AC Power Cord

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Here is everything you will need to know about NEMA Connectors.

You will learn:

NEMA connectors are essential for linking electronic devices to power sources, accommodating either alternating current (AC) or direct current (DC). AC is commonly used in residential, office, and commercial environments, whereas DC is usually supplied by batteries.

While household connectors often have two or three prongs, the global industry employs hundreds of varied connectors. Each type is tailored to specific amperage (A) and voltage (V) needs.

In America, connectors are designed for current ratings from 15 to 60 amps and voltage ratings spanning 125 to 600 volts. They come in numerous configurations with diverse blade shapes, sizes, and alignments to prevent interchangeability, ensuring they meet specific requirements for voltage, current capacity, and grounding.

All U.S. manufacturers comply with NEMA standards, facilitating uniformity across the industry. NEMA standardization delineates plug and receptacle pin configurations based on their respective amperage and voltage specifications.

Refer to the diagram illustrating NEMA 2-20, NEMA 6-50, and NEMA 24-15 models, each with unique pin setups. These models differ by amperage and voltage, with 2-20 and 6-50 rated for 250V, and 24-15 rated for 347V.

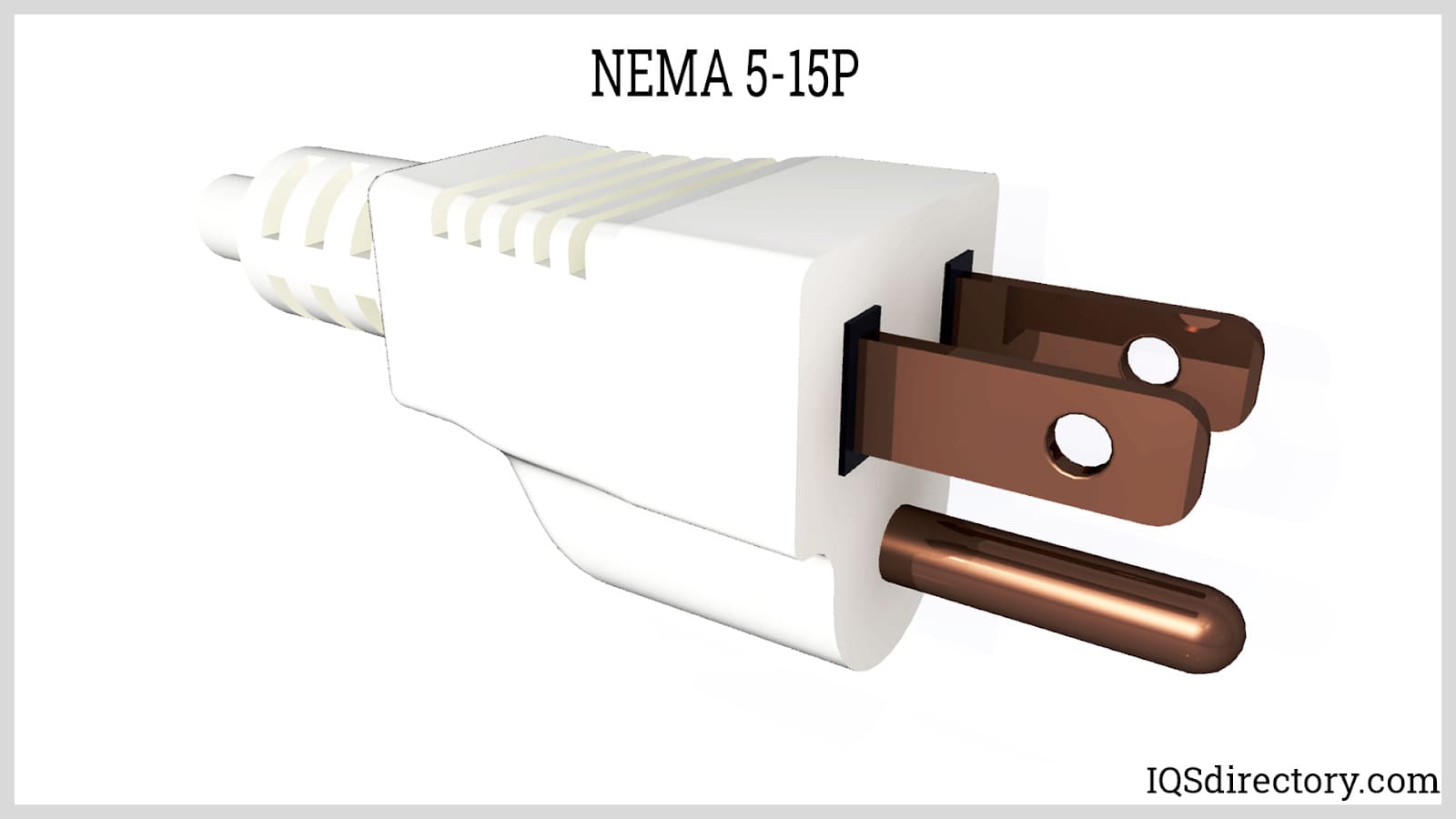

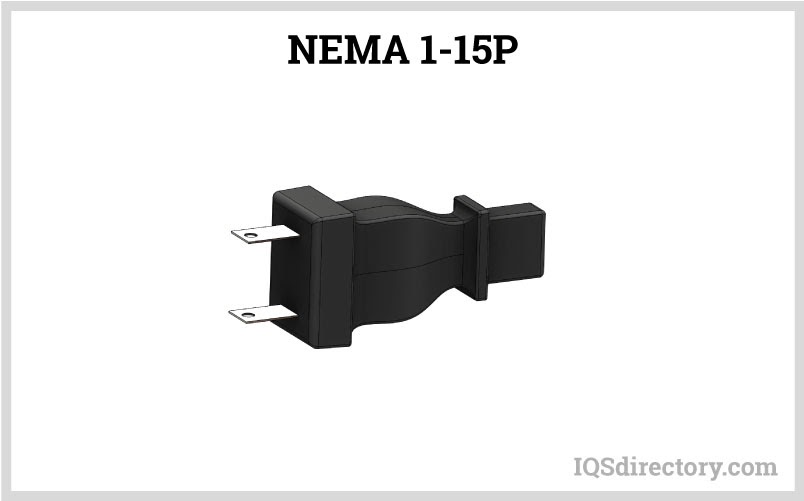

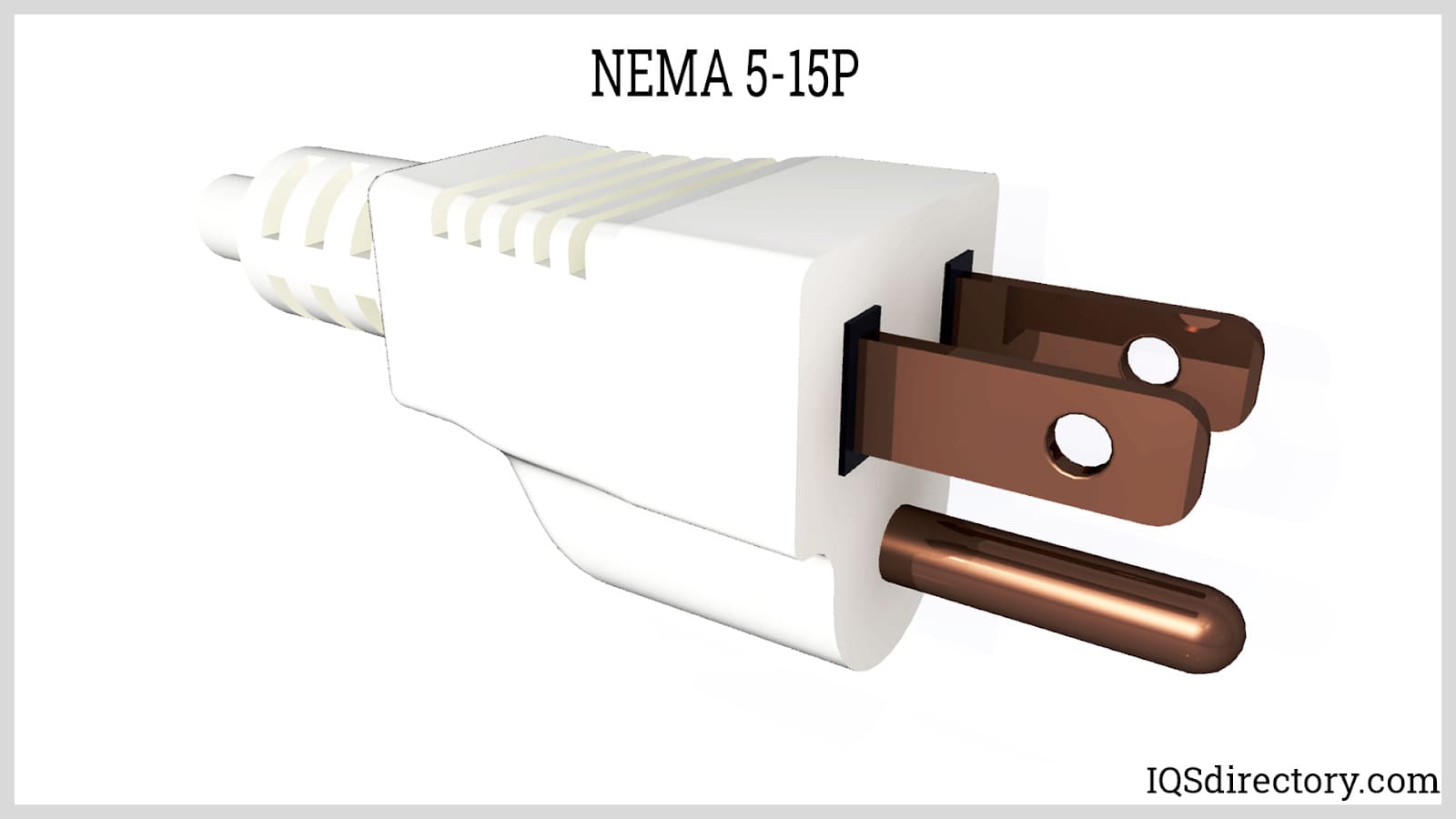

Electrical plugs and receptacles in the United States follow the quality standards of the NEMA. The two most common connectors are NEMA 1-15P and NEMA 5-15P, which have molded rubber bodies and prongs of steel or brass with a zinc, tin, or nickel coating. Other connectors have differently placed prongs and increased voltage.

Connectors are categorized into locking and non-locking types. Locking connectors feature curved prongs that twist to secure them in place after insertion. Non-locking connectors, with straight blades, are commonly used for computers, appliances, and everyday applications. Locking plugs and receptacles are designed to prevent accidental disconnection or displacement of the connector.

The following provides a brief overview of various NEMA connectors used in both home and industrial settings.

Among non-locking connectors, NEMA 1 and NEMA 5 are the most common. NEMA 1 features two blades without a ground, while NEMA 5 includes two blades with a ground. Recent regulations require builders to install NEMA 5 receptacles with ground plugs, leading to the gradual phase-out of the NEMA 1 series.

In the NEMA standardization system, the first number indicates the plug configuration, detailing the number of poles, wires, and voltage. Grounding types include options such as two-pole three-wire or four-pole five-wire. Non-grounded connectors match the number of wires to poles, as they don’t need a grounding wire. The second number denotes the amp rating, followed by "P" for plug or "R" for receptacle. For instance, a NEMA 5-15R is a 125V, two-pole, three-wire receptacle rated for 15 amps.

Typically, the ground pin is positioned upward to prevent metal objects from touching the live line. This orientation also keeps falling objects from hitting the neutral and live connections, ensuring safety.

