Environmental Test Chambers

Anyone considering a testing chamber for their products should have a clear understanding of what they are and how they function before making a purchase. An environmental test chamber is a precision-engineered system designed to simulate specific environmental conditions, allowing manufacturers to assess a product’s performance under controlled variables. These chambers can replicate humidity levels, temperature fluctuations, and even pressure changes to analyze how materials respond to various conditions.

Environmental testing plays a crucial role in ensuring product quality and durability. By exposing products to controlled temperature, humidity, and pressure conditions, companies can verify compliance with industry standards and identify potential weaknesses before products reach the market. These chambers provide detailed readings and allow users to set precise parameters, ensuring repeatable and reliable testing results in an easy-to-control format.

Environmental chamber manufacturers offer a diverse range of models, including climate chambers, temperature chambers, and systems designed for thermal shock testing. Understanding the specifications of these chambers—such as their humidity, temperature, and pressure capabilities—will help determine the most suitable option for specific testing needs while offering valuable insight into their operation and functionality.

Benefits of Environmental Test Chambers

Installing an environmental test chamber in your facility offers numerous advantages, primarily by ensuring the quality and durability of your materials and finished products. These chambers allow manufacturers to conduct rigorous in-house testing, verifying that every product meets high-performance standards before reaching the market. By identifying design flaws early in the development process, businesses can prevent costly production errors and avoid financial losses associated with defective products.

Another significant benefit of having an environmental test chamber on-site is the ability to eliminate the need for third-party testing services. Conducting tests internally not only provides greater control over testing conditions but also helps reduce the costs associated with outsourcing, making product development more efficient and cost-effective.

Applications of Environmental Test Chambers

Environmental test chambers serve a critical role in evaluating product performance and reliability across various conditions. As mentioned, these chambers ensure that products meet industry standards by assessing their response to temperature, humidity, and pressure variations. However, their capabilities extend beyond meeting basic quality thresholds—they can also push products to their breaking points, allowing manufacturers to establish clear safety guidelines and operational limits.

By exposing products to extreme conditions before they reach consumers, companies can proactively detect and correct weaknesses, enhancing overall product efficiency and longevity. Identifying and addressing design flaws before production reduces the likelihood of costly warranty claims and replacements, providing financial protection for both manufacturers and warranty providers.

A wide range of industries rely on environmental test chambers to ensure their products meet strict performance and durability standards. Automotive, electronics, construction, medical, pharmaceutical, food, packaging, and engineering sectors all depend on these testing systems to validate humidity and temperature resistance. Given their ability to simulate diverse environmental conditions, environmental test chambers represent a valuable investment for any company committed to delivering high-quality, reliable products.

The History of Environmental Test Chambers

The origins of environmental test chambers trace back to 1951, when Charles Conrad invented the first functional model. Built in Holland, Michigan, this pioneering chamber was literally crafted on the front porch of his home. Conrad’s goal was to develop a system capable of achieving a wide temperature range, and his invention succeeded in reaching as low as -125 degrees Fahrenheit. Following this breakthrough, he established Conrad Inc. and secured a patent for his system in 1954.

Over time, Conrad’s innovation evolved, giving rise to more advanced and specialized environmental testing chambers. As the industry expanded, manufacturers continuously improved upon the original design by increasing the range of temperatures and humidity levels these chambers could simulate. Additionally, advancements in engineering have led to the development of more compact and portable models, making them suitable for laboratories and manufacturing facilities where space efficiency is a priority.

How Environmental Test Chambers Work

A fundamental understanding of environmental test chambers can help users operate them more effectively. Whether working with a walk-in test chamber, humidity chamber, climate chamber, stability chamber, or temperature test chamber, mastering the basics of their operation ensures precise testing conditions. These chambers provide solutions for a variety of environmental concerns—for instance, a humidity chamber can be used to fine-tune humidity control for a product.

