Carrying Cases

Carrying cases have become an indispensable part of our daily lives, seamlessly serving a vast array of purposes. They protect our belongings during transit, ensuring they move from point A to point B without damage. When a case fails, the consequences can range from financial and material losses to a moment of frustration. Fortunately, with the option to purchase or customize a high-quality case for virtually any need, ensuring safe and intact delivery is no longer a matter of chance.

These cases come in an impressive variety of shapes, sizes, and materials. While many are rectangular, some feature recesses or pockets to hold items securely. Others take the form of tubes with sealed end caps or hinged sides. They might be designed internally or externally to conform to the contours of their contents. Carrying cases can also be flame retardant, static-free, resistant to electromagnetic interference, or waterproof. Their construction may vary from hard-sided to soft-sided, single-chambered to compartmentalized, and some even include wheels for effortless transport.

Far more than simple boxes or bags, custom carrying cases deliver superior protection, making the transport of delicate, sensitive, unruly, or hazardous items, equipment, or materials both safe and efficient. The ideal size, shape, and material for each case depend entirely on the unique requirements of its contents, ensuring every item arrives at its destination in perfect condition.

Carrying Cases FAQ

What are carrying cases used for?

Carrying cases are designed to protect and transport items safely. They are used for tools, electronics, medical equipment, documents, musical instruments, and more, keeping contents secure from impact, moisture, or static damage.

What materials are carrying cases made from?

Carrying cases can be made from plastics, aluminum, wood, metals, fabric, nylon, polyester, PVC, neoprene, or leather. Each material offers different benefits such as durability, waterproofing, or lightweight portability.

What is the difference between hard and soft carrying cases?

Hard carrying cases are rigid and often molded from plastic, aluminum, or wood for maximum protection, while soft cases are made from fabric or vinyl, offering flexibility, lighter weight, and water resistance.

What types of custom features can carrying cases include?

Custom carrying cases can feature foam inserts, compartments, wheels, recessed handles, locking systems, or branding elements. Interiors may be tailored to fit specific items for enhanced protection and organization.

How are plastic carrying cases manufactured?

Plastic cases are made using blow molding, injection molding, or rotary molding. These methods shape molten or heated plastic into durable, lightweight cases that may later be fitted with hinges, handles, or foam interiors.

What are ATA shipping cases?

ATA shipping cases meet airline transport standards set by the Air Transport Association. Built with reinforced plywood and laminate shells, they are durable, mobile, and often customized with foam interiors for safe air transit.

What industries rely on carrying cases?

Industries such as medical, military, electronics, construction, entertainment, and trade shows rely on carrying cases to protect, organize, and transport sensitive equipment, instruments, tools, and promotional materials.

Bagging and Boxing Up History

The history of carrying cases traces back to the humble satchel, a limp sack with handles, which was the first of its kind to be sold commercially. In 1826, Godillot of Paris revolutionized the concept with the patenting of a bag featuring a hinged iron frame. This innovation, known as the "carpet bag," marked the beginning of the luggage industry. As transportation advanced, so did the need for sturdier containers capable of safeguarding personal belongings on increasingly ambitious journeys.

By the 1850s, the briefcase emerged—a rectangular case specifically crafted to hold business papers, effectively transforming it into a portable desk for professionals. Meanwhile, heavy, curved-top steamer trunks, constructed from wood and iron, became essential for carrying clothes and personal items aboard ships and trains during the Industrial Revolution. These trunks were waterproofed by coating their exteriors with sap, making them both practical and durable.

Louis Vuitton elevated the concept with his creation of slatted trunks, sheathed in canvas on the outside and fitted with drawers inside. These trunks featured flat tops for easy stackability—a design that not only redefined luggage functionality but also established a brand that remains iconic to this day.

Initially, the handling of these robust trunks was left to servants and porters. However, as common people without hired help began traveling by stagecoach and later by automobile, there arose a need for lightweight yet sturdy bags. By the late 19th century, leather luggage became increasingly popular, and in 1897, the first advertisement for a "suit case" appeared.

The 20th century ushered in dramatic changes. By the 1930s, air travel had gained traction, driving demand for lightweight cases capable of accommodating diverse items. In 1950, Germany’s Rimowa company designed the first aircraft aluminum case, a model whose essential design remains unchanged from its 1952 iterations. Today, manufacturers of such cases continue to thrive, as showcased on IQS Directory.

