Wire Baskets

Wire baskets are made from a series of wires that are woven together or welded to form a shape of a basket. They can also be defined as containers that are made by use of an openwork pattern of metal...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

The content of this article contains everything you will need to know about wire handles and bucket handles.

You will learn:

A wire handle made of metal is attached to buckets, pails, and similar types of containers to aid in lifting and carrying. These handles are composed of strong and durable metals capable of bearing considerable weight. Engineered to support the container's load, wire handles improve the ease, simplicity, and effectiveness of moving and transporting a variety of containers.

Wire handles are crafted from selected materials to ensure exceptional strength, longevity, and a long service life. They find usage in diverse applications, including lifting pots in ecologically sensitive areas, managing tools, moving baskets with wire mesh filled with parts, and in the canning industry for maneuvering sizable cans during painting and coating procedures. The construction of these handles can vary depending on the materials employed, which may consist of wood, metal, plastic, rubber, or other specialized types.

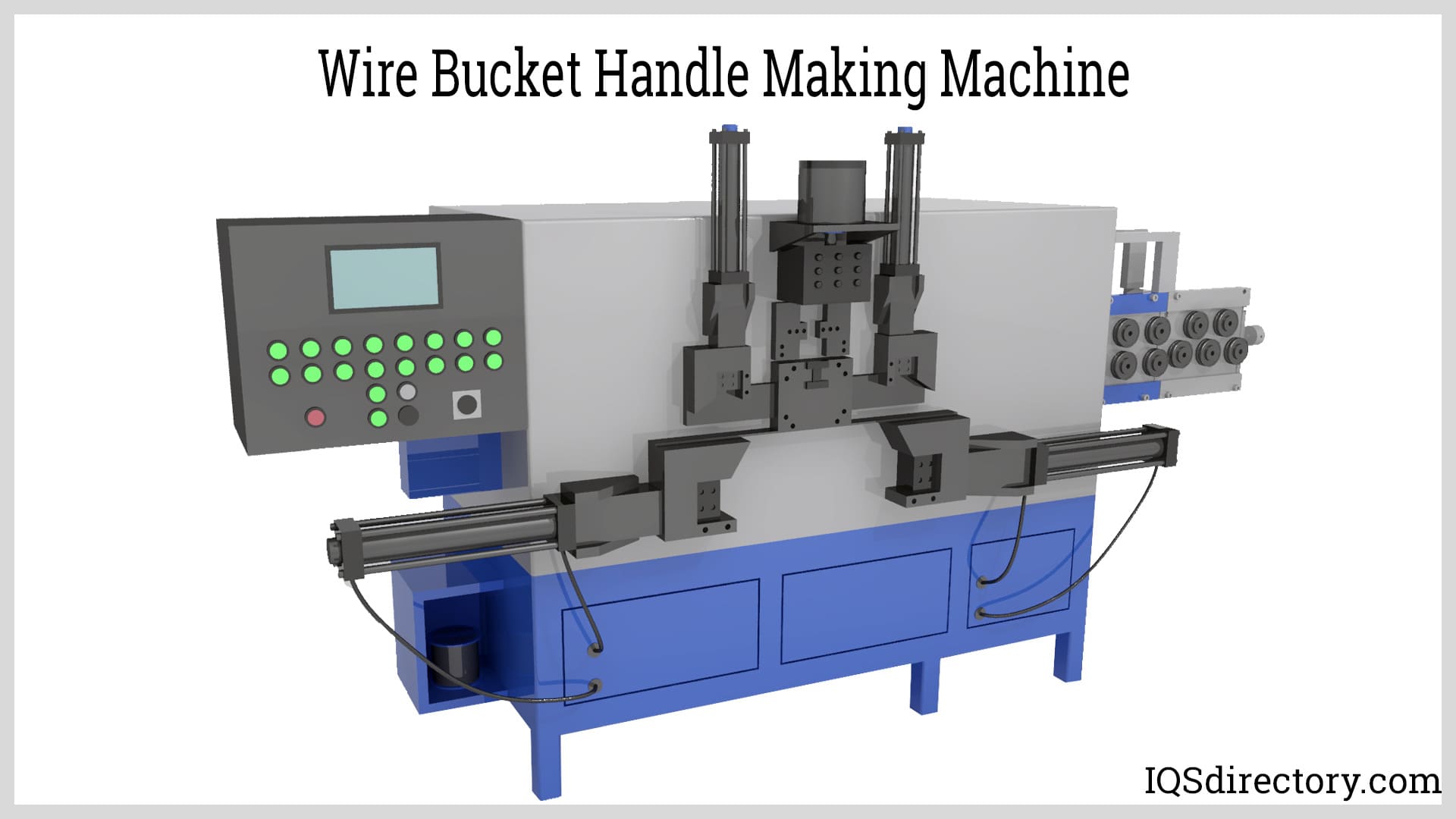

Manufacturing wire handles involves wire forming, a technique that uses various machinery and compressive forces, including CNC (computer numeric control) equipment. This method, which has been employed for centuries, is utilized to produce a diverse range of tools and decorative objects. While the core principles of wire forming remain consistent, the process includes drawing the wire to the required length and then bending and shaping it to achieve the intended design.

In addition to various alloys, traditional metals like stainless steel, steel, aluminum, copper, and nickel are employed in wire forming based on the specific needs of the handle being produced. The properties of these metals affect both the forming process and the final attributes of the handle.

All these metals can withstand the stresses involved in bending, shaping, and forming during the wire forming process. The selection of a specific metal depends on factors such as the handle type, the kind of bucket or container, and the load it needs to support. Additionally, in some cases, the appearance of the metal might also be a consideration in the selection process.

Wire forming, like many manufacturing techniques, involves a range of methods rather than a single approach. Central to all these processes is bending, where the wire is shaped at different angles. For more intricate handles or complex designs, the wire often undergoes multiple shaping steps to achieve the final form.

In wire forming, regardless of the specific technique used, force is applied to the wire by deforming it through compression along its length, or axial direction. Different methods may involve applying force both parallel to and perpendicular to the wire's length, as well as at various angles, depending on the handle's design requirements.

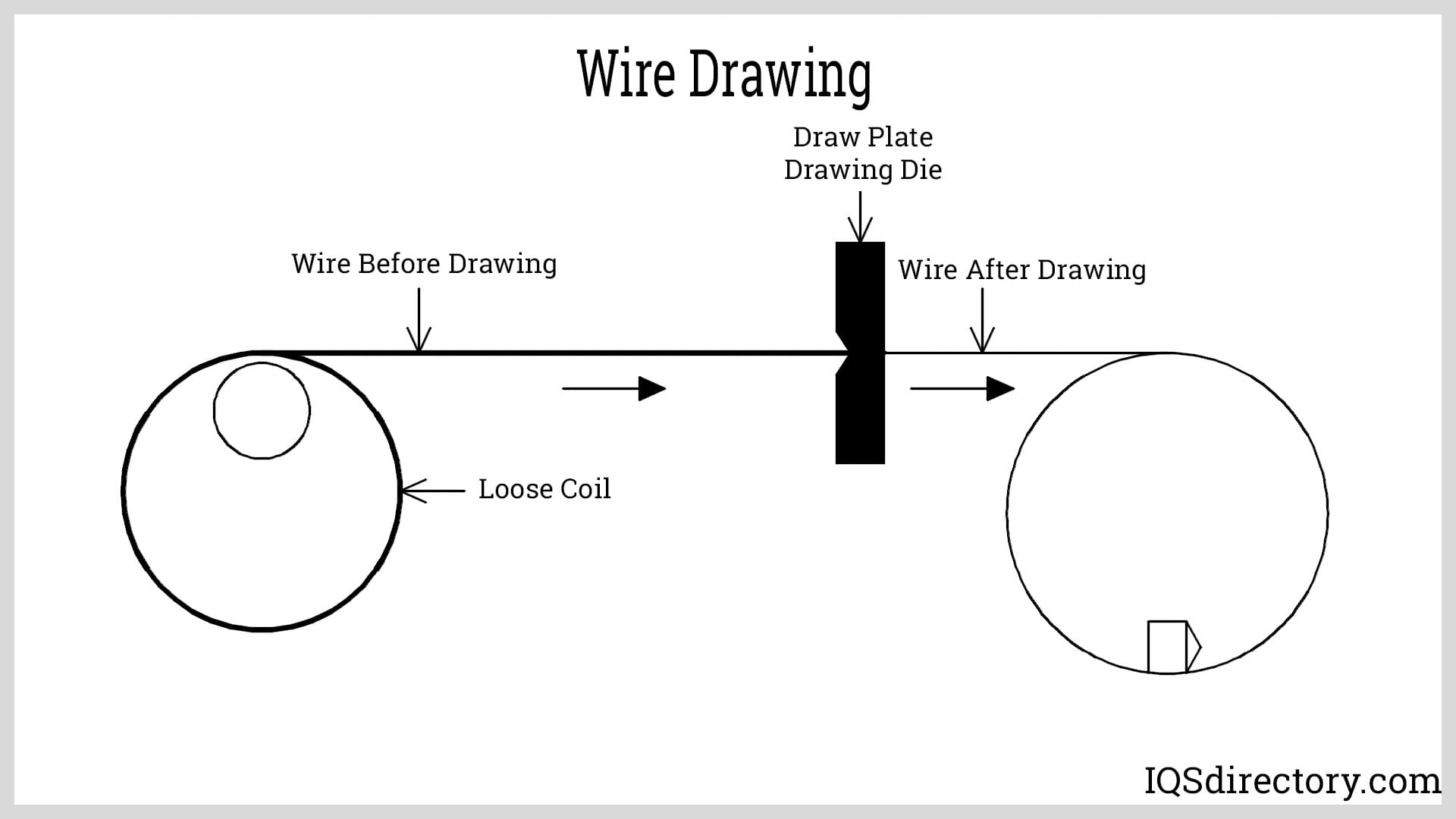

Prior to shaping and forming wire into handles, it undergoes a drawing process where it is pushed through and then pulled out of a die. This step is essential for adjusting the wire's thickness to the required diameter for forming. The drawing process allows for the creation of various diameters without needing to stock multiple wire sizes.

