Electric Motors

An electric motor is a device that transforms electrical energy into mechanical energy. It receives electrical power from a battery or the power grid and produces mechanical energy in the form of a rotating shaft.

Once a mere scientific novelty, electric motors are now found in nearly every aspect of modern life, from power tools and elevators to toothbrushes and even toys. Even in gasoline-powered vehicles, electric motors operate windows, ventilation fans, and windshield wipers.

Electric motors are essential to modern civilization. Without them, much of daily life and industry would come to a halt. Looking ahead, electric vehicles will dominate our roads, and factories will rely on robots powered by electric motors. Understanding electric motors is crucial for their correct application.

While all electric motors share the basic function of converting electrical energy into mechanical energy, the methods they use for this conversion can vary significantly. There are four main types of electric motors based on how they convert energy: servo motors, synchronous motors, induction motors, and electrostatic motors, also known as capacitor motors.

Electric Motors FAQ

What is the basic function of an electric motor?

An electric motor converts electrical energy into mechanical energy, producing motion through a rotating shaft. This process relies on the interaction between electric current and magnetic fields to create force and rotation.

Who invented the first electric motor?

The first electric motor with stator and rotor components was built in 1827 by Ányos Jedlik. Earlier demonstrations were made by Michael Faraday in 1821 and Peter Barlow in 1822. Thomas Davenport later patented the first commercial motor in 1837.

What is the difference between AC and DC motors?

AC motors use alternating current and can operate in single or three-phase forms, while DC motors rely on direct current and allow adjustable speed and torque. Phase converters can adapt one power source to run the other type of motor.

What are brushed and brushless motors?

Brushed motors use mechanical brushes and commutators to deliver current to the rotor, making them cost-effective but less efficient. Brushless motors use electronic controllers and sensors for commutation, offering greater efficiency and reliability.

Why are bearings important in electric motors?

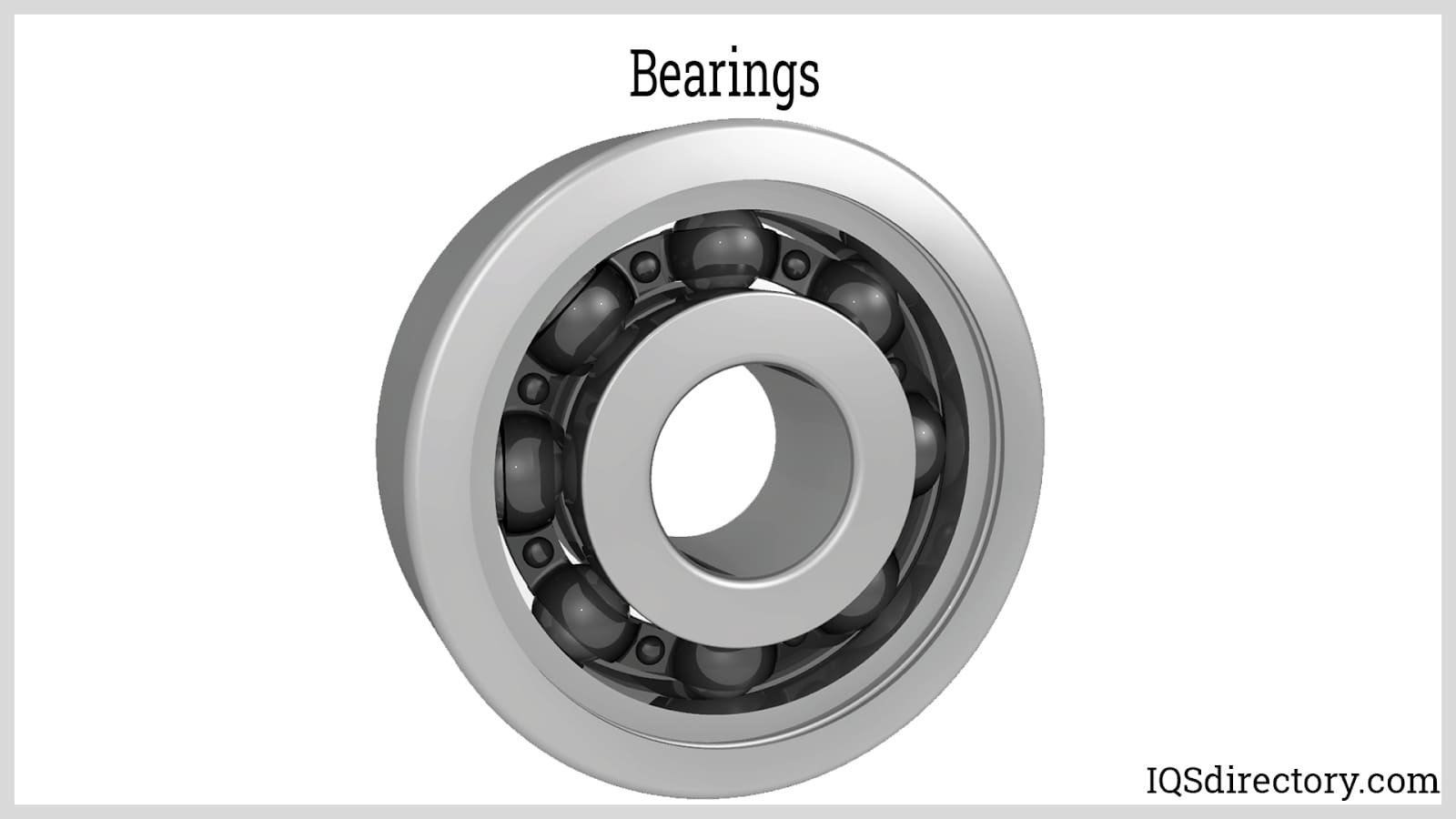

Bearings support the rotor and allow it to spin smoothly on its axis. Faulty or worn bearings can cause unusual noises, vibration, and motor failure, making them critical for long-term reliability and safe operation.

What factors should be considered when selecting an electric motor?

Key factors include power supply compatibility, horsepower, torque, RPM, voltage, current ratings, and environment. Oversized motors waste energy, while undersized motors underperform. Proper installation and protection against vibration, dust, and heat are also essential.

