Die Cutting

Die cutting is a precision manufacturing process that involves stamping or cutting two-dimensional shapes from flat sheets of various materials, including rubber, fiber, paper, and metal. This method is commonly integrated with laminating services and serves as a key finishing process for numerous industrial and commercial applications.

The term "die cutting" can sometimes be misleading, as its definition varies across different industries. While the primary function is cutting, die cutting can also include shaping, forming, and compressing materials to achieve specific contours and structural integrity. In some cases, it is used for embossing, perforating, or scoring materials, expanding its role beyond simple material separation.

This process is widely valued for its efficiency, precision, and ability to produce high volumes of identical parts with minimal material waste. Whether used in automotive, packaging, textiles, or electronics, die cutting remains an essential method for creating uniform, high-quality components with consistent performance.

Die Cutting FAQs

What is die cutting used for in manufacturing?

Die cutting is used to stamp or cut two-dimensional shapes from flat sheets of materials like rubber, paper, fabric, and metal. It ensures precision, high-volume output, and uniform parts across industries such as packaging, automotive, and electronics.

How did die cutting originate?

Die cutting began in the mid-1800s in the shoe industry, replacing manual leather punching with presses that cut precise shapes. It quickly improved efficiency, expanded to new materials, and evolved into modern automated, CAD-driven systems used today.

What are the main benefits of die cutting?

Die cutting offers speed, cost efficiency, and versatility. It reduces material waste, eliminates the need for heat, and supports materials such as cardboard, foam, metal, and textiles, making it essential for industries from packaging to automotive.

What types of machines are used for die cutting?

Common machines include rotary presses for high-volume runs, flatbed machines for flexible batch cutting, and laser cutters for intricate or thick materials. Each machine type is chosen based on material, design complexity, and production speed needs.

What products are commonly made with die cutting?

Die cutting produces gaskets, seals, vibration absorbers, bandages, circuit boards, labels, cartons, and stickers. It also creates consumer goods like retail bags, ID cards, and textiles, ensuring consistent, high-quality parts for varied applications.

What is kiss cutting in die cutting?

Kiss cutting slices only the top layer of a material, leaving the backing intact. This method is commonly used for stickers, adhesive tapes, and foam pads that need to be peeled away from a backing sheet easily.

When should a company outsource die cutting versus buying a machine?

Outsourcing suits businesses needing specialized production, certifications, or short runs without major equipment investment. Purchasing a machine is best for companies with consistent volume, specific material needs, or long-term cost savings goals.

The History of Die Cutting

Die cutting originated in the mid-1800s as a time-saving innovation in the shoe industry. Before this process, shoemakers manually punched holes in leather, a labor-intensive and inconsistent method. The introduction of die cutting presses allowed shoemakers to cut leather into precise shapes using pre-designed dies, greatly improving efficiency and uniformity.

By the early 1900s, the industry experienced major advancements, including the development of the swing arm clicker press. This innovation enabled manufacturers to cut multiple shapes and sizes simultaneously, paving the way for the mass production of materials such as plastic and metal tubing.

During the 1950s, die cutting technology became more compact and versatile. Engineers designed smaller machines, including handheld and tabletop models, making die cutting more accessible to smaller businesses and independent craftsmen.

The early 2000s marked a technological revolution in die cutting, driven by computer-aided design (CAD) software and automation. High-precision robotic systems and high-pressure presses emerged, enabling the cutting of thicker and harder materials with greater accuracy and speed.

Today, die cutting is not just an industrial and commercial process but has also become a widely used tool for crafters and hobbyists. Compact, programmable machines such as the Cricut Expression allow users to cut intricate designs using digital or physical cartridges, making die cutting an essential tool for creative projects in homes, classrooms, and workshops.

Benefits of Die Cutting

Die cutting offers numerous advantages, whether you’re investing in a personal die-cutting machine or seeking professional die-cutting services. This method is valued for its versatility, precision, and efficiency, making it an essential tool across multiple industries.

