Dumpers

What is a Dumper?

A dumper is a type of machine designed to tilt or open at the rear to unload its contents. This article will explore different types of dumpers and their applications in various industries.

How Dumpers are Used

Material handling containers are typically moved or emptied using dumpers, tilters, or inverters. Dumpers and tilters work by tilting containers (such as boxes, drums, and bins) to empty their contents, while inverters (also known as upenders) rotate the container 180 degrees to reposition its contents. These machines are commonly used in industries such as trash management, recycling, food processing, trucking, transportation, and manufacturing. Designed for maximum flexibility, dumpers, tilters, and inverters enhance product handling and efficiency, reduce costs and time associated with storage, retrieval, and positioning, and minimize product damage and workplace hazards.

Types of Dumpers

Material handling containers are typically moved or emptied using dumpers, tilters, or inverters. Dumpers and tilters work by tilting containers (such as boxes, drums, and bins) to empty their contents, while inverters (also known as upenders) rotate the container 180 degrees to reposition its contents. These machines are commonly used in industries such as trash management, recycling, food processing, trucking, transportation, and manufacturing. Designed for maximum flexibility, dumpers, tilters, and inverters enhance product handling and efficiency, reduce costs and time associated with storage, retrieval, and positioning, and minimize product damage and workplace hazards.

Benefits of Using Dumpers and Dump Hoppers

Efficient management of raw materials directly influences the output of finished goods. The cost of production is affected by how frequently workers handle products, which increases the risk of human error and safety hazards. By utilizing a dump hopper, less time is spent adjusting the hopper and handling materials. This results in workers completing tasks more quickly and safely. Moreover, the simplicity of using these hoppers reduces training costs and can enhance worker satisfaction.

Maintaining a clean, organized production area with dump hoppers in every commercial or industrial setting boosts productivity. Employees can work in a safer, more comfortable environment, free from congestion, whether the area is visible to the public or not. When not in use, empty dump hoppers can be conveniently stacked for storage.

The benefits of providing workers with the proper forklift dump hopper or dumpster for safety cannot be overstated. Dumping hoppers help protect operators from accidents and exposure to debris or hazardous materials. Supplying workers with dumping hoppers not only promotes safety but also supports the organization by saving time, reducing costs, and lowering employee turnover.

Dumper Images, Diagrams and Visual Concepts

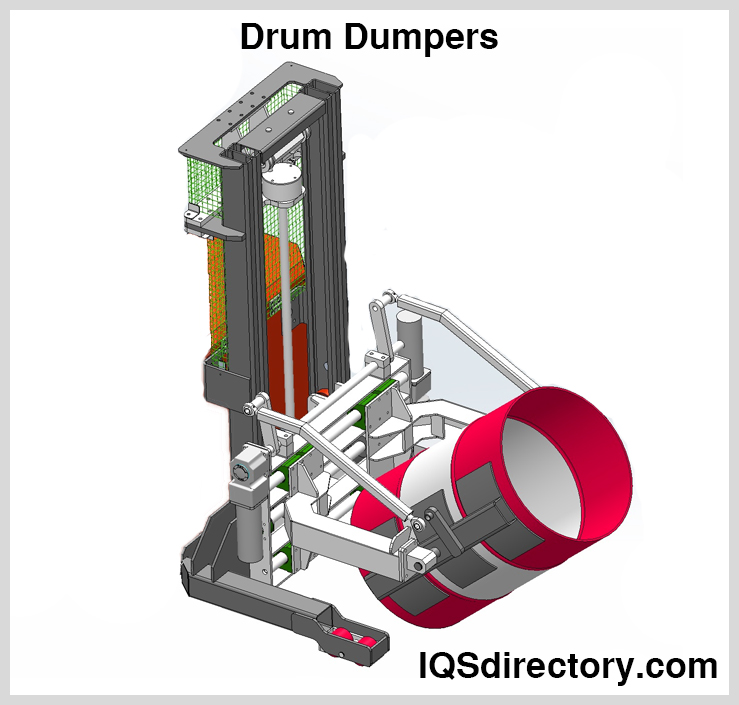

Drum dumpers are made to help with the ergonomic handling of various industrial pails and drums.

Drum dumpers are made to help with the ergonomic handling of various industrial pails and drums.

