Stainless Steel 304

Stainless steel grade 304 is an austenite stainless steel that is the most widely used and versatile of the various grades of stainless steel. It is a part of the T300 series stainless steels with...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at stainless steel grades.

Read further to learn more about topics such as:

Stainless steel grades consist of a mix of carbon, iron, 10.5% to 30% chromium, nickel, molybdenum, and other alloying materials. This adaptable metal is extensively used in crafting products, tools, equipment, and infrastructure across a multitude of industrial, commercial, and residential settings.

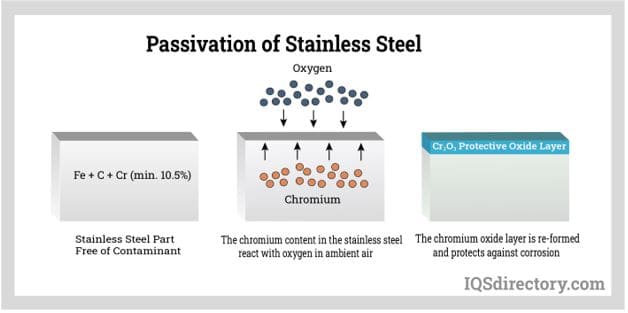

The superior attribute of stainless steel is its resistance to corrosion, which is largely credited to the presence of chromium. This alloying component interacts with oxygen found in air and water to create a thin, stable layer of chromium oxide that safeguards the metal's surface underneath. Molybdenum enhances its anti-corrosive properties by preventing pit formation on this protective coating. This oxide layer can self-repair after minor damage, although severe exposure to chlorides, strong cleaners, high salt content, humidity, or heavy abrasion may lead to rust development.

Beyond their corrosion resistance, stainless steels boast remarkable mechanical qualities like high strength, toughness, ductility, fatigue resistance, and wear resistance. They are capable of withstanding extreme temperatures, pressures, and cryogenic environments. Their non-reactive nature with most chemicals makes them suitable for use in chemical processing equipment and containers. Additionally, stainless steels are prized for their aesthetic appeal, offering a shiny, bright, and attractive finish.

Stainless steel grades are classified into five main categories. Each stainless steel type is engineered for specific industrial applications, driven by variations in crystal structure, alloy composition, mechanical properties, and corrosion resistance. Understanding the categories of stainless steel is critical for selecting the best material for manufacturing, construction, industrial processing, chemical equipment, and specialized engineering projects. In this chapter, we present an in-depth overview of each primary stainless steel grade category, highlighting key features and suitable uses.

Austenitic stainless steel is the most common type of stainless steel, named after English metallurgist Sir William Chandler Roberts-Austen. It constitutes the backbone of the stainless steel industry, encompassing the 200 and 300 series, with popular designations including 304 and 316 stainless steel.

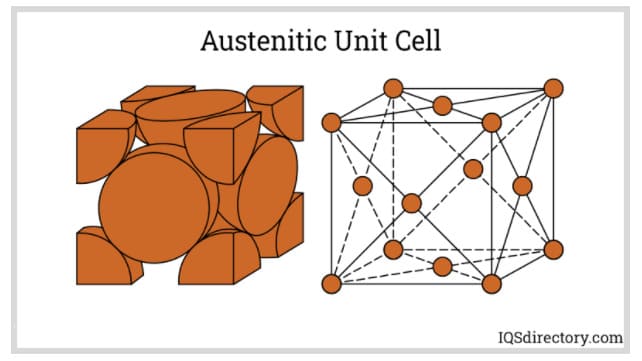

Austenitic stainless steels have a face-centered cubic (FCC) crystal structure, which is stabilized by the addition of nickel, manganese, and nitrogen. This FCC structure is maintained at all temperatures. Austenitic stainless steels typically contain moderate to high levels of nickel, ranging from 8-12%, along with significant amounts of manganese and nitrogen, which stabilize the austenitic structure. However, these additions increase the cost of the material. Carbon is present in only low concentrations.

Austenitic stainless steels cannot be hardened through heat treatment; instead, they are cold worked to enhance their strength, hardness, and surface finish. They are generally non-magnetic but can become slightly magnetic after cold working. These steels offer excellent formability and weldability. With a high chromium content (16-30%), austenitic stainless steels also exhibit superior chemical resistance, making them ideal for food processing, medical equipment, chemical tanks, and marine environments where high corrosion resistance is critical. Industry leaders often choose 304 stainless steel for kitchen appliances, while 316 stainless steel's enhanced molybdenum content allows it to resist chlorides and saline exposure, common in petrochemical and offshore projects.

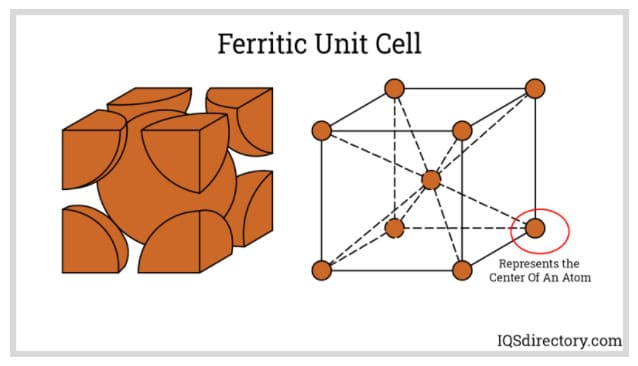

Ferritic stainless steels have a body-centered cubic (BCC) crystal structure and feature high chromium content, ranging from 11% to 27%, with only small amounts of nickel. Their low carbon content (about 0.03%) makes them highly ductile and formable. However, like austenitic steels, ferritic stainless steels cannot be hardened through heat treatment.