One of the greatest benefits of die cutting is its compatibility with a wide range of materials, including cardboard, rubber, foam, fabric, and metal sheets. This adaptability makes it an ideal process for industries such as packaging, automotive, textiles, and electronics.

Speed and efficiency are also key strengths of die cutting. The process allows for high-speed production with minimal material waste, ensuring cost-effective manufacturing. Additionally, unlike some fabrication methods, die cutting does not require heat, reducing both energy consumption and workplace injury risks.

Another advantage of die-cutting technology is its variety of machine options. Industrial-scale die cutters can handle large production runs, while small, portable die-cutting machines cater to crafting and prototyping needs. Depending on the application, these machines are available in manual, hydraulic, pressurized, or electric-powered models.

Modern die-cutting machines also incorporate digital technology for enhanced precision. Many computerized die-cut machines use CAD software, allowing for customized, intricate designs with minimal error margins. This integration of automation and technology has further expanded the capabilities and applications of die cutting, making it a go-to process for businesses and individuals alike.

Process and Design of Die Cutting

Die cutting is a cold-forming process that shapes and cuts materials without heat, preserving their physical properties while ensuring precision and efficiency. Instead of relying on thermal energy, die cutting employs brute force, using a press to cut materials into desired shapes and sizes.

The process begins with placing the material on a flat surface, typically supported by a backing layer and auxiliary tools that allow the die to pass through smoothly. Once positioned, the die is pressed against the material, applying force perpendicularly or at an angle to achieve a precise cut.

Selecting the Right Die

Manufacturers choose dies based on application requirements. Dies are typically categorized into two sections:

- Cutting dies for shearing materials into specific shapes

- Forming dies for shaping materials without completely cutting through

The function of the die determines its design, tooling, and method of operation.

Choosing the Right Machine

Selecting an appropriate die-cutting machine depends on several factors:

- Material type (e.g., metal, rubber, plastic, fabric)

- Complexity of the design

- Production volume and speed requirements

- Preferred cutting method (rotary, flatbed, laser, etc.)

