Wire Displays

Wire shaping is a complex method that encompasses a wide range of dimensions, forms, and textures. The technique of creating a usable product by wire bending and shaping is known as custom wire forms...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at wire baskets.

The article will bring more detail on topics such as:

This chapter delves into wire baskets, highlighting the manufacturing processes and materials that form the backbone of these versatile storage solutions.

Wire baskets are constructed by interlacing or fusing wires to shape the basket. These containers are notable for their open metalwork design, providing a unique structure.

Wire baskets provide similar versatility to plastic baskets for organizing and decluttering spaces at home. They are frequently found in grocery stores as an eco-friendly replacement for plastic shopping baskets. Perfect for a range of items, wire baskets serve as robust and effective storage options.

In garages, they can often be hung on walls for storage. Unlike plastic bins, wire baskets have a more natural and elegant appearance. Similar to a transparent plastic container, wire baskets allow for easy visibility of stored contents.

Wire baskets generally lack lids, unlike many plastic storage options, making them excellent for holding frequently used items, such as sports equipment stored in garages.

Encouraging air circulation, wire baskets are perfect for drying slightly damp cleaning cloths. They come in various shapes and styles beyond the typical rectangles, including round, square, or oval designs, reminiscent of wicker baskets.

Some decorative baskets made from black metal are designed mainly as eye-catching home accents.

Compared to sheet metal baskets, wire baskets have lower tensile strength and weight capacity. However, they excel in managing open space, which improves airflow and drainage. This design accelerates drying and draining, reducing downtime between washing processes.

The generous open space of wire baskets facilitates efficient drainage, minimizing debris build-up. They often eliminate the need for additional wash processes. Open space is crucial in ultrasonic cleaning because it allows sound waves to penetrate effectively, providing thorough cleaning, unlike closed sheet metal baskets.

In heat treating applications, the airflow in wire baskets allows faster heating and cooling, improving efficiency and production speed.

Wire baskets use fewer materials, reducing costs, although welding individual joints can increase expenses by enhancing strength and stability.

Several crucial aspects need attention before forming a wire basket.

If challenges arise during production, they could compromise the basket's functionality. Here's a rundown of important factors in designing custom wire baskets.

The weight and size of items the basket holds are vital. Inadequately designed baskets may not support items effectively, compromising their utility.

Custom designs must account for the surface condition needs of the items stored. Delicate items needing protection require different handling than those where small surface abrasions are permissible.

Parts finishing processes often involve harsh chemicals. Thus, basket materials must withstand lengthy chemical exposure to ensure durability.

Temperature exposure affects coatings and metal alloys differently. High temperatures may weaken steel alloys, while low temperatures can cause brittleness. Prolonged exposure challenges coatings, so knowing the specific temperatures and exposure durations is critical for maintaining performance.

Often overlooked, the storage site's environment, such as exposure to sea air or airborne chemicals, can deteriorate a basket. Understanding air quality is essential for optimizing basket properties.

These considerations are crucial in designing custom wire baskets for material handling or parts washing.

Wire basket creation involves several steps:

Begin by measuring the intended space. For instance, a basket might be 20 x 16 inches with a 5-inch height.

Trim the cloth to the desired dimensions, marking and removing excess corners using a marker and tin snips for clean edges.

Bend the sides using a straight edge, such as a piece of wood. Use pliers to secure the structure, wrapping the wires to keep the corners in place securely.

In many industries, robust washing baskets and custom parts containers are necessary. Material selection is pivotal as it dictates the basket's durability and utility.

Let's explore commonly used materials in crafting wire baskets, ensuring they meet long-lasting operational standards while protecting sensitive items.

Plain steel offers an economical option for crafting, with excellent tensile strength and ease of shaping, but it’s less suitable for all applications.

Plain steel's main drawback is rusting easily if not treated. Continuous outdoor exposure accelerates corrosion. Moisture and salty air also contribute to rusting.

