Cold Headed Parts

Cold headed parts refer to a type of finished or stock shape created through a specialized process known as cold working or cold forming. While the terms "cold working," "cold forming," and "cold heading" are often used interchangeably, cold heading is actually a subset of the broader category of cold working or cold forming. Specifically, cold heading involves enlarging sections at the ends of tubular pieces, such as rods or wires. To fully understand cold heading, it is important to view it within the larger context of cold working processes.

The History of Cold Headed Parts

The use of "cold" methods for working metal dates back to prehistoric times. Early examples include ductile metals like silver and gold, which were hammered with stones into sheets and then used to create jewelry and supplement armor. Interestingly, the advancement of cold working processes didn't truly gain momentum until the modern era. While Leonardo da Vinci designed the first known cold rolling mill in 1480, the first confirmed mill was built in 1615, primarily for producing tin and lead plates. The cold rolling of iron and steel began to develop shortly after, with significant growth occurring during the Industrial Revolution.

Modern cold working techniques began to take shape within the past few centuries. Germany's military ordnance industry played a key role in advancing these processes towards the end of World War II. After the war, American manufacturers, both military and consumer, increasingly adopted cold working techniques. Between 1950 and 1969, the use of cold-worked steel in the U.S. grew tenfold.

Defining Cold Working

The term "cold working" can be somewhat misleading, as it implies that these metallurgical processes take place at very low temperatures. In reality, cold working refers to processes that occur without the application of extreme heat. Rather than preheating the material, cold-worked materials are simply processed and shaped by machines at ambient temperatures, typically around normal room temperature.

Cold working is defined by two main characteristics. Technically, it refers to any metallurgical shaping process that happens below the material’s recrystallization temperature. Recrystallization involves the formation of new grains within a material when it is exposed to elevated temperatures. Although cold working usually takes place at room temperature, it can also occur at slightly higher temperatures, as long as the material does not reach its recrystallization point. Additionally, cold working is characterized by using mechanical stress instead of heat to induce shape changes. While specific actions and machinery vary depending on the material and desired outcome, most cold forming processes rely on applying extreme pressure to create plastic deformation in metals, resulting in the desired internal and external properties. This reliance on mechanical pressure sets cold working apart from other methods, such as hot working (which uses heat to deform metals), die casting (where molten metal is poured into molds), and screw machining (which removes metal rather than reshapes it).

Cold working is favored in manufacturing because it allows for more precise shaping and superior surface finishes compared to other metalworking methods. The process's quality, versatility, and simplicity make it essential in a wide range of industrial applications. Cold-headed parts are used in industries like construction, automotive, hardware, stamping, injection molding, aerospace, agriculture, recreation, furniture, electronics, pyrotechnics, packaging, and upholstery.

How Cold Working Works

The visible shape changes that metals undergo during cold-working are a direct result of changes occurring at the microscopic level. To understand how cold-working works, it’s essential to grasp two key concepts: work hardening and dislocations.

Work hardening (or strain hardening) and cold heading are both closely related to the concept of cold working, so much so that they are often used interchangeably. However, neither is exactly the same as cold working. The key distinction is that cold heading is a subset of cold working, while work hardening is a by-product or effect of cold working. Work hardening refers to the strengthening of metal that occurs directly from plastic deformation, which is the process cold working uses to reshape metal into precise dimensions.

Cold working causes work hardening through plastic deformation, which also creates microscopic dislocations in the material. In materials science, a dislocation refers to a defect in the crystalline structure of a material. When a material is subjected to enough mechanical stress (from work and energy applied to it), it experiences plastic deformation—the breaking of bonds between atoms and the rearrangement of the material’s atomic structure. Plastic deformation contrasts with elastic deformation, where bonds between atoms stretch but do not break. As dislocations from plastic deformation accumulate and interact with one another, atomic movement within the material becomes increasingly difficult. Eventually, the material’s crystalline movement becomes nearly impossible. In other words, the material becomes resistant to further deformation, hardening or strengthening it. Therefore, cold working and work hardening are inextricably linked, though not identical. To find these hardened materials, visit IQS Directory’s company list.