The drawing die is typically a drawplate attached to a device, featuring an opening with the desired diameter. As the wire's initial diameter is larger than the drawplate's opening, the end of the wire must be tapered to fit. This tapering can be achieved through simple methods such as hammering or using a rolling mill.

To enhance the wire's ductility, it undergoes annealing and pickling to eliminate oxidation. This treatment helps prevent breakage during the drawing process. Additionally, friction is minimized by applying substances like beeswax, paraffin, or lubricant. After these preparatory steps, the wire is ready to be drawn through the dieplate.

The wire is fed into the back of the drawplate through a hole slightly smaller than the tapered end's diameter. As the wire progresses through the drawplate, a tool attached to the tapered end pulls it at a steady, constant rate. Maintaining a uniform pulling speed is crucial for achieving a consistent diameter throughout the wire.

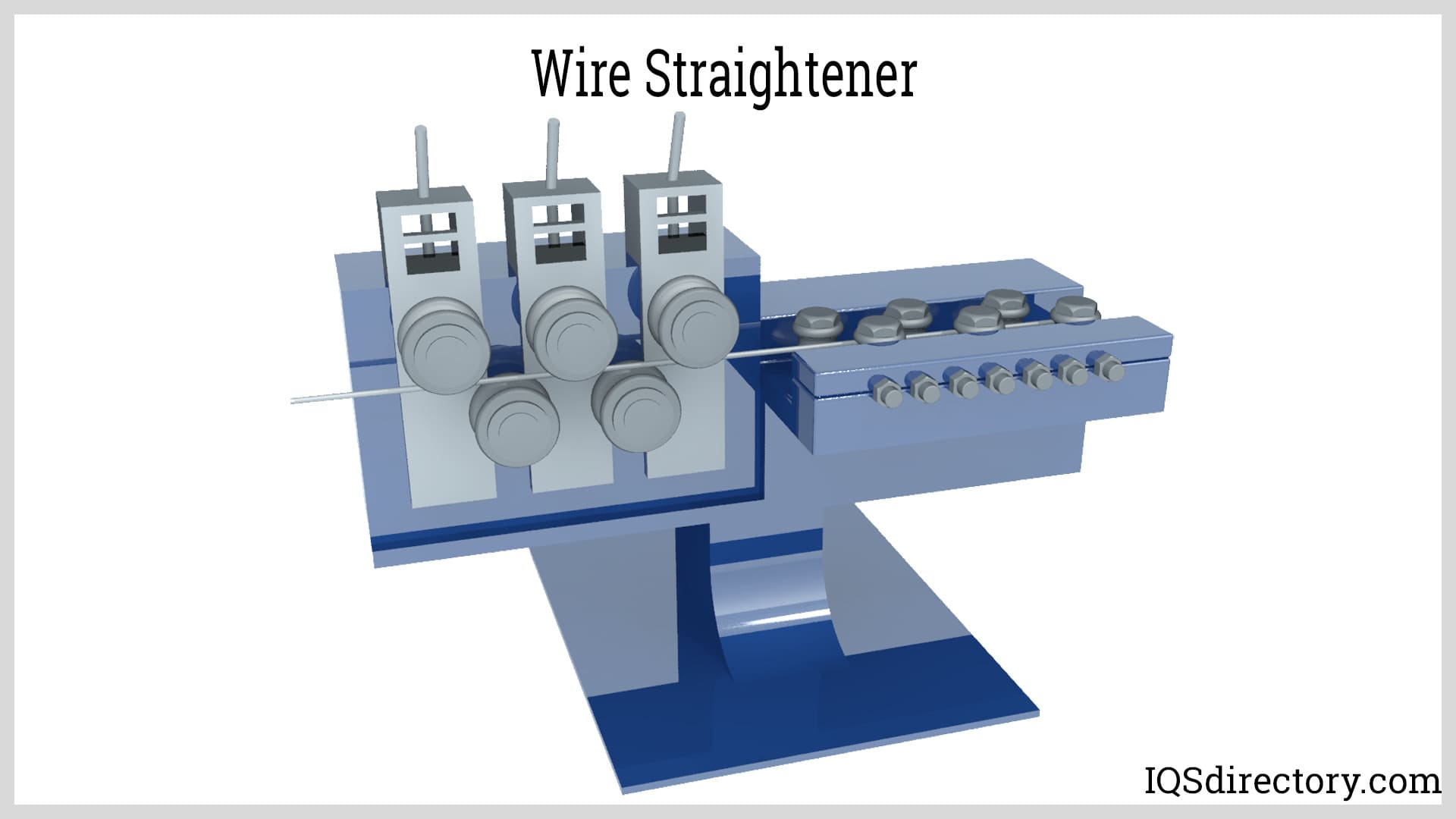

Wire straightening aims to correct any distortions, imperfections, or deformities caused during the drawing process. This is achieved using a wire straightening machine, which features a series of adjustable rollers designed to align the wire according to its diameter. The straightening process facilitates the forming and shaping of the wire into handles and eliminates any kinks.

Wire that has been stored for long periods often becomes warped and stressed, requiring straightening. Straightening machines adjust the wire by flexing it in various directions to alleviate the residual stress caused by its curvature.

The shaping and forming process entails applying force to the prepared wire to alter its contour and achieve the desired handle shape and various configurations. While manual shaping is possible, it is more commonly accomplished using dies and cutting machinery to ensure precision and consistency.

The type of force applied during the shaping process depends on the handle's requirements and can include twisting, stamping, bending, swaging, extrusion, and upsetting. Among these methods, upsetting specifically involves compressing the wire along its length to refine its shape.

While bending is the most frequently used technique for forming wire handles, other methods are also crucial for achieving the desired strength and shape. The wire undergoes a series of operations and treatments during the shaping process to produce the final handle with the necessary design, configuration, and properties.

Four-slide wire handle forming offers an alternative to traditional power presses that work in a single direction. This method enables the creation of complex and varied shapes by shaping the wire from four different directions. It is particularly well-suited for high-volume production of wire handles, as it allows for rapid and efficient bending of wire into various handle designs.

A four-slide wire handle forming machine operates with four fixed-position slides arranged in a square around a central forming mandrel or tool. Additional slides can be incorporated for functions such as cutting, feeding, and other specific tasks. The slides are moved by four shafts on the machine's exterior, which are powered by bevel gears. The wire handle's shape is defined by a shaping tool attached to each slide, which cuts and molds the wire into the desired handle form.

Typically, the metals used for making wire handles are durable enough to endure the stresses encountered during use. However, depending on the handle’s application, additional finishing coatings may be applied to enhance their longevity. These coatings are especially important for handles exposed to acidic, caustic substances, or harsh industrial environments. The finishing process can involve dipping or spraying, depending on the manufacturing requirements. Some metals are more receptive to coatings and are chosen specifically for this property.

