Data Acquisition Systems

Data acquisition systems are designed to convert analog waveforms into digital values that can be processed by computers. This conversion occurs through the process of data acquisition, which involves sampling real-world physical phenomena—such as light, fluids, or gases. Sensors in the system detect these phenomena and translate them into analog signals, which are then passed through specialized hardware. This hardware transforms the analog input into digital numerical values, creating a standardized format that computers can interpret and analyze.

These systems are often referred to by the acronyms DAS or DAQ

. DAQ, short for "data acquisition," commonly refers to both the acquisition process and the full range of associated technologies, including hardware and software components. In contrast, DAS more specifically denotes the complete data acquisition system itself.

History of DAS

Modern data acquisition systems are, by historical standards, a relatively recent development. At their core, the concept behind DAS is straightforward: data can be recorded in a usable form and then interpreted for practical application. By that definition, even the manual recording of thermometer readings and acting on them qualifies as a basic data acquisition system.

The evolution of modern DAS began in the early 1960s with IBM’s development of advanced computer and hardware complexes. The first official data acquisition machine, the IBM 7700 Data Acquisition System, debuted in 1963. A year later, IBM introduced the 1800 Data Acquisition and Control System, which marked a key innovation with its complex disk storage capability. In 1981, IBM launched the Personal Computer and Scientific Solutions line, integrating data acquisition technology with the growing world of personal computing.

Since then, DAS technology has advanced dramatically, becoming both more powerful and more accessible. Today’s systems are fully electronic, capable of processing input from multiple channels simultaneously. As a result, the global data acquisition market has seen sustained growth, with some forecasts predicting nearly 40% growth over just a five-year span from 2015 to 2020.

Advantages of DAS

The use of data acquisition systems brings a wide array of advantages. The precision, adaptability, ease of use, and strong processing capabilities of modern DAS are leveraged across numerous industries to enhance efficiency and reduce operational costs. While the initial setup—designing the system, investing in the necessary hardware and software, and providing training—can be time-consuming and financially demanding, these upfront commitments are typically offset over time. In the long run, the transition to DAS proves to be a worthwhile investment that delivers measurable returns.