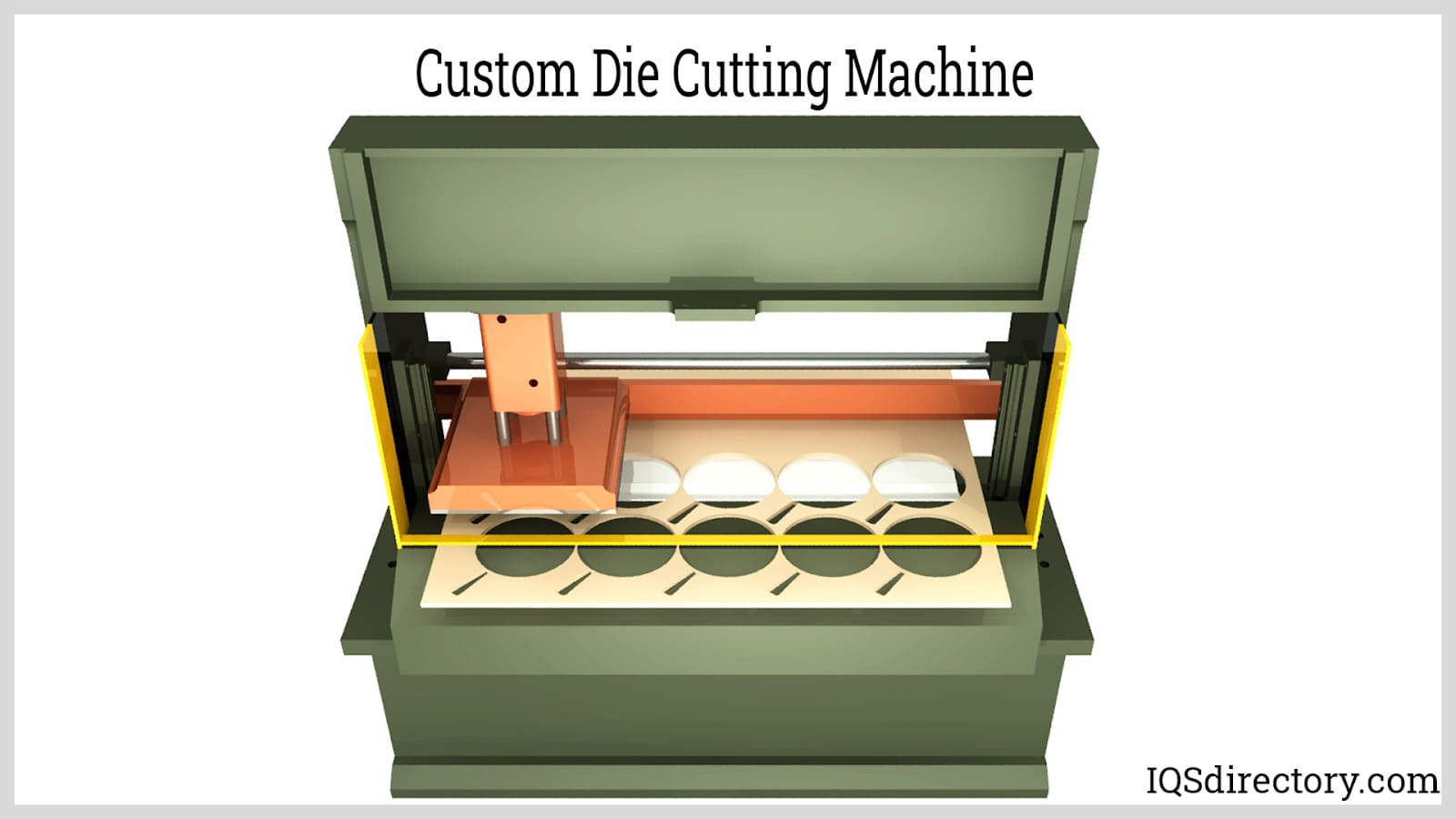

Custom Die Cutting

For specialized applications, manufacturers offer custom die cutting solutions. Customization allows for:

- Blades tailored to precise cutting applications

- Specialized dies designed for unique shapes

- Stacked cutting of multiple material layers for efficiency

By integrating custom dies, precision tooling, and automated programming, manufacturers can optimize the die-cutting process to meet specific design requirements while maintaining speed, accuracy, and minimal waste.

Cutting Machinery Used

Die cutting machines come in various configurations, each designed to create precise and efficient cuts based on the material and application. The machines differ in cutting methods, speed, and complexity, making them suitable for different industries. Below are some of the key presses, dies, and cutting machines used in the die cutting process.

- Flat laser cutters—for cutting flat sheets of material

- Rotary laser cutters—for cutting continuous web materials

Laser cutting offers high precision, no-contact cutting, and minimal material waste, making it ideal for custom or complex designs.

- Rotary Press

- A continuously operating machine, the rotary press cuts material as it rotates, making it one of the fastest and most efficient die-cutting options. Typically paired with rotary dies, rotary presses are ideal for high-volume production in industries such as packaging, labels, and textiles.