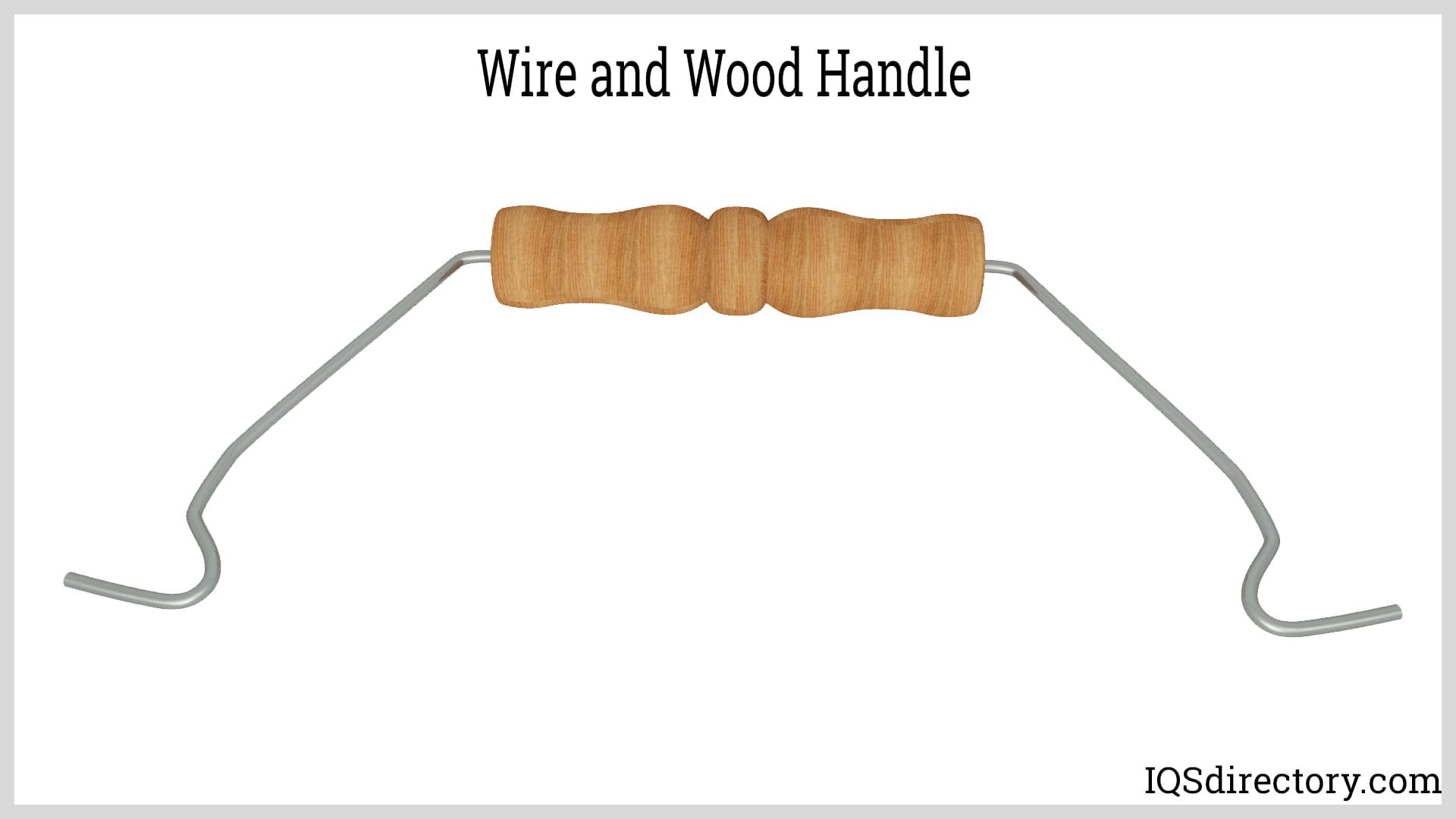

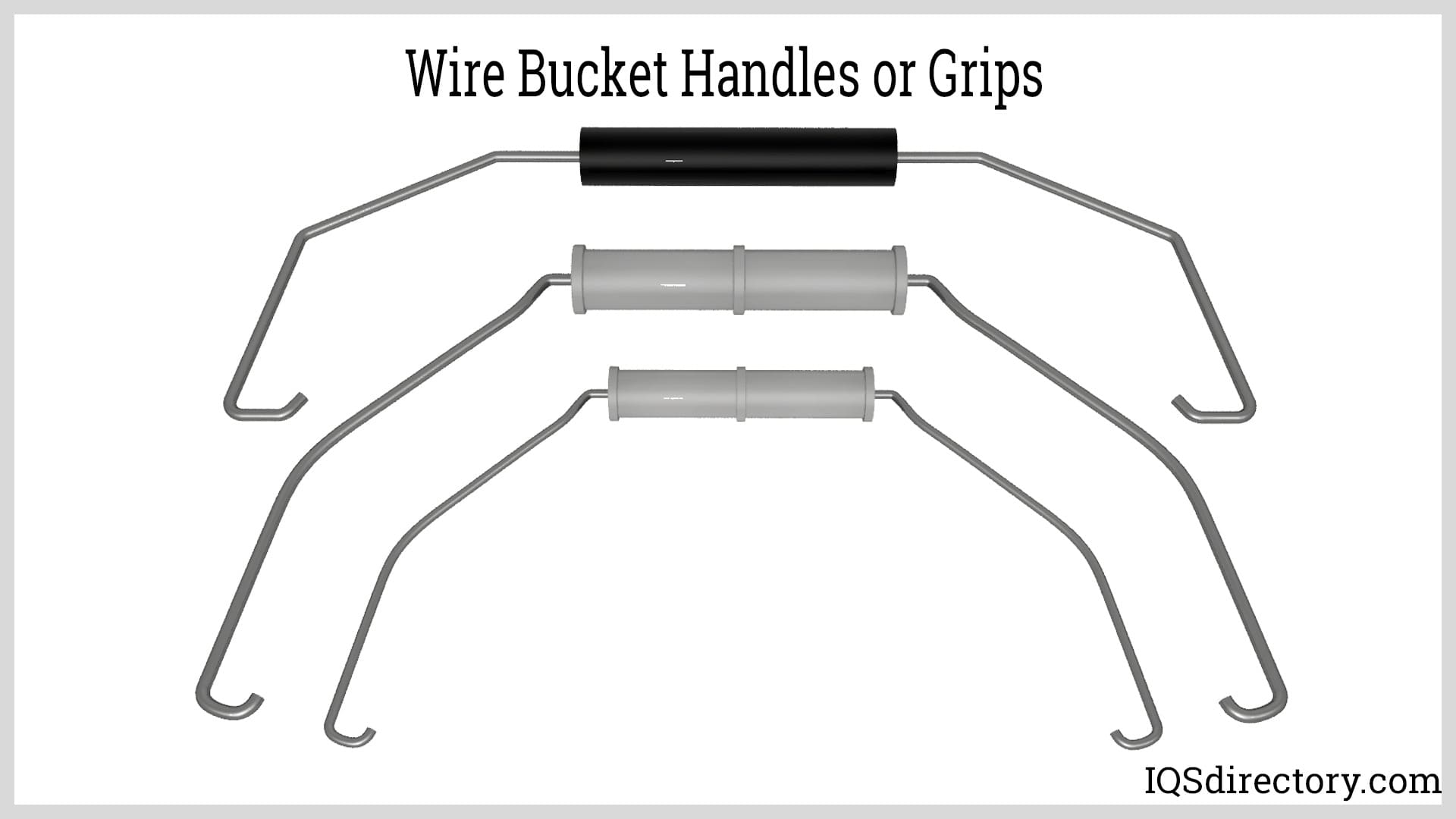

Not all wire handles incorporate grips, but when they are used, they are typically applied during the bending process. As the wire is straightened and fed from a reel into the die, the grip is positioned at the top of the die. The wire is then pushed through the center of the grip. Solid grips are attached to the wire handle as the machine exerts force and bends the wire into its final shape.

The materials for wire handle grips range from lightweight plastics for less demanding uses to robust materials for construction, manufacturing, and industrial settings. Regardless of material, all grips generally share a cylindrical shape with a central hole to facilitate attachment to the wire handle. Common materials for these grips include wood, plastic, and rubber.

Wire handles are affixed to buckets or pails to facilitate their transport along with their contents. The handle must be capable of supporting the load, depending on the material inside the bucket. Selecting the appropriate wire is crucial to meet the demands of the load it will bear. In industrial and construction settings, handles need to be robust, resilient, and constructed from wire that can withstand tough conditions.