Advantages and Disadvantages Cold Working

Cold working processes offer numerous advantages for both consumers and manufacturers.

Cold Forming Economic Benefits

Energy Savings

Hot forming processes often require heating large and small metallic components to very high temperatures, making cold forming processes a significant energy-saving alternative.

Waste Minimization

Cold working helps reduce waste materials. Since the metals are primarily altered through punch and die manufacturing, they remain intact even during plastic deformation. In contrast, processes like CNC machining, welding, cutting, and drilling produce scraps and unused material. While recycling is often possible, it can be time-consuming.

High Production Rates

Cold working processes can produce between 50 to 400 parts per minute, whereas methods like screw machining can only generate 1 or 2 parts per minute.

Cost Reduction

The efficiency and productivity of cold working processes directly benefit consumers by significantly reducing part costs. On average, consumers can lower part costs by 40-60% when purchasing cold worked products.

Qualitative Benefits of Cold Forming

Increased Product Strength

Cold-formed parts typically have a solid construction that often doesn’t require secondary operations. Small cold-formed products, such as screws and fasteners, are often stronger than those made from multiple combined pieces. Moreover, work hardening from repeated pressure on cold worked materials enhances the tensile strength and hardness of the finished product.

Increased Product Consistency

Cold working processes ensure high consistency and reproducibility, even at high output rates. One of the key differences between hot and cold forming is the tighter dimensional tolerances achievable in cold working. Unlike metals that expand with heat and contract with cooling (as in hot forming), cold working occurs at room temperature, making it easier to predict and achieve precision.

Improved Surface Finishes

Cold working typically yields better surface finishes due to the absence of cooling and oxidation during the process. Cold working helps create a more compact and efficient grain structure at the atomic level, leading to enhanced strength and hardness in the metal.

Challenges of Cold Forming

Increased Internal Stress

Cold working often results in increased internal stress or strain in the material. To counteract this, annealing (heating and cooling metal) is commonly used, especially when multiple cold working steps are required. Annealing softens the material slightly, relieving tension and improving ductility. Manufacturers frequently alternate between cold working and annealing steps to produce stock forms and fasteners with the necessary properties for various applications.

Reduced Metal Ductility

As previously mentioned, the plastic deformation involved in cold working reduces the ductility of metal, limiting its ability to undergo further plastic deformation. This can be mitigated by using specific metals, such as low-carbon steel.

Limited Range of Available Materials

While many commercially processed metals can be cold worked, the process is most effective with raw materials that are already relatively soft and ductile, such as aluminum, since cold working relies on pressure rather than heat.

- Limited Range of Finished Products

Although machines like multi-die headers can achieve more complex shapes, cold working is generally better suited for forming simpler shapes. For example, cold plates are often produced through machining processes, which contribute significantly to the product’s final price. When more complex shapes are formed, the loss of ductility can make such shapes undesirable.

Materials and Products of Cold Working

Cold working is most often applied to raw materials like steel, aluminum, and copper, with steel being particularly favored due to its strength and economic viability. Other metals processed using cold working methods include titanium, iron, and brass. Advances in metallurgy continue to expand the range of metallic elements and alloys that can be effectively cold worked.

The products created through cold working techniques are typically smaller items such as cold-headed fasteners (e.g., universal rivets) and electrical contacts. Cold working is responsible for producing some of the most commonly sought-after components, including:

These components can take various shapes, including:

- Different types of heads (e.g., hexagon heads or round heads)

- Threads

- Steps

- Grooves

- Tapers

These products and shapes are often made from stock forms such as cold-heading wire, plate, and sheet. While cold working can be used to produce larger items, current technology makes it more practical for producing smaller and less complex components. However, the range of cold-formed products continues to expand, driven by advancements in manufacturing software. These improvements are allowing for faster production and the creation of increasingly complex components, such as spark plugs and axles.

Cold Headed Part Images, Diagrams and Visual Concepts

Cold heading, the process of continuously forming a specific shape or design from a metal wire without adding heat.