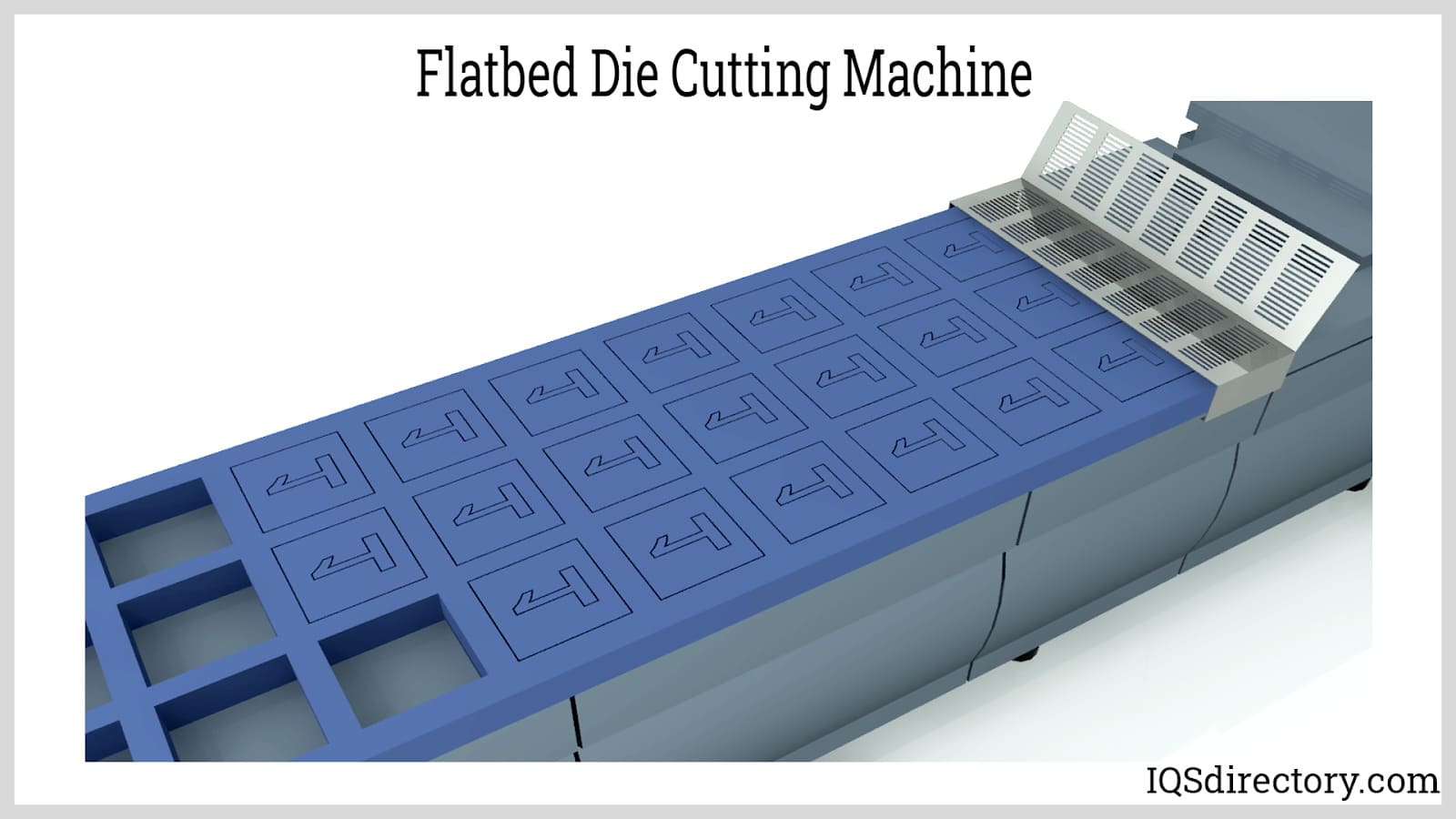

- Flatbed Die Cutting Machine

- Flatbed presses apply force perpendicularly to the material, typically using hydraulic pressure. Although not as fast as rotary presses, they offer lower tooling costs and greater flexibility in cutting shapes. These machines excel in cutting stamps, stickers, and laminated materials and are often used for kiss-cutting and precision cuts in batch production.

- Laser Die Cutting Machine

- CNC-operated and driven by a 3-axis table, laser die-cutting machines use high-intensity laser beams to cut intricate shapes. They are available in two configurations:

- Rotary Die

-

Rotary dies are cylindrical and are specifically designed to be mounted on a rotary press. Typically sold in sets, these dies enable continuous cutting operations, making them highly efficient. Common applications include corrugated boxes, plastic parts, foam, rubber, and textiles.

