Electronic Connectors

Electrical connectors are a diverse group of devices, all of which serve the common purpose of completing an electrical circuit. These connectors offer a convenient method for forming circuits that can be easily disassembled when necessary.

The most recognizable connectors are those found at the ends of power cords and in wall outlets. They facilitate the transmission of electric power, typically alternating current (AC), from a power source to a device. Other connectors are used to establish electrical circuits between different pieces of equipment. Connectors are often designed for flexibility, allowing circuits to be created and maintained temporarily, especially in the case of portable appliances. However, they can also provide a more permanent connection, as seen in applications like television cables, where they link wires or machines in a fixed manner.

Applications of Electrical Connectors

The commercial use of electricity is a cornerstone of the modern world, making electrical connectors crucial components in a vast array of industrial, commercial, and consumer products across numerous industries. By definition, the electronics industry is deeply intertwined with the use of electronic connectors. Devices such as computers, mobile phones, audiovisual equipment, telecommunications systems, and various electronic boards all rely on these connectors to function. One notable trend is the miniaturization of connectors as electronic products become increasingly compact. Other industries, including automotive, medical, and industrial sectors, also depend on connectors for their own specialized electronic products.

Components of Electrical Connectors

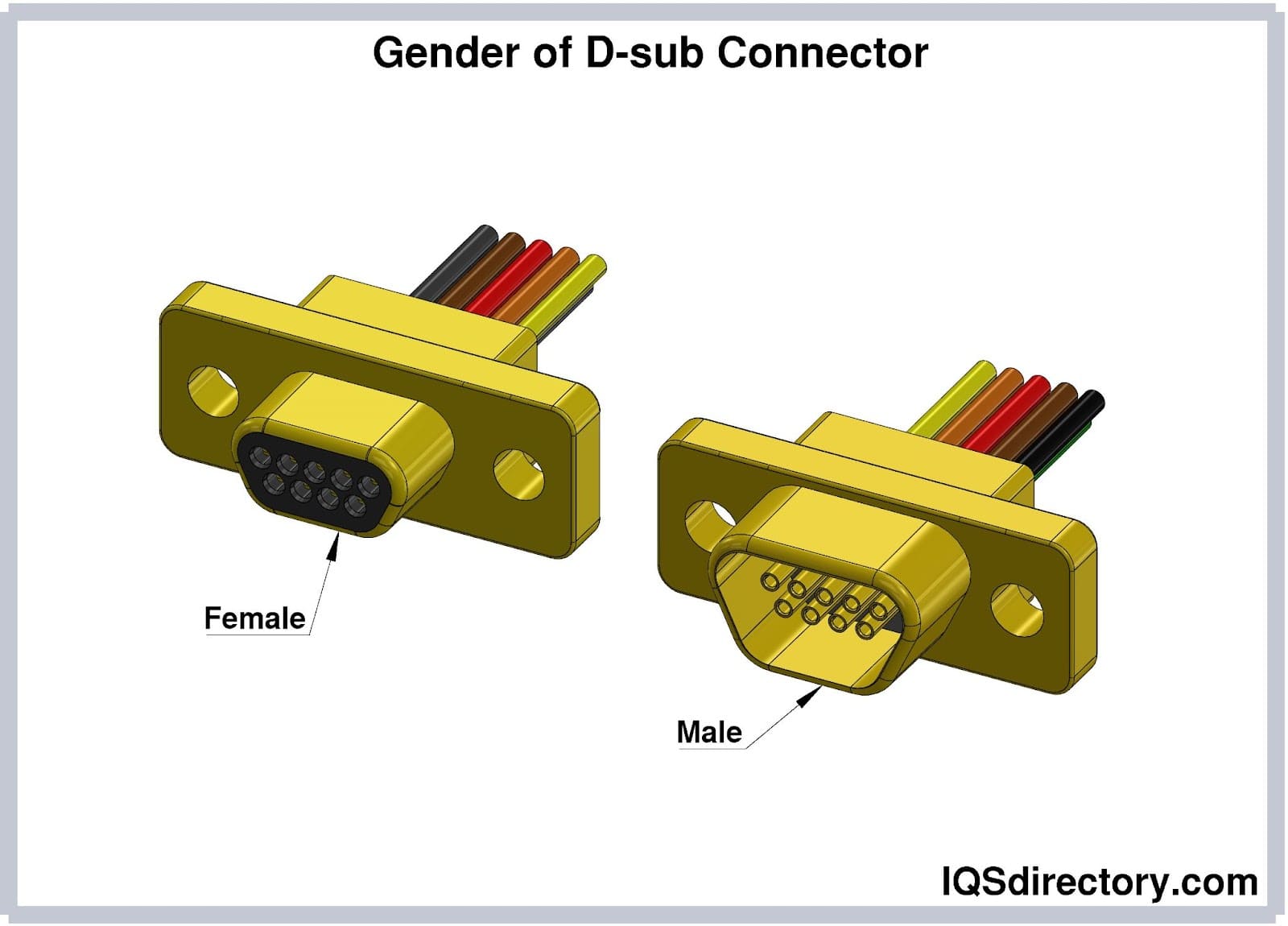

The term "connector" can be somewhat misleading because it can refer to two very different types of equipment. This confusion stems from the definition of a connector: an electromechanical component responsible for completing an electrical circuit. An electrical circuit is completed when two conductive components (i.e., metal pieces) on separate pieces of equipment form a connection. In general, there are two types of connectors: male connectors and female connectors. These connectors operate independently but must work together to establish the connection. Male electrical connectors typically have metal extensions or pins (e.g., power plug prongs) that create connections by fitting into matching receptacles or sockets found in female connectors (e.g., wall sockets). The term "pinout" refers to the electrical contacts or pins of the male connector, which vary widely in terms of the number and configuration of available pins. The pinout is critical in the construction and functionality of the connector. Moreover, the term "connector" can be confusing for another reason: it sometimes refers not just to a single male or female connector, but also to a pair of such connectors working together as a unit. For clarity, this article will generally use "connector" in the context of individual male or female components.

Although connectors are diverse in design, they typically consist of a few common components. The contacts or terminals are the parts responsible for creating the electrical connection, while the housing protects the contacts from external elements. Contacts and terminals are typically made from non-corrosive metals with high conductivity, though other materials that conduct electricity, such as silicon or carbon, can also be used. Commonly used metals for electrical contacts include beryllium copper, phosphor-bronze, brass, and modified copper. The housing of a connector is usually made of plastic, though other insulating or dielectric materials may also be used. The housing may also be further subdivided into insert and enclosure portions. Connectors are important yet fragile components that can be vulnerable to mechanical or chemical threats. To protect against these risks, many connectors feature strain relief mechanisms to redirect unwanted mechanical forces and various protective measures against chemical damage. For example, seals between the insert and enclosure help protect against water, moisture, or oil, while plated or anodized shells guard against corrosion.