What are common causes of electric motor failure?

Failures may result from damaged coils, worn commutator brushes in DC motors, faulty bearings, or electrical issues like power surges. Proper inspections, maintenance, and protective housing can help extend motor lifespan and prevent breakdowns.

The History of Electric Motors

In 1821, Michael Faraday demonstrated the use of electrical power from a battery to make a wire rotate around a magnet in a pool of mercury. A similar experiment was carried out in 1822 by Peter Barlow, who used a star-shaped wheel known as the Barlow Wheel, dipping its tips into mercury as it turned.

In 1827, Hungarian scientist and priest Ányos Jedlik created what he called an "electromagnetic self-rotor," the first electric motor with components of a stator and rotor, much like the motors we recognize today.

In 1837, Thomas Davenport was granted the first patent for an electric motor intended for commercial use. While Davenport's design was ahead of its time, it wasn't until long after his patent expired that reliable batteries and electrical grids were developed to power his motor economically.

By the late 19th century, with efficient electric power sources now available, electric motors played a pivotal role in the industrial revolution. These early inventors laid the groundwork for a wave of subsequent innovators, all working to refine and enhance the efficiency and performance of electric motors.

Principles of Electricity

To effectively use electric motors, it is essential to grasp the fundamental principles of electricity.

Electricity involves the movement of electrons from one atom to another within a conducting medium, such as a wire. Early scientists thought of electricity as a "fluid" that behaved like liquid flowing through pipes. This analogy remains useful for modern technicians, electricians, and engineers.

In this analogy, electrical charge represents the quantity of electrical "fluid," voltage indicates electrical pressure, and current measures the electrical flow rate. Since like charges repel each other, electric current flows from areas of positive charge to areas of negative charge.

In 1820, Hans Christian Ørsted discovered that an electric current creates a magnetic field. Building on this, André-Marie Ampère formulated Ampere's Law, which states that when two wires are placed in parallel and an electrical current flows through one, a current is induced in the other.

To help remember this concept, John Ambrose Fleming created the left-hand rule: using the left hand, point the thumb upward to show the direction of motion for the motor, the forefinger forward to show the direction of current, and the middle finger sideways to indicate the direction of the magnetic field.

This interaction between electricity and magnetism allows an electric current to physically move a magnet, and vice versa.

Electric Motor Design

From the early experimental motors, which were essentially magnets spinning inside wire loops, a multitude of innovations and variations has emerged. One of the most significant distinctions between types of electric motors is whether they are designed to operate on direct current (DC) or alternating current (AC).

A phase converter can be used to convert AC power into DC power for a DC motor, enabling it to run indirectly using an AC power source. Similarly, there are phase converters that change DC power into AC power, allowing AC motors to operate.

Motors also differ in their size, the number of stator and rotor magnetic poles, rotational speed, and voltage and current ratings. Motors with a mechanical power output of less than one horsepower (746 watts) are referred to as fractional horsepower motors (FHP motors). Additionally, motors with adjustable RPM rates are classified as variable speed motors.

Electrostatic motors stand apart from other types, operating on the principle of attraction and repulsion between electric charges. These motors are typically used in small-scale applications like micro-mechanical systems (MEMS).

This overview is by no means exhaustive but aims to highlight the wide variety of electric motors available from manufacturers.