NEMA 1 plugs feature a standard two flat prong design, with a two-pole, two-wire non-grounded configuration rated for 125 V. While this design has been widely used for many years, it is gradually being replaced by grounded plugs. The image below shows the most common type in the NEMA 1 series: the NEMA 1-15 P.

The NEMA 2s series is obsolete and no longer produced. It was a two-wire, 250V series.

NEMA 3s is a planned series featuring 277 V, two-wire configurations, and an ungrounded design.

NEMA 4s is an upcoming series designed to support 600 V, with two-wire configurations and an ungrounded setup.

NEMA 5s feature two poles, three wires with two blades, and a grounding pin. One blade is wider than the other, and they plug into NEMA 5 receptacles. The most common types are NEMA 5-15, 5-20, and 5-30.

NEMA 6s features three-wire grounding for 208 and 240 V circuits. Typically manufactured for commercial or industrial use, these connectors come in various sizes and pin configurations for ground and hot pins. They offer excellent performance and reliability.

NEMA 7s are two-pole, grounded connectors rated for 277 V. The NEMA 7-15 plug and receptacle feature angled current-carrying pins and a U-shaped ground.

NEMA 8s is a proposed design featuring three wires, two poles, and a grounding system, rated for 480 V.

NEMA 9s is designed to be similar to NEMA 8 but with a 600 V rating.

NEMA 10s are now obsolete and have been superseded by NEMA 14-30 and NEMA 14-50.

NEMA 11s are designed for three-phase 250 V applications, featuring three wires, three poles, and an ungrounded configuration. Available in 20, 30, and 50 amp versions.

NEMA 12s is planned for future introduction as a three-wire, three-pole, ungrounded configuration for three-phase, 480 V applications.

NEMA 13s, set for future introduction, is similar to NEMA 12 but differs in that it will be rated for 600 V.

NEMA 14s are four-wire, grounded outlets with a 15 to 60 amp rating and 250 V capacity. They are suitable for charging electric vehicles and powering electric ranges.

NEMA 15s is similar to NEMA 14 but supports three-phase power without a neutral conductor.

NEMA 16s is set for future release and will feature a four-wire, three-pole, grounded, three-phase design with a 480 V rating.

NEMA 17s is comparable to NEMA 16 but has a 600 V rating.

NEMA 18s is an alternative to NEMA 14 and NEMA 15, offering a 120Y208V three-phase ungrounded configuration.

NEMA 19s is set for future release, offering a 277/480Y four-wire, three-pole, ungrounded configuration.

NEMA 20s is similar to NEMA 19 but features a 247/600Y ungrounded configuration.

NEMA 21s, set for future introduction, will feature a 120/208Y, five-wire, three-pole configuration with neutral, three-phase power, and grounding.

NEMA 22s is comparable to NEMA 21, designed for 277/480Y applications.

NEMA 22s is comparable to NEMA 21, designed for 277/480Y applications.

They are two-pole, grounded with a 347 V rating, and primarily used in Canada.

NEMA TT-30 plugs are designed for recreational vehicles, providing 120 V and 30 A of power.

Locking connectors provide a secure fit by keeping connectors firmly connected. Their plugs feature curved blades that allow for rotation when inserted into the receptacle, ensuring a stable connection.

Most locking connectors are intended for commercial and industrial applications. Miniature or midget locking connectors, marked with "ML," are designed for spaces where larger connectors are unsuitable. These come in three different varieties.