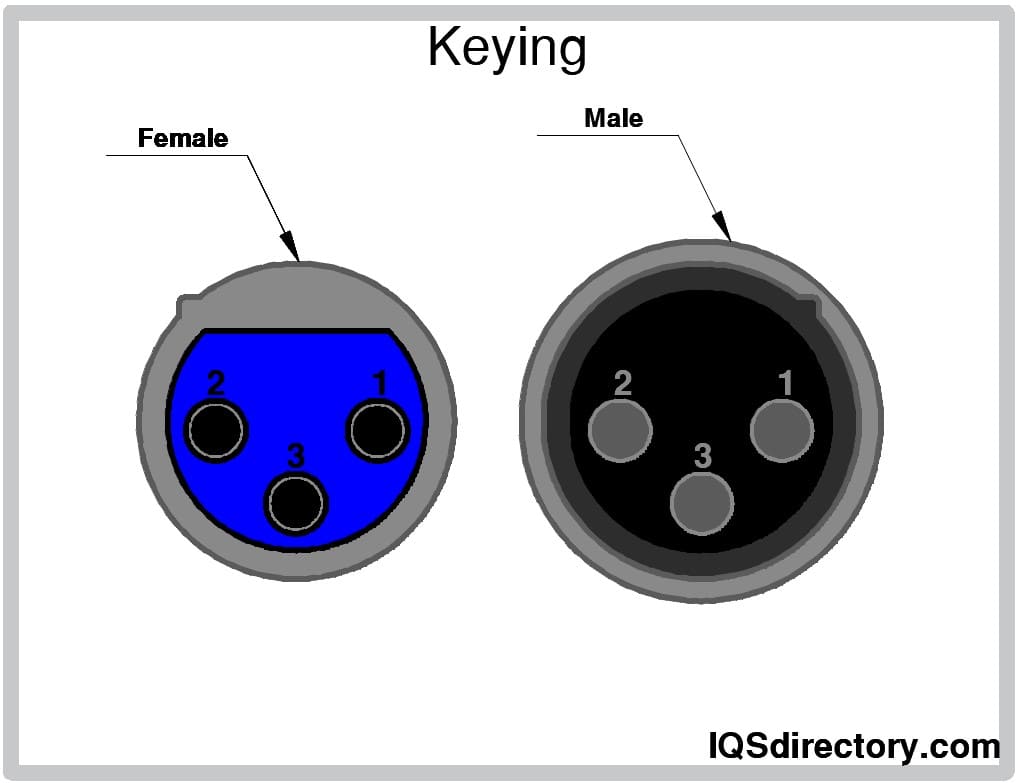

Connectors often include locking and keying features. The metal contacts in male and female connectors create the electrical connection. Each contact in a connector must "mate" with a corresponding contact in the other connector. To secure this connection, many connectors have features that "lock" the connection in place, preventing accidental disconnections. Additionally, connectors often incorporate a mechanical feature that ensures only the correctly aligned connectors can mate together. This feature is known as keying, or polarizing. Keying ensures that connectors are used only in the correct orientation, which is crucial for maintaining proper functionality and preventing damage. Forcing a connector into an incorrect position could damage the connector, highlighting the importance of proper keying in ensuring the correct connection.

Electrical Connector Images, Diagrams and Visual Concepts

Electronic connectors are devices that joins electronic circuits for industrial machinery, consumer electronics, communications, and commercial appliances.

Electronic connectors are devices that joins electronic circuits for industrial machinery, consumer electronics, communications, and commercial appliances.

Electronic connectors have a male component or plug and female component or the socket.

Electronic connectors have a male component or plug and female component or the socket.

Keying, a feature of electronic connectors that avoids incorrect mating orientation to prevent mechanical and electrical damage to the pins from dangerous and incompatible connections.

Keying, a feature of electronic connectors that avoids incorrect mating orientation to prevent mechanical and electrical damage to the pins from dangerous and incompatible connections.

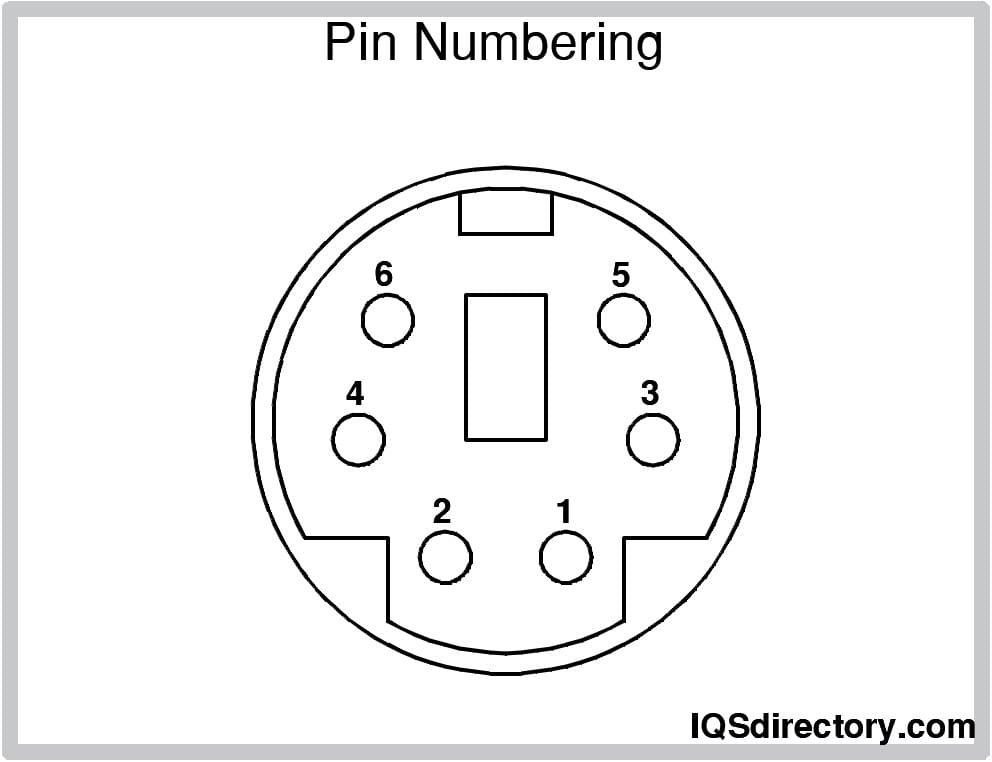

A number is assigned to a specific pin based on a sequence designated by a standard and in an anti-clockwise direction.

A number is assigned to a specific pin based on a sequence designated by a standard and in an anti-clockwise direction.

Board-to-board connectors join two printed circuit boards either perpendicular or parallel configuration.

Board-to-board connectors join two printed circuit boards either perpendicular or parallel configuration.