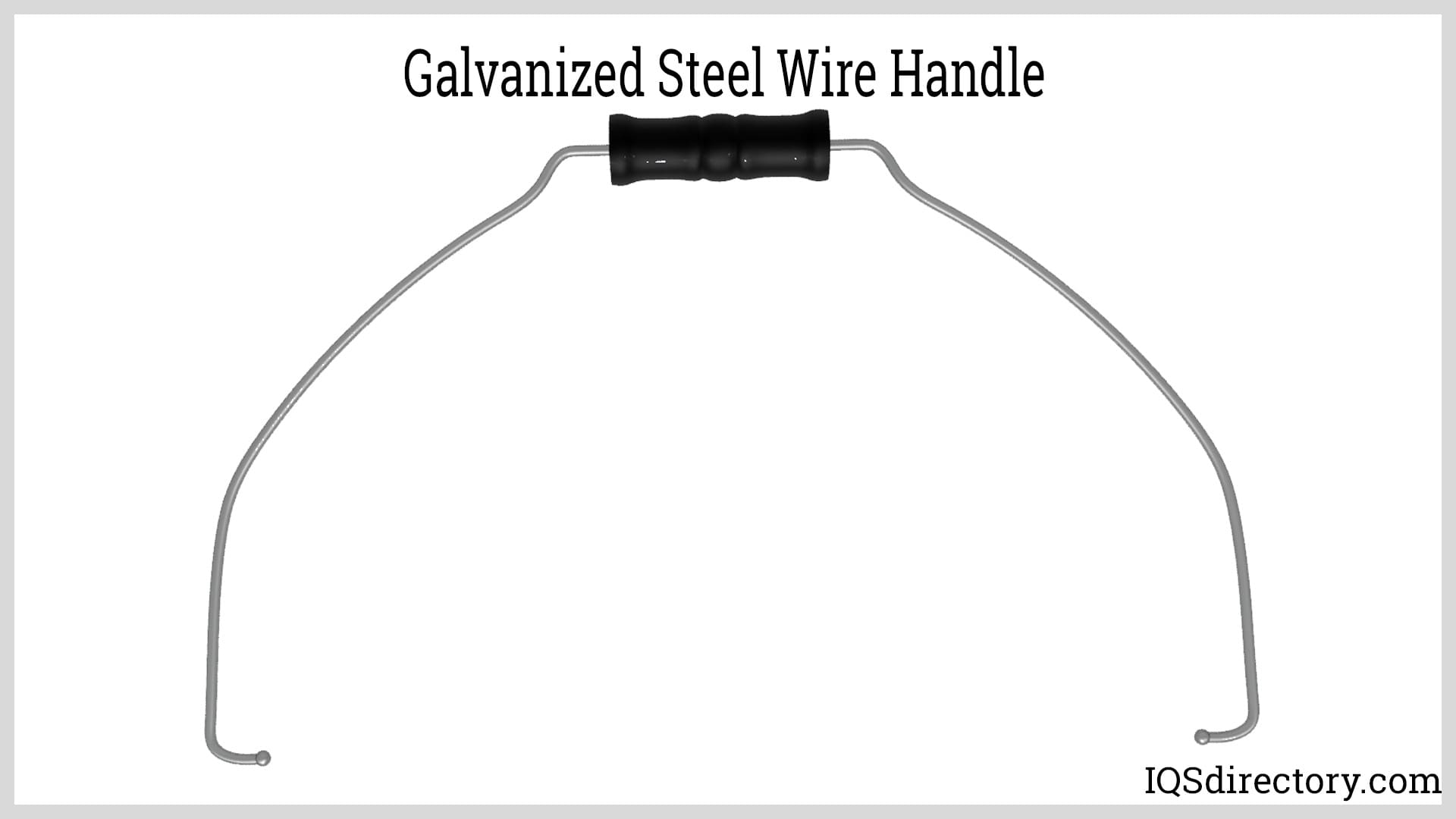

Among the different types of wire used for making wire handles, galvanized steel is a top choice due to its rust resistance, durability, strength, and long-lasting performance. Galvanization, the process used to apply a zinc coating to iron or steel, involves various techniques to ensure an even and effective coating. These methods help protect the wire from corrosion and extend its lifespan.

Hot dipping is a widely used galvanization method where the wire undergoes several steps to apply a zinc coating. Initially, the wire is cleaned to remove dirt, grease, and other contaminants using a caustic solution, which is then rinsed off. Next, the wire is pickled in an acidic solution for further cleaning, followed by another rinse. To ensure proper adhesion of the zinc, the wire is treated with a flux before being immersed in molten zinc. The wire remains in the zinc bath until it reaches the same temperature as the bath.

Galvanized iron wire, similar to galvanized steel wire but made from iron, benefits from a zinc coating that shields it from rust and corrosion while leveraging the strength of iron. Its popularity in manufacturing wire handles stems from its malleability, allowing it to be easily shaped and formed into various handle designs. Regardless of the specific manufacturing process, galvanized iron wire can be cut, shaped, bent, and formed to suit different handle applications. Its key advantage is durability, as once installed on a bucket or pail, it remains securely in place without requiring frequent adjustments or replacements.

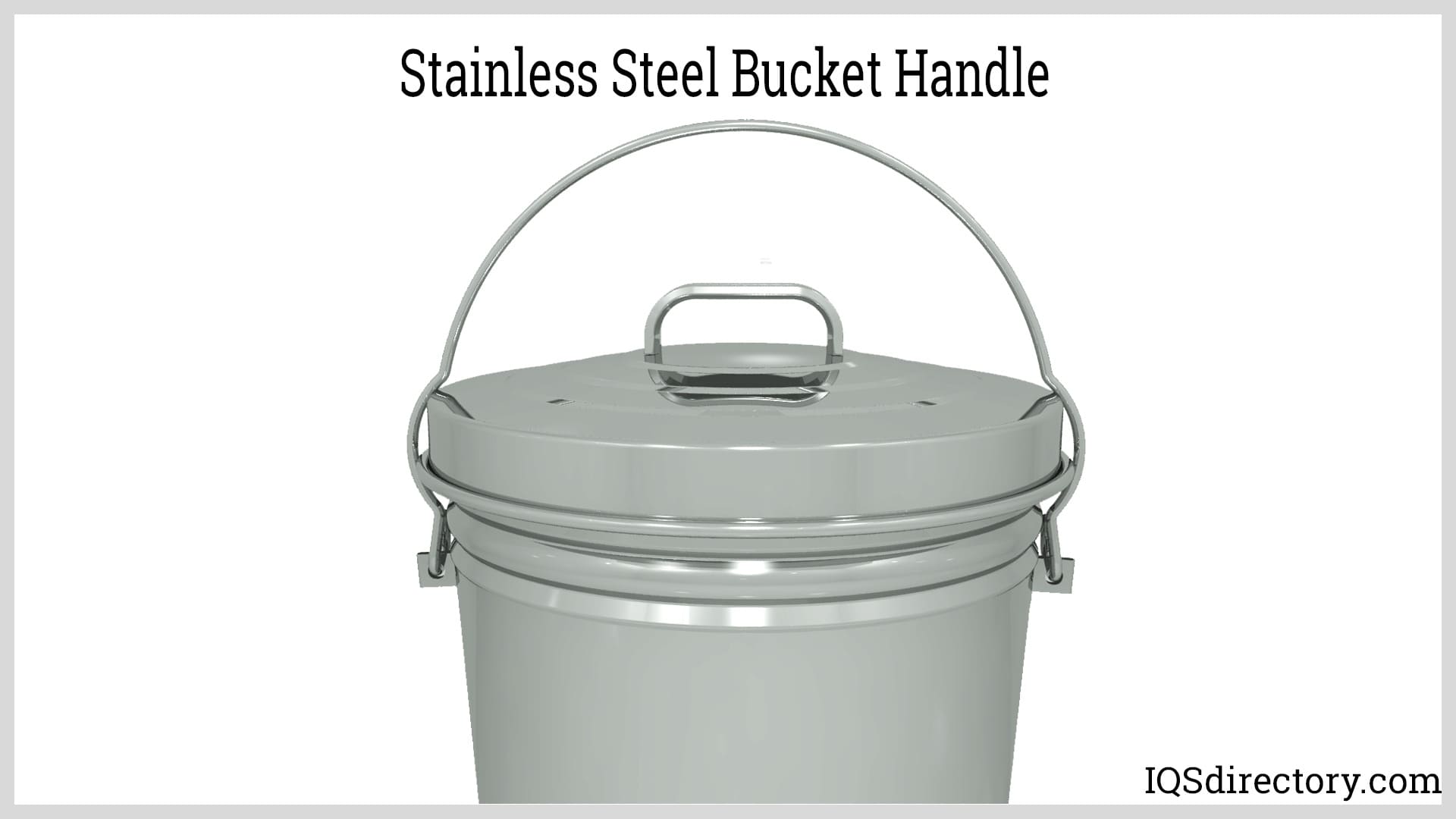

Stainless steel handles are commonly paired with stainless steel buckets or pails. Among the various metal options, stainless steel stands out for its resilience and is available in numerous alloys, each tailored for specific environments and conditions. The processes for bending and shaping stainless steel handles are similar to those used for other wire handle types.

Stainless steel offers a smooth, visually appealing surface, which contributes to its use in buckets and handles. The even texture of stainless steel makes handles comfortable to grip and use. Depending on the industry, stainless steel handles may be designed with or without additional grips to suit specific needs.

Series 304 and 316L are the most frequently used stainless steel grades for manufacturing bucket handles, known for their versatility and popularity. Stainless steel grade 304, often referred to as 18/8, is an austenitic steel that can be extensively drawn to create bucket and pail handles. Grade 316L, another austenitic stainless steel, includes molybdenum, enhancing its corrosion resistance and making it suitable for challenging environments.