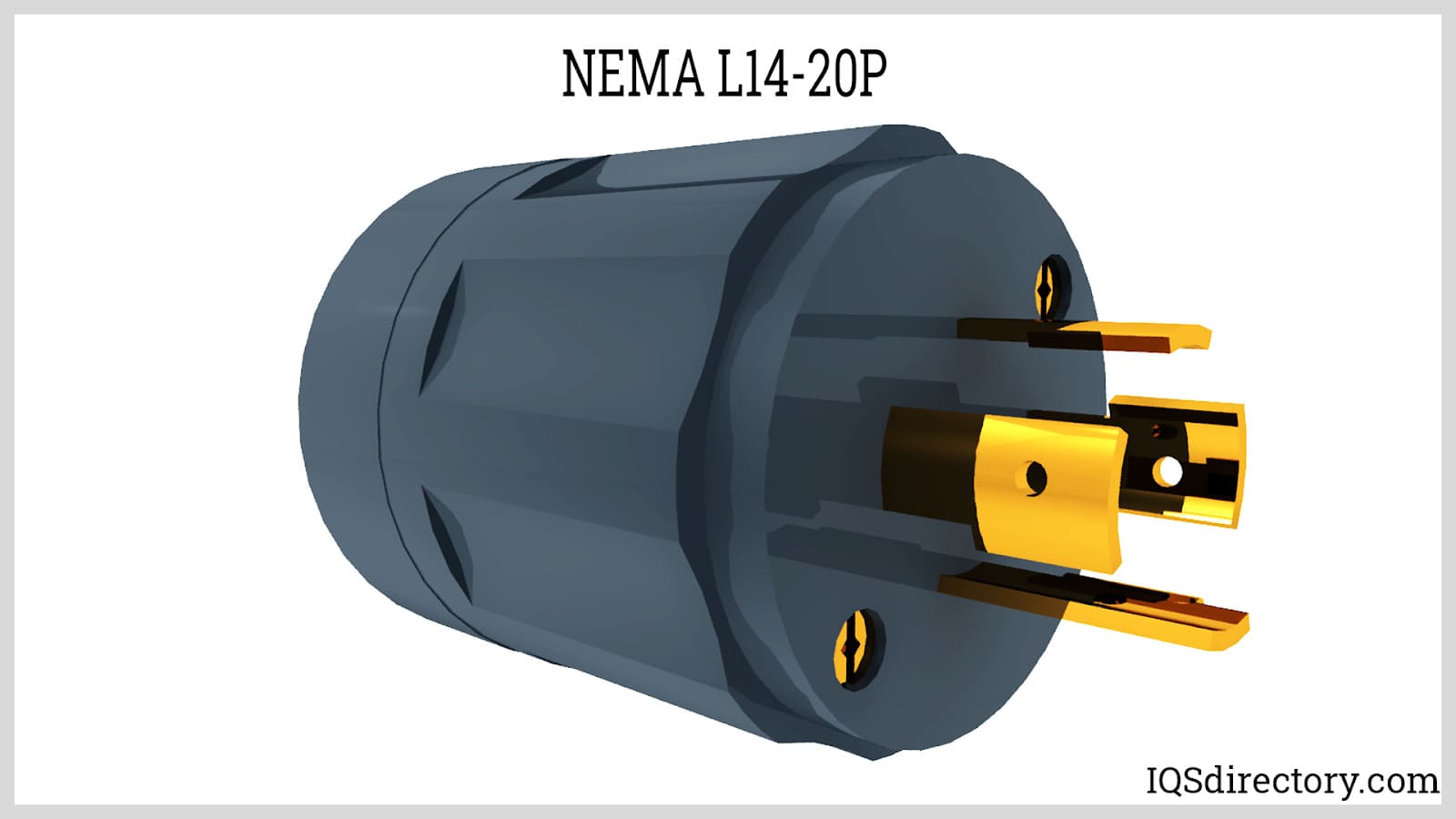

Locking connectors are identified by an "L" before the series number, such as NEMA L6, NEMA L7, or NEMA L10, distinguishing them from other NEMA connectors.

NEMA L1 connectors are single-pole plus neutral, two-wire, ungrounded, and designed for 125 V single-phase applications. They are suitable for use in 15 amp scenarios.

NEMA L2 are two-pole, two-wire, ungrounded single-phase connectors rated for 250 V and designed for 20 amp applications.

NEMA L3 and L4 were neither developed nor specified.

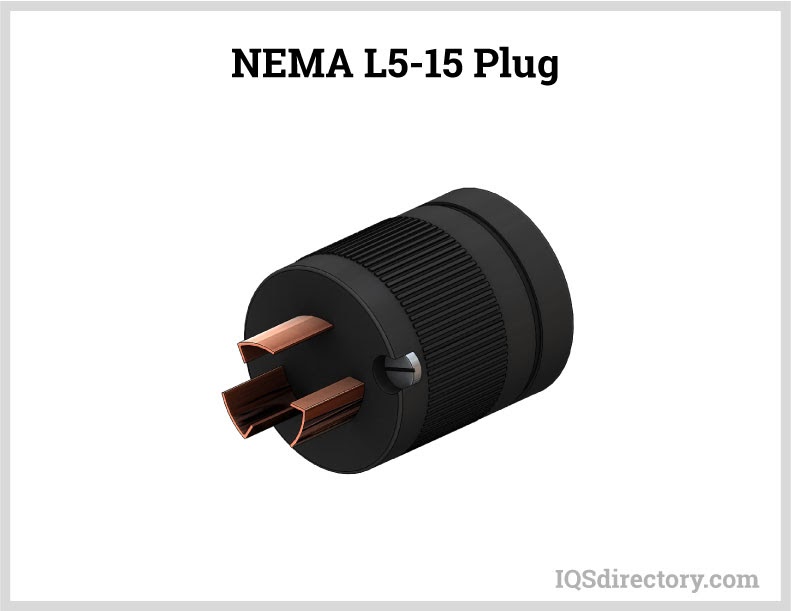

NEMA L5 connectors are two-pole, grounded, and rated for 125 V. They are commonly used at marinas, campsites, and RV parks.

NEMA L6 connectors are rated for 250 V and feature a two-pole, three-wire design, accommodating voltage ratings of 208 or 240 V without a neutral connection. The phase configuration depends on the voltage. These connectors are ideal for technical applications like servers and UPS units.

NEMA L7 are grounded two-pole connectors rated for 277 V, ideal for commercial lighting.

NEMA L8 connectors are two-pole, grounded devices rated for 480 V, designed for three-wire circuits.

NEMA L9 has the same configuration as NEMA L8 but is rated for 600 V.

NEMA L10 connectors are two-pole plus neutral, three-wire, ungrounded, single-phase units rated for 125/250 V and are now deprecated.

NEMA L11 connectors are three-pole, three-wire, ungrounded, 250 V, three-phase units available in 15, 20, and 30 amp configurations.

NEMA L12 shares the same configuration as NEMA L11 but with a 480 V rating.

NEMA L13 connectors are three-pole, three-wire, ungrounded, and rated for 600 V in a three-phase configuration.

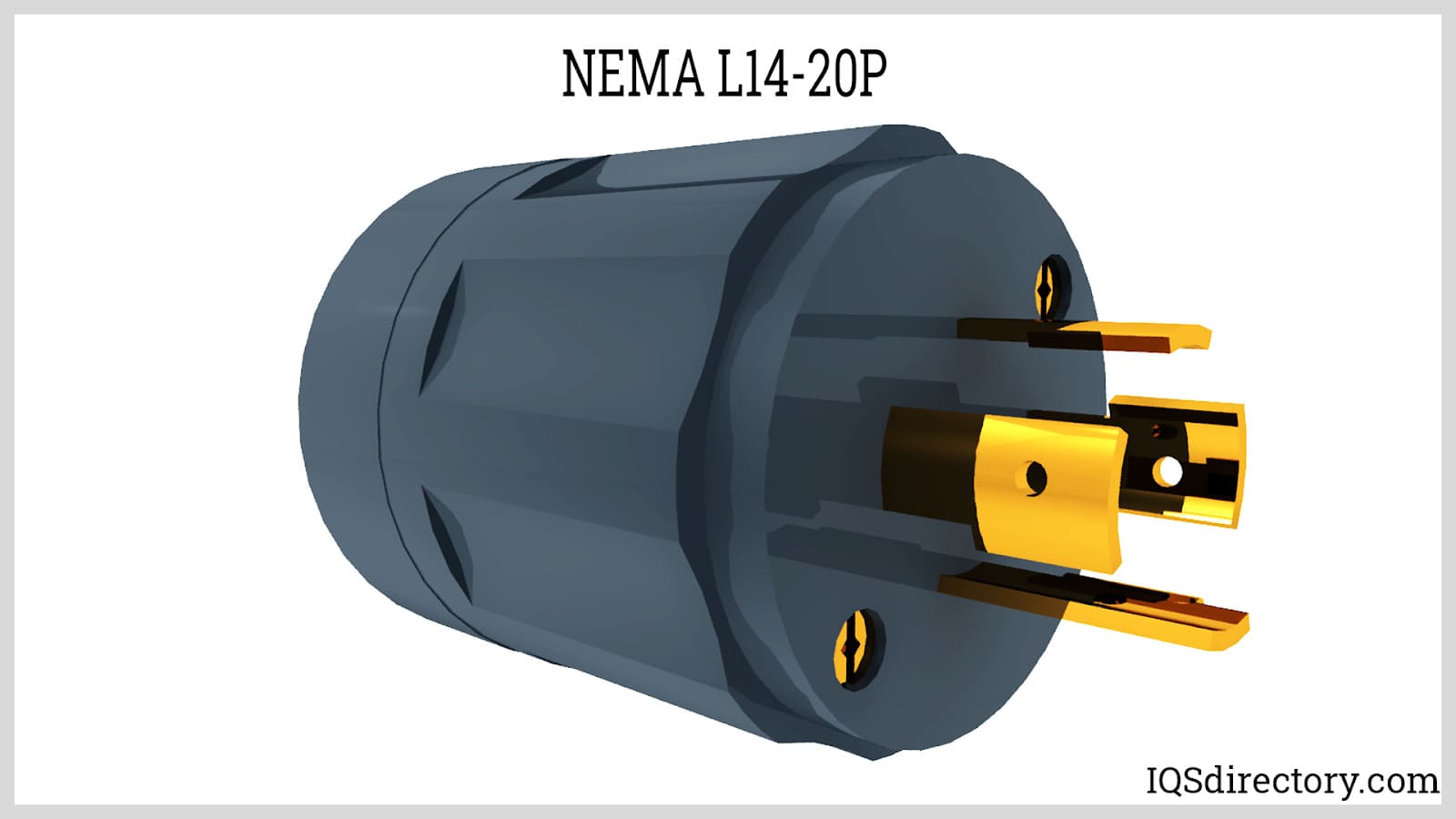

NEMA L14 connectors are three-pole, grounded, and rated for 125/250 V. They are designed for three-pole, four-wire circuits with 240 or 208 V and a 120 V neutral. Commonly used in household generators and amplifier racks for large audio systems.