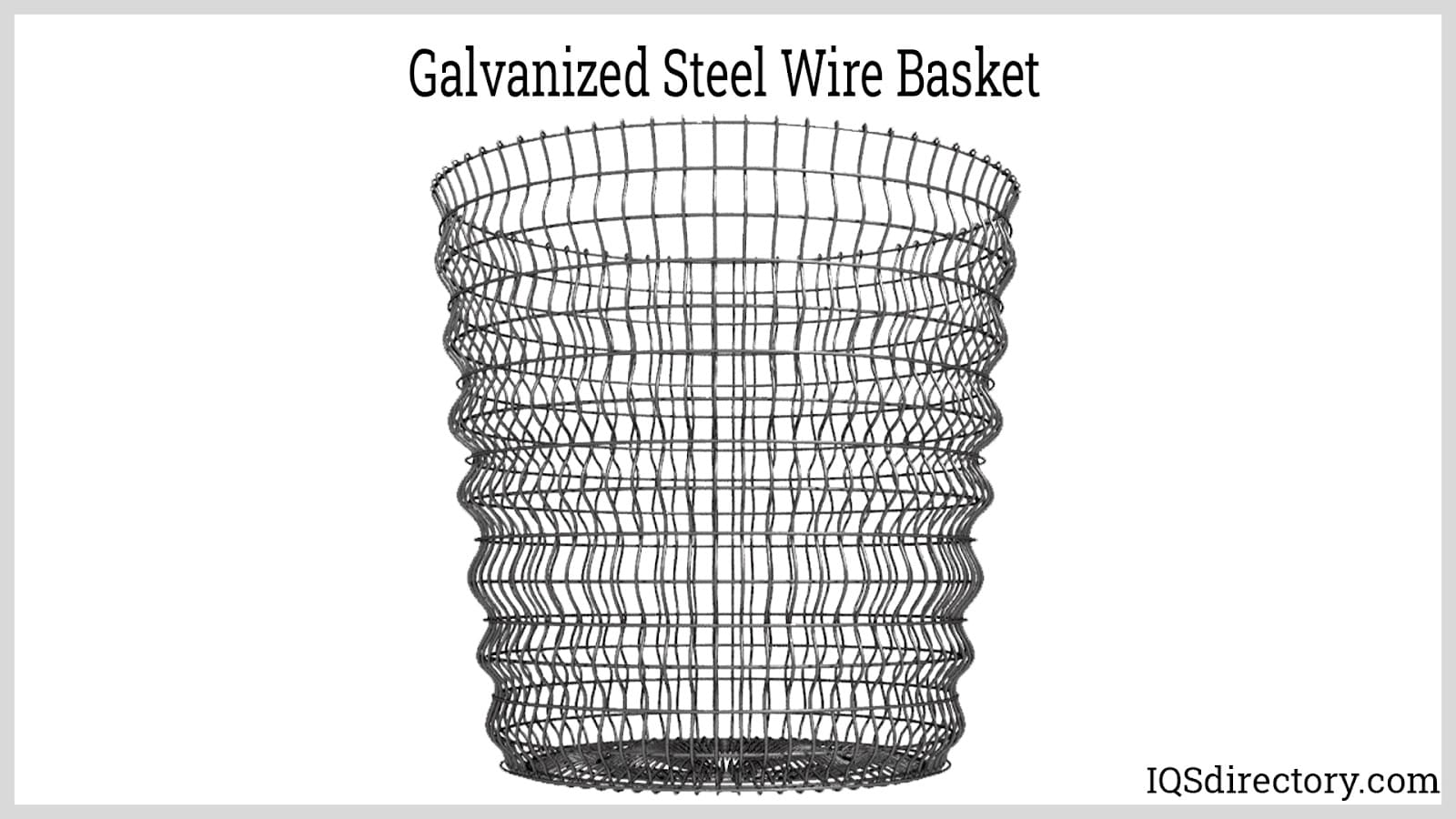

Galvanization, done by covering steel with zinc, enhances versatility.

Common methods include:

This involves immersing the steel in molten zinc.

Similar to electroplating, a thin zinc layer is applied.

Galvanization forms a zinc layer that shields steel from environmental harm, enhancing resistance to moisture and corrosive substances. However, welding can pose risks by releasing toxic zinc fumes. Ideal when corrosion resistance is prioritized.

Stainless steel is available in numerous grades, with 304 and 316 being prominent for their reliability.

These alloys offer outstanding resistance to rust, far outmatching plain steel. Despite differences, they share critical advantages such as:

The application suitability depends on the grade, with grades 304 and 316 being optimal for various uses, particularly those involving contact with corrosive conditions.

Inconel features various grades, akin to stainless steel. Inconel refers to nickel-chromium austenitic alloys noted for their excellent resistance to temperature and chemicals.

Tailored for high-pressure and high-temperature settings, Inconel withstands intense conditions, making it an ideal choice for demanding applications.

Wire baskets come in various types, each designed for specific purposes based on their intended use and location. These baskets are ideal for organizing and storing cutlery or household items. Typically made from steel, they offer corrosion resistance and the durability to support heavy items without collapsing. Below are some popular types of wire baskets frequently used in kitchens and other household settings.

