Cooling Towers

A cooling tower is an enclosed structure designed to remove heat from water—or other fluids—used in industrial plants and various process systems. While cooling towers come in many shapes, sizes, and configurations, they all operate on the same fundamental principle: evaporative cooling. In this process, heat from the circulating water is transferred to the surrounding air through evaporation, effectively lowering the water’s temperature. Depending on their specific application or design, cooling towers may also be referred to as evaporative condensers or fluid coolers.

Evaporative cooling is governed by the wet bulb temperature—the lowest temperature to which water can be cooled under current atmospheric conditions. The efficiency of a cooling tower hinges on this temperature, as it sets the baseline for how much heat the system can remove. The rate at which water evaporates and transfers heat to the air indicates the cooling tower’s performance. The wet bulb temperature of the air entering the tower is therefore a critical indicator of effectiveness. Organizations like the American Society of Mechanical Engineers (ASME) and the Cooling Technology Institute (CTI), which offers technical and educational resources for the industry, recommend designing and testing cooling towers based on this entering wet bulb temperature. These measurements are typically obtained using a device called a psychrometer.

A Brief History of Cooling Towers

In Ancient Greece, Rome, and the Middle East, porous water pots and open ponds were used to take advantage of evaporative cooling, providing some relief from the heat. However, it wasn’t until the 1800s and the rise of the industrial age that mechanical devices were developed to cool air through water evaporation. One of the earliest known inventions in this area was a British patent from 1819, which detailed an evaporative cooler for cooling liquids. The emergence of early cooling towers paralleled the invention of condensers for steam engines, which required a steady supply of cool water. A U.S. patent from 1899 described a water cooling tower designed to cool “large quantities of condensing-water,” noting that the same water could be reused continuously “with peculiar efficiency and economy.”

By the early 20th century, inventors in the United States had filed numerous patents for devices referred to as “wet boxes,” “desert coolers,” “drip coolers,” and eventually “swamp coolers.” Among the earliest of these direct evaporative coolers was a wooden frame wrapped in wet burlap, using fans to push air into the space being cooled. A 1906 patent introduced a water cooling tower system equipped with nozzles, sprayers, and troughs that could “repeatedly distribute the water with great uniformity over the whole horizontal sectional area of the tower.” Over time, this foundational technology evolved into modern cooling tower designs, enhanced by the development of circulating systems, integrated motors and fans, and the invention of advanced plastics and other durable materials.

Applications of Cooling Towers

Heat dissipation is a common and often essential process in any industrial plant. Cooling towers used to manage recycled process water are employed across nearly all heavy industries, including steel production, food and beverage manufacturing, oil and gas refining, pulp and paper mills, chemical processing, and cement manufacturing. These towers also supply cooled water to power plants, which generate significant excess heat during electricity production, helping maintain a steady flow of liquid for their heat exchange systems. At power plants, chimney-style cooling towers release this excess heat as a visible plume of water vapor—condensed steam vented into the atmosphere.

In large commercial, medical, and industrial HVAC (heating, ventilation, and air conditioning) systems, cooling towers are a standard component in the construction of office buildings, airports, convention centers, hospitals, high-rises, hotels, and manufacturing facilities. These HVAC cooling towers play a direct role in regulating indoor comfort and, in turn, contribute to the health, well-being, and productivity of the people inside. Because of their size—much larger than typical HVAC units—and the space they require, cooling towers are usually installed outdoors, either on rooftops or in less trafficked areas of a building’s property.

How Cooling Towers Work

In an evaporative cooling tower, warm water is pumped or sprayed into the top of the tower, where it encounters cooling air drawn in from the atmosphere. As the water meets this incoming air, evaporation occurs, pulling heat away from the water in the process. Once the water is cooled, it exits through the base of the tower and is returned to the machinery or industrial system for reuse. After absorbing heat from the operation, the warmed water is recirculated back to the top of the cooling tower, and the cycle continues.

While the goal is to continuously recirculate the water, losses do occur through evaporation, blowdown (which removes water containing concentrated dissolved solids or sediment), drift, and occasional leaks. To maintain system efficiency and compensate for this water loss, “make-up water” is added throughout operation to ensure adequate water levels and sustain performance.

