Stainless Steel 304

Stainless steel grade 304 is an austenite stainless steel that is the most widely used and versatile of the various grades of stainless steel. It is a part of the T300 series stainless steels with...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at stainless steel tubing.

The article will bring more detail on topics such as:

This segment will explore the characteristics of stainless steel tubing, detailing its manufacturing process and its functional uses.

Stainless steel tubing is a durable and long-lasting material noted for its corrosion resistance and low upkeep needs. The sizing and types of stainless steel tubes are tailored to the particular demands of the application and its envisioned use.

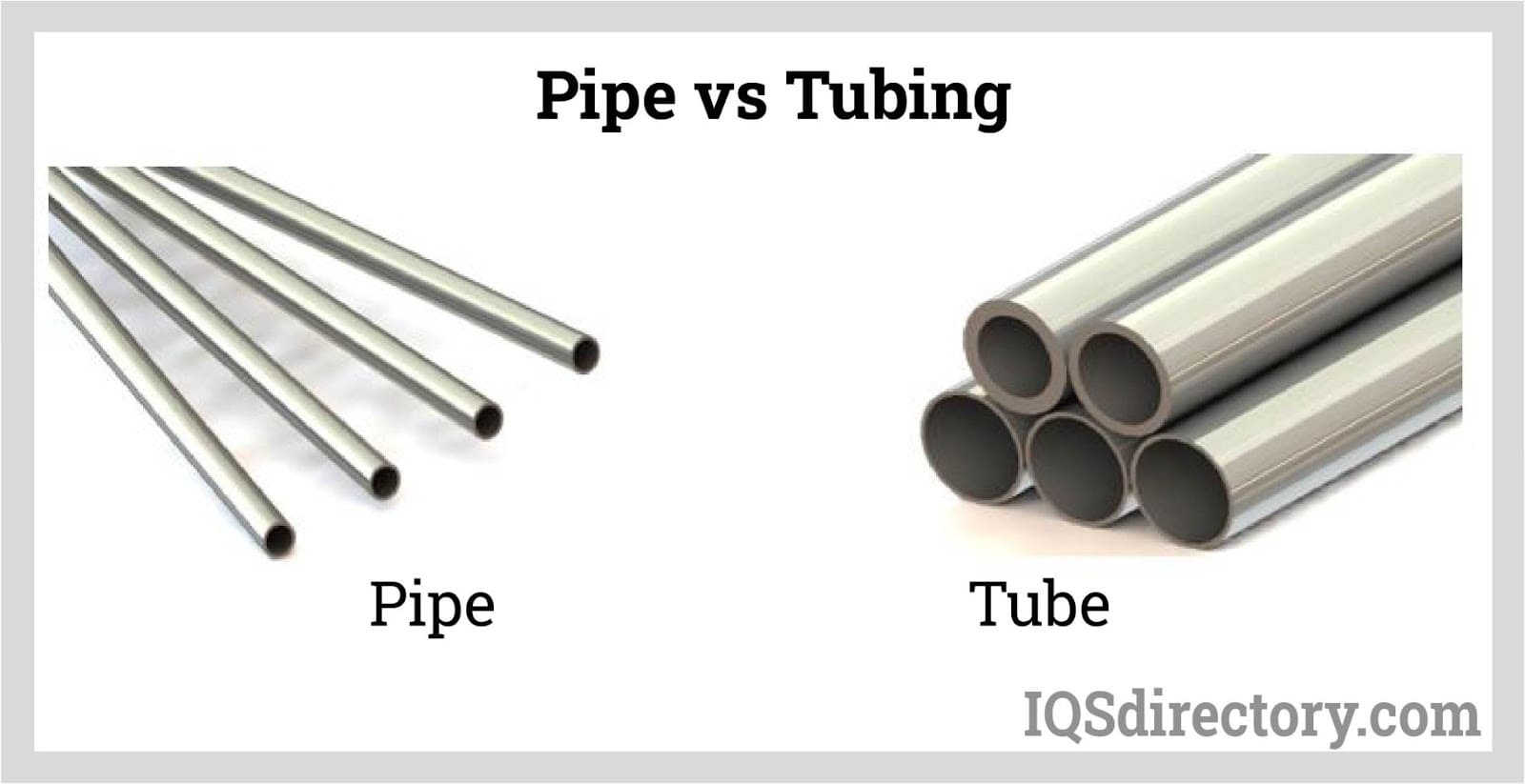

Many individuals often confuse piping with tubing because both feature a round cross-section and are typically believed to perform similar tasks. Nevertheless, unlike pipes, which are usually circular, tubes can also be square or rectangular.

The essential difference between pipes and tubes is in their applications. Pipes are predominantly employed for conveying gases and liquids and are measured by their internal diameter (ID), whereas tubes are generally structural components, measured by their external diameter and wall thickness.

Thanks to its strength, corrosion resistance, and minimal maintenance needs, stainless steel is a favored material for architects and manufacturers. For structural purposes, it is vital that stainless steel tubing be accurately sized according to its outer diameter and wall thickness. The selection of the tubing type is based on specific applications, which may include fractional, hypodermic, square, or metric tubing.

Multiple methodologies are applied in the manufacturing of stainless steel tubing, such as:

This method involves the following steps:

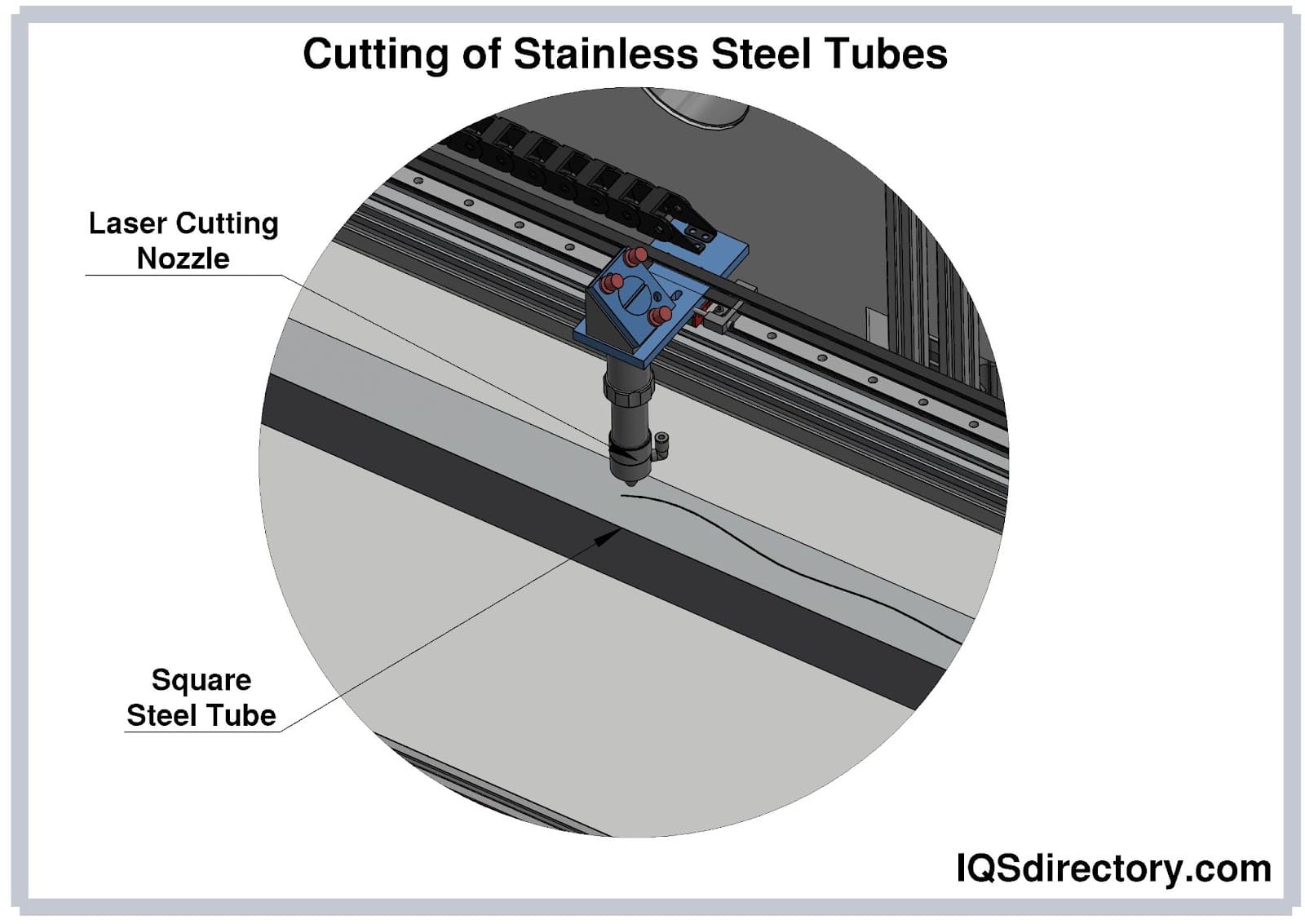

In the rolling and welding operation, continuous deformation of stainless steel coils into tubes is done on a tube mill. Techniques like TIG, high-frequency, and laser welding are employed to connect the strip edges. Depending on the welding technique, edge preparation might be necessary to secure a high-quality weld. To finalize, the weld bead on both the inner and outer diameters is removed via scarfing, sanding, or bead rolling, tailored to the ultimate application and specifications.