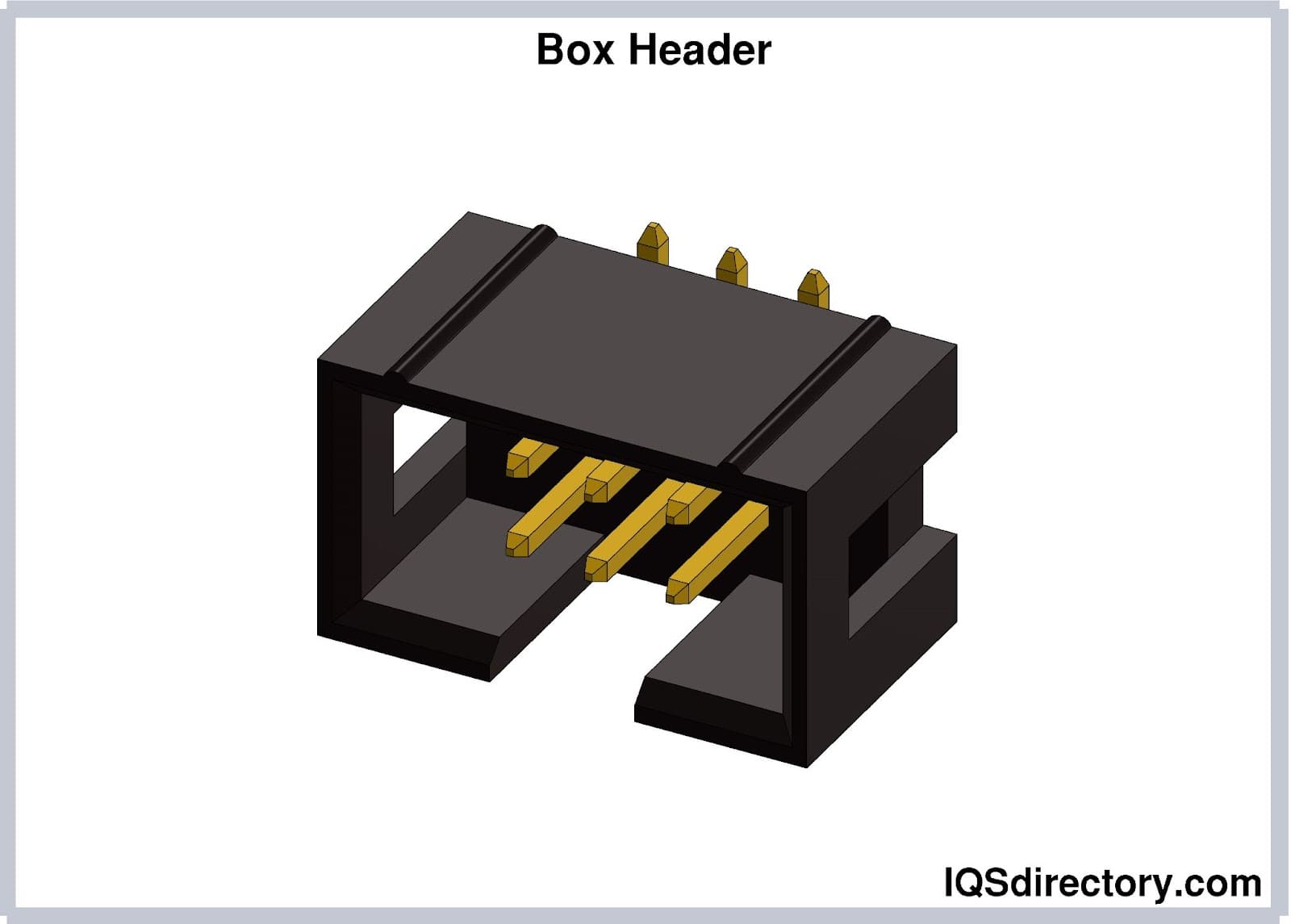

Box headers, the terminals are surrounded by their header.

Box headers, the terminals are surrounded by their header.