Electric Motors Images, Diagrams and Visual Concepts

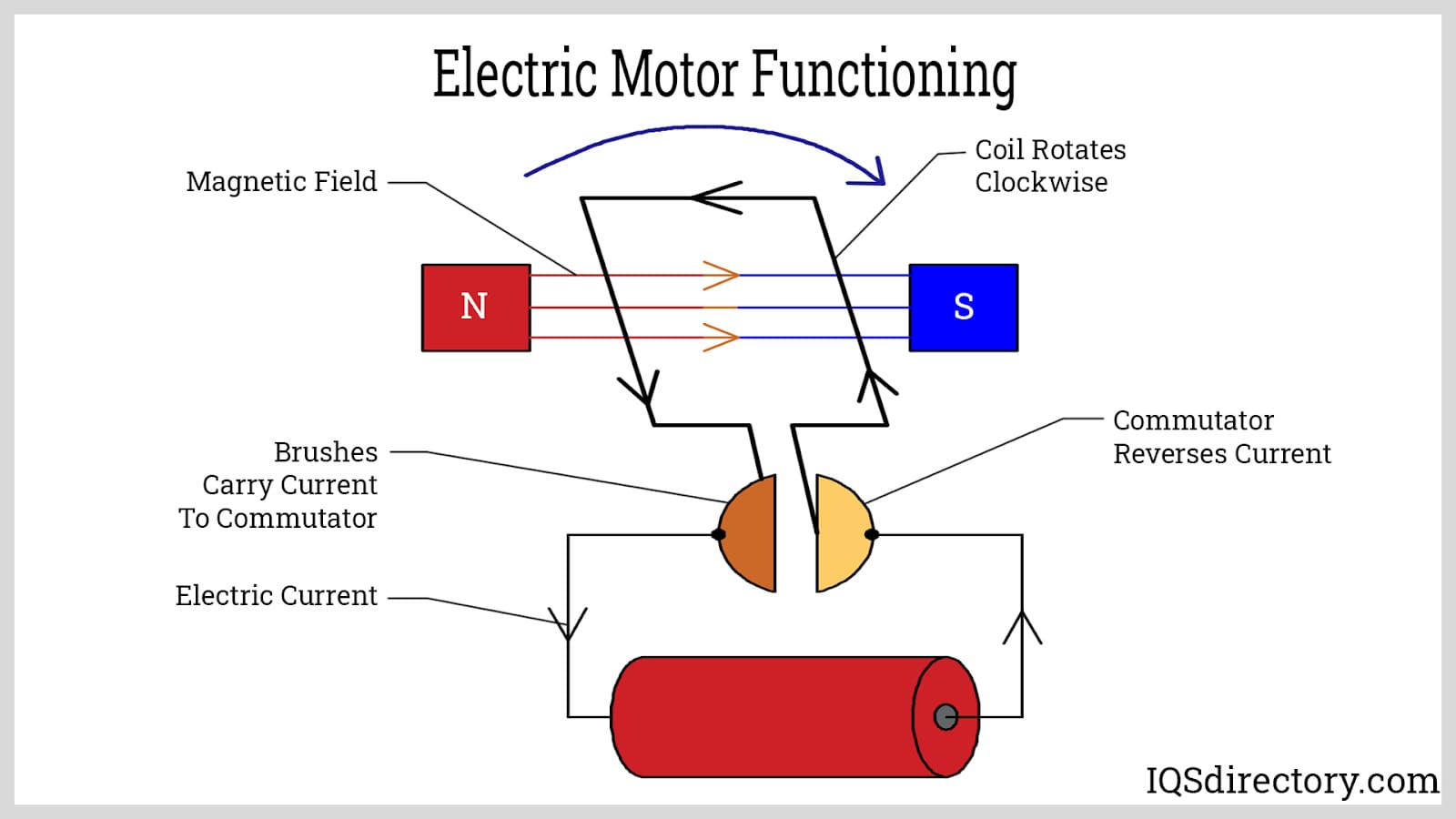

Electric motors function by changing electrical power to mechanical power.

Electric motors function by changing electrical power to mechanical power.

The conversion of electrical power to mechanical power creates force within the motor from the interaction between the electric current and the magnetic field.

The conversion of electrical power to mechanical power creates force within the motor from the interaction between the electric current and the magnetic field.

Bearings supports the rotor and allow the rotor to spin on its axis.

Bearings supports the rotor and allow the rotor to spin on its axis.

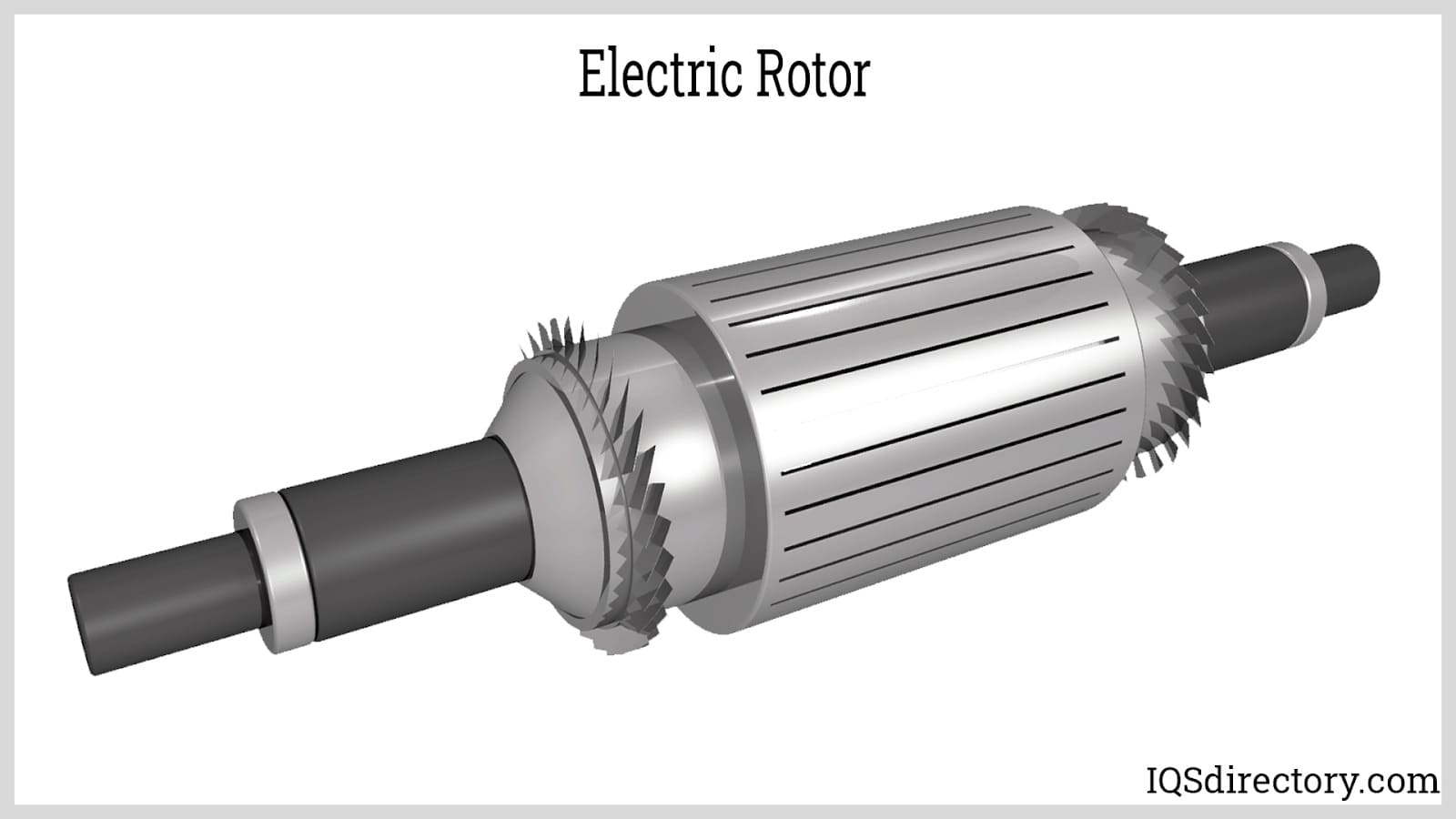

The rotor is the mobile part which supplies the mechanical power and generally holds the conductors that carries current and stator magnetic field which applies force to spin the shaft.

The rotor is the mobile part which supplies the mechanical power and generally holds the conductors that carries current and stator magnetic field which applies force to spin the shaft.

