Copper

Copper is a naturally occurring metal that is widely utilized in commercial and industrial applications due to its numerous advantageous properties. It derives its name from the Latin phrase aes cyprium, meaning "metal of Cyprus," referencing the island where it was historically mined.

As a native metal, copper is found in a directly usable metallic state, eliminating the need for extensive processing before use. It is also a fundamental chemical element on the periodic table, represented by the symbol Cu and assigned the atomic number 29.

The History of Copper

- Historical Uses

- Copper is one of the oldest known metals used by humans, with historians and archaeologists suggesting that only gold and meteoric iron were utilized before it. Its use dates back to the Copper Age, and some of the earliest copper artifacts, such as a pendant from northern Iraq, are believed to be around 9000 BC. Between 6000 and 3000 BC, Native Americans in Michigan and Wisconsin cold-worked copper to craft weapons, tools, and decorative objects. In the ancient world, the Greeks and Romans extensively used copper and its alloys, such as bronze, for temple roofs, coins, jewelry, sculpture embellishments, weapons, and armor. Copper was equally significant in early civilizations across India, Israel, Turkey, Iran, and Egypt. The Egyptians, in particular, demonstrated ingenuity in their use of copper, fashioning cookware, dishes, agricultural tools, saws, chisels, knives, mirrors, and razors. They even incorporated copper compounds into cosmetics.

- As civilizations advanced, people began extracting copper from ore. One of the oldest known copper mines, the Great Copper Mountain in Sweden, operated from the 10th century until 1992 and supplied two-thirds of Europe’s copper through the 17th century. During this period, copper was widely used in weaponry and sculpture making. In the 18th century, shipbuilders began using copper sheathing and plating to protect underwater hulls from corrosion. By 1876, the first modern electroplating plant, the Norddeutsche Affinerie, opened in Hamburg, marking another milestone in copper processing.

- From the late 1800s through the 1990s, global copper mining surged, particularly in the United States. However, as environmental concerns grew, many high-pollution mines were shut down. Despite this, copper remains indispensable across industries today, with applications spanning jewelry, biofouling prevention, and high-tech fields. The metal has become increasingly crucial in computer manufacturing, electronics, and telecommunications. Traditional telephone lines, composed of twisted copper wire pairs, are now being repurposed for high-speed communications as a cost-effective alternative to fiber optics. Additionally, copper is replacing aluminum in computer chips due to its superior conductivity, allowing for reduced conductor channel lengths and widths, leading to faster processing speeds. As electric vehicles gain prominence, copper continues to play a significant role in their development.

- Material Use Evolution

- Archaeologists believe copper’s progression in material use followed a distinct sequence: first, cold working of native copper, followed by annealing, smelting, and finally, lost-wax casting.

- The invention of copper smelting occurred at different times across the globe. Evidence suggests that China developed smelting techniques before 2800 BC, Central America adopted them around 600 AD, and West Africa between the 9th and 10th centuries AD. Investment casting, or lost-wax casting, emerged between 4500 and 4000 BC in Southeast Asia. Additionally, scientific analysis of the famous frozen mummy, Ötzi the Iceman—who lived between 3300 and 3200 BC—revealed high levels of arsenic in his hair, suggesting he was involved in copper smelting. Carbon dating further confirms that humans were mining copper in Cheshire, UK, as early as 2280 BC.

- Approximately 4000 years after the advent of smelting, humans began alloying copper. During the Bronze Age, civilizations such as the Egyptians, Sumerians, and Vincas combined copper with tin, arsenic, and other metals to create bronze, a harder and more durable material. Later, the Greeks and Romans refined copper metallurgy further by developing brass, a copper-zinc alloy that became widely utilized.

- Copper’s technological evolution continued into the Industrial Revolution. In 1830, German scientist Gottfried Osann accidentally discovered powder metallurgy while attempting to determine copper’s atomic mass. This breakthrough enabled the use of powdered metals to create new materials and products, significantly expanding copper’s applications. In 1949, the Finnish company Outokumpu introduced flash smelting, a more energy-efficient method of extracting copper using chemical reactions that convert raw materials into copper matte, iron oxides, and sulfur dioxide.

- Today, powder copper is frequently sintered to construct heat pipes and has been developed into numerous specialized alloys for diverse applications. Purity standards for copper have reached unprecedented levels; for instance, electrical copper wiring—second only to silver in conductivity—must be at least 99.98% pure to meet industrial standards. With ongoing advancements in engineering and manufacturing, the future promises even more innovative applications for this versatile metal.