Cold heading, the process of continuously forming a specific shape or design from a metal wire without adding heat.

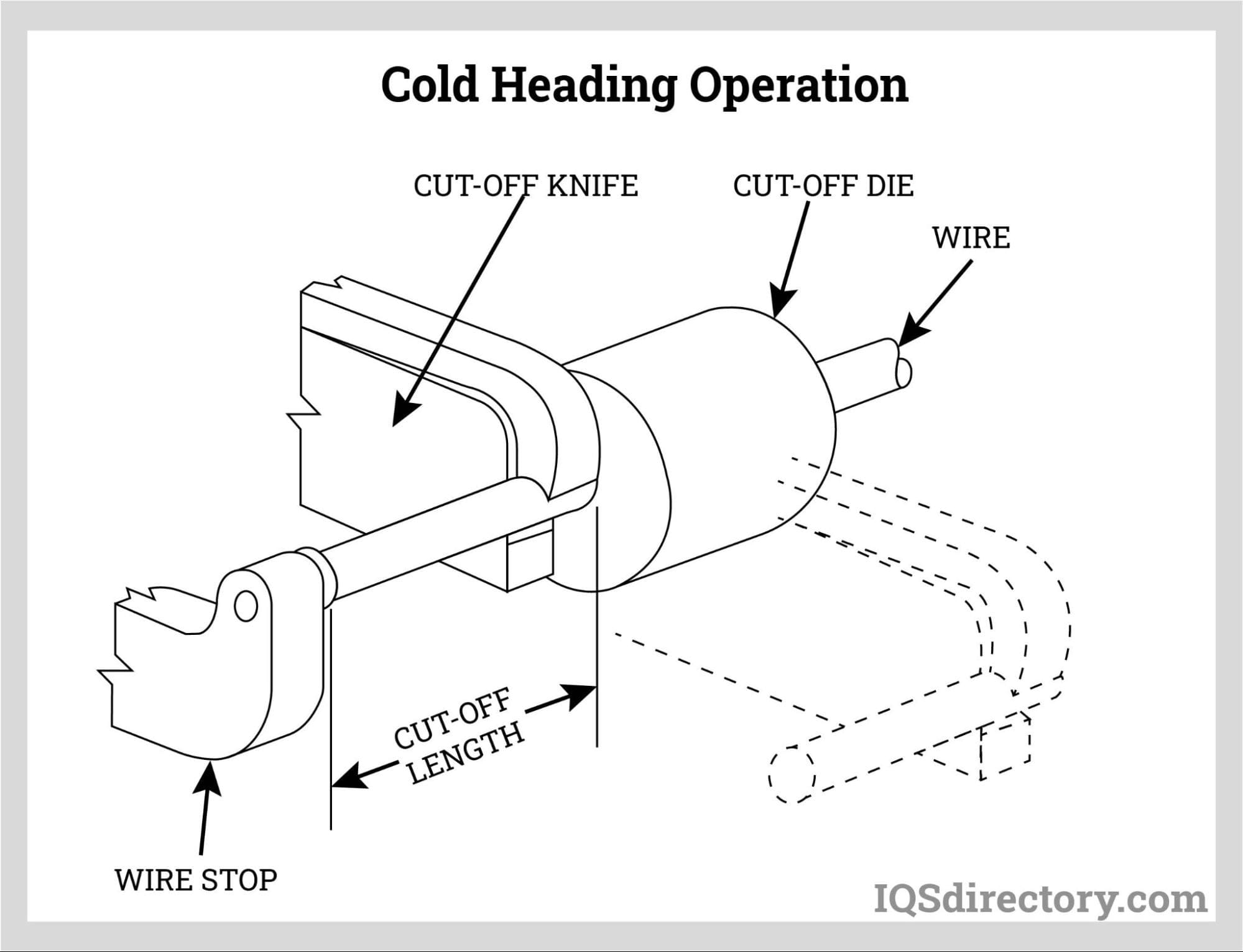

Cold headers have a specific method to cut and measure a piece of the wire coil.

Cold headers have a specific method to cut and measure a piece of the wire coil.