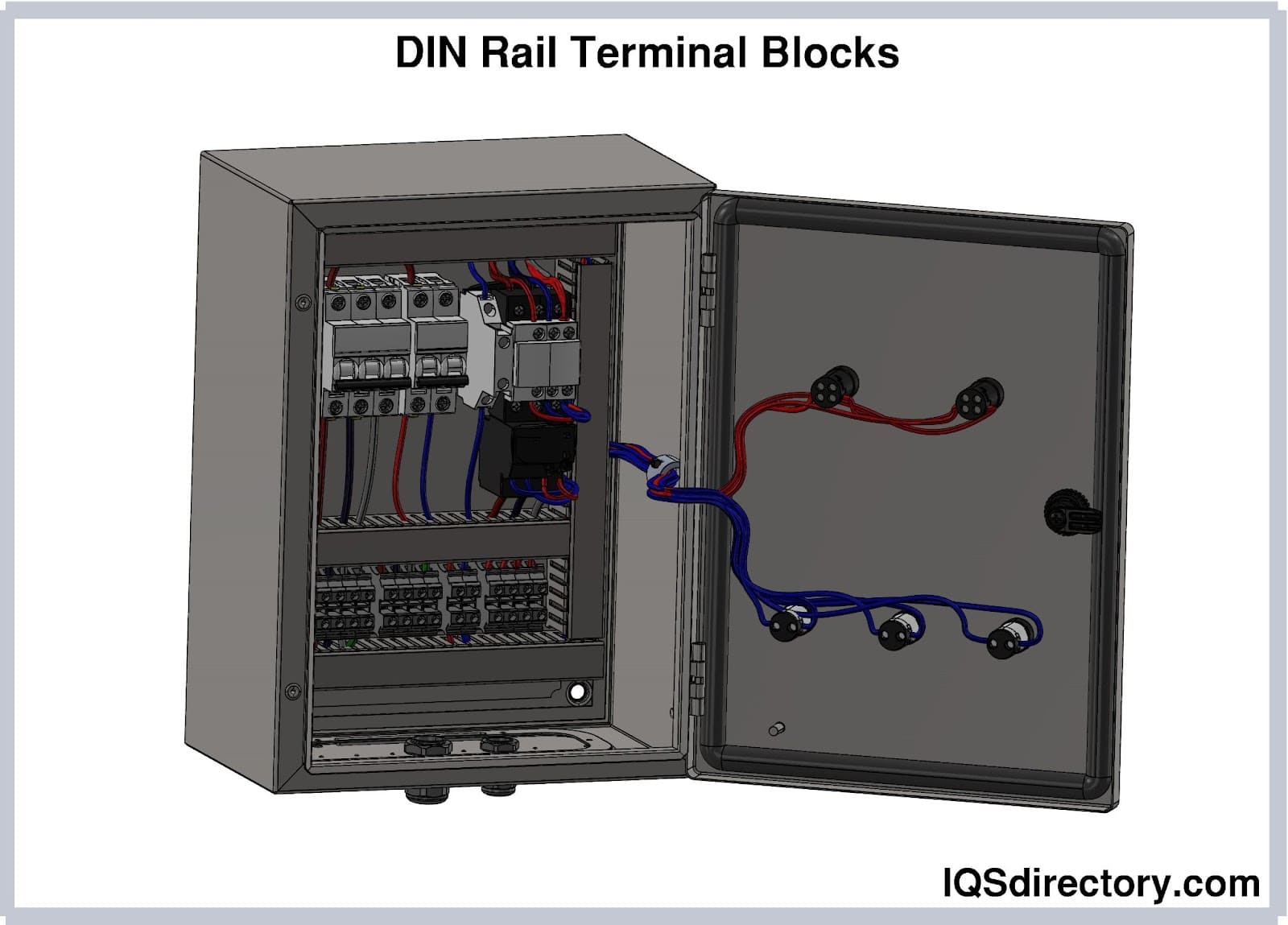

Terminal blocks are an insulated block that fastens or terminates two or more wires together.

Terminal blocks are an insulated block that fastens or terminates two or more wires together.