Advantages of Copper

There are countless reasons to appreciate copper and its alloys. One of its most significant benefits is its sustainability. Copper is naturally abundant and easily recyclable, making it an environmentally friendly material. In fact, due to its high recyclability, nearly as much copper is recovered and reused each year as is newly mined, with recycled copper maintaining nearly the same value and performance as virgin material.

Beyond its environmental benefits, copper is highly cost-effective. It is widely available and affordable, yet remarkably durable, often lasting for decades with minimal maintenance. This longevity makes it a smart investment across various industries.

Copper’s non-sparking nature is another invaluable attribute, particularly in hazardous environments where combustible or explosive vapors and gases are present. This makes it an ideal material for use in oil rigs, chemical plants, and other safety-critical applications where ignition risks must be minimized.

Additionally, copper is exceptionally easy to alloy, allowing it to be adapted for a vast range of applications. If pure copper does not meet the specific mechanical or physical properties required—such as enhanced hardness or strength—numerous copper-based alloys exist that can provide the necessary performance, ensuring copper remains one of the most versatile metals available.

Production Process of Copper

The first step in copper manufacturing is preform fabrication, which involves using copper powder and powder flakes sourced from powder plants. These preforms serve as the foundation for various copper products.

Once the preforms are ready, manufacturers can utilize a range of processes to shape and refine copper into final products. These processes include drawing and cold drawing, casting, hot and cold rolling, forging, and extrusion. Each technique is chosen based on the intended application and desired material properties.

Copper mills frequently employ cold drawing for wire and rod production, as this method enhances both strength and electrical conductivity. Foundries cast parts using scrap copper and ingots, ensuring efficient material utilization. Brass mills, which handle both copper and copper alloys, rely on hot and cold rolling, drawing, forging, and extrusion to produce durable and high-performance products. Since pure copper is naturally soft and unsuitable for structural applications, brass mills primarily work with copper alloys to improve strength and workability.

After a brass or copper shape has been formed, additional secondary operations may be performed to refine or enhance its properties. These processes include annealing, which adjusts the temper of the copper, as well as bending, stamping, welding, etching, engraving, polishing, and the application of clear protective coatings to improve durability and aesthetic appeal.

- Alloys

- Copper boasts over 400 alloys, each formulated with varying copper content and unique characteristics suited to specific applications. These alloys can be broadly categorized into seven main groups: copper, high copper alloys, brasses, bronzes, copper-nickels, copper–nickel–zinc (nickel silver), leaded copper, and special alloys.

- Among the most well-known copper alloys are brass—a combination of copper and zinc—and bronze, which consists primarily of copper and tin. Both alloys retain a significant copper content while exhibiting enhanced mechanical and corrosion-resistant properties.

- Other widely used copper alloys include aluminum bronzes, silicon bronzes, phosphor bronze, cupronickel (copper-nickel), and copper-silver, each offering distinct advantages in strength, conductivity, or resistance to environmental conditions.

- Additional specialized copper alloys include beryllium copper, copper-steel alloys, and copper-stainless steel alloys, which are designed for high-performance applications requiring exceptional strength, conductivity, or corrosion resistance. The vast diversity of copper alloys ensures its continued relevance across a broad spectrum of industries.

Copper Images, Diagrams and Visual Concepts

Copper in it raw state before processing.

Copper in it raw state before processing.

