AC DC Power Supply

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on High Voltage Power Supplies .

This article will take an in-depth look at high voltage power supply.

The article will look at topics such as:

This section explores the fundamental concepts of high voltage power supplies, delving into their design, construction, and key operational principles.

A high voltage power supply is a device responsible for converting a low voltage into a substantially higher voltage, typically ranging from 1kV to 360kV, and extending up to 500kV in some advanced systems. These power supplies can operate with both AC and DC inputs, often with DC inputs like 12Vdc or 24Vdc being more economical.

High voltage outputs find applications across a diverse array of fields such as scientific research, industrial processes, medical devices, and telecommunications. Engineered to supply electrical energy to different loads, these power supplies are used from lighting systems in homes and factories to various electrical components. Examples include power transformers, high voltage capacitors, and unique units such as Cockcroft-Walton and Van de Graaff generators.

Many high voltage power supplies come with adjustable outputs, controlled via a computer interface or directly on the device. These are employed across numerous sectors, including but not limited to the medical industry, telecommunications, and energy spectrum analysis. They are characterized by high output voltage stability—usually within ±1%, efficiency ratings of over 70%, and safety features against overcurrent and short circuits, with minimal leakage current when switched off.

In using high voltage power supplies, it’s vital to employ specialized output connectors to prevent insulation failure, arcing, and accidental contact. For operations extending beyond 20kV, appropriate connectors ensure safety and reliability.

Voltage is broadly classified into high, medium, and low categories, with specific thresholds differing by region. In the United States, entities like the National Electrical Code (NEC) and National Electrical Manufacturers Association (NEMA) provide guidelines and standards for these classifications. Industries handling electrical currents and voltages adhere to these set standards.

Moreover, the American National Standards Institute (ANSI) also oversees and regulates these standards. In accordance with ANSI standard C84.1-1989, voltages are grouped into five categories:

The NEC voltage standards are categorized as:

High and extra-high voltages are generated at power plants to improve electricity transmission efficiency over long distances.

Medium voltage spans from 1kV to 69kV, though ranges might vary globally. This level of voltage is channeled from substations to varied end-users, including industrial, commercial, and residential consumers. The higher voltage in medium voltage systems allows efficient electricity transmission over longer distances.

Low voltage ranges from 0 to 1000 volts in AC systems and up to 1500 volts in DC systems. Such voltages power various applications, such as computers, home lighting, and even substantial industrial machines, representing a safe, reliable, and practical electricity source.