The process using high-speed automated part formers or cold headers which is capable of transforming simple wire into an intricately designed parts.

The process using high-speed automated part formers or cold headers which is capable of transforming simple wire into an intricately designed parts.

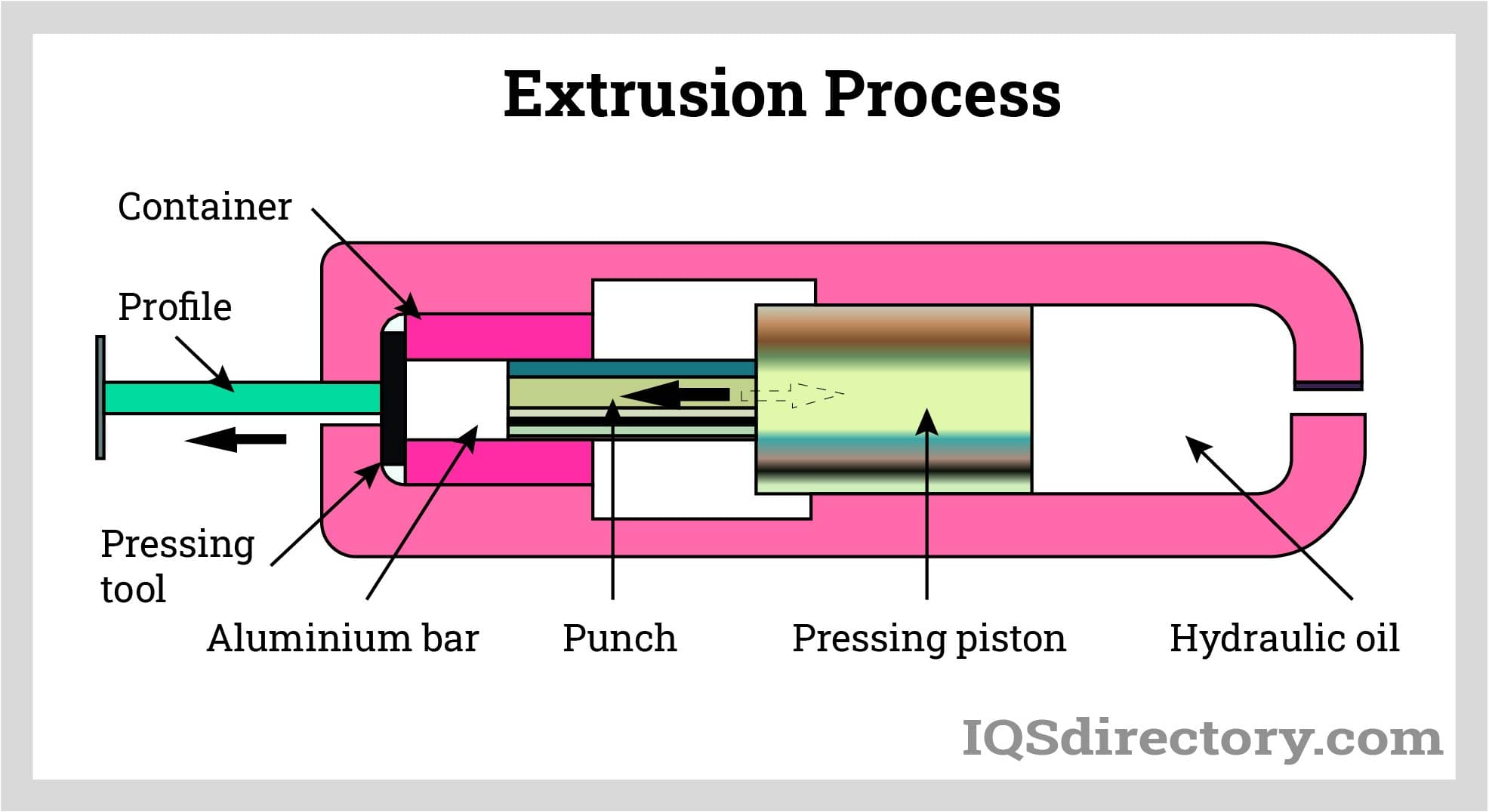

Cold heading extrusion, the process of increasing the length while decreasing the diameter.