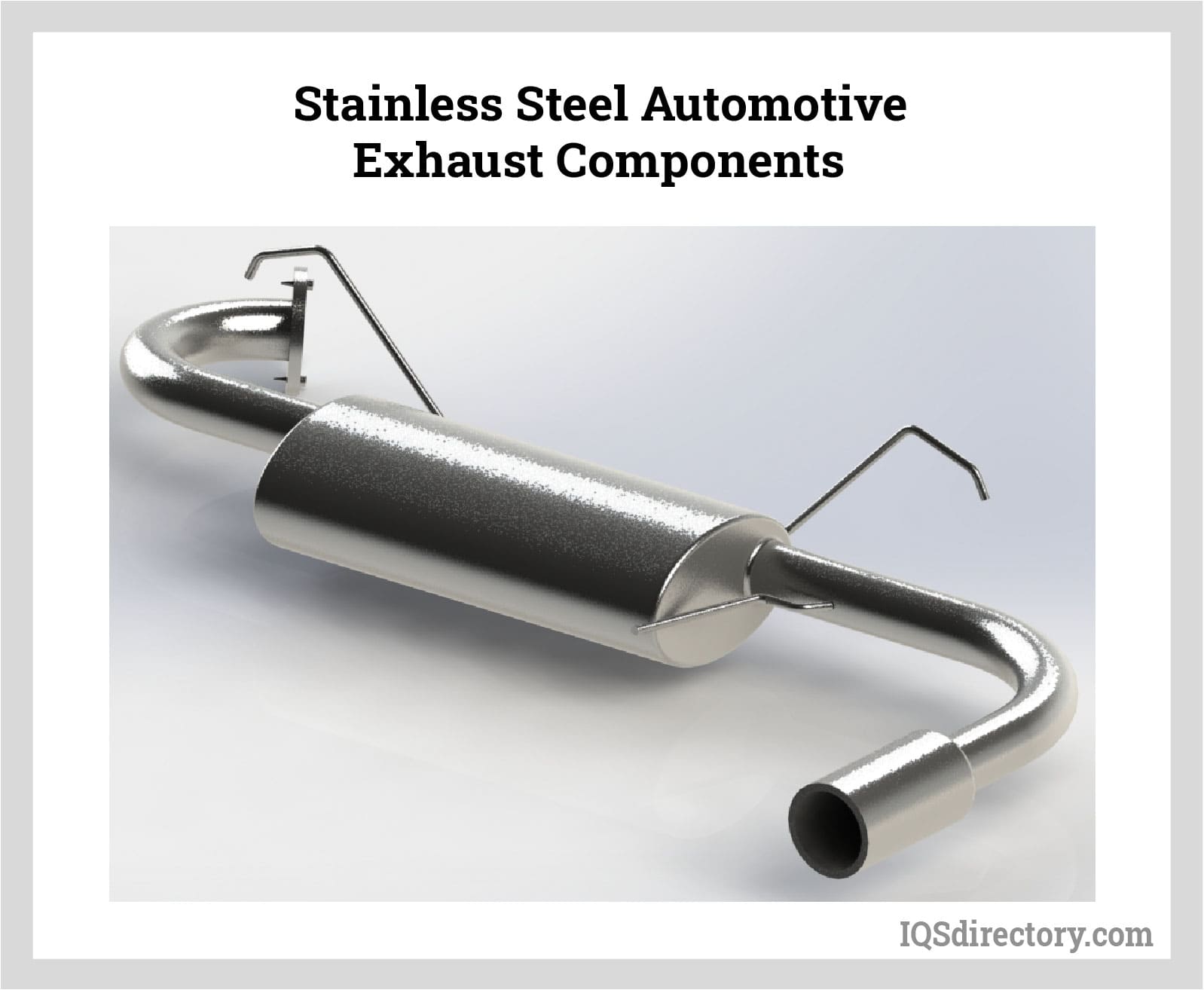

Ferritic stainless steels are magnetic and have high thermal conductivity, making them suitable for applications like boilers, automotive exhaust systems, and heat exchangers that involve heat transfer. They feature a low coefficient of thermal expansion, which ensures dimensional stability across a wide temperature range. Additionally, their ferritic structure provides excellent resistance to stress corrosion cracking, enabling them to endure exposure to chlorides, high humidity, and elevated temperatures. Common ferritic stainless steel grades include 409 and 430, which are preferred for architectural panels, household appliance parts, and moderately corrosive operating conditions due to their cost-effectiveness.

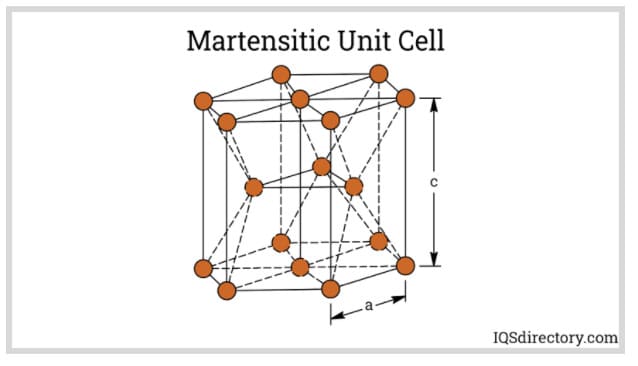

Martensitic stainless steels have a body-centered tetragonal crystal structure and contain 11.5-18% chromium along with 0.1-1.2% carbon. The high carbon content contributes to their relatively high strength and brittleness. However, the low nickel content in martensitic stainless steels results in reduced corrosion resistance. They are classified into two types based on carbon content: low carbon martensitic steels (0.05-0.25% carbon), which offer better corrosion resistance, and high carbon martensitic steels (0.61-1.50% carbon), which provide greater strength but are more brittle.

The hardness and strength of martensitic stainless steels can be enhanced through heat treatment processes such as age hardening, annealing, quenching, and tempering. Typical martensitic grades, such as 410 and 420 stainless steel, are popular in the production of surgical instruments, turbine blades, and cutlery, where wear resistance, toughness, and some corrosion protection are necessary. These steels are magnetic and impact-resistant but are challenging to weld and form due to their brittleness.

Ferritic and martensitic stainless steels are classified under the 400 series, which are sought after for products such as shafts, valves, and fasteners subjected to high strength and moderate corrosion exposure.