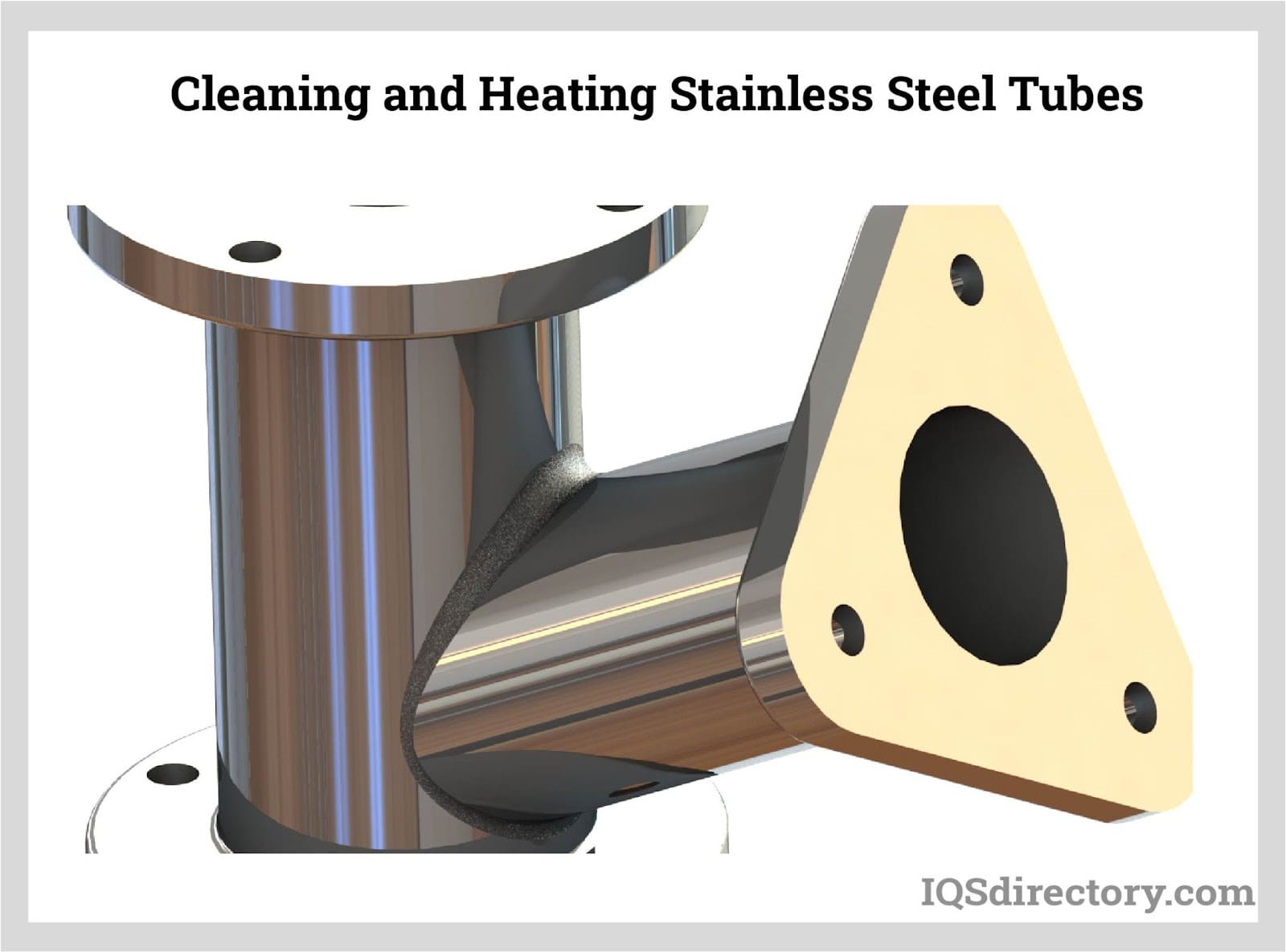

The newly formed stainless steel tubes are cut to industry-specific lengths. They are subsequently cleansed to remove impurities. Thereafter, the tubes are subjected to heat treatment to relieve any stresses caused during welding and forming. This process takes place in a continuously rolling hearth furnace fitted with precise temperature controllers and recorders. Post heat treatment, the tubes are straightened and undergo pickling to eliminate surface scales.

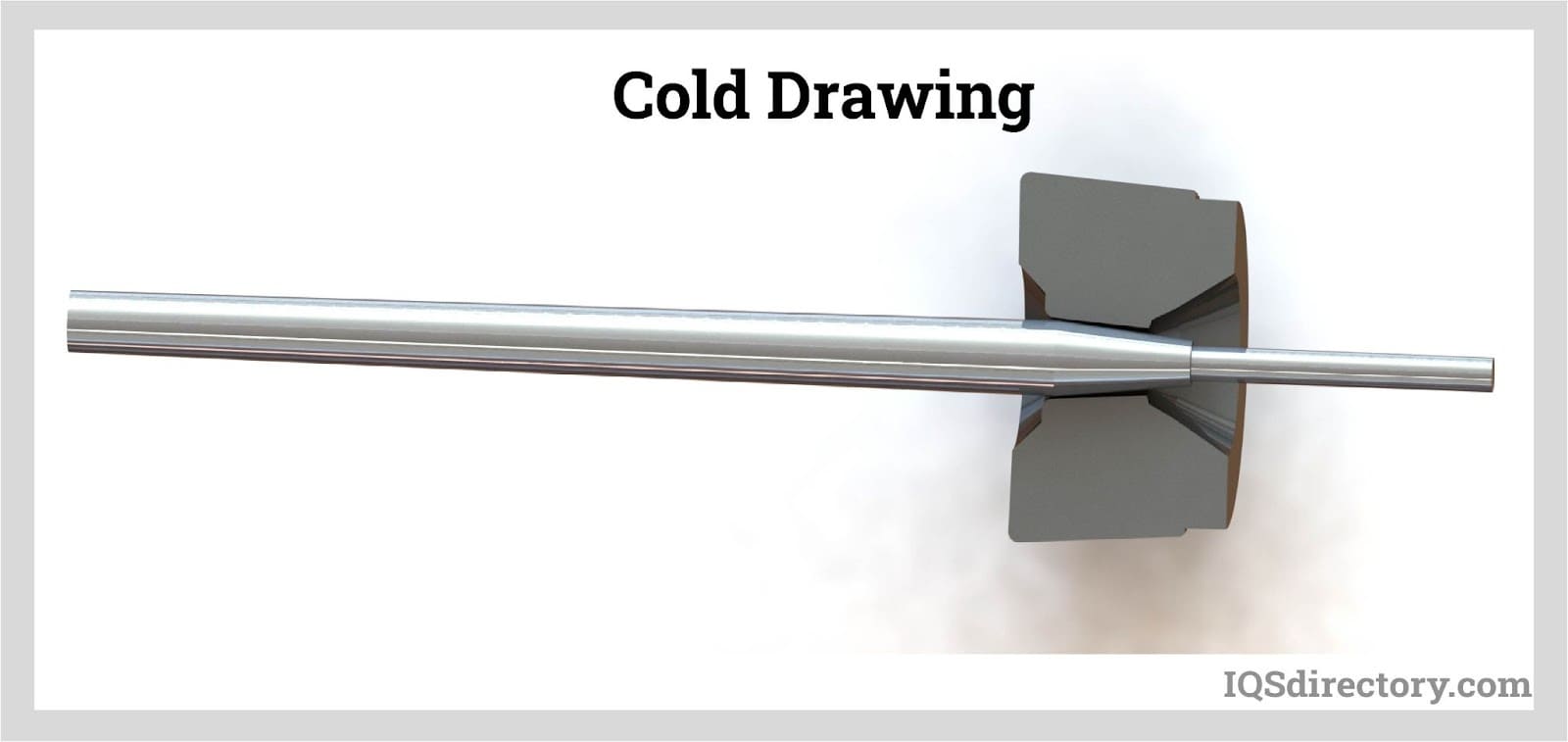

For instances where desired sizes aren't obtainable from the mill, a cold drawing process may be adopted. During cold drawing, the tubes or pipes are coated with a soap and oxalic solution serving as a lubricant to diminish friction. The tube or pipe is then drawn over a bench, utilizing die plugs during the cold drawing operation.

Subsequently, the extended tube or stainless steel pipe undergoes cleaning, heat treatment, pickling, and straightening. Final products are marked with computerized inkjet technology. Before passing to stainless steel pipe exporters, the pipes or tubes are labeled with information regarding the material grade, heat number, size, and the stamp of a third-party inspection. Rigorous testing and quality control follow, succeeded by appropriate packaging and shipping. Stainless steel pipes and tubes are utilized in various applications due to these steps.