Cold heading extrusion, the process of increasing the length while decreasing the diameter.

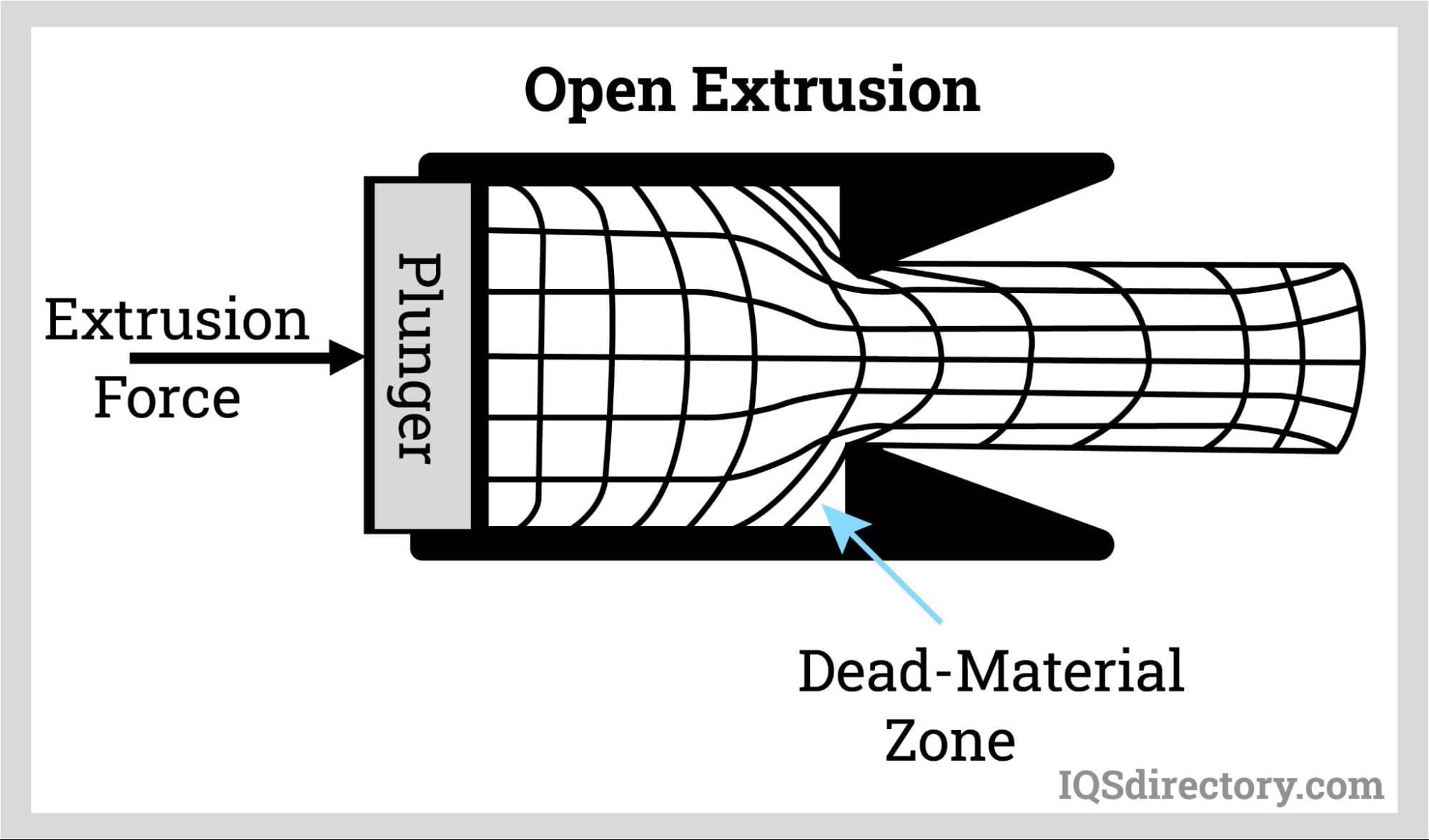

Open extrusion allows the extruding part of the tool to be located close to the top side of the die.

