Broaching

Broaching is a material removal process used to shape or form a wide range of materials. While it is primarily an external process, both external and internal boroaching can be performed by manufacturers.

As a metal removal service, broaching can be applied to various materials, including ferrous and nonferrous metals, plastics, and wood.

Broaching History

Broaching is a relatively recent development in cutting processes, with a brief yet impactful history.

It began as a viable machining process in the early 1850s, initially used by manufacturers and metalworkers to cut keyways in pulleys and gears. These applications dominated until after World War I, when weapons manufacturers started using broaching to rifle gun barrels. From the 1920s to the 1930s, engineers made significant advancements in broaching machine design and form grinding. These innovations allowed manufacturers to produce broached products with tighter tolerances and lower production costs.

Today, broaching is used in a wide range of applications, and its potential continues to expand. As time progresses, we can expect even more advancements and innovation with this young process.

Benefits and Advantages of Broaching

Broaching offers numerous advantages, including high productivity, speed, accuracy, close tolerances, versatility, cost-effectiveness, and smooth surface finishes.

Productivity and Efficiency

The broaching process is quick and fully automated, typically taking only a few seconds to complete. This efficiency allows for high-volume production runs, making broaching both cost-effective and fast.

Accuracy and Tolerances

Broaching enables precise cuts over large production runs, achieving close tolerances that are essential for many applications.

Versatility of Broaching

The main limitation of broaching is the size of the part being machined, specifically the length and width. Other than that, broaching can handle a wide range of part configurations.

Finishing Process

Unlike other methods that require additional finishing steps, broaching produces a high-quality surface finish right from the start, eliminating the need for further finishing on the completed parts.

Broaching Process Details

The broaching process varies depending on the method chosen by the manufacturer. These methods differ based on the specific use, purpose, motion, construction, and function being addressed. However, broaching is generally classified into two categories: surface broaching and internal broaching.

The Setup

To begin the broaching process, manufacturers use a workpiece and a broach machine. Broach machines are equipped with toothed tools, which have pre-formed tooth shapes that progressively vary in length. These can be designed for hole shapes, squares, irregular shapes, or gear hobbings. Instead of cutting with a single point, the broach consists of a series of single-point cutting tools arranged linearly to cut or remove material.

Surface Broaching

Surface broaching is the simplest broaching method and can be performed in one of two basic ways:

- The workpiece moves while the broach remains stationary.

- The broach moves against the surface of the stationary workpiece.

Internal Broaching

In the internal broaching process, manufacturers begin by clamping the workpiece into a holder known as a work holder. Inside the broach machine, an elevator moves the broach tool above the work holder. The broach then moves side to side through the workpiece, entering through at least one hole. If necessary, like during spiral splining, the broach also rotates.

Design of Broaching Machine Configuration

When preparing to broach a part, manufacturers consider two key factors in broach machine configuration: whether the broach cutting tool will be internal or external, and the specific production requirements. Production requirements focus on details such as the number of pieces needed per hour or the total production run.

These factors directly influence which machine will be the most efficient for the job. If an internal broach machine is needed, manufacturers will also evaluate the ratio of the broach’s length to its diameter, helping them determine whether a pull or push action machine is the best choice. Other factors that affect the decision include the type of drive, power source (hydraulic vs. electromechanical), automation capabilities, and the ability to convert between different setups.

All decisions are based on the specific application requirements to ensure the results meet your needs.

Applications of Broaching

Broaching services are widely used to efficiently form industrial parts and products of various shapes and sizes. This process creates features like slots, hole shapes, serrations, internal splines, and more, both on the interior and surface of a workpiece.

Customers and manufacturers prefer broaching for its precision and efficiency, especially since it doesn't require heat, which further enhances its accuracy.

Industries that commonly rely on the broaching process for part production include automotive manufacturing, aviation and aerospace, transportation, power generation, injection molding and assembly, and consumer products.

Products Produced by Broaching

The most commonly broached products are gears, with gear manufacturers available here on IQS Directory. Other broached items include sprockets, pulleys, fastener heads and threading, nuts and bolts, spline shafts, keyways, smaller wheels, gun components, industrial machinery parts, and tools such as bushings and wrenches.