Testing begins by opening the chamber and carefully placing the product inside. Once the test subject is securely positioned, the chamber is sealed, and the operator configures the necessary environmental parameters. If using a pressure chamber, for example, the desired pressure level is selected. Users can also control the rate at which the chamber reaches the specified environmental threshold, allowing for precise simulation of real-world conditions.

Once the test starts, the chamber’s stainless steel interior adjusts to meet the programmed conditions. Technicians closely monitor the product throughout the process, observing its reaction to various stressors. These stressors include:

- Extreme temperatures, ranging from -120°F to 662°F

- Thermal shock, caused by sudden and drastic temperature shifts

- Moisture and humidity, with ranges from 10% to 98% RH

- Electrodynamic vibrations, replicating mechanical stress

- Electromagnetic radiation, simulating exposure to electrical fields

- Cyclical corrosion, mimicking long-term environmental wear

Additionally, these chambers can simulate harsh weathering conditions, such as exposure to sunlight, sand, dust, salt spray decay, and rain. In more extreme cases, they can even replicate a vacuum environment to assess material performance in space-like conditions.

The thermal shock effect produced by rapid temperature changes can be particularly destructive, causing materials to crack or fail. As the chamber temperature rises or falls, engineers study how the item responds, identifying the exact point at which it burns, freezes, or fractures. These observations help manufacturers refine designs to enhance durability and resilience.

Humidity chambers function similarly, testing a product’s ability to withstand moisture exposure. While many electronic components have a maximum humidity rating of 20-30% RH, manufacturers often test beyond this limit to ensure superior product quality and performance under extreme conditions.

The Importance of Comprehensive Testing

To guarantee the reliability of their products, manufacturers should subject their items to multiple types of testing. At a minimum, temperature and humidity testing should be conducted, but stability and stress testing are also highly beneficial.

- Stability testing evaluates a product’s long-term performance under fluctuating environmental conditions.

- Stress testing measures the amount of force an item can withstand before breaking. These tests can range from a few pound-feet per square inch to hundreds, depending on the material and intended use.

By determining a product’s breaking point, engineers gain critical insight into its durability. If an item fails under stress, adjustments can be made to reinforce the design, ensuring that the final product is both structurally sound and capable of withstanding real-world conditions.

Types of Environmental Chambers Available

Environmental test chambers come in a wide range of designs, each tailored to specific testing needs. Some are dedicated to controlling individual environmental factors, while others combine multiple conditions to simulate complex real-world scenarios. Humidity chambers regulate moisture levels within a controlled space, ensuring products can withstand varying degrees of humidity. Temperature chambers, on the other hand, are capable of reaching extreme heat and cold, often incorporating thermal shock testing to evaluate how materials respond to sudden temperature fluctuations.

For more versatile testing, combination chambers integrate both temperature and humidity controls, allowing for a more comprehensive analysis of product durability. Other specialized chambers include climatic chambers, which simulate various weather conditions, pressure chambers that assess performance under different atmospheric pressures, and stability chambers, which examine how products endure over time. Some models are even designed to test a product’s reaction to continuous vibrations, offering valuable insights into mechanical durability. While less common, these chambers are essential in industries where products experience constant motion or mechanical stress.

Size variations also play a crucial role in chamber selection. Walk-in chambers are ideal for testing large batches of delicate items or for accommodating sizable equipment, offering ample space for thorough analysis. In contrast, tabletop or bench-top chambers provide a compact solution for smaller-scale testing, making them a practical choice for facilities that focus on individual components or limited sample sizes.

Choosing the right chamber involves evaluating both testing requirements and manufacturer capabilities. Different industries benefit from specific chamber types, with electronics manufacturers often relying on pressure and temperature chambers to ensure their products withstand harsh operating conditions. The method of access is another key consideration. While walk-in chambers accommodate larger quantities and offer ease of use, they come with higher costs and installation challenges. Bench-top models, being more compact and easier to integrate into existing workspaces, are commonly found in manufacturing facilities where engineers and factory workers conduct on-site quality testing.