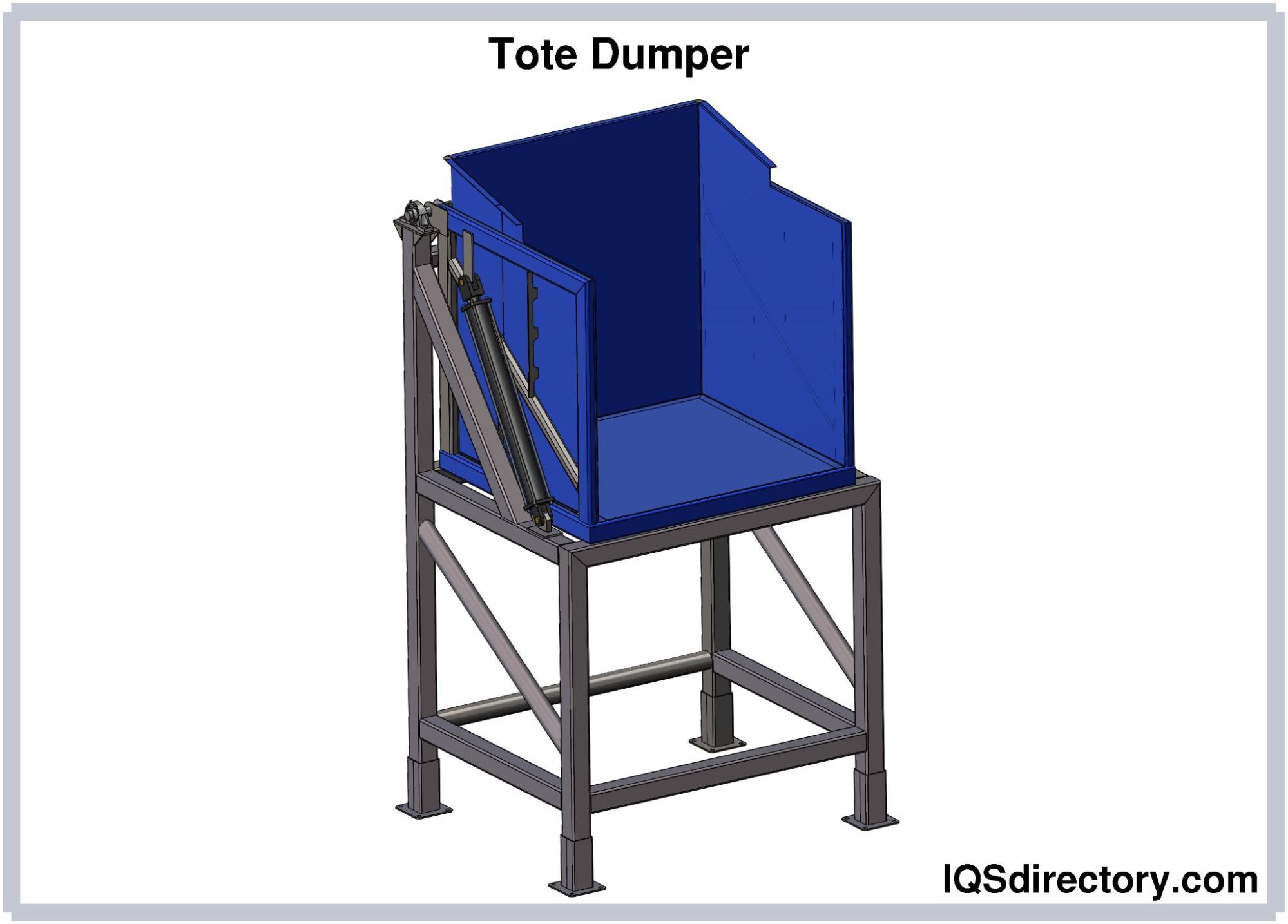

A tote dumper is a device that lifts and tips huge containers to safely and precisely empty bulk goods.

A tote dumper is a device that lifts and tips huge containers to safely and precisely empty bulk goods.