Broaching Images, Diagrams and Visual Concepts

Broaching, a machining process where a sharp, hardened, toothed tool removes material from a workpiece in a consistent, continuous, and accurate way.

Broaching, a machining process where a sharp, hardened, toothed tool removes material from a workpiece in a consistent, continuous, and accurate way.

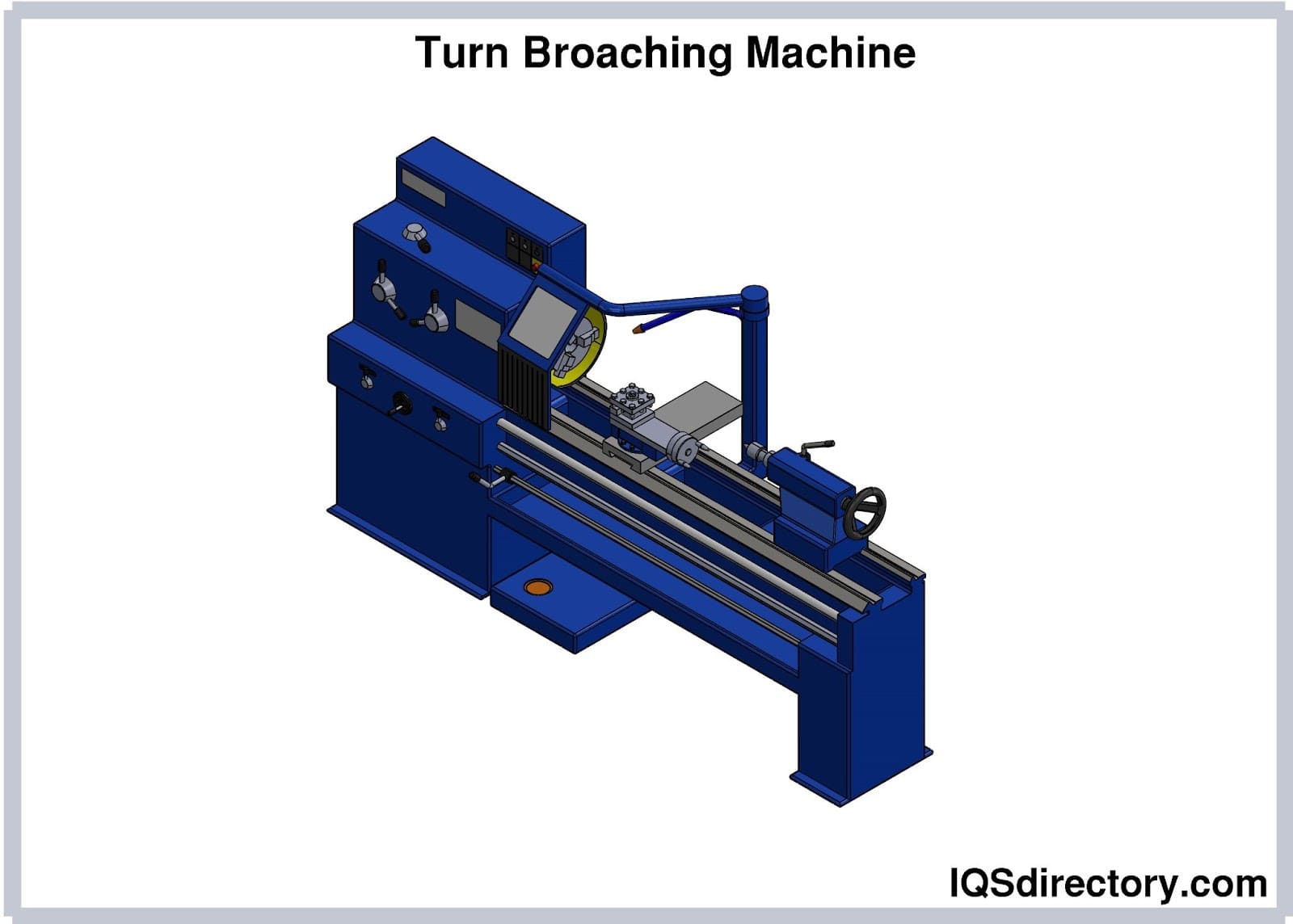

Turn broaching machines are used for circular, linear, and spiral cutting surfaces.