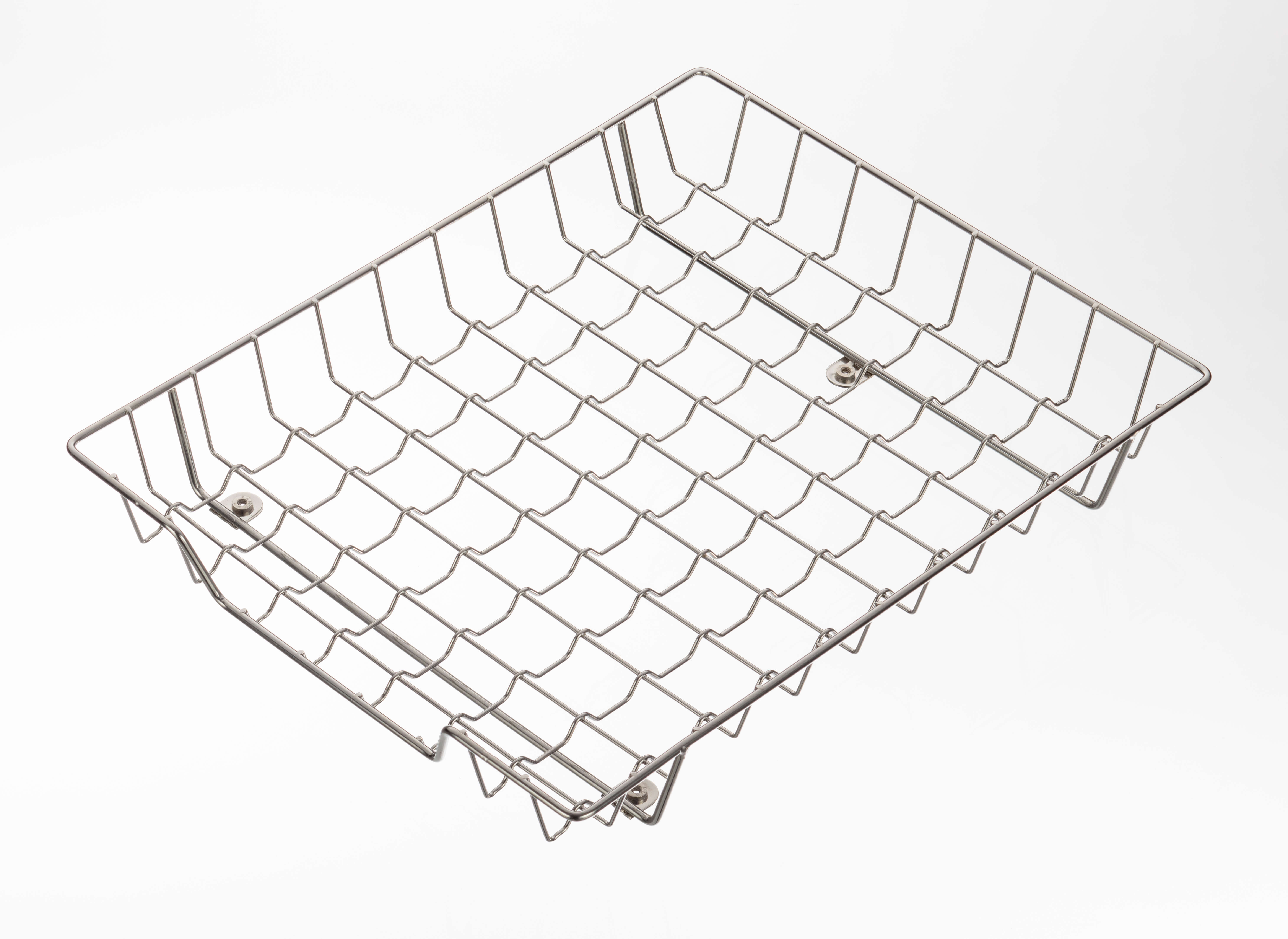

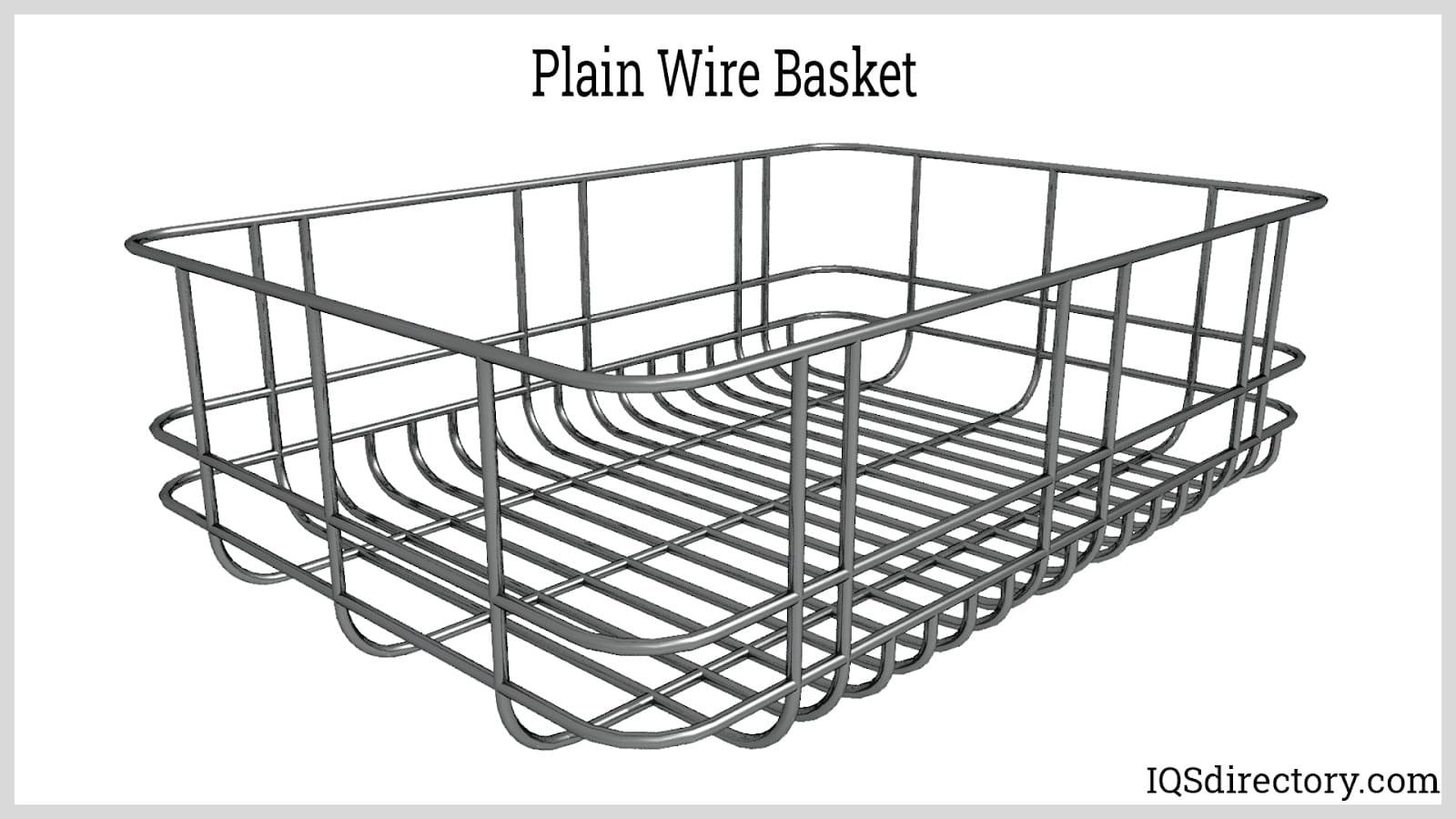

The plane wire basket is a popular choice in modular kitchens due to its ease of use and functionality. Made from densely woven steel wires, it forms a rectangular container that's both sturdy and versatile. These baskets are ideal for storing a variety of kitchen items, making organization simple and efficient.

These baskets are available in diverse shapes and sizes to meet various needs. They are cost-effective due to their simple manufacturing process and the ease of sourcing raw materials. Ideal for kitchen use, these sturdy baskets can handle heavy loads without issue. For even greater strength, thicker steel wire is used, enabling them to support the weight of the heaviest ceramic utensils.