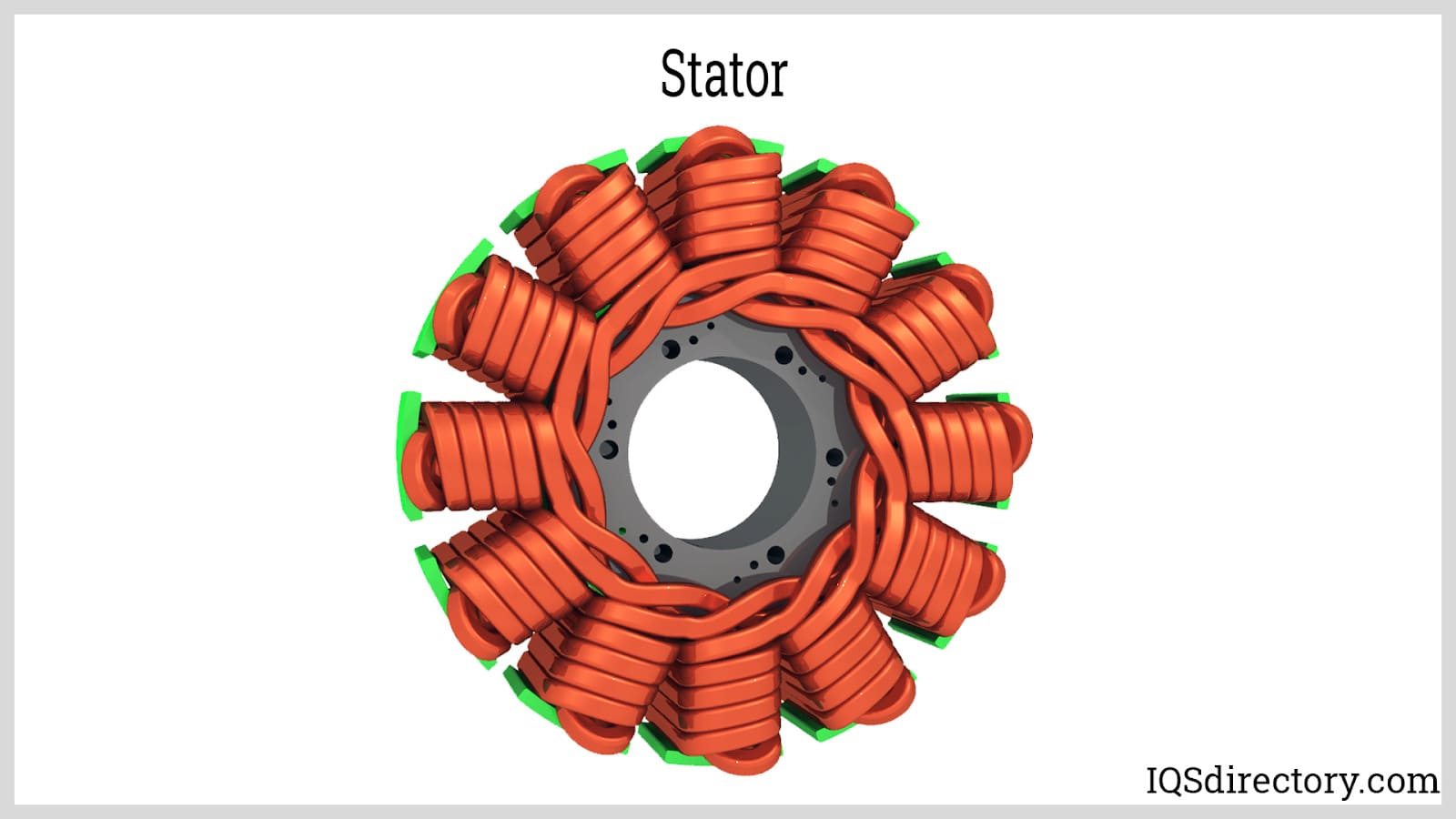

A stator surrounds the rotor, and generally holds the field magnets which produces the magnetic field when passing through the rotor winding.

A stator surrounds the rotor, and generally holds the field magnets which produces the magnetic field when passing through the rotor winding.