Turn broaching machines are used for circular, linear, and spiral cutting surfaces.

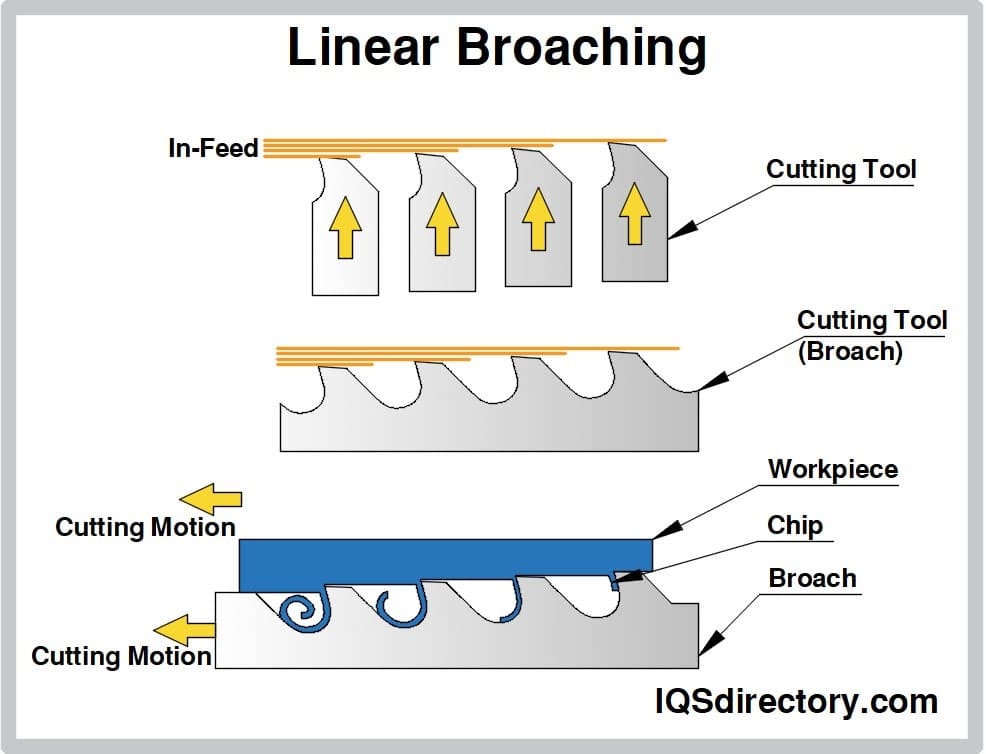

Linear broaching is where a tool moves linearly against the workpiece surface, cutting as it moves.

Linear broaching is where a tool moves linearly against the workpiece surface, cutting as it moves.

