CO2 Lasers

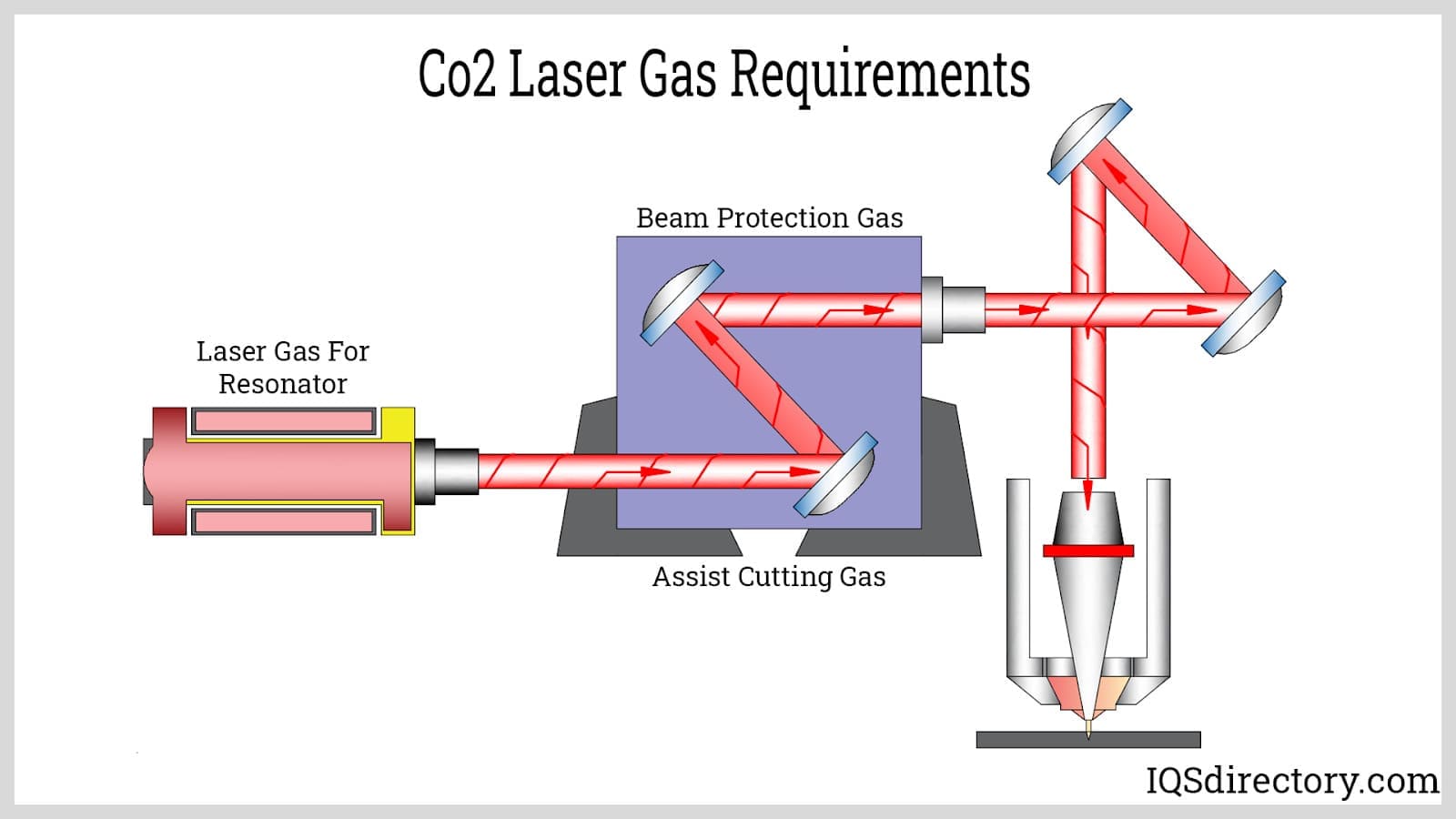

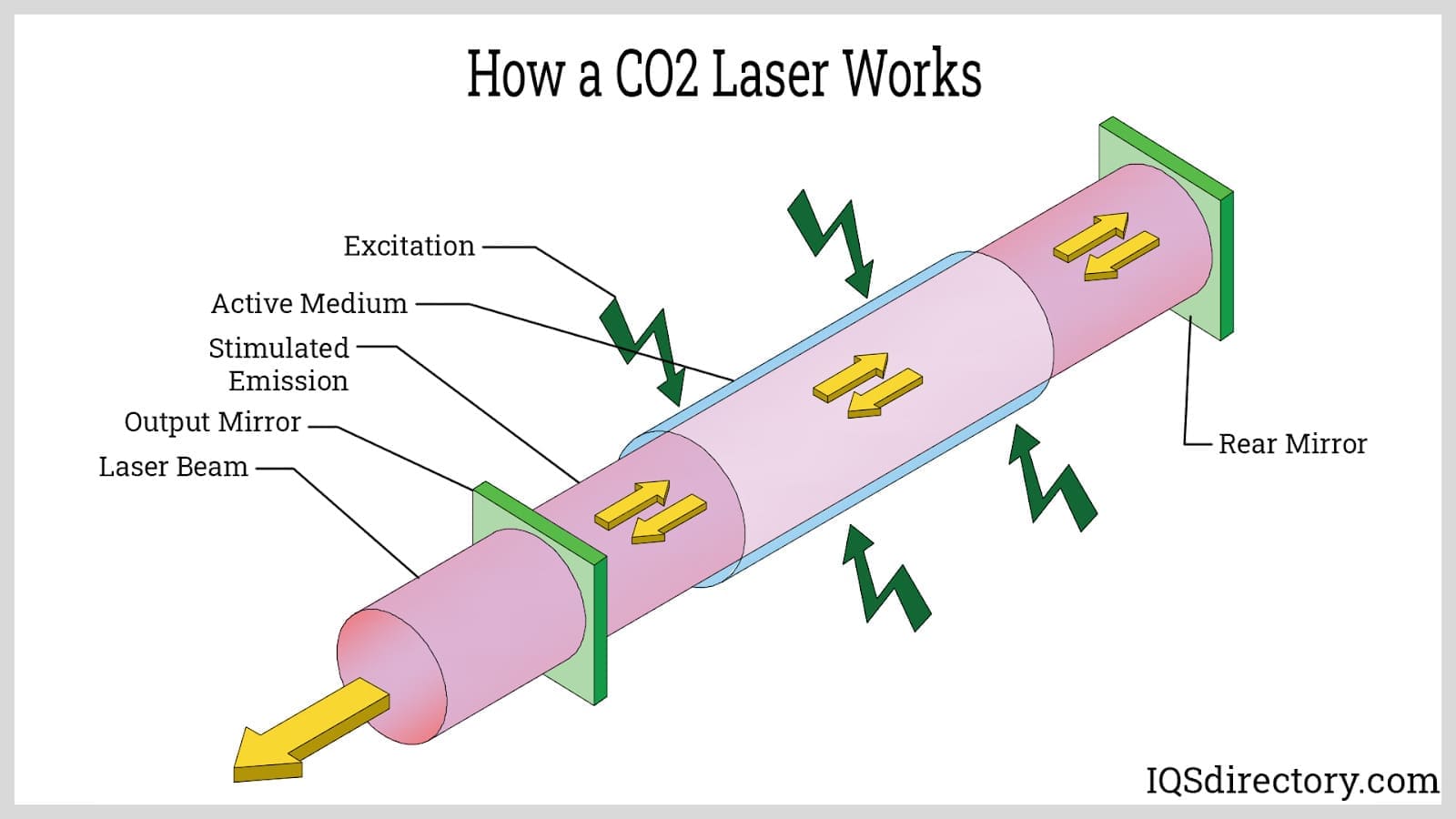

One of the earliest lasers that still operates successfully is a specific type of gas laser called the CO2 laser. When energy is sent through a gas-filled tube in a CO2 laser, light in the long-wavelength infrared spectrum is produced. As the gain medium, it relies on a gas combination that includes carbon dioxide (CO2), helium (He), nitrogen (N2), and possibly some hydrogen (H2), oxygen (O2), water vapor, and xenon (Xe). One can operate the electrical gas discharge with radio frequency, DC, or AC. Mirrors are also located at the tube's terminus. One of the mirrors reflects all light completely, while the other lets some light through.