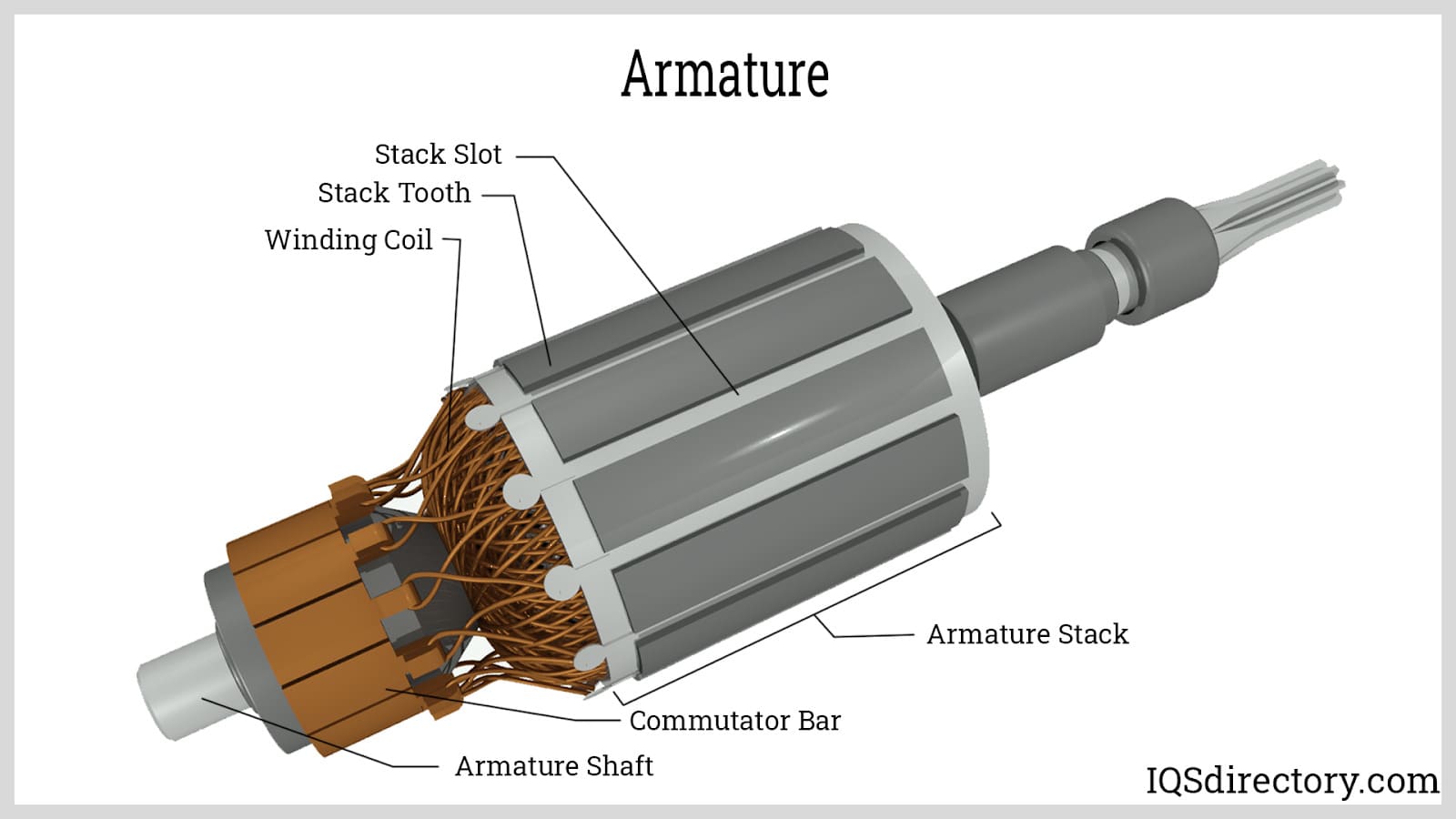

The armature has the electrical current passes through which generates torque.

The armature has the electrical current passes through which generates torque.

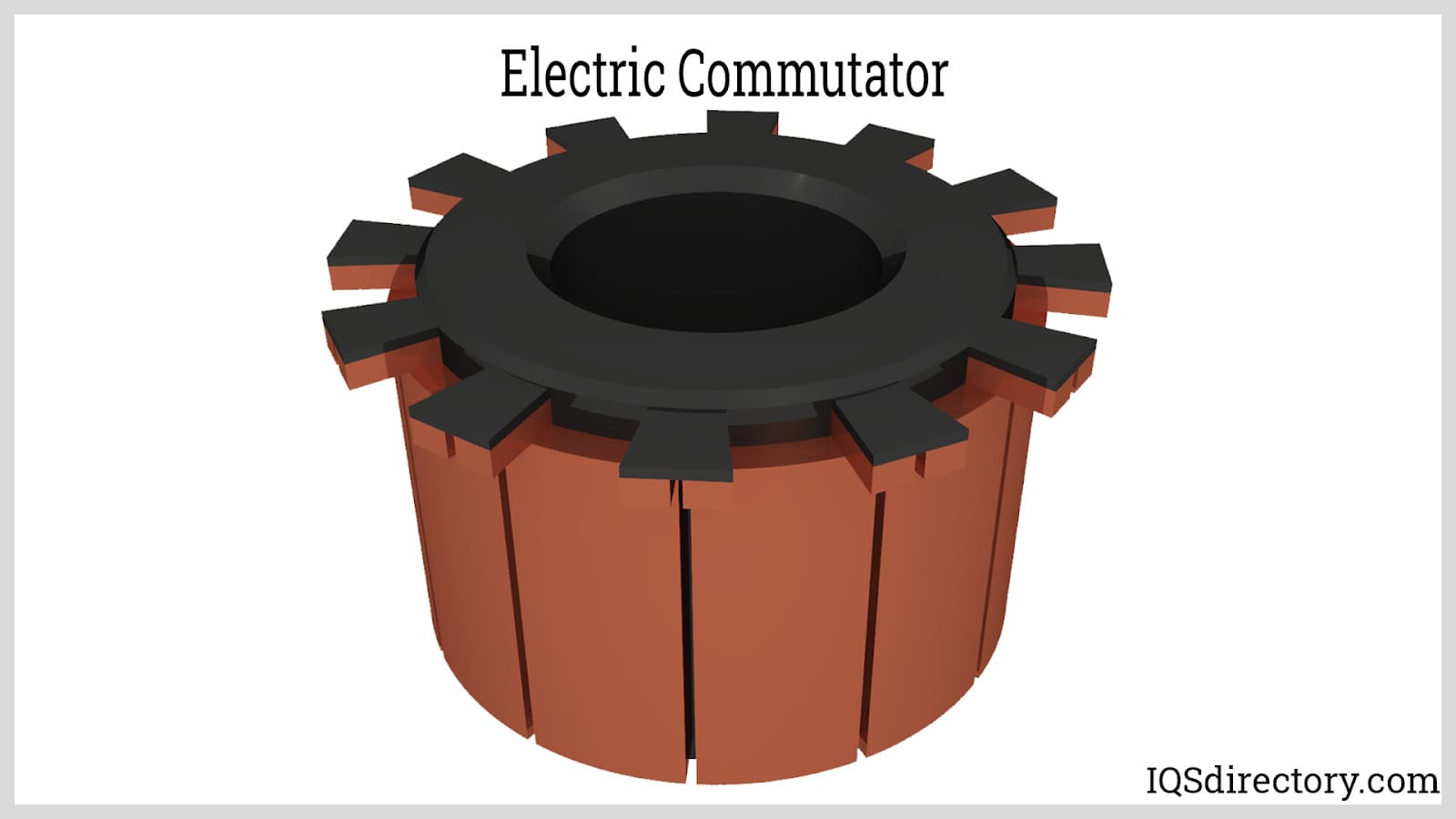

A commutator, a rotary electric switch which supplies alternating current or direct current to the rotor.

A commutator, a rotary electric switch which supplies alternating current or direct current to the rotor.