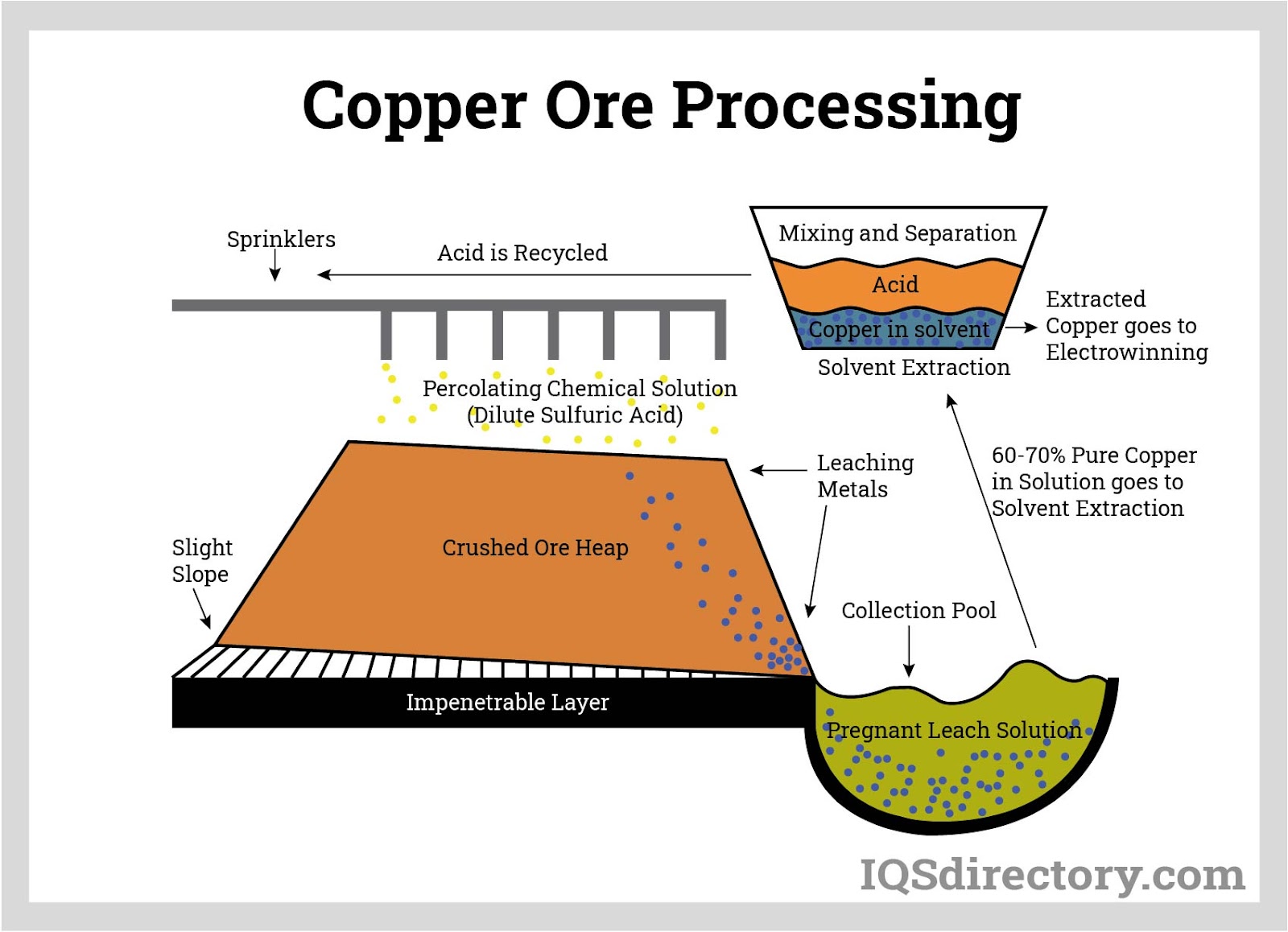

The process that turns raw copper ore into usable material by crushing into a fine sand, then sits in chemicals to particulate water-repellent, air is passed through the mixture which the copper floats to the surface, and the copper froth is thickened and smelted into refined copper.

The process that turns raw copper ore into usable material by crushing into a fine sand, then sits in chemicals to particulate water-repellent, air is passed through the mixture which the copper floats to the surface, and the copper froth is thickened and smelted into refined copper.

Copper after processing has been completed.

Copper after processing has been completed.

Beryllium copper, a combination of 0.5% to 3% beryllium and copper which creates a high strength, non-magnetic, and non-sparking alloy.

Beryllium copper, a combination of 0.5% to 3% beryllium and copper which creates a high strength, non-magnetic, and non-sparking alloy.