Open extrusion allows the extruding part of the tool to be located close to the top side of the die.

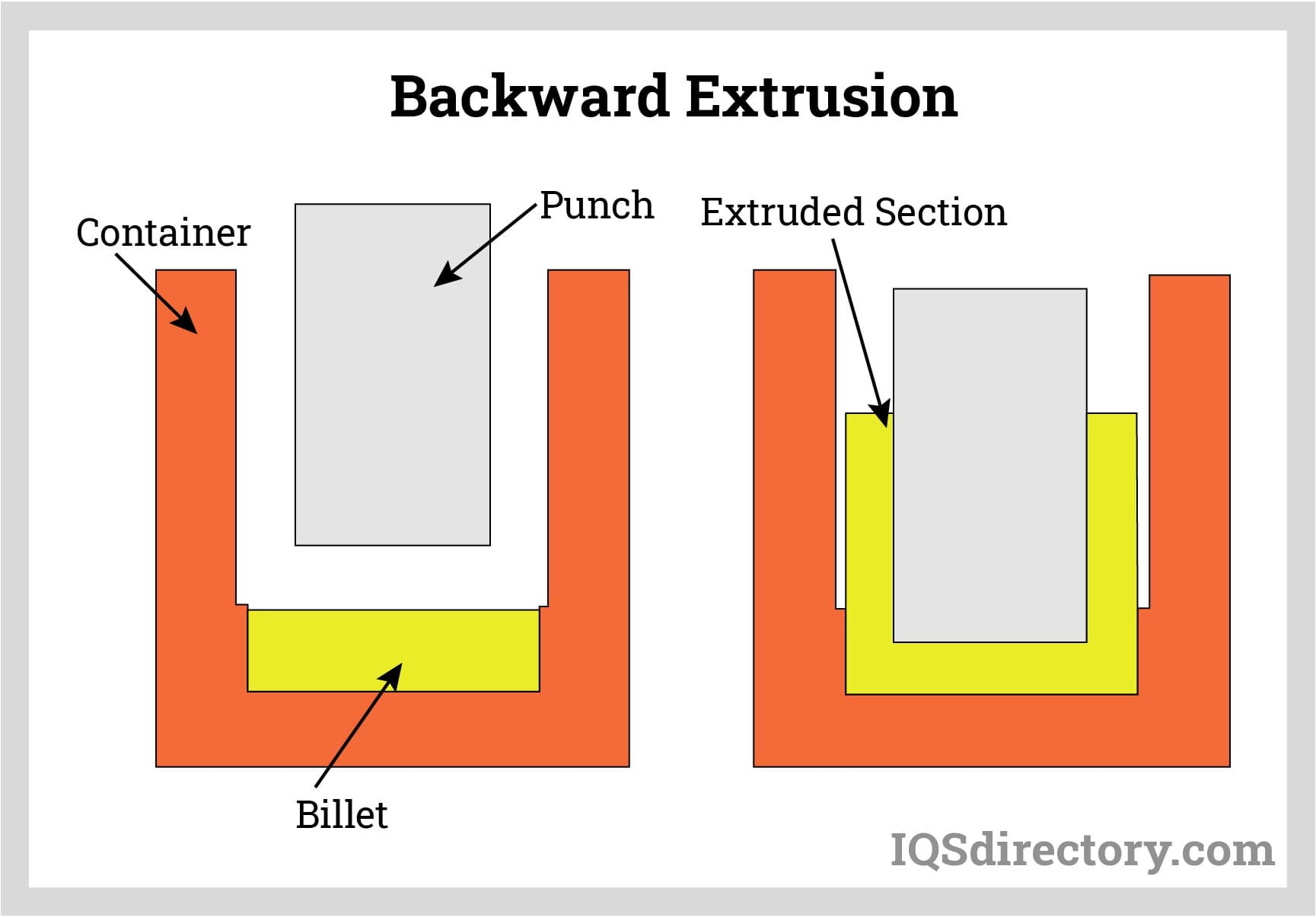

Backward extrusion a pin is driven into the part contained inside the die thus making hollow parts.