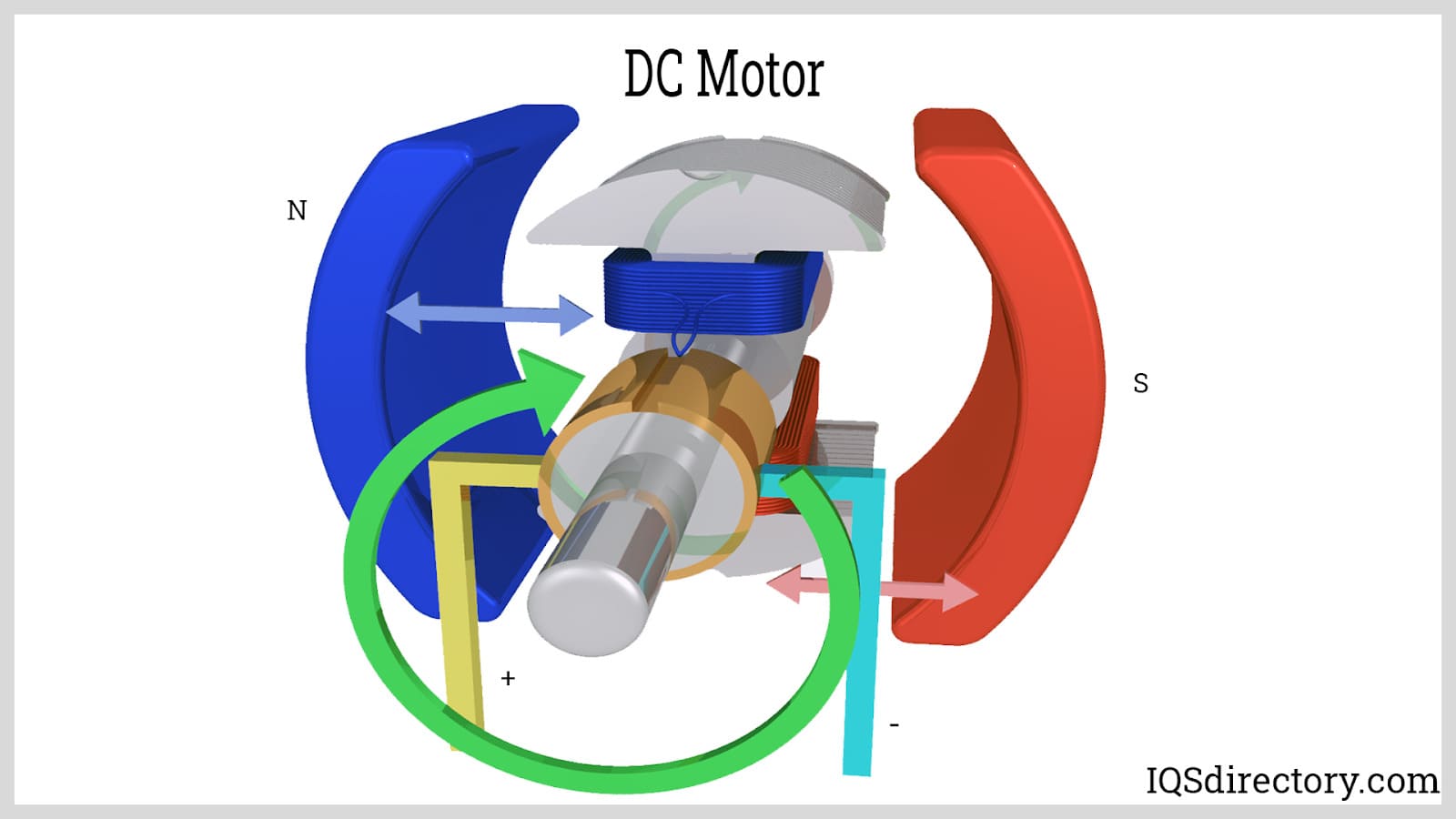

DC motor is a type of rotary electrical motor which converts electrical energy from direct current into mechanical energy.

DC motor is a type of rotary electrical motor which converts electrical energy from direct current into mechanical energy.

An AC motor is an electric motor that consists of a stator with a coil that is supplied with a current to convert an alternating current into mechanical power.

An AC motor is an electric motor that consists of a stator with a coil that is supplied with a current to convert an alternating current into mechanical power.