- Steel Rule Die

- Steel rule dies are sharpened, thin blades embedded in rubber and mounted on a solid wood block. The rubber surrounding the steel rule helps eject the cut pieces, while the die and rubber pad crush and cut materials such as foam, plastic, and rubber with immense force. These dies allow for batch cutting of multiple sheets.

- Heavy Duty Steel Rule Die

- Heavy-duty steel rule dies, like the clicker die, feature thicker blades (ranging from .056" to .112") to cut through tough materials. They are widely used for plastics, Kevlar, fabric, rubber, leather, and composite materials, producing gaskets, vibration absorbers, and industrial parts.

- Conventional Die

- Conventional dies provide exceptional accuracy and intricate cuts, including fold lines, scores, perforations, and partial cuts. They are commonly used for corrugated boxes, folding cartons, plastics, gaskets, textiles, and foam. These dies feature high-density plywood as a support structure, with blade thickness ranging from .028" to .056".

- Swing Arm Cutting Press

- Also known as a clicking press, the swing arm cutting press gets its name from its hydraulic arm motion, which allows for precise cutting of small parts. It is well-suited for both small-scale and large-scale production.

- Traveling Head Cutting Press

-

This press features a motorized cutting head that moves along a frame, allowing for automated cutting operations. It is frequently used in high-volume manufacturing and provides consistent precision for a wide range of materials.

Each die-cutting machine and press is designed to cater to specific materials and production needs, ensuring that manufacturers can efficiently produce high-quality products while minimizing waste and cost.

Die Cutting Applications

Die cutting plays a crucial role in a wide range of industries, providing precise and high-quality stamped components for paper, plastic, foam, and metal products. Customers prefer die cutting for its ability to create clean, uniform shapes with consistent accuracy and efficiency.

Die-cut products are extensively used in medical, craft, packaging, shipping, hydraulic, electronic, and consumer industries, where precision and uniformity are critical.

Commonly Produced Die-Cut Products

Die cutting is used to manufacture a diverse array of products, including:

- Gaskets and seals – Essential for hydraulic systems, automotive engines, and industrial machinery

- Vibration absorbers – Used in automotive and mechanical applications to reduce noise and vibration

- Medical bandages and adhesives – Applied in healthcare and first aid products for sterile and accurate application

- Plastic handle bags – Commonly used in retail packaging and shopping bags

- Circuit boards and ID cards – Essential for electronics, security systems, and financial applications

- Labels, stickers, and adhesive tapes – Applied in branding, logistics, and consumer packaging

- Cartons, corrugated envelopes, and paper packaging – Widely used in shipping and e-commerce industries

- Fabric and metallic die cuts – Used in apparel, furniture, and industrial applications

- Keys and precision metal parts – Manufactured for security and hardware applications

Specialized Die Cutters for Different Materials

Different types of die-cutting machines are specifically designed for cutting, shaping, and customizing various materials, such as:

- Paper and cardstock – Used for crafts, greeting cards, packaging, and labels

- Plastic and foam – Utilized for protective packaging, gaskets, and consumer goods

- Metal sheets – Applied in hardware, industrial components, and automotive parts

- Fabric and leather – Essential for clothing, upholstery, and accessories

Die cutting offers high precision, versatility, and cost-effective production, making it an indispensable process in modern manufacturing and product design.

Variations and Similar Processes to Die Cutting

Die cutting has evolved into multiple specialized techniques, each catering to different materials, precision levels, and production requirements. These variations enhance the flexibility and efficiency of the process, allowing for diverse applications across industries.

- No tooling costs since it does not require physical dies.

- Minimal material waste due to precise tolerances.

- Best for prototyping and short runs, but slower than rotary or steel rule die cutters for high-volume production.

- Used for foam pads, adhesive bandages, gaskets, and rubber parts.