Backward extrusion a pin is driven into the part contained inside the die thus making hollow parts.

Types of Cold Headed Parts

-

Cold Extrusion

A cold working process in which materials are forced through dies or around punches to create variable lengths and cross-sectional or profile shapes.

Cold Formed Steel

Steel components that are fabricated through the cold forming process.

Cold Headed Bolts

One of the most common components produced using cold heading metal forming processes. These, along with screws and pins, make up a large portion of cold headed fasteners.

Cold Headed Pins

Manufactured by producers of cold headed parts, these pins have heads formed through the punch and die process. You can find companies that manufacture these pins on IQS Directory.

Cold Headed Rivets

Used to fasten materials by spreading the tip via hammering and protruding through the material.

Cold Headed Screws

Made from a wide range of metal alloys, these threaded fasteners require a screwdriver or Allen wrench for securing.

Cold Heading Wire

Created using either hot or cold processes depending on what’s most appropriate for producing cold headed parts. The wire must be suited to cold processing and the final intended use of the finished part.

Impact Extrusion

A cold forming process that produces collapsible tubes from soft metals by striking with a punch or ram.

Orbital Forming

An alternative to cold heading that not only allows for fastener production but also expands the capabilities of tool fastening.

Stainless Steel Pins

Cylindrical fasteners made from a steel alloy known for its high tensile strength, durability, and resistance to heat and wear, even in harsh or corrosive environments.

Steel Pins

Fasteners made from steel wire, sharpened at one end and headed at the other.

Processes of Cold Working

Cold working operations can be categorized into four primary methods: squeezing, bending, drawing, and shearing. Some of the most common cold working operations include cold rolling, cold forging, extrusion, sizing, swaging, cold roll forming, and drawing.

Squeezing Methods

As the name suggests, squeezing methods involve applying cold working through various forms of compression, such as rollers, hammers, presses, and other machinery. These methods are often similar to those used in hot-working processes.

Cold Rolling

This is one of the most common cold working methods. It involves passing metal through a pair of rollers to reduce it to a sheet with uniform thickness.

Extrusion

Extrusion is a popular cold working process where material is pushed through a die with a smaller diameter than the material itself. This method relies on extreme pressure and is most effective with softer materials like aluminum and tin, as opposed to harder materials like iron and steel. Essentially, extrusion is the opposite of drawing, where material is pulled through rather than pushed. You can find manufacturers who are able to do this process here.

Cold Forging

Cold forging involves shaping metal by compressing it in a cavity that resembles the desired shape. This category includes processes like cold heading (which creates enlarged sections at the end of a piece) and upsetting (which enlarges sections elsewhere on the piece). Cold forging can be seen as the opposite of extrusion, as it increases the diameter of a piece, although both are compression-based processes. Extrusion methods are often incorporated into larger cold forging operations.

Sizing Methods

Sizing processes are similar to squeezing methods. They involve compressing material to achieve a specific thickness. In contrast, swaging methods reduce the diameter of tubular metal by hammering.

Bending Methods

Bending methods deform material around an axis, changing its shape without altering its volume.

Cold Roll Forming Machines

Like cold headers, cold roll forming machines are commonly found in cold working shops. These machines perform a variation of bending using a series of rolls made of steel or roller dies. The rolls are used to shape smooth-surfaced strips and sheets of metal into specified cross-sectional shapes by continuously passing them between the rollers.

Drawing Methods

Drawing methods are also widely used in cold working. These methods involve filing or hammering a rod to a point and then placing it into a small hole or die. A grip is secured to the pointed end of the rod, and the metal is pulled through the die. This process stretches the rod while reducing its diameter, affecting both the shape and the volume of the material.