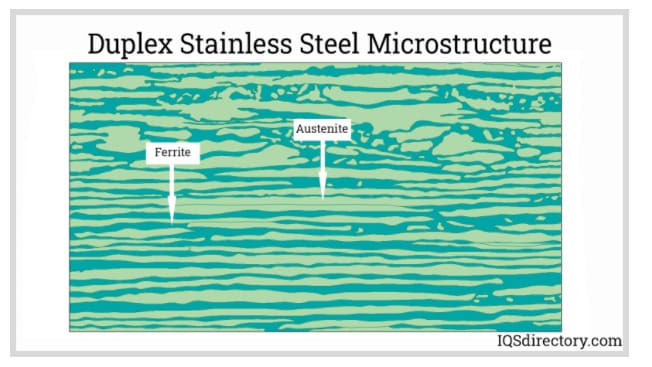

Duplex stainless steels feature a microstructure that includes both austenitic and ferritic phases in roughly equal proportions. They offer approximately twice the strength of conventional austenitic and ferritic stainless steels. While their toughness, ductility, and formability surpass those of ferritic steels, they do not reach the level of austenitic steels. Duplex stainless steels benefit from good resistance to stress corrosion cracking, a trait inherited from the ferritic phase. Corrosion resistance in duplex stainless steels can vary significantly depending on composition; increased levels of nickel, molybdenum, and nitrogen enhance resistance to pitting and crevice corrosion. Additionally, duplex stainless steels are generally more cost-effective compared to austenitic stainless steels.

Duplex grades such as 2205 and super duplex (e.g., 2507) are extensively used in oil and gas, pulp and paper, and chemical processing industries due to their exceptional combination of mechanical strength and corrosion resistance. Their effective performance in environments with aggressive chemicals, chloride-rich atmospheres, or fluctuating temperatures makes them a top choice for pressure vessels, desalination plants, and marine structures. Duplex stainless steels are increasingly favored for projects seeking low life-cycle costs, improved strength-to-weight ratios, and sustainability.

Precipitation-hardened (PH) stainless steels contain small amounts of copper, aluminum, titanium, and molybdenum. After alloying these elements, the stainless steel undergoes age hardening treatment, which causes these elements to precipitate as hard intermetallic compounds. This precipitate phase obstructs the movement of dislocations defects in the crystal lattice structure thereby enhancing the steel's strength and hardness. PH stainless steels offer corrosion resistance comparable to that of austenitic stainless steels.

PH stainless steels are categorized into three types: martensitic, austenitic, and semi-austenitic. Austenitic PH steels maintain their crystal structure at all temperatures. Semi-austenitic PH steels retain their austenitic structure after solution treatment and quenching, but this structure can be converted to martensitic through cryogenic treatment or cold working. The most well-known grade in this group is 17-4 PH, which delivers exceptional mechanical properties while maintaining moderate corrosion resistance, and is widely used for aerospace components, high-performance shafts, and precision hardware.

When choosing among stainless steel grades, consider factors such as corrosion resistance required by the application, the strength or hardness specifications, weldability, formability, and economic considerations. Consulting with leading stainless steel manufacturers or certified suppliers can help narrow material options, source mill test reports, and ensure that fabrication meets specific project parameters. For more detailed guidance, reference our stainless steel grades comparison chart or speak directly with an expert to match grade specifications to your industry requirements.

Stainless steel is a versatile and corrosion-resistant alloy used across countless industries, from construction and automotive to food processing, chemical manufacturing, and medical devices. There are over 150 stainless steel grades, but only about 15 are widely used in commercial applications. The most recognized grading system is established by the Society of Automotive Engineers (SAE), which classifies stainless steels with three-digit numbers. Additional standards such as the Universal Numbering System (UNS) for Metals and Alloys and region-specific grade notations cater to international and industry requirements. Understanding stainless steel grades is critical for selecting the right material specifications for durability, performance, and compliance in specialized environments.

The stainless-steel grades and their key properties include:

Grade 201 stainless steel is an austenitic stainless alloy featuring 16-18% chromium and 3.5-5.5% nickel, making it a cost-effective alternative to grade 304 and higher nickel grades for applications where lower cost is a priority. Grade 201 delivers less corrosion resistance than nickel-rich alloys, but excels in yield strength, formability, and weldability due to additions of manganese and nitrogen. Its high work-hardening rate and ease of fabrication make it well-suited for household appliances, cookware, transport components, and architectural trim.

Grade 202 stainless steel is also austenitic, containing 17-19% chromium, 4-6% nickel, and 7.5-10% manganese. It is popular in environments needing moderate corrosion resistance, good precipitation hardening capabilities, and high mechanical strength even at low temperatures. While similar to grade 302 in toughness and forming ability, grade 202’s lower yield strength and cost-effective composition favor its use in utensils, restaurant equipment, and structural frameworks. Grade 202’s machinability in annealed form and suitability for various welding processes add to its manufacturing versatility.

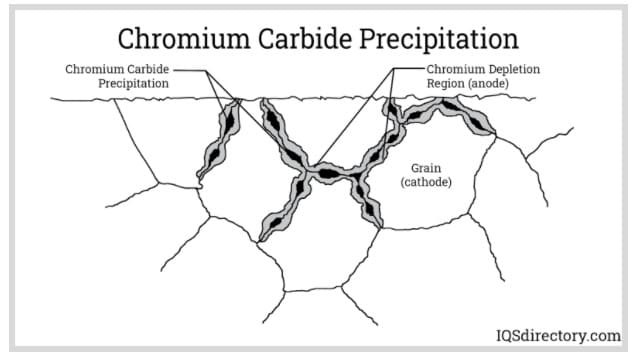

Grade 301 stainless steel, an austenitic alloy, provides comparable general corrosion resistance to grade 304 in many environments at ambient temperatures. It contains 16-18% chromium and lower nickel than 304, so corrosion resistance diminishes in highly corrosive or high-temperature exposures. Known for its high tensile and yield strength, 301 is favored in cold-worked conditions for applications requiring elevated strength, such as railcar components, automotive molding, and springs. Cold working induces magnetism, while the annealed form offers exceptional ductility and formability for stamping and forming operations. Post-weld annealing is recommended to prevent intergranular corrosion. Variants like grade 301L offer improved ductility and weldability, while 301LN enhances work hardening rate and does not usually require annealing.