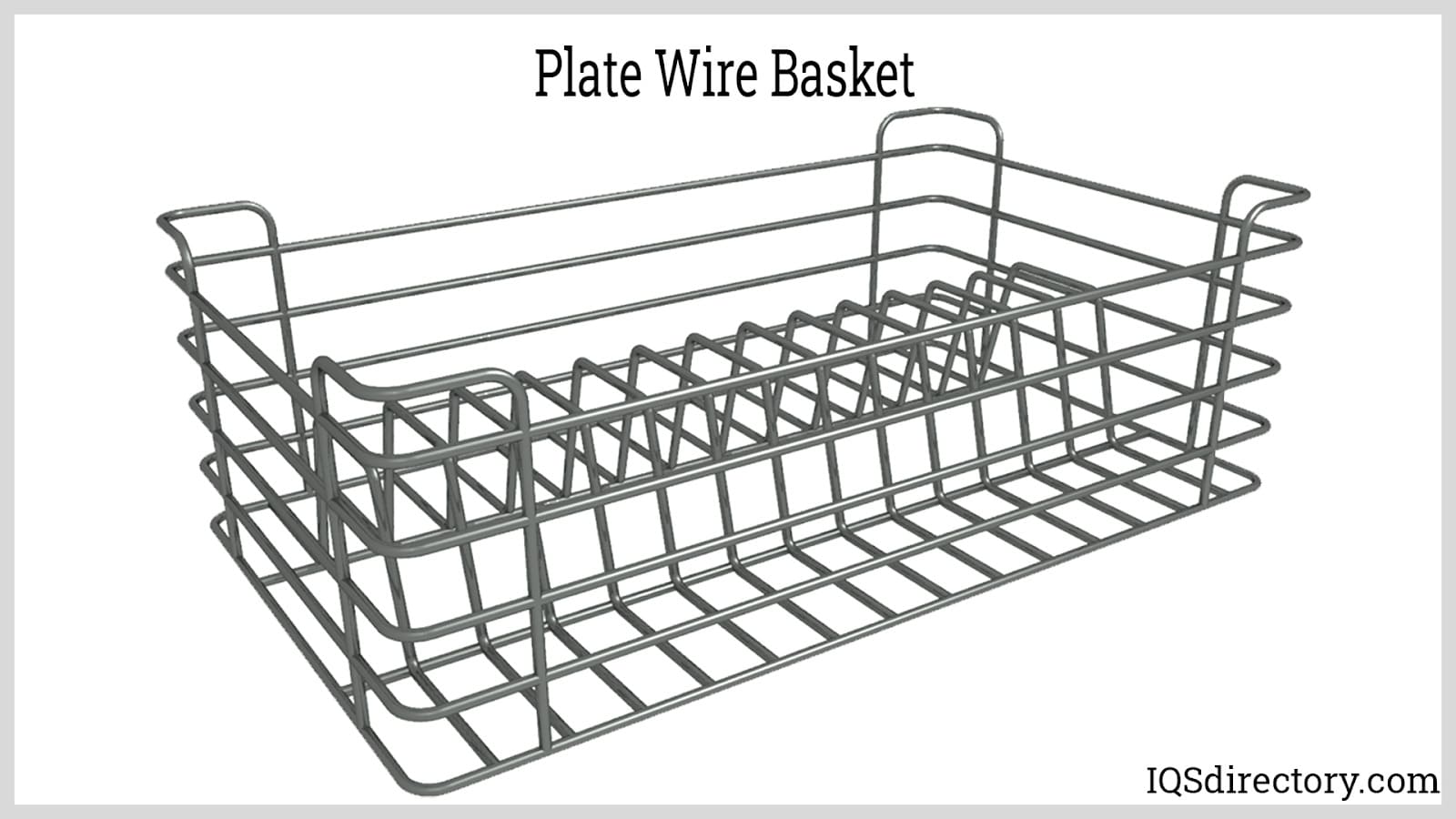

Plate baskets are widely used in countries such as India. These versatile baskets are ideal for serving meals and holding multiple items simultaneously. They also serve as organized storage solutions for kitchen utensils, making them a practical choice for both serving and organizing.

Due to the artistic design and nature of the basket, plate baskets are relatively expensive.

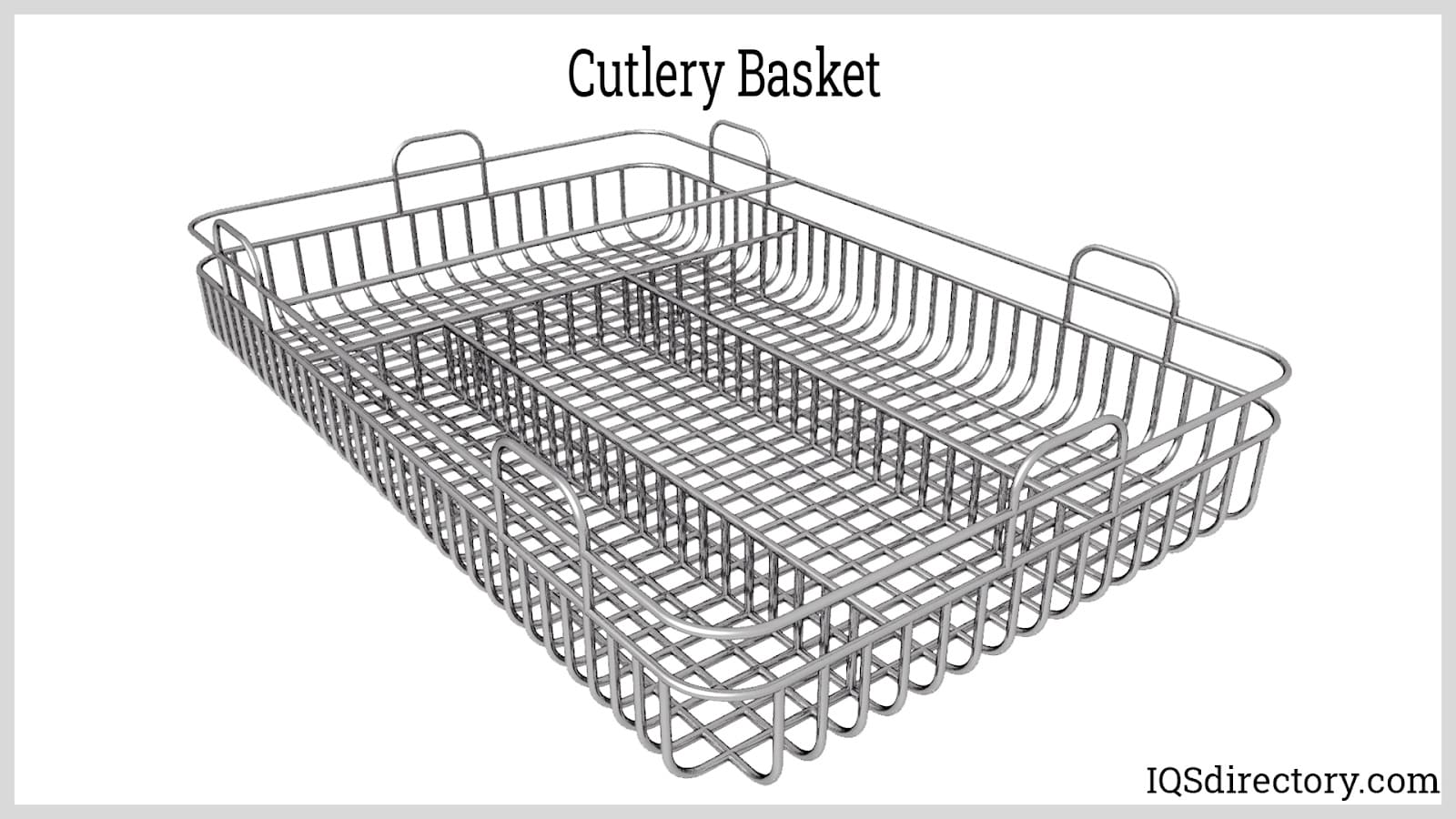

The cutlery baskets are crafted from a durable perforated sheet at their base, making them essential for holding small and delicate utensils such as forks, knives, and spoons. Many of these wire baskets feature molded compartments, which help organize and separate different types of kitchen items efficiently.

This versatile basket is highly functional due to its compartments, but its practical design often makes it relatively pricey on the market.