Extrusion, gun drilling, and piercing are typical approaches for creating seamless stainless steel tubing. Among these, extrusion offers the utmost consistency in exterior diameters, which results in the most concentric internal diameters. Furthermore, extrusion is particularly effective for manufacturing long-length seamless steel coil tubing. Starting with a hot-extruded seamless pipe, the basic material proceeds through cold processing.

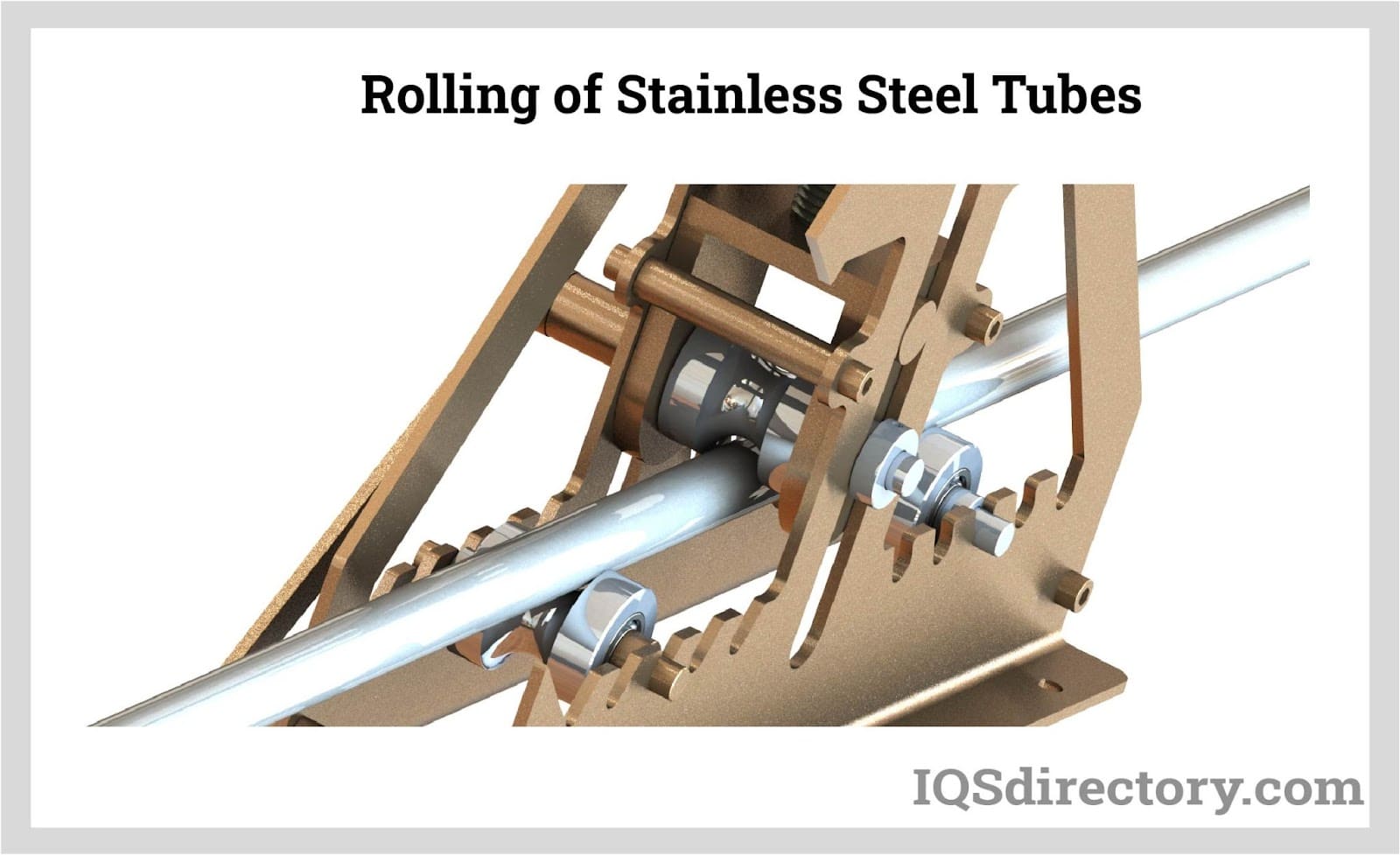

In this stage, the raw material is shaped into a long, straight form using tube reducers or pilger mills. Cold pilgering is a longitudinal cold-rolling method that reduces both wall thickness and diameter in one move, maintaining consistent outside and inside diameters. This can yield cross-section reductions over 90% in one cycle for particular materials.

During the reduction, lubricants are applied to both external and internal diameters of the tube, which are later degreased in anticipation of annealing. This method generally produces stainless steel tubes in lengths between 40 and 160 feet. Cold reduction is especially efficient for producing seamless stainless steel tubing intended for coil applications.

Using specialized machinery, a straight tube is cold-drawn into a coiled form. Cold drawing reduces the outside diameter, inside diameter, and wall thickness, causing the tube to elongate as it is drawn.

Floating plug drawing engages pulling tubing through a conical die while introducing a floating plug within the inside diameter. The final dimensions for inside diameter and wall thickness are dictated by the die and plug sizes. This technique yields a more consistent and smooth finish, ideal for light-wall items.

Conversely, sink drawing pulls tubing through a conical die to set the resulting inside diameter and wall thickness based on the drawing and specifications. This approach applies to high-pressure scenarios that necessitate greater wall thickness. The inside diameter typically has a slightly rougher finish than floating plug drawing.

Lubricants assist in the drawing by being applied to both the outer and inner diameters of the tubes. The lubricant is then degreased, generally in a large solvent tank, suited for most end-use applications like medicinal or liquid transfer purposes.

Following cold reduction, stainless steel tubing and coils undergo annealing, which reduces internal stresses and rejuvenates the crystalline form, easing subsequent cold processing. Rapid cooling shifts the material from a hardened, brittle state to a softer, pliable form.

This annealing step is repeated until the tube satisfies specific dimensions, including outside diameter, inside diameter, and wall thickness.

This kind of tubing must conform to rigorous ASTM standards and pass detailed inspections for flaws before reaching customers.

