Die Stamping

Die Stamping is a peculiar kind of forming tool. It is commonly used to cut, bend and mold metal sheets precisely. Die stamping is also known as “stamping tool” or simply “tooling.”

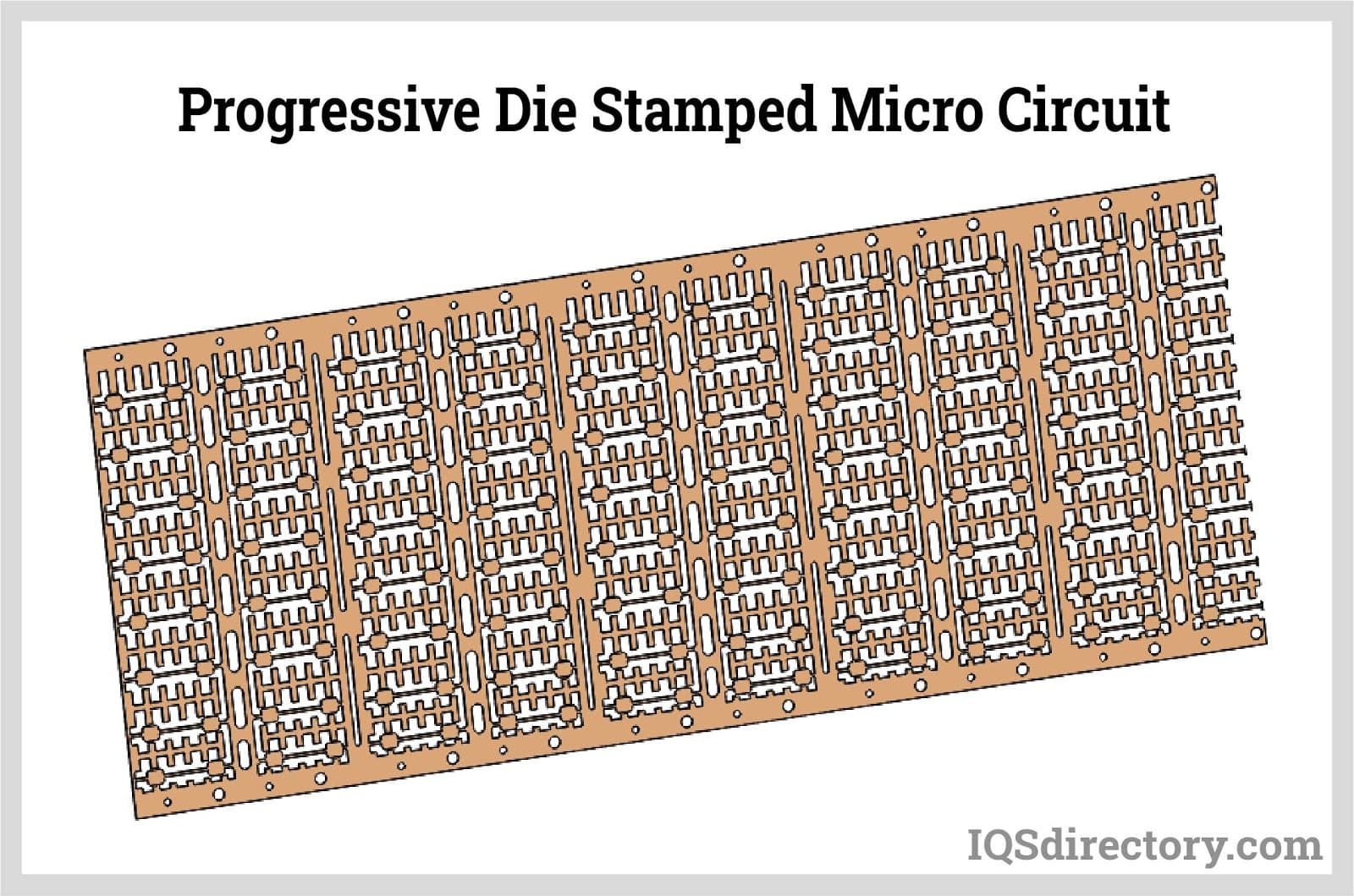

Die stamping can create parts ranging between various sizes. For example, it can create parts as big as used in the automotive industry. It can also produce miniature parts like those used in microelectronics.