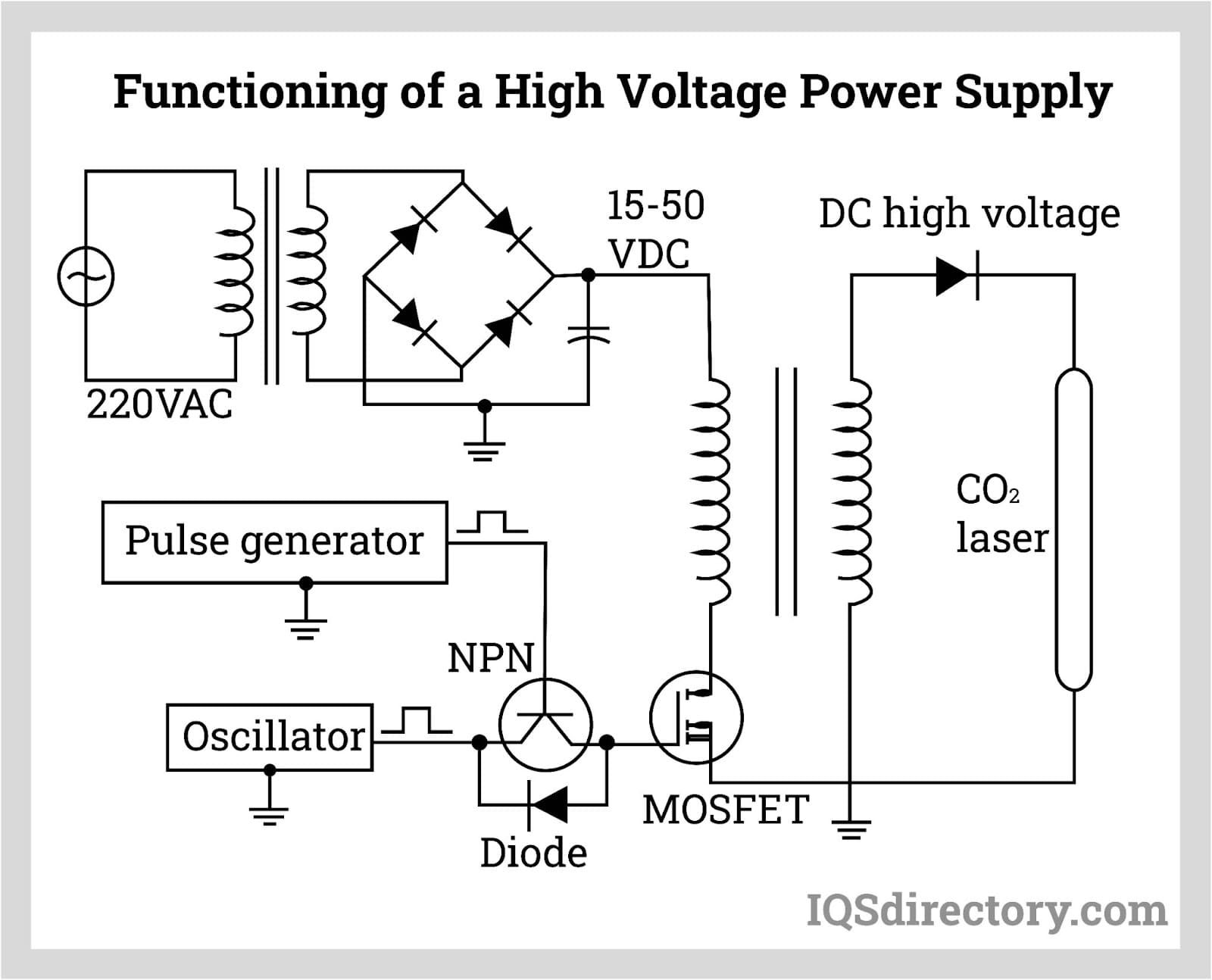

The core functionality of a high voltage power supply revolves around converting a lower input voltage with low frequency into a higher output voltage. This transformation is performed using power conversion topologies based on SMPS (Switched-Mode Power Supply) technology. An SMPS uses a switching regulator to efficiently manage power conversion.

The transfer of power from an AC or DC source to a DC load utilizes high-frequency switches, like MOSFETs, and high-frequency transformers. These crucial components enable the conversion of a low input voltage into a higher output voltage. The high-frequency switches rapidly toggle between on and off states. When the switch is off, no power is conducted; hence, energy storage components like capacitors or inductors fill the power gap. This continuous toggling is instrumental in minimizing energy waste.

Essentially, a high voltage power supply is an advanced conversion circuit designed to transform filtered DC bus voltages, stemming from rectified mains input. This input is turned into high-frequency AC with the help of high-frequency switches which adjust duty cycles to control power transfer adeptly.

The resulting high-frequency AC is enhanced using a high-frequency transformer. Upon increasing the voltage, it undergoes rectification, multiplication, and filtration in the secondary stage of the high-frequency transformer to yield the required output voltage levels.

Furthermore, high voltage power supplies incorporate circuitry enabling users to modify output voltage levels, accompanied by fail-safe protection systems to ensure safe operation.

A high voltage power supply constitutes various components, each tailored to serve a specific function. Below are the main components:

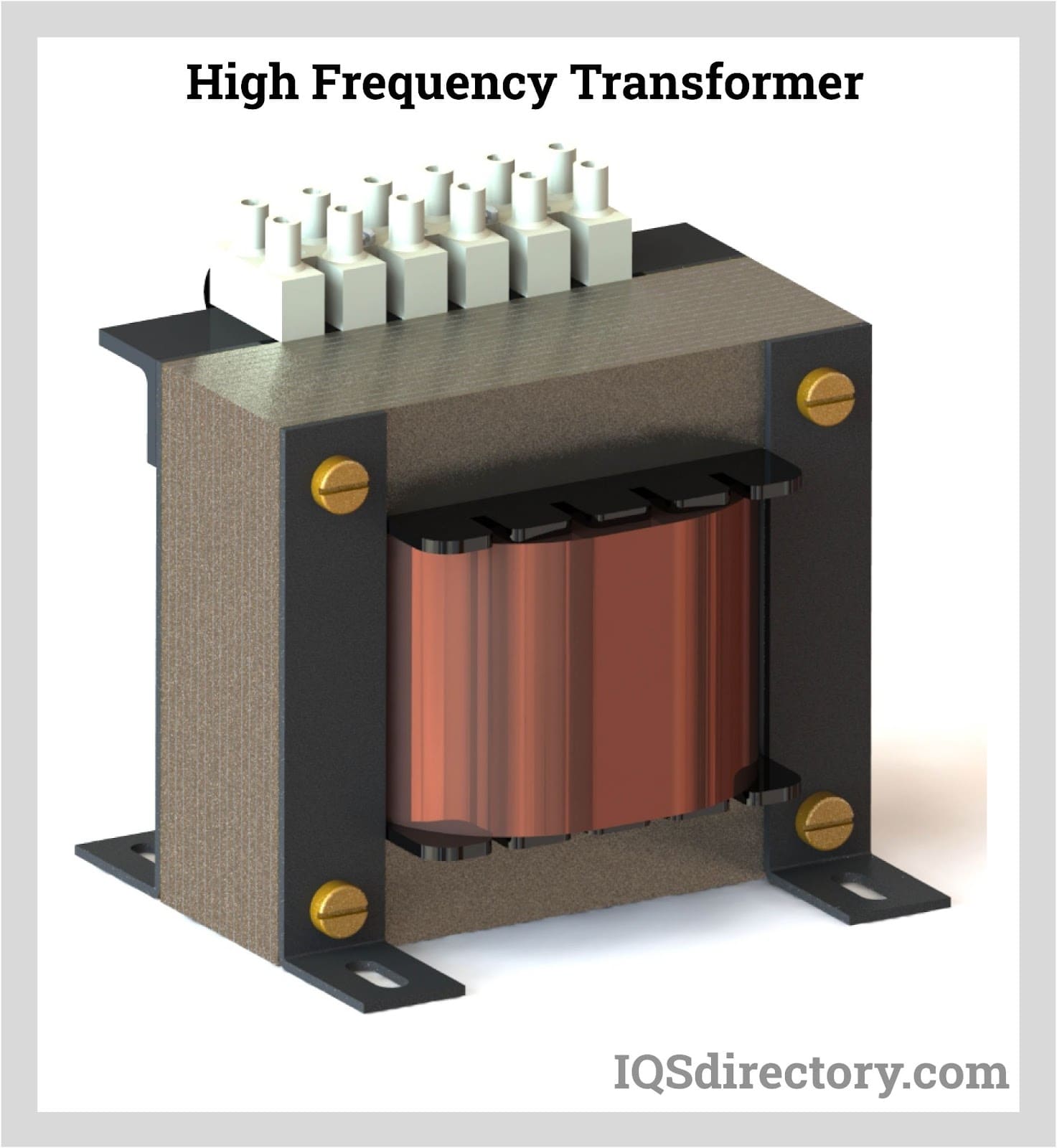

Transformer – This component is fundamental in transferring electrical energy between circuits while maintaining frequency. It can elevate (step-up) or lower (step-down) AC voltage levels and segregates electronic components from the AC power source. The transformer's primary winding connects to the AC source, generating AC current, while the secondary connects to loads. These windings are electrically isolated; voltage is induced in the secondary winding via electromagnetic induction. High-frequency transformers are predominantly used in high voltage power supplies.