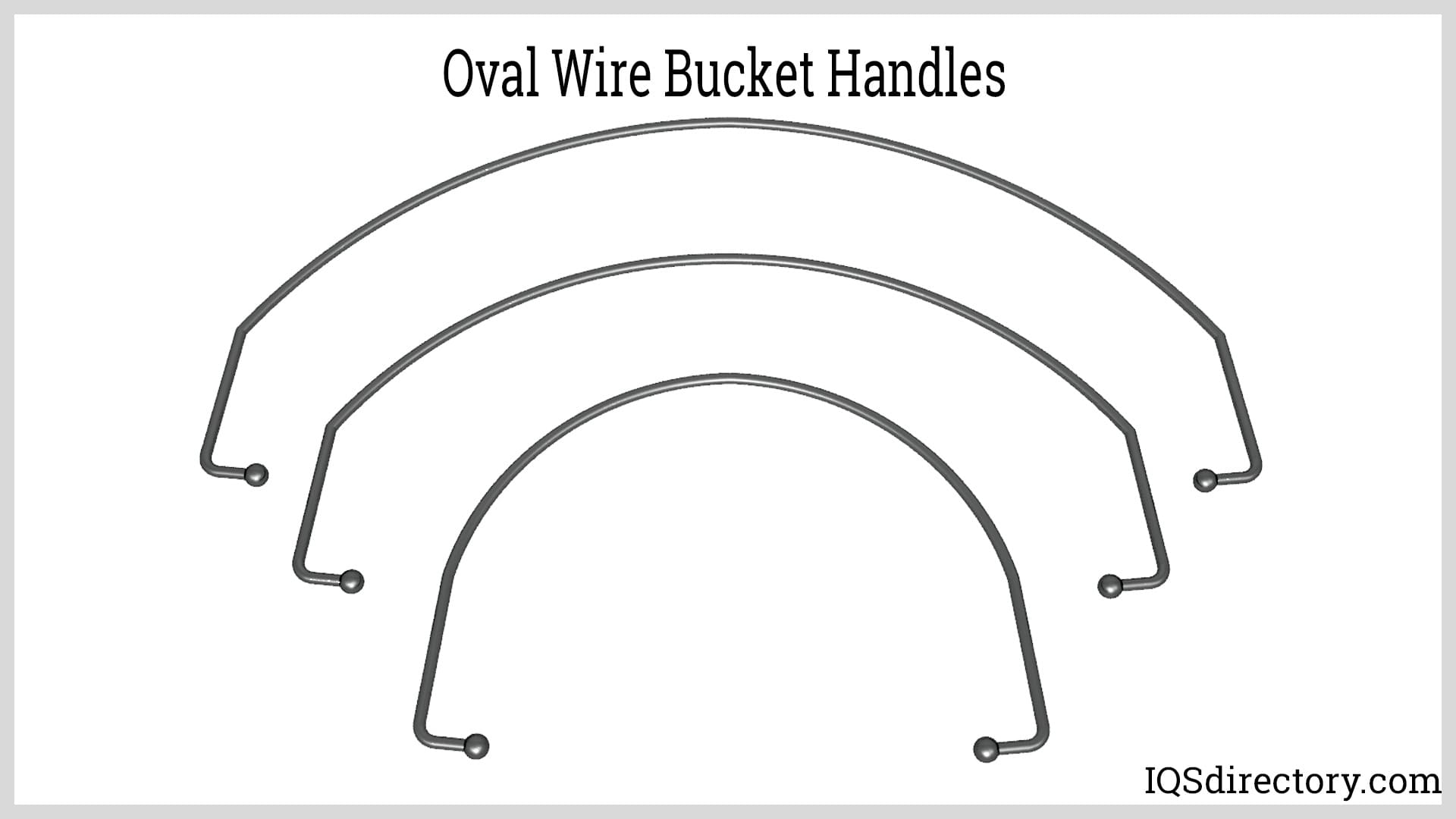

Wire handles come in an extensive array of shapes, sizes, and designs, tailored to match the diverse range of buckets and pails. Despite their straightforward design, wire handles must be specifically crafted to accommodate the bucket's or pail's capacity, as they support the load's weight. Different handle shapes are designed to ensure they can handle heavy and bulky materials effectively.

The type of wire handle used depends on the bucket or pail it is intended for. Plastic buckets, which are generally less durable, typically feature lighter wire handles suitable for handling lighter loads. In contrast, metal buckets, designed for more demanding tasks, require wire handles made from various materials and diameters to support heavier loads and withstand tougher conditions.