How Data Acquisition Systems Work

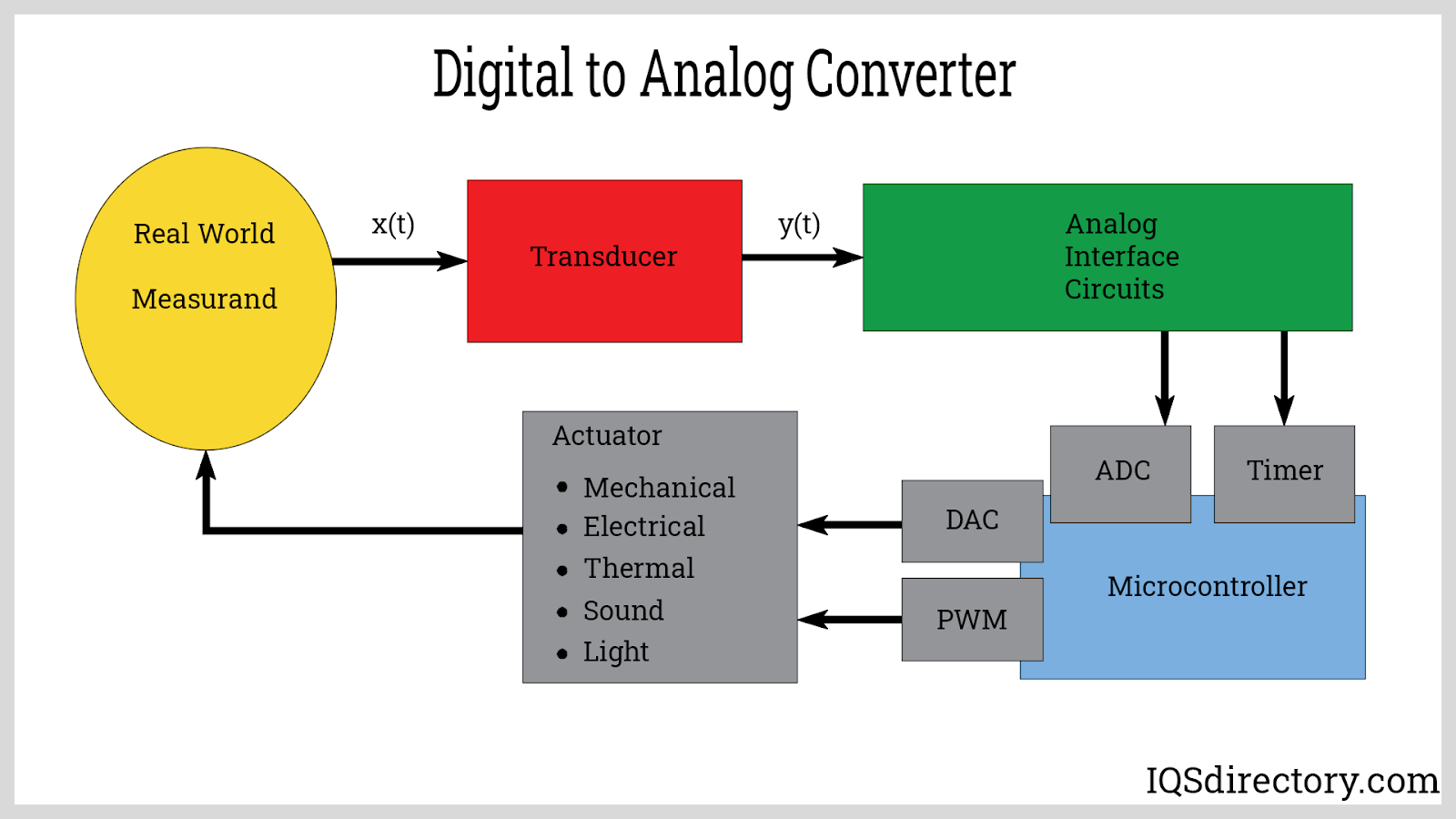

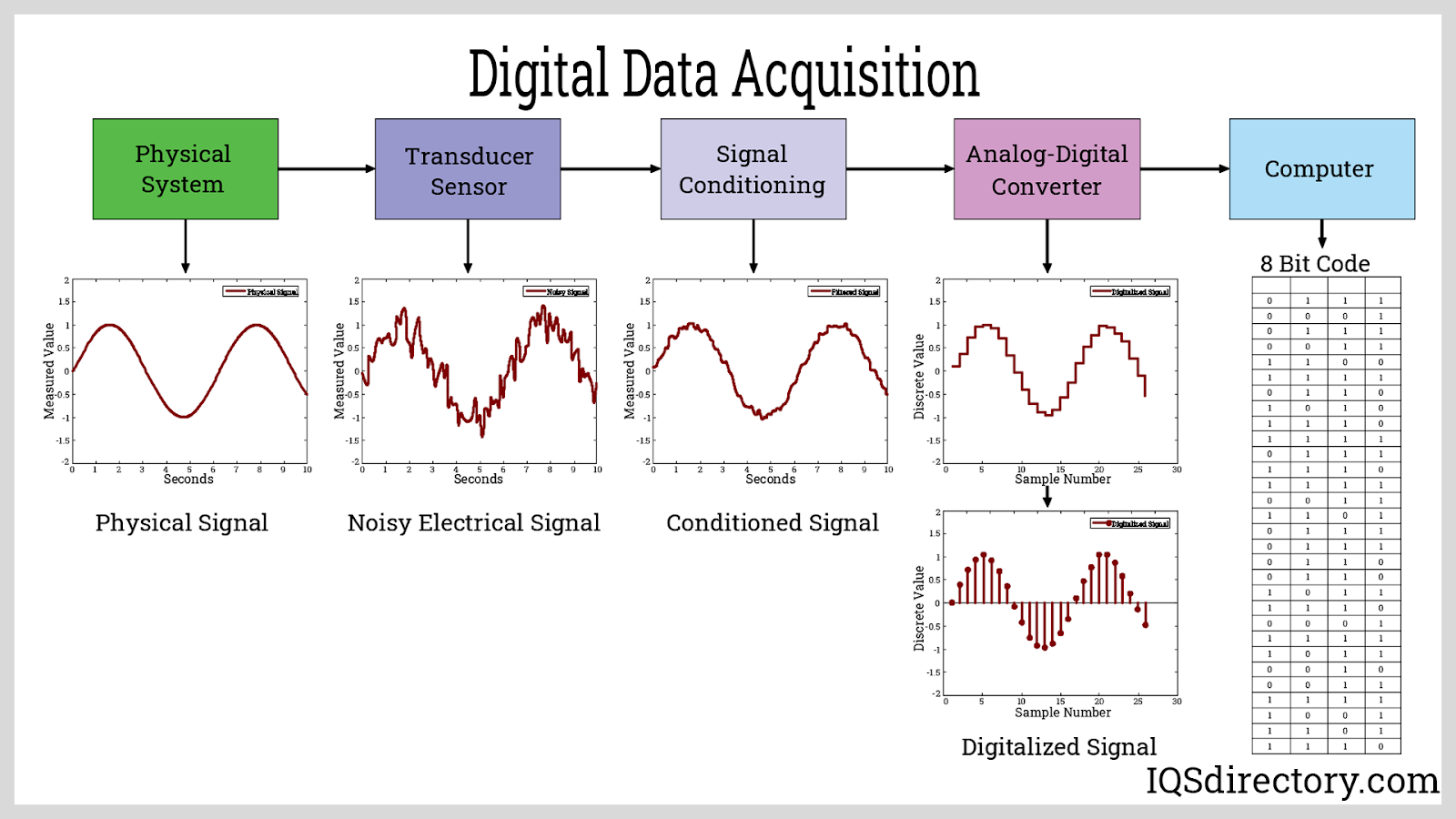

To function effectively, data acquisition systems (DAS) must capture data from some type of physical phenomenon. DAS systems can measure a wide range of physical properties, including light intensity, fluid flow, gas pressure, temperature, and force. These phenomena are typically represented by analog signals, which are continuous signals characterized by their level (intensity) and frequency (variation over time). In practical terms, an analog signal is often synonymous with an electrical signal, as electricity is one of the most common analog phenomena. Sensors in a DAS convert their interactions with physical phenomena into various electrical signals, such as voltage, current, and resistance.

These electrical signals form the foundation of digital values within the data acquisition system. However, before these signals can be converted into digital values, an intermediate step is necessary—this step is called signal conditioning. Signal conditioning is performed by specialized circuitry, which is typically part of the DAS hardware and often provides power to the sensor as well. Conditioning is critical because electrical signals are prone to distortion, making them difficult to process and interpret.

Signal conditioning can involve different methods, including amplification and filtering. Sensors, when interacting with physical phenomena, often extract energy from the systems they monitor. As a result, the electrical signals generated are often too weak to be directly converted into a digital form. Amplifying these signals boosts their intensity to a level that makes digital conversion possible. Even if amplification is not necessary, most signals need filtering, as they may be noisy (e.g., disrupted by electrical interference) or too intense (e.g., characterized by high frequency) for smooth digitization. Filters, often placed after amplifiers, adjust the signal so that it is ready for digital conversion.

Once the signal is conditioned, it can undergo conversion. Analog-to-digital converters (ADCs) are the components responsible for this task. ADCs sample the conditioned signals at high speeds, often in intervals of fractions of a second, converting them into binary data (1s and 0s). ADCs are capable of rapidly switching between multiple input channels, ensuring efficient data collection across various sources.