Shearing Methods

Shearing methods may seem unrelated to typical cold working processes, as they involve the mechanical cutting of material. However, shearing is classified as a form of cold working because it cuts material without removing excess (like in screw machining) or applying excessive heat (like hot working). For example, die cutting machines shape material by cutting, and water jet machines use high-pressure water to cut material. These methods qualify as cold working because they yield similar effects on metal, such as maintaining dimensional accuracy without surface hardening or warping.

Many shops also offer additional cold working operations, such as piercing, trimming, thread rolling, and pointing, to accommodate the diverse needs of various industries. If a feature cannot be created directly through cold working, it is often possible to add it through a secondary operation. As a result, cold heading service providers may also offer services like knurling, drilling, patching, tapping, shaving, milling, and broaching as required.

Cold Working Equipment

Cold working equipment and processes are diverse, as they cater to a wide range of operations. However, there are fundamental tools and methods that are commonly used across most cold working tasks.

One of the most common tools in cold machining is the die. Dies are used to shape and direct the material to achieve the desired dimensions. These tools are typically made from high-strength materials such as tool steel or tungsten carbide. Dies often work in conjunction with punches, which transfer the force required from the machine to the part being formed. The force applied must exceed the material’s elastic limit to induce plastic deformation, ensuring that the metal takes on the shape dictated by the punch and die. In a typical process, a metal blank is placed into a die, and a punch strikes it with sufficient force to create the intended shape.

There are two primary variations in die usage: single die and multi-die methods. In a single die system, the material remains in the same die and is punched multiple times. Alternatively, in a multi-die system, the material is moved between several dies during the punching process. These variations are reflected in the use of the cold header, a common tool in cold working shops. While a single die, two-blow header may be suitable for simpler cold heading processes, the production of more complex or customized products requires a multi-die, multi-blow header. Multiple dies allow for progressive reduction in the material’s size and provide the flexibility to create a variety of shapes, such as eccentric, offset, square, or elliptic designs. Additionally, multi-die systems enable the creation of features such as collars, necks, lugs, flats, or fins along the length of the stock shape or blank.

Cold Headed Parts Terms

-

Anti-Seize Compound

A compound applied to the threads of fasteners to prevent galling of mating surfaces and enhance corrosion resistance, allowing parts to be disassembled later.

Bearing Stress

The stress applied by a fastener to a joint face.

Chatter

Surface imperfections caused by slight movements of the tool away from or toward the workpiece, resulting in rough or unsatisfactory finishes.

Clamping Force

The force exerted by the fastener on the joint.

Clench

The ability of a fastener to secure previously separated materials.

Cold Work

A metalworking process where metal is deformed at room temperature, typically by methods such as hammering, drawing, or forming.

Concentricity

The condition in which the centers of two fastener surfaces align.

Creep

The permanent deformation of a fastener caused by prolonged stress and heat.

Die Impression

The part of the die surface that shapes the forged material.

Eccentricity

The difference between the centers of a fastener’s surface at different points.

Extrusion

The process of forcing metal through a die orifice in the direction of applied energy (forward extrusion) or in the reverse direction (backward extrusion), where the metal typically follows the contour of the punch or moving tool.

Fatigue Strength

A fastener's ability to resist fracture under varying stress conditions over time.

Heading

The process of shaping wire, rod, or bar stock in dies to form parts with cross-sectional areas greater than the original material. Heading typically involves creating a head on a metal part through cold forming.

Impression

A cavity or series of cavities machined into a forging die to shape the workpiece during forging.

Insert

A piece of steel securely fixed in a die, often used to fill a cavity, replace a portion of the die, or act as a small die with a specific impression fastened to a master die.

Joint

The materials that are joined together by the fastener.

Lead Thread

A measurement indicating the length from the beginning of a thread to the point where the thread reaches its full size.

Overtapping

The process of tapping a thread after plating to ensure its tolerances meet specifications, enabling proper assembly of internal and external threads.

Pitch

The distance between two adjacent threads on a fastener.

Preload

The initial tension applied to a fastener after tightening, which typically decreases over time.

Ram

The main reciprocating part of a press, guided within the press frame, to which the punch or upper die is attached.

Shank

The part of a fastener that lies between the head and the threaded portion.