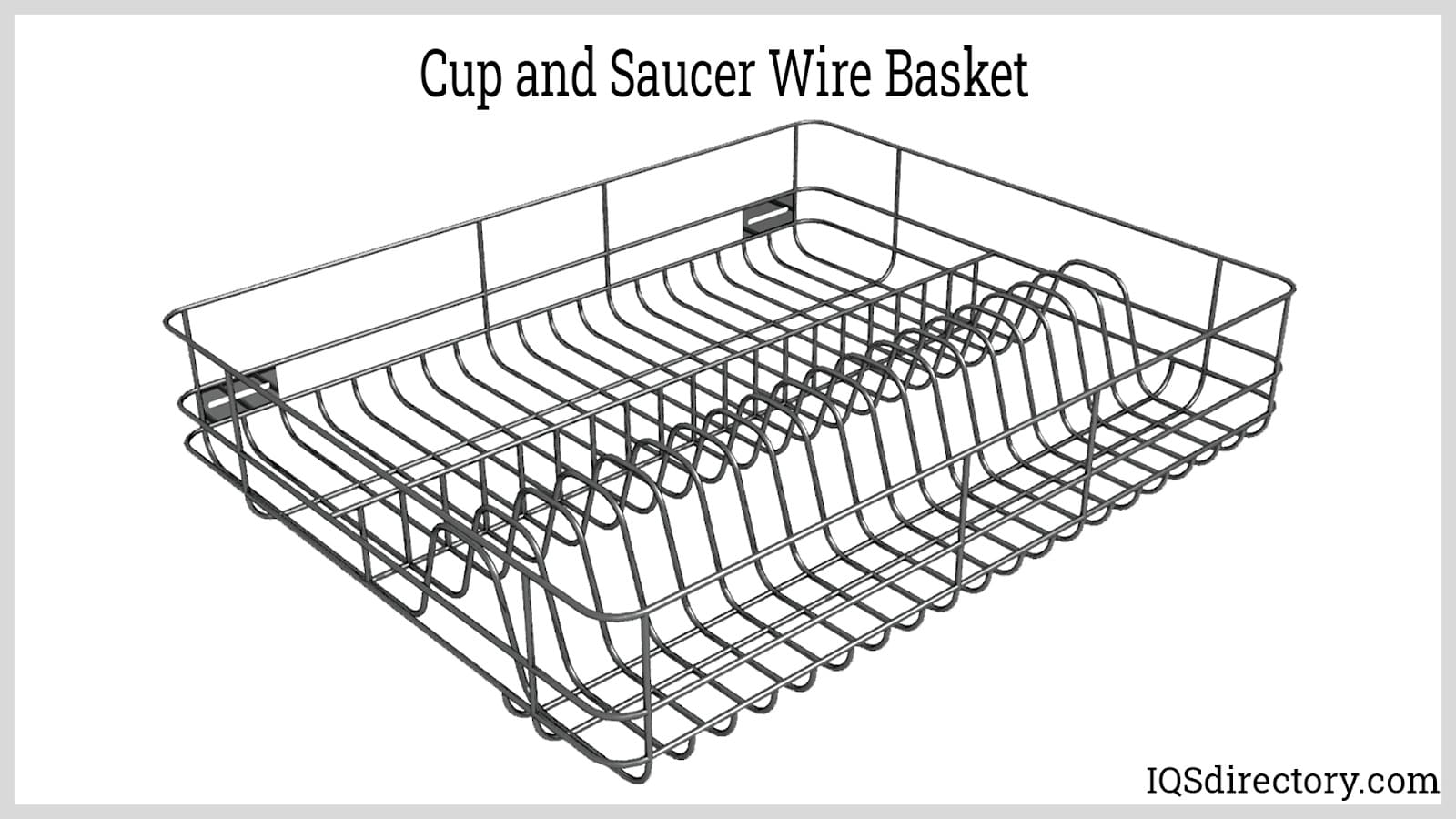

The cup and saucer basket, true to its name, is designed specifically for storing cups and saucers. It features separate compartments to keep cups and saucers organized and apart. Unlike a plain wire basket, this type of basket boasts a more artistic and refined design.

Compared to a plain wire basket, the cup and saucer basket is relatively more expensive.

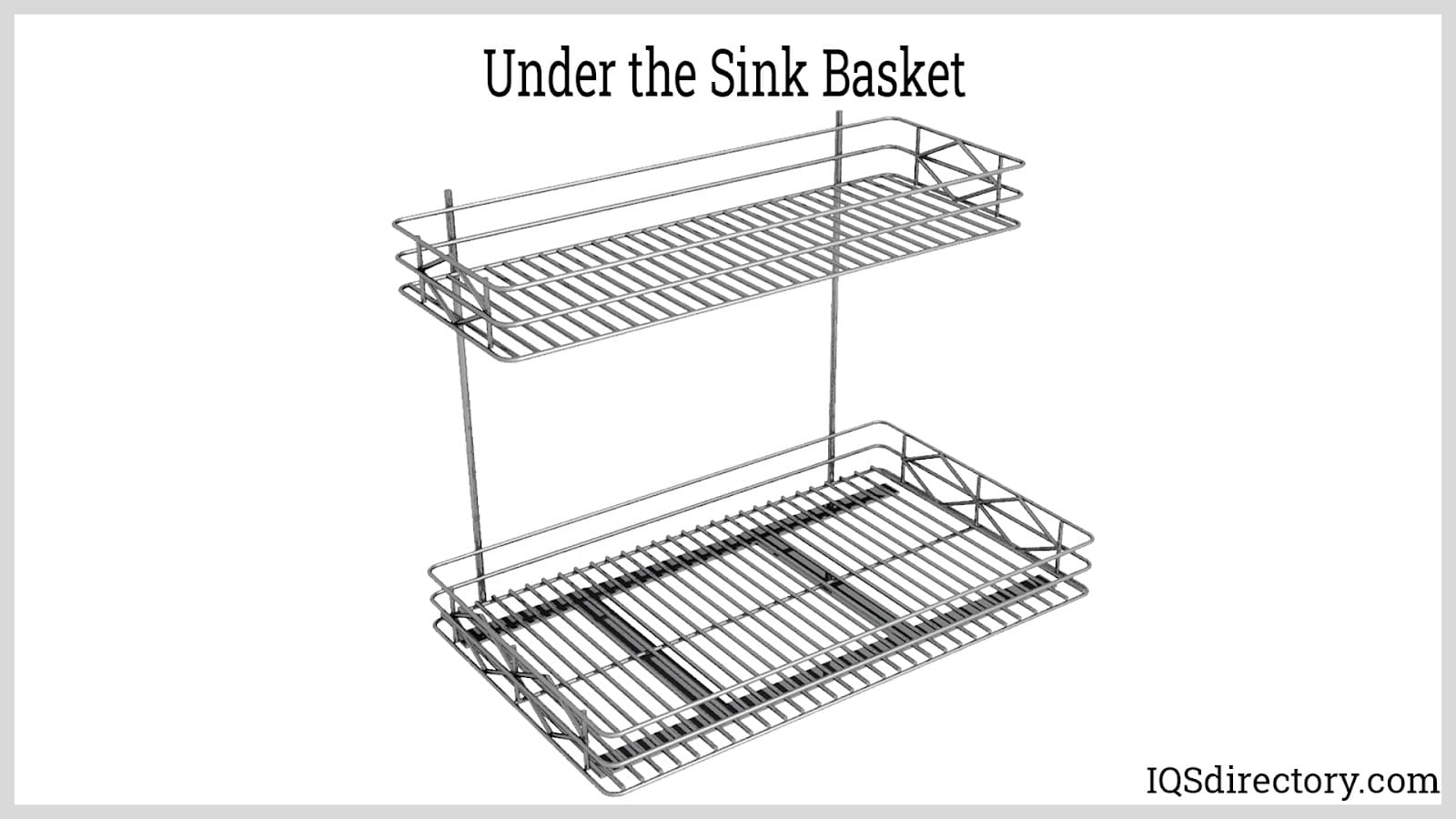

The under-sink basket is a storage solution designed to fit beneath the sink. It neatly holds cleaning supplies like soaps, pads, scrubs, and detergents, keeping them organized and out of sight. This basket helps maintain a tidy and clutter-free appearance in your kitchen or bathroom.