After the signals are digitized, they need to be transferred to a computer for the system to be useful. This process is typically handled by a bus, which transports the digitized data. While the bus is sometimes considered a separate component, it is generally categorized as part of the DAS hardware. The collection of components involved in digitizing and transporting data—the signal conditioner, ADC, and bus—can be referred to as a data acquisition module. The method of transferring data through the bus depends on the telecommunications protocol in use. In industrial applications, personal computer (PC) data acquisition is widely employed, requiring a connection to a host computer to download the collected information. Different types of connections, such as parallel, serial, USB, or Ethernet ports, are used to establish this link. Wireless connections (known as DAQifi) have recently been introduced, offering an alternative to traditional wired connections. DAS hardware may also connect via data acquisition cards, which interface directly with a host computer.

While the ADC can be considered the "heart" of the DAS, the computer acts as the "brains" of the system, controlling all operations and transforming the raw digital data into usable information for the end user. The computer typically runs two types of software: application software and driver software. Application software provides the user interface and enables interaction with the system, while driver software ensures communication between the application software and the DAS hardware.

Choosing DAS

A core characteristic of data acquisition (DAQ) systems is their variety. When selecting the right DAQ system and manufacturer, it is essential to carefully assess your specific application(s). However, it's important to balance the specificity of your needs with the flexibility offered by the DAQ system. While different types of DAQ systems may share certain fundamental features, these features—such as the type and performance of an analog-to-digital converter (ADC) or the quality of the computer software—are crucial for ensuring a high-quality system.

The following examples provide a broad overview of how the choice of a DAQ system is heavily influenced by its intended use:

Measuring Through a DAS Sensor

As previously mentioned, almost any physical property can be measured by some form of DAS sensor. However, not all variables in an industrial setting need to be measured. Therefore, it is more efficient to choose a DAQ system with the minimum number of sensors necessary for your application, rather than one that offers an excessive number of sensors. The first step in determining this is to clearly identify the specific data you need to measure.

Power Provision

USB-based DAQ systems offer several benefits, including the ability to provide power to peripheral devices and higher bandwidth (up to 12 Mbits/s). Since USB devices can also supply power, only one cable is needed to connect the DAQ device to the computer, which typically has at least one USB port. The choice of power source will also depend on the environment in which the DAQ system operates.