- Commonly used for sticker sheets, foam adhesives, and bumper pads that are meant to be peeled off from a backing sheet.

Each die cutting variation serves a unique function, allowing manufacturers to optimize production processes based on material type, precision requirements, and volume needs. By selecting the appropriate technique, industries can maximize efficiency, minimize waste, and enhance product quality across applications ranging from packaging and electronics to automotive and industrial components.

- Rotary Die Cutting

- This process involves feeding sheets or continuous rolls of material between a cylindrical die and an anvil, where angled blades crush and cut the material. Rotary die cutting offers higher precision, consistently maintaining tolerances as tight as .02 inches, making it more reliable than manual steel rule die cutting.

- Rotary Steel Drum Cutting

- A hybrid of rotary and steel rule die cutting, this technique is specifically designed for cutting large components such as boxes, garments, and industrial parts with greater accuracy and efficiency.

- Ultrasonic Die Cutting

- This modern technology utilizes ultrasonic vibrations from a metal horn to cut and heat-seal edges simultaneously. It is particularly effective for thermoplastic materials prone to fraying. However, ultrasonic die cutting is limited to thin materials and small part widths.

- Laser Die Cutting

- A high-precision method that allows for cutting thicker and harder materials that traditional steel rule dies cannot handle. It is ideal for cutting steel thicker than .5 inches, as well as ABS, acrylics, aluminum, brass, copper, composites, and cured fiberglass.

- Crush Cutting

- A method where materials are completely cut through, producing clean, full cuts. Both rotary and steel rule die cutting can perform crush cutting.

- Kiss Cutting

- Designed for adhesive-backed materials, kiss cutting cuts only the top layer, leaving the backing intact.

- Blanking Operations

- This method involves a single press movement to cut an entire profile from a flat material. The die applies uniform pressure at all contact points, making it highly efficient for mass production.

- Trimming Operations

- A process where manufacturers trim excess material around a pre-processed shape to refine its profile. The discarded materials are recycled to reduce waste.

- Notching Operations

- Notching involves using progressive dies to remove sections from a material’s edges. This step-by-step approach is often employed for creating specific shapes in metal sheets.

- Die Cutting Through Bending

- This technique applies pressure from a die to bend material at a precise angle. A common application is forming materials at a 90-degree angle for structural or aesthetic purposes.

- Die Cutting Through Piercing

- A process that punches holes of specific shapes (circles, squares, or custom patterns) into a material. Piercing is commonly used for ventilation panels, decorative elements, and industrial applications.

- Lancing Operation

- Lancing involves slitting or slicing a material without completely severing it from the strip. This method is often used in progressive die setups for controlled cutting.

- Die Cutting Through Shearing

- The simplest die-cutting operation, shearing slices material in a straight line, making it ideal for producing rectangular and square-shaped blanks.

- Stamping or Pressing

- Also known as pressing, this process stamps sheet metal into a net shape using a blank or coil metal and a stamping press. Stamping is commonly applied in automotive, aerospace, and appliance manufacturing for producing structural metal components.

Die Cutting Images, Diagrams and Visual Concepts

Rotary die cutting machines operate in continuous production mode at a lower cutting pressure and constant speed.

Rotary die cutting machines operate in continuous production mode at a lower cutting pressure and constant speed.

The retail items made from die cutting.

The retail items made from die cutting.

Kiss cutting is a method for cutting into a material where the upper layers are pierced, but the back layer is left intact.

Kiss cutting is a method for cutting into a material where the upper layers are pierced, but the back layer is left intact.

The flatlbed die cutting is suitable for cutting thicker sheets or multiple sheets as the machine is capable of exerting a considerably amount of force.

The flatlbed die cutting is suitable for cutting thicker sheets or multiple sheets as the machine is capable of exerting a considerably amount of force.

Things to Consider When Choosing Die Cutting

When deciding on die cutting, the first major consideration is whether to outsource the service to a die cutting company or to invest in your own die cutting machine.