NEMA L15 is a 250 V, 30 A connector with four prongs. It features a single-piece grounding system, along with polarized and water-resistant plugs and connectors.

NEMA L16 connectors are three-pole, grounded, and rated for 480 V in three-phase circuits.

NEMA L17 shares the same configuration as NEMA L16 but is rated for 480 V.

NEMA L18 connectors are four-pole, ungrounded, and designed for 120/208 V three-phase, four-wire circuits.

NEMA L19 connectors are three-pole, four-wire, ungrounded devices designed for three-phase 277/480 V applications, available in 20 or 30 amp versions.

NEMA L20 is identical to NEMA L19 but has a voltage rating of 347/600 V.

NEMA L21 connectors are four-pole, grounded with a 120/208 V rating. They are built for dusty, damp, and wet environments and feature a watertight seal.

NEMA L22 connectors are four-pole, grounded, and rated for 277/480 V in three-phase, four-wire circuits, including neutral and ground. The middle pin serves as ground, while the right-angle blade on the tab is designated for neutral.

NEMA L23 has the same configuration as NEMA L22 but with a 347/600 V rating.

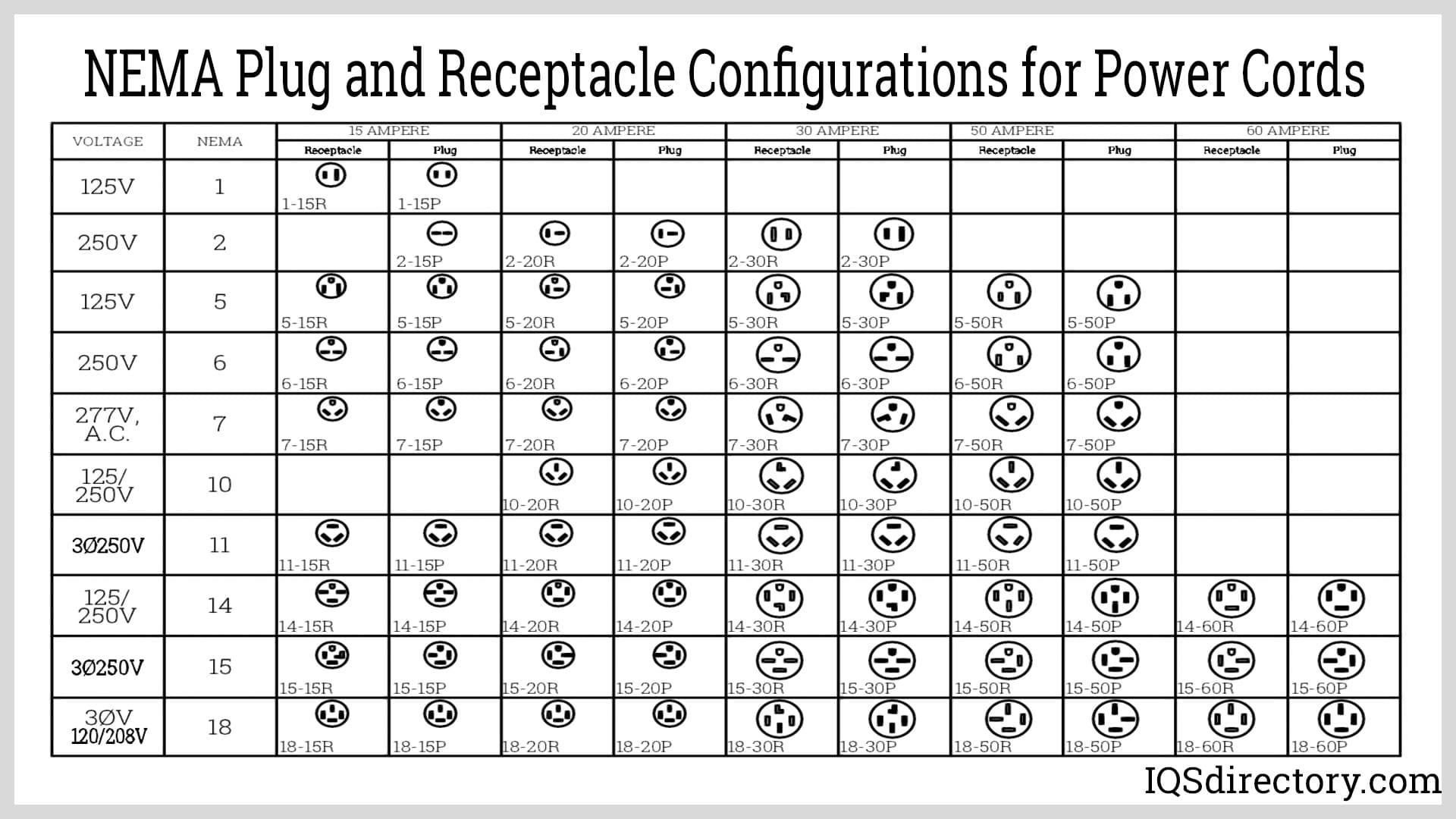

The chart below visually illustrates the various NEMA plug and receptacle configurations.

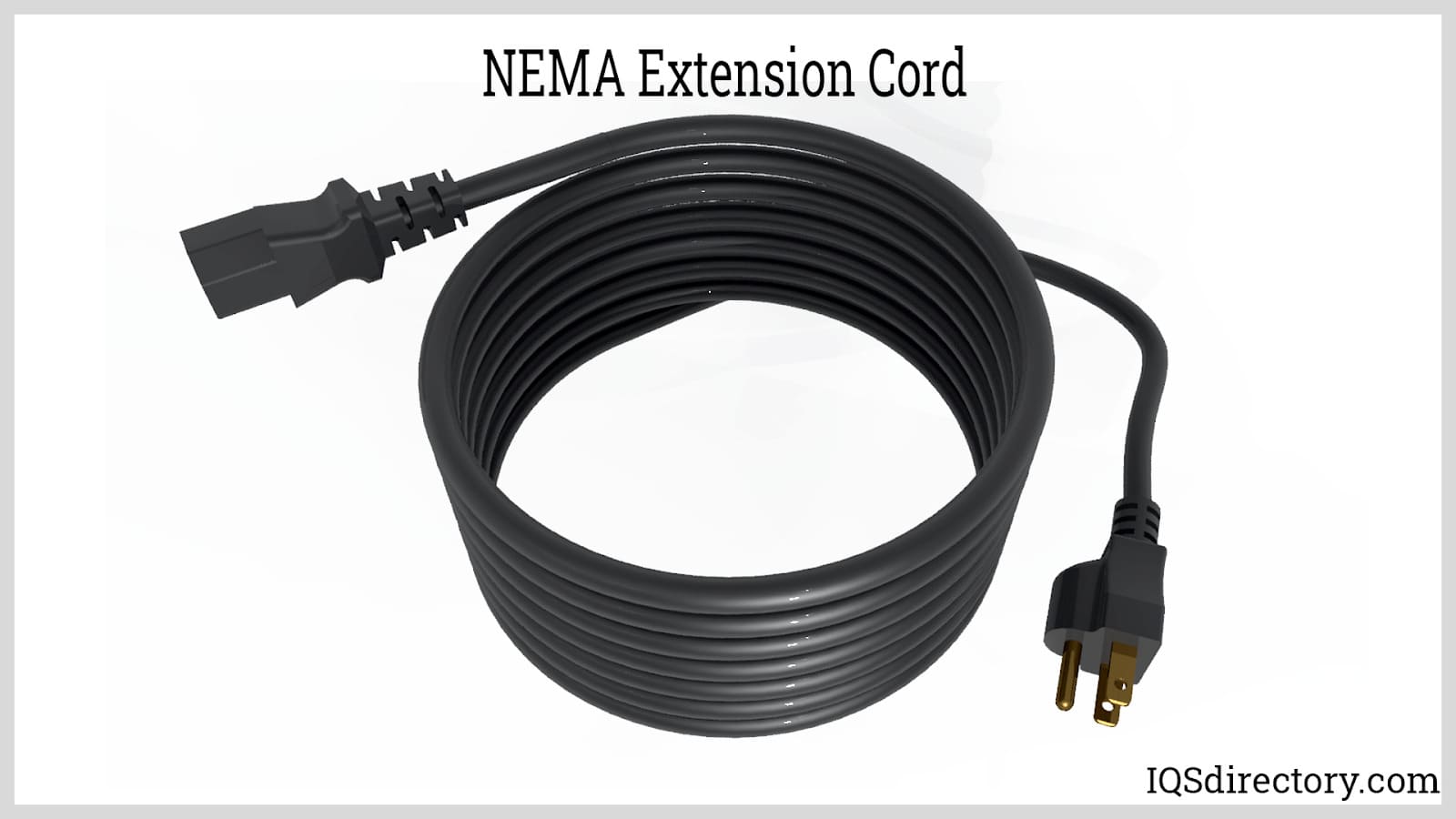

Just like in all areas of electricity transfer, power cords come in various types to accommodate different voltage and amp requirements. Their main function is to carry current from a power source to a device that receives the power.