Important Components of Environmental Test Chambers

The functionality of an environmental test chamber depends on several critical components. Central to its operation are the electronic systems that regulate internal conditions. Insulated conductors and protected wiring ensure stable performance, even as extreme temperature or pressure changes occur within the chamber.

Each chamber type contains specific mechanisms to alter environmental conditions. Temperature chambers utilize powerful heaters and freezers to create precise thermal shifts, allowing for rapid exposure to different temperature extremes. Pressure chambers incorporate vacuum systems and regulators that adjust internal air pressure to match specified conditions.

Modern environmental chambers often include additional features that enhance testing accuracy and ease of operation. Some models integrate video monitoring systems, enabling real-time observation of the testing process. Others include viewports that provide a direct line of sight into the chamber, allowing for post-test inspection. High-end chambers may even feature reach-in gloves, permitting direct manipulation of test subjects without compromising the controlled environment.

Control systems have also evolved significantly. Older chamber models rely on analog controls, often requiring manual adjustments such as turning a small wheel to modify humidity levels. More advanced systems, however, utilize digital interfaces with LCD screens, offering precise settings and automated programming for more efficient and consistent testing.

Environmental test chambers are invaluable tools across industries, providing controlled conditions for evaluating product performance under extreme circumstances. Whether selecting a chamber for humidity, temperature, pressure, or vibration testing, understanding the various types and components ensures optimal results for product development and quality assurance.

Design of Environmental Test Chambers

Can a testing chamber be customized to suit your facility’s specific needs? Absolutely. Many aspects of its design can be tailored to optimize performance and integration within your workspace. One of the most adaptable features is the chamber's size. While the unit's overall dimensions must accommodate the operational requirements of the test environment, adjustments can be made to minimize its width and length for a more efficient footprint.

Beyond size modifications, various design enhancements can further refine the chamber’s functionality. Custom inspection equipment can be integrated to provide enhanced monitoring, while viewing ports can be adjusted for better visibility. Upgrading to a stainless steel interior offers increased durability and resistance to harsh testing conditions. Additional computer components can be installed to improve system management, and web-enabled capabilities can be incorporated to allow remote operation and real-time data tracking. These features ensure that your testing chamber is optimized for efficiency and precision.

Another significant upgrade is the implementation of advanced computer programming. This software enhancement enables automated testing cycles, streamlining processes and improving consistency. With programmable testing routines, your facility can conduct experiments around the clock, even when employees are offsite. This level of automation not only increases productivity but also reduces the need for manual intervention, allowing for more efficient resource allocation.

Safety Standards of Environmental Test Chambers

Environmental test chambers are subject to rigorous safety standards to ensure proper operation and compliance with regulatory guidelines. One of the most critical requirements is meeting OSHA’s insulation standards for freezing chambers, which ensure that extreme temperature fluctuations do not pose hazards to workers. Additionally, test chambers must undergo stress testing to verify their structural integrity and operational reliability.

A walk-in chamber presents unique safety considerations. Although it is not classified as a confined space—since it is not designed for continuous employee occupation—it must still comply with specific regulations. The interior space of these chambers may require a permit, particularly if there is a possibility of hazardous atmospheric conditions that could affect worker safety. Ensuring compliance with OSHA guidelines requires staying up to date with their latest regulations and consulting representatives to confirm adherence to industry standards.

Choosing the Right Environmental Test Chamber Manufacturer

Selecting the right manufacturer for an environmental test chamber requires thorough research to ensure the best fit for your facility’s needs. Evaluating a company’s product range, reputation, and industry standing is essential. Does the manufacturer specialize in the type of chamber you require? Are their products known for reliability and performance? Understanding a manufacturer’s track record helps determine whether their solutions align with your testing objectives.

However, the best manufacturer on the market may not always be the most suitable choice for your specific requirements. Budget constraints, for example, might necessitate selecting a company that offers high-quality bench-top models at a more affordable price rather than an industry leader with premium models outside your budget. In such cases, working with manufacturers that provide cost-effective solutions while maintaining performance standards is a strategic approach.