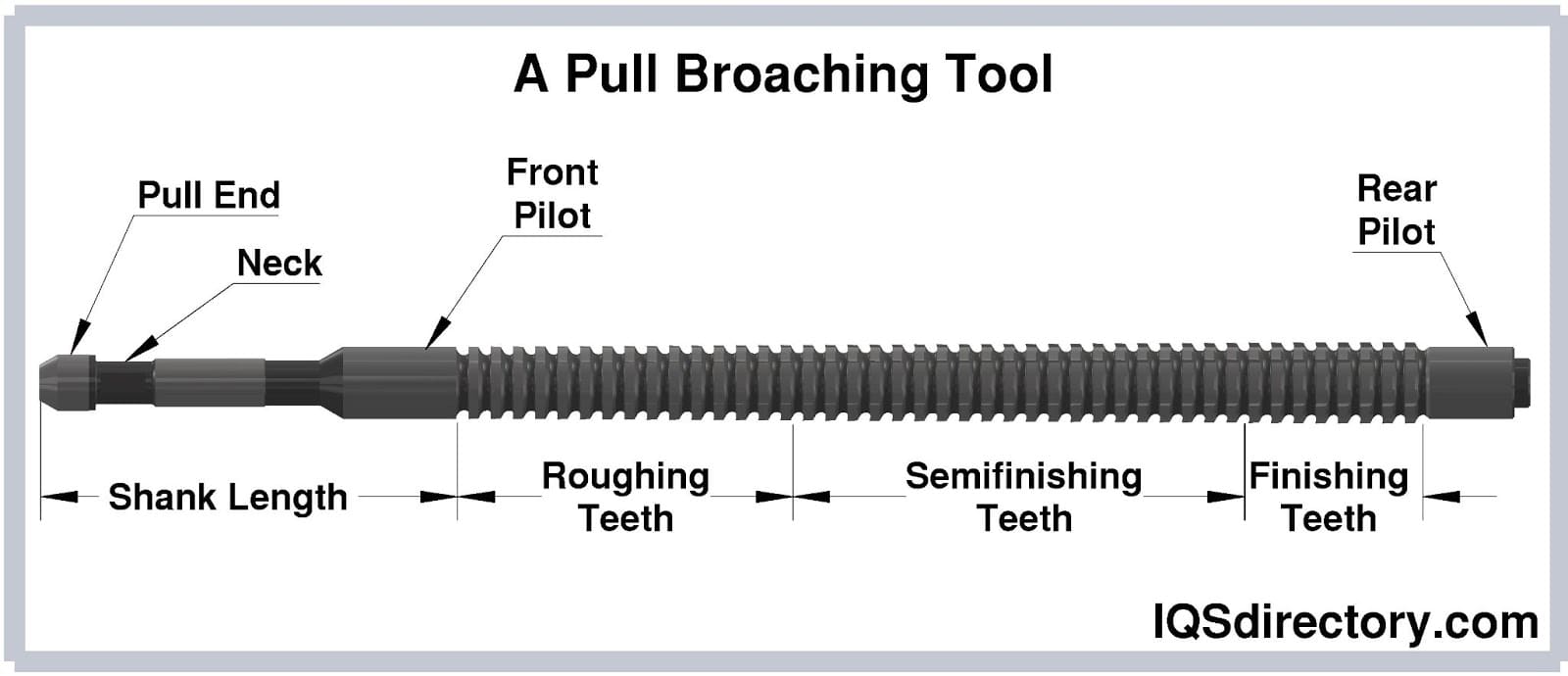

Pull broaching, a workpiece is held in place as the broach is pulled through.

Pull broaching, a workpiece is held in place as the broach is pulled through.