The 1960s introduced wheeled trolleys, simplifying the movement of baggage through airports and train stations. Then, in 1972, Bernard Sadow obtained the first U.S. patent for "Rolling Luggage." This groundbreaking invention sparked a revolution, and within two years, multiple companies were producing their own variations, transforming modern travel and the transport of fragile goods.

The innovations continued into the new millennium. In 2000, Rimowa launched the first polycarbonate luggage, which proved to be lighter and more durable than its metal counterparts. Just four years later, Samsonite unveiled The Spinner, a wheeled suitcase designed for unparalleled maneuverability. Capable of being pushed, pulled, or spun in any direction, this invention revolutionized airport navigation, making travel easier and more convenient than ever.

Uses for Carrying Cases

Carrying cases serve a wide range of purposes, ensuring the safe transport and storage of various items. Papers remain dry and organized in plastic cases, briefcases, or portfolios. Musical instruments, electronic equipment, medical instruments, and chemicals are safeguarded from shock, moisture, and extreme temperature changes within waterproof cases that feature custom foam interiors. These interiors are often tailored to fit the specific items, providing maximum protection. Anti-static foam used inside protective cases, adds an extra layer of security by preventing static discharge, which could otherwise damage electronic devices during transit. Manufacturers specializing in such foam can be found on IQS Directory.

Small items like sewing notions, beads, and other craft accessories are best stored in cases with segregated compartments. Plastic carrying cases offer convenient and organized storage for these items, making them easy to transport. Hobbyists, construction workers, and mechanics often rely on form-fitted carrying cases to keep their tool sets organized and ready for use. Specialized cases are also available for items such as computers, archery gear, fishing equipment, golf clubs, photography equipment, makeup, and art supplies. Firearms require locking, specially designed gun cases for secure transport, whether for commercial purposes or private use.

Many carrying cases are designed with dual functionality, such as doubling as display cases for trade shows and sales presentations. Heavy duty, rolling cases for speakers, lighting, and sound equipment, provide entertainers and production crews the ability to take their show on the road. Sturdy, rolling cases for speakers, lighting, and sound equipment allow entertainers and production crews to travel with their setups securely. In the medical field, rugged cases enable the transport of vital equipment and supplies, empowering doctors to provide care in remote or challenging conditions. Road cases, a specific type of carrying case, offer robust protection for sensitive equipment during transit, ensuring everything arrives intact and ready for use.

Carrying Case Images, Diagrams and Visual Concepts

Carrying cases are a way of organizing and transporting a collection of similar or dissimilar items.

A hard case is a type of carrying case that is made from molded plastic, aluminum, laminated wood, or different types of metals which are the most secure and durable forms of carrying cases.