Computer Compatibility

The type of computer used for the DAQ system will depend on its intended application. For field operations, a DAS compatible with a laptop is ideal, offering portability. On the other hand, if processing power is more critical than portability, a DAS that connects to a desktop or even a heavy-duty industrial computer may be the best option.

Wireless Connections

Wireless DAQ systems, or DAQifi, are advantageous in situations where low upfront costs, flexibility, and portability are essential. These systems use wireless connections between the hardware and software, providing greater mobility and fewer physical constraints, making them well-suited for remote or dynamic applications.

Data Loggers

Data loggers are especially effective for detecting irregular patterns over time. They are useful for design verification in product development environments and are ideal for field operations due to their portability. Data loggers collect data over extended periods, making them suitable for monitoring ongoing processes or long-term experiments.

Switch Box

A switch box is another useful tool for industrial testing and verification. It acts as a conduit for signals between test subjects and other measurement equipment, such as oscilloscopes or counters. Switch boxes are versatile components that can be integrated into a variety of industrial testing setups to manage and direct signals.

In summary, the best DAQ system for your application depends on the specific needs of your operations. By carefully evaluating factors like the number of sensors, power requirements, computer compatibility, and the potential benefits of wireless or portable systems, you can select the DAQ solution that provides the optimal balance of performance and cost-effectiveness.