Figure 1

Figure 1

The end products produced by stamping die are called “piece parts.” Different types of dies have different capacities to manufacture piece parts per cycle. Some dies can produce and process up to 1500 piece parts in one minute.

Quick links to Die Stamping Information

Basic Working of Die Stamping

In the process of die stamping, usually no heat is produced. Still, the piece parts come out as a bit heated. The friction produced during the processing of metal sheets in the press explains the heat. Following are some of the actions involved in the die stamping process:

- Cutting

- The most commonly used functionality of die stamping. It is performed by hardened steel called “tool steel”. Tool steels cut the metal sheet put in between into desired end products.

- Trimming

- Gives a part or sheet a specific profile by trimming or shaping the product’s exterior boundary.

- Notching

- When the cutting is performed on the outer crease of the metal sheet to give it a strip-like shape, it is said to be notched.

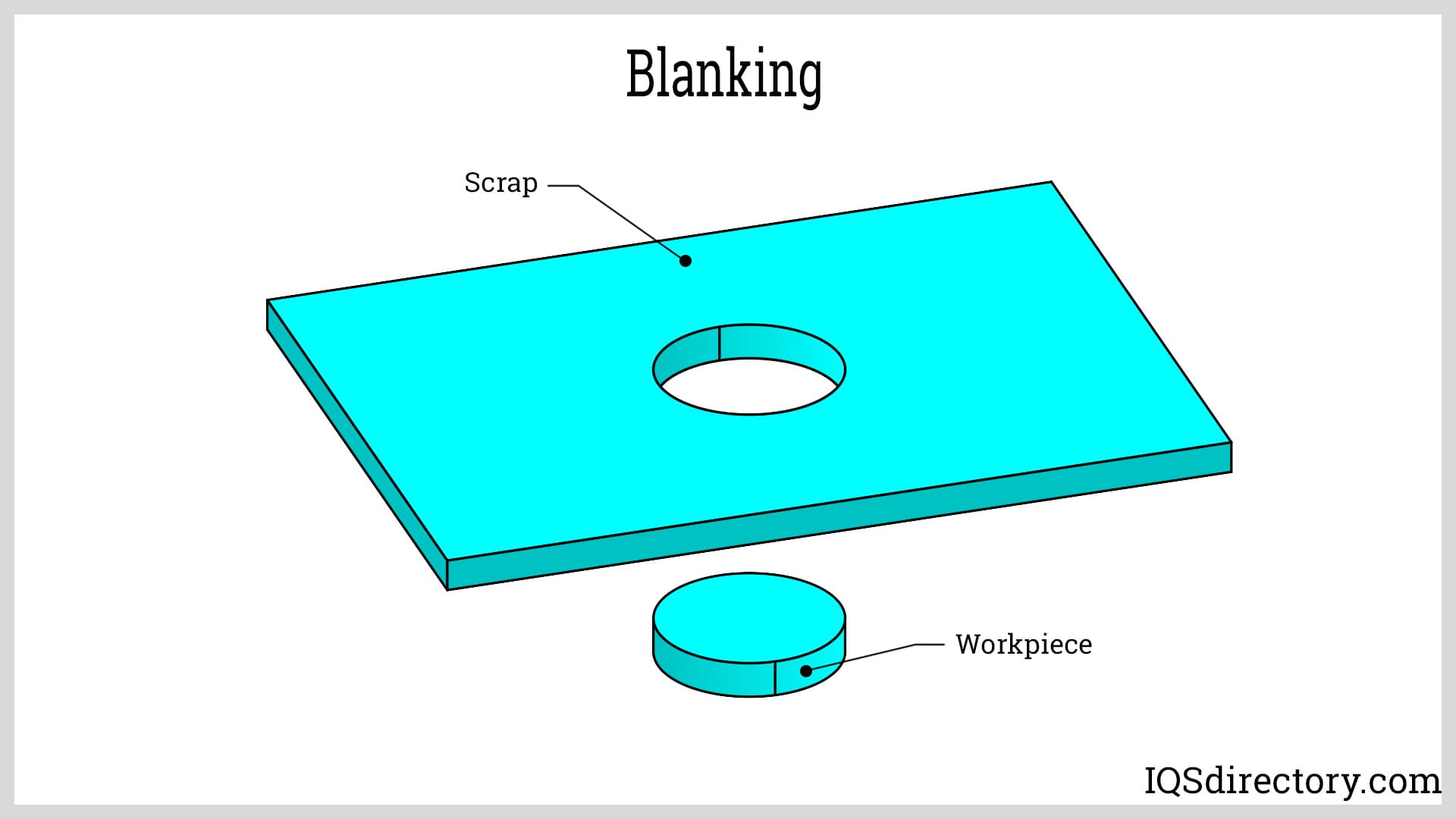

- Blanking

- In blanking, the finished part (piece part) of a metal sheet is cut away from it.