Working Principle of CO2 Lasers

After being stimulated by an electric current, nitrogen molecules present in the CO2 gas mixture gain energy (e.g. become excited). Nitrogen is used in this process since it can maintain this excited state for a longer period. Additionally, nitrogen does not release energy in the form of light or photons while in this state. The high-energy vibrations that the nitrogen creates stimulate the molecules of carbon dioxide. The laser them reaches a condition known as population inversion. At this point, there are more excited particles than unexcited particles. To create a beam of light, the nitrogen atoms must release energy from photons, which causes them to lose their excited state. This occurs when excited nitrogen atoms come into contact with extremely cold helium atoms, producing the nitrogen to emit light.

Types of Carbon Dioxide Lasers

DC Glass Lasers

The basic component of a DC grass laser is a long, delicate glass container filled with a laser gas combination. The laser optics are often directly mounted to the glass to encapsulate the laser mixture and create the laser resonator. A high-voltage DC discharge ionizes the gas inside the glass container to create a laser beam.

DC glass lasers are distinguished by very slow modulation speeds. Due to the drawback of continuously turning on and off high-voltage DC electricity, one cannot modify them quickly. This significantly slows the processing speed of lasers and lowers throughput, especially in imaging applications that demand precise laser pulsing.

Figure 3: DC Excited Lasers

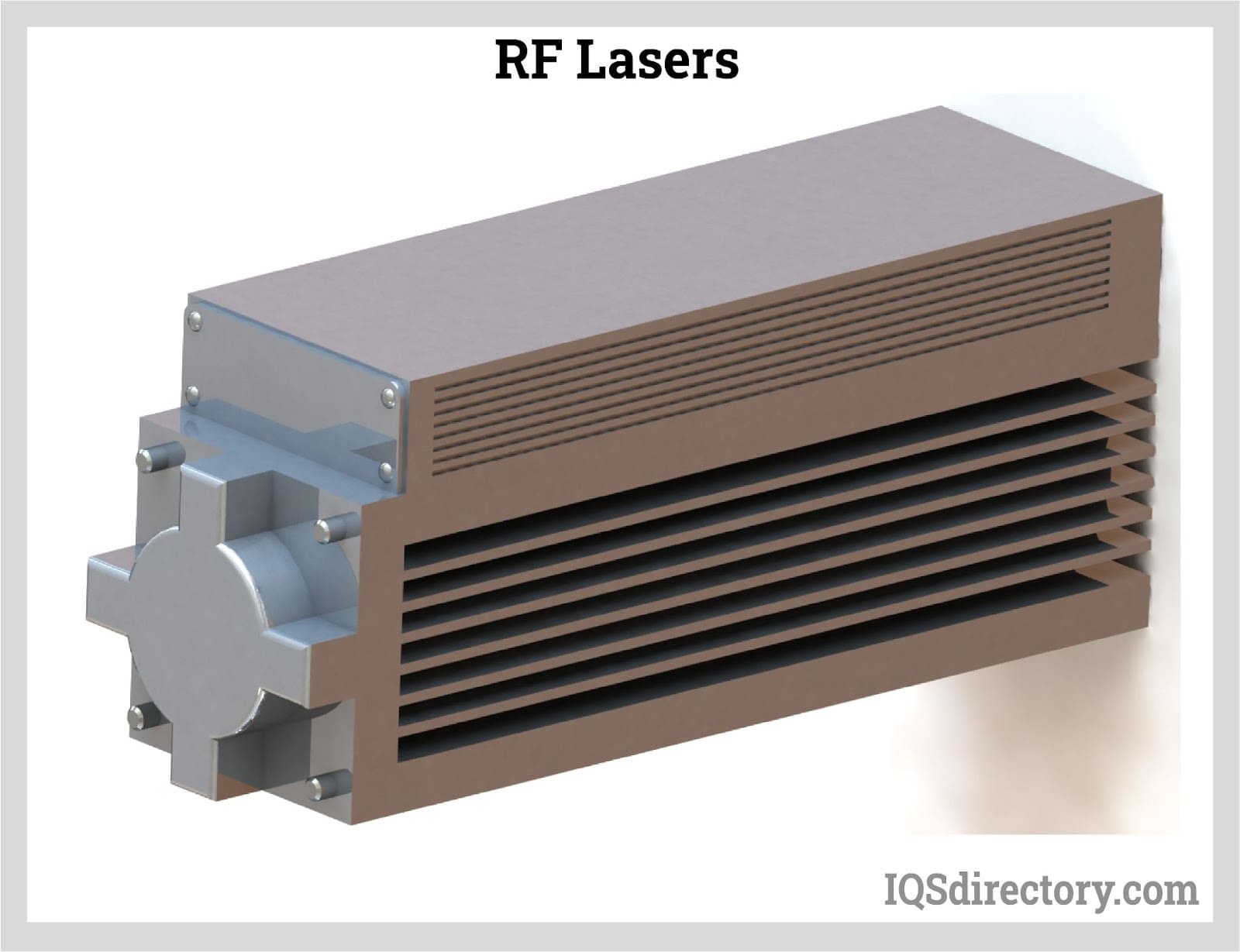

RF Lasers

In an RF metal laser, the laser gas combination is housed in a hermetically sealed metal chamber. For the laser to produce a laser beam, ionized gas plasma is produced using carefully controlled radio frequency energy. RF metal lasers have compact, robust, and integrated air-cooling architecture.

These lasers are built to function without water cooling and high voltage. This makes it safer for RF metal lasers to operate practically anywhere.

In addition, RF metal lasers are modern lasers with a low total cost of ownership. RF metal lasers are made to be long-lasting, deliver the best performance with excellent laser beam quality, have an endless service life, and contribute to operator safety.