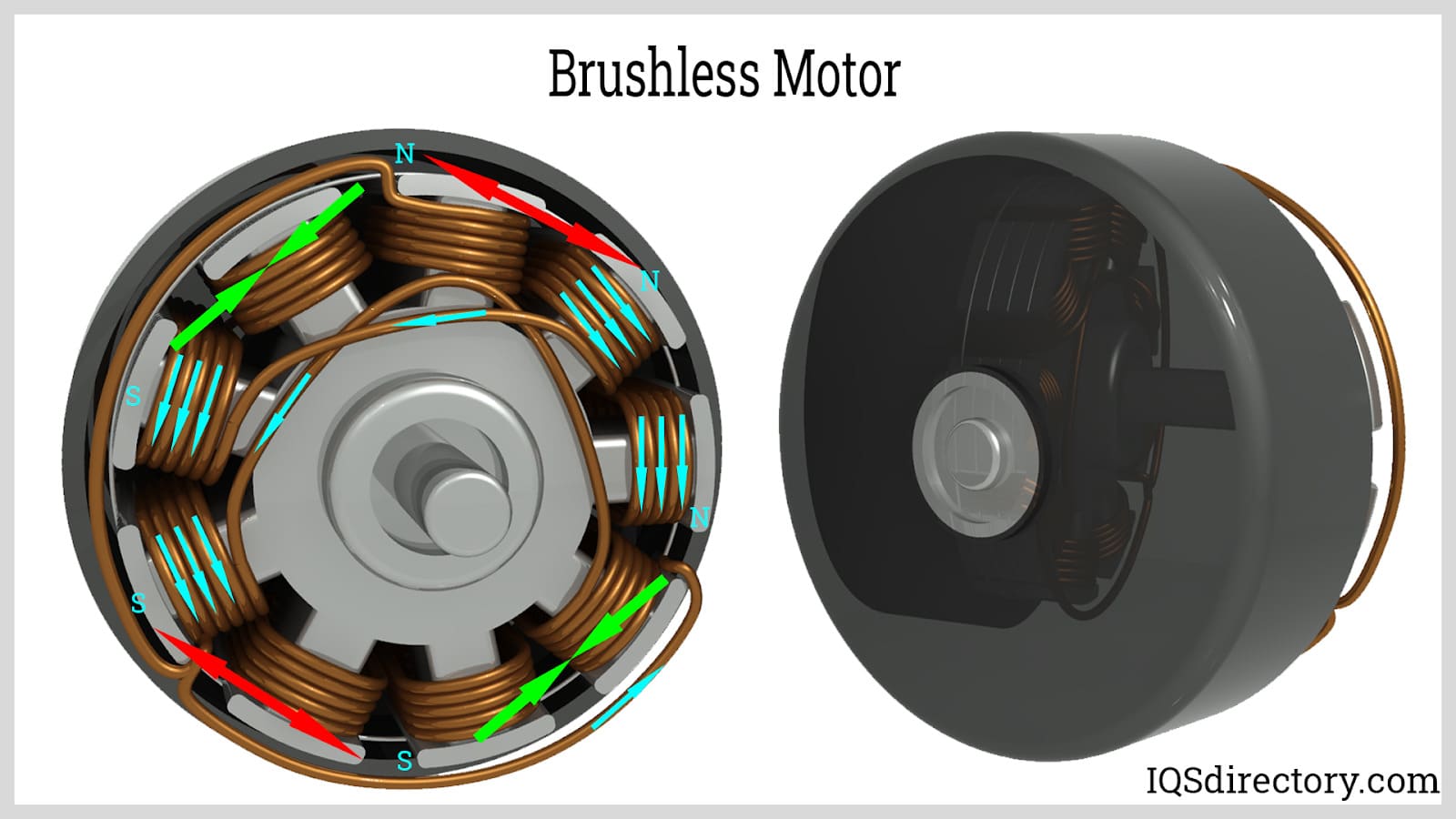

A brushless motor, a type of DC motor utilizing an electronic controller to turn DC currents to the windings creating a magnetic field.

A brushless motor, a type of DC motor utilizing an electronic controller to turn DC currents to the windings creating a magnetic field.

Electric Motors Types

-

12V Motors

These electric motors operate on 12 volts, a unit of electrical energy, converting it into mechanical energy used to power various machinery or equipment.

3 Phase Motors

A type of electric motor powered by a three-phase electrical load, commonly used in electric power transmission systems.

AC Motors

Alternating current (AC) motors generate their magnetic field through an electromagnet powered by the same AC voltage as the motor coil. They can operate in either single-phase or three-phase forms, allowing current cycles to change direction. AC motors come in four basic types: single-phase induction motor, three-phase induction motor, single-phase synchronous motor, and three-phase synchronous motor. DC motors, on the other hand, are always single-phase.

Brushed Motors

These motors use mechanical brushes to commutate coils on the rotor as it rotates. Brushed motors are generally more cost-effective compared to brushless motors.

Brushless Motors

These motors allow for commutation of the stator coils using an external power drive, eliminating the need for brushes.

DC Motors

Direct current (DC) motors are known for their adjustable speed and torque capabilities. They include a rotor and a stator with a permanent magnetic field, offering variable performance.

Electrical Motors

Motors that convert electrical energy into mechanical motion through the use of magnetism. Unlike engines, which rely on fuel, electrical motors use electricity to produce motion.

Gear Motors

These motors combine a gear head with the motor to reduce the speed of the motor, achieving the desired RPM.

Induction Motors

Induction motors generate rotation in the coils by inducing current through changing magnetic fields rather than directly delivering rotation. The torque is produced in loops by the changing magnetic field in the field coils.

Linear Motors

These motors produce motion solely along a single linear axis, where the converted mechanical energy moves the equipment or machinery.

Permanent Magnet Motors

These motors have magnets embedded in the rotor assembly, which align with the rotating magnetic field of the stator.

Servo Motors

Servo motors feature shafts that move to specific angular locations, not freely rotating. They are used in motion control applications such as robotics, hard disk drives, and more. Servo motors, equipped with built-in microcontrollers, allow precise angular adjustments on command. Stepper motors, used in robotics and 3D printers, are even more precise but more complicated and expensive to control.

Single Phase Motors

These motors operate on single-phase electrical power, where all voltage supplies are synchronized as one unit, distributing alternating current (AC) power.

Stepper Motors

Stepper motors operate without commutators. All commutation is handled externally by the motor controller, allowing the motor to be stepped at audio frequencies for fast, precise starting and stopping at controlled orientations.

Synchronous Motors

Synchronous motors operate at a constant speed even under full load. They use three windings in the stator section with a rotating area, ensuring no slip. Nikola Tesla is credited with creating the first AC motor in 1887. Synchronous motors, a type of AC motor, use a rotating magnetic field produced by the rotor and current passing at the same rate. In contrast, induction motors (also a type of AC motor) are asynchronous and function based on electromagnetic induction, where a voltage is induced across the rotor as it moves through the magnetic field. Induction motors tend to be less expensive, while synchronous motors offer constant speed with variable torque.

Electric Motor Operation

The basic operation of an electric motor can be understood by visualizing a simple design consisting of just a rotor and a stator. As the names suggest, the rotor rotates while the stator remains stationary.

The rotor is a rod that spins around its long axis, with an arm extending from the rod. At the tip of this arm is a permanent magnet. The stator is a rod placed parallel to the rotor, positioned outside the rotor's swing radius.

The stator rod is wrapped with wire, and when electric power is applied, current flows through the wire, generating a magnetic field around the stator. This magnetic field transforms the stator into an electromagnet. The electromagnetic field then attracts the permanent magnet on the rotor, causing it to move.

A switching system, which includes wire brushes on the stator and metal strips on the rotor, completes the circuit. This system alternately energizes and de-energizes the electromagnet, depending on whether the rotor magnet needs to be attracted.

To produce mechanical power, a shaft is attached to the rotor. As the rotor spins, the shaft rotates as well, powering attached components such as wheels, drills, pumps, or fan blades.

While this basic design is inefficient and flawed (for example, the rotor would be better balanced with two arms instead of one), it demonstrates the core principle of electric motors: converting electrical energy into magnetism and then into mechanical power. In most motors, a more advanced system using a commutator with brush-and-contact systems cyclically switches the magnetic poles to improve efficiency, ensuring the rotor magnet is attracted when it moves toward the stator and repelled when it moves away.

When categorizing electric motors by construction, they generally fall into two main categories: brushed motors and brushless motors. Brushed motors are typically a type of DC motor, utilizing a wound rotor (armature), a commutator, and a permanent or wound magnet stator. The motor is named after its commutator, which is fitted with numerous brushes. These brushes allow the current to flow through them and reach the rotor. There are five primary types of brushed motors: DC shunt-wound motors, DC series-wound motors, DC compound motors, permanent magnet DC motors, and separately excited motors.