To further ensure the reliability of a manufacturer, it is advisable to consult authoritative sources such as OSHA and the Better Business Bureau. OSHA provides insights into compliance with safety standards, while the BBB offers independent ratings and customer reviews to assess a company’s reputation. By verifying a manufacturer’s adherence to regulatory requirements and evaluating customer experiences, you can make an informed decision that balances quality, cost, and compliance.

Environmental Test Chamber Images, Diagrams and Visual Concepts

An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly.

An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly.

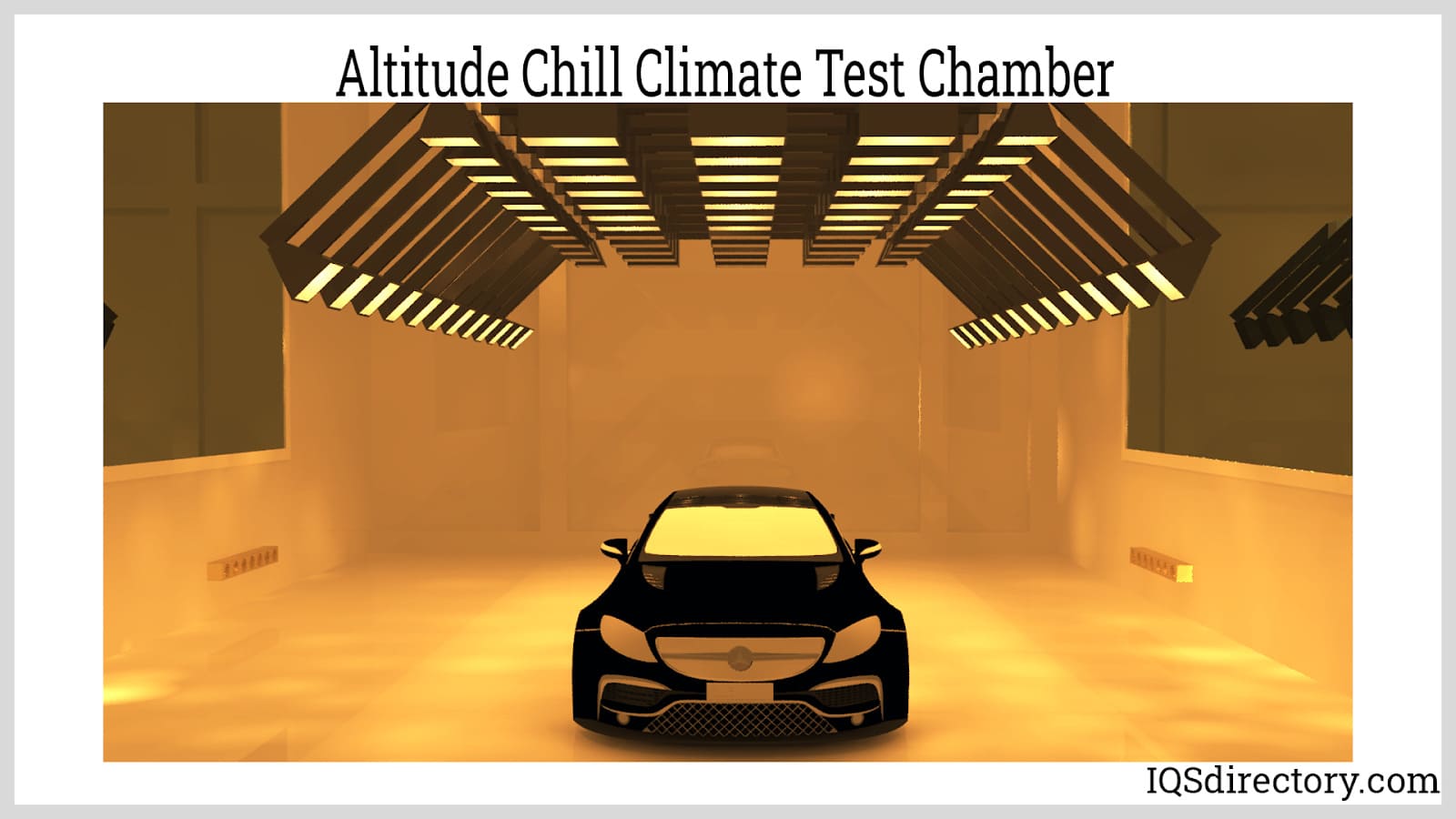

An example of testing a car to certain environmental conditions that might be experienced.

An example of testing a car to certain environmental conditions that might be experienced.