Grade 302 stainless steel is an austenitic alloy with about 18% chromium and 8% nickel and a slightly higher carbon content than 304. With high toughness, tensile strength, and resistance to oxidation, 302 is applied in high-stress parts, fasteners, and springs. Its work hardening characteristics require slow machining speeds with chip breaks to prevent build-up. Resistance and shielded fusion welding are appropriate, with post-weld annealing crucial for optimal corrosion performance. Grade 302 often finds use in the manufacture of washers, screens, and medical instruments.

Grade 304 stainless steel is the most widely used austenitic alloy due to its exceptional combination of corrosion resistance, ductility, and mechanical strength. Composed of 18% chromium and 8% nickel, it offers excellent resistance to atmospheric corrosion, oxidation, and chemical exposure across various temperature ranges. Commonly known by its 18/8 designation, grade 304 is ubiquitous in kitchenware, food processing, architectural fixtures, and chemical containers. However, it may experience pitting and stress corrosion cracking in chloride-rich environments. Variants like 304L (low carbon) reduce susceptibility to sensitization during welding, while 304H (high carbon) increases strength for high-temperature service. 304 is a top choice for formability and deep drawing, though post-process annealing is needed after severe cold work. Its widespread acceptance is driven by its compatibility with sanitary standards, ease of cleaning, and proven long-term performance.

Grade 305 stainless steel, with 18% chromium and at least 10% nickel, is optimized for deep drawing applications due to its high nickel content and low work hardening rate. The alloy exhibits excellent resistance to corrosion and chemicals with moderate carbon content. It is well-suited for parts requiring extensive shaping without cracking, such as electronic components and cold-headed fasteners. Suitable welding processes include resistance and fusion welding (oxyacetylene is not recommended).

Grade 309 stainless steel has a minimum of 22% chromium and 12% nickel, granting superior resistance to oxidation and scaling at elevated temperatures. Its low carbon content reduces the risk of carbide precipitation. Valued for high tensile and creep strength, it’s used in high-temperature industrial processes, furnace parts, and heat exchangers exposed to saline or oxidizing conditions. Annealing after cold working ensures maintained ductility for demanding processing environments.

Grade 316 stainless steel is the second most common austenitic stainless steel, distinguished by its enhanced corrosion resistance thanks to elevated molybdenum, as well as its favorable chromium and nickel balance. This makes 316 especially suitable for harsh chemical, marine, and pharmaceutical processing environments prone to pitting, crevice corrosion, or exposure to aggressive chlorides and seawater. It readily resists acids and alkalis and maintains weldability and formability. Variant 316L (low carbon) is chosen for extensive welded assemblies—such as pharmaceutical and food processing equipment—reducing the risk of intergranular attack. 316H offers improved strength and creep resistance for high-temperature service. Common applications include fasteners, valves, pumps, marine parts, and architectural components.

Grade 321 stainless steel is a titanium-stabilized austenitic alloy, engineered for high-temperature stability and superior resistance to intergranular corrosion following welding or exposure to elevated temperatures. This makes it advantageous in aircraft exhaust systems, flexible expansion joints, chemical processing equipment, and furnace parts. Its variant, 321H, increases carbon for enhanced strength and creep resistance in high-temperature ranges.

Grade 347 is a niobium-stabilized austenitic stainless steel. Like 321, it inhibits carbide precipitation, which ensures superior intergranular corrosion resistance after welding or prolonged heating—vital for components in chemical processing, expansion joints, and high-temperature piping. 347 also outperforms 321 in oxidation resistance, making it ideal in steam turbine parts and exhaust manifolds.

Grade 409 ferritic stainless steel is stabilized with titanium and/or niobium to enhance corrosion resistance and weldability at high operating temperatures. Used extensively for automotive exhaust systems, catalytic converters, and heat exchangers, it offers good mechanical properties, forming capability, and weld performance (arc, spot, seam welding). Light surface rusting can occur, so it’s not suitable for decorative finishes, but cost efficiency and durability make it a top automotive material.

Grade 410 is a heat-treatable martensitic stainless steel containing 11.5% chromium. Through hardening and tempering, 410 achieves increased wear resistance, making it suitable for industrial machine parts, refinery equipment, and fasteners such as bolts, screws, and bushings. Its chemical resistance covers a range of mild acids, foodstuffs, and water exposure. Welding should be accompanied by preheating and post-weld annealing to reduce cracking. 410 also retains machinability after heat treatment, being used in turbines, valves, and pump components.

Grade 420 stainless steel is a high-carbon martensitic alloy (0.15–0.45% C, minimum 12% Cr), offering excellent hardness and tensile strength after proper heat treatment. Although its corrosion resistance is lower than austenitic or ferritic grades, it provides adequate protection in mild acid, alkali, and food-handling environments. 420 is extensively used for blades, surgical instruments, cutlery, dies, needles, and bushings. Its annealed state allows easier machining, but fully hardened 420 is chosen for critical wear applications. Users in the medical, food, and tool industries benefit from its edge retention and polishability.

Grade 420HC stainless steel’s higher carbon content delivers increased surface hardness, edge retention, and ease of sharpening—prioritizing requirements for cutlery, folding knives, and outdoor tools. 420HC’s mid-range pricing, reliability, and satisfactory rust resistance (though less than austenitic types) make it the preferred choice in the hunting, fishing, and sporting goods sectors. Budget knife manufacturers appreciate the blend of formability, cost savings, and maintenance requirements. While sharpening is straightforward, users should expect to resharpen more frequently than premium steels.

420J2 is a highly affordable stainless steel grade with good general corrosion resistance in domestic, medical, and industrial environments. Its strength and impact resistance after hardening and tempering, alongside fine machinability and annealing range of 730°C to 790°C, allow it to be manufactured into scissors, surgical instruments, budget knives, hairdressing shears, and decorative blades. Industries benefit from its cost-effectiveness, easy fabrication, and adaptability in both hand and precision tools.