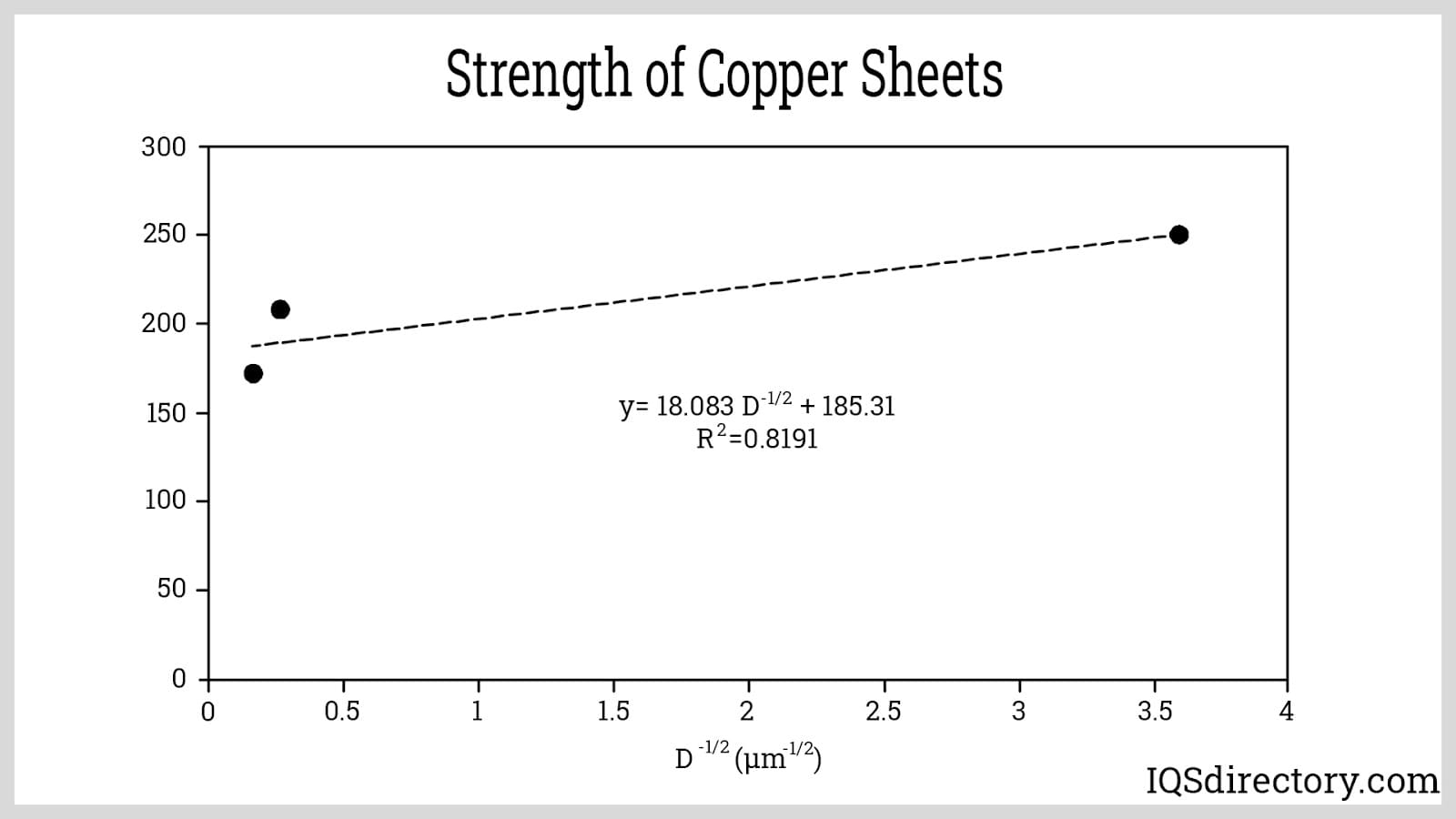

The copper sheet are a highly malleable and workable metal with electrical, thermal conductivity, and corrosion resistance.

The copper sheet are a highly malleable and workable metal with electrical, thermal conductivity, and corrosion resistance.

The strength of copper sheets can increase based on what other elements or alloys added to the material.

The strength of copper sheets can increase based on what other elements or alloys added to the material.

ETP copper has a minimum conductivity value of 100% IACS which makes it useful for electrical applications and those requiring low resistance levels.

ETP copper has a minimum conductivity value of 100% IACS which makes it useful for electrical applications and those requiring low resistance levels.

Copper Types

- Beryllium Copper

- The strongest and most durable copper alloy, containing between 0.5% and 3% beryllium, an alkaline earth metal primarily used as a hardening agent. This alloy offers exceptional strength, conductivity, and corrosion resistance, making it ideal for demanding applications.

- Brass Bars

- Solid, straight, and uniform preforms, billets, and blanks supplied to metalworking facilities for machining, forging, or extrusion processes.

