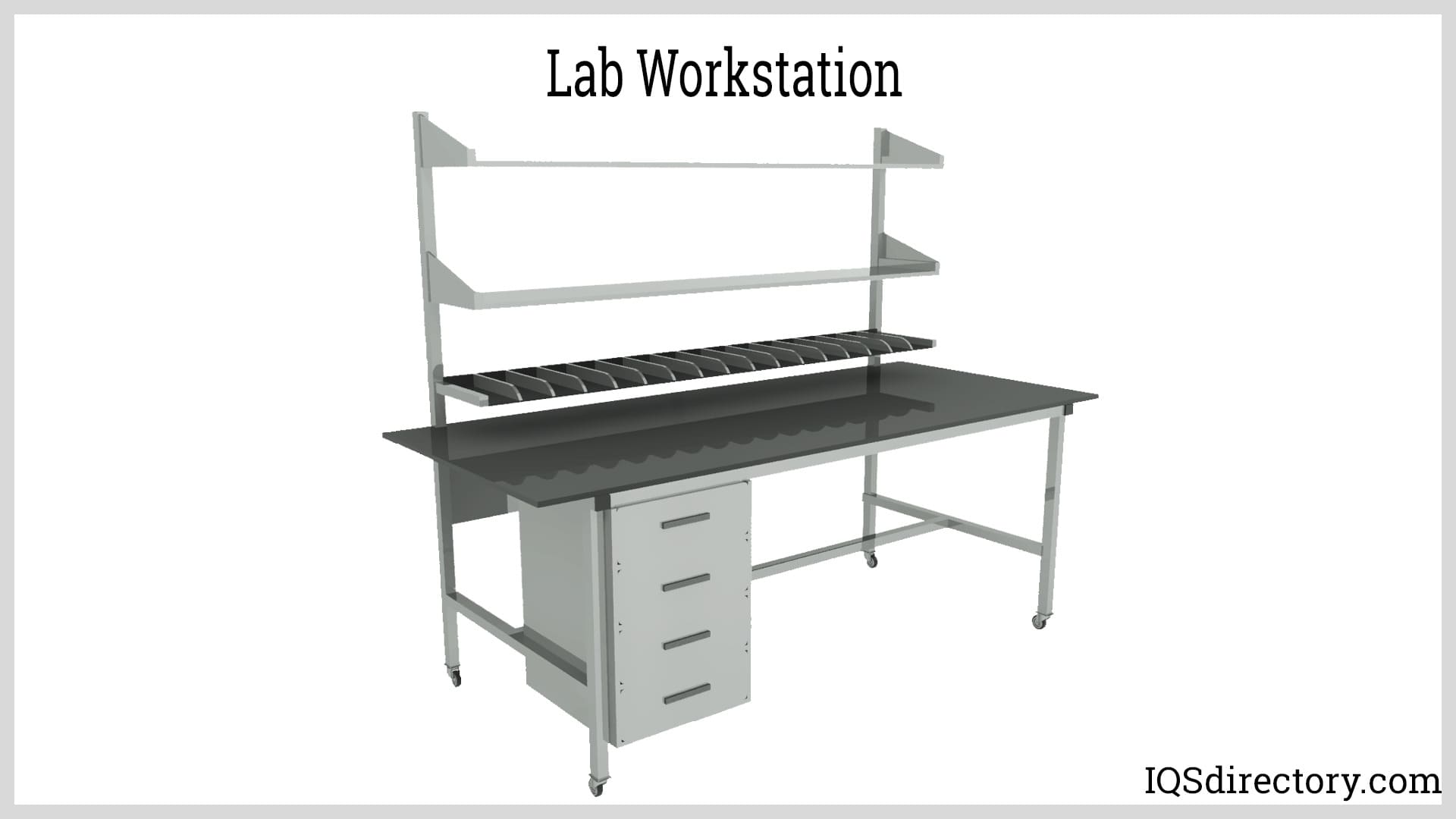

An adjustable work bench is a tool that allows the user to adjust and regulate the height of the work surface to a more ergonomic and comfortable position for the safe and effortless performance of work...

A lab bench is a specially designed bench or table that is able to assist in the performance of laboratory experiments and tasks, including the handling of reagents and test samples. Part of the design process for...

Metal grating is a metal product produced by perforating metal sheets or joining bars of metal to form a grid. They are a metal product that is widely used in various industries as stairs, platforms, scaffolding, and protective coverings...

A mezzanine is an intermediate floor installed in a building between the main floor and the ceiling that is partly open to the main floor. They have a low ceiling and project out over the main floor but do not completely cover it...

A mezzanine floor is a middle floor that is installed between the ceiling and the ground floor to provide extra space for storage, assembly operations, or office space. The normal design for a mezzanine floor is 25% of the flooring of a building or smaller...