This type of basket is typically painted or coated with a protective material to guard the steel against corrosion in its intended environment. Due to the additional coating, this wire basket tends to be relatively more expensive.

The dish draining basket is an essential kitchen tool, designed to efficiently drain utensils while protecting wooden surfaces from damage. It features a base tray that collects any dripping water, keeping your countertop clean and dry.

Once the utensils are dry, they can be removed and arranged in their designated spots. The dish draining basket is lightweight and features plastic compartments, making it unsuitable for carrying heavy items. Exceeding its weight limit could lead to potential damage or failure.

The bin basket plays a crucial role in maintaining a clean kitchen or household. It can be discreetly placed under or behind furniture, keeping waste and unwanted items contained. These wire baskets can be easily emptied when full, helping to keep the kitchen hygienic and prevent unpleasant odors from spreading.

The bin basket features a gauze-like metal sheet with tiny perforations and a fully enclosed metal or plastic base. Compared to other wire baskets, bin baskets are relatively more expensive.

Wire baskets aren't just for the kitchen—they're also used in various other settings. They're found in surgeries, shopping baskets, and food containment units, showcasing their versatility beyond the kitchen.

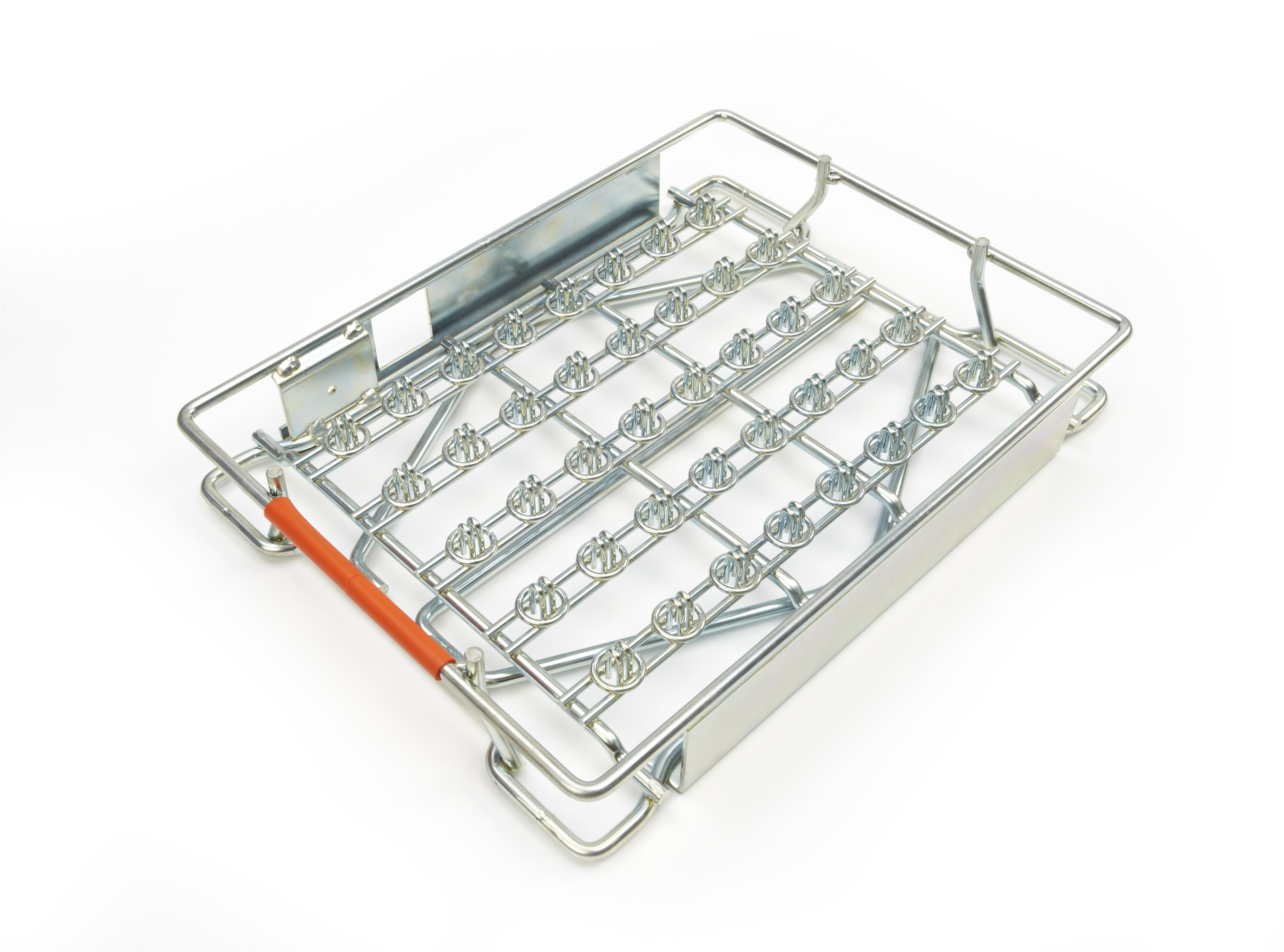

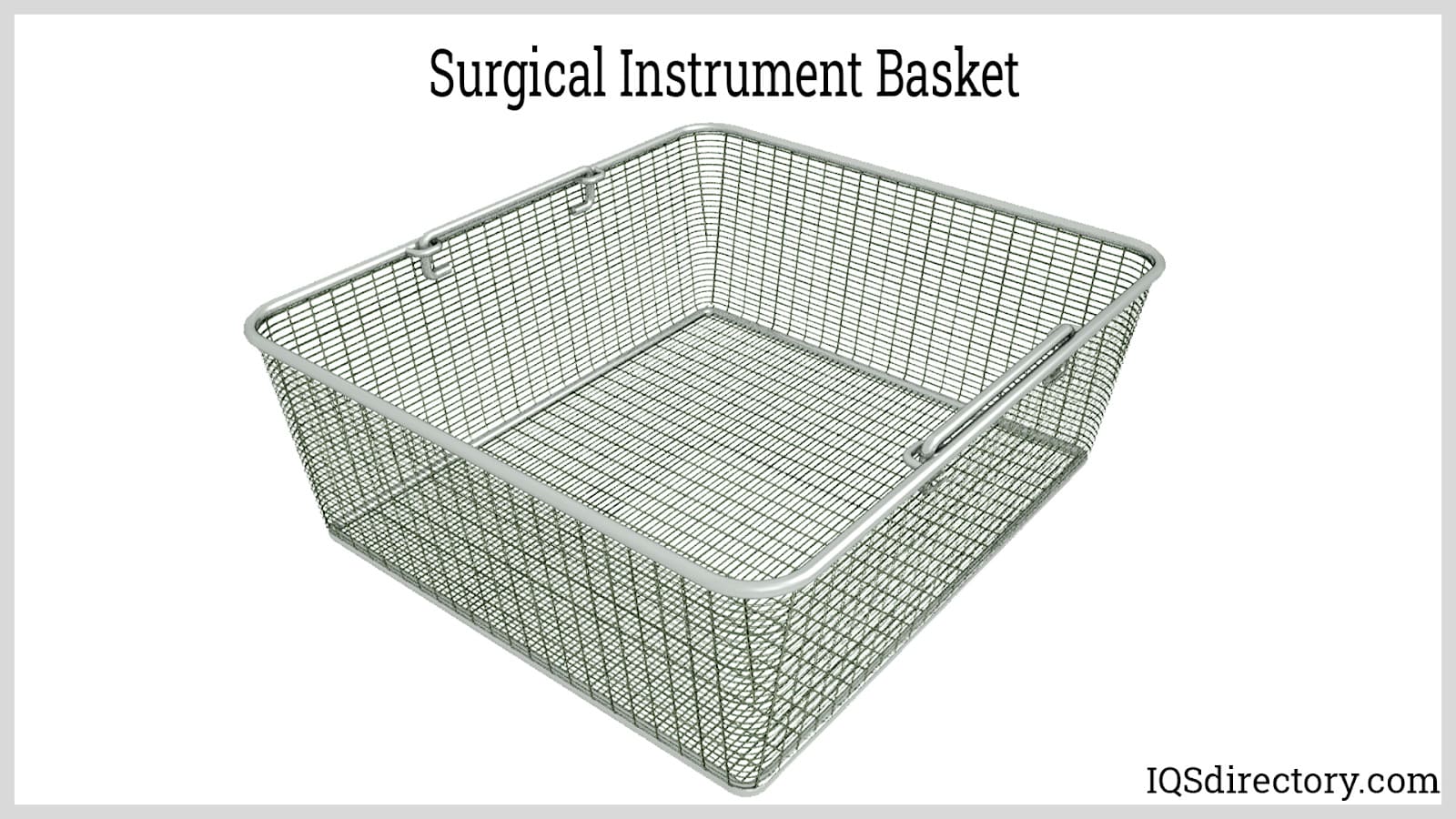

These trays feature a distinctive rectangular design with a fine wire mesh that has very small openings. They are specifically designed for cleaning and sterilizing tiny instruments. The small openings ensure that no instruments can fall through the basket.

Smaller, finer mesh baskets with tiny apertures are designed for sterilizing delicate and sharp instruments. They help prevent cuts and ensure that small, intricate tools are safely managed without risk of loss.

Wire shopping baskets are commonly used in supermarkets to handle multiple items, especially those that are difficult to carry, such as frozen goods. These baskets are ideal for customers who need to transport a variety of products easily.

These shopping baskets are crafted from a mesh of woven steel wires, designed to support heavy loads while remaining relatively lightweight when empty.

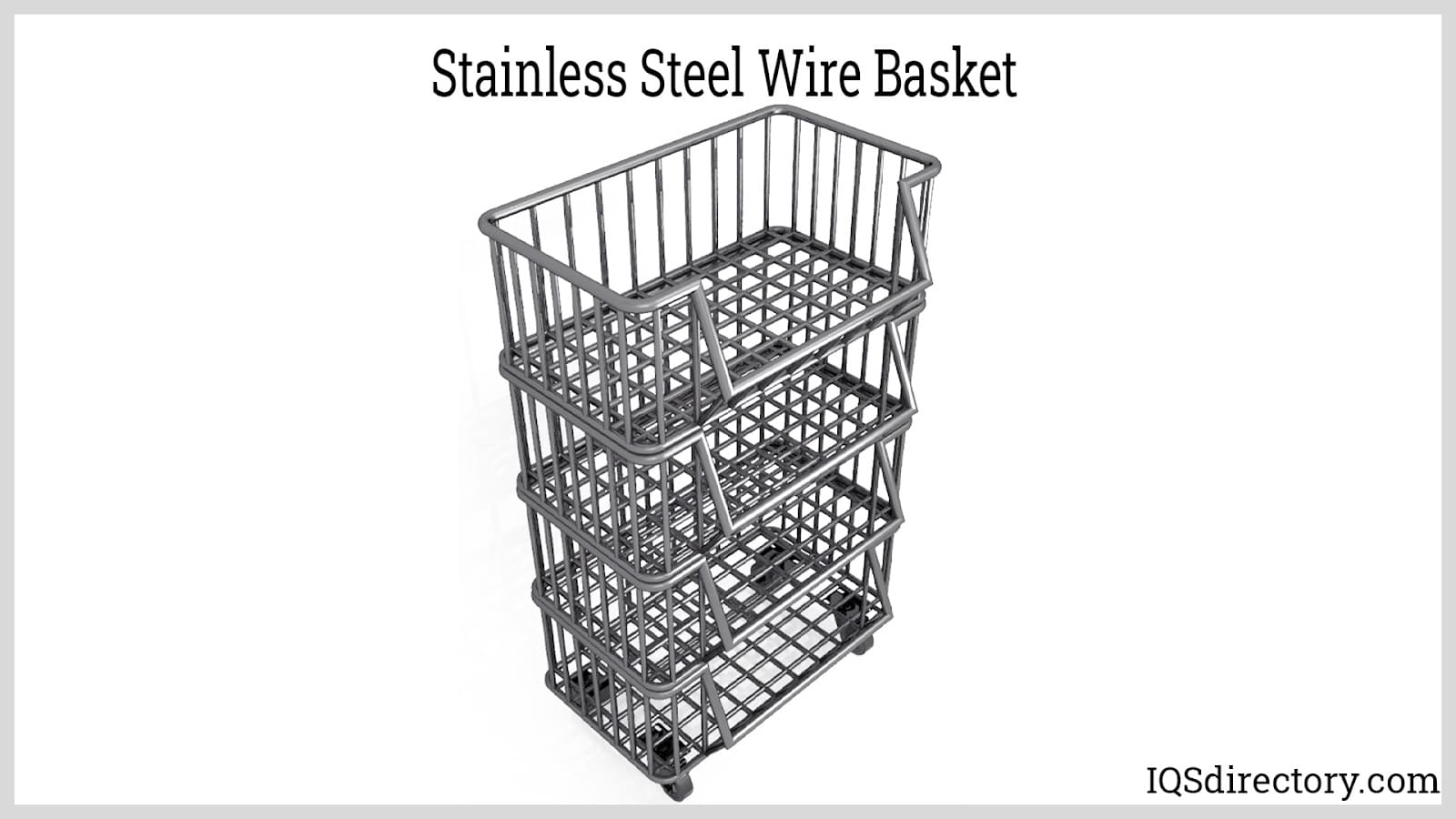

These wire baskets are crafted from stainless steel and feature either a high-quality vinyl coating or chrome wire plating. Designed to keep items neatly organized in one place, they help prevent clutter and maintain order.