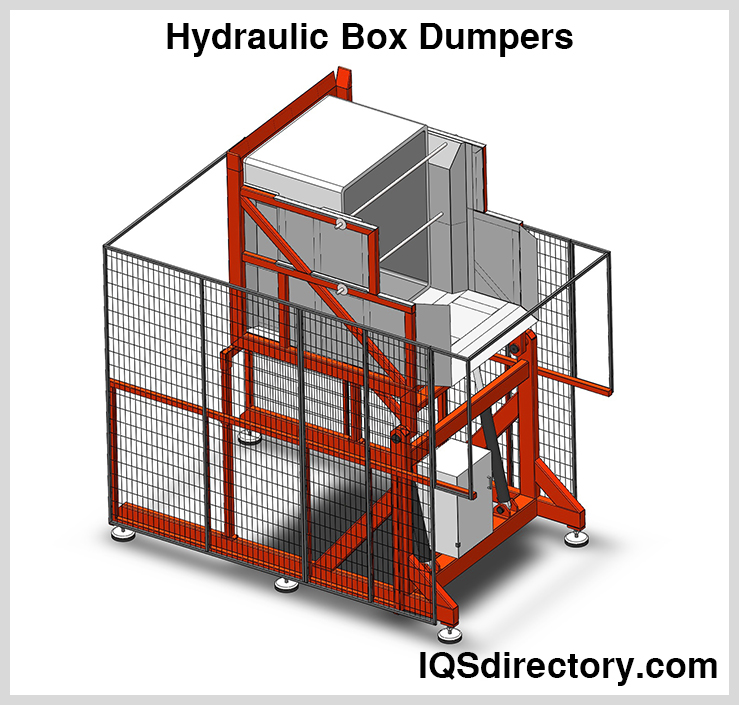

Hydraulic box dumpers will lift and empty Gaylord boxes to improve productivity and lessen operator fatigue.

Hydraulic box dumpers will lift and empty Gaylord boxes to improve productivity and lessen operator fatigue.

