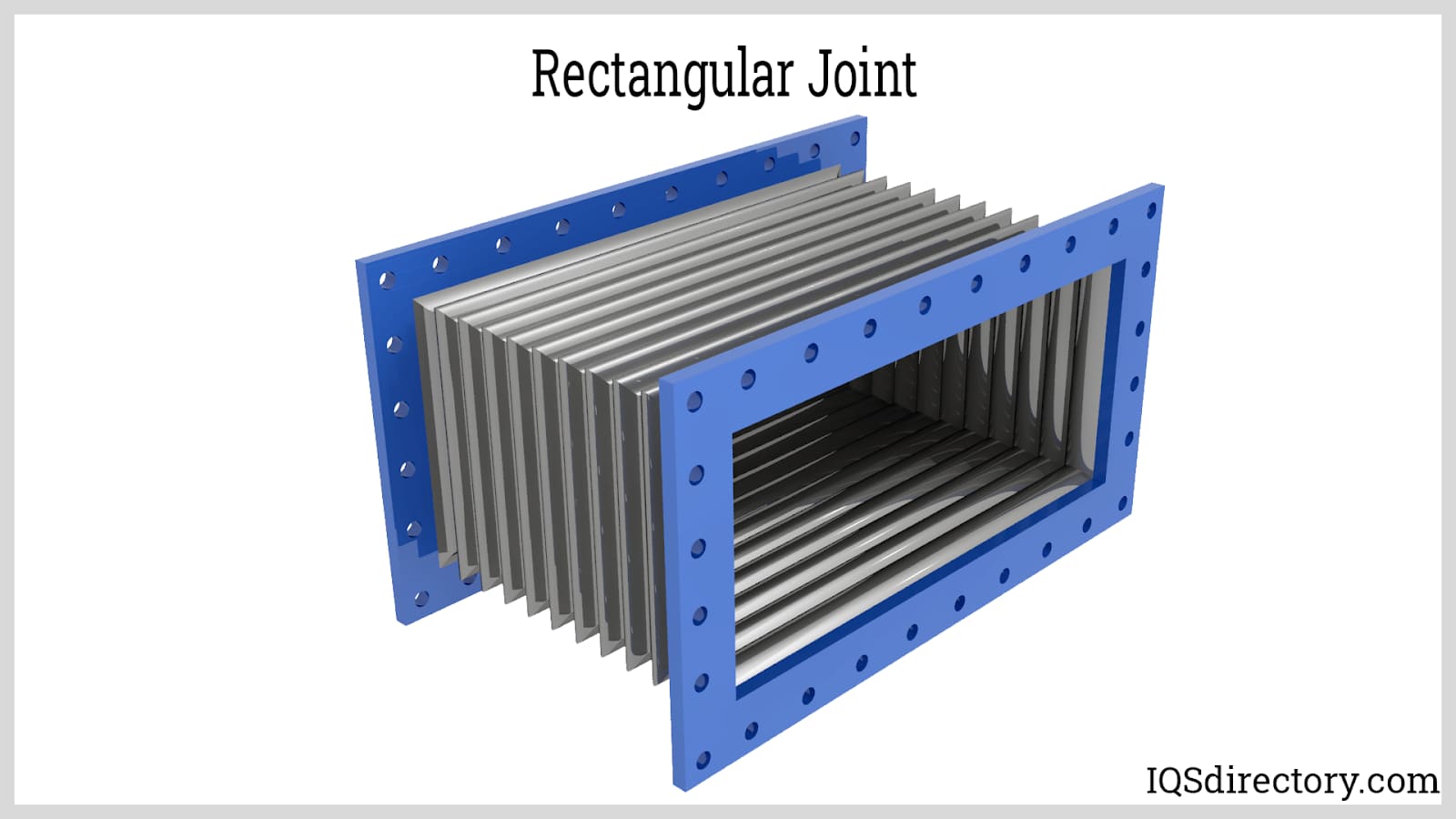

Expansion Joints

Expansion joints are specifically designed to allow for movement, as their name implies. These components help absorb the movement of pipes, ducts, and other pipeline parts caused by thermal and mechanical vibrations. In industrial applications, expansion devices come in various forms. Thermal expansion and contraction cause changes in the length of piping systems as they heat up and cool down. The amount of thermal expansion that occurs depends on several factors, including the length of the piping run, the temperature difference, and the pipe's material. For example, a 100-foot (30.5 m) run of carbon steel pipe will expand by 1.82 inches (4.6 cm) when its temperature rises from 70 to 300 °F (21 to 148.9 °C). In contrast, if the same pipe were made of 300-class stainless steel, it would expand by 2.61 inches (6.6 cm). Various techniques have been developed to accommodate these thermal movements, as expansion and contraction can subject the piping system to considerable strain.

How Expansion Joints Work

Metal expansion joints are used to accommodate thermal expansion and relative movement in pipes, containers, and machinery. Depending on the specific application, they may feature one or more metal bellows, connectors at both ends, and tie rods. Bellows are flexible components designed to reduce motion in the piping system. They are typically made from a combination of rubber and metals, which allow them to stretch during expansion and compress during contraction. As the temperature of the pipe increases, metal expansion joints contract to absorb the movement and relieve pressure on the pipe. Materials such as stainless steel and nickel alloys are commonly used to create metallic bellows.

Materials Used for Expansion Joints

Metal Joints

Metal expansion joints are essential in applications with significant thermal expansion. As the temperature of the pipe increases, the metal expansion joint contracts to absorb the movement, relieving pressure on the anchors and the pipe itself.

Rubber Joints

Rubber is highly effective at absorbing vibrations and shock waves, making it ideal for handling thermal expansion. These expansion joints are particularly useful for reducing the transfer of noise and vibration from other equipment, providing protection for sensitive components like pumps. Additionally, they serve as shock absorbers, mitigating damage caused by pressure surges or seismic activity.