Grade 430 is a ferritic chromium stainless steel, favored for cost-conscious applications requiring resistance to organic and nitric acids, oxidation, and stress corrosion cracking. Its low carbon and nickel content makes it less ductile but more affordable, commonly used in kitchen appliances, automotive trim, dishwashers, and architectural panels requiring routine cleaning, heat, and moderate corrosion resistance. Its machinability and ease of forming are balanced by low work hardening rates.

Grade 434, another widely-utilized ferritic stainless steel, stands out due to its significant molybdenum content, improving pitting and crevice corrosion resistance. Widely specified for automotive trim, high-temperature applications, and decorative interiors, it withstands conditions up to 1500°F. While its strength is comparable to 430, it is preferred in more aggressive environments where enhanced corrosion or oxidation is required. Like other ferritic types, 434 is cold-formed, not heat treatable for hardness.

Grade 440 series stainless steels (440A, 440B, 440C, and 440F) are distinguished by high carbon content, reversibly enhancing hardness, wear resistance, and strength post heat-treatment. Grade 440C, with the highest carbon, is widely used for cutlery, ball bearings, surgical instruments, and valve components due to its high degree of polish, edge retention, and hardness. Grades 440A and 440B are slightly softer, providing some machining and forming advantages but with lower ultimate hardness. Grade 440F offers improved machinability for high-volume part production. Despite excellent mechanical performance, 440 stainless steels are less suited to prolonged high-temperature or highly corrosive settings compared to the 300-series; 440C, however, does approach the corrosion resistance of grade 304 in certain applications.

When evaluating stainless steel grades for your project, consider industry requirements such as corrosion resistance (pitting, crevice, and stress corrosion cracking), mechanical properties (hardness, tensile and yield strength, ductility), temperature resistance, formability, weldability, machinability, and cost efficiency. Select the grade that aligns with the operational, aesthetic, and regulatory needs of your environment. Consulting with a knowledgeable supplier or engineer can help ensure the most effective and compliant material choice for your application.

Stainless steel is shaped and formed to suit various manufacturing and production needs. Suppliers and manufacturers produce raw stainless steel in forms that match the intended applications. Coils are commonly used in products like kitchen appliances, automotive parts, and medical instruments, while stainless steel bars are utilized to create cutlery, plumbing components, and construction materials.

Stainless steel coils are flat strips rolled from stainless steel sheets, with thicknesses ranging from 0.02 mm to 6 mm (0.0008 inch to 0.23 inch). The production begins with stainless steel slabs, which are processed through a Z mill a series of rollers to produce these coils. The Z mill process creates wide coils known as mill edge coils.

The wide coils are further processed through a slitting operation, which cuts them into narrower strips, resulting in coils known as strip coils, slit coils, banding, or simply strips. The winding method of these coils determines their type, which can be pancake, ribbon, or bobbin. Typically, coils are wound with even edges on a strip, and their outer diameter (OD) is limited to ensure safe handling.

Stainless steel coils are incredibly versatile and find application across numerous industries. In the automotive industry, stainless steel is used extensively for vehicle structures due to its strength and resistance to corrosion. In the food production sector, stainless steel coils are essential for manufacturing equipment such as countertops and processing machines, ensuring hygiene and durability. Beyond these major applications, stainless steel coils are also utilized in aerospace, defense, pipelines and fittings, and construction, highlighting their broad utility and importance in modern manufacturing and infrastructure.

Stainless steel bars are available in various forms, including rods, rounds, and round bars. They are produced from different grades of stainless steel, with grades 304 and 316 being the most common. Stainless steel bars can come in flat, round, hexagonal, octagonal, or square shapes, depending on the manufacturer. While they can be used in their original form, they are often melted down and reworked into channels, tubing, or extruded angles for further applications.

Among the various forms of stainless steel, bars are the most economical due to their greater volume compared to other forms. They are also easier to ship and process with predictability. The different shapes of stainless steel bars indicate their intended applications and the processes they will undergo. For instance, round bars might be used in machining and manufacturing parts, while flat bars could be utilized in construction and structural applications. The choice of shape and grade ensures that the stainless steel meets specific requirements for strength, durability, and functionality.

The manufacturing process of stainless steel begins with melting the raw materials, a process that typically takes eight to twelve hours. Once melted, the stainless steel is cast into bars, which are then hot rolled into various shapes. After rolling, the bars are annealed, which involves heating them to a high temperature and then cooling them through quenching or air hardening to achieve the desired properties. Following cooling, the stainless steel undergoes a descaling or pickling process to remove the oxide film that forms during hot forming. This ensures a clean surface and prepares the stainless steel for further processing or finishing.

Stainless steel foil consists of thin strips with a thickness of 0.2 mm (0.008 inch) and a width of 300 mm (12 inches) or less. It retains all the properties of stainless steel and is utilized in a variety of applications including the production of heat exchangers, capacitors, and fuel cells. A significant application of stainless steel foil is in the manufacture of sensitive medical instruments and food processing equipment due to its durability, corrosion resistance, and ability to maintain cleanliness.

Several grades of stainless steel are used in the fabrication of stainless steel foil, including grades 301, 304, 316, 409, 430, and duplex 2205. These grades are chosen based on the specific requirements of the application, such as corrosion resistance, strength, or temperature tolerance. Stainless steel foil can come in different forms, including full hard, half hard, and quarter hard, which refer to the degree of hardness and flexibility of the foil. Full hard foil is the most rigid and least flexible, while half hard and quarter hard foils offer progressively more flexibility, making them suitable for different manufacturing and industrial uses.

Among the various grades of stainless steel foil, grade 304 is the most commonly used due to its adaptability, versatility, and availability. It offers high performance at a relatively low cost. The qualities of grade 304 that make it ideal for foil production include its low thermal and electrical conductivity, non-magnetic properties, and excellent corrosion resistance. Additionally, grade 304 is easily formable, allowing it to be shaped into various configurations with ease. These attributes make it a preferred choice for applications requiring high-quality performance in demanding environments.