Upon the tubing’s completion to specified parameters, it undergoes hydrostatic testing to validate its structural integrity, crucial for confirming the tubing meets all necessary standards. Hydrostatic testing delivers valuable data, including:

Stainless steel coil tubing can either be neatly rolled onto spools for shipment or straightened and cut to the customer’s specified lengths. Ensuring traceability and manufacturer identification, products might be polished and marked accordingly.

A small metal tool or mandrel is placed inside a tube to keep its shape during the drawing. This provides support during the drawing process, preventing wrinkling. The tube passes through a die with a smaller opening than the original tube width. As the tube moves through the die, it contracts to the desired diameter. The technique permits exact tolerances and specifications.

DOM Tubing begins from CREW (Cold-Rolled Electric Resistance Welded) tube or a hollow form. To initiate, the larger ERW tube is "tipped" to enable the trolley to clasp it. This trolley utilizes a sort of conveyor belt to haul the tube through the die. Once "tipped," a carbide mandrel is inserted into the raw tube’s bore. Lubricated with a solvent, the tube is gripped at the pointed end by the trolley jaws, pulling the pipe through the die.

The die and mandrel set the final tube dimensions, including both the external and internal diameters. A high-angle die reduces the thickness of a thick-walled tube, while a low-angle die does the opposite for a thin-walled tube. Achieving the correct diameter-to-thickness (D/t) ratio depends on deliberate picks of the die's angle and position.

The DOM process may demand several passes, depending on factors like polishing requirements, dimensional needs, and specific mechanical or metallurgical specs. For instance, significant reduction for the final tube might necessitate incremental passes. Further surface treatments might also be required to hit desired standards.

After drawing, the mandrel is extracted. One technique involves applying pressure to rotate the tube through rollers. Compressing the tube allows it to release the mandrel, and subsequent drawing might be needed for the expected finish.

Today, CAD technology replaces traditional trial-and-error in die design. CAD's precision in die creation improves drawing processes, raising efficiency, reducing lead time, and cutting costs. For example, CAD allows precise determinations of die angles for both thick and thin-walled tubes, eliminating undue time and expense.

The final output is analyzed with Finite Element Method (FEM) techniques, evaluating aspects like pressure, temperature, and material properties. More advanced modeling tools have largely outmoded trial-and-error methods.

MSC SuperForm is noteworthy software employing FEM for modeling material flow, forming stresses, pressures, and trimming processes. This data assists engineers to define die and mandrel shapes, optimize lubrication, and other cost-saving initiatives.

Standards from ASTM International provide globally recognized benchmarks for the stainless steel tubing industry, ensuring uniformity and quality. These cover criteria such as chemical makeup (grades), tube wall thickness (inches), fractional radii and wall thickness (millimeters), working pressures (essentially in psi), and weight (regularly expressed in pounds per foot).

Stainless steel tubing comes in various types and configurations, each differing in several ways. For instance, tubes can vary in quality, be either seamless or welded, have different radii, lengths, or wall thicknesses, and may be either polished or unpolished.

While the terms "tube" and "pipe" are often used interchangeably, there is a key difference between them, particularly in terms of material organization and tolerancing. Tubing is primarily used for structural purposes, where the outer diameter is crucial for determining its strength and stability. In applications like medical devices, where precise outer diameters are necessary, tubing plays a critical role. Conversely, pipes are designed for transporting gases or liquids, and the internal capacity is more important to ensure efficient flow. The round shape of pipes helps them handle the pressure of the fluids passing through them effectively.

Pipes are typically categorized by their nominal size and schedule, which dictates the wall thickness. They are ordered based on the Nominal Pipe Size (NPS) standard, with a specified schedule number indicating the wall thickness. Different pipe sizes can have the same schedule number, but the actual wall thickness will vary accordingly.

Tubes, on the other hand, are generally ordered by their wall thickness and outside diameter, though they can also be specified by outside diameter and inside diameter or by inside diameter and wall thickness. Tube thickness is often indicated by a gauge number, and the inside diameter (ID) is a theoretical measure.

While pipes are exclusively round, tubes can come in various shapes such as square, rectangular, or cylindrical. Pipes are designed to handle larger-scale applications and are available in sizes from 12 inches to several feet, whereas tubing is usually employed in smaller-scale applications.

While tubing is characterized by three dimensions—outside diameter, inside diameter, and wall thickness—only two of these dimensions can be specified with tolerances, leaving the third as a theoretical value. Tubing is usually ordered and maintained to stricter tolerances and specifications compared to pipe. Pipe is generally ordered based on the Nominal Pipe Size (NPS) standard, which includes a nominal diameter and schedule number. Both tubes and pipes can be cut, bent, flared, and fabricated to meet various requirements.

Several key characteristics differentiate tubes from pipes:

304 stainless steel tube is a cylindrical, hollow machine and piping component manufactured of a specific steel alloy and commonly used to transfer fluids and gasses. 304 stainless steel is commonly used in industrial, commercial, and even domestic contexts since it has the great tensile durability and strength that almost all steels are recognized for, and good forming and welding qualities.

Originally referred to as 18/8 stainless steel due to its composition of approximately 18% chromium and 8% nickel, 304 stainless steel's elemental makeup can vary. Typically, it includes carbon and iron, with chromium content ranging from 18% to 20% and nickel from 8% to 18%. For enhanced weldability, low-carbon variants like 304L are used, while high-carbon variants such as 304H offer improved performance at elevated temperatures. The specific alloy chosen for a tube application depends on its intended use.

Although the initial cost of 304 stainless steel tubing may be higher compared to some alternatives, its durable elemental composition significantly extends the tube's lifespan. This results in reduced long-term costs related to replacements and maintenance. Additionally, despite eventual repair or replacement needs, 304 stainless steel can be easily melted down and recycled, further reducing costs and environmental impact.

316 stainless steel tubes are cylindrical, hollow components made from a specific steel alloy grade, primarily used for transporting fluids and gases. Known for its high tensile strength and excellent forming and welding properties, 316 stainless steel is utilized in a variety of settings, including industrial, commercial, and residential applications. With a melting point ranging from 1,350 to 1,400 degrees Celsius, this material is suitable for high-temperature applications.