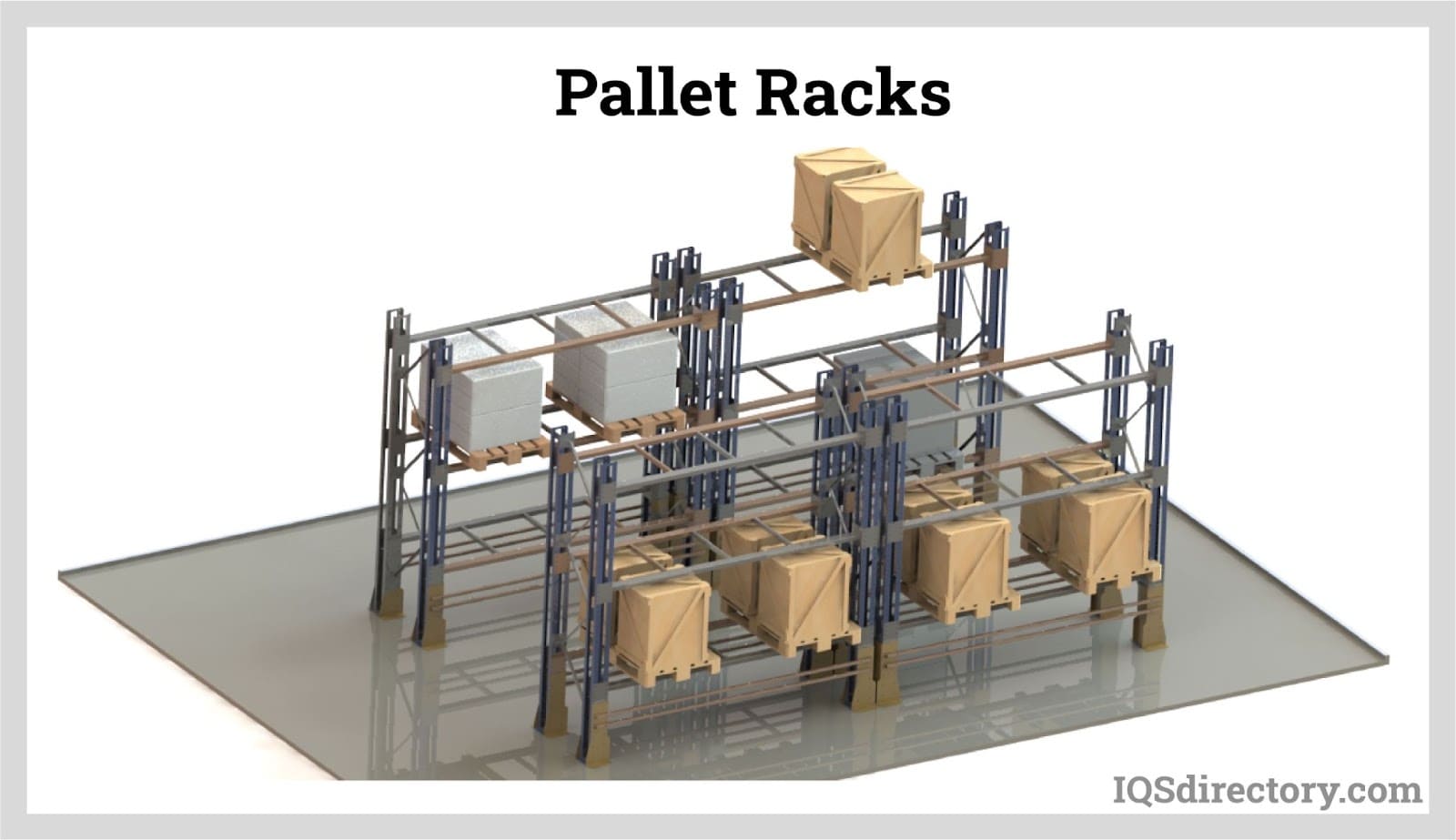

A pallet rack is an upright structure made of steel framing with beams and connectors that are bolted, welded, or clipped together to form a shelving unit to store inventory and equipment. In warehousing, pallet racks are...

A portable workbench is a flexible and mobile work surface that is designed to function in multiple environments for the purpose of preparing, constructing, or servicing a wide variety of industrial and commercial applications...

Storage rack, also known as racking, is a structure that stores items and materials and comprises at least two upright (vertical) frames, horizontal beams, and some sort of decking (bars, panels, meshes, or none)...

Warehouse racking, also known as storage or pallet racking, is a material handling system suitable for mass storage of goods unitized on skids or pallets. It allows efficient utilization of space while providing easy access to stockpiled items for better inventory control...

A workbench is a sturdy flat, smooth, molded surface that comes in a variety of sizes designed for specific tasks. They can be very complex for engineering design work, complicated machining, and intricate precision tooling or be a highly finished wood table for woodworking, metal work, and project design...

A work equipment platform is an elevated platform or surface in a manufacturing or production site that provides easy access to equipment and machinery. The raised space of a work equipment platform...