This basket features a robust, dense mesh that enhances its strength and holding capacity. It securely accommodates garage tools or various equipment, regardless of their weight, shape, or size.

The wire baskets mentioned above represent some of the most commonly used types and their applications. However, this chapter only covers a few examples, and many other less common wire baskets are also available.

This chapter will explore the various applications and advantages of wire baskets.

Wire baskets are versatile tools used frequently in our daily lives. Their common applications include:

Wire baskets are commonly used in many households for organizing and storing items. In garages or sheds, they help keep small tools and equipment neatly contained and easily accessible. For example, they can hold car or machinery tools in one convenient location. In the kitchen, wire baskets are versatile, used for storing utensils, dishes, cups, or even food items. Additionally, some wire baskets are adapted to function as drying racks for washed kitchenware.

Wire baskets are frequently used to carry multiple items simultaneously. In shopping malls and supermarkets, customers use them to transport various products before checkout, thanks to their strength and ability to hold heavy loads securely. Additionally, wire baskets are sometimes custom-designed for bicycles, providing a practical solution for cyclists who need to transport items. These baskets can be easily strapped to bikes, offering a convenient and durable carriage option.

Wire baskets are essential in healthcare settings for the sanitary cleaning of surgical instruments. Their porous design facilitates effective washing, allowing detergents to flow through and thoroughly cleanse the instruments inside.

Certain equipment requires heating to very high temperatures. Wire baskets, which have high melting points, are used as containers for objects needing heat treatment. They are commonly utilized for degreasing car parts or cleaning instruments in heated environments.

In home environments, wire baskets are often used for various purposes. Some are specifically designed as frying baskets for restaurants or high-volume kitchens due to their high heat resistance and excellent storage capabilities. Additionally, wire baskets are useful for storing food items before they are prepared or served.

Wire baskets are employed to organize and transport various goods and products. In shipping operations, these baskets help manage and arrange items efficiently during transit.

Wire baskets are utilized in agriculture for storing a variety of farm produce. In certain cases, they also serve as sieving tools.

Wire baskets have become incredibly useful in our daily lives due to their many advantages. In the shipping industry, they simplify inventory management by making it easy to move and organize items. The wire mesh allows for clear visibility of products, so it's simple to identify and locate items without having to open sealed boxes or containers. This visibility saves time and eliminates the guesswork of searching through packed boxes.

Wire baskets are also popular in food processing and home use due to their ease of reuse and cleaning. They are particularly useful for washing food items like potatoes, as their design allows dirt and water to flow through, making the cleaning process efficient and effective.

Wire baskets are also a cost-effective choice because the materials used in their manufacture are relatively inexpensive compared to wooden racks, which can deteriorate over time. Wire baskets are durable and resistant to weight and corrosion, making them a long-lasting solution.

Despite their many benefits, wire baskets do have some drawbacks. They are not suitable for transporting confidential items or small goods. For instance, it would be unprofessional for a security company to use wire baskets for transporting money to a bank, and they are not practical for displaying small products in malls and supermarkets.

If not used properly, wire baskets can lead to loss of contents through the gaps in their weave. Cargo bay loaders must ensure that items placed in wire baskets are secure and won't fall through the openings during transport. Additionally, the exposed nature of wire baskets makes the contents vulnerable to damage from fire, water, or theft. Unlike sealed containers, wire baskets provide no protection against these risks, making it easier for items to be stolen or damaged.

Organizing wire baskets can be challenging, especially when they vary in shape and size. Their rigid structure means they cannot be compressed to save space. Additionally, their metal construction adds extra weight to the cargo, which can be a significant issue in the transportation industry. This additional weight can complicate logistics and lead to unexpected expenses.

In summation, wire baskets are containers made from woven wires that can also be used in place of plastic baskets and are used to store or organize materials in both household and commercial lines of work. Wire baskets make working easier as they organize the materials in such a way as to save time going through the various materials.

Wire shaping is a complex method that encompasses a wide range of dimensions, forms, and textures. The technique of creating a usable product by wire bending and shaping is known as custom wire forms...

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration...

A wire handle is attached to a bucket, pail, or other type of container to make it easy to lift the container and transport it. They are made of durable and sturdy metals capable of lifting several pounds...

A wire rack is a level wire form utilized to stock and exhibit a number of products, usually retail. The bottom surface on which such goods are stored is made of several latticed or interlaced metal strands...

Wire mesh is fabricated by the intertwining, weaving, or welding of wires of various thicknesses to create proportionally equal parallel rows and intersecting columns. Also known as wire fabric, wire cloth, or...

A coil spring is an elastic element made of metal or heavy plastic in the form of curls or ringlets of round wire or cord that is wrapped around a cylinder. The winding of a coil spring can be loose or tight in a helical shape depending on the application for which it is made...

Coil springs called compression springs can store mechanical energy when they are compressed. These open-coiled, helical springs provide resistance to compressive loading. When these springs are...

Contract manufacturing is a business model in which a company hires a contract manufacturer to produce its products or components of its products. It is a strategic action widely adopted by companies to save extensive resources and...

Extension springs are helical wound springs that are so closely coiled together to create initial tension in the coils. This initial tension creates resistance against the force applied to its ends for extension. The initial tension helps determine how closely and...

Hardware cloth is a woven mesh made by interlacing various sizes of wire to form a metal fabric that can be used for animal cages, fence material, strainers, and filtering screens. The differences between the various types of hardware cloth...

The phrase "wire mesh" describes two- or three-dimensional structures constructed of two or more metallic wires connected by various techniques. In a wide range of settings, wire mesh products are...

Springs are a flexible machine element that store mechanical energy when subjected to tensile, compressive, bending, or torsional forces. When the spring is deflected, it stores energy and at the same time exerts an opposing force...

A torsion spring is a mechanical device that stores and releases rotational energy. Each end of the torsion spring is connected to a mechanical component. As the spring is rotated around its axis on one end, the winding of the spring is tightened and stores potential energy...

Welded wire mesh is a series of wires that are welded where the individual wires cross. The openings of the mesh varies depending on the type of wire used and the function of the mesh. Regardless of size and wire, welded wire mesh is permanent and...

Wire cloth is a woven (or nonwoven) sheet or web material with a series of openings across the surface. Wire cloth is also known as: Metal Fabric or Metal Cloth; Wire Mesh, Metal Mesh, or Alloy Mesh...