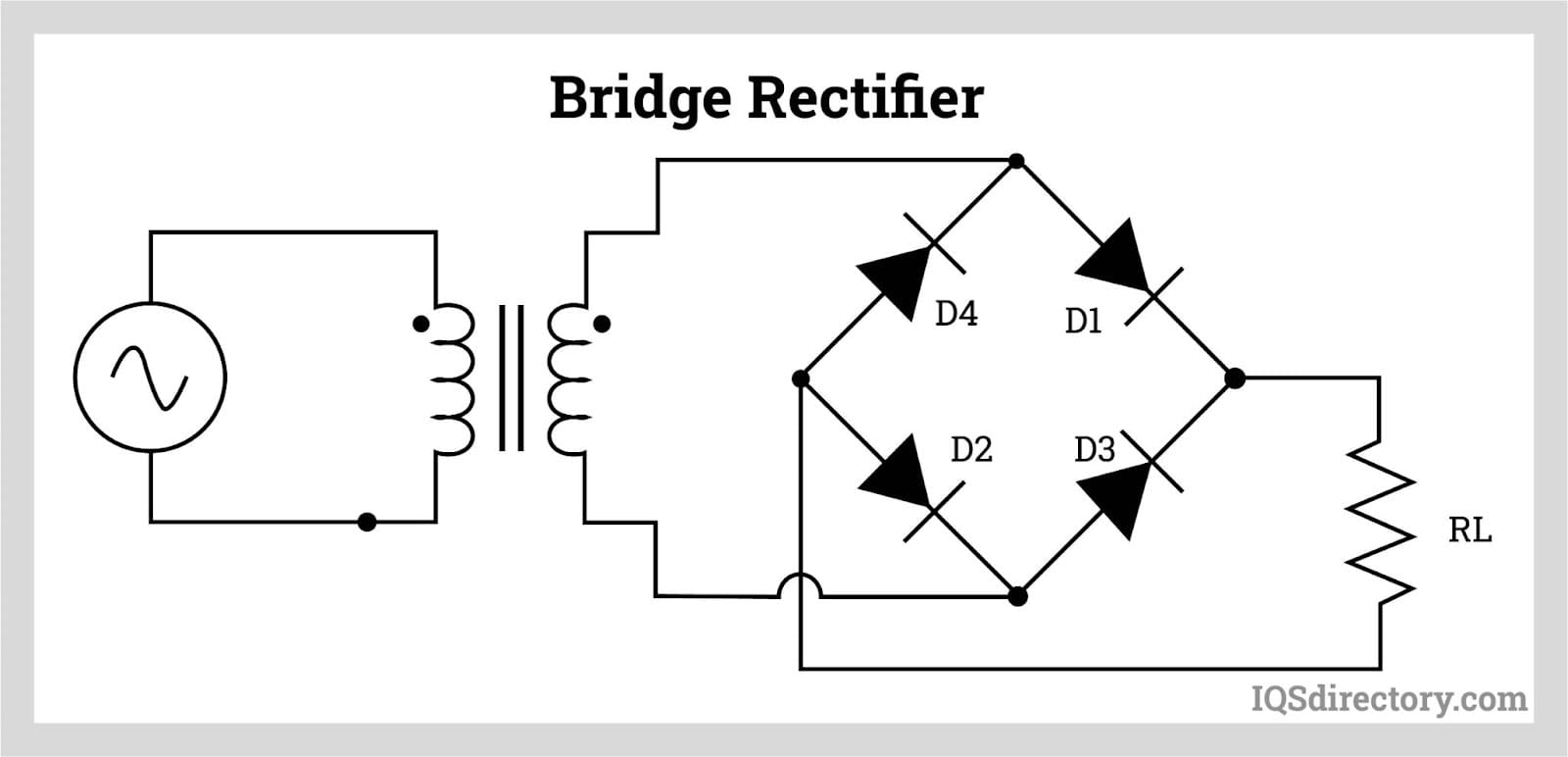

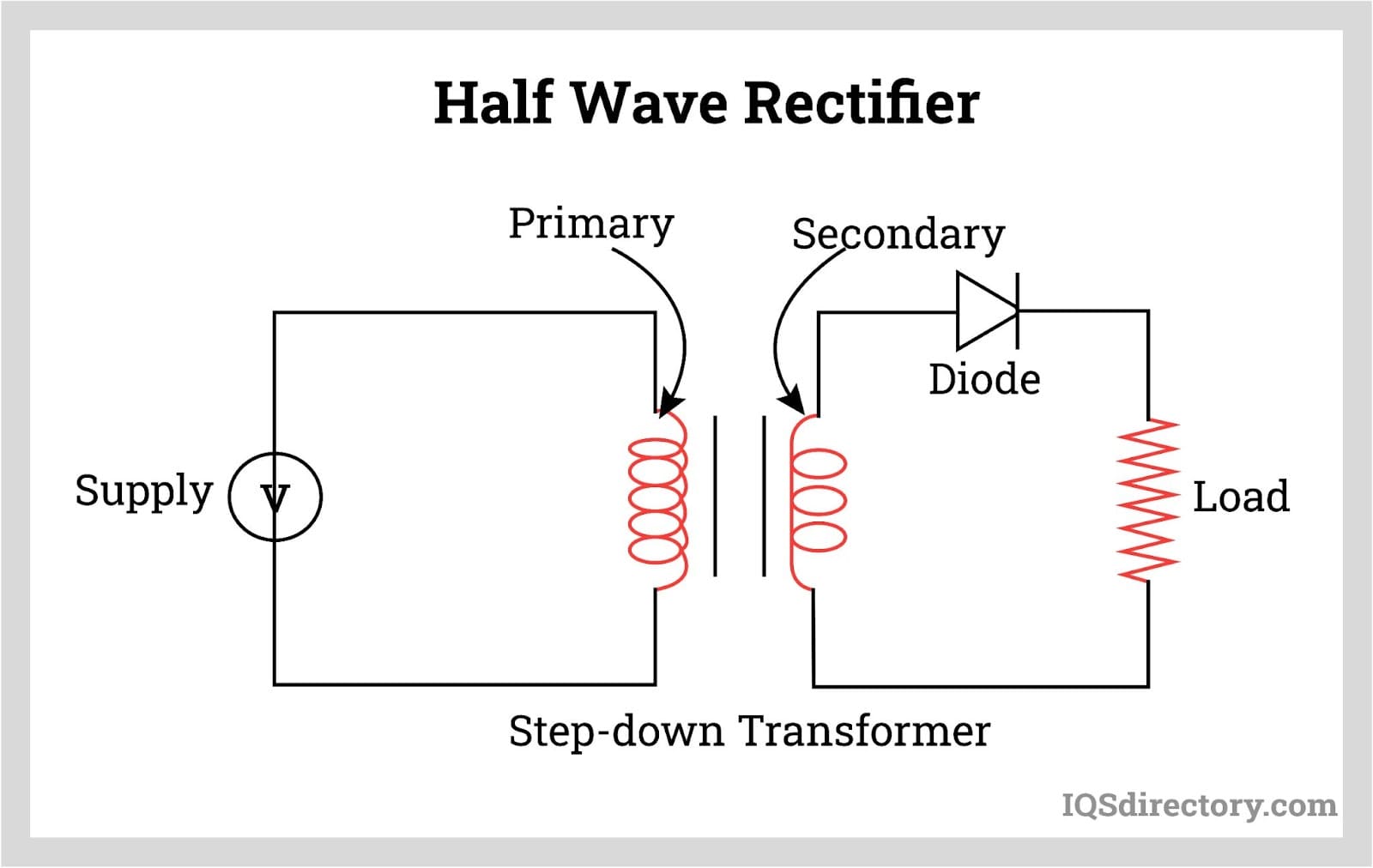

Rectifier – This vital component converts alternating current (AC) into pulsating direct current (DC). A basic rectifier example is a rectifying diode functioning as a rectifier when biasing forward.

Rectifier circuits are mainly categorized as half-wave, full-wave center-tapped, and full-wave bridge rectifiers.