Data Acquisition System Images, Diagrams and Visual Concepts

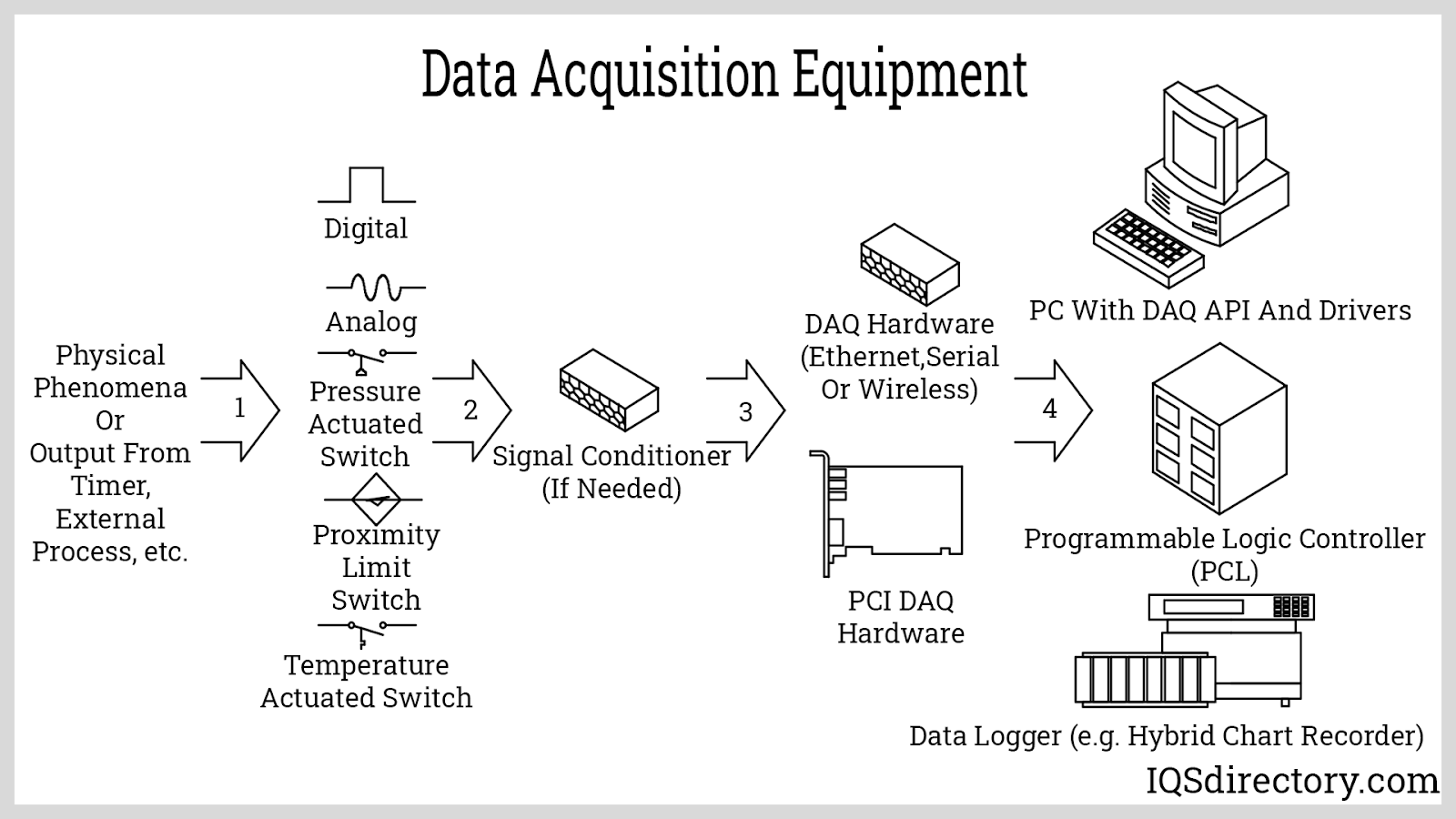

Data acquisition devices contain signal conditioning circuitry, as well as an analog-to-digital converter which needs a computer to function.

Data acquisition devices contain signal conditioning circuitry, as well as an analog-to-digital converter which needs a computer to function.

Data acquisition systems require cards to provide the different measurement functions for for acquiring, storing, and processing data.

Data acquisition systems require cards to provide the different measurement functions for for acquiring, storing, and processing data.

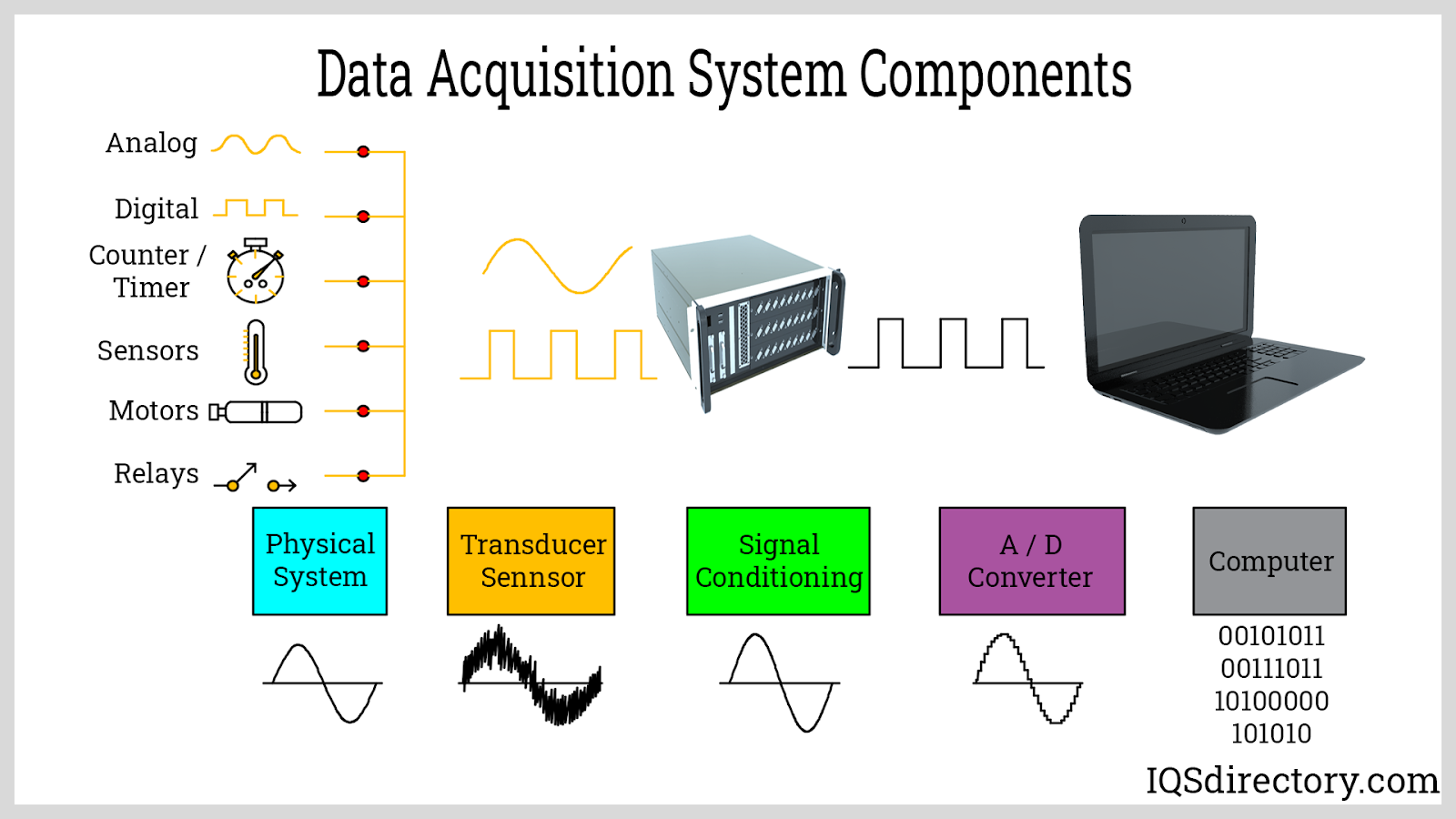

The different components used in data acquisition and what is require for the parts to operate.

