CNC Machining

CNC machining is a manufacturing technique that uses specialized computer programs to guide the automated design and production of highly precise parts across various industries. CNC, which stands for computer numerical control, encompasses a wide range of manufacturing processes used to produce either small or large quantities of identical precision parts with speed and efficiency.

CNC Machining Overview

While CNC milling is the most widely used type of CNC machining, many offer a variety of detailed operations. These may include CNC cutting, CNC drilling, and CNC grinding, often integrated into a single system with CNC tool changers that automatically select the correct tool for each task. Additionally, many CNC services offer prototype machining at the start of production, whether for long-term or short-run projects, to ensure that customer requirements are met. The use of prototypes and CNC machining as a whole reduces waste material and minimizes errors. With precision machining, human error is significantly minimized since the tools are fully automated, allowing a single operator to oversee multiple machines. While this automation can reduce the workforce, it remains crucial to monitor operations and equipment closely. Without consistent maintenance and calibration, CNC machines may lose their accuracy. Therefore, it's vital to consider both the client's specifications and the equipment's needs to ensure the successful production of automated products.

CNC Machining Images, Diagrams and Visual Concepts

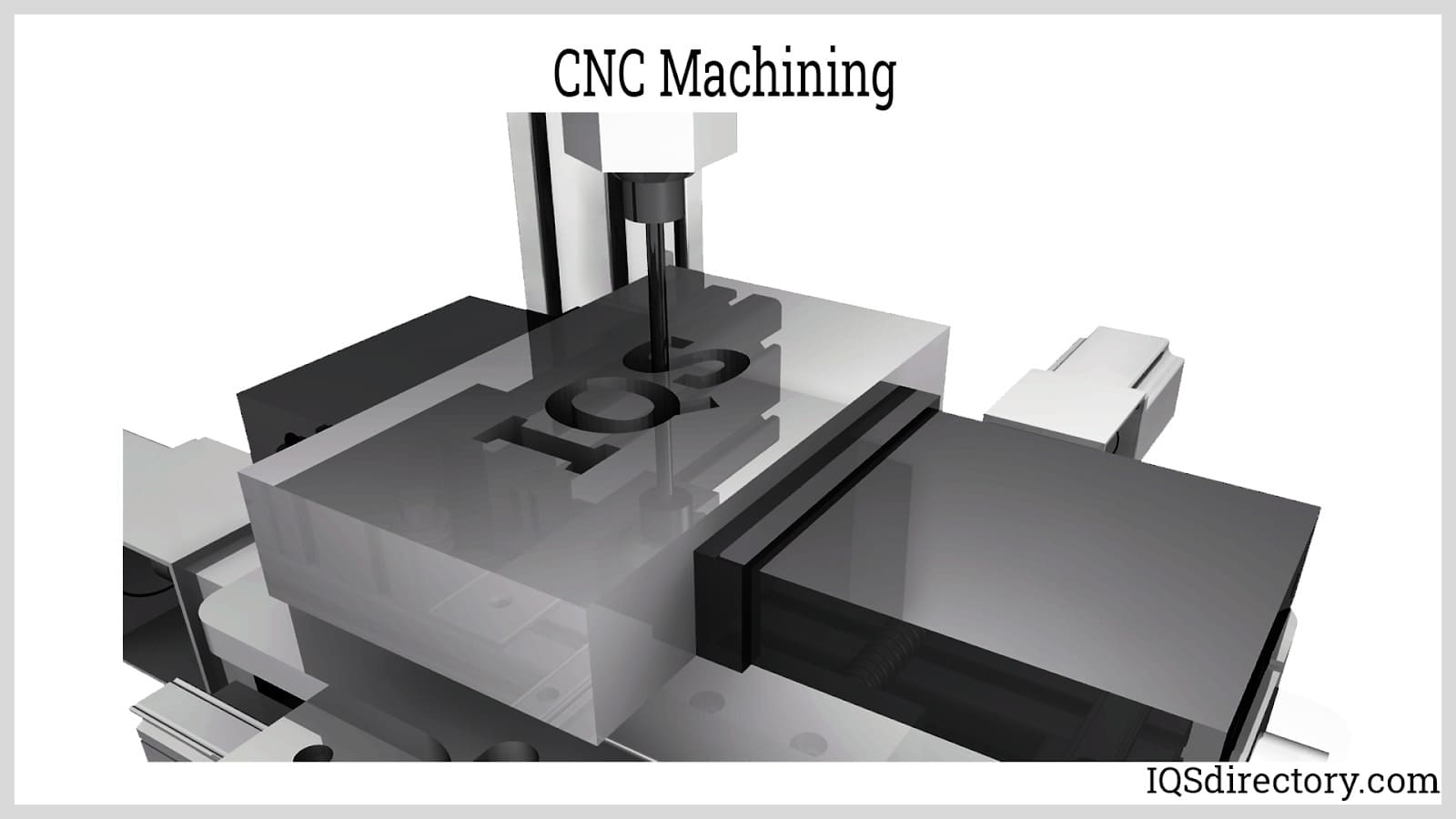

CNC machining is an electromechanical process that manipulates tools around three to five axes, with high precision.

CNC machining is an electromechanical process that manipulates tools around three to five axes, with high precision.

Examples of parts made using CNC machining with precision and accuracy.

Examples of parts made using CNC machining with precision and accuracy.