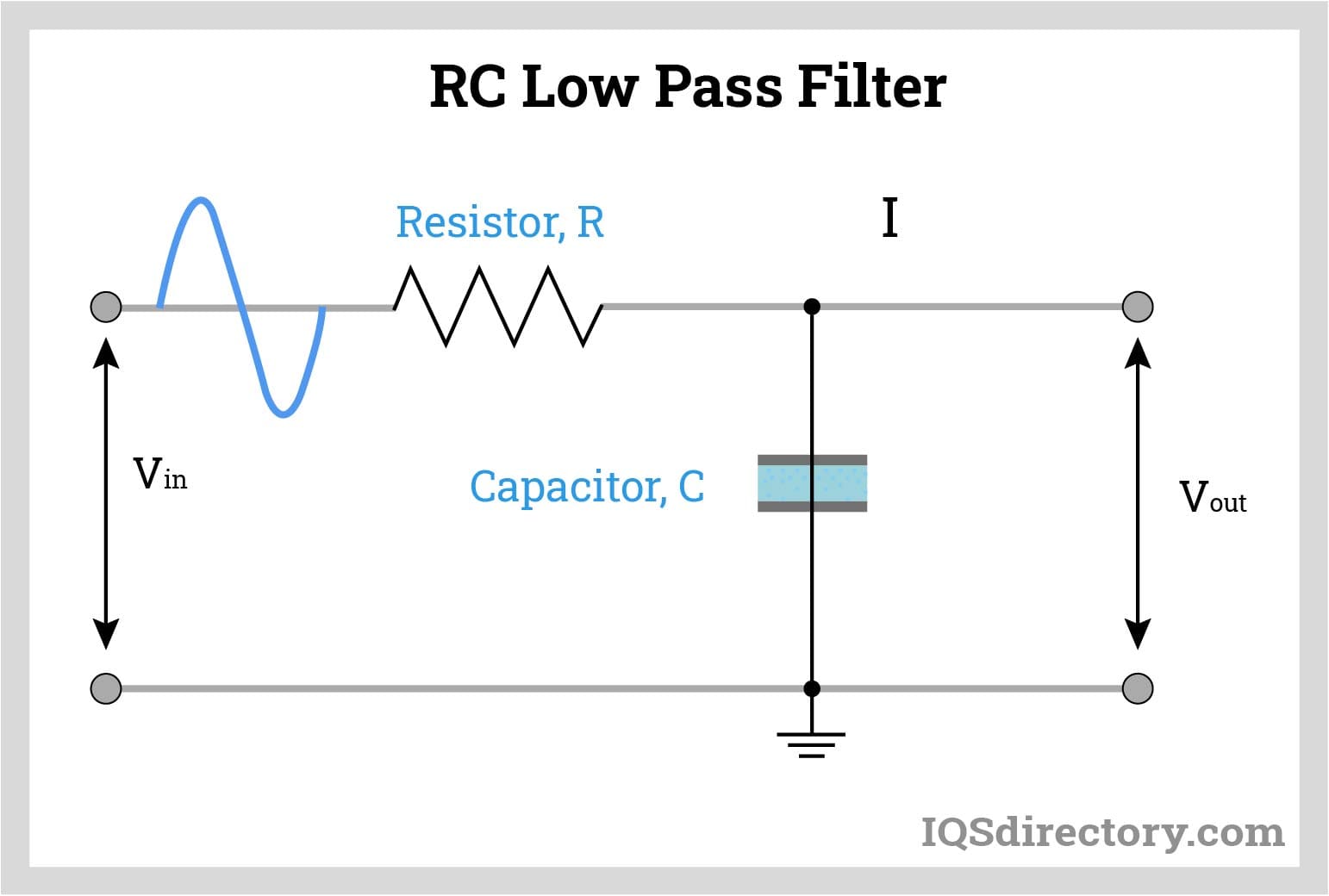

Filter – Filters are indispensable for eliminating ripple content from DC outputs. They convert the rectifier's pulsating DC into smoother DC signals. Primary filter types include capacitance filters and resistor-capacitor (RC) filters. Capacitance filters are straightforward and affordable, while RC filters allow selective frequency passage. RC filters mainly comprise high-pass and low-pass filters.

Ripple denotes undesired AC content post-rectification. This AC fraction can harm loads, making filters vital to smooth signals and reduce AC content.