Stainless steel foil is a thin, flexible material that can be layered and wrapped around equipment, objects, and other items to provide protection. Its flexibility and durability make it ideal for a wide range of applications, from shielding sensitive components to providing a protective layer in various environments. Readily available from manufacturers and online, stainless steel foil is valued for its strength and longevity, making it a popular choice for both industrial and consumer uses.

Stainless steel plates are available in various sizes and thicknesses, typically starting from slabs that are 4 inches thick or more. To achieve the desired dimensions, these slabs undergo cold or hot rolling processes. Hot rolling involves passing the slabs through rollers at high temperatures to reduce their thickness, while cold rolling is used for applications requiring enhanced strength or precise thickness. Stainless steel plates can be made from various grades, with grades 304 and 316 being among the most commonly used due to their versatile properties.

The primary distinction between stainless steel plate and stainless steel sheet lies in their thickness. Stainless steel is classified as a plate if its thickness is 6 mm (0.25 inch) or greater. In contrast, stainless steel sheet has a thickness less than 6 mm and is typically measured in gauges. Both plates and sheets can be measured in millimeters as well, but their thicknesses and the units of measurement used (inches for plates and gauges for sheets) help differentiate them. This classification impacts their applications, with plates often used in structural and heavy-duty applications, while sheets are commonly used for lighter, more precise uses.

Stainless steel plate is widely used in the production of various products because of its durability, ease of maintenance, and attractive appearance. The application of stainless steel plate depends on its specific grade. Among the most common grades are 304 and 316, with grade 304 further categorized into 304, 304H, and 304L.

Stainless steel rods are available in various shapes and are utilized in support structures, appliances, and machinery. Their sizes vary based on metal content and intended application, with diameters ranging from 1.5 mm to 152.4 mm (0.0625 in to 6 in). In construction, they serve as reinforcement for masonry and fence posts.

A distinctive feature of stainless steel rods is their alloy composition, which differs from that of stainless steel bars. Rods typically have lower carbon content and higher manganese content, enhancing their wear resistance. While high carbon content increases hardness and brittleness, making the material prone to cracking, the higher manganese content in stainless steel rods improves their durability.

Stainless steel rods are produced through an extrusion process involving a stainless steel billet. This process starts by heating the billet until it becomes malleable but not molten. The heated metal is then pushed through a hardened steel die by hydraulic force, shaping it into the final rod form. Once extruded, the rods are directed to the drawing area, where they undergo further processing, including pointing, drawing, straightening, or cold rolling.

The shapes of stainless steel rods include:

Stainless steel sheets are thin, flat pieces of stainless steel with a thickness of less than 6 mm (0.25 in). These sheets are created by passing stainless steel slabs through a Z mill, which compresses them to the desired thickness. Typically, stainless steel slabs are at least four inches thick, necessitating the use of multiple rollers in the Z mill to achieve the final sheet thickness.

The rolling process can be either hot or cold. In hot rolling, stainless steel slabs are heated above their recrystallization temperature, allowing them to be reduced to a thickness of 0.28 mm (0.011 in) more quickly than in cold rolling. Cold rolling, on the other hand, involves passing the metal through the rollers of a Z mill multiple times at room temperature to achieve precise thicknesses and dimensions.

Stainless steel plates and sheets are produced through the same process but differ in thickness. Sheets are less than 6 mm (0.25 in) thick, whereas plates exceed 6 mm (0.25 in) in thickness. In addition to their measurements in millimeters or inches, stainless steel sheets are also measured in gauges, which use a different scale compared to gauges for other metals.

Stainless steel strips are thin, long, and narrow extensions of stainless steel sheets, often referred to as stainless steel coils. They come in various widths and standard lengths, though custom lengths are available to suit specific applications or customer preferences. Their popularity stems from their exceptional strength and smooth, lustrous finish.

Stainless steel strips are produced using either cold rolling or hot rolling processes. Cold rolled stainless steel strips have thicknesses ranging from 0.1 mm to 3 mm (0.004 in to 0.12 in) and widths between 100 mm and 2000 mm (4 in to 79 in). These strips are known for their smooth, flat surfaces, precise measurements, and excellent mechanical properties. They can also be further processed into coated plates.

Hot rolled stainless steel strips are available in thicknesses from 1.8 mm to 6 mm (0.07 in to 0.23 in) and widths ranging from 50 mm to 1200 mm (2 in to 47 in). These strips have lower hardness, making them easier to process and stretch compared to cold rolled strips. However, hot rolled stainless steel strips typically have a dark, rough surface due to the scale that forms during the heating process.

Stainless steel strips are produced from series 200, 300, and 400 stainless steels and are categorized into several grades: austenitic, ferritic, martensitic, duplex, PH (precipitation-hardening), and super austenitic. These diverse grades are tailored to meet the requirements of various applications, ranging from aerospace and automotive manufacturing to home appliances and electronics.

Stainless steel wire serves a variety of applications, including spring wire, cutting wire, cold heating wire, and roping wire. Each type is designed with specific properties to suit its intended use. Stainless steel wire gauges range from 14 AWG to 44 AWG, with additional gauges available to meet custom requirements. The gauges are also distinguished by the grade of stainless steel used in their manufacture.

Spring wire is the most commonly used type of stainless steel wire, manufactured from 300 series and 400 series stainless steels. The choice of grade depends on the desired properties, spring design, and fabrication method. A key feature of stainless steel spring wire is its capacity to endure different levels of heat.

Cutting stainless steel wire is prized for its rigidity and surface hardness. It exhibits excellent machinability and maintains consistent dimensional tolerances. This type of wire earned its name due to its ability to retain its roundness during cutting. Its exceptional machinability allows for rapid cutting, which extends the lifespan of cutting tools.