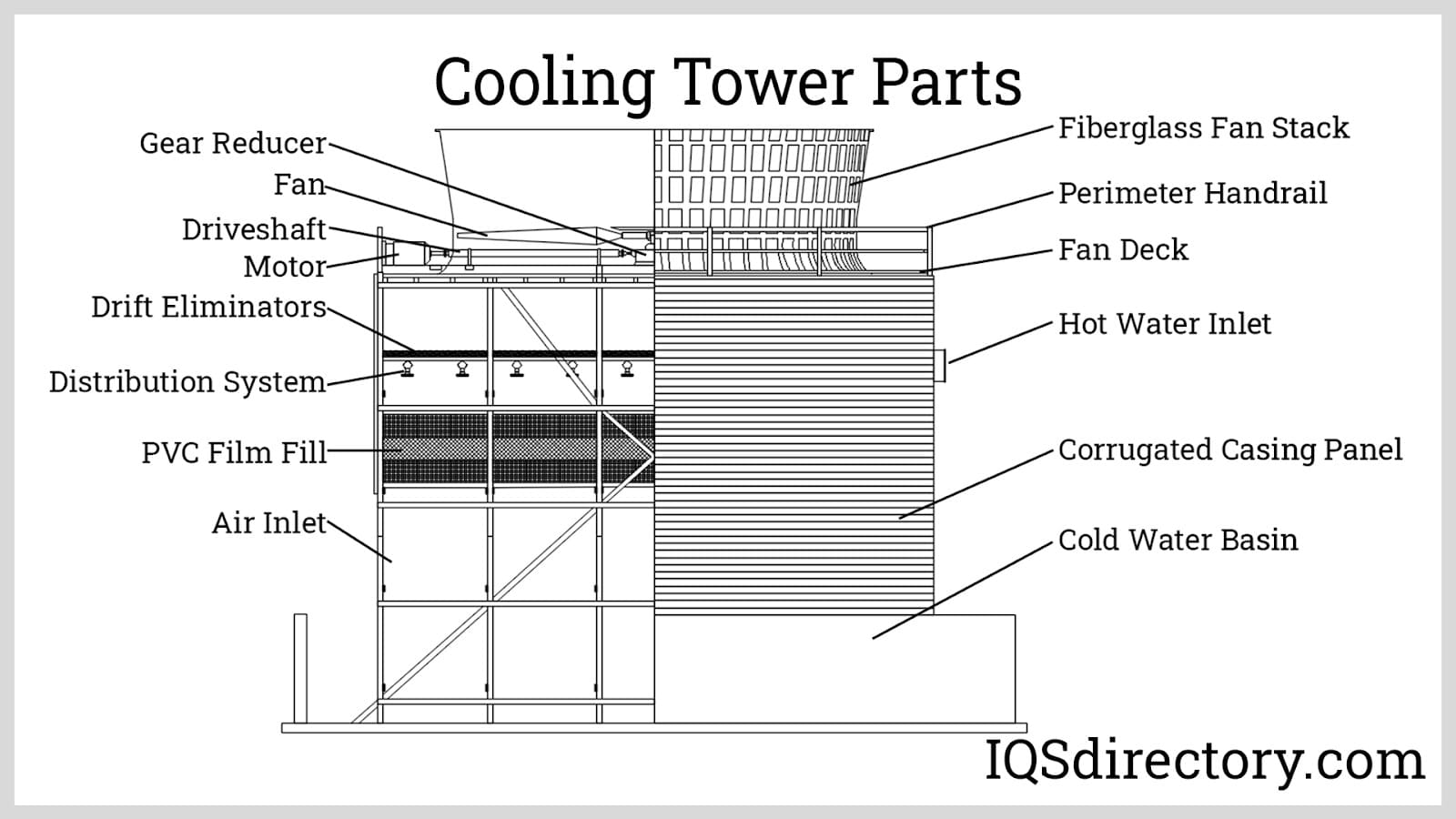

Main Components of Cooling Towers

- Fill Material

- This thermal component is the main area available for transferring heat from hot water to cool air. Fill is usually honeycombed or corrugated in pattern, which maximizes the water surface area. It is usually made of PVC (polyvinyl chloride), PP (polypropylene) material, or stainless steel.

- Water Distribution Deck (or Wet Deck)

- This component is usually a set of nozzles that uniformly sprays water to wet the fill material as it is being cooled. This maximizes heat transfer.

- Air Inlet and Air Outlet

- These are the points where cool air enters and warm air exits the tower. The air inlet may be on one side of the tower (in a cross-flow design) or it may be located near the bottom (in a counter-flow design).

- Intake Louvers

- These equalize airflow into the fill and keep water inside the tower.

- Drift Eliminators

- These are placed next to the fill to capture water droplets in the air stream that would otherwise be lost to the environment as vapor.

- Cool Water Basin

- This is located at the bottom of the tower beneath the fill. It collects the cooled water from the tower and may also serve as the foundation for the main structure.

- Mechanical Components and Instrumentation

- Fans, pumps, and motor drive mechanisms (e.g., gearboxes, driveshaft) move air and deliver the desired airflow. Sensors, sensor connectors, and cables may be mounted to detect vibration, high-frequency gear, and bearing faults. Instrumentation is also needed for measuring hot and cold water temperatures and measuring the flow of make-up water and the blowdown rate. All of these components impact energy efficiency and the amount of maintenance required.

- Casing or Shell

- This is the enclosure, which can be made of chemically treated wood, aluminum, hot dip galvanized steel, ceramic, or reinforced plastics (e.g., glass fiber material to reinforce plastic or other resins). The casing contains the water as it recirculates through the cool tower and provides structural support for the tower fan system and other internal components. The structure may need to be resistant to vibration, high wind load, and corrosion.

Fill Material

This thermal component provides the primary surface area for heat exchange between hot water and cool air. Designed in honeycomb or corrugated patterns to maximize surface exposure, the fill promotes efficient evaporation. It is commonly made from PVC (polyvinyl chloride), polypropylene (PP), or stainless steel.

Water Distribution Deck (or Wet Deck)

Typically composed of nozzles, this system evenly sprays warm water across the fill material, ensuring uniform coverage to optimize heat transfer during the cooling process.

Air Inlet and Air Outlet

These openings manage the airflow through the tower. Cool air enters through the air inlet—either on the side in a cross-flow design or near the base in a counter-flow design—while the air outlet allows warm, moisture-laden air to exit the tower.

Intake Louvers

Installed at the air entry point, louvers regulate and equalize airflow into the fill area while minimizing water splash-out, helping to keep the system efficient and enclosed.