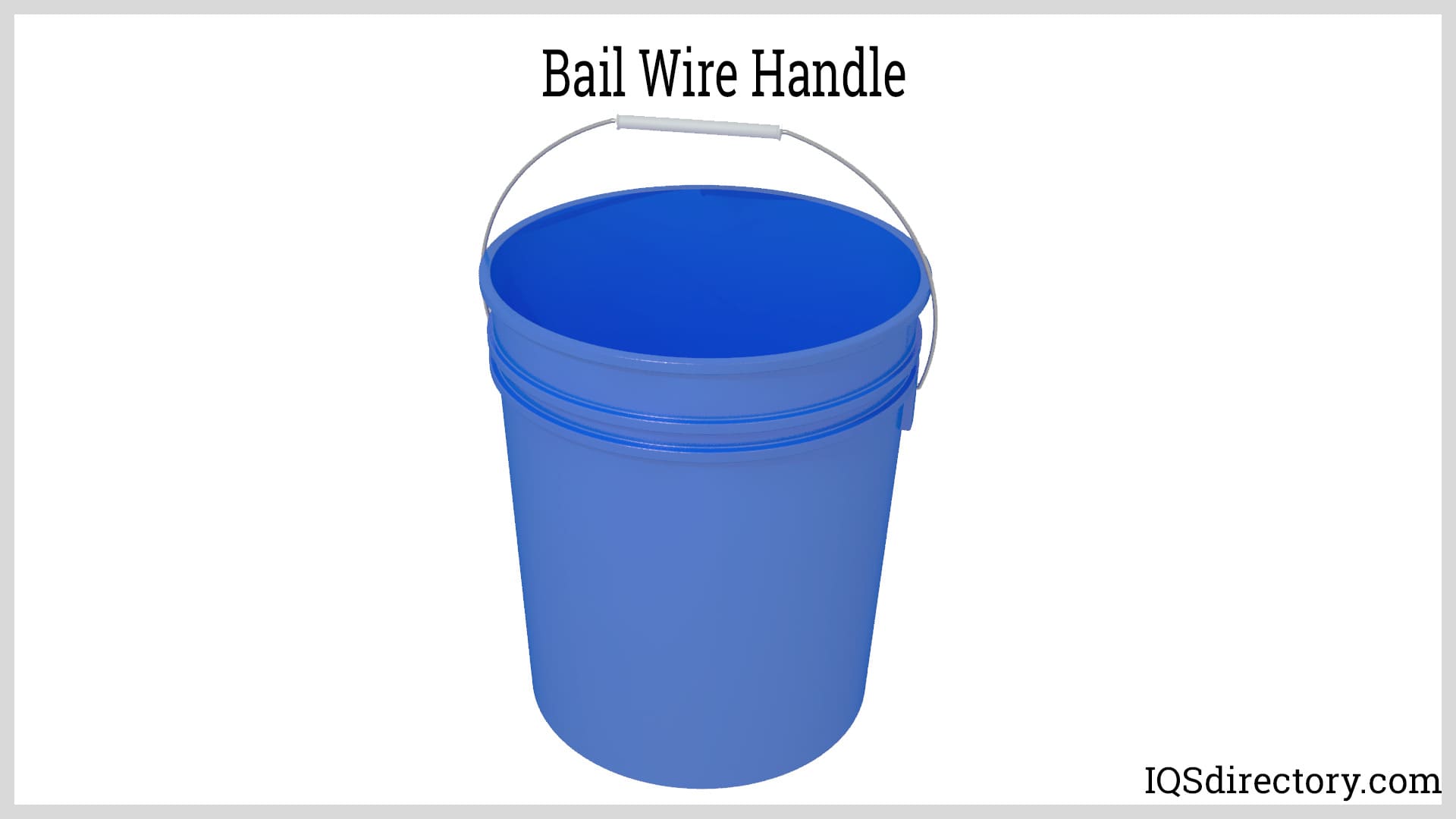

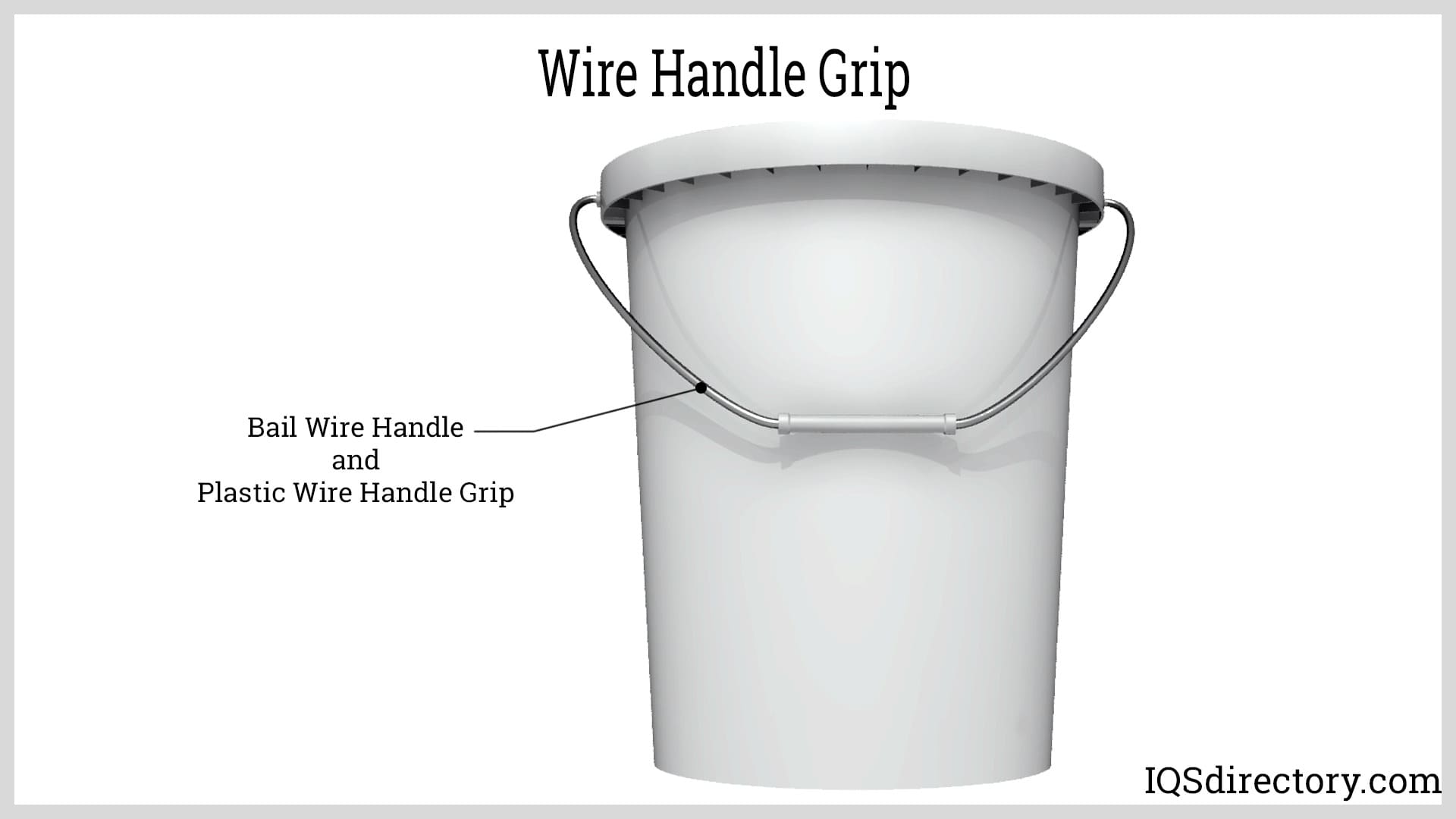

A bail wire handle is secured to a bucket through loops at the ends of the handle or an inward bent angle that is inserted into the bucket's material. These looped and bent designs allow the handle to pivot to either side, making it easier to pour out contents or add materials. Bail wire handles are commonly found on cookware and paint buckets because they can be moved out of the way during use.

As with the majority of wire handles, bail wire handles are made of exceptionally sturdy metals such as galvanized steel or galvanized iron due to the weight of the materials they carry. The varieties of bail wire handles include ones for decorative buckets or pails for carrying flowers or other decorations.

Fixed wire handles can either be permanently attached or adjustable, depending on their intended application. They are commonly used with a range of buckets and pails, but are particularly suited for metal containers that demand robust and durable handles.

Despite the name "fixed" wire handles, not all are permanently attached. Some may be secured with screws, loops, or hooks, which must be robust to handle the demands placed on them. The term "fixed wire handle" typically refers to handles that are either welded to the container or otherwise securely fastened. These welded handles are especially common in industrial settings for moving parts after various treatments.

One distinctive type of fixed wire handle features two wires held together by a central grip or handle, with each wire connected to the container through separate attachments. This style is often used for decorative purposes rather than functional applications.

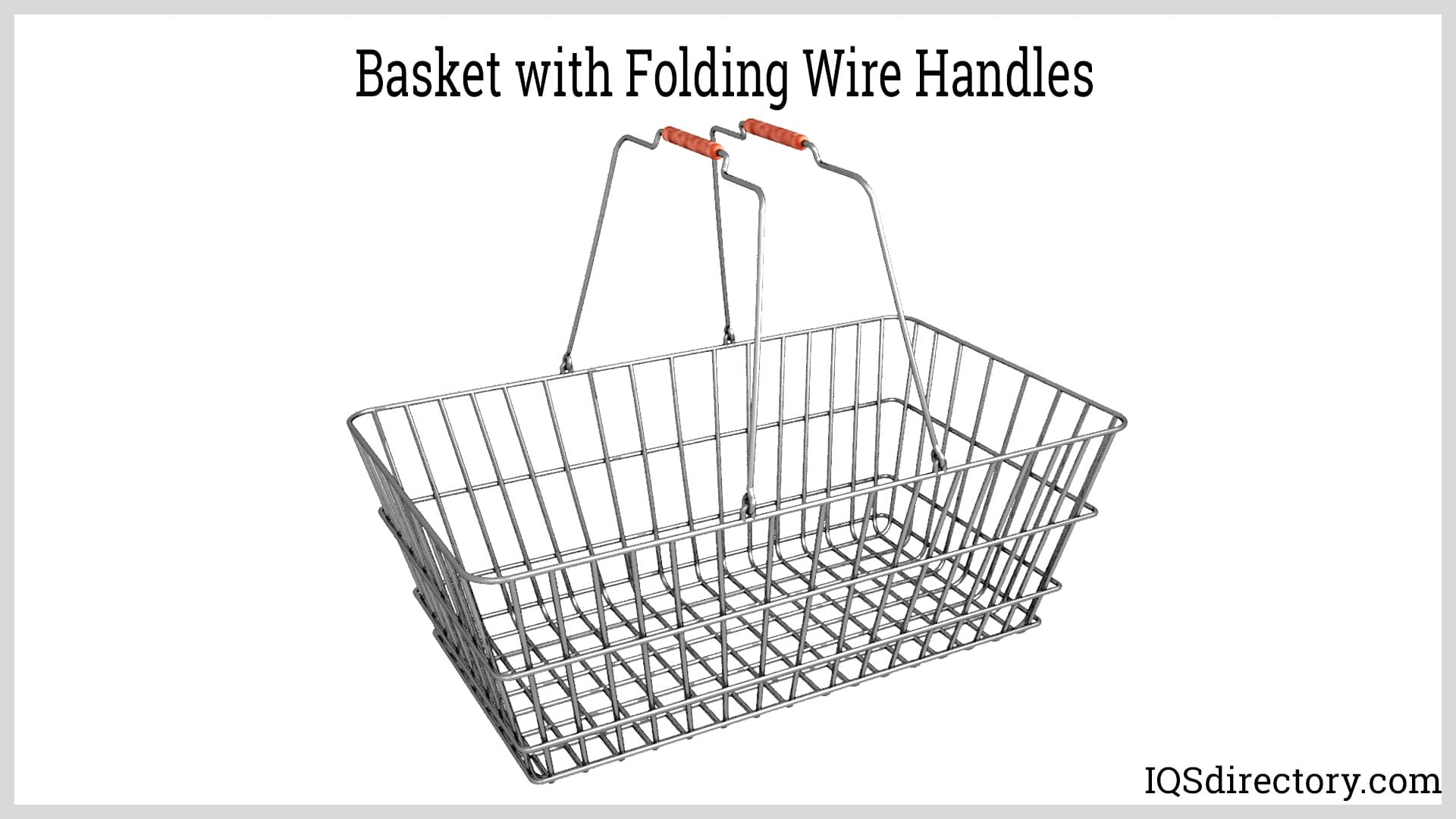

Folding wire handles come in various designs and are commonly used with grocery baskets. Similar to two-wire fixed handles, they consist of two wires attached on either side of the container. When not in use, these handles can be folded down, resting along the edges of the container.

Folding handles are frequently used in industrial environments where space is constrained and containers are employed for transporting parts. These handles allow for easy organization of containers, such as part baskets, when they are not in use. Additionally, containers with folding handles can be stacked neatly, facilitating quick and efficient access.

Given their frequent use, folding handles must be constructed from exceptionally durable materials to guarantee their effectiveness and longevity. This is particularly critical in industrial environments, where a failure in a wire handle can lead to significant damage and safety risks.