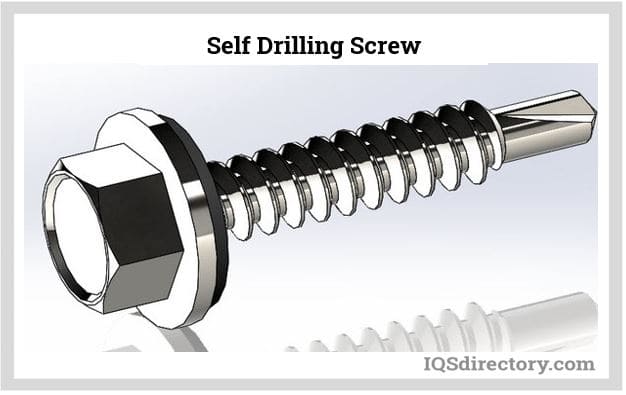

Cold heating stainless steel wire is utilized in the production of bolts, nuts, nails, and screws. It is manufactured to stringent industrial standards to ensure the reliability of these connectors. Key characteristics of cold heating stainless steel wire include its high tensile strength and a stable microstructure that maintains its properties over time.

Roping stainless steel wire is specifically designed for assembling wire rope and comes in various sizes and diameters. Unlike other types of stainless steel wire, roping wire is used together with other wires, whether they are similar or different. The key factors for roping stainless steel wire include its diameter, which affects the overall diameter of the wire rope, and its tensile strength. Additionally, it must be exceptionally flexible to effectively integrate with other wires in the rope assembly.

Thanks to its exceptional mechanical properties and corrosion resistance, stainless steel is used in a wide range of products, equipment, and structures. Applications of various stainless steel grades include, but are not limited to:

Grade 201 stainless steel is utilized in a variety of applications, including structural components, decorative materials, household items, cooking utensils, windows, doors, automotive parts, railroad cars, and trailers.

Grade 202 stainless steel is processed into sheets, coils, and plates for use in manufacturing household items, kitchenware, structural components, automotive trim, hose clamps, and railway cars.

Grades 301 and 301LN stainless steels are utilized in a variety of applications, including aircraft components, structural parts for railcars, automobiles, trucks, and trailers, as well as in appliances, cooking utensils, kitchenware, wiper blade clips and holders, screen frames, and curtain walls.

Grade 301L stainless steel is employed in the production of pressure vessels, door and drainage components, utensils and appliance parts, as well as structural elements for railcars.

Grade 302 stainless steel is frequently used in food handling equipment, cooking utensils, kitchenware, pressure vessels, and medical tools. It is commonly available in various forms, including springs (such as conical compression springs), screens, cables, and wires.

Grade 304 stainless steel is widely used in the manufacture of deep-drawn sinks, pans, pots, and troughs. It is also employed in mechanical fasteners (such as nuts, bolts, and screws), industrial plant equipment (including pressure and storage vessels, and tubing), kitchenware, cutlery, cooking utensils, decorative items, and architectural paneling.

Grade 305 stainless steel is commonly used to manufacture deep-drawn parts, including cups, pans, bowls, eyelets, rivets, and screws.

Grade 309 stainless steel is utilized in the construction of boilers, furnaces, ovens, heat exchangers, kilns, aircraft engines, and automotive exhaust components.

Grade 316 stainless steel is widely used in the construction of chemical storage tanks, heat exchangers, reactors, furnaces, and other process equipment. It is especially favored for marine environments and the refinery industry due to its superior corrosion resistance. Additionally, Grade 316 is employed in architectural panels and railings.

Grade 321 and Grade 347 stainless steels are utilized in a range of applications including aircraft and aerospace components, expansion joints, bellows, furnace parts, heat exchangers, heating element tubing, and chemical process equipment.

Grade 409 stainless steel was originally developed for automotive exhaust systems. Its applications have since broadened to include catalytic converters, mufflers, fuel filters, heat exchangers, and agricultural machinery.

Grade 410 stainless steel is used in the manufacture of cutlery, knives, flatware, cutting tools, bolts, bushings, and nuts. It is also utilized in constructing petroleum fractionating equipment, gas turbines, pumps, shafts, and valves.

Grade 420 stainless steel is commonly used in the production of cutlery, surgical and dental instruments, scissors, blades, and other cutting tools. Grade 420HC and Grade 420J2 are specifically employed in more economical knives and cutting tools.

Grade 430 stainless steel is used in the manufacture of kitchen utensils, sinks, dishwasher linings, pipes, tubes, and automotive trim.

Grade 434 stainless steel is utilized in automotive trim, furnace chambers, range hoods, gas burners, steam iron bases, flatware, and chemical process equipment.

Grade 440 stainless steel is used in the manufacture of valves, valve seats, ball bearings, and cutlery.

Stainless steel screws offer exceptional mechanical properties and corrosion resistance, making them ideal fasteners for a wide range of environments.

Self-drilling screws are designed to create their own hole as they are driven into the material, eliminating the need for a pre-drilled or pre-punched hole. They are typically used with softer and thinner materials.

Self-tapping screws are designed to create their own holes as they are driven into the material, making them versatile for use in wood, plastic, and metal substrates.