Drift Eliminators

Located adjacent to the fill, these components capture water droplets carried by the outgoing air stream, minimizing water loss and environmental impact by reducing drift.

Cool Water Basin

Situated at the base of the cooling tower, this basin collects the cooled water that has passed through the fill. It also often serves as the structural foundation for the entire tower system.

Mechanical Components and Instrumentation

This includes fans, pumps, motors, gearboxes, and driveshafts responsible for maintaining consistent airflow and water circulation. Sensors, connectors, and cables monitor conditions such as vibration and bearing wear. Additional instrumentation tracks hot and cold water temperatures, as well as flow rates for make-up water and blowdown—critical for energy efficiency and system maintenance.

Casing or Shell

The tower’s outer structure encloses the cooling process and supports internal components such as the fan system. It may be constructed from chemically treated wood, aluminum, hot-dip galvanized steel, ceramic, or reinforced plastics like fiberglass-reinforced resin. The casing must withstand environmental stressors such as vibration, wind load, and corrosion.

Cooling Tower Design and Customization Considerations

Cooling towers are classified based on the way air moves through the structure—specifically by airflow direction (either counter-flow or cross-flow) and draft type (mechanical or natural). These towers also vary in shape, including round or bottle-shaped models, rectangular units, and hyperboloid designs often associated with power plants. Each configuration offers distinct benefits and limitations, and the optimal design depends on a variety of factors: the specific application, user requirements, cost, and even local climate conditions. Because evaporative cooling is influenced by environmental elements such as outside temperature, relative humidity, and wind speed, location plays a critical role in tower efficiency.

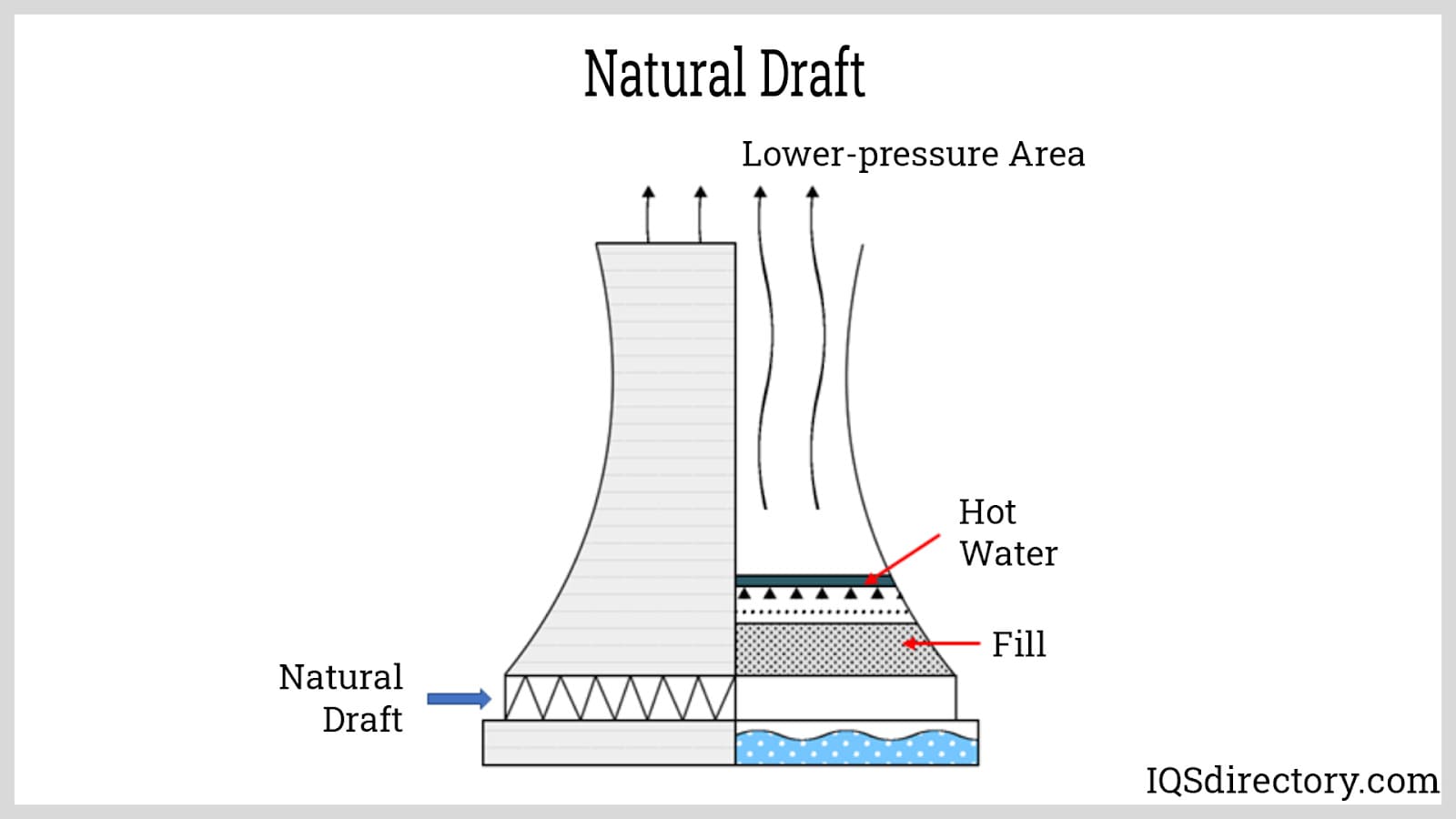

Natural draft towers operate without fans, using a tall chimney structure to create an updraft driven by the pressure and temperature differences between the cooler external air and the warmer air inside the tower. These towers function best in open environments where wind direction and velocity enhance performance. They are uncommon in HVAC applications but are frequently used at nuclear and large coal-fired power plants, where their hyperboloid design efficiently handles massive water volumes.