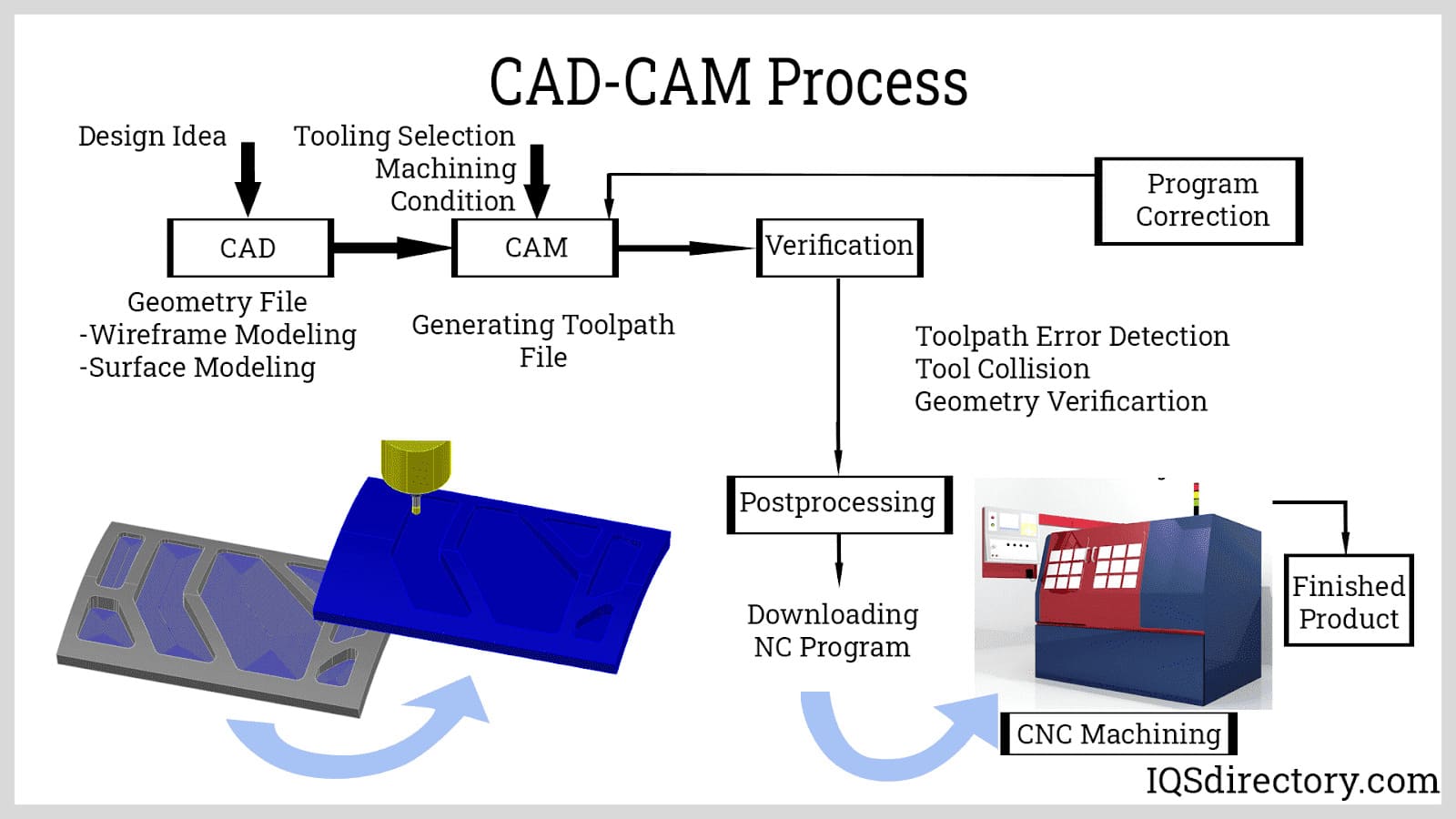

CAD-CAM, descriptive term for the software used for designing components using a CNC machine.

CAD-CAM, descriptive term for the software used for designing components using a CNC machine.

THe different tools used in CNC machining.

THe different tools used in CNC machining.