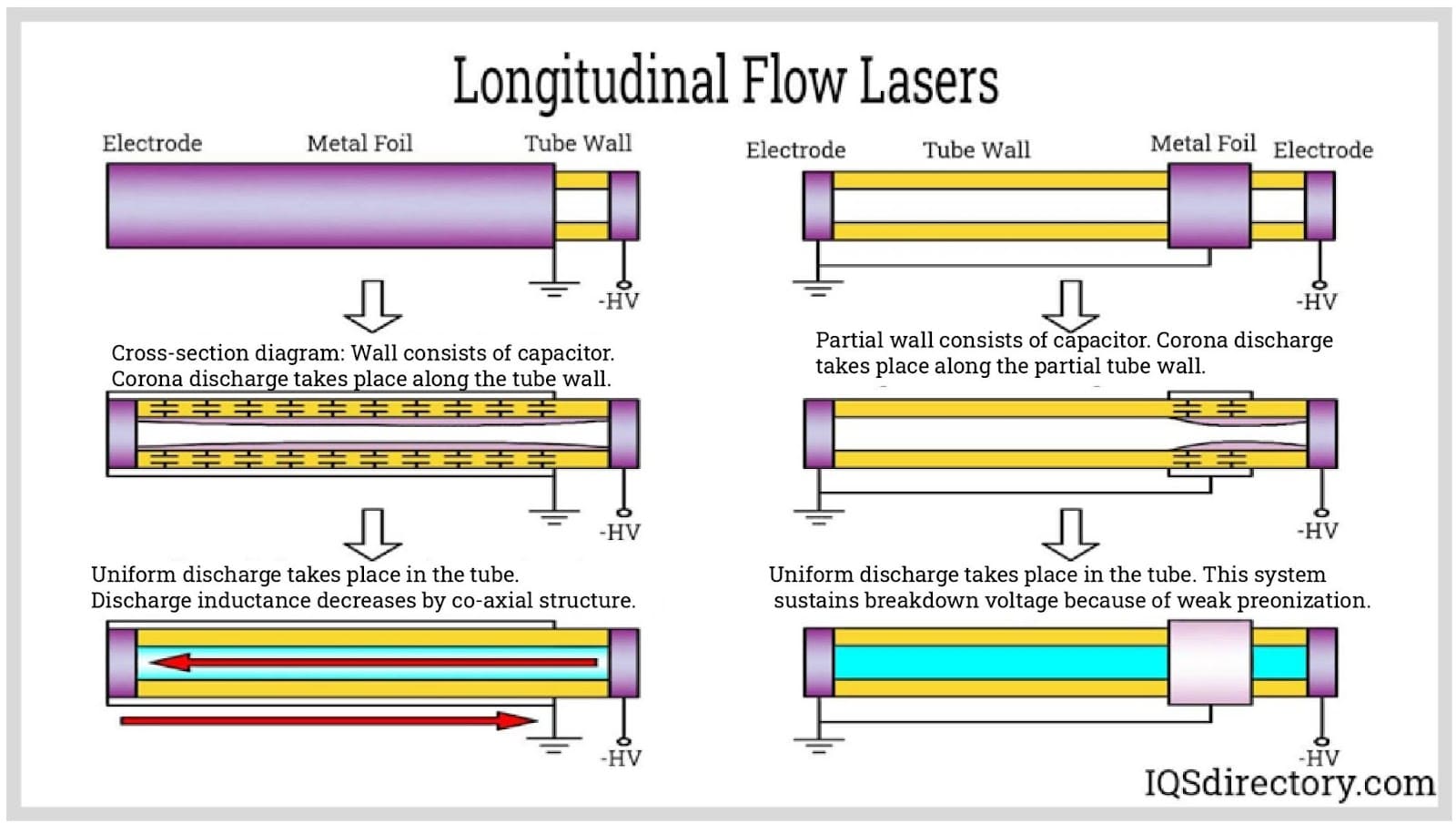

Longitudinal Flow Lasers

Longitudinal flow lasers, which have straightforward designs, are most commonly used in applications as lasers with high power outlet. These lasers constantly use a vacuum pump to draw laser gas via a discharge tube. Through a direct current discharge, some of the gas mixture's carbon dioxide is broken down into carbon monoxide and oxygen. Through many pumps in the system, the gas mixture is continuously circulated, improving the elimination of heat loss.

Sealed Carbon Dioxide (CO2) Gas Lasers

Numerous sealed CO2 lasers with output powers of 10 to 240 W are used for engraving, marking, and cutting materials like plastics, wood, ceramics, and even thin metals. Industrial users can benefit from sealed lasers' small size, robust design, and operational lifetimes of more than 35,000 hours. In addition, they are easy to integrate and need little maintenance, and they can be mounted on robotic arms or moving gantry systems.

Waveguide Lasers

A waveguide laser uses a waveguard in place of a sealed tube. It has a resonator with a surface area that is relatively large compared to its volume. As a result, heat loss can be removed efficiently. The fundamental advantage of employing a waveguide is that it effectively eliminates beam divergence, allowing for the maintenance of high optical intensities over a considerable distance.

Gas Dynamic Carbon Dioxide Lasers

These are a form of chemical laser for multi-megawatt powers, such as anti-missile weapons, where the energy is provided by a chemical reaction rather than a gas discharge.

Applications of CO2 Lasers

- The CO2 laser is commonly employed in industrial settings, such as cutting and welding, because of its tremendous power.

- Additionally, carbon dioxide lasers can be utilized as a scalpel during operations like neurosurgery and gynecology.

- CO2 lasers can be used in fabrication.

- CO2 lasers are also used in dermatology and skincare to treat both benign and malignant skin conditions, remove scars, smooth out wrinkles, and restore sun-damaged skin.

- CO2 lasers are effective for use in bloodless procedures and microsurgery.

Benefits of CO2 Lasers

- Straightforward application

- Many applications

- Continuous output

- Effective functionality

- High electricity production

- Enhanced output power with longer gas tubes

Choosing the Proper CO2 Laser Manufacturer

To ensure the most positive outcome when purchasing a CO2 laser from a CO2 laser manufacturer, it is important to compare several companies using our directory of CO2 laser manufacturers. Each CO2 laser manufacturer has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each CO2 laser business website using our proprietary website previewer to learn what each company specializes in. Then, use our simple RFQ form to contact multiple CO2 laser businesses with the same form.