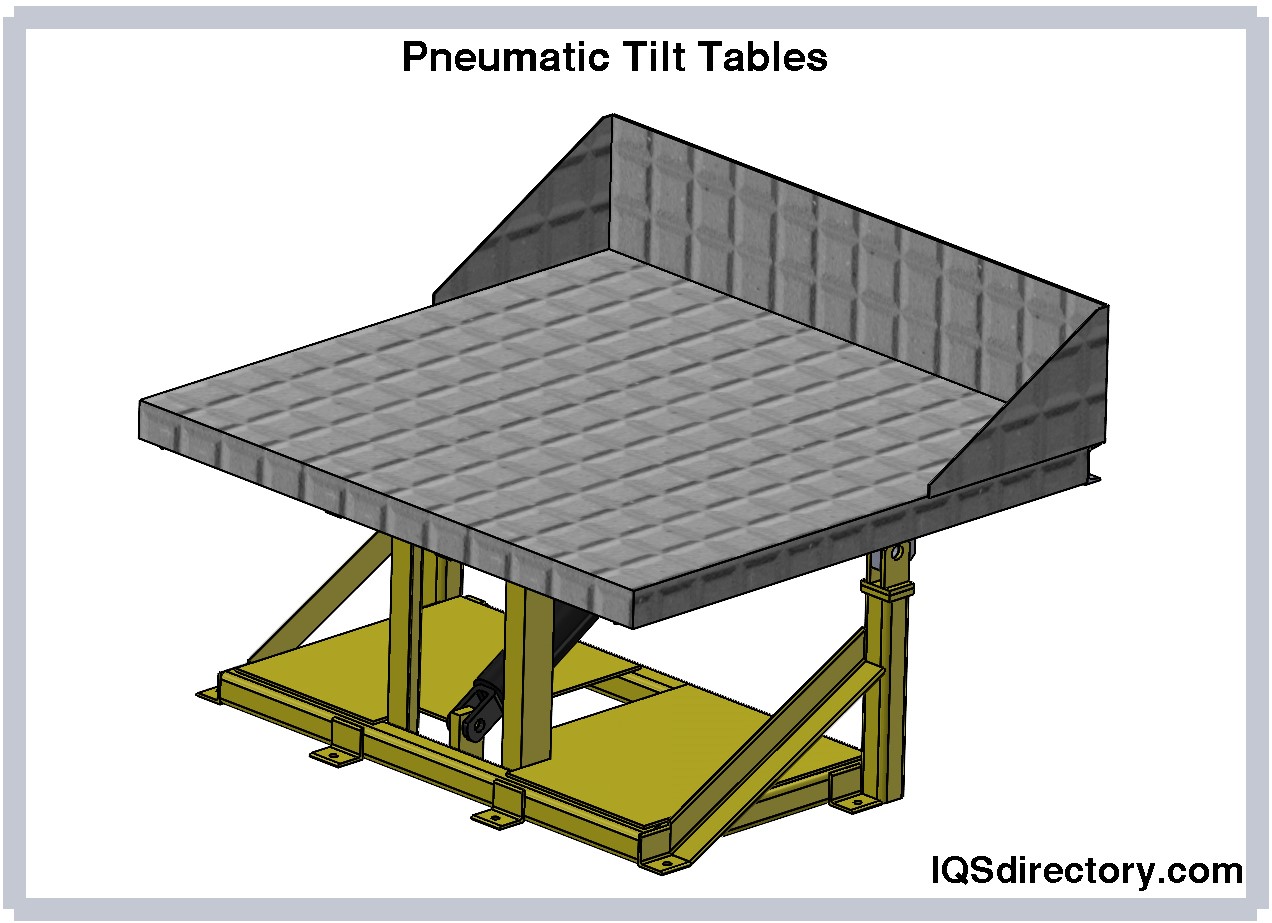

These let users adjust the tilt angle with factory air to a convenient height or position.

These let users adjust the tilt angle with factory air to a convenient height or position.

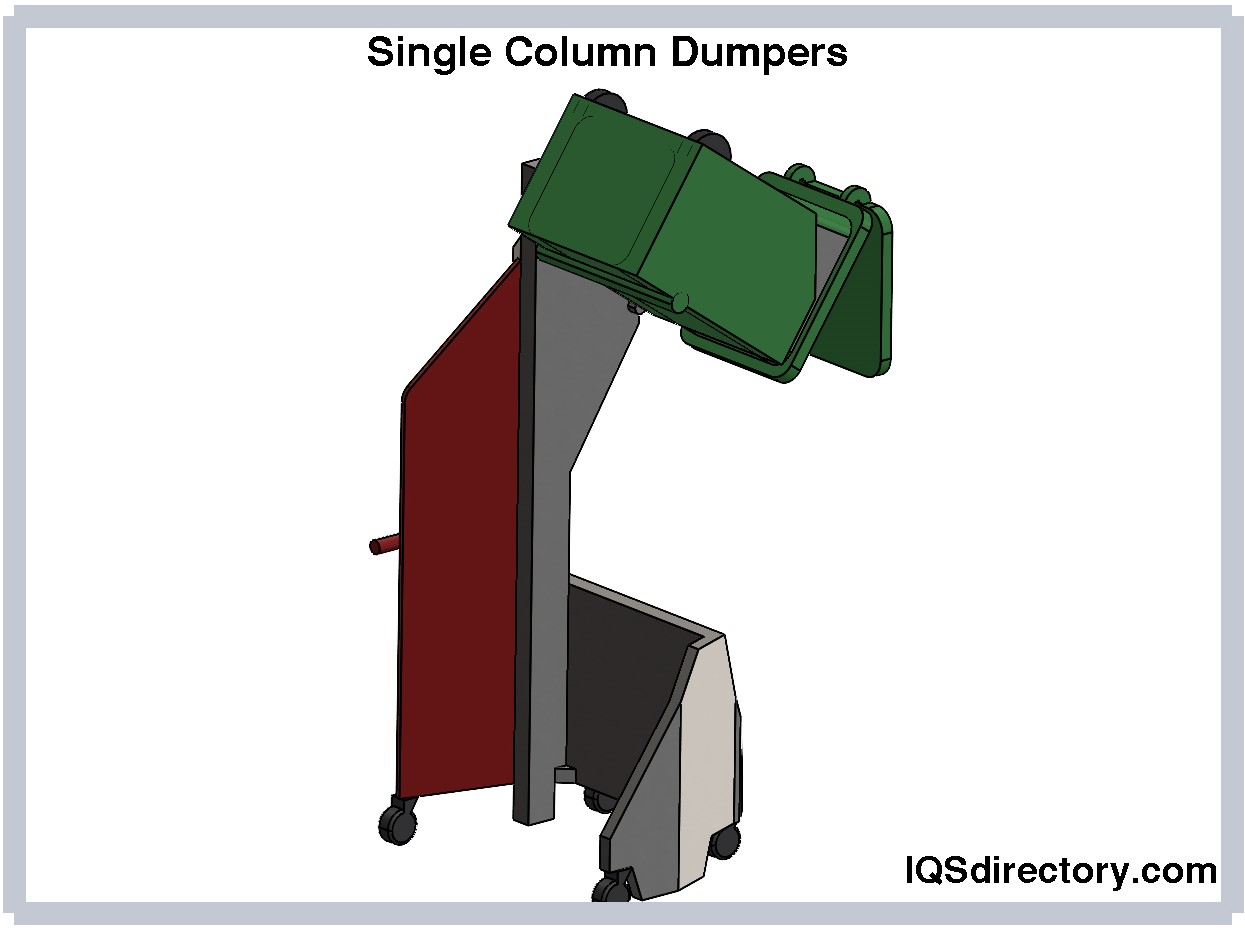

A single column dumper is the best choice when carrying light loads of heavy goods.