Grade 316 stainless steel is primarily composed of iron, with carbon being a crucial addition for steel production. To achieve stainless properties, chromium must be present at levels of 10% or more. What sets grade 316 apart is its molybdenum content, which enhances its corrosion resistance compared to many other alloys. Variants of grade 316, such as 316H, 316L, and 316Ti, are commonly available in finished products and tube stock forms.

Grade 316L, a low-carbon variant, offers improved weldability, whereas grade 316H, a high-carbon variant, is better suited for high-temperature applications. Additionally, 316Ti, which contains up to 0.5% titanium, also performs well in high-temperature conditions.

A corrugated stainless steel tube, often abbreviated as CSST, is a hollow cylindrical object with a multi-layered construction. It serves as an alternative to traditional steel piping for transporting gases. This type of tubing is widely used in gas distribution systems, as well as in residential and commercial settings for gas heating, transport, and appliance connections.

Corrugated stainless steel tubes are gaining popularity due to their numerous advantages over traditional gas flow systems. Their excellent corrosion resistance allows them to handle both volatile gases and high pressure effectively.

The dual-layer construction of these tubes facilitates easy bending and shaping, which reduces the need for additional stainless steel fittings and connectors, thereby minimizing the risk of costly and dangerous gas leaks. The flexibility, lightweight nature, and compact size of CSST contribute to easier installation and lower labor costs, alongside material savings. While the tubing is generally hidden inside walls, the outer plastic coating, available in black or yellow, meets aesthetic and safety standards.

The tubing consists of two layers: an inner seamless stainless steel coil made from cold or hot rolled alloyed steel strips, and an outer plastic layer. The chromium in the stainless steel provides outstanding corrosion resistance, essential for many gas supply applications. The plastic coating enhances flexibility and provides an additional layer of protection against potential gas leaks if the stainless steel fails.

Corrugated stainless steel tubing, like other stainless steel tubing products, comes in various shapes and grades to suit different applications.

Hypodermic tubing is a typical medium for administering medicine or medicines under the skin. Hypodermic tubing, whether used for injection or removal, enables a quick supply of fluids. As a result, this stainless steel tubing is commonly used to make hypodermic needles for medical applications. It is a thin, cylindrical, hollow length of stainless steel, usually 316 or 304 grade, with a puncturing point at one end to form a needle.

The size of hypodermic tubing significantly impacts its applications. For instance, large-diameter hypodermic tubes are preferred for blood donation procedures because their wider bore allows for a faster blood draw compared to smaller or average-sized tubes. Conversely, small-diameter hypodermic tubes are unsuitable for blood donation, as their narrow size can damage red blood cells, rendering the blood unusable. Besides medical applications, hypodermic tubing is also utilized in various fields such as electrical, mechanical, and chemical industries for functions like spacers, cannulas, guide wires, and capillary tubes.

A stainless steel pipe is a cylindrical conduit made from stainless steel, designed to carry substances such as water, gas, oil, or other materials. Its excellent resistance to corrosion makes it ideal for use in environments with high temperatures, corrosive fluids, and high levels of contaminants.

Stainless steel's advantageous properties make it the preferred material for pipe fabrication. Its resistance to corrosion, low maintenance needs, ease of cleaning, and long-term cost-effectiveness contribute to its widespread use. Despite a higher initial investment compared to other metals, stainless steel offers lower maintenance and replacement costs over time.

Stainless steel pipe fittings are essential components used to connect or seal the ends of pipes and tubing, facilitating various configurations such as offsets, in-line connections, mounting, and multiport setups. Since bending pipes can be labor-intensive and costly, fittings are often employed to join two straight sections of pipe at angles necessary for different layouts.

As crucial elements in flow and plumbing systems, pipe fittings must efficiently handle all fluids, gases, and particulates that might be present. Stainless steel is a favored material for these fittings due to its exceptional strength, durability, and resistance to corrosion in challenging environments.

Stainless steel pipe fittings are widely utilized across various industries, including paper and pulp, petrochemical, automotive, water treatment, dentistry, medical, food processing, semiconductor, and aerospace sectors. In fields such as food processing and healthcare, where hygiene and ease of cleaning are critical, stainless steel is often preferred due to its sanitary properties. The long-term benefits of stainless steel, such as enhanced durability and reduced maintenance costs, often outweigh its higher initial expense. Even though fittings might eventually require repair or replacement, stainless steel's recyclability further contributes to cost savings and waste reduction.

Stainless steel square tubing consists of a hollow, pipe-like structure with four equal-length sides, made from various steel alloys. While these tubes can serve in gas and fluid transfer applications similar to their cylindrical counterparts, they are predominantly employed in structural and support frameworks due to their unique shape and strength properties.

Stainless steel square tubing is used in the construction, architectural, building, material handling, mounting, metal working, and framing sectors for a wide range of goods such as shelving, support beams, racks, grids, stepladders, partitions, and rails. While other materials may be utilized, stainless steel is particularly well suited to these applications.

Although various materials can be used, stainless steel is particularly advantageous for these applications. Despite its higher initial cost compared to other materials, stainless steel's inherent durability extends the lifespan of the tubing, reducing long-term expenses associated with replacements and maintenance. Even though square tubing will eventually require repair or replacement, its recyclability helps to minimize costs and environmental impact.

Stainless steel tubes are hollow, cylindrical structures used both as components in machinery and as conduits for fluid transport. The prevalent use of stainless steel in tubing is attributed to its beneficial properties, making it the preferred material for manufacturing these tubes.

The most frequently used stainless steel grades for tubing are 304 and 316. Stainless steel offers several benefits, including excellent corrosion resistance, easy cleaning, minimal maintenance, and overall cost-effectiveness. While the initial cost of stainless steel may be higher compared to other metals, its long-term maintenance and replacement costs are generally lower.

This section will explore the various applications and benefits of stainless steel tubing, as well as the factors to consider when choosing the right tubing for specific needs.