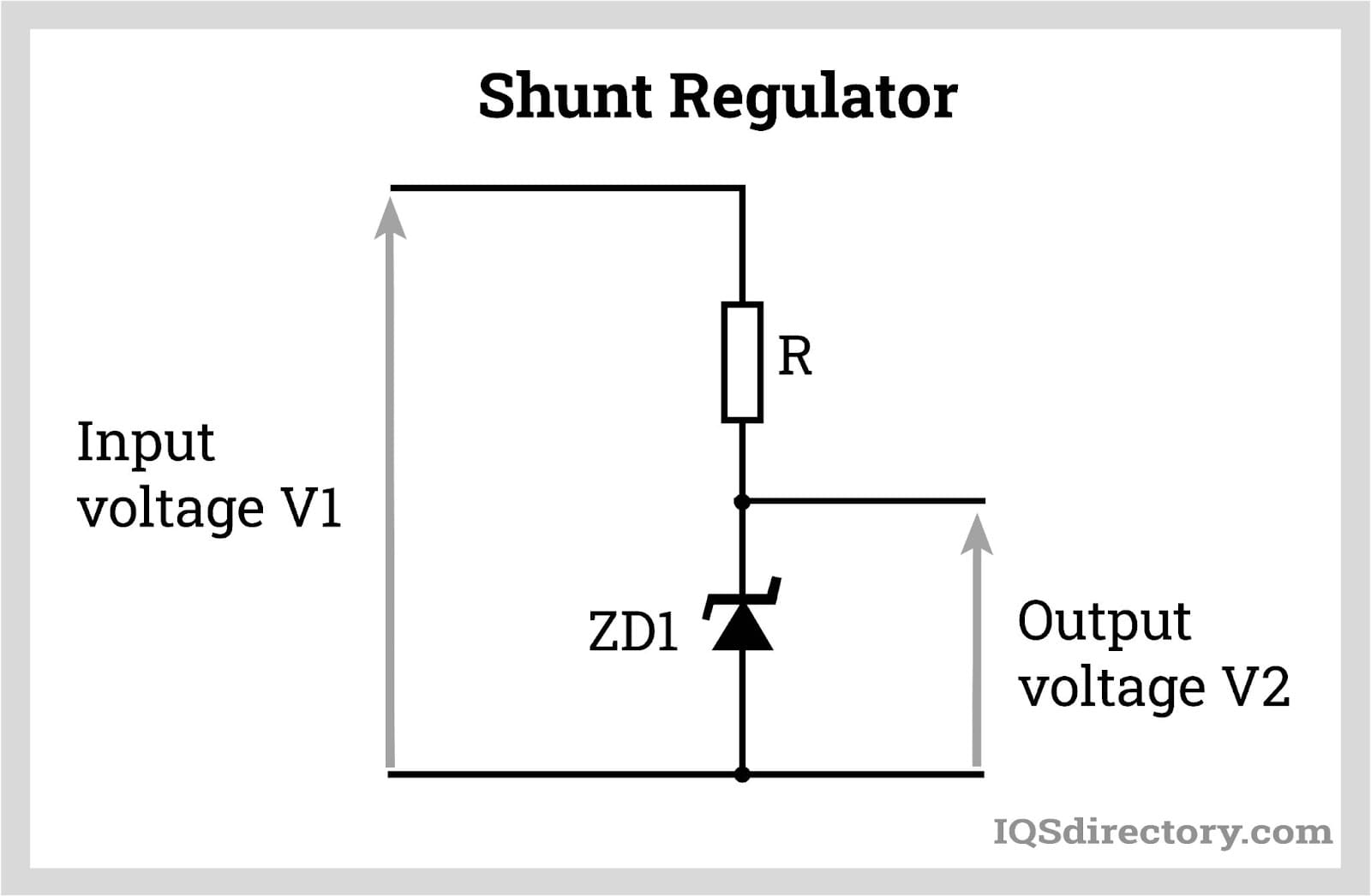

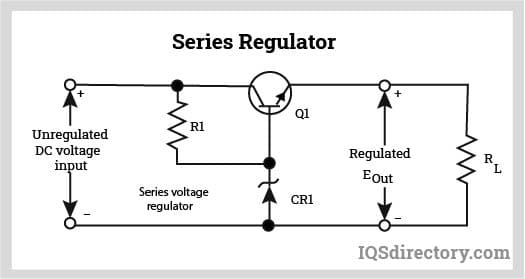

Regulator Circuits – Regulator circuits maintain a stable DC output. A consistent output voltage is crucial for load operation, which is achieved by voltage regulation despite input fluctuations.

Common voltage regulator types include shunt and series voltage regulators.

When choosing high voltage power supplies, several key considerations are vital:

Power Supply Style – This refers to various configurations like internal or open frame, DIN rail, PCB mount, and rack-mounted styles. A PCB mount power supply is crafted for attachment to printed circuit boards. Internal or open frame models integrate into instruments or machines, sometimes with removable covers. Rack-mounted power supplies fit directly onto racks, whereas DIN rail power supplies attach to DIN rails.

Input Voltage – High voltage power supplies accommodate different input voltages, spanning single-phase AC, three-phase AC, or DC input. Matching the power supply with the right input voltage ensures proper function.

Output Specifications – These specifications comprise output channels, polarity, and maximum current, power, and voltage values. High voltage supplies offer negative, positive, or reversible output polarities and can be single or multiple output configurations.

User Interface – High voltage power supplies offer an array of user interfaces, including computer interfaces, digital front panels, or analog front panels. Some models are equipped with software for performance monitoring and control. Displays range from analog meters and digital readouts to video displays. Certain power supplies allow for analog signal monitoring of output voltage.

High voltage power supplies come in various types to address the needs of industrial, scientific, and commercial applications. Understanding the different categories and their unique capabilities is crucial for professionals seeking the right solution for their high voltage power delivery requirements. Below, we explore the major types of high voltage power supplies, including their use cases, key features, and typical specifications.

Modular high voltage power supplies feature detachable cables, allowing users to connect or disconnect them as needed for flexibility and serviceability. These modular power supply units are designed primarily for OEM (Original Equipment Manufacturer) applications, where integration into complex instrumentation or larger electronic systems is essential. They are commonly utilized in industries requiring customized high voltage modules for testing systems, automation, and analytical devices.

Unlike standard bench-top solutions, modular units generally lack a front panel for manual operation. Control and monitoring are typically managed via remote analog or digital interface protocols, such as RS-232 or Ethernet. The input power for these high voltage power supplies can be either AC or DC, depending on the specific model, making them ideal for embedded high voltage design projects where remote programmability, compact size, and reliability are paramount.

Rack-mount and bench-top high voltage power supplies provide flexible, scalable solutions for laboratory, industrial, and research environments. With output voltages spanning from 500 volts (V) to 360 kilovolts (kV) and power ratings from 10 watts (W) to over 100 kilowatts (kW), these HV power supplies are well-suited to demanding applications such as plasma ignition systems, oil well monitoring equipment, ion milling, particle accelerators, electron beam evaporation, and laboratory plasma research. They often include advanced features like precise voltage regulation, current limiting, and user-friendly digital displays.

These high voltage power sources are preferred when high reliability, easy integration, and convenient access are needed in high energy physics labs, semiconductor fabrication, and academic research facilities.

The Monoblock high voltage power supply refers to a pre-assembled module that combines a high voltage power supply, filament power supply, control electronics, and an integrated X-ray tube into a unified, cost-effective unit. This compact, plug-and-play solution is extensively used in X-ray analysis, medical imaging equipment, security scanning, and non-destructive testing (NDT) systems. The Monoblock design minimizes installation time and lowers maintenance costs, offering reliable high voltage generation for controlled environments.

Application-specific high voltage power supplies are custom-engineered to meet the unique requirements of particular devices or processes. These tailored voltage sources serve critical roles in advanced applications such as electrostatic chucks for semiconductor manufacturing, high voltage power feed systems in scientific instrumentation, mass spectrometers, image intensifiers for night vision and medical devices, photomultiplier tubes (PMTs), capillary electrophoresis, ion implanters, and electron microscopes. Manufacturers offer customized designs with monitoring functions, polarity reversal, and high-precision voltage regulation to maximize compatibility and efficiency for niche markets.