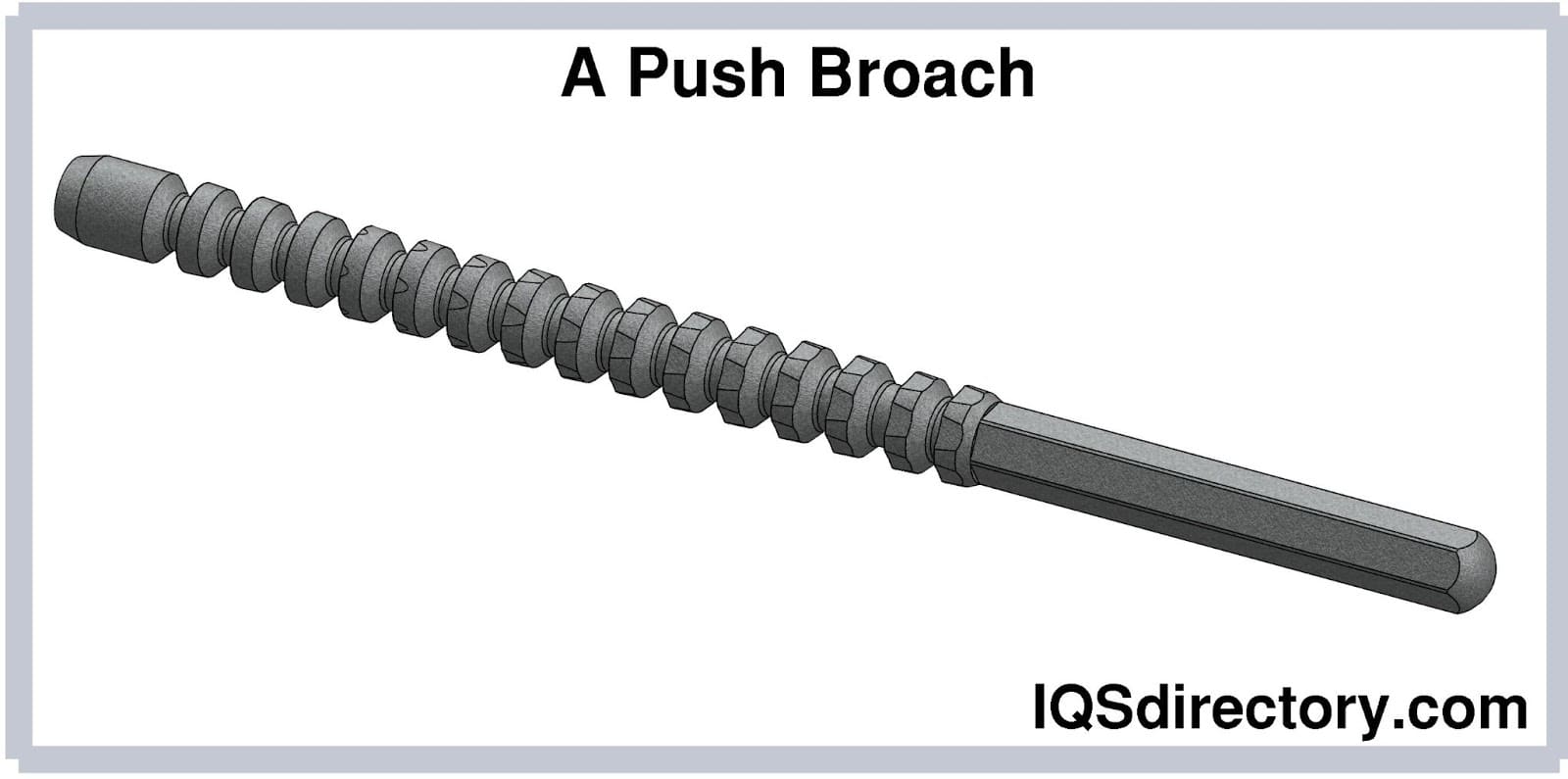

A push broaching tool is shorter which can endure the compressive forces applied as it goes through the workpiece.

A push broaching tool is shorter which can endure the compressive forces applied as it goes through the workpiece.