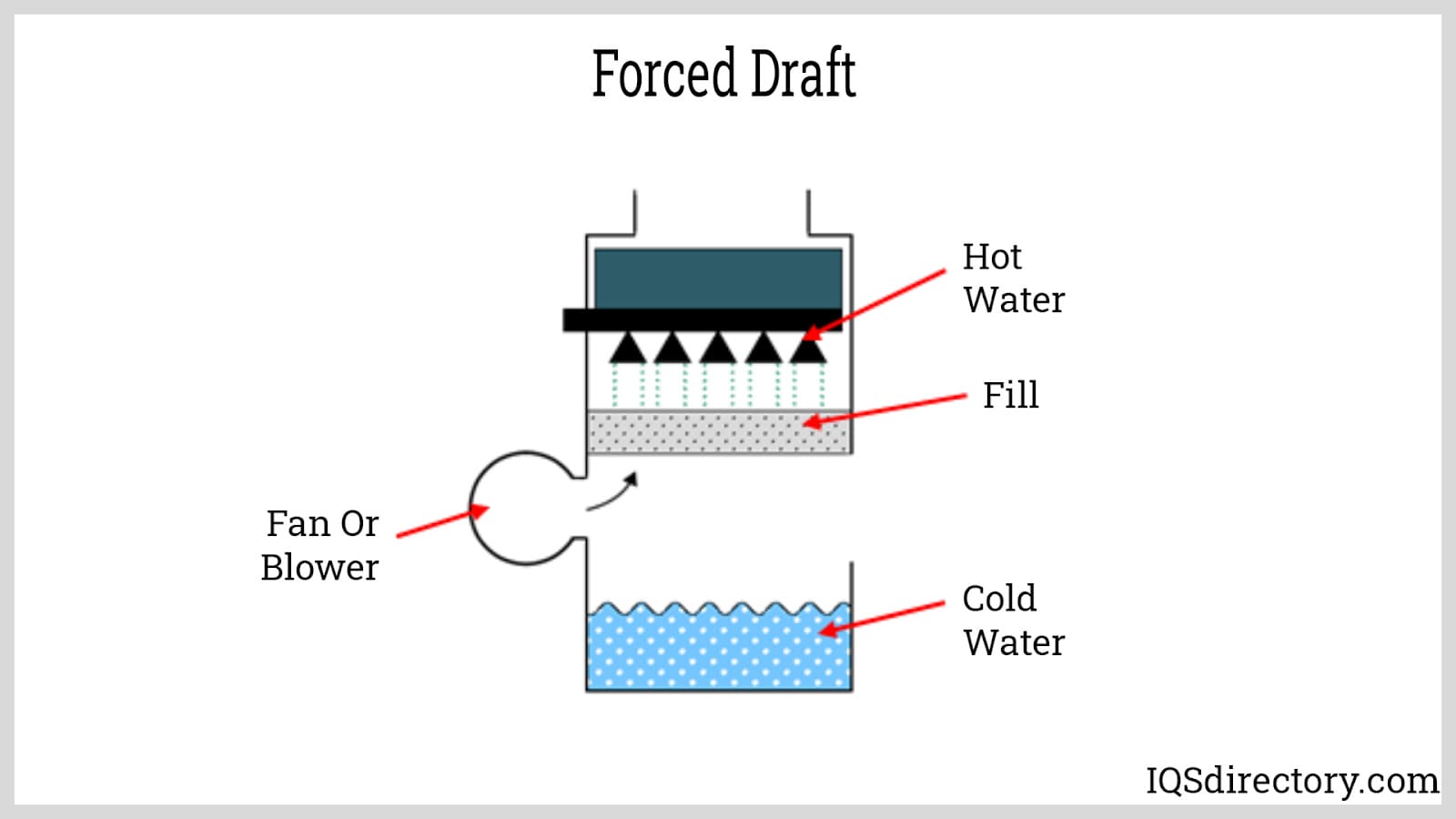

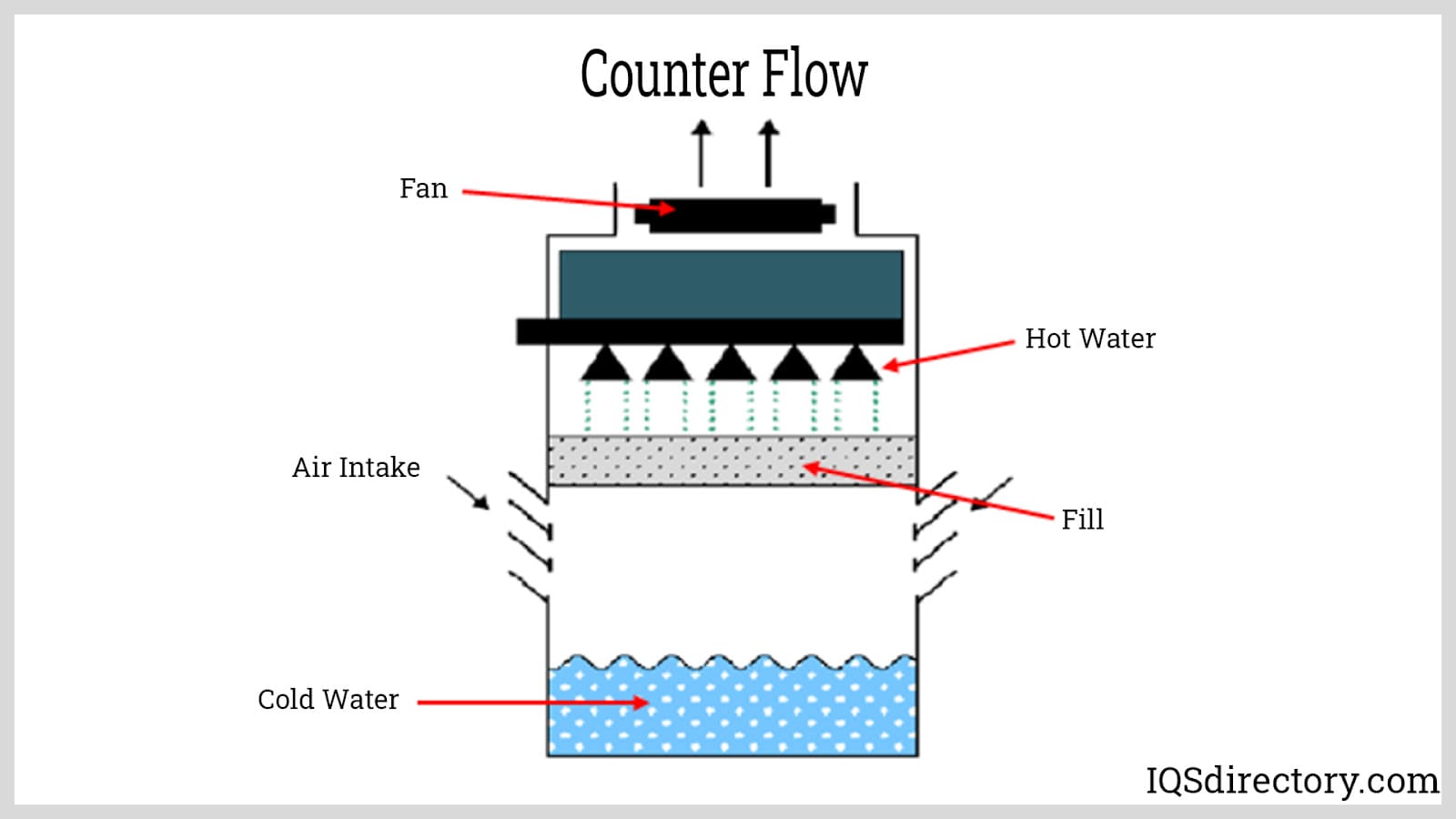

Mechanical draft towers rely on electrically powered fans to move air through the system and can utilize either a cross-flow design, where air flows perpendicular to the falling water, or a counter-flow design, where air flows in the opposite direction. Counter-flow models tend to require less space and have a more compact footprint than cross-flow towers. Though mechanical towers are typically more expensive to operate due to their moving parts, they offer greater flexibility in placement and are widely used in HVAC and refrigeration applications.

The round or bottle shape is favored in industrial settings because it maximizes cooling efficiency in a relatively small footprint. These towers are available in a variety of capacities and can be either factory-assembled or constructed on-site. Rectangular towers are more common in large air-conditioning systems, particularly in commercial buildings.

Beyond basic design, user-specific considerations—such as safety, noise control, and resistance to erosion or chemicals—also influence tower selection:

- Wooden towers, while historically common, are vulnerable to fire and decay in their constantly moist environment. Chemically treated wood is falling out of favor due to environmental and health concerns.

- Fiber-reinforced polyester and hot-dip galvanized steel towers offer strong, rot-resistant construction and long service life, though steel units can be expensive, heavy, and difficult to transport or customize. They also require skilled labor for assembly.

- Plastic towers are lightweight yet strong, easier to customize, and more practical for transportation and on-site installation than their steel counterparts.

In sensitive environments—such as near schools, hospitals, or residential areas—noise may be a critical factor. In such cases, cooling towers can be specially engineered to minimize acoustic disruption, ensuring compliance with local noise regulations and maintaining comfort for nearby occupants.

Cooling Tower Safety and Maintenance Considerations

Warm, moist environments provide ideal conditions for the growth of microorganisms and biofilms that can compromise the performance of cooling equipment and pose serious health risks. Cooling towers and evaporative condensers, which use fans to circulate air through recirculated water systems and release significant amounts of water vapor into the atmosphere, require consistent upkeep. Regular maintenance, cleaning, and the application of biocides are essential. In many regions, inspections for harmful Legionella bacteria—linked to Legionnaires’ disease, a severe pneumonia-like illness—are also mandated by local and state regulations. Monitoring the quality of make-up water, whether sourced from groundwater or surface water, is another important factor in ensuring the safe operation of a cooling tower.

Under the Clean Air Act Amendments of 1990, the Environmental Protection Agency (EPA) enforces rules aimed at reducing emissions of hazardous air pollutants from industrial process cooling towers, further emphasizing the need for proper system management.