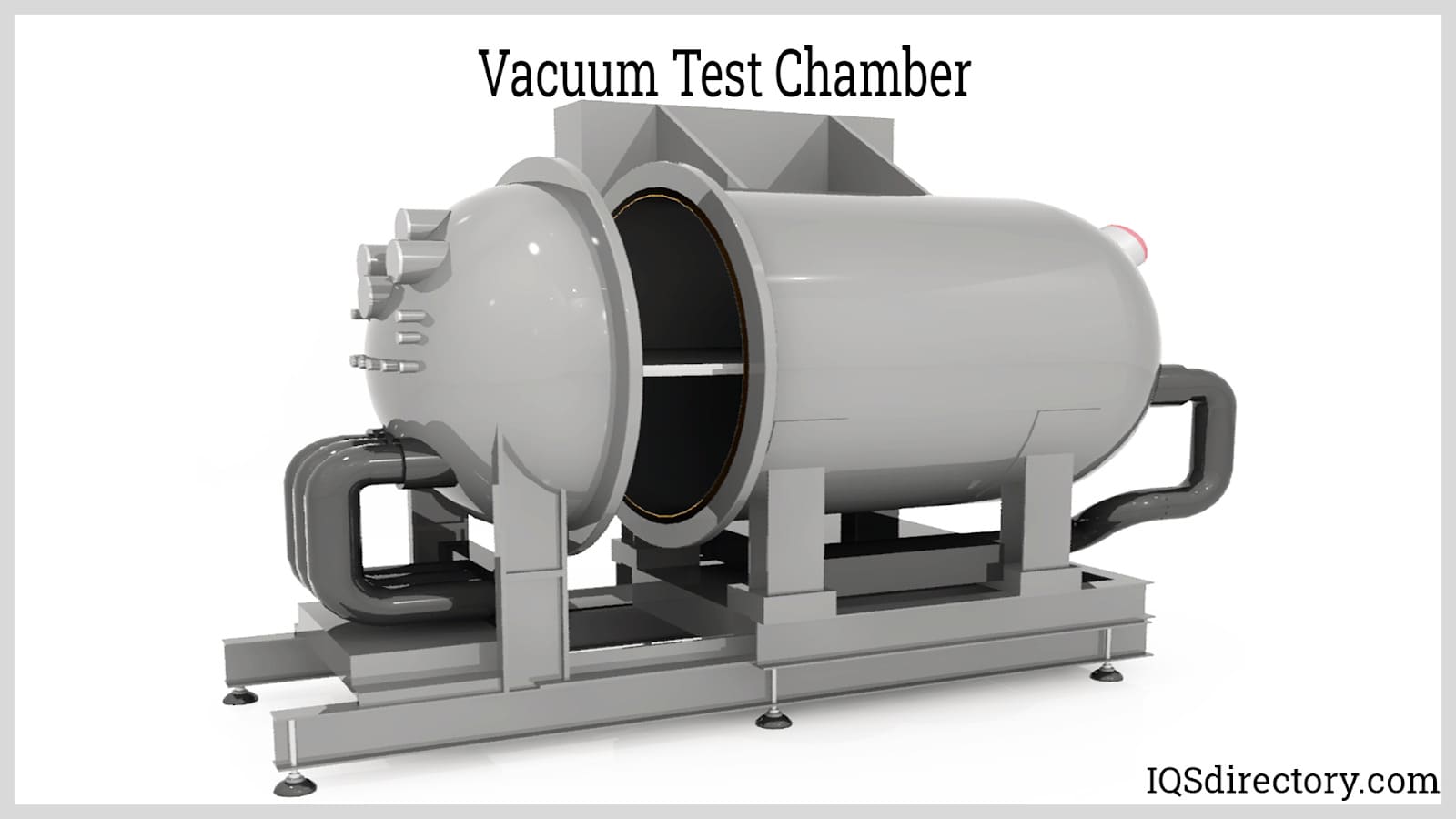

Vacuum chambers creates a low pressure environment by removing air and other gases from an enclosed space.

Vacuum chambers creates a low pressure environment by removing air and other gases from an enclosed space.

Humidity Chambers producing environmental conditions to test products or components when affected by both heat and moisture.

Humidity Chambers producing environmental conditions to test products or components when affected by both heat and moisture.

Stability test chambers are used to determine a products shelf life and the conditions that causes the products to deteriorate.

Stability test chambers are used to determine a products shelf life and the conditions that causes the products to deteriorate.

Used to test components for conditions that could be experienced during the usage of the component.

Used to test components for conditions that could be experienced during the usage of the component.

Environmental Test Chamber Types

- AGREE Chambers

- Designed to facilitate rapid temperature fluctuations, AGREE chambers can achieve changes of 41-104°F (5-40°C) per minute, even when handling large loads. These chambers feature removable floors, allowing for seamless integration with vibration test systems to assess product durability under mechanical and thermal stresses simultaneously.

- Altitude Chambers

- Simulating the effects of low pressure, altitude chambers recreate conditions found at elevations of up to 200,000 feet above sea level. These chambers help determine how materials and components withstand the decreased atmospheric pressure experienced in aerospace, defense, and high-altitude applications.

- Benchtop Test Chambers

- Compact and efficient, benchtop test chambers accelerate test times for smaller items while maintaining precise environmental controls. These chambers are ideal for laboratories and facilities with limited space, ensuring reliable results for product quality assessments.

- Cryogenic Chambers

- Capable of reaching extreme low temperatures, cryogenic chambers operate from -238°F to absolute zero, creating conditions necessary for testing materials and components used in cryogenics, aerospace, and scientific research.