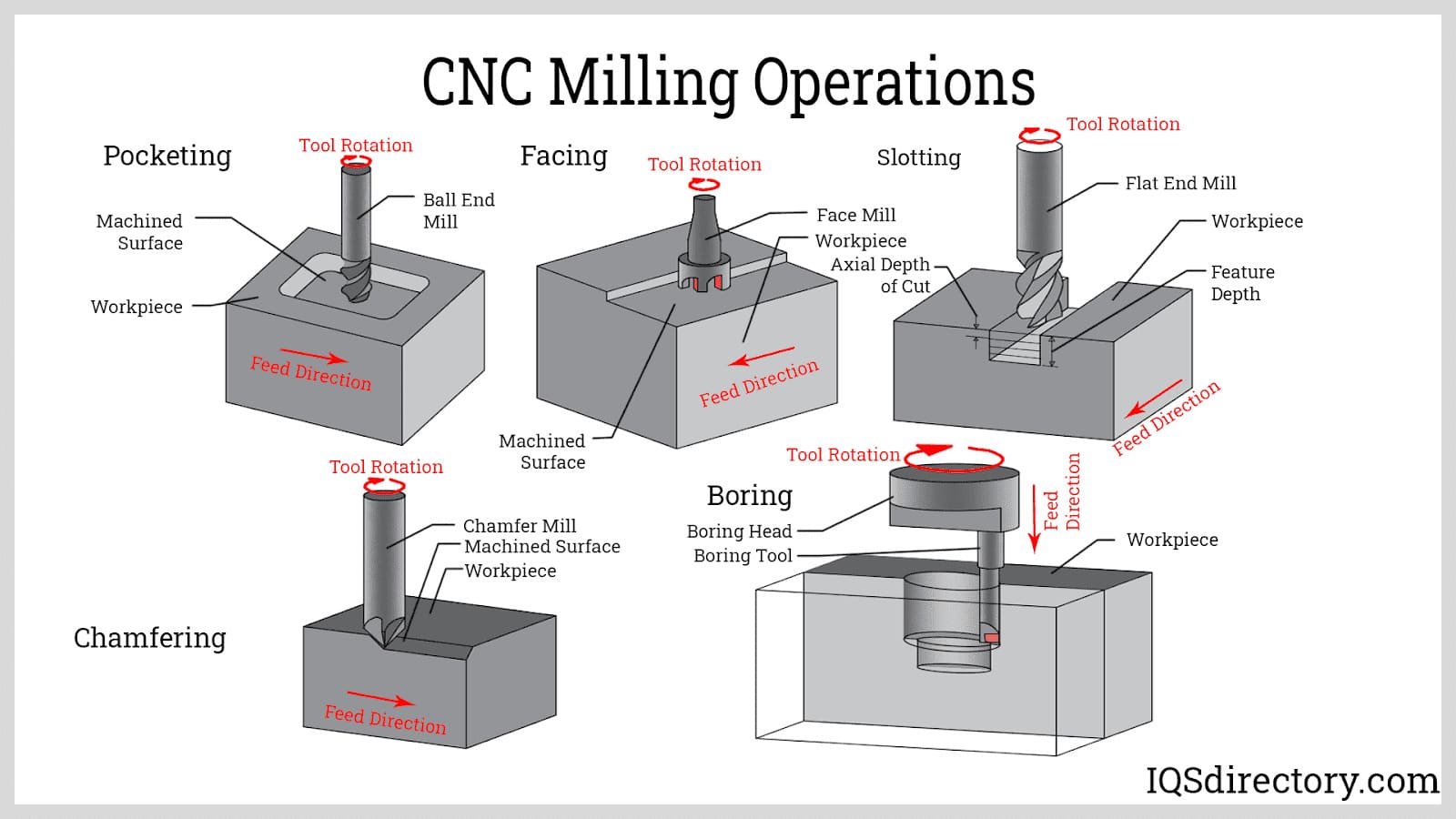

Operations and configurations that are used during the milling process.

Operations and configurations that are used during the milling process.

CNC Machining Types

-

CNC Cutting

A precise manufacturing process that uses various mechanical techniques in conjunction with computer numerical control (CNC) software to remove excess material and create complex two-dimensional and three-dimensional shapes.

CNC Drilling

Utilizes computer-controlled machines to bore precise holes or threads into materials of varying composition and thickness.

CNC Grinding

Uses an abrasive wheel, disc, or belt to perform automated material removal and surface finishing in a variety of industrial and commercial applications.

CNC Machine Shop

A facility where materials are shaped and processed using CNC machines.

CNC Machines

Machines that use computer logic to guide the design and production of precision parts through automated processes.

CNC Manufacturing

A production process that employs specialized computer software to direct complex automated machinery in the design and creation of precision parts and components.

CNC Milling

Also referred to as "CNC turning," it is one of the most common forms of CNC machining. CNC milling machines are classified by the number of axes they use, typically featuring at least three axes (X and Y for horizontal movement and Z for vertical). Some machines may use five axes with additional pivot points for more intricate movements.

CNC Punch Machines

Machines that use computer numeric control systems to cut parts with precision.

CNC Services

Operations provided by CNC machine shops that integrate all steps of the design and production of precision parts using computer-controlled machinery.

CNC Work

Refers to all tasks performed using computer numerically controlled machinery, which enables the efficient, accurate, and fast production of precision parts.

Machine Work

The process of shaping materials into precise forms through various mechanical techniques.