Triple output high voltage power supplies, such as the Model 3603, are designed to supply three distinct, independently adjustable outputs often required in electron microscopes and advanced scientific equipment. Featuring a compact footprint, RS-232 remote control interface, safety interlocks, and status LEDs, these power supplies are ideal for scanning electron microscopes (SEM), which require precise control of filament, bias, and accelerator voltages. With advanced microprocessor-based control, these units provide exceptional voltage stability, low noise, and programmable settings, ensuring high-resolution imaging and consistent operation in critical research and manufacturing processes.

Users can remotely program all voltage outputs via the RS-232 port. A C-based demo tool enables monitoring of supply set points, measured outputs, and real-time thermal management. The acceleration output voltage ranges from -500V DC to -30kV DC, the Wehnelt bias voltage from 0 to -2kV DC, and the filament voltage from 0 to 5V DC, offering exceptional versatility for advanced electron optics applications.

Quad output high voltage power supplies meet the needs of instruments and devices that require four separate voltage rails, ensuring independent control and maximum flexibility. For instance, the Model 1930 power supply provides an anode voltage of 25kV, a focus voltage adjustable between 5 to 8kV, a G1 voltage set at -150V, and a G2 voltage ranging from 200 to 800V. These multi-output high voltage modules are essential for complex scientific equipment, such as image intensifiers, research-grade X-ray systems, or high-performance cathode ray tube (CRT) displays, supporting simultaneous operation of multiple subsystems without signal interference.

Single output high voltage power supplies, such as the Model 2591, offer outstanding voltage stability, ultra-low stored energy, and minimal ripple for sensitive applications. Their design is optimized for focused ion beam (FIB) systems, semiconductor wafer processing, and analytical instrumentation that require consistent, isolated voltage output. Ultra-low stored energy at the output prevents damage to sensitive semiconductors during arc or short circuit events, making these units highly dependable for precision laboratory and industrial systems. The output voltage is adjustable from 0.01 to 30kV.

Programmable bipolar high voltage power supplies, such as Model BP2592, are specifically engineered for electrostatic processes that require frequent voltage polarity reversal. Ideal for electrostatic precipitators, MEMS device testing, and scientific research, these supplies handle continuous short circuits without incurring damage. Onboard safety features, remote interface options, and a front panel polarity switch facilitate user operation and integration into automated test setups. The programmable output voltage spans from -30 to +30kV DC, ensuring adaptability for applications demanding both positive and negative high voltage outputs.

Single output unipolar high voltage power supplies, including the Model 550, are designed for embedded, compact, and cost-sensitive applications where reliable, continuous DC output is critical. These high voltage units are robust against sustained short circuits and feature integrated safety circuits, such as ground leakage detection, for enhanced protection. Adjustable output ranges from 100 to 5000V make these supplies ideal for sensor biasing, photomultiplier tubes (PMT), medical devices, and automated testing equipment, providing stable, ripple-free DC power to ensure system integrity.

X-ray high voltage power supplies, like the Model XPS50P50, are purpose-built for powering X-ray tubes and generators in medical imaging, material inspection, and industrial radiography systems. These specialized units deliver highly stable, high voltage DC output to the anode while simultaneously providing precision filament current for the X-ray tube. Advanced safety features protect against arcs, overvoltage, and short circuits, and support for both local and remote (computer-controlled) operation streamlines integration into automated X-ray systems. The beam current and anode voltage, adjustable from +2kV to 50kV, ensure optimal dose and image quality for diverse imaging applications. Front panel trimpots and programming voltages enable real-time control, while built-in safety interlocks enhance operator and equipment safety.

Flyback transformers are essential components in switched-mode power supplies (SMPS) used to generate high voltage outputs from lower voltage inputs, especially in compact devices and high voltage modules. By temporarily storing energy in a magnetic field and then transferring it to the secondary winding, flyback transformers enable compact, efficient high voltage conversion with galvanic isolation. This makes them ideal for CRT displays, laser power supplies, electric propulsion systems, and a range of consumer and industrial high voltage power applications. Their gapped core construction facilitates high energy storage and regulated high voltage pulses.

The Cockcroft-Walton generator, also known as a voltage multiplier, converts low AC or pulsed DC voltage into very high DC voltage by using a ladder network of capacitors and diodes. It is widely used in particle accelerators, medical X-ray machines, photomultiplier tube bias supplies, and HV test equipment due to its ability to provide high voltage at low current with minimal weight. These high-efficiency, cost-effective generators are valued for simple construction, low maintenance, and scalability, supporting voltage levels up to hundreds of kilovolts for laboratory and industrial applications.

When selecting a high voltage power supply, it is vital to assess your application's voltage and current requirements, load characteristics, regulation needs, safety standards, and control interface preferences. Leading manufacturers offer both standard and customized high voltage solutions developed with advanced circuit topologies, including linear, switching, and resonant designs. Modern HV supplies integrate enhanced diagnostics, digital monitoring, and comprehensive protection circuits to ensure longevity and safe performance in critical systems.

Engineers and procurement professionals searching for a high voltage power supply for sale should consider key factors such as power density, cooling method, integration options (analog/digital control), efficiency, ripple performance, and after-sales support. Consulting with reputable high voltage power supply manufacturers can streamline the evaluation and purchasing process, helping you secure reliable, long-lasting solutions optimized for your application—in fields ranging from scientific research, electronics manufacturing, and industrial process control to medical imaging and semiconductor testing.

This chapter will explore the various applications and advantages of high voltage power supplies.