Power cords typically consist of copper wire surrounded by insulating material and a protective non-conductive covering, as illustrated in the diagram below. Each power cord includes a plug, socket, and cord. Critical power cords may feature a locking mechanism on the plug to prevent accidental disconnections.

Power cords are rated by voltage or kilovolts, indicating their power transfer capacity. The amperage rating depends on the cord's wiring, the number of current-carrying conductors, and its length. Cords with three current-carrying conductors or those over fifty feet long experience a decrease in amperage.

The wire gauge rating follows the American Wire Gauge (AWG) standard. A 12 AWG wire is designed for 120-volt cords and outlets. In the AWG system, a lower number indicates a thicker wire.

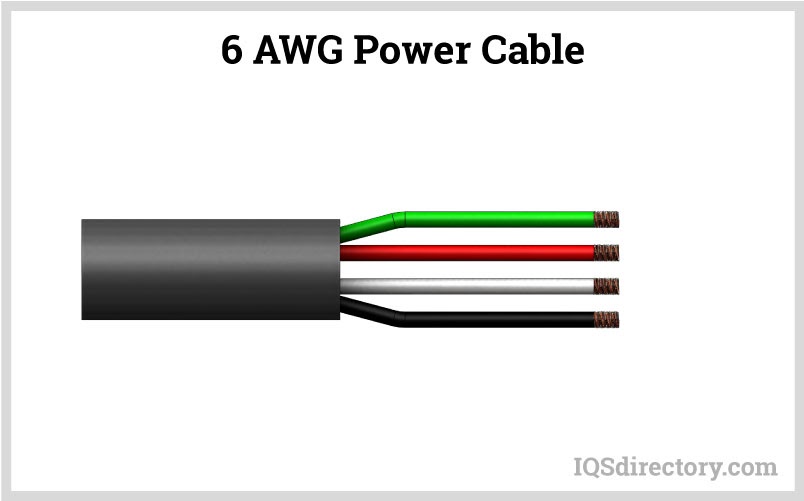

The image below shows a 6 AWG cable with 4 conductors and grounding, rated for 45 amps.

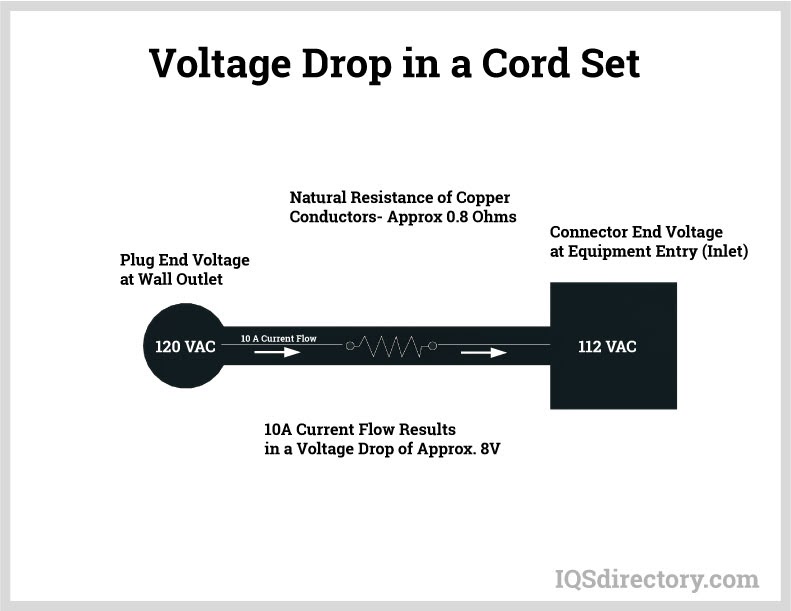

The longer the power cord, the greater the voltage drop due to power loss from the connector to the end of the cable. A cord longer than 50 feet may require a higher AWG rating to account for its length and significant voltage drop.

Voltage or power drop generates heat. Too much heat buildup can damage a wire or the power cord. The example below shows the amount of power drop in a 100 foot power cord set.

Electrical enclosures are a cabinet or box designed to protect electrical equipment and prevent electrical shock. They are made from plastic, steel, stainless steel, or aluminum and are rated for their protection against hazards and other environmental conditions. Part of the function of an enclosure is to protect electronic equipment from electromagnetic (EMI) and radio frequency (RFI) interference.

NEMA offers thirteen types of enclosures, each rated for specific usage conditions and levels of protection. Here are six of the most common types.

| NEMA Enclosure Types | |

|---|---|

| Rating | Protects against |

| NEMA1 | General Purpose Indoor, prevents accidental contact of personnel with the enclosed equipment |

| NEMA 3R | Windblown dust, vertical rain, severe external corrosion |

| NEMA 4 | dust, watertight, splashing rain, hose directed water, severe external condensation |

| NEMA 4X | dust, rain, splashing rain, hose directed water, ice, corrosion resistant |

A Type 1 enclosure is a general-purpose indoor enclosure designed to protect against dirt and accidental contact with people. It is suitable for use in standard factory environments.

Type 3R enclosures are designed to protect against rain, sleet, and ice damage. Ideal for outdoor use, these enclosures are constructed from galvanized steel and are commonly used as meter cabinets, filtered fans, and utility boxes.

A Type 4 enclosure is designed for both indoor and outdoor use, offering protection against accidental contact with equipment, as well as dirt, rain, sleet, snow, windblown dust, and water. It also safeguards against ice damage. The door clamps on three sides to ensure a watertight seal. Type 4 enclosures are ideal for industrial applications, including wiring enclosures, hydraulic controls, and operator consoles.

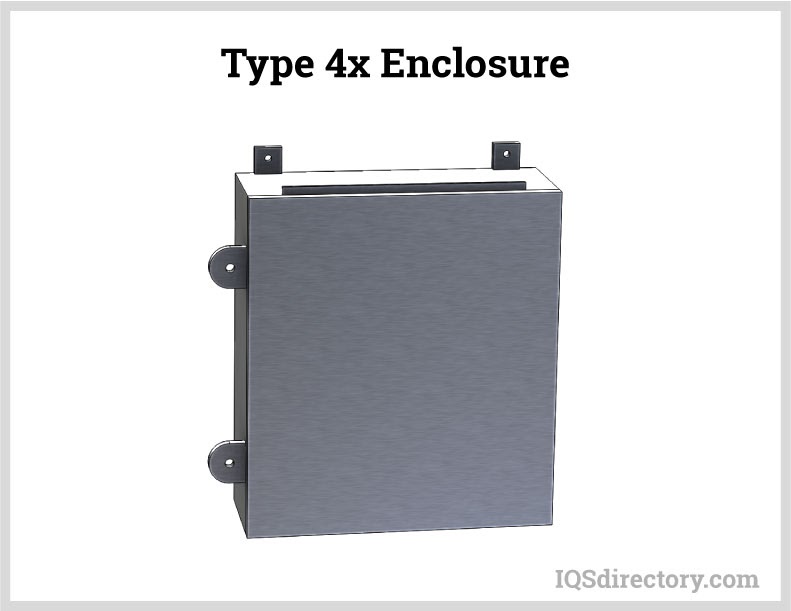

Type 4X enclosures offer the same protection as Type 4 enclosures but include additional corrosion and rust resistance. They are designed to withstand being hosed down and are commonly used in marine environments, paper manufacturing, industrial food processing, oil and gas drilling, refining, and water treatment.