Additionally, safety codes such as NFPA 214 establish fire protection standards for both field-erected and factory-assembled cooling towers. These standards address the combustibility of construction materials and fill, ensuring greater safety in tower design and operation.

Choosing a Cooling Tower Manufacturer

Many companies manufacture or distribute cooling tower equipment, though the majority are small to mid-sized businesses. Fewer than a dozen large-scale manufacturers operate globally. Competition in this market centers on key product characteristics—particularly psychrometric performance, energy efficiency, and overall cost, including long-term maintenance and operational expenses.

Choosing the right manufacturer is not simply about finding a reputable company—it’s about finding one whose products and services align with your specific needs. A critical first step in selecting a supplier is understanding whether the manufacturer offers fully engineered cooling towers directly or if they rely on original equipment manufacturer (OEM) partners for production and delivery. It’s also important to assess whether the company can provide replacement parts or spare components promptly, along with comprehensive maintenance and quality assurance services, such as warranties and access to dependable mechanical systems.

One way to begin your search for a suitable cooling tower manufacturer is by consulting the company directory linked at the top of this page.

When properly engineered and maintained, cooling tower systems can last around 20 years while consistently delivering the required water temperature and flow rate to support efficient plant or system operations. For a tailored solution, consider working directly with cooling tower designers who can provide systems that are optimized to meet your exact performance and efficiency requirements—many of whom are listed here on IQS Directory.

Cooling Tower Images, Diagrams and Visual Concepts

How a cooling tower exchanges heat by transfering the tempature between the air and water.

How a cooling tower exchanges heat by transfering the tempature between the air and water.

Cooling tower are broken down into structural (static equipment), mechanical (rotating equipment), and electrical parts.

Cooling tower are broken down into structural (static equipment), mechanical (rotating equipment), and electrical parts.

Natural draft cooling towers utilize no mechanical drivers or fans to create air flow through the cooling tower.

Natural draft cooling towers utilize no mechanical drivers or fans to create air flow through the cooling tower.

Forced draft cooling towers uses fans or blowers to force air into the cooling tower.

Forced draft cooling towers uses fans or blowers to force air into the cooling tower.

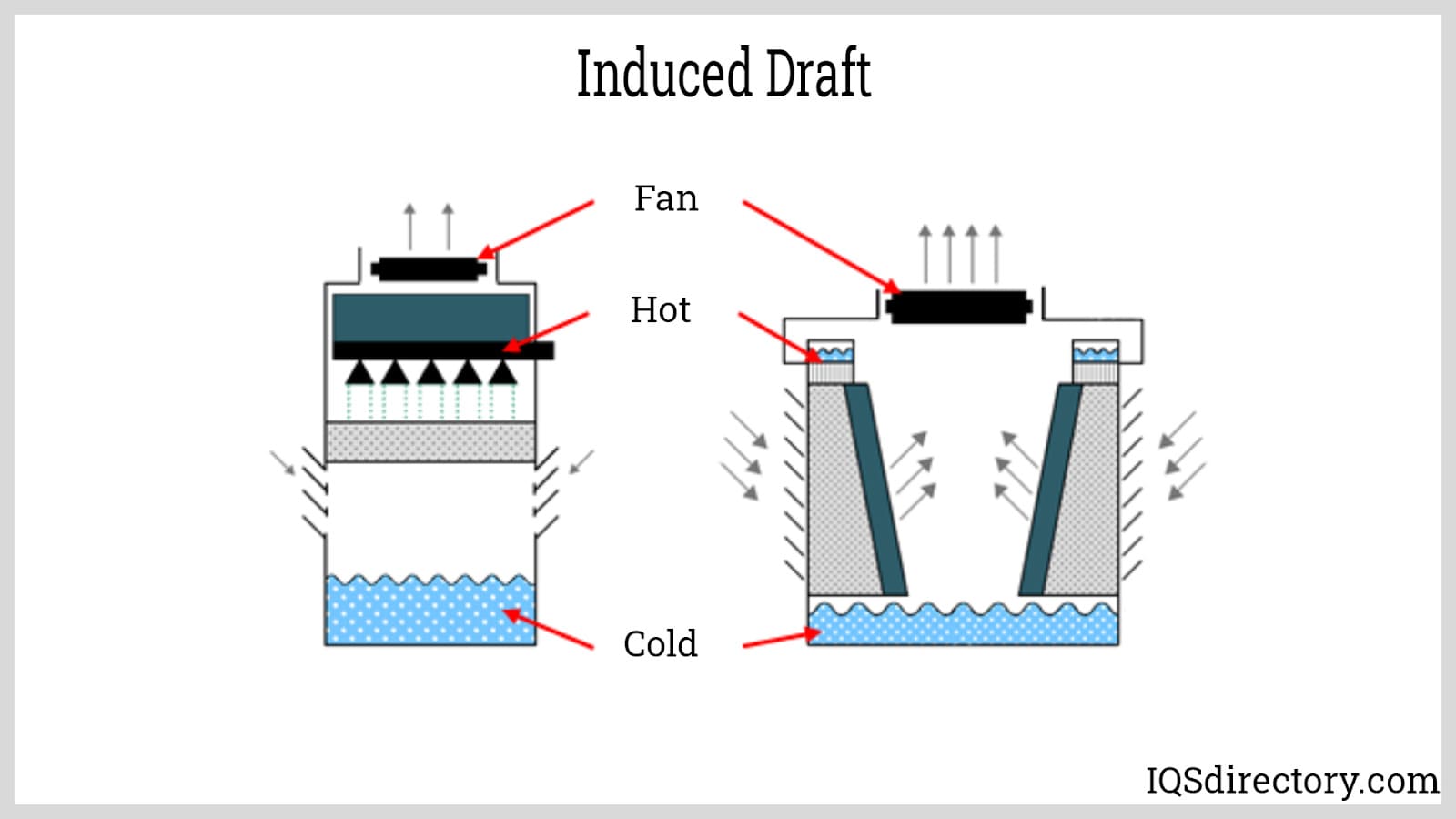

Induced Draft cooling towers have fans located at the top that draws air from the air intake louvers at the bottom or sides of the tower.