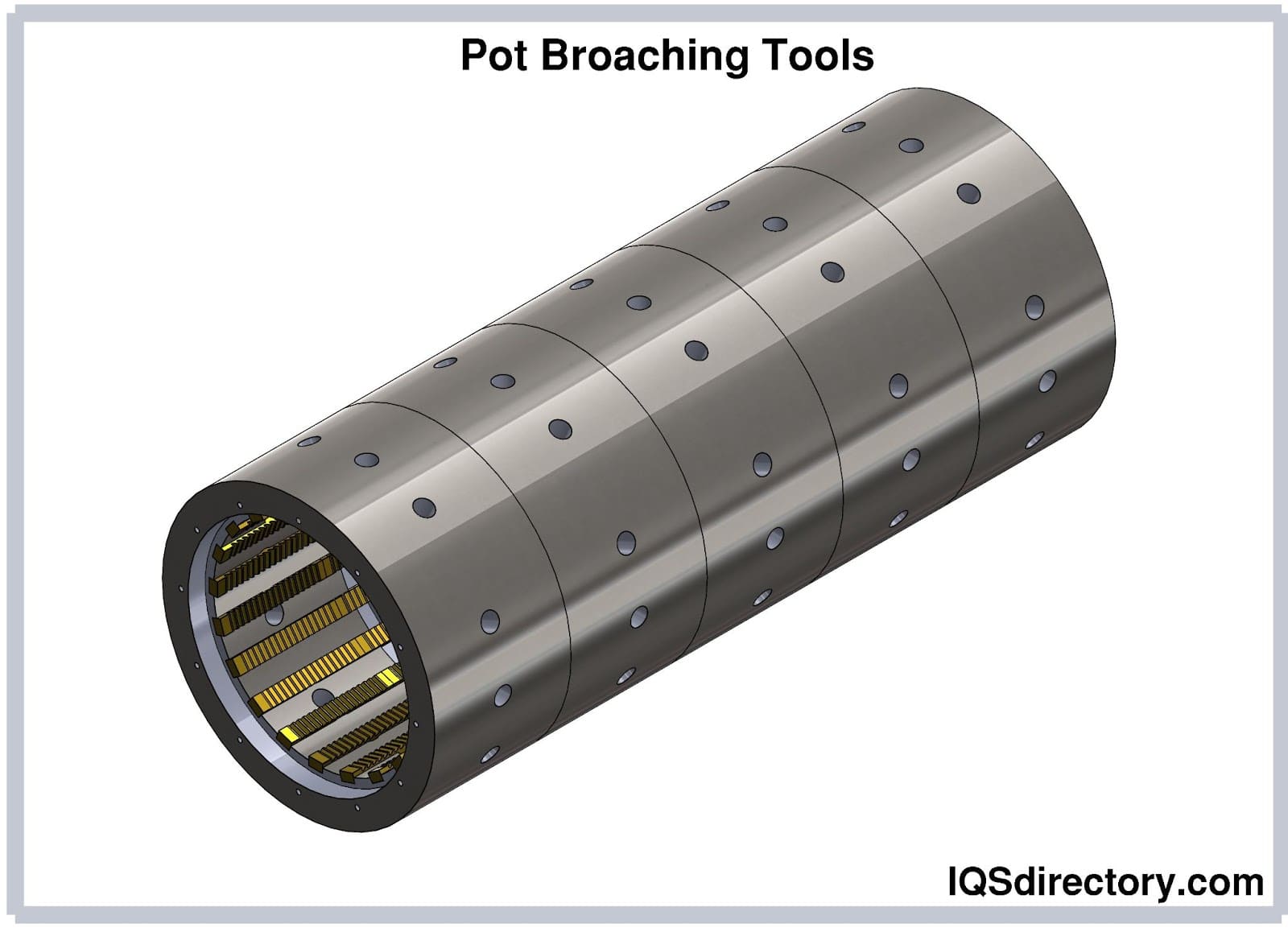

In pot broaching, the tool remains stationary as the workpiece is pushed or pulled through it.

In pot broaching, the tool remains stationary as the workpiece is pushed or pulled through it.

The process of blind broaching is used on parts designed to not have a pass through.

The process of blind broaching is used on parts designed to not have a pass through.

Types of Broaching Machines

During the broaching process, manufacturers utilize a range of broaching machines capable of machining to precise measurements, down to the square millimeter. These machines typically combine push or pull broaching tools with cutting teeth and include equipment such as automatic lathes, CNC Swiss lathes, and rotary transfer machines.

Vertical Broaching Machine

In most broaching job shops, vertical broaching machines are commonly used, supporting both external and internal broaching. As the name suggests, these machines operate vertically on a workpiece and are powered by hydraulic presses, adding mobility since they can be moved from one area to another. Vertical machines are categorized based on their operation: table-up, pull-up, and pull-down or push-down machines.

Vertical Table-Up Machine

Vertical table-up machines feature a stationary broach with the workpiece mounted on a movable table. These machines offer flexibility, meeting cell concept manufacturing needs, and are particularly suited for short-run production. After one or two years, they can be retooled for different applications. Vertical table-up machines typically have stroke lengths ranging from 30 to 90 feet, with a capacity of 5 to 30 tons.