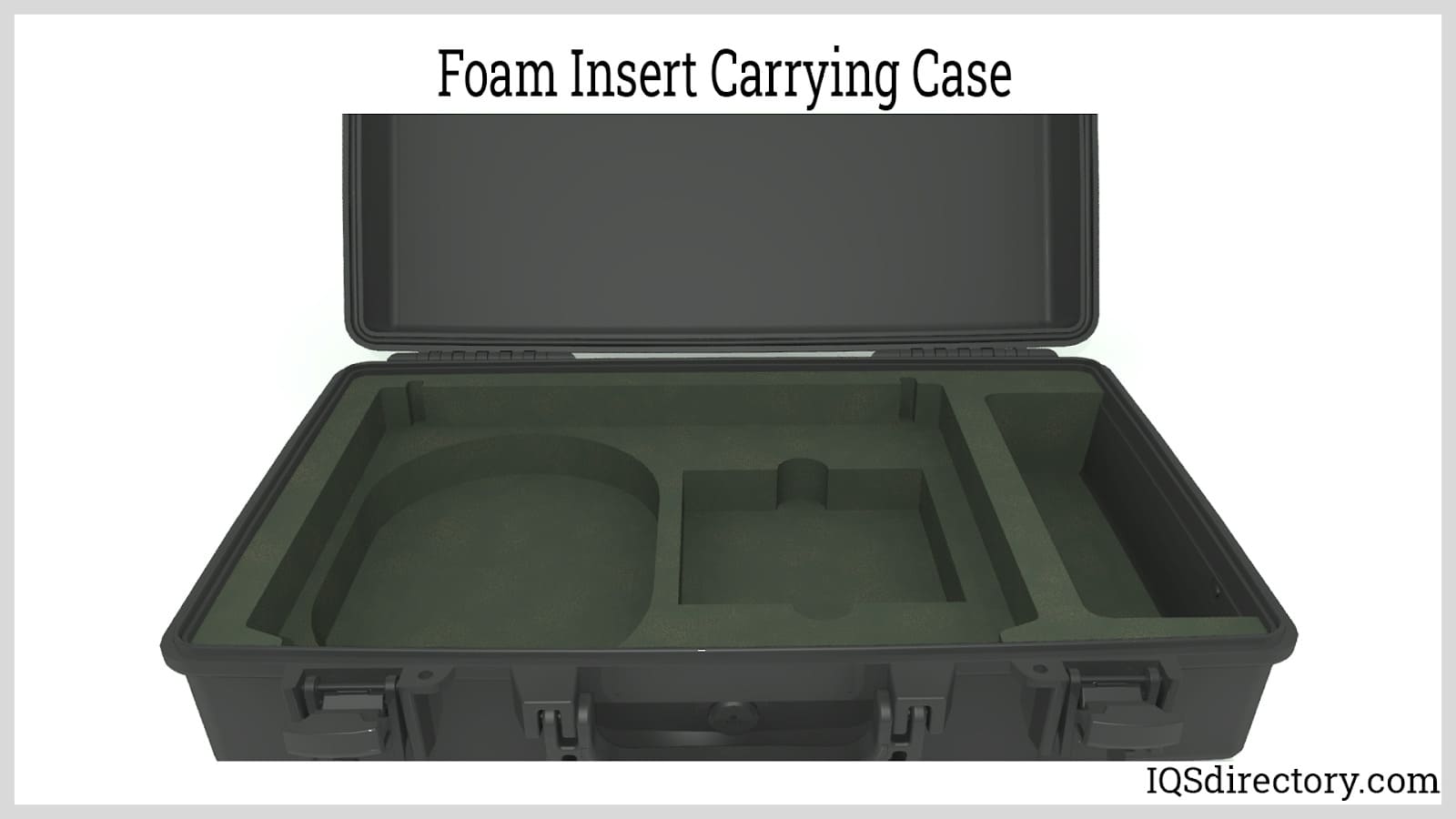

Foam insert carrying cases are like divider cases, that are divided into sections using soft foam material which is cut to the exact shape of the items to be carried.

Tool carrying cases can be standard or custom designed in any size or configuration which protects the contents from moisture, salt spray, dust, and immersion.

Soft sided cases that are made from fabrics, canvas, or vinyls making the sace water and dust resistant.

Hard Carrying Cases

Hard carrying cases are essential for protecting and transporting valuable or sensitive items, offering durability and versatility across a range of uses.

Shipping Containers

The Air Transport Association (ATA) sets clear standards for airline shipping containers, with ATA300 being the widely recognized benchmark. These containers are divided into three categories, each specifying an expected service rating. ATA cases are crafted to meet the rigorous standards of category I. Typically constructed from plywood, they feature an ABS plastic or polypropylene outer laminate shell and a double aluminum angle frame reinforced with nickel-plated steel corners. Designed for functionality, they are often equipped with wheels and multiple fold-away handles. The interiors may either be open or outfitted with custom foam inserts to securely stabilize items during transit.

Trade Show Cases

Trade show cases are often rated ATA category I for their robustness. These cases are designed to ship and store goods for conventions and trade shows while serving multiple purposes. Once opened, they can transform into tables, desks, or display racks, offering versatility at events. Interiors may include shelves, drawers, bins, or pegboards, allowing for organized storage and presentation. They can be used as standalone units or linked together to form intricate yet portable point-of-sale kiosks.

Aluminum Cases

Aluminum cases offer both standard models and custom-manufactured options tailored to specific design requirements. Available in virtually any size—whether deep, shallow, wide, or long—they maintain a balance of lightweight construction and heavy-duty performance. These cases range from small attaché-style designs to large containers capable of carrying woodworking or metalworking machines, often with molded pockets for accessories. Some aluminum cases are collapsible, allowing for compact storage when not in use. Their durability and lightweight construction make them ideal transit cases for delicate gear, particularly for items shipped by air.

Hard Plastic Protective Cases

Hard plastic protective cases are a practical choice for a wide range of applications due to their affordability, lightweight construction, and durability. These cases can be crafted through blow molding, injection molding, or rotary molding techniques, allowing for virtually any shape and size to accommodate custom designs and components.

Blow Molding

This process begins with a piece of plastic called a parison, slightly heavier than the finished product. The parison, with a hole at one end, is clamped into a mold and heated until pliable. Compressed air is then blown into the hole, expanding the plastic to conform to the mold's shape. After cooling and hardening, the mold is removed, and the parts are prepared for trimming and assembly. Blow-molded cases may be lined with foam or used as-is for product containment.

Injection Molding

Injection molding involves forcing molten plastic into a mold or die. Once the plastic cures, the mold is removed, leaving the shaped part ready for assembly. After manufacturing, case components such as hinges, handles, latches, or locks can be installed on the exterior. Foam interiors may also be added, including pick-and-pluck foam, a customizable solid block or sheet of foam that consumers can adjust to fit specific items.

Rotary Molding

Rotary molding, or roto-molding, merges the precision of blow molding with advanced automation. This method uses a rotating set of molds to move the parison through multiple stations. The process integrates various shaping steps into one efficient cycle, enabling the creation of intricate plastic cases quickly and effectively.

Molded Plastic Cases

These cases offer exceptional versatility, with features like drawers, bins, and compartments for additional organization. They may include hinged tops that flip open to reveal telescoping trays, as well as adjustable or fixed compartments in numerous configurations to suit different needs.

Military Use Cases

Plastic cases designed for military applications must adhere to strict military specifications (mil specs) outlined by government regulations. These cases, made from plastics, wood, or metal, are built to transport munitions, medical supplies, radio or sonar equipment, tools, food, or confidential materials securely and efficiently. Their robust construction ensures reliability under demanding conditions.

Soft Carrying Cases

Soft carrying cases offer a versatile solution for transporting and protecting items, with designs that are typically sewn or heat-fused for durability. These cases may feature multiple pockets on the inside or outside, providing ample storage options. They can be reinforced with frames made of wood, plastic, or metal, or they may remain freestanding. Closures can vary, including locking flaps, snaps, zippers, or hook-and-loop fasteners, ensuring secure containment.

Neoprene Cases

Neoprene is an ideal material for crafting flexible, waterproof cases, often used to carry electronics and photographic equipment. Its unique properties include acting as both an anti-static barrier and a shock absorber, offering enhanced protection. While neoprene is typically black, it can be laminated with colored fabrics to achieve different aesthetic finishes.

Nylon Cases

Nylon stands out as a durable and cost-effective material for soft carrying cases. It is available in a wide range of colors and textures, making it suitable for tote bags designed to carry tools, small equipment, and accessories. Nylon cases can be personalized with company names or logos using embroidery, screen printing, or rubber stamping, making them popular for professional and team use.

Polyester Cases

Polyester offers a lower-cost alternative to nylon while accommodating similar designs. Although it is less durable, polyester is still widely used for creating cases that serve everyday needs, maintaining affordability without compromising on basic functionality.

PVC Cases

PVC (polyvinyl chloride) is a versatile material that can be woven, laminated, heat-sealed, or embossed to create custom plastic cases. These cases often imitate other materials while retaining the practical advantages of plastic. Frequently, PVC fabric is laminated onto fiberboard to provide structural stiffness, making it an inexpensive yet effective alternative to leather for certain applications.

Leather Cases

Leather continues to be a classic choice for carrying cases, prized for its traditional aesthetic, durability, and sophisticated appearance. However, leather cases are typically more expensive and require maintenance that plastic or metal cases do not. As a result, leather is often reserved for high-end briefcases and small luggage pieces, appealing to those who prioritize elegance alongside functionality.

Other Carrying Case Types

Catalog Cases

Catalog cases are popular among business executives and trade show exhibitors for their practicality. With multiple compartments, they provide organized storage for a variety of items, including files, documents, and presentation materials, ensuring easy access during professional engagements.

Graphic Cases

Graphic cases are specifically designed for transporting large visual materials such as maps, blueprints, and other oversized documents. These cases offer the necessary protection to prevent bending or damage during transit.

Hazardous Materials Cases (HAZMAT)

HAZMAT cases are built to safely transport potentially harmful substances, including gases, explosives, and corrosive materials. These specialized cases meet strict safety standards to ensure secure containment during handling and transportation.

Instrument Cases

Instrument cases protect and transport various tools and equipment, ensuring they remain secure and intact during movement. These cases are commonly used in industrial settings for shipping and storing delicate or specialized instruments.

Panel Mount Cases

Panel mount cases are designed to accommodate panels that hold and separate field service equipment. These cases enhance organization and accessibility, making them a practical solution for professionals working in technical or field-based roles.

Rack Mount Cases

Rack mount cases include integrated racks or shelves to stack equipment in an organized and accessible manner. These cases are ideal for storing and transporting systems such as computer networking equipment and other technical components.

Sample Cases

Sample cases are essential for showcasing products during retail launches, trade shows, conferences, and business presentations. These cases provide a convenient way to transport and display product samples, helping businesses spread awareness and highlight product features in professional or promotional settings.

Tool Cases

Tool cases are specifically designed to hold, organize, and protect a wide range of tools and equipment. Their durable construction and thoughtful design make them indispensable for hobbyists, mechanics, and professionals in various industries.

Carrying Case Manufacturers

With the wide availability of custom plastics manufacturers, industrial sewing shops, and metalworking facilities, finding an appropriate carrying case—whether standard or custom-designed—should be straightforward. A reliable manufacturer will guide you in selecting the right materials for the intended use while creating a design that balances functionality with visual appeal.

When choosing a manufacturer, it is essential to work with one that fully understands the scope of your project and is committed to delivering a product that meets your needs at a fair price. For heavy-duty cases, the manufacturer should prioritize durability, using robust materials without compromising on quality. Any special features, such as recessed handles, wheels, or custom hinges, should be incorporated into the design with careful consideration. Similarly, labels, logos, or other branding elements should be discussed and included in the cost planning early in the process.

Timely delivery is another critical factor when selecting a manufacturer. The chosen provider should ensure the use of high-quality materials, skilled craftsmanship, and an awareness of their environmental and community impact. For a convenient list of carrying case manufacturers offering a variety of designs and options, you can refer back to the top of this page.

Carrying Case Terms

Acrylonitrile-Butadiene-Styrene (ABS)

A durable plastic commonly used in industrial applications, including as an outer laminate for shipping cases.

Angle

An aluminum covering placed on the outer corners of shipping cases to reinforce and protect them.

Anti-Static Foam

A specially treated, non-conductive foam made of polyfoam or polyethylene. It is ideal for cushioning magnetic media and is commonly used in cases for transporting sensitive computer equipment.

Base

The bottom portion of a carrying case, designed to sit flat during loading or use.

Blocking

The use of wood or foam inside a case to secure and support items, enhancing the interior's effectiveness and providing stability.

Casters

Rotating wheels mounted in a metal frame, enabling the easy mobility of heavy objects such as furniture or electronic equipment.

Cavity Cut-Out

A space cut directly beneath an encased item, often used for storing cables, owner’s manuals, or other accessories.

Coupler

A device designed to connect and secure multiple cases together for efficient handling or transport.

Cubed Foam

Also known as "diced foam," this material consists of one-inch cubes of polyester foam with corners lightly attached, allowing users to easily remove sections to create custom spaces for encased objects.

Electrostatic Discharge

The release of electrical energy caused by the movement of electrons when two objects come into contact and then separate, which can be a concern for sensitive electronic equipment.

Embossing

A process involving the application of heat and pressure to create raised designs or logos on a surface.

F-B

An abbreviation for "front to back," often used to describe the depth of a case.

Foil Embossing

A decorative technique that combines embossing with foil stamping, creating a raised and metallic effect on the surface.

Foil Stamping

A method where a stamp is pressed into foil, transferring the design or outline to the case’s surface.

G-factor

A measurement used to evaluate the durability of an item, particularly in terms of its ability to withstand impact or vibration.

Hand Slot

A precisely cut section in the foam interior of a case, designed to make it easier to remove the encased item.

L-R

An abbreviation for "left to right," commonly used to describe the width of a case.

Load Capacity

The maximum weight a case can effectively support and transport without compromising its structure or functionality.

Neoprene

A synthetic rubber known for its versatility and resistance to wear from chemicals, extreme temperatures, and hazardous conditions, widely used in industrial applications.

Polyethylene (PE)

A lightweight, durable plastic that is stain-resistant and impervious to damage from chemicals, fluids, or temperature variations.

Polymer

A compound made up of multiple linked units of elements like hydrogen or silicon, forming the basis for many plastic and rubber materials.

Polypropylene (PP)

A durable polymer that functions as both a fiber and a plastic. It is stronger but less commonly used than polyethylene due to its unique properties.

Skid

The damage that occurs when a case is dragged or mishandled during transportation.

Skid Runners

Protective attachments applied to a case to prevent or minimize damage caused by skidding during movement or handling.

More Custom Carrying Case Information

More Carrying Case Manufacturers