Induced Draft cooling towers have fans located at the top that draws air from the air intake louvers at the bottom or sides of the tower.

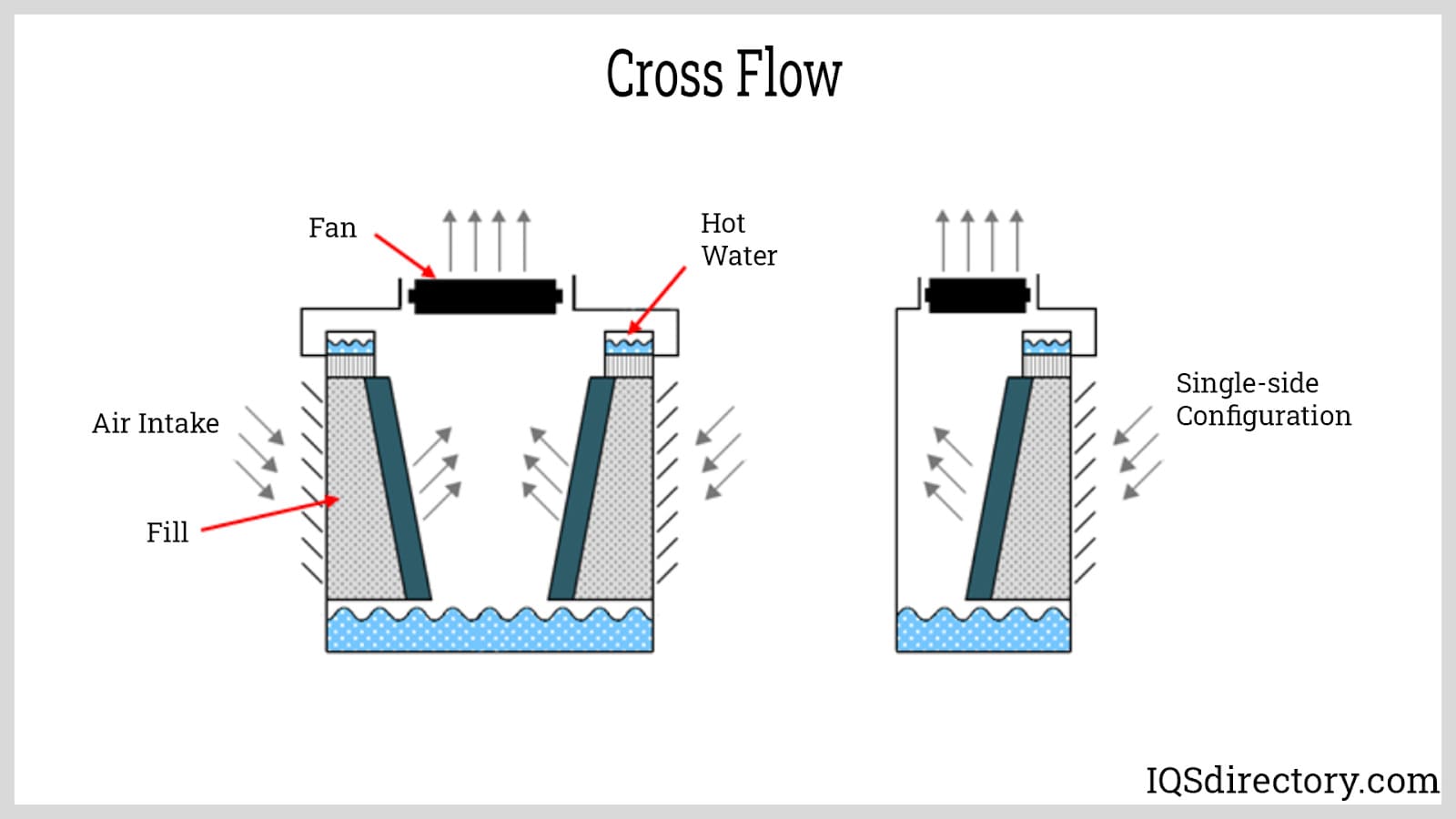

Cross-flow configuration, air flows horizontally through the fills across the downward fall of water.

Cross-flow configuration, air flows horizontally through the fills across the downward fall of water.

Counter-flow cooling towers has air flows parallel but opposite to the fall of water, with a pressurized-spray distribution system.

Counter-flow cooling towers has air flows parallel but opposite to the fall of water, with a pressurized-spray distribution system.

Cooling Tower Types

-

Air Conditioner Cooling Towers

These fiberglass structures are used to cool large buildings—such as hospitals, schools, and some office complexes—by supporting air conditioning systems.

Ceramic Cooling Towers

Favored for their aesthetic appeal, ceramic cooling towers tend to be more expensive than other types, though they remain popular in applications where appearance is a consideration.