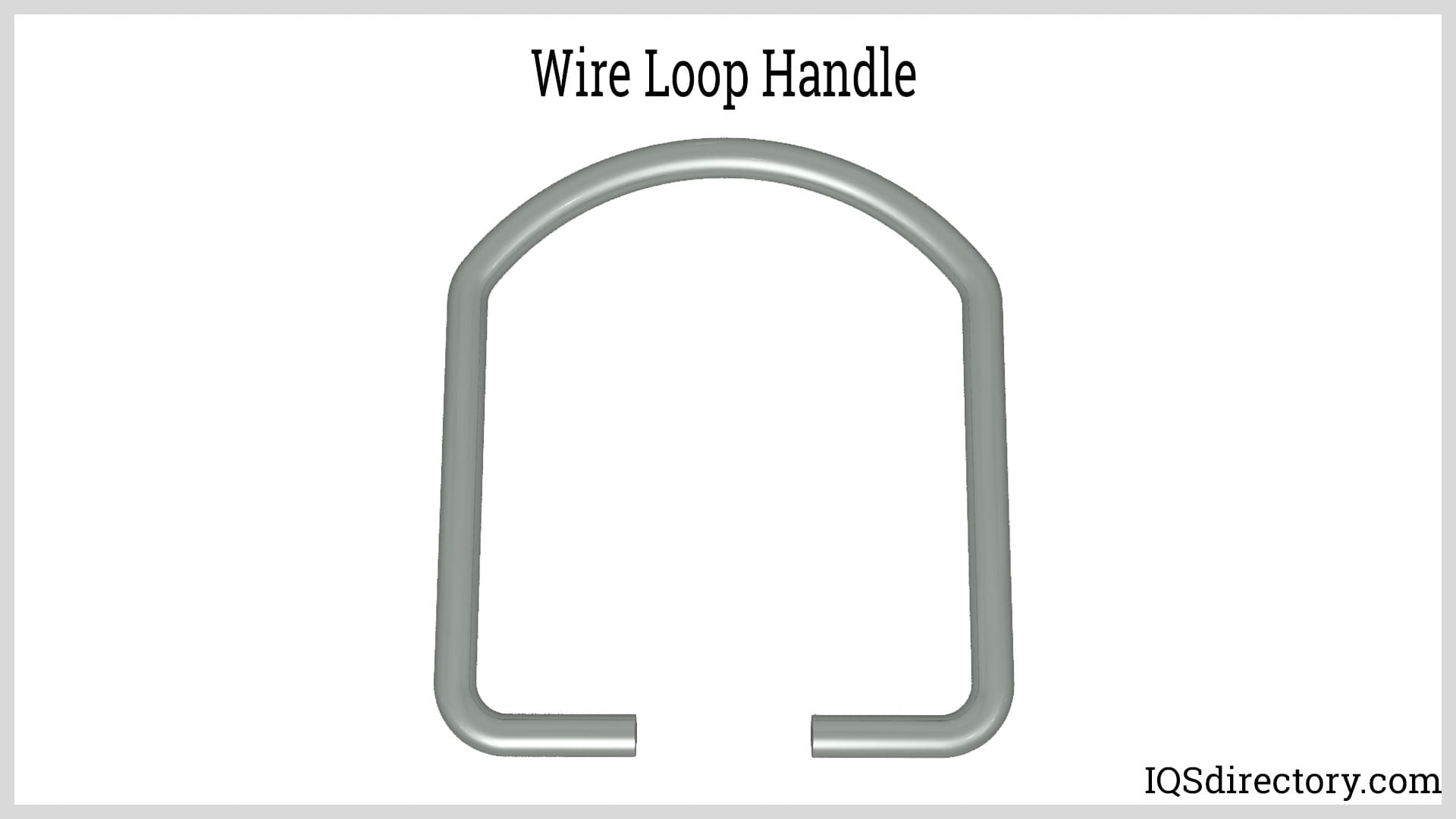

Wire loop handles are compact handles made from a single wire with both ends fixed to a tool. When used with buckets, pails, or containers, they typically consist of two looped wires permanently affixed to either side of the container. Methods for attaching wire loop handles range from welding to using crimped brackets.

Wire loop handles are valued for their strength and reliable attachment to containers. Often, in the case of plastic buckets, these handles are integrated into the bucket or pail during the molding process.

While the term "wire loop handle" might suggest that all handles are loop-shaped, this is not always the case. Wire loop handles can come in various shapes, including rectangular, square, round, and looped, depending on their application. When used with tools, they typically take the form of a loop. The design of wire loop handles varies widely based on their intended use and the weight they need to support.

Wire frame bucket handles are distinctive in that they are constructed from various types of wire and are integrated into the container, bucket, or pail itself. They act as the structural framework for the container, with handles positioned on opposite sides. These handles come in different types, ranging from those designed for office wastebaskets to highly durable versions used for transporting parts and components.

Despite the variety in wire frame bucket handles, all are designed to be robust and durable. The primary difference lies in the type of wire used to construct the frame. In industrial applications, wire frame bucket handles typically provide the structure for baskets or solid containers.

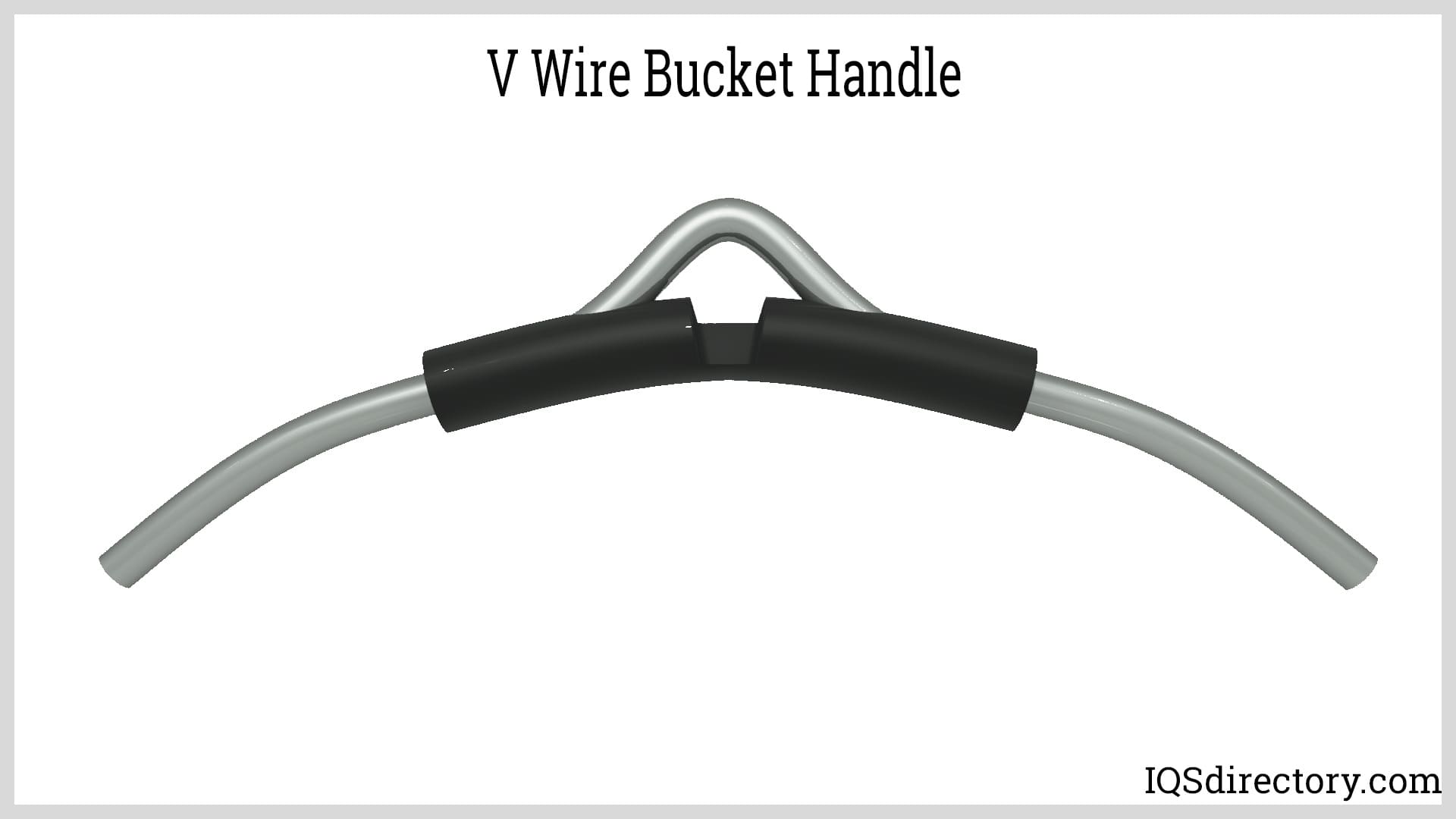

V wire bucket handles are a distinctive type of handle featuring a bend at the top in the shape of an inverted V. This design allows the bucket to be hung on a nail, clip, or hook. Depending on their application, V wire bucket handles may also include a grip that extends outward from the V shape, providing additional functionality.

V wire bucket handles feature a bail-type design, enabling the handle to swivel across the top of the bucket for convenient placement. These handles are made from exceptionally strong wire to support heavy loads. They are commonly used in applications such as livestock feeding and for transporting water or feed.

Grips for wire bucket handles generally share a similar design: a cylindrical shape with a central hole for attachment to the wire handle. The main differences among them lie in the material used and whether the grips feature ridges or a smooth surface.

Grips are designed to make lifting a bucket or pail easier, more comfortable, and secure. They can be firmly attached to the wire handle or designed to be adjustable. Grips are crafted from various materials, including plastics like silicone and polyethylene, as well as wood, all selected for their strength and durability. Some grips feature finger-molded designs with indentations or slots to enhance user grip.

Wire handle bucket grips are essential for handling hot materials, as they prevent heat from transferring up the wire handle. They also play a crucial role in lifting very heavy loads, offering a more secure grip on both the bucket or pail and its contents.

Given the variety of wire handles, grips are available in a range of sizes to accommodate different wire handle dimensions. They can fit wire gauges from 0.091 to 0.187 and are designed to securely handle loads up to five gallons (19 liters).