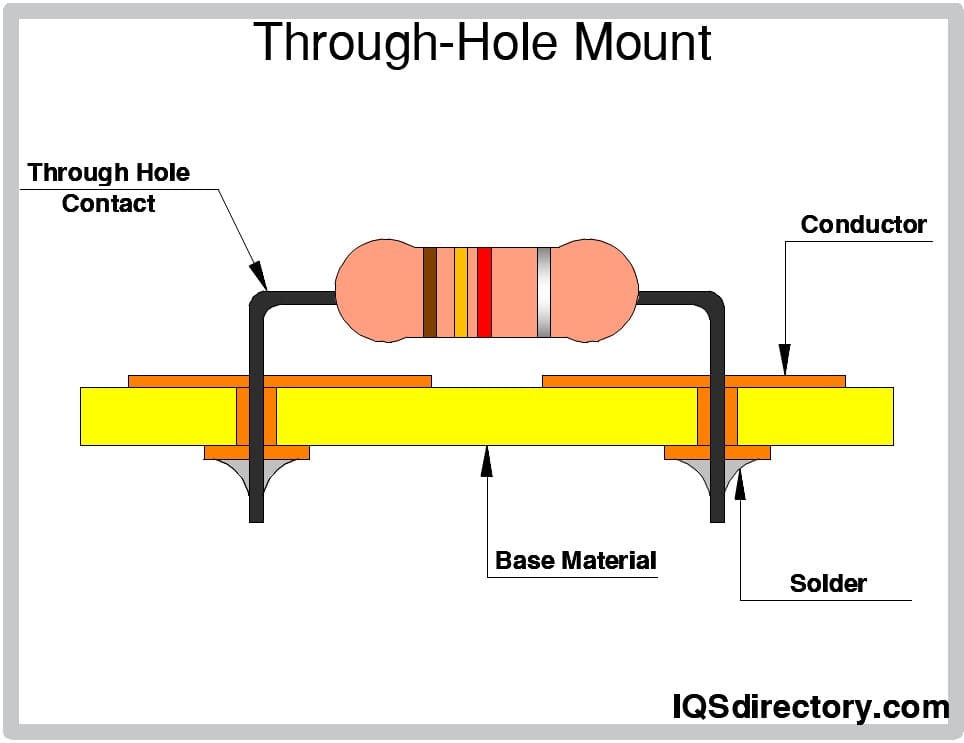

Soldering, the process of joining two or more electronic parts together by melting a solder around their contacts or terminals.

Soldering, the process of joining two or more electronic parts together by melting a solder around their contacts or terminals.

Types of Electrical Connectors

Electrical connectors are essential components used in a variety of appliances and applications. They can be categorized based on factors such as the type of power they transmit, their physical construction, and the intended purpose they serve. Here are several common types of connectors:

AC and DC Power Connectors

AC power connectors come in various genders, geometries, and configurations to transfer alternating current (AC) through electronic devices. These connectors are used across many industries, including residential, industrial, and commercial sectors. Power connectors link devices to a power source and are categorized into AC or DC types, where AC is used for long-distance power transmission, and DC is used for devices that require steady current. Examples include AC power plugs, sockets, and electrical cords.

These connectors are used in both AC and DC applications and are often found in small power connections, solar panels, and battery arrays. Amp connectors are essential for providing a reliable link in power-related applications.

Used to connect cables to electronic components, these connectors provide a secure, conductive connection, ensuring proper signal and power transmission.

Barrel Connectors

Common in consumer electronics, barrel connectors have two contacts and are often used to adapt AC power from a wall outlet for portable electronics. AC-to-DC conversion is essential in portable electronics, and barrel connectors facilitate that process.