- Drive-In Chambers

- Built to accommodate oversized products, drive-in chambers allow for large-scale testing, making them essential for evaluating vehicles, industrial machinery, and aerospace components. These chambers are especially useful for batch testing multiple large items under controlled environmental conditions.

- Engineering Stress Screening (ESS) Chambers

- ESS chambers push products to their limits by rapidly cycling temperatures through high-velocity air conditioning. This process identifies weak points in materials and components, ensuring product reliability before reaching the market.

- Environmental Chambers

- Designed to replicate real-world environmental conditions, these chambers provide controlled settings for engineering tests. They simulate variables such as temperature, humidity, and pressure to evaluate product performance across diverse operating environments.

- High Altitude Simulation (HAS) Chambers

- Specialized for aviation and aerospace testing, HAS chambers reproduce the environmental extremes encountered during flight. These chambers allow engineers to assess how aircraft components respond to the pressures and temperatures experienced at cruising altitudes.

- Humidity Chambers

- Humidity chambers simulate various moisture conditions, enabling the evaluation of how materials and electronics react to prolonged exposure to high humidity levels. They are widely used in industrial and biotechnology applications where moisture resistance is critical.

- Mixed Flowing Gas (MFG) Chambers

- MFG chambers expose electronic components to controlled mixtures of pollutant gases while maintaining precise temperature and humidity levels. These chambers help assess corrosion resistance and longevity in harsh industrial environments.

- Reach-In Chambers

- Engineered for user convenience, reach-in chambers often feature shelves and other organizational amenities, allowing for easy product placement and monitoring during testing. These chambers support a variety of environmental testing needs within a manageable workspace.