Horizontal Broaching Machine

Horizontal broaching machines have a horizontal design and are typically gear or screw-driven, powered by either hydraulics or mechanics. These machines are often used for finishing and roughing engine blocks. Horizontal machines are gaining popularity as they are capable of performing very long strokes, free from the limitations of vertical machines. Horizontal broaching machines can be further divided into internal, surface, and chain-broaching types.

Chain Broaching Machine

For modern production demands, chain-broaching machines are frequently preferred. These surface broaching machines feature a continuous chain where workpieces are mounted, eliminating the need for a return stroke.

Specialized Machinery

Specialized broaching machines are designed for specific or semi-specific applications. Keyway broach machines, for example, are made specifically for broaching keyways. Other semi-specific machines, such as turn-broaching or rotary broaching machines, cut various shapes from linear to circular and spiral. These robust tools are ideal for cutting steel and cast-iron crankshafts.

Custom Machinery

Manufacturers can adapt or create custom machinery for specialized tasks. For instance, they may assemble peripheral cutters in segments to perform different functions. They can also use standardized components to rough or finish workpieces as needed.

Ways to Broach

-

Blind Broaching

This is another term for external broaching, which refers to the surface-level broaching process.

Broaching Job Shops

Facilities dedicated to offering broaching services, specializing in the broaching process.

Gear Hobbingr /> A process where a broaching machine is used to cut gear teeth.

Internal Broaching

This involves using a broach tool to make precise cuts on the inside of a workpiece, typically on a pre-existing hole.

Keyseaters

Machines designed to create keyway holes inside locking mechanisms.

Keyway Broaching

A process where keyseater machines are used to create keyways in various materials.

Pot Broaching

An external broaching method specifically used to form gears.

Production Broaching

A process where a machine is used to mass-produce a single product in large quantities.

Rotary Broaching

Also called wobble broaching, this is a well-established broaching method used on automatic lathes and is now also gaining popularity with rotary transfer machines and CNC Swiss lathes.

Spline Cutting

A broaching process used to cut grooves along the length of a spline shaft.

Spline Shafts

Shafts with grooves created through the broaching process.

Surface Broaching

This process involves using a broach tool to precisely cut the surface of a workpiece.

Vertical Broaching

A type of broaching that uses cutting tools with successively larger teeth.

Variations and Similar Processes

-

Gear Hobbing

This process forms gears by externally broaching grooves onto the external surface of the gear.

Vertical Broaching

Typically used for higher volumes of products, vertical broaching creates hole indentations and grooves with a spline shaft containing successively larger teeth, which are strong enough to cut through metals. These can either create holes that go all the way through the workpiece or make shallow indents through blind broaching.

Pull Broaching

In pull broaching, the broach cutting tool is pulled through the part in a single pass.

Push Broaching

The second most common type of broaching, push broaching is often used for short-run jobs. Broaching job shops commonly perform this with a hydraulic press or a hand-operated arbor press.

Pot Broaching

Pot broaching involves inverting machinery movements. The broaching tool stays stationary while the workpiece is pushed through it. This method is called "pot broaching" due to the hollow casing of the broach, which resembles a pot.

Lathe Broaching

Broaching on a lathe, which spins at high rotations, is another service offered by broaching job shops.

Rotary Broaching

In rotary broaching, the broach tool is held at a 1° angle to the workpiece, with the cutting face positioned as close as possible to the centerline of the part. The tool and part are stationary, while the broach holder spins on a spindle, causing the tool to move in a "wobble" motion. Rotary broaching is popular because it doesn’t require a full broach machine and can be performed with just a lathe, Swiss lathe, milling machine, or screw machine.

Production Broaching

The term "production broaching" refers to the high-volume fabrication of broached parts in specialized broaching job shops. It applies to various types of broaching, such as keyway broaching, rotary broaching, vertical broaching, and more.