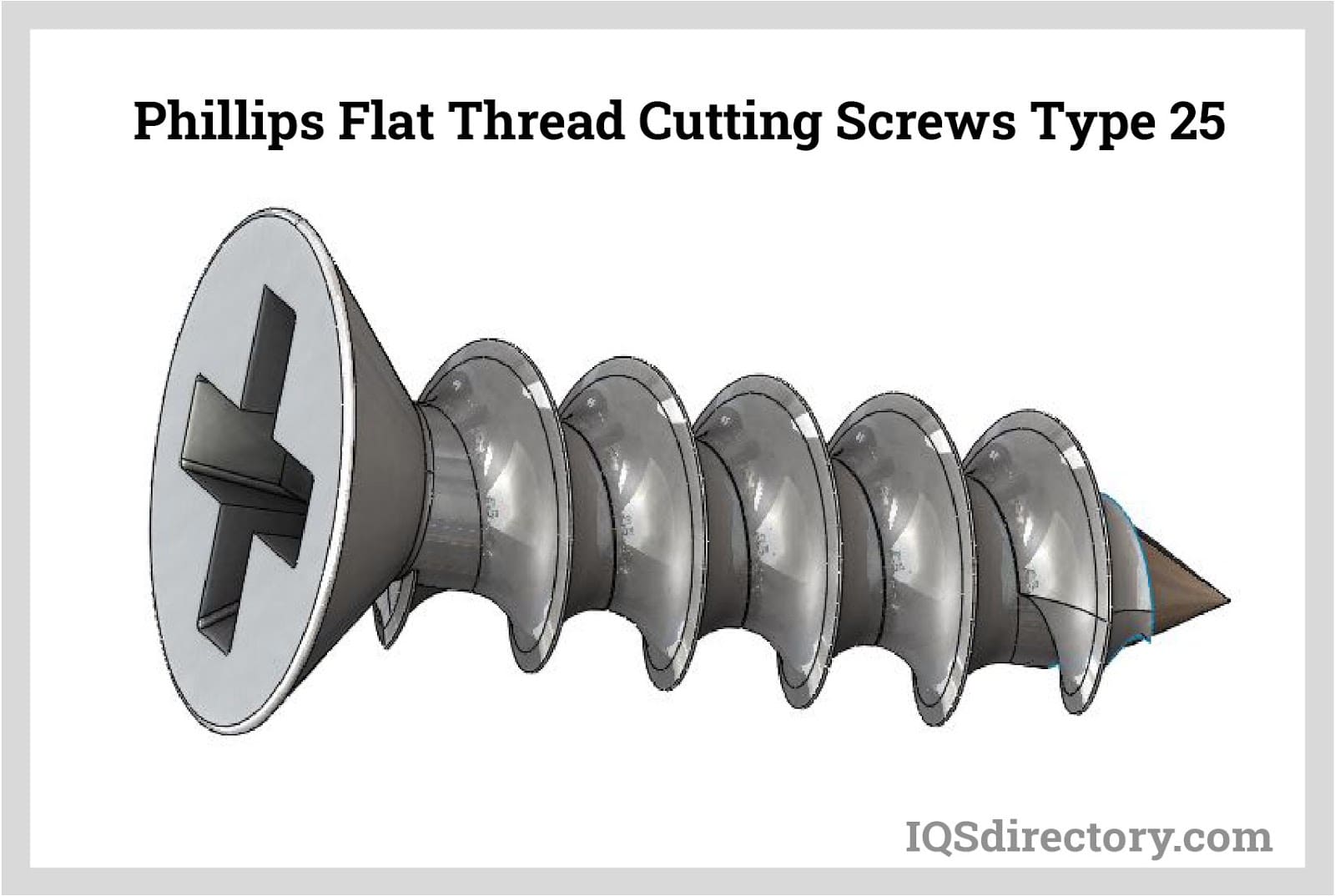

Thread-cutting screws are designed to create threads in pre-drilled holes within a material, enabling a secure fit as they are driven in.

Cleveland-Cliffs is a global leader in stainless steel production for the automotive, construction, and power industries. With over 150 years of experience, the company is the largest flat-rolled steel manufacturer in North America. One of its key objectives has been to significantly reduce emissions from steel production, achieving substantial progress over the past decade. Cleveland-Cliffs produces more than 50 grades of stainless steel.

Source 21 specializes in manufacturing stainless steel coils and strips, offering custom processing for any grade of stainless steel. The company employs rolling techniques to reduce the thickness of stainless steel, achieving precise gauges and thicknesses tailored to customer specifications. This rolling process ensures a consistent gauge, minimizing the risk of weakness or deformation. Using Z milling, Source 21 gradually reduces the thickness of the stainless steel to produce high-quality coils and strips.

NAS is a leading producer of high-quality stainless steel in the United States, specializing in both cold and hot rolled coils, sheets, and plates across a range of grades. The company primarily focuses on grades 201, 301, 304, 309, 310, 316, and 321, which are available in standard stainless steel forms. NAS is also one of the largest steel recyclers, committed to reducing waste and promoting metal reuse.

Metalmen Sales is a leading on-demand supplier of stainless steel with over 100 years of industry experience. Their metalworking processes include rolling, slitting, tempering, shearing, and heat treating to produce high-quality stainless steel. The company maintains a vast inventory of stainless steel products, including foil, rods, bars, strips, coils, sheets, and plates, available in a wide range of grades, including PH stainless steel.

Cada is a distributor specializing in basic stainless steel grades, many of which are annealed or tempered. They offer stainless steel in various finishes, including rough gray, dull, bright silvery, and mirror. To prevent damage during shipping, Cada provides stainless steel with a PVC coating. With 35 years of industry experience, the company serves sectors such as the automotive industry, oil and gas production, appliance manufacturing, and chemical processing.

Stainless steel grade 304 is an austenite stainless steel that is the most widely used and versatile of the various grades of stainless steel. It is a part of the T300 series stainless steels with...

Stainless steel is a type of steel alloy containing a minimum of 10.5% chromium. Chromium imparts corrosion resistance to the metal. Corrosion resistance is achieved by creating a thin film of metal...

Stainless steel can be fabricated using any of the traditional forming and shaping methods. Austenitic stainless steel can be rolled, spun, deep drawn, cold forged, hot forged, or stippled using force and stress...

Stainless steel tubing is a multifaceted product that is commonly utilized in structural applications. Stainless steel tubing diameters and variations vary greatly based on the application requirements and are...

Perforated stainless steel is cut, punched, or stamped to produce a precise pattern of holes or apertures. It is used for functional reasons, such as filtration or ventilation, and aesthetic ones, such as architectural accents...

Stainless steel hinges connect two components while allowing them to move in relation to one another. They can have various leafs shaped like rectangles and other forms depending on the type of stainless steel hinge. Stainless steel hinge leafs are...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...

Titanium metal, with the symbol Ti, is the ninth most abundant element in the earth‘s crust. It does not occur in large deposits, yet small amounts of titanium are found in almost every rock...