Stainless steel tubing is utilized across a wide range of applications, from industrial machinery to automotive exhaust systems. It serves primarily to facilitate the movement or control of gases and liquids. Stainless steel tubing is particularly effective in handling high temperatures and corrosive substances, making it adaptable for various uses. Its versatility allows it to be employed in numerous contexts, limited mainly by budget and creativity.

This type of tubing is suitable for a variety of environments and can withstand prolonged exposure to the elements without rusting or deteriorating. It finds applications in industries such as construction, outdoor equipment, automotive manufacturing, and kitchenware, thanks to its resistance to corrosion and durability.

Stainless steel tubing offers several advantages over other materials. Its key benefits include exceptional durability, the ability to transport both cold and hot liquids and gases, resistance to chemical corrosion, and flexibility in terms of grades and dimensions. Additionally, it can be manufactured cost-effectively for low-pressure systems.

Despite its advantages, stainless steel tubing comes with a higher manufacturing cost compared to other metals. The processes involved in producing stainless steel tubes are also expensive. The assembly of stainless steel components can be challenging, and care must be taken to avoid wear and tear during installation. If the chromium oxide protective layer is damaged, it can lead to increased friction and potential issues during assembly.

When assembling stainless steel parts, friction and heat can cause the components to bond at the molecular level, creating a rough surface that may require special anti-jamming compounds to minimize wear. Some stainless steel tubes may eventually need repair or replacement.

Several factors should be considered when choosing stainless steel tubing:

The choice of steel grade depends on the specific conditions the tubing will be exposed to. Extreme pH levels, high stresses, temperatures, and crevice corrosion can affect performance. Austenitic steels, such as 304 and 316 alloys, maintain their strength and corrosion resistance across a broad temperature range.

Strength: The maximum force that a metal can withstand before breaking or deforming.

Ductility: The ability of a material to be shaped, such as being drawn into a wire, without losing its strength or breaking.

Toughness: The capacity of a metal to absorb energy and deform before fracturing.

Austenitic stainless steel is available in various forms, including bars, wires, tubes, pipes, sheets, and plates. However, many products require additional machining or forming to meet specific application needs.

Designers often choose stainless steel for its aesthetic appeal, whether it features a shiny, matte, electro-polished, pickled, or black oxide finish. Austenitic stainless steel tubing can accommodate these treatments, including the commonly applied passivation process.

While high-performance austenitic stainless steel tubing may have a higher initial cost, it is a worthwhile investment due to its durability and suitability for its intended application. Using corrosion-resistant materials can reduce downtime, maintenance, and replacement costs. Life-cycle costing can provide a comprehensive comparison of various materials, assessing both current and future expenses.

Stainless steel tubing is a multifaceted product that is commonly utilized in structural applications. Stainless steel tubing diameters and variations vary greatly based on the application requirements and are widely employed in a wide range of industrial sectors. It is manufactured by three processes namely seamless, metal spinning, and tube milling. Although the names are sometimes used interchangeably, there is one significant distinction between tube and pipe, notably in how the material is arranged or ordered and the classification.

Stainless steel grade 304 is an austenite stainless steel that is the most widely used and versatile of the various grades of stainless steel. It is a part of the T300 series stainless steels with...

Stainless steel is a type of steel alloy containing a minimum of 10.5% chromium. Chromium imparts corrosion resistance to the metal. Corrosion resistance is achieved by creating a thin film of metal...

Stainless steel grades each consist of carbon, iron, 10.5%-30% chromium, nickel, molybdenum, and other alloying elements. It is a popular metal used in various products, tools, equipment, and structures that serve in many industrial, commercial, and domestic applications...