Things to Consider When Choosing Broaching

Expense of Broaching

Broaching is a job-specific machining process, meaning each type of broach is designed for a specific shape and geometry. This limitation makes it a highly specialized option with narrow use cases. Custom broaching requires creating entirely new tools, which significantly increases manufacturing costs. Because of these factors, broaching can be expensive.

To help reduce costs, manufacturers often perform broaching in specialized broaching job shops. These facilities use specialized machines, such as the P machine, to make the broaching process more cost-effective.

Machine Parts and Broaching

When determining which machine parts are suitable for broaching, keep in mind that while broaching has its limitations, it can still be controlled to ensure precision and efficiency in the process.

- The workpiece should be free of any obstructions along the surface length.

- Workpieces with curves in multiple planes cannot be machined effectively, as broaching primarily works in a single plane.

- The part being machined must be able to handle the forces applied during broaching.

- For internal broaching, the workpiece must have a hole that allows the broach to enter.

Finding the Right Broaching Manufacturer

Once you determine that broaching is the right service for your needs, it's essential to find the right manufacturer. The ideal manufacturer will work within your specified timeline, focus on meeting your requirements, and strive for customer satisfaction. While broaching can be costly, the right manufacturer will aim to provide the best service at the most competitive price.

To find a suitable provider, check the list of reputable broaching companies we've provided at the top of this page. Reach out to them with your specifications and any questions you may have.

Broaching Terms

-

Broach

A metal cutting tool equipped with a series of cutting teeth.

Chip Breakers

Notches on the broach tool that facilitate chip removal during the cutting process. The semi-finishing and roughing sections of the broach contain chip breakers, which run parallel to the tool's axis.

Chip Load

The fixed thickness of material removed by each tooth of the broach as it enters the workpiece. The type of broach tool used determines the chip load.

Chip Space

The gap between the teeth of a broach that collects chips during the cutting operation.

Cutting Teeth

The teeth of the broach, which are divided into three sections: roughing, semi-finishing, and finishing teeth. The roughing teeth are smaller, and the size of the teeth increases progressively towards the finishing section.

External Broach

A broach used to cut along the external surface of a workpiece.

Face Angle

The angle of the cutting edge of a broach tooth.

Finishing Teeth

Teeth designed for finishing a surface, typically arranged at a constant size at the end of the broach.

Front Pilot

The front pilot ensures the axial alignment of the broaching tool and the starting hole, checking the size of the starting hole. A rear pilot serves a similar purpose at the rear end.

Gullet

Another term for "chip space."

Hook Angle

The face angle of a broach tooth, which refers to the angle of the cutting edge relative to the direction of movement.

Internal Broach

A broach that is pushed or pulled through a hole in the workpiece to shape the hole to the desired size and form.

Overall Length

The total length of a broach tool.

Pitch

The distance between the cutting edge of one tooth and the same point on the next tooth.

Pull Broach

A type of broach that is pulled through or over the surface of the workpiece during an operation.

Push Broach

A type of broach that is pushed through or over the surface of the workpiece during an operation.

Roughing Teeth

The first teeth to make cuts during a broaching operation, typically taking heavier cuts than semi-finishing teeth.

Round Broach

A broach with a circular section, typically used for making round cuts.

Shear Angle

On surface broaches, the angle between the cutting edge of a shear tool and the line perpendicular to the broach's axis. Broach teeth designed at a shear angle improve surface finish and reduce tool chatter. The shear angle is particularly important when cutting adjacent workpiece surfaces.

Shear Cutting Tooth

A type of tooth used on surface and external broaches, designed to avoid a right angle with the direction of broach motion.

Side Relief

A clearance on both sides of each tooth to reduce friction and tool wear as the sides of the broach teeth rub against the sides of the slot being broached.

Surface Broach

An external broach used to cut flat or contoured surfaces on a workpiece.

Tooth Depth

The height of the tooth or broach gullet, measured from the root to the cutting edge.

Tooth Land

The part of the tooth that supports the cutting edge as it undergoes stress during the broaching process.

Tooth Pitch

The distance between teeth on a broach. The tooth pitch is influenced by factors such as the length of the cut and the type of material being worked on.