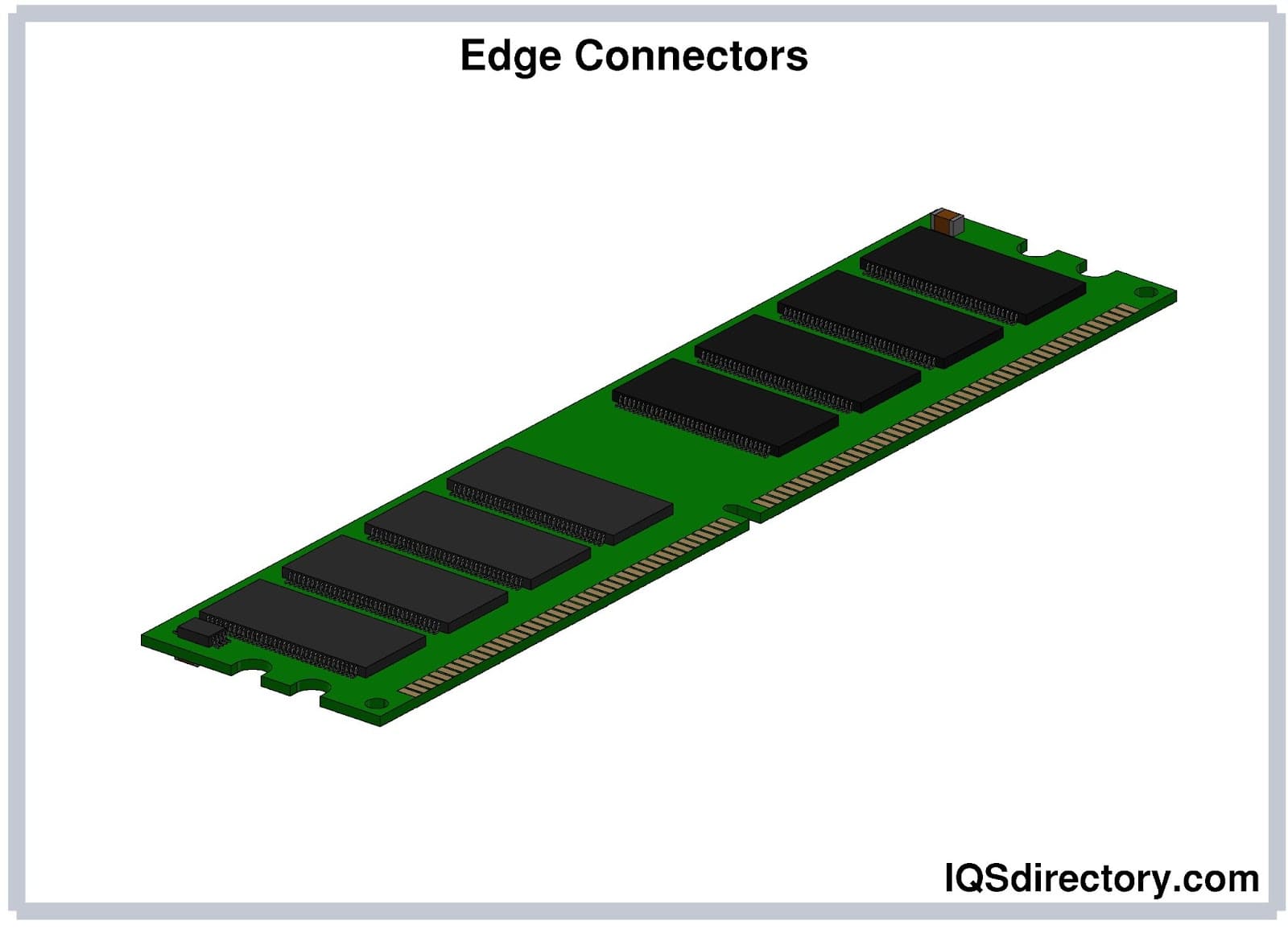

Card Edge Connectors

These are used in personal computers to create connections between components such as processors, motherboards, and graphics cards. Card edge connectors are designed to handle the heat generated inside PCs and are built to withstand high temperatures.

Coax Connectors

Coax connectors, primarily used in video applications, are single-conductor connectors with braided shields. They were once popular for data transmission in the 1980s and are still in use today for certain audio and video connections.

DIN Connectors

Round multi-pin connectors, such as the DIN and mini-DIN plugs, are typically used in audio applications. These connectors provide secure and reliable connections for equipment like audio systems and video devices.

D-Sub Connectors

D-sub connectors were initially designed for early computer models and are used today in commercial equipment. They are named for their "D" shape and are commonly found in network ports, electrical systems in aircraft, and computer video outputs.

Used to transmit electricity between power sources and devices, these connectors ensure that electrical power flows correctly to devices requiring it.

Fiber Optic Connectors

These connectors are designed for optical fiber systems and are used to transmit light signals between fiber optic cables and other components.

IEC Connectors

Commonly used to provide AC power for desktop PCs, IEC connectors feature male pins inside IEC computer sockets and are an example of how gender in connectors is determined by the presence of pins or extensions.

Military Connectors

Manufactured to military specifications (MIL-SPEC), these connectors are used in applications that require durability and reliability in challenging environments.

Modular Connectors

These connectors allow for the assembly of identical or similar sections to form the ideal connector size or type for the application.

PCB Connectors

Used in printed circuit boards, these connectors transmit electrical signals between two PCBs or between a PCB and another electrical circuit.