The different components used in data acquisition and what is require for the parts to operate.

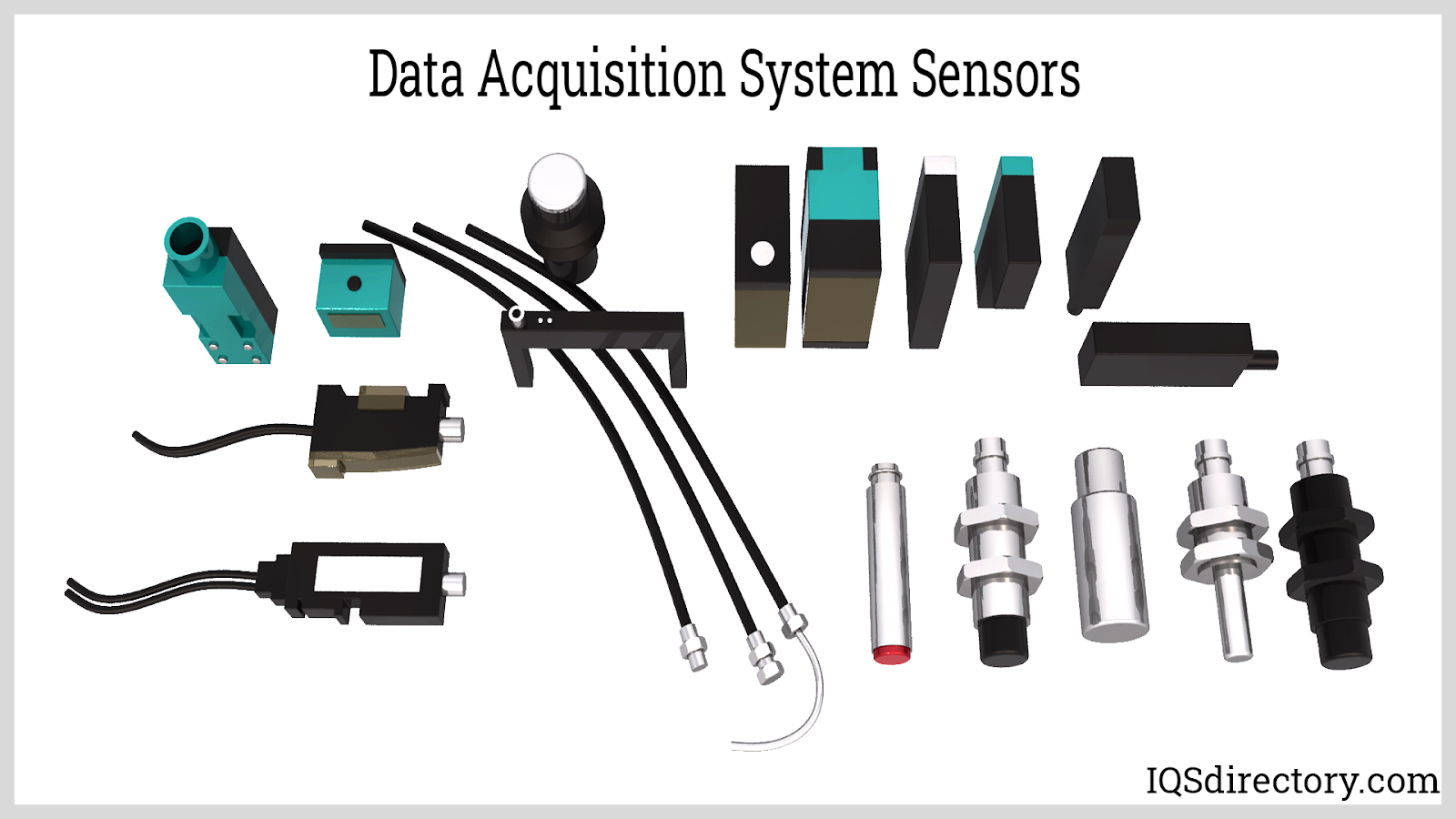

Sensors convert physical values to produce an output of electrical signals.