- Brass Plates

- Flat, thin, rectangular or square pieces of brass, a copper-zinc alloy, used in various industrial and decorative applications.

- Brass Rods

- Solid, straight brass preforms used as billets and blanks in machining and manufacturing processes, offering strength, corrosion resistance, and versatility.

- Brass

- A metal alloy composed primarily of copper and zinc, known for its durability, corrosion resistance, and attractive golden appearance, widely used in decorative and functional applications.

- Bronze

- An alloy of copper and tin, renowned for its strength, resistance to corrosion, and historical significance in tools, sculpture, and marine applications.

- Copper Bars

- Straight, solid copper products that can be extruded into various cross-sectional shapes, including circular, square, triangular, and custom geometries, used in electrical and industrial applications.

- Copper Billets

- Large, solid pieces of pure copper that are cut into smaller sections for extrusion, forging, or machining into copper tubing, rods, or bars.

- Copper Coil

- A thermally and electrically conductive component used in various systems and machinery. Typically made from copper wire or tubing, it is bent and wound into a spiral shape to enhance heat transfer and conductivity in electrical, HVAC, and industrial applications.

- Copper Pipe

- A highly conductive metal pipe with excellent electrical and thermal conductivity, widely used in plumbing, heating, and cooling systems.

- Copper Sheet

- A flat product formed through the rolling process, used in roofing, electrical shielding, and decorative applications due to its malleability and corrosion resistance.

- Copper Strip

- A long, narrow sheet of copper with a length many times its width, utilized in electrical components, automotive applications, and industrial processes requiring thin, flexible copper materials.

- Copper Suppliers

- Manufacturers and distributors of preformed copper and copper alloy billets, blanks, and finished parts, catering to various industries, including construction, electrical, and plumbing.

- Copper Tubes

- Hollow copper products with excellent corrosion resistance and heat transfer properties, widely used in HVAC, plumbing, and industrial applications where durability and efficiency are critical.

Properties of Copper

This reddish-orange metal is classified as a transition metal, highlighting its exceptional ductility, malleability, and ability to efficiently conduct heat and electricity. In its pure form, copper is remarkably soft, making it easy to machine, shape, and form while maintaining durability. It is also nonmagnetic, allowing for specialized applications where magnetism must be avoided. By introducing alloying elements, additional properties such as increased hardness and strength can be achieved, further expanding its versatility across various industries.

Applications of Copper

Copper serves a wide range of purposes across numerous industries. Manufacturers rely on it for producing commercial and household products, conducting electricity, transmitting power, conveying fluids, and facilitating heat transfer. Its natural antimicrobial properties make it an effective material for repelling microbes, while its durability and aesthetic appeal contribute to its use in architectural applications.

Copper and its alloys play a vital role in various industries, including automotive, architectural, building construction, electronics, food processing, marine, aerospace, wiring, power generation, lighting, and telecommunications. Its adaptability and performance make it an essential material for both functional and decorative applications.

Products Produced With Copper

Copper suppliers specialize in producing preforms such as billets, blanks, copper strip, and sheet copper, which serve as the foundation for further fabrication into finished products and components. Copper strip and sheet metal are flat, flexible, and typically supplied in rolls, much like copper coil. Copper tubes are commonly processed into copper piping systems, offering excellent durability and conductivity. Brass rod, brass plate, and brass bar, being thicker and more rigid, are solid uniform pieces often drawn or extruded into specific shapes to meet various manufacturing needs.

These preforms are further fabricated into an extensive range of products, including piping systems, propellers, hardware, kitchenware, small springs, wires, adapters, electrical connectors, lighting components, valves, coins, offshore drilling equipment, microchips, and roofing materials.

How to Choose the Right Copper Manufacturer

So, you’re ready to purchase a copper product, but with copper available worldwide, where do you begin? How do you choose the right supplier?

Navigating the market can be overwhelming, which is why we’ve compiled a list of high-quality copper manufacturers for you. You’ll find it by scrolling up toward the top of this page. Take some time to explore each supplier’s website, carefully reviewing their offerings. Identify three or four that align with your needs—whether that means providing the specific products or forming services you require, offering customization options, or being geographically positioned to deliver efficiently.

Once you have a shortlist, reach out to each supplier individually with detailed inquiries about their lead times, pricing, and capabilities. Clearly outline your specifications and ensure they can meet your requirements. Pay attention to customer service as well—working with a supplier who prioritizes your application rather than just their bottom line can make all the difference. Compare your options, select the best fit, and move forward with confidence.