Phone Connectors

These connectors, which are typically 1/4 inch in diameter, are used for telephone connections and other audio applications, such as connecting headphones to audio equipment.

Pin connectors use short, stiff pins to create electrical connections between circuits. Pin headers are typically used to form internal connections in electronic devices.

These connectors are used to transmit power from a source to devices that rely on electricity to function. They can come in various forms, such as plug-and-socket or terminal-based connectors.

Radio Frequency (RF) Connectors

Designed to function at radio frequencies, RF connectors are used in telecommunications equipment. They often pair with coaxial cables to enable high-frequency data transmission.

RCA Connectors

Commonly used in audio and video applications, RCA connectors are found in coaxial and composite-video cables. They are most often used for consumer electronics such as televisions and stereo systems.

Speaker Cable Connectors

These connectors are used to ensure secure, corrosion-free connections between speakers and amplifiers. Examples include banana plugs, screw terminals, and binding posts.

USB Connectors

USB connectors are commonly used for data and power transmission in electronic devices. They come in various forms, such as USB-A, USB-B, USB-mini, and USB-micro, depending on the device and application. USB connectors provide a convenient, standardized method for connecting peripherals like printers, phones, and cameras.

Wire Connectors

Wire connectors are used to connect multiple wires to electrical circuits, ensuring a secure and stable connection for power or signal transmission. These connectors are found in nearly every electrical system, from home wiring to complex industrial applications.

Each type of connector serves a unique purpose, offering specific features suited for its intended function. Whether it's providing power, data, or audio signals, connectors are integral to modern electronic systems and devices.