- Salt Spray

- Salt spray chambers evaluate corrosion resistance by subjecting materials to a saline mist. Test specimens are suspended within the chamber while a controlled fog of salty residue is introduced, allowing for visual assessment of corrosion effects in real time.

- Temperature Chambers

- Designed to test the impact of temperature variations on materials, temperature chambers subject products to thermal cycling, either as an independent process or in conjunction with altitude and vibration testing. These chambers are essential for industries requiring thermal endurance validation.

- Thermal Cycling or Stress Screening Chambers

- These chambers expose products to rapid and extreme temperature fluctuations within a single enclosure. Alternating between cold and hot conditions over a set number of cycles, they assess material expansion, contraction, and overall durability.

- Test Chambers

- Enclosed systems that create controlled testing environments, test chambers support a range of experiments across industries. They enable precise replication of environmental variables to ensure product reliability and compliance with industry standards.

- Thermal Shock Chambers

- Thermal shock chambers rapidly transfer products between two separate compartments—one containing extremely cold conditions and the other maintaining high temperatures. This abrupt shift in thermal exposure helps identify structural weaknesses and material vulnerabilities.

- Thermotron Chambers

- Combining thermal and dynamic testing capabilities, Thermotron chambers provide shock and vibration testing to assess product resilience. These chambers are commonly used in aerospace, automotive, and military applications where exposure to extreme conditions is expected.

- Vacuum Chambers

- Vacuum chambers create near-total atmospheric removal, replicating the conditions of deep space or high-altitude environments. These chambers are essential for aerospace testing, semiconductor development, and research applications requiring minimal air resistance.

- Vibration Chambers

- By applying controlled shock vibrations at varying frequencies, vibration chambers evaluate how materials and assemblies withstand movement, shaking, and impact. These chambers can be used in conjunction with temperature and humidity testing, with built-in sensors capturing detailed responses.

- Walk-In Chambers

- Offering a range of sizes to accommodate large objects and multiple users, walk-in chambers support extensive testing needs. They are frequently used for batch testing and large-scale environmental simulations, ensuring products maintain integrity under prolonged exposure to varying conditions.

Environmental Test Chamber Terms

- Absolute Humidity

- The total amount of water vapor present in a given unit of air, regardless of temperature.

- Absolute Vibration

- The measurement of an object’s vibration relative to a fixed reference point in space, allowing for precise assessment of mechanical movement and stability.

- Accelerated Life Testing

- A testing method that applies stress to a product during its development phase, subjecting it to extreme conditions beyond what it would typically experience in normal use. This process evaluates quality and durability before mass production.

- Accelerated Stress Testing

- A post-production testing process designed to identify defects by exposing products to high levels of stress before they reach the market. This helps detect manufacturing flaws that may lead to premature failure.

- Aggravated Testing

- A procedure that subjects a product to greater stress levels than it would normally endure during standard operation. This testing helps establish guidelines for safe usage and determines operational limits.

- Air-To-Air Thermal Shock

- Also known as two-zone thermal shock, this testing method rapidly transfers a product between a hot and a cold chamber to induce sudden air temperature changes, revealing weaknesses in material durability.

- Ambient Environment

- The surrounding environmental conditions, including temperature and humidity, whether indoors (internal) or outdoors (external).

- Atmospheric Pressure

- The force exerted by the atmosphere at a given location, measured at 14.7 psi at sea level. Changes in atmospheric pressure impact product performance, especially in aerospace and high-altitude applications.

- Batch Testing

- A testing method in which multiple items are evaluated simultaneously under identical conditions to ensure uniform quality and reliability.

- Burn-In

- A process used to accelerate a product’s aging by continuously operating it at elevated temperatures. This method identifies early failures and assesses long-term durability.

- Calibration

- The comparison of an object or system’s performance against a known standard to determine its efficiency, identify errors, and improve accuracy.

- Corrosion

- The gradual degradation of metal due to chemical reactions, such as oxidation, which can weaken structures and reduce product lifespan.