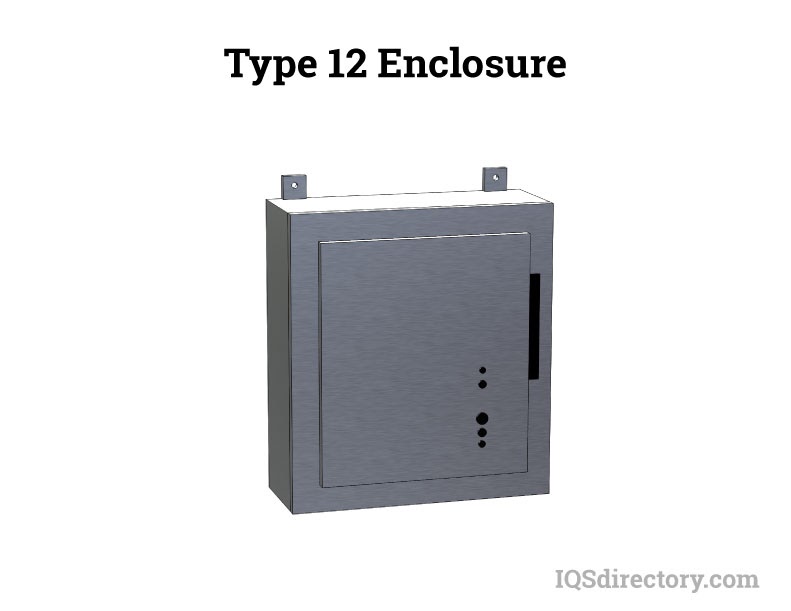

Type 12 enclosures can be either mounted or freestanding. Constructed from 14-gauge steel with welded seams, they are non-corrosive and designed to protect against flowing liquids. Knockouts may or may not be included.

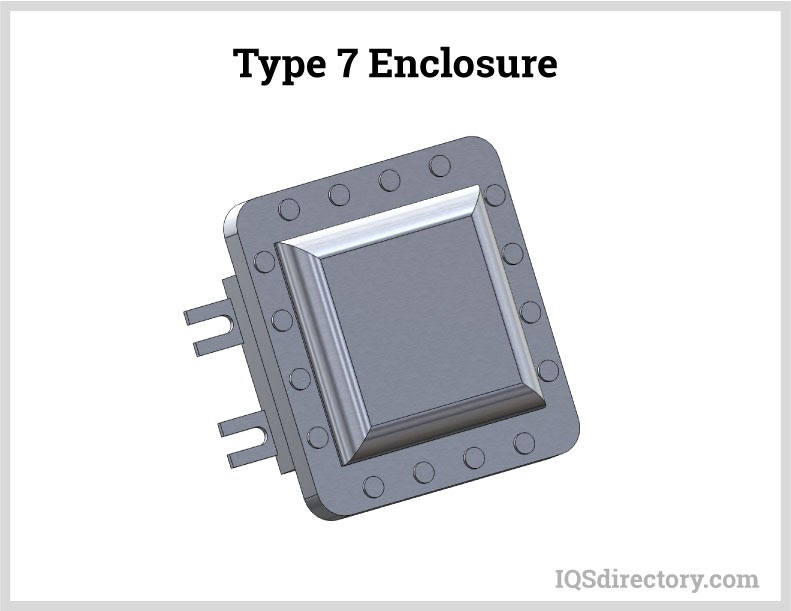

Type 7 enclosures are designed for hazardous locations according to National Electrical Code (NEC) Articles 500 to 506. Often called explosion-proof, they are intended for indoor use in Class I, Groups A, B, C, and D environments, which include areas with flammable gases or potentially explosive materials.

When evaluating the protection of components, fixtures, or enclosures, ingress protection (IP) ratings are commonly used. The IP Rating system measures the intrusion of water and solid particles. In some cases, electrical components may have both a NEMA rating and an IP rating.

Although their rating scales differ, both can offer guidance on the quality and protection of electrical components. Below is a simplified version of IP classifications.

| Ingress Protection Classification | |||

|---|---|---|---|

| First Number | Second Number | ||

| IP | Protection Provided | IP | Protection Provided |

| 0 | No Protection | 0 | No Protection |

| 1 | Protected against solid objects up to 50mm e.g. accidental touch by hands | 1 | Protected against vertically falling drops of water e.g. condensation |

| 2 | Protected against solid objects up to 12mm e.g. fingers | 2 | Protected against direct sprays of water up to 15 degrees from the vertical |

| 3 | Protected against solid objects up to 2.5mm e.g. fingers | 3 | Protected against direct sprays of water up to 60 degrees from the vertical |

| 4 | Protected against solid objects up to 1mm e.g. fingers | 4 | Protected against water sprayed from all directions - limit ingress permitted |

| 5 | Protected against dust - limit ingress (no harmful deposit) | 5 | Protected against low pressure jets of water from all directions - limited ingress permitted |

| 6 | Totally protected against dust | 6 | Protected against strong jets of water e.g. for use on ship decks - limited ingress permitted |

| 7 | Protected against the affects of immersion between 15cm and 1m | ||

| 8 | Protected against long periods of immersion under pressure | ||

The United States, as outlined by NEMA standards, offers a diverse range of plugs and sockets to meet the needs of appliances, machinery, heavy-duty equipment, and unique electrical requirements. This variety suggests that there are ample options available to accommodate the needs of other countries as well.

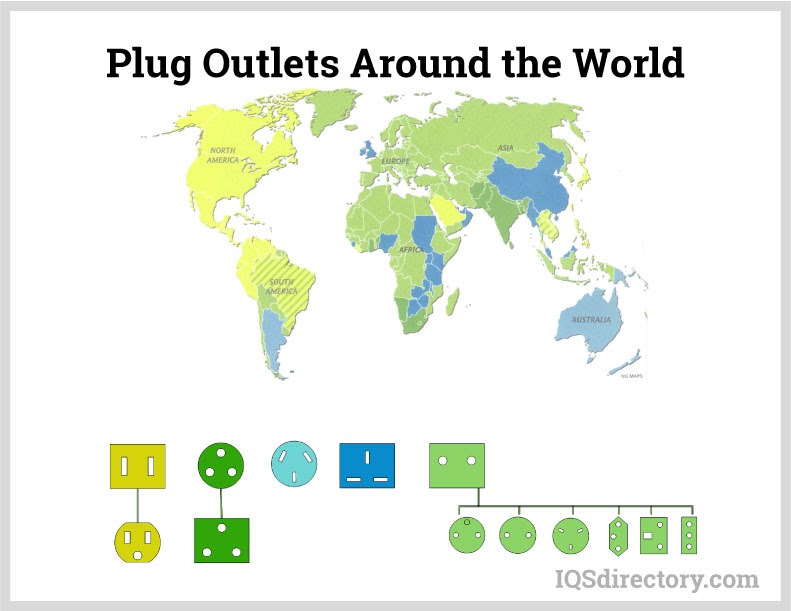

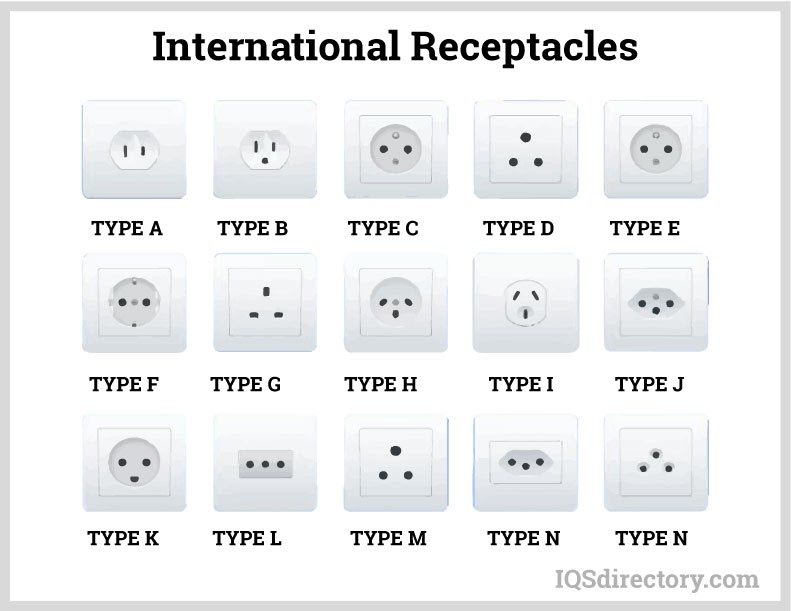

Despite the numerous plugs and receptacles in North America, many different types exist globally, each with varying voltage and amp requirements. To simplify this, the U.S. Department of Commerce International Trade Administration has assigned letters from A to O to different connector types, as shown on the map below.