Overseas Copper Market

Copper is an abundant and cost-effective material, widely available domestically. However, despite its accessibility, many American companies still import their copper products. In fact, the United States ranks as the third-largest importer of copper and copper products globally. The leading exporter of copper ore is Chile, supplying a significant portion of the world’s raw copper. One exception to U.S. copper imports is copper powder, which is primarily sourced and produced domestically.

With the growing presence of the global copper market, large economies such as the United States and the United Kingdom have established strict standards and trade policies to regulate quality, purity, and compliance. These regulations ensure that imported copper meets industry requirements and maintains high performance across various applications.

Despite the heavy reliance on imports, purchasing copper from American companies offers distinct advantages. Domestic suppliers operate in a highly competitive market, often leading to more competitive pricing. Additionally, buying locally ensures faster shipping times and more efficient customer support. If any issues arise with a product, returns and problem resolution are significantly easier compared to dealing with overseas suppliers, making domestic copper sourcing a practical and reliable choice.

Copper Terms

- Aging

- A variety of surface treatments applied to copper to create an "aged" or "antique" appearance, enhancing its aesthetic appeal for decorative and architectural applications.

- Bending

- A mechanical process in which rollers, bending shoes, or mandrels are used to shape metal tubes, rods, or other forms into curved sections, ensuring precision and structural integrity.

- Brake Forming

- A specialized bending technique used to shape sheets, strips, or plates of metal by pressing them against a die, creating precise angular bends.

- Brass

- A copper alloy primarily composed of zinc, known for its durability, corrosion resistance, and distinctive golden hue.

- Brazing

- A metal joining process in which a non-ferrous filler material is melted to bond metal pipes or tubes, creating strong, leak-resistant connections.

- Bronze

- A copper alloy primarily containing tin, valued for its strength, resistance to corrosion, and historical significance in toolmaking, sculpture, and marine applications.

- Castings

- Metal components produced by pouring molten metal into a mold, allowing it to cool and solidify into a predefined shape, commonly used in industrial and artistic applications.

- Cleat

- A small copper strip used as a fastening element for securing sheet copper components, particularly in roofing and architectural installations.

- Cold Forging

- A metalworking process in which metal is hammered or pressed into shape at room temperature, enhancing its strength and dimensional accuracy.

- Deoxidized Copper

- Copper that has been treated with a deoxidizer, such as phosphorus, to reduce oxygen content, improving its weldability and corrosion resistance.

- Extrusion

- A manufacturing process in which heated metal is forced through a die to create continuous shapes with uniform cross-sections, commonly used for producing tubes, rods, and profiles.

- Flashing

- Thin copper sheet material used in construction to prevent or redirect water penetration, providing a durable, weather-resistant barrier in roofing and siding applications.

- High Conductivity Copper

- A standard grade of copper used in electrical applications, capable of delivering 100% electrical conductivity, making it ideal for wiring, busbars, and power transmission.

- Hydroforming

- A metal shaping technique that uses hydraulic pressure to mold sheet metal between a male die and a rubber piece, allowing for precise and complex geometries.

- Laminating

- A bonding process in which metal sheets or strips are adhered to substrates such as aluminum, plywood, or steel using adhesives, resulting in high-strength composite materials.

- Mechanical Treatments

- Surface finishing techniques such as grinding, polishing, and buffing, used to enhance the appearance and functionality of metal surfaces.

- Patina

- The natural protective layer that forms on copper surfaces over time due to atmospheric corrosion, creating a distinctive green or brown finish often sought for architectural applications.

- Roll Forming

- A continuous metal forming process in which sheet or strip metal is passed through rollers to achieve a specific shape, commonly used in manufacturing structural components.

- Scrap

- Excess or leftover metal from cutting and fabrication processes, typically collected for recycling to minimize waste and reduce material costs.

- Soldering

- A joining process that uses a melted filler metal to create watertight seals, commonly applied in roofing, gutters, and plumbing systems.

- Spinning

- A metal forming technique in which a hand tool shapes a rotating metal workpiece, often used for creating symmetrical, cylindrical, or conical parts.

- Stamping

- A fabrication method in which metal sheets or strips are shaped using a die in a press or hammer, enabling the production of precise, high-volume parts.