Sensors convert physical values to produce an output of electrical signals.

This component provides support for inputting and outputting binary signals.

This component provides support for inputting and outputting binary signals.

Data acquisition systems uses remote sensing technologies within radar and sonar applications to calculate their efficiency.

Data acquisition systems uses remote sensing technologies within radar and sonar applications to calculate their efficiency.

Variations of DAS

As previously mentioned, data acquisition systems (DAS) are highly variable because the physical data they rely on can differ greatly. For example, measuring temperature requires different equipment and procedures compared to measuring pressure. There are various components, devices, and types of data acquisition systems designed to meet a wide range of applications. Some of the most common variations include data acquisition cards and stand-alone DAQ machines (often referred to as data loggers).

PC Plug-In Cards

Data acquisition cards are electronic hardware devices that must be physically inserted into a computer. These cards fit into motherboard slots, such as PCI or PCI Express, and use the internal bus of the PC to access its memory. Historically, DAQ cards have been used to reduce the overall cost of implementing and operating DAS. However, they are limited by factors like low channel counts and inconsistent accuracy, making them increasingly outdated as more advanced DAS options are developed.

Stand-Alone Machines (Data Loggers)

The most distinct type of data acquisition system is the stand-alone DAQ system. As the name suggests, these systems operate independently of a separate PC. While they can be integrated into a larger data acquisition setup, they are often used separately from a computer. Stand-alone DAQ systems require special data logger software and internal memory (SD cards are commonly used) to function properly and process data. Even though they can operate without a PC, these machines usually allow data to be downloaded to a computer via connections like GPIB or USB. Stand-alone DAQ systems are often synonymous with data loggers, which are defined as devices that can store data. Examples of data loggers include plug-in boards and serial communication systems. A typical example is the temperature recorder, which can be mechanical, analog, or digital. These devices collect temperature data, digitize it, and transfer it to a computer for further analysis, such as in laboratory research or weather stations.

Parts & Accessories

The individual components of a DAS can vary just as much as the systems themselves. For example, analog-to-digital converters (ADCs) are crucial in DAS. These high-speed digitizers come in different forms, such as successive approximation ADCs, voltage-to-frequency ADCs, dual-slope integrating ADCs, and Sigma Delta ADCs. Another critical component is the application software, which is often written in common programming languages like C++ to allow users to customize its functionality. Some versions of DAS, however, come with ready-to-run software that does not require further programming. This software also manages how digital data is stored, whether in volatile RAM or permanent storage like a hard drive.

An example of a DAS accessory is the breakout box. When the number of input channels exceeds the number of available ports, a breakout box can consolidate multiple signals into a single signal, which the DAS can then properly process.

Applications of DAS

Data acquisition systems (DAS) are commonly used for various types of testing, field studies, troubleshooting, and research. These systems are essential for monitoring processes and making adjustments as needed. Manufacturers utilize DAS to test a wide range of technical products.

DAS, with general-purpose programming instead of industry-specific applications, proves valuable across many industries. For instance, in the medical field, DAS is used for collecting clinical trial data through centralized web-based systems and local electronic data capture systems. In the industrial sector, DAS is used to acquire data via chart recorders and PC-based systems. In aerospace, DAS collects data through flight data acquisition units and structural dynamics test systems. In wastewater management, DAS is used to gather data on wastewater toxicity and treatment effectiveness. Other industries heavily relying on DAS include food processing, oil refining, paper production, steel manufacturing, chemical production, cement manufacturing, and textiles.

One of the most common forms of DAS in industrial environments is Supervisory Control and Data Acquisition (SCADA). SCADA is an intricate system of data acquisition devices and sensors networked to a central control hub with extensive monitoring and intervention capabilities. SCADA systems coordinate large-scale industrial operations, often over wide geographical areas. While SCADA systems vary just like smaller DAS, they can be broken down into fundamental components, including SCADA software, sensors, field controllers, and network equipment.

In a SCADA system, sensors and actuators do not send data directly to a computer. Instead, they communicate with local "computers" called field connection controllers, typically remote terminal units (RTUs) or programmable logic controllers (PLCs). RTUs are simpler, while PLCs are more sophisticated and versatile. Field controllers reformat the sensor data to conform to the SCADA system’s communication protocol before passing it on to the central hub, which may consist of one or multiple computers. SCADA systems can operate on either wired or wireless networks, with communication protocols like Modbus RTU and Modbus TCP/IP being widely used.

At the central SCADA hub, computers can react automatically to the data received from the field controllers. These hubs often feature human-machine interfaces (HMIs), allowing users to view data and manually intervene in industrial processes if necessary. RTUs can also receive commands from the central SCADA system and perform actions based on sensor data. Some advanced RTUs, known as smart RTUs, can execute simple actions independently without central command.