Chillers Cooling Towers

These towers serve as an auxiliary method for removing waste heat, typically in processes that utilize both air and liquid chiller systems.

Closed Loop Cooling Towers

In this system, the cooled water or fluid is never directly exposed to air, preserving fluid purity and reducing contamination risks.

Cooling Tower Design

The overall design of a cooling tower directly influences its cost, performance, and energy efficiency, making design a critical consideration in selection and installation.

Cooling Tower Manufacturers

These are companies dedicated to the production of equipment designed specifically to cool industrial or commercial fluids.

Cooling Tower Systems

Also known as heat rejection systems, these towers remove excess heat from circulating fluids by transferring that heat into the air.

Counterflow Cooling Towers

These feature opposing flows—air moves upward while water moves downward—enhancing thermal efficiency through compact vertical airflow patterns.

Cross Flow Cooling Towers

Designed with perpendicular airflow, air moves horizontally across the tower while water flows vertically downward, often making these easier to maintain.

Disinfection Cooling Towers

Used in facilities that handle drinking water or wastewater, these systems aid in eliminating bacteria, chemicals, and other impurities.

Evaporative Cooling Towers

These towers use the evaporation of a portion of the working fluid—usually water—to extract heat from the remaining liquid and cool it near the ambient wet-bulb temperature.

Fiberglass Cooling Towers

Known for excellent corrosion and weather resistance, fiberglass towers are ideal for challenging environments or chemical-heavy applications like water treatment.

HVAC Cooling Towers

Used in tandem with water-cooled chillers or condensers, HVAC cooling towers are a core part of commercial and industrial air conditioning systems.

Hyperbolic Cooling Towers

These towers feature a hyperboloid shape to maximize structural efficiency and naturally induce airflow, a design commonly used in power generation.

Industrial Cooling Towers

These large-scale systems reject heat by cooling water and other working fluids through evaporation, releasing heat into the atmosphere.

Mechanical Draft Cooling Towers

Equipped with fans, these towers either push air through the system (forced draft) or pull air through from above (induced draft), making them suitable for compact or space-limited installations.

Natural Draft Cooling Towers

Relying on natural air buoyancy rather than mechanical fans, these towers are best for high-capacity applications like thermal power plants.

Open Circuit Cooling Towers

In these systems, water is sprayed within the tower and comes into direct contact with the incoming air to achieve evaporative cooling.

Water Cooling Towers

These are the foundational type of cooling tower, using airflow to remove heat from water, commonly applied in HVAC and water treatment systems.

Cooling Tower Terms

-

Air Conditioner Cooling Towers

These fiberglass structures are used to cool large buildings—such as hospitals, schools, and some office complexes—by supporting air conditioning systems.

Ceramic Cooling Towers

Favored for their aesthetic appeal, ceramic cooling towers tend to be more expensive than other types, though they remain popular in applications where appearance is a consideration.

Chillers Cooling Towers>

These towers serve as an auxiliary method for removing waste heat, typically in processes that utilize both air and liquid chiller systems.

Closed Loop Cooling Towers

In this system, the cooled water or fluid is never directly exposed to air, preserving fluid purity and reducing contamination risks.

Cooling Tower Design

The overall design of a cooling tower directly influences its cost, performance, and energy efficiency, making design a critical consideration in selection and installation.

Cooling Tower Manufacturers

These are companies dedicated to the production of equipment designed specifically to cool industrial or commercial fluids.

Cooling Tower Systems

Also known as heat rejection systems, these towers remove excess heat from circulating fluids by transferring that heat into the air.

Counterflow Cooling Towers

These feature opposing flows—air moves upward while water moves downward—enhancing thermal efficiency through compact vertical airflow patterns.

Cross Flow Cooling Towers

Designed with perpendicular airflow, air moves horizontally across the tower while water flows vertically downward, often making these easier to maintain.

Disinfection Cooling Towers

Used in facilities that handle drinking water or wastewater, these systems aid in eliminating bacteria, chemicals, and other impurities.

Evaporative Cooling Towers

These towers use the evaporation of a portion of the working fluid—usually water—to extract heat from the remaining liquid and cool it near the ambient wet-bulb temperature.

Fiberglass Cooling Towers

Known for excellent corrosion and weather resistance, fiberglass towers are ideal for challenging environments or chemical-heavy applications like water treatment.

HVAC Cooling Towers

Used in tandem with water-cooled chillers or condensers, HVAC cooling towers are a core part of commercial and industrial air conditioning systems.

Hyperbolic Cooling Towers

These towers feature a hyperboloid shape to maximize structural efficiency and naturally induce airflow, a design commonly used in power generation.

Industrial Cooling Towers

These large-scale systems reject heat by cooling water and other working fluids through evaporation, releasing heat into the atmosphere.

Mechanical Draft Cooling Towers

Equipped with fans, these towers either push air through the system (forced draft) or pull air through from above (induced draft), making them suitable for compact or space-limited installations.

Natural Draft Cooling Towers

Relying on natural air buoyancy rather than mechanical fans, these towers are best for high-capacity applications like thermal power plants.

Open Circuit Cooling Towers

In these systems, water is sprayed within the tower and comes into direct contact with the incoming air to achieve evaporative cooling.

Water Cooling Towers

These are the foundational type of cooling tower, using airflow to remove heat from water, commonly applied in HVAC and water treatment systems.