Caring for Electrical Connectors

While most mechanical products require careful maintenance, electric connectors especially demand attention. This is largely due to the nature of the connections they establish: electrical and temporary. Electrical connections are vulnerable to chemical threats because of their reliance on metal, while temporary connections face mechanical stresses from the constant making and breaking of connections. Metal contacts in connectors are susceptible to issues like soiling or oxidation. In certain environments, such as those in mobile devices or hospital equipment, chemical threats may be even more pronounced due to exposure to harsh conditions or sterilization chemicals. Additionally, the repeated physical cycles of connecting and disconnecting male/female connectors can cause wear over time due to vibration, abrasion, and other factors. Given the wide variety of connectors, it’s crucial to follow the recommended care procedures—both preemptive and maintenance-focused—specific to each connector type. Regularly reassessing the chemical and mechanical condition of your equipment ensures optimal performance and longevity.

Choosing Connectors and Suppliers

When selecting a connector for a specific application, there are several important factors to consider:

Technical Specifications

Connectors are highly precise components that require careful consideration of compatibility. It’s essential to ensure that different connectors can work together, as their appearance can sometimes be misleading. One example is the pitch of connectors, which refers to the distance between the centers of individual contact pieces (male and female). If the pitch of a male and female connector is similar but not identical, they will not be compatible.

Performance Specifications

Carefully assess the conditions under which the connector will be used. Different connectors are designed to handle varying electrical currents, voltages, and temperature ranges. Other design features can also impact performance; for example, a low pitch (the small distance between contact centers) can result in electrical interference, or arcing, which can degrade the connector's effectiveness.

Durability

The term "mating cycles" refers to how long a connector can be expected to last under normal use, factoring in mechanical stress and wear. This period can vary widely between different connectors. Consider the duration you require for a specific connector combination and use the datasheet information to choose the appropriate one. For example, permanent electronic installations that don’t require frequent disconnections won’t need connectors with a high number of mating cycles.

Versatility

Since connectors are typically used to form temporary circuits, they are likely to be involved in systems where the overall design may change over time. Consider connectors that offer flexibility, such as those with extra contacts, allowing them to adapt to future changes in their mechanical environment.

Given the broad variety of electrical connectors and the critical roles they play across different industries, manufacturers must design them for ease of identification and assembly, while keeping costs reasonable. It’s also essential to choose a reliable manufacturer or supplier who can provide valuable guidance on selecting the right connectors for your needs. When selecting a supplier, ensure that the company has a strong business reputation, financial stability, and a commitment to using the latest technology and equipment.

Electronic Connectors Terms

-

Action Pin Contact

A type of contact featuring a split pin that ensures gas-tight retention when used with a printed circuit board.

Angular Misalignment

The loss of signal at a connector due to skewed fiber end face angles.

Back Mounted

A connector configuration where the connector is fixed to the interior of a box or panel, with its flanges used for mounting.

Body

The main or largest section of a connector to which all other components are attached.

Bulkhead

A type of connector inserted into a panel cutout from the component side of the panel.

Center Fastener

A fastening device positioned in the center of two mating connectors. One connector has a threaded screw that connects to a threaded bushing on the mating connector.

Connector Plug

A device that terminates an electrical or optical cable.

Connector Receptacle

The stationary part of a connection that mates with a plug. Receptacles are typically mounted on a panel or bulkhead.

Contact

An electrically conductive component used in multi-circuit connectors.

Contact Durability

The number of withdrawal and insertion cycles a connector can endure while maintaining performance within specified parameters.

Dust Cap

A protective cover for connectors, designed to shield them from dust and foreign debris.

Extraction Tool

A tool used to remove a contact from a connector.

Flange

A protruding part of a connector containing holes for mounting it to a panel or mating connector.

Guide Pin

A component used to align mating connectors and prevent contact damage due to mismating.

Holding Strength

The ability of a connector to remain securely attached to a wire or cable under tension.

Interface

The surfaces of a multi-contact connector that face each other when the connector is mated.

Jack

A connection point where a plug is inserted to establish electrical circuit connections.

Jumper

A short fiber optic cable with connectors on both ends.

Loss

The reduction in signal power caused by defects in connectors, splices, or fibers. Loss is measured in decibels (dB).

Panel Mount

A method of attaching a connector to a panel, board, or frame.

PC (Physical Contact)

Refers to an optical connector in which the fiber ends physically touch, reducing backreflection and insertion loss.

Sealing Plug

A plug used to seal unoccupied contact cavities, crucial for environmental connectors.

Withstanding Voltage

The maximum voltage a connector can withstand for one minute without showing signs of electrical breakdown.