As international travel increases and reliance on electronic devices grows, manufacturers have created adapters to meet the needs of various countries. While standardization would simplify things, it’s unlikely to happen in the near future.

The first two types of international plugs, A and B, are commonly used in the United States, Canada, Mexico, and Japan. These are the plugs and receptacles we encounter daily. However, as shown in the diagrams, plugs and receptacles in other countries differ significantly from what we are used to.

The United States, Canada, Mexico, and Japan use two-pin, ungrounded configurations.

The United States, Canada, Mexico, and Japan – three-pin configuration with grounding.

Europe, South America, and Asia – features two pins and is ungrounded.

India – features three pins with grounding.

France, Belgium, Poland, Slovakia, and Czechia – two-pin and grounded.

Europe and Russia, excluding the United Kingdom and Ireland – two-pin, grounded plugs.

The United Kingdom, Ireland, Malta, Malaysia, and Singapore use a three-pin, grounded configuration.

Israel, the West Bank, and the Gaza Strip – three-pin and grounded

Australia, New Zealand, China, and Argentina – options include two-pin ungrounded or three-pin grounded configurations.

Switzerland & Liechtenstein – features three pins with a grounded design.

Denmark & Greenland – three-pin configuration with grounding.

Italy & Chile – three-pin configuration with grounding.

South Africa – three-pin, grounded configuration

Brazil and South Africa – three-pin configuration with grounding.

Thailand – three pins and grounded

Here is the international plug chart from Webber Electronics, located in North Ridge, OH.

As electronics began to advance in the early 20th century, manufacturers recognized the need for standardized safety and uniformity in electrical components. In response, the International Electrotechnical Commission (IEC) was established in 1906 as a non-profit, non-governmental organization to develop standards for electrotechnical devices.

In 1926, the Electric Power Club and the Associated Manufacturers of Electrical Supplies merged to create the National Electrical Manufacturers Association (NEMA), aiming to standardize electrical equipment for consumer safety. NEMA now sets standards specifically for North America.

The IEC, an international organization with over 80 member countries including the United States, develops standards through the expertise of thousands of electrical and electronics professionals. IEC standards are numbered from 60000 to 79999, such as IEC 60548. Below is a selection of some IEC standards.

Below are examples of NEMA standards. Each code is prefixed with letters such as EWS, MG, or ICS, representing water service (EWS), motors and generators (MG), and industrial control systems (ICS). Other letter combinations specify the particular applications for each code.

Although the IEC and NEMA have similar goals, they differ in several key aspects. Here are some of the main differences.

NEMA simplifies selection by focusing on horsepower and voltage. In contrast, IEC standards demand more detailed specifications.

NEMA products offer broader applications, while IEC products are smaller, more affordable, and designed for specific operating conditions.

NEMA products come fully assembled, whereas IEC products feature a modular design.

NEMA products feature an open design and require safety covers, while IEC contactors are designed to be finger-safe.

NEMA does not certify products directly but collaborates with the National Institute of Standards and Technology (NIST) and ASTM International. In contrast, IEC partners with certifying organizations like the System for Conformity Testing and Certification of Electrotechnical Equipment and Components (IECEE) and the International Organization for Standardization (ISO).

Using IEC and NEMA guidelines offers various benefits based on your specific needs. The chart below outlines some of the key differences between them.

| IEC vs. NEMA | |

|---|---|

| IEC vs. NEMA: Pros and Cons | |

| Less expensive | Less expensive |

| Less versatile (Designed to meet life/current requirements in specific applications) | More versatile (Rating are broad and apply to many different applications) |

| More compact device | Large sized device |

| Caters to global market | Specific to North American market |

| Reacts faster to overloads | Better at withstanding short circuits |

| Finger safe | Requires safety covers |

Common NEMA connectors are often overlooked but play a crucial role in specialized applications. These connectors are designed to offer enhanced protection and safety, ensuring reliable performance in various settings.

When working with electrical outlets, power surges are a major concern as they can damage electrical components and devices. Power surges are a common issue in electrical systems, and every location must address them by providing adequate protection to prevent damage.

Although power surges are brief, lasting only a millisecond, they can cause significant damage if not properly protected against. The most common solution is a surge protector, which can either be easily connected to any electronic device or integrated into the device itself.

Surge protectors are classified by their joule rating, which indicates the amount of energy they can dissipate. A higher joule rating means the surge protector can absorb more energy, offering better protection.

Simply put, a surge protector shields electronic or electrical equipment from damage caused by power surges, voltage spikes, or brief bursts of energy. Also called a transient suppressor, it is installed on an alternating current (AC) line.

A surge protector allows current to flow to connected devices. If voltage exceeds safe levels, it redirects the excess to the outlet's ground, which runs alongside the hot and neutral wires. Grounding wires offer a safe pathway for current in case of system failure.

The PoE (Power over Ethernet) is a groundbreaking device that enables both power and data transmission through a single cable. This innovation reduces the need for additional wiring, enhances safety, and simplifies installation, saving both time and cost. By delivering DC power via Ethernet cables, it eliminates the need for separate outlets.

A servo motor needs a stable, reliable, and straightforward power supply to effectively manage power flow to and from the motor. The primary challenge for a servo motor supply is its ability to endure harsh operating conditions, including voltage fluctuations, high spikes, electromagnetic interference (EMI), shocks, vibrations, and extreme temperatures.

A PDU, or Power Distribution Unit, manages and distributes electrical power. At its most basic, it's a power strip without surge protection. On a larger scale, PDUs serve as a crucial link between the power source and various types of equipment in buildings. Essentially, a PDU is an industrial-grade power strip with broader and more critical functionalities.

On a work site, plugging all necessary devices into a single power supply isn't feasible. To power multiple devices simultaneously, a PDU is needed. It transforms one power source into several outlets, enabling all devices to operate at once.

A PDU, surge protector, and power strip all serve to protect against power surges. The key difference lies in the level of protection they offer, measured in joules.

Among the various electrical components, power strips are the most common and widely used. Typically, they include a surge protector or circuit breaker to cut off current when a certain voltage is reached. Power strips consist of multiple electrical sockets connected to a cable, allowing several devices to be plugged in. Essentially, they function as miniature PDUs and come in both surge-protected and non-surge-protected designs.

When selecting a power strip, it's crucial to match it to the devices you'll plug in. Power strips are equipped with 15 or 20 amp circuit breakers to protect against dangerous overloads.