A single column dumper is the best choice when carrying light loads of heavy goods.

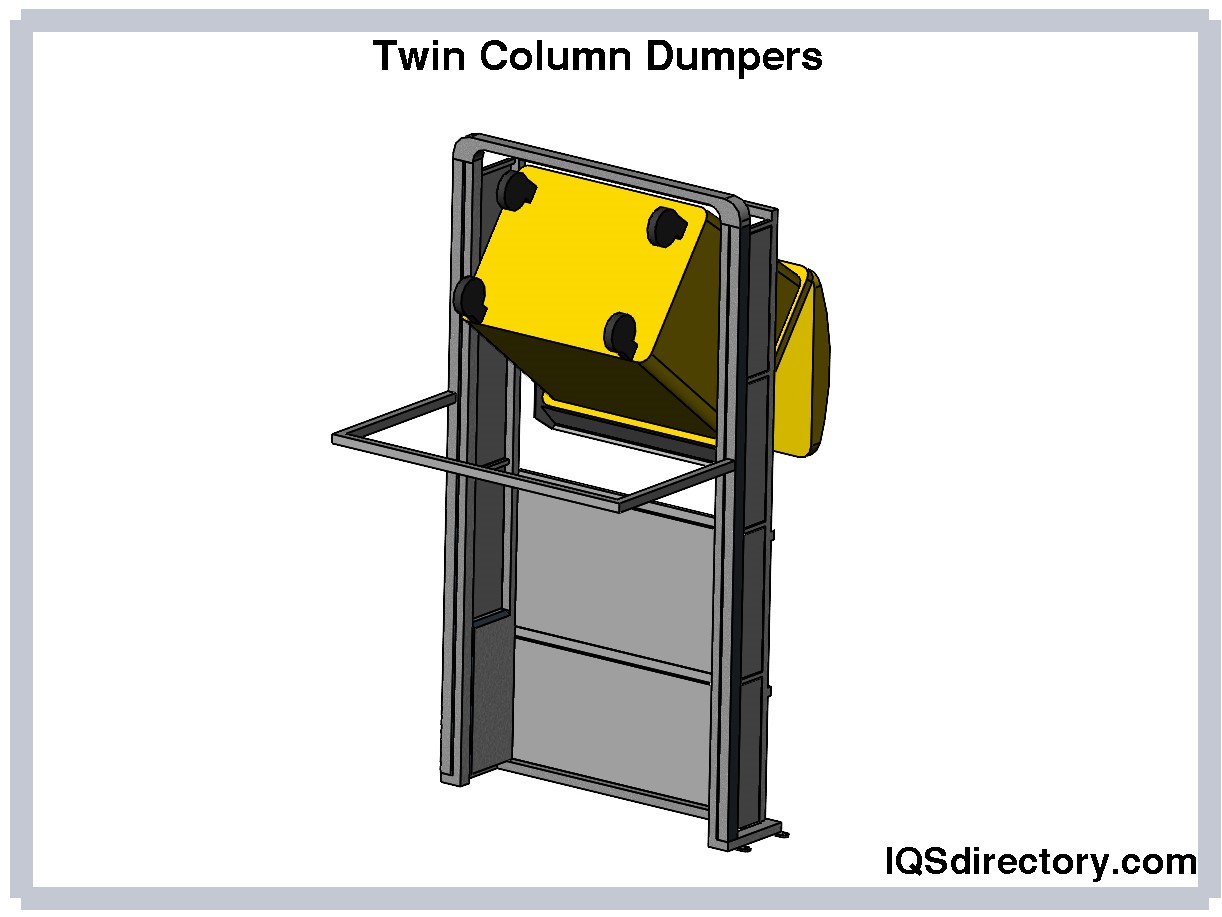

A twin-column dumper is a fantastic alternative for industrial facilities that dump loads of heavy, thick goods throughout the day.

A twin-column dumper is a fantastic alternative for industrial facilities that dump loads of heavy, thick goods throughout the day.