- Critical Frequency

- The specific frequency at which an object begins to experience destructive vibrations, leading to potential failure or damage.

- Damping

- The process of reducing vibration in an object to improve stability and performance.

- Dew Point

- The temperature at which air becomes saturated with moisture and condensation begins to form, indicating maximum water vapor capacity.

- Dry Room

- An environmental chamber designed to maintain humidity levels below a 14°F (-10°C) dew point, providing controlled low-moisture conditions for sensitive materials and products.

- Environment

- The sum of internal and external conditions—such as temperature, humidity, electricity, and precipitation—that impact a product’s performance and durability.

- Environmental Stress Screening

- A testing method that determines how an object or system responds to thermal changes, ensuring it functions effectively under varying environmental conditions.

- Frequency

- The rate at which a wave oscillates, measured in cycles per second (hertz, Hz). Frequency analysis is critical in vibration testing and mechanical stability assessments.

- Highly Accelerated Life Test (HALT)

- A reliability test that subjects products to extreme conditions to reduce development time and improve confidence in long-term performance.

- Highly Accelerated Stress Test (HAST)

- A testing procedure that exposes products to high temperature, humidity, and pressure to evaluate reliability. Also referred to as the Autoclave Test or Pressure Cooker Test (PCT), HAST simulates harsh environments for accelerated aging.

- Hermetic

- A completely airtight seal that prevents external contaminants from affecting an object’s internal environment, commonly used in sensitive electronic and aerospace applications.

- Life Cycle Testing

- A process in which a product is exposed to stresses comparable to its expected real-world conditions to determine its longevity and durability.

- Liquid-To-Liquid Thermal Shock

- A testing method that subjects a product to alternating immersion in hot and cold liquids, inducing rapid temperature fluctuations that assess material integrity.

- Product Recovery Time

- The time it takes for a product to return to its normal operating state after undergoing testing. Recovery time varies depending on sensor placement within the test load.

- Psi (Pounds Per Square Inch)

- A unit of pressure measurement that indicates the force exerted per square inch of surface area.

- Relative Humidity

- The percentage of water vapor present in a given unit of air compared to the maximum amount the air can hold at a specific temperature.

- Relative Vibration

- The measurement of an object’s vibration relative to a fixed point on the object itself, useful in assessing internal movement and stability.

- Remote Conditioners

- Devices that deliver temperature-controlled air to non-accessible, hard-to-reach, or oversized test subjects. These conditioners enable flexibility in temperature testing across a variety of industries.

- Saturation Humidity

- The maximum amount of water vapor that a given unit of air can retain at a specific temperature. When relative humidity reaches 100%, the air is fully saturated.

- Stress

- Any external force or condition that may negatively impact an object’s performance, structural integrity, or longevity.

- Temperature/Humidity/Bias (THB) Test

- A product reliability test that exposes an object to high humidity levels at a constant temperature over extended periods. This test exceeds the duration of standard HAST testing.

- Thermal Cycling

- A testing procedure in which an object is subjected to extreme temperature changes within a single chamber, simulating real-world environmental fluctuations.

- Thermal Shock

- A condition in which rapid temperature changes induce stress on an object, potentially leading to cracks, fractures, or material failure.

- Three-Zone Thermal Shock

- A specialized thermal shock test in which an object is transferred between hot and cold chambers with an intermediate step at room temperature. This simulates more gradual environmental transitions.

- Transfer Time

- The duration required to move a test subject from one chamber to another, a crucial factor in thermal shock and environmental transition tests.

- Upstream Recovery Time

- Also referred to as downstream recovery time, this measures how long it takes for air temperature in a test chamber to stabilize after transferring an object between environmental zones. Measurements are taken either before or after the test load to ensure consistency.

- Vibration

- The oscillatory motion of an object around an equilibrium point, which can impact product durability and functionality. Vibration testing assesses resistance to shaking, bumping, and other mechanical stresses.