SCADA systems are prevalent in industries such as power generation, water utilities, oil and gas, steel production, and mass transit. They are used to manage processes like regulating water flow (e.g., from a reservoir to a tank) or controlling mass printing for marketing materials.

Fundamental Features of DAS

Data acquisition systems (DAS) are designed to interpret a wide array of physical phenomena across diverse environments, making these systems highly adaptable and varied. The components of a DAS can differ widely, with many specialized parts tailored to specific applications. Despite these differences, all DAS share a core set of essential components, even though their appearance and functionality may vary.

The primary components of a DAS include sensors, specialized hardware (such as signal conditioning circuitry and analog-to-digital converters), and dedicated software.

Sensors Also known as transducers, sensors are essential in data acquisition systems because they convert physical data into digital values, enabling the system to measure and process real-world phenomena.

DAQ Hardware DAQ hardware serves as the interface between the signal and a computer. While most hardware sets need to be connected to a computer to function, some can operate independently. The key hardware components typically include signal conditioning circuitry and analog-to-digital converters (ADCs). The signal conditioning circuitry modifies the signals from the sensors to a format that can be more easily digitized. The ADCs then convert the conditioned signal into digital data, which is crucial for further processing and analysis.

Software Programs Data acquisition systems are controlled and accessed through specialized software programs. These programs are often written in general-purpose programming languages such as Java, Pascal, Lisp, and BASIC. The software resides on a computer and processes all the data flowing through the sensors and hardware. Once processed, the data can be analyzed and applied practically by the end user.

When selecting a DAS, it is crucial to discuss your specific application needs with potential suppliers of data acquisition systems. You can refer to the list of manufacturers at the top of this page for more information on available products.

Data Acquisition System Terms

-

Accuracy

The total of all error factors within a data acquisition device.

Aliasing

The misrepresentation of high-frequency signals as lower-frequency ones. These are expected errors that arise from the discrete sampling process used in devices like analog-to-digital (A/D) converters.

Anti-Aliasing Filter

A device that reduces signals outside the desired frequency range, placed before the analog-to-digital converter (ADC) in an instrumentation system. It ensures that only the desired frequencies are sampled by the ADC.

Analog

A signal that can vary continuously within a range between two extremes.

Analog-to-Digital Conversion (A/D)

The process of converting an analog signal into a digital value that can be processed and stored on a computer.

Asynchronous

The transfer of data between sending and receiving systems in the form of binary sequences (zeros and ones). For accurate interpretation, the receiving system must know where to begin reading the sequence.

Automated Local Evaluation in Real Time (ALERT)

A data transmission protocol used in flood warning systems.

Calibration

The adjustment of a device to improve its accuracy and ensure precise readings.

Common Mode Range

The required voltage range relative to the datalogger ground within which both inputs of a differential measurement must fall for accurate readings.

Data Retrieval

The process of receiving data from devices like RTUs, data loggers, or field recording systems. This can occur locally or remotely.

Differential Input

An input channel setup with two signal wires for each input: one for the signal and one for the return. The voltage difference between these wires is measured.

Differential Measurements

Analog measurements that assess the voltage difference between two inputs. These measurements are less affected by noise and can eliminate errors caused by ground potential differences between sensors and the datalogger.

Digital I/O Ports

Input/output ports that monitor status, read SDM peripherals, or interface with SDI-12 sensors and external devices.

Excitation

The electrical current or voltage supplied to a transducer to enable its operation.

External Signal Conditioning

The process of using external devices to modify a sensor’s signal so that it can be read by an incompatible device. Signal conditioning can range from simple to complex.

Jitter

The variation or displacement of a signal from its intended position, often occurring periodically.

Queue

A temporary storage area for data awaiting processing or transmission.

Resolution

The smallest measurable change in a signal that can be detected by a system.

Sample Rate

The frequency at which measurements are taken.

Sampling

The process of calculating a signal’s value at specific time intervals.

Sampling Frequency

The number of times per second an analog signal is measured during the A/D conversion process.

Sensitivity

The smallest detectable change in a signal that an instrument can register.

Sensor

A device that reacts to a physical stimulus (e.g., light, sound, pressure) and produces an electrical signal or alters its electrical properties, such as resistance.

Supervisory Control and Data Acquisition (SCADA)

A system used for monitoring and controlling industrial processes by collecting data and ensuring efficient regulation. SCADA systems are commonly used in water treatment plants.

Transducer

A sensor that converts physical energy into electrical signals that data loggers can measure and record. Examples include thermocouples and strain gauges