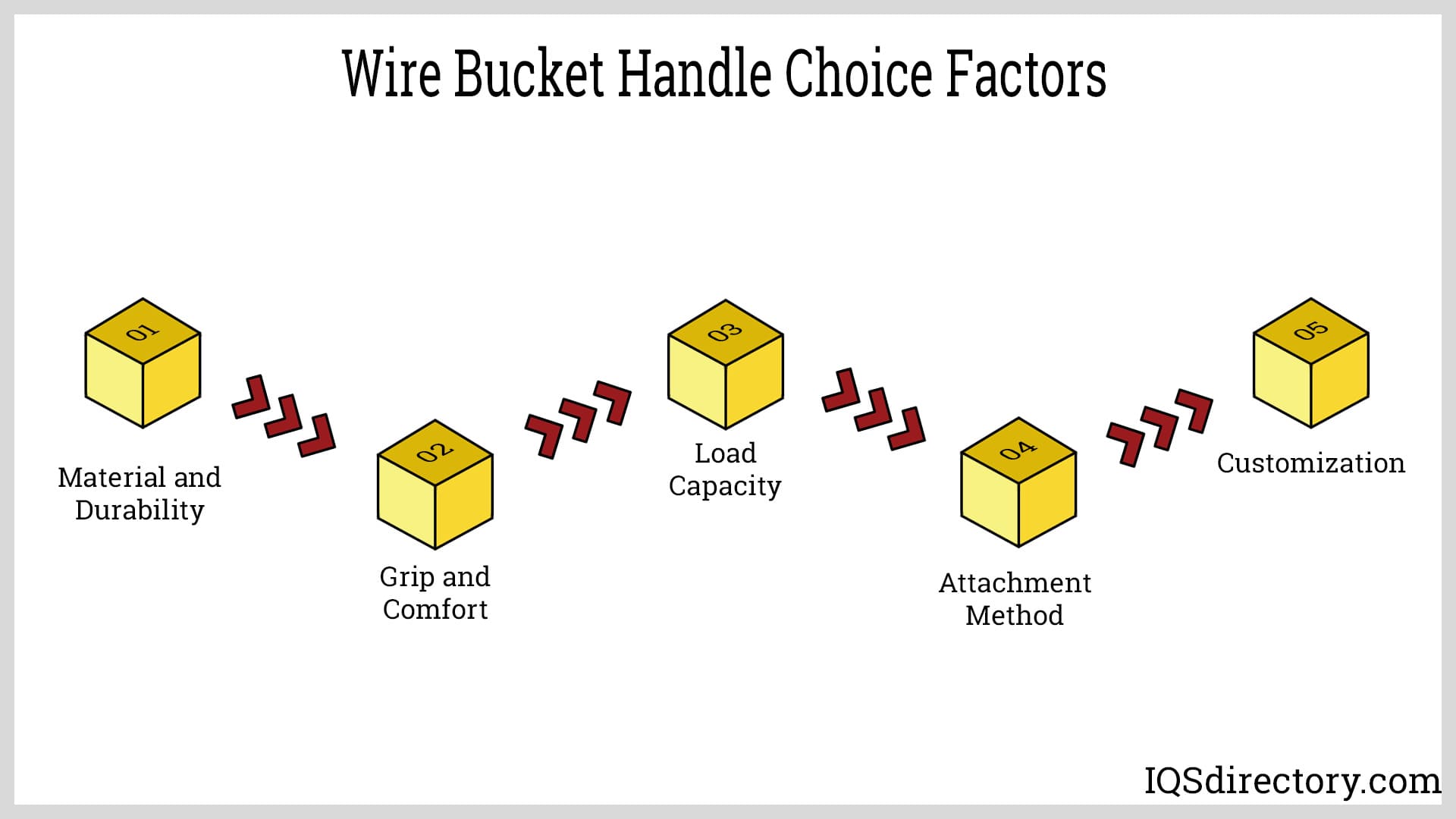

Choosing the right wire handle for a bucket or pail involves several key considerations. The wire's strength is crucial to ensure it can support the load and the bucket itself. Additional factors to consider include the type of grip, the handle's load capacity, and the method of attachment. While some handles are designed to be universal, selecting one tailored to the specific requirements of its intended use is important for optimal performance.

With numerous material options available for bucket and pail handles, it can be challenging to make a choice. Galvanized steel and galvanized iron are among the most widely used metals for wire handles because of their durability and strength. The key attribute for these metals is their resistance to rust and corrosion, ensuring the handles remain reliable under various conditions.

Wire handles typically feature a smooth surface for comfortable gripping. However, if the wire's diameter is too small, it can dig into the hand. To address this issue, plastic, rubber, or wooden grips are often added to provide protection. For metal buckets, handles are sometimes equipped with additional grips to safeguard against hot contents.

The load capacity of a bucket plays a vital role in determining the appropriate handle for it. Standard formulas for calculating container volume are used to establish a bucket's capacity. It's essential that the wire handle's strength aligns with the bucket's weight capacity, which can range from a few pounds or liters to several pounds or liters based on the bucket's size. This consideration is crucial to prevent handle failure when lifting loads that exceed their rated capacity, which can be particularly significant in some situations.

Wire handles can be attached to buckets in various ways, including being molded into the bucket, or affixed using rivets, screws, or welding. The molded method, commonly used with plastic buckets during manufacturing, offers a secure and permanent attachment. Screws and rivets allow for more flexibility, enabling changes to the handle type as needed. On the other hand, welded handles are permanently attached and remain in place for the entire lifespan of the bucket or container.

The selection of a bucket handle significantly impacts the bucket's lifespan. A well-chosen handle not only extends the bucket's durability but also ensures safe and effective use. A securely attached handle guarantees that the bucket can endure frequent use without the risk of failure or breakage.

Manufacturers emphasize that standard bucket handles may not suit every application. Often, a customized bucket handle is required to address specific needs and conditions. In these situations, engineers and designers collaborate with customers to create a wire bucket handle tailored to meet specialized requirements beyond typical use.

Certain applications may involve extreme or harsh environments where buckets need to withstand tough conditions. For instance, in scientific laboratories, specialized buckets might be necessary to handle unusual fluids and substances under test. Similarly, clean rooms often demand buckets that are both hygienically clean and highly durable to meet stringent cleanliness and durability standards.

It's noteworthy that the seemingly simple bucket handle can play a vital role in industrial operations and scientific research. Often taken for granted, wire bucket handles are crucial for their function. They ensure a secure grip on loads, facilitate easy transport, and are designed for durability to meet specific application conditions, highlighting their importance despite being frequently overlooked.

Wire baskets are made from a series of wires that are woven together or welded to form a shape of a basket. They can also be defined as containers that are made by use of an openwork pattern of metal...

Wire shaping is a complex method that encompasses a wide range of dimensions, forms, and textures. The technique of creating a usable product by wire bending and shaping is known as custom wire forms...

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration...

A wire rack is a level wire form utilized to stock and exhibit a number of products, usually retail. The bottom surface on which such goods are stored is made of several latticed or interlaced metal strands...

Wire mesh is fabricated by the intertwining, weaving, or welding of wires of various thicknesses to create proportionally equal parallel rows and intersecting columns. Also known as wire fabric, wire cloth, or...

A coil spring is an elastic element made of metal or heavy plastic in the form of curls or ringlets of round wire or cord that is wrapped around a cylinder. The winding of a coil spring can be loose or tight in a helical shape depending on the application for which it is made...

Coil springs called compression springs can store mechanical energy when they are compressed. These open-coiled, helical springs provide resistance to compressive loading. When these springs are...

Contract manufacturing is a business model in which a company hires a contract manufacturer to produce its products or components of its products. It is a strategic action widely adopted by companies to save extensive resources and...

Extension springs are helical wound springs that are so closely coiled together to create initial tension in the coils. This initial tension creates resistance against the force applied to its ends for extension. The initial tension helps determine how closely and...

Hardware cloth is a woven mesh made by interlacing various sizes of wire to form a metal fabric that can be used for animal cages, fence material, strainers, and filtering screens. The differences between the various types of hardware cloth...

The phrase "wire mesh" describes two- or three-dimensional structures constructed of two or more metallic wires connected by various techniques. In a wide range of settings, wire mesh products are...

Springs are a flexible machine element that store mechanical energy when subjected to tensile, compressive, bending, or torsional forces. When the spring is deflected, it stores energy and at the same time exerts an opposing force...

A torsion spring is a mechanical device that stores and releases rotational energy. Each end of the torsion spring is connected to a mechanical component. As the spring is rotated around its axis on one end, the winding of the spring is tightened and stores potential energy...

Welded wire mesh is a series of wires that are welded where the individual wires cross. The openings of the mesh varies depending on the type of wire used and the function of the mesh. Regardless of size and wire, welded wire mesh is permanent and...

Wire cloth is a woven (or nonwoven) sheet or web material with a series of openings across the surface. Wire cloth is also known as: Metal Fabric or Metal Cloth; Wire Mesh, Metal Mesh, or Alloy Mesh...