High voltage power supplies are engineered to deliver elevated output voltages. They are valuable in the following areas and applications:

Maintaining a constant load at high supply voltages, such as those provided by high voltage power supplies, results in lower current. This is crucial for industrial processing machinery, which consumes significant power. Using low voltage in such machinery would require a very high current to achieve the necessary power, leading to the need for large conductors. These large conductors not only waste copper but also incur high installation costs. Conversely, high voltage allows for a lower current to deliver the same power, minimizing conductor size and reducing overall costs.

The size of circuit breakers is based on the amount of current they need to handle. Higher currents necessitate larger, more expensive circuit breakers, which can become bulky and complex to install. By reducing the current required for efficient operation, industries can save on wiring and electrical components, and decrease heat losses. This, in turn, improves the electrical efficiency of the system.

While high voltages offer several advantages, they also come with certain drawbacks, which are outlined below:

The specification parameters for high voltage supplies include:

Components of a high voltage power supply, such as transformers, switchgears, and switches, require regular maintenance to ensure optimal performance. To extend the lifespan of switchgears, consider the following measures:

Infrared inspections, conducted while equipment is energized, help identify loose bus connections before they lead to system failure. Routine maintenance checks can then address these issues.

Circuit breakers should be operated manually each year to keep contacts clean and ensure smooth operation of mechanisms.

Environmental factors like moisture, heat, and dirt can rapidly deteriorate insulation, conductive materials, and protective devices. Regular cleaning, inspection, tightening, lubrication, and exercising of switchgears are essential. Reconditioning may be necessary if on-site maintenance fails to meet current industry standards.

During reconditioning, the equipment is disassembled, cleaned, and inspected. Damaged parts are refurbished or replaced as needed. Pivot points are lubricated before reassembly and testing to ensure compliance with industry standards.

Monitoring equipment performance, such as circuit breakers, provides insights into its lifespan and helps focus maintenance efforts where needed most.

Upgrading equipment and performing short circuit analysis ensure switchgear components are properly rated to prevent catastrophic damage from improper short circuits.

Predictive maintenance tools use continuous online monitoring to detect potential failures that might be missed in periodic inspections.

For transformers, monthly checks should include monitoring the oil level in the oil cap to prevent system damage. Ensure the silica gel holes are clean for proper breathing action.

Daily checks should include verifying the oil level in the main and conservator tanks, ensuring it remains at the correct level. The silica gel should be inspected and replaced if it turns pink, and any leakage should be promptly sealed.

Annually, inspect oil pumps, air fans, and cooling equipment for the control circuit and transformer. A detailed list of annual checks and activities is outlined below:

When working with high voltage, it is crucial to ensure that the system can handle the required voltage levels. The withstand voltage is influenced by factors such as creepage distance, insulation distance, and the shape of the electrode. Creepage distance is defined as the length along the surface of the insulator between two conductive parts. Insulation distance refers to the thickness of the insulator when it completely covers the conductive parts. Over time, the withstand voltage may decrease due to factors like humidity and dirt, potentially leading to discharge and leakage as voltage increases. Therefore, selecting appropriate insulating materials is essential for maintaining long-term insulation performance.

Improper handling of high voltages can result in severe electric shock or even fatal outcomes.

Below are some safety precautions to follow when working with high voltages:

A high voltage power supply is a type of power supply that is used to convert a low input voltage to a high output voltage, usually between hundreds and thousands of kilovolts. The output voltage of a high voltage power supply can be adjusted either locally or through the use of a computer interface. High voltage supplies have a variety of uses such as in medical imaging, telecommunications, and power distribution amongst others. When using high voltage supplies it’s essential to make use of a special connector to prevent arcing, insulation breakdown and accidental human contact. The components that make up a high voltage power supply are a transformer, rectifier, filter, and regular circuits.

The factors to consider when choosing a high voltage power supply are: the output specifications that the high voltage power supply is required to have, the power supply style, input voltage, and user interface. There are various types of high voltage power supplies some of them are: Monoblock, rack high voltage power supply, bench top high voltage power supply, DIN rail power supply, X-Ray generator, and many more.

High voltage power supplies are important because they produce a high output voltage that has many important uses, such as in power distribution, testing the performance of electrical insulation of power devices. They are also used in electrospinning and electrospraying in the pharmaceutical and automobile industries. The specification parameters for high voltage power supplies are: input voltage, output voltage, ripple, stability, stored energy, pulsed operation, line regulation, and load regulation. It’s essential to maintain components of high voltage supplies such as switch gears and transformers to ensure proper operation and a long life span. High voltages should be handled with care to avoid fatal injuries.

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

Electronic connectors are devices that join electronic circuits. They are used in assembling, installing, and supplying power to electrical devices. Connectors are an important component of every electronic equipment used in...

An electric switch is a device – usually electromechanical – that is used to open and close an electric circuit. This disables and enables the flow of electric current, respectively...

A NEMA connector is a method for connecting electronic devices to power outlets. They can carry alternating current (AC) or direct current (DC). AC current is the typical current found in homes, offices, stores, or businesses...

A power cord is an electrical component used for connecting appliances to an electrical utility or power supply. It is made from an insulated electrical cable with one or both ends molded with connectors...

Push button switches are electrical actuators that, when pressed, either close or open the electrical circuits to which they are attached. They are capable of controlling a wide range of electronic gadgets...

Thomas Edison developed the power distribution system in 1882. He wrapped a copper rod in jute, a soft shiny fiber from plants, as an insulator. The jute wrapped copper rod was placed in a pipe with a bituminous compound...