-

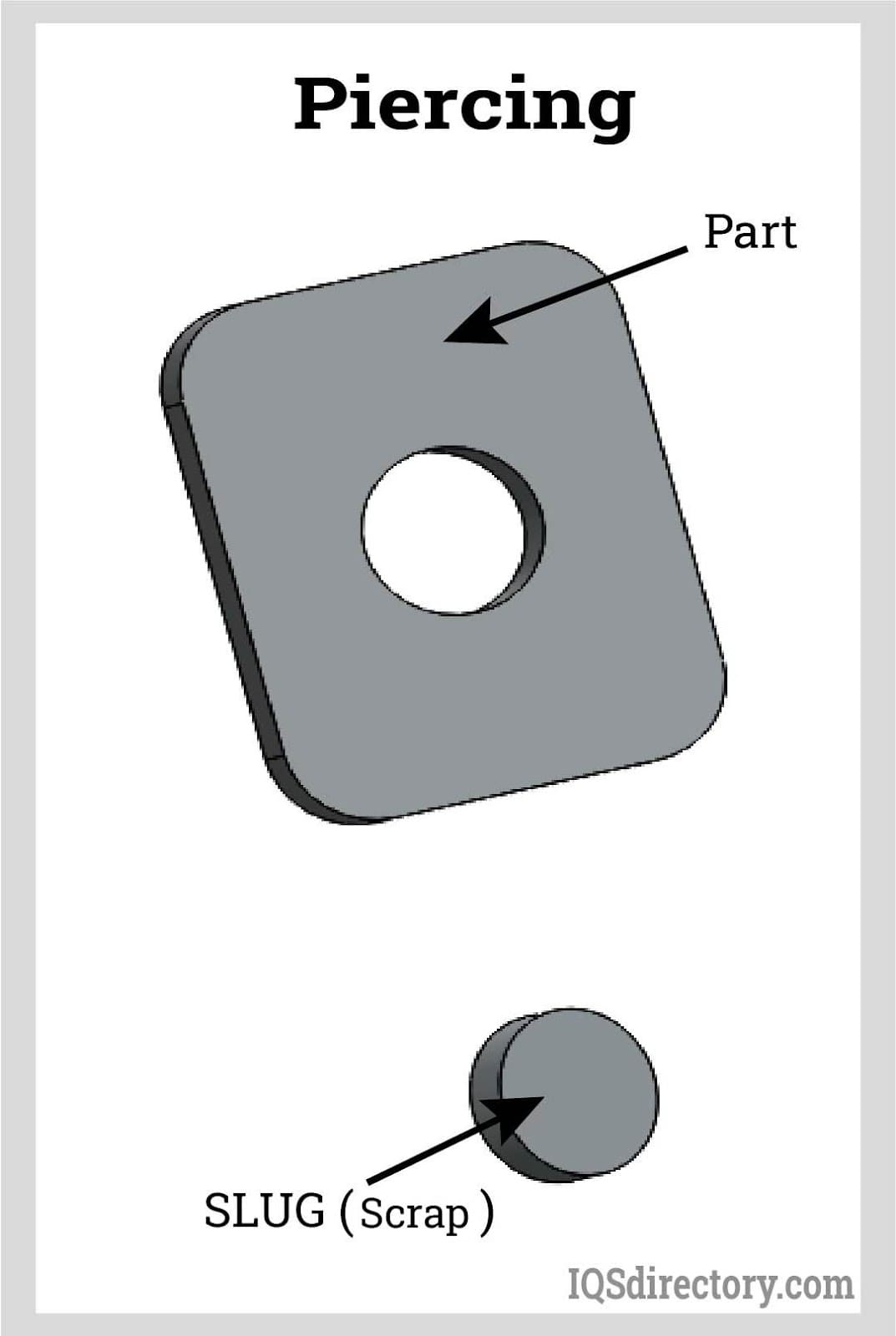

- Piercing

- The perforation of the product or sheet. The piercings can be of different shapes i.e., circle, square, or even some special shapes as desired. The difference between blanking is shown in the figure above.

- Lancing

- The metal is carved to make webs or delicate patterns.

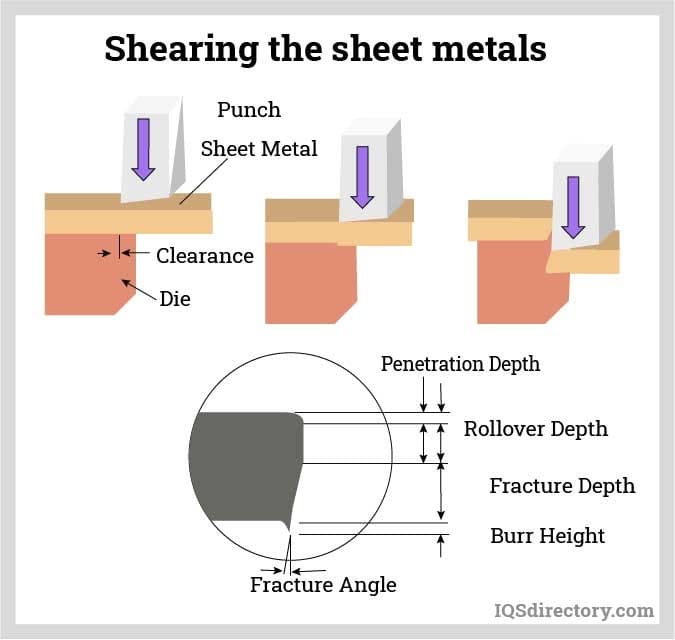

- Shearing

- Cutting of metal in straight lines to create differently shaped blocks is known as shearing.

-

Types of Die Stamping

There are different types of die Stamping based on the production method and output flow. One can decide which one to use depending on what results are to be expected from each type.

- Simple or Line Die Stamping

- The simplest of all production methods. Line die stamping operates once per each press slide stroke. It can perform blanking and piercing and is often used by small scale manufacturers.

- Compound Die Stamping

- A more cost-effective alternative to simple die stamping. It can handle more than one operation per cycle. Compound die stamping can do piercing and blanking simultaneously rather than one by one.

- Progressive Die Stamping

- Has multiple work surfaces which are used by the press in stages to produce end piece parts. It is rather efficient and smooth for complex and large-scale production units. It is widely used in the automotive and electronic industries.

- Transfer Die Stamping

- Unique line dies that are timed together and appropriately positioned an even distance apart. The piece parts are transferred using special moving rails positioned within the press. One of the many benefits includes the rapid processing of large volumes simultaneously.

Applications of Die stamping in the Industry

Die stamping has its major use in the automobile industry. Almost every part of an automobile can be and is manufactured with the help of this tool. Figure 1 shows some of the parts, including the parts as big as the automobile body sides.

The second largest application is in the medical industry. Delicate and precise medico-electronic to surgical instruments can be carved out with the help of Die stamping.

Moreover, household electronics like dishwashers and equipment used in the construction industry also utilize die stamping.

Reasons to Invest in Die Stamping

- Die stamping incurs lower costs compared to other processes because of lower die and secondary costs.

- It has a variety of operational and forming methods to choose from.

- The hard tooling allows the user to produce the same designs repeatedly without degradation.

- It can serve small as well as large scale manufacturers with the appropriate type of die tamping.

- The production variety of die stamping has cross industrial applications.

- Different types of die stamping offer either manual or automated processes depending on one’s resources and requirements.

- It produces quick and precise end products.