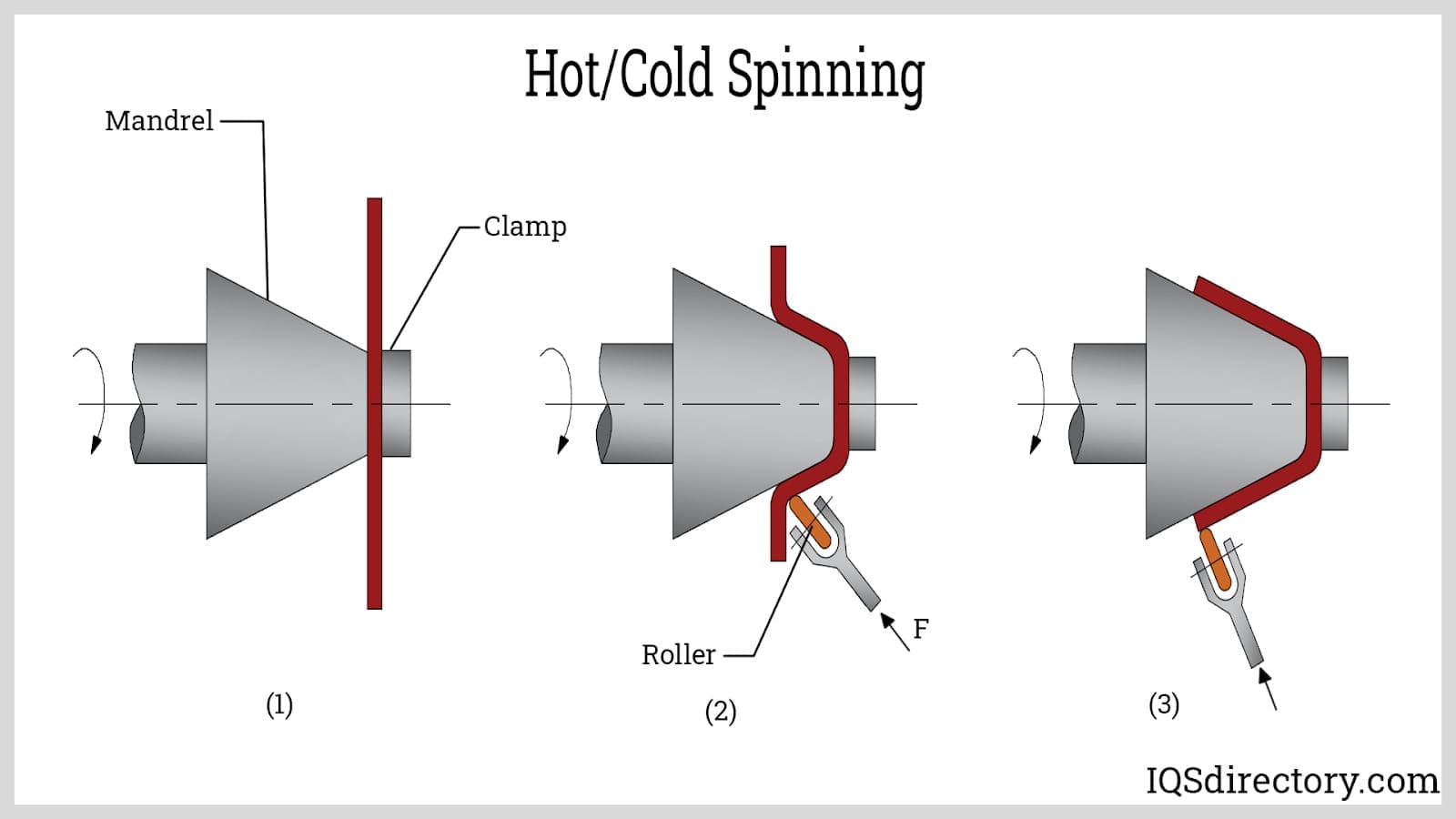

Stainless steel can be fabricated using any of the traditional forming and shaping methods. Austenitic stainless steel can be rolled, spun, deep drawn, cold forged, hot forged, or stippled using force and stress...

Perforated stainless steel is cut, punched, or stamped to produce a precise pattern of holes or apertures. It is used for functional reasons, such as filtration or ventilation, and aesthetic ones, such as architectural accents...

Stainless steel hinges connect two components while allowing them to move in relation to one another. They can have various leafs shaped like rectangles and other forms depending on the type of stainless steel hinge. Stainless steel hinge leafs are...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...

Tube bending is one of the fabrication methods used to form tubes permanently by bending them. In many circumstances, bent tubes are more useful than in their straight form. Bent tubes are an integral part of many instruments, such as...

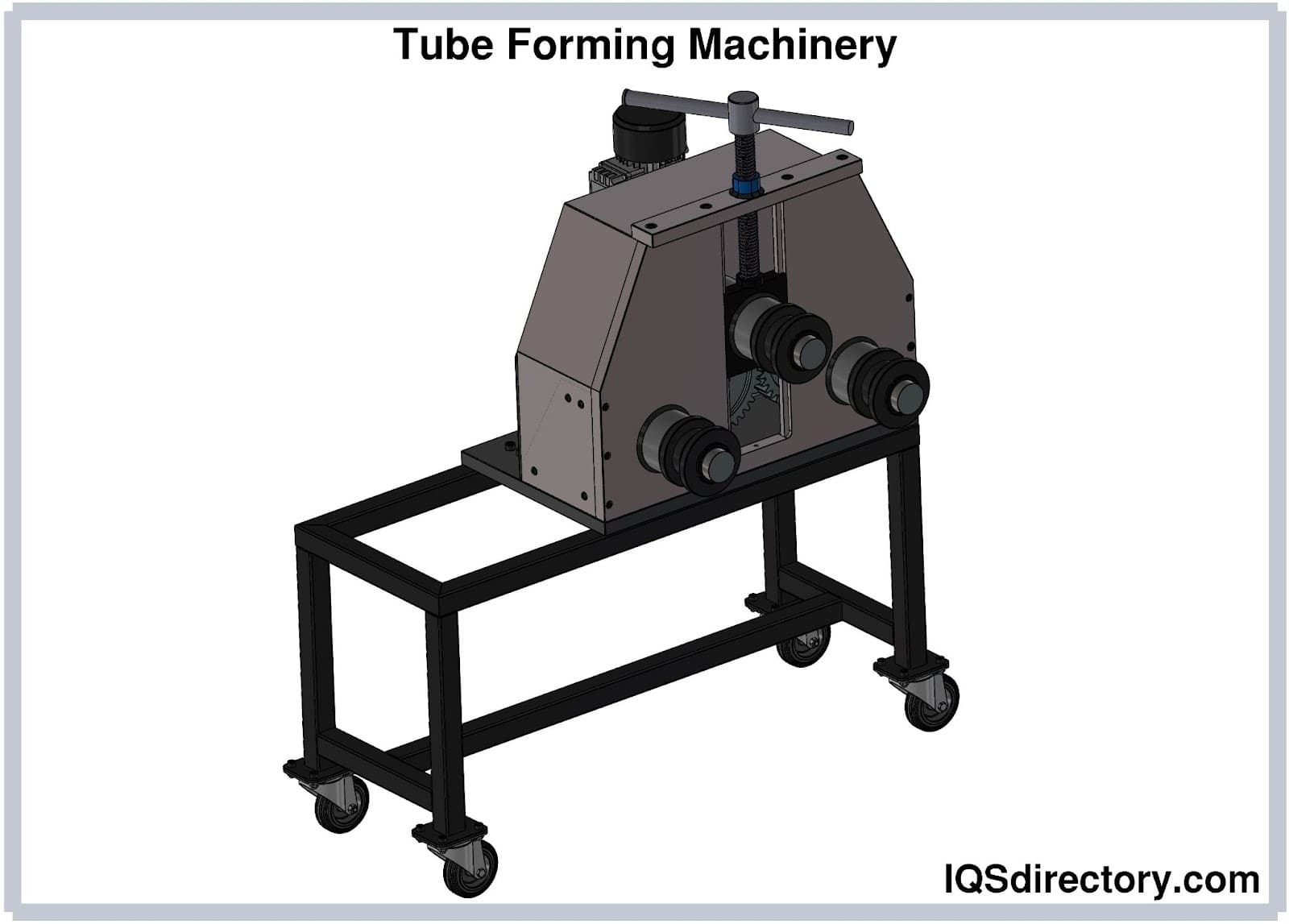

Tube fabricating machinery refers to machinery that either bends, cuts, or forms tubes and pipes into various shapes and sizes permanently. These machines work tubes constructed from materials with high ductility and malleability such as...