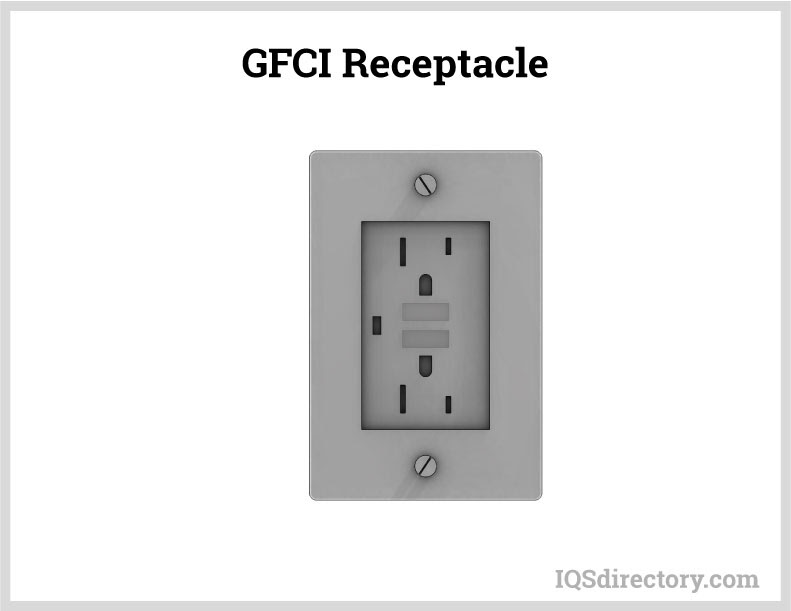

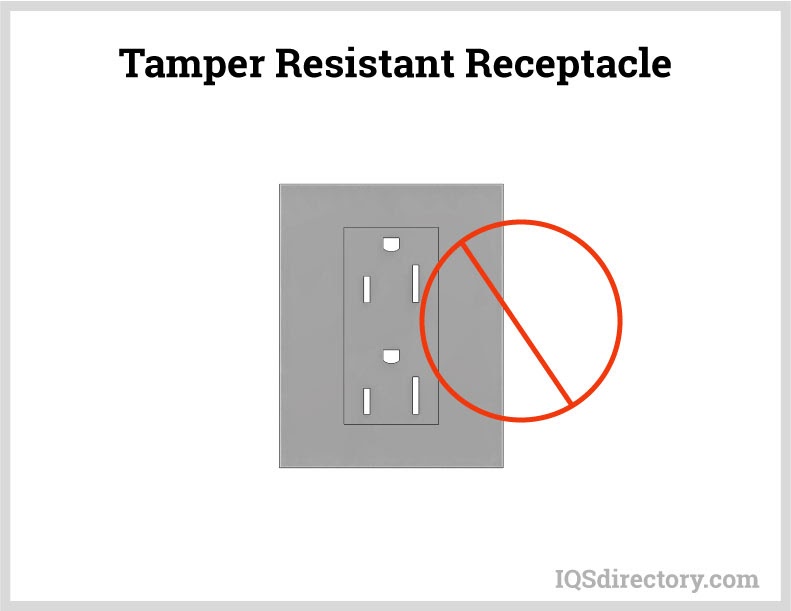

All our items need easy access to electricity, as electronics are present in every room, from the kitchen to the bedroom. Regulatory agencies like IEC and NEMA set standards and guidelines for safe electrical use. Below are some essential safety devices that have become standard for powering electrical equipment.

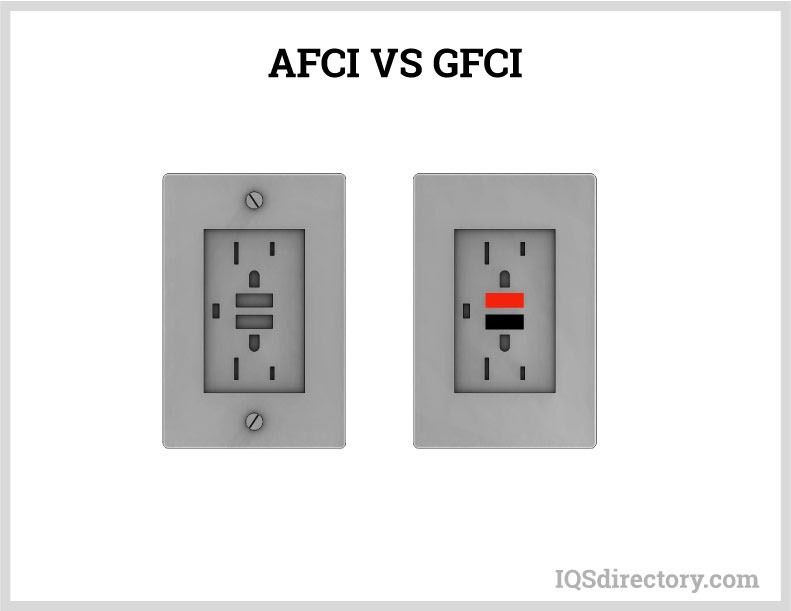

A GFCI prevents electric shock by monitoring the current flow between the hot and neutral wires. If it detects a deviation of just 4 milliamps, it immediately cuts off the power supply.

TR receptacles are designed to prevent electrical shocks by ensuring that nothing plugged in can be energized unintentionally. They feature spring-loaded shutters that block the contact openings and only open when both shutters are pressed simultaneously, offering effective protection against electrical hazards.

An arc fault occurs when current flows through an unintended path, generating intense heat at the arc's location, which can ignite nearby materials. An Arc Fault Circuit Interrupter (AFCI) is designed to detect these arcs and reduce the risk of fire. Although GFCI and AFCI devices may look similar, they serve different purposes: GFCIs protect against electrical shock, while AFCIs guard against fires.

Surge protectors prevent voltage spikes that can harm electronics like TVs, computers, and smart appliances. Although a voltage surge may last only microseconds, it can reach up to 1000 volts. Surge protectors block or divert this excess current to protect your devices.

When regular electrical current flows through the circuit, choke coils or capacitors connected to the hot wire help direct it through the device. During voltage spikes or surges, the excess is diverted into the green ground wire, as illustrated in the diagram, to protect the power outlet and connector from potential damage.

Weather-resistant receptacles are designed to endure rain, snow, humidity, ice, and other forms of moisture. They safeguard the outlet from corrosion and other potential hazards. You can identify weather-resistant receptacles by the "WR" marking on the faceplate, as shown in the example below.

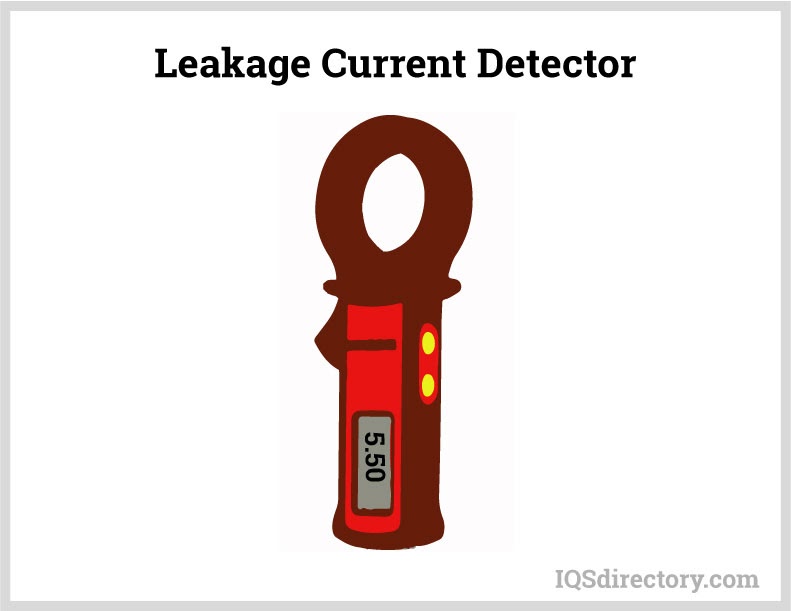

In an electrical connection, some current may flow through the ground conductor, a phenomenon known as leakage. Most of this leakage occurs through the insulation around the conductors and the protective filters. If leakage goes undetected, it can cause a GFCI to trip. To identify the source of the leakage, a leakage detector is used. This device is clamped onto a conductor to measure the current value and pinpoint the leakage source.

Wiring for AC and DC power is color-coded to simplify identification. The IEC provides color codes for AC branch circuits, and the chart below outlines common color codes used in the United States. However, since these codes are not standardized nationwide, variations may exist depending on the region.

| Color Coding | |||

|---|---|---|---|

| Function | Label | Common Color | Alternate Color |

| Ground | PG | Bare, Green or Green-Yellow | Green |

| Neutral | N | White | Grey |

| Line, Single Phase | L | Black or Red (2nd Hot) | |

| Line, 3-Phase | L1 | Black | Brown |

| Line, 3-Phase | L2 | Red | Orange |

| Line, 3-Phase | L3 | Blue | Yellow |

Black electrical wires are commonly used to transfer power and can also serve as switch legs.

Red electrical wires serve as secondary live wires and can function as switch legs. They are also used to connect hardwired smoke detectors to the power system.

Blue and yellow electrical wires are not used for outlet wiring. Instead, they serve as live wires within conduits. Yellow wires can act as switch legs for ceiling fans, structural lights, and outlets controlled by light switches. Blue wires are typically used as travelers in three- or four-way switch configurations.

White and gray electrical wires are both neutral wires, with white being the most commonly used.

Green electrical wires serve as the grounding component for electrical circuits, connecting to the grounding terminal. They provide a failsafe mechanism for safely directing electricity away in case of a fault.

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

A power cord is an electrical component used for connecting appliances to an electrical utility or power supply. It is made from an insulated electrical cable with one or both ends molded with connectors...

Thomas Edison developed the power distribution system in 1882. He wrapped a copper rod in jute, a soft shiny fiber from plants, as an insulator. The jute wrapped copper rod was placed in a pipe with a bituminous compound...

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

Electronic connectors are devices that join electronic circuits. They are used in assembling, installing, and supplying power to electrical devices. Connectors are an important component of every electronic equipment used in...

An electric switch is a device – usually electromechanical – that is used to open and close an electric circuit. This disables and enables the flow of electric current, respectively...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

Push button switches are electrical actuators that, when pressed, either close or open the electrical circuits to which they are attached. They are capable of controlling a wide range of electronic gadgets...