Brushless motors, which often fall into the DC motor category, eliminate many of the complications of brushed motors. Instead of brushes, brushless motors use sensors (typically Hall effect sensors) to transfer the current to the rotor. These motors feature a permanent magnet external rotor, a three-phase coil, sensors, and drive electronics, making them more efficient and reliable than their brushed counterparts.

Things to Consider When Purchasing Electric Motors

Proper installation of large motors is crucial for ensuring the safety of the motor, the workplace, and personnel.

For safety, the motor should be placed in a location where its rotating shaft cannot catch workers' clothing and where its power cords will not pose a tripping hazard. Noise from motors can also contribute to hearing loss, which can be mitigated by using padded housings or requiring workers to wear hearing protection.

If the motor is not mounted securely, excessive vibration may occur, leading to internal damage that could go unnoticed until the motor breaks down. Motors should be shielded from water, dust, vibration, impact, and extreme temperatures unless they are specifically designed to withstand such conditions. Additionally, if the motor has ventilation slits on its casing, these should not be obstructed or placed against a wall to prevent overheating.

Electric motors can generate electromagnetic interference that may disrupt electronic communication systems. The magnets within a motor may also cause disturbances to nearby electronics.

Typically, a motor should simply be connected to the appropriate power source and can operate with minimal maintenance for years. However, some motors are equipped with internal fuses to protect against power surges, while others require external circuit protection. Motors in heavy-duty industrial settings often need scheduled inspections and maintenance by certified professionals, while smaller motors, such as those in household appliances, require little to no maintenance.

One of the first considerations when selecting a motor is whether it can operate with the available power supply. AC motors require AC power or a power converter, while DC motors require DC power or a power converter.

Electric motors are primarily classified by their RPM (rotations per minute), power output (in watts or horsepower), and voltage/current ratings.

Some motors operate at a fixed speed, while others have variable speeds. Gearboxes can adjust the motor's shaft speed, either increasing or decreasing it. In general, for a given motor, slower speeds result in greater torque.

Motor power output is an important economic factor. Too much power could lead to wasted energy, while too little power will prevent the motor from functioning effectively.

If the voltage or current is too low, the motor will fail to operate. Too much voltage or current could damage the motor.

NEMA (National Electrical Manufacturers Association) provides a standardized chart for motor sizes, which can help in choosing the right motor.

To find a list of industrial motor manufacturers, you can check company listings on IQS Directory.

Repair for Electric Motors

Customer service professionals often advise asking the simple question, "Is it plugged in?" when equipment fails to turn on. While this may seem trivial, it becomes more relevant when dealing with larger motors. In such cases, it’s important to inspect the entire dedicated motor circuit to ensure there are no gaps between the power source and the motor connections. Additionally, checking the fuses and circuit breakers is crucial.

Another common reason a motor may fail to operate is damaged coils. If the insulation on the coils fails, it can cause a short. In this case, the affected coil will need to be replaced.

For DC motors, worn commutator brushes can also lead to operational issues. Replacing the brushes is often an easy and inexpensive fix. Additionally, the permanent magnets can be replaced or upgraded to rare earth magnets to enhance performance.

If a motor produces loud or unusual noises, it is likely a sign of a bearing issue. Bearings can last for years or fail unexpectedly. To prevent further damage to the motor and the surrounding environment, it is best to turn off the motor and have it thoroughly inspected.

Electric Motors Terms

-

1 Horsepower Electric Motor

Typically used to power slow-moving vehicles like tractors and other agricultural equipment, as well as high-power tools and appliances, such as table saws and pool pumps.

2 Horsepower Electric Motor

Electric motors with a power output of two horsepower.

AC (Alternating Current)

Electric current whose direction of flow periodically reverses. Alternating current is commonly available in both single-phase and three-phase forms.

Air Gap

The space between the rotor and the stationary stator in an electric motor.

Amps

The unit of electric current in the meter-kilogram-second system, equivalent to the steady current produced by one volt applied across a resistance of one ohm.

Armature

The rotating part of a motor, particularly in DC or universal motors.

Back End

The end of the motor that holds the coupling or driving pulley, also known as the drive end.

Brush

A material that conducts current from the power supply to the armature windings in a motor.

Commutation

The process of converting direct current to alternating current, which can go in both directions.

Core

The part of the stator and rotor, usually made of iron, constructed from cylindrical laminated electric steel.

Cycles Per Second (Hertz)

The number of complete reversals of the flow of alternating current per unit of time.

Duty Cycle

The relationship between operating and non-operating times, or the repeatable operation at varying loads.

Enclosures

The housing or frame of a motor, categorized into two main types: open and totally closed.

Endshield

The motor housing component that supports the bearing and protects the internal electrical and rotating parts. Also known as an "end bracket" or "end bell."

Fractional Horsepower

A motor typically smaller than those with a continuous rating of one horsepower. The motor’s frame size can categorize it as fractional horsepower.

Front End

The opposite end from the coupling or driving pulley, often referred to as the commutator end.

Gearhead

The part of the gearmotor that contains the gearing, converting the basic motor speed to the rated output speed.

Horsepower

A function of torque and RPM (revolutions per minute), measuring the power output of a motor.

Jackscrew

An adjustable screw on the base or motor frame used to position a motor.

Load

The force or burden placed on a motor by the driven machine, often expressed as the torque needed to overcome the machine's resistance.

Motor

A device that converts electrical energy into mechanical energy to turn a shaft.

Relay

A device that uses changes in one electric circuit to control the operation of other devices, either in the same or another circuit.

Rotor

The rotating component of an induction motor, made of stacked laminations.

RPM

Revolutions per minute, indicating how many times the motor’s shaft rotates in a minute.

Shaft

The rotating part of the motor that extends past the bearings and connects to the driven equipment.

Stator

In an AC induction motor, the stator consists of laminations with a central hole for the rotor and slots for the windings.

Torque

The turning force generated by a motor or gear motor shaft, often described in pounds.

Volts

The potential difference between two points in a conducting wire with a constant current of one ampere.