Precision Laser Machining

The cutting of parts using CNC-controlled lasers, ensuring high levels of accuracy and precision.

Precision Machining

The process of using computerized machines to ensure exact dimensions and tolerances during production.

Prototype Machining

The creation of a single or low-volume conceptual model or "mock-up" of a product using CNC machinery. Prototypes are used to verify feasibility and design, though they are often less efficient than later production models.

Using a CNC Machine Shop

When selecting the appropriate CNC machine shop, it's essential to consider the specific processes needed to design and manufacture a part. Key factors include dimensional capacity, software compatibility, material handling capabilities, production volume, and the available machinery. These aspects can vary significantly between different CNC providers. The diameter capacity of a machine, for example, is typically expressed as a range, indicating both upper and lower limits, while volume requirements are often presented similarly. Material capabilities should be clearly defined, as different materials—ranging from metals and plastics to glass, ceramics, and wood—require specialized machines.

Some machine shops use a limited selection of machines, while others offer a broad range of equipment. In addition to standard operations like drilling, grinding, cutting, and milling, services such as broaching, etching, honing, casting, forging, and screw machining may also be available. Although CNC machining usually produces precision parts that require little to no additional finishing, optional secondary operations like anodizing, electroplating, heat treating, stress relieving, lapping, polishing, painting, and welding may be provided. These processes are all controlled by specific software, often utilizing various computer languages. G-code is the most widely used language, but some manufacturers may employ bitmap, conversational, drawing exchange format (DXF), M-code, or product-specific software.