Outsourcing Die Cutting Services

If you choose to work with a die cutting company, begin by researching reputable manufacturers. Use online directories, industry recommendations, and customer reviews to narrow down your options.

- Browse company websites and compare capabilities, machinery, and past projects.

- Contact at least three to four manufacturers to discuss your specific requirements, such as material type, part complexity, order volume, and industry standards.

- Ask about lead times, pricing, customization options, and compliance with any necessary certifications.

- Evaluate each company's response and select the one that best aligns with your budget, timeline, and quality expectations.

Investing in a Die Cutting Machine

If purchasing your own die cutting machine, consider the following key factors:

- Cutting Requirements and Machine Type

- Not all die cutting machines are the same. The best machine depends on material type, thickness, shape complexity, and production volume. Machines range from manual models for small-scale cutting to automated rotary or laser die cutters for high-volume precision work.

- Requirements for Die Type

- Different machines require specific die types and sizes, so verify compatibility between your machine and the dies you intend to use. Ensure the machine can accommodate steel rule dies, rotary dies, or laser cutting dies, depending on your needs.

- Installation Requirements and Machine Portability

- Consider how long it takes to set up the machine and whether it fits within your workspace. If portability is a priority, opt for compact, lightweight models that can be easily moved and reinstalled.

- Storage of the Die Cutting Machine

- Die cutting machines require adequate storage space. Evaluate your available storage capacity before purchasing to avoid overcrowding and potential damage to the machine or dies.

- Cost Requirements

- A die cutter is a long-term investment, so factor in initial costs, maintenance, and potential upgrades. Research different models, compare pricing, and choose a machine that offers the best balance of cost and efficiency for your production needs.

- Choosing the right die cutting solution—whether outsourcing or purchasing a machine—depends on production needs, budget, and long-term goals. A thorough evaluation of these factors ensures efficient operations, cost savings, and high-quality results tailored to your specific industry.

Die Cutting Terms

- Air Holes

- Small holes in die cutters designed to release trapped air from die cavities, preventing deformations in die-cut materials.

- Anvil

- The flat surface that supports materials during the die cutting process.

- Automated Feed Systems

- Mechanized components in certain die cutting machines that continuously and automatically supply material to the die cutter.

- Capacity

- The maximum width of material that a die cutting machine can accommodate.

- Chisel Punches

- Blades positioned either on the die or another part of the press that create precise separations in die-cut materials.

- Composite

- A material formed by layering and bonding woven sheets with resin to achieve specific properties. The individual layers remain physically distinct rather than blending completely.

- Deflection

- An unintended deviation in the top die plate from parallel alignment, which can affect cutting precision.

- Die Blade

- A steel blade fixed to the die, responsible for penetrating and cutting through the material.

- Dieboard

- A structural component, often made from plywood, into which steel rule die blades are embedded for cutting operations.

- Kevlar

- A trade name for aramid fibers developed by DuPont. Known for their exceptional strength, stiffness, and high melting point, Kevlar fibers are commonly used in composite material construction. They are lighter and stiffer than fiberglass but more expensive.

- Kiss Cut

- A die cut that only penetrates the top layers of the material without cutting through the backing layer.

- Knifing

- The process of inserting steel die blades into the dieboard of a steel rule die to create the cutting edges.

- Nicks

- Small indentations in a die rule that prevent complete cutting, often used to hold pieces together during processing.

- Plastic Die Cutting

- A method of cutting plastic sheets by pressing them against a die-formed cutting edge to achieve precise shapes.

- Punch

- The die component that creates the actual cut or shape by applying force to the material.

- Through Cutting

- A die cutting method where the material is completely cut through, separating individual pieces from the main sheet.

- Ultrasonic

- Refers to sound waves above 20 kHz, a frequency beyond human hearing, often used in ultrasonic die cutting for clean and precise cuts.

- Web

- A continuous roll of material used in rotary die cutting and other automated processes.