Once the appropriate facility, materials, and software are selected, the CNC machining process begins with collaboration between the manufacturer and the client. Using computer-assisted design (CAD) and computer-aided manufacturing (CAM), along with advanced programming techniques like photo imaging, the product can be fully conceptualized in-house. These programs convert the product's design into code that directs the machinery. Raw materials, typically in the form of billets or other stock shapes, are loaded into the machine. These materials, often pre-cast, forged, rolled, or extruded, may be provided by the client or the machine shop itself.

In cases where multiple machines are required, workers may transfer materials between processes, though automation can handle this step as well. Once materials are set, the software is activated. The computer system provides a series of commands that control the positioning, pressure, depth, and other movements necessary for the production of parts. These movements allow CNC machines to produce high-precision, identical parts in rapid succession, something that would be far more time-consuming if done manually.

Since its inception in the 1970s, CNC machining software and capabilities have evolved significantly. Despite the technical complexity of machining and coding, CNC systems feature user-friendly interfaces that are more accessible to beginners than the machines they automate. Many manufacturers offer a hands-on approach, allowing clients to take an active role in designing parts and creating the schematic for production. Often, a prototype or working model is created before mass production to ensure efficient use of materials and machinery. Although manual operations can also produce prototypes, CNC machining offers rapid prototyping, and since the code is stored, the final product will be an exact replica of the prototype. Once production ends, the code can be archived for future use. This capability ensures that CNC machining delivers high-precision, high-quality parts quickly and consistently, meeting the exact specifications of industries such as automotive, aerospace, military, metallurgy, and more. CNC manufacturers provide not just a finished product, but also assistance in the design, optimization, and enhancement of operations as needed.

CNC Machining Terms

-

A-Axis

A CNC machining tool that uses circular axis motion or a slide along the x-axis; values along the A-axis represent the degrees of rotation around the x-axis.

Absolute System

A CNC machining system that refers to all positional dimensions relative to a shared datum point, including both feedback and input.

Analog

Referring to a CNC machining system that uses electrical voltage ratios or magnitudes to represent the physical positions of the axes.

American Standard Code for Information Exchange (ASCII)

A data transmission code established by the American Standards Association.

Axis

The relative movements of a workpiece or CNC machining tool that moves along a primary direction, typically consisting of three linear axes—X and Y for horizontal movement and Z for vertical movement—set at ninety-degree angles from each other.

Axis Inhibit

A feature of a numerically controlled unit that allows CNC machine operators to withhold command information from CNC machining and milling tool slides.

Axis Inversion

Also known as Mirror Image. A CNC machining service command used to create a reversed or mirrored part by swapping the plus and minus values along a given axis. This process makes a left-oriented part using a right-handed tool path; circular interpolation also involves this reversal.

Basic Control Language (BCL)

A CNC machining controller language that uses EIA/ANSI 494 software.

B-axis

Circular motion of CNC machining tools along and around the Y-axis.

Block

A single line of NC code containing enough information for CNC machining tools to execute a single arc or line movement.

Block Delete

A function that allows the CNC machine control system to ignore a selected block of code at the CNC machining operator's discretion.

CAD/CAM

Computer-Aided Design / Computer-Aided Manufacturing; the use of computers to assist both CNC tool development and the manufacturing phase of CNC processes.

Computer-Aided Design (CAD)

The use of computers to assist in the design phase of CNC machining.

Computer-Aided Manufacturing (CAM)

The use of computers to assist in manufacturing processes through computerized control of the tooling process.

Clockwise Arc

Coordination between two axes creates an arc with a curvature in the clockwise direction relative to the part being machined and the Cartesian planes.

Counterclockwise Arc

Coordination between two axes creates an arc with a curvature in the counterclockwise direction relative to the part undergoing precision CNC machining and the Cartesian planes.

Linear Interpolation

A CNC control function that generates data points between given coordinate positions to allow simultaneous movement along one or more axes in a linear path.

Manual Part Programming

The process of manually writing a manuscript in the machine control language format that defines a series of commands for a CNC machine.

Modal

A function where CNC machining computer systems retain information until new data is received to replace it.

Offset

A displacement of a precision CNC machining tool along an axial direction, which is the difference between the actual length and the inputted CNC milling tool length.

Overshoot

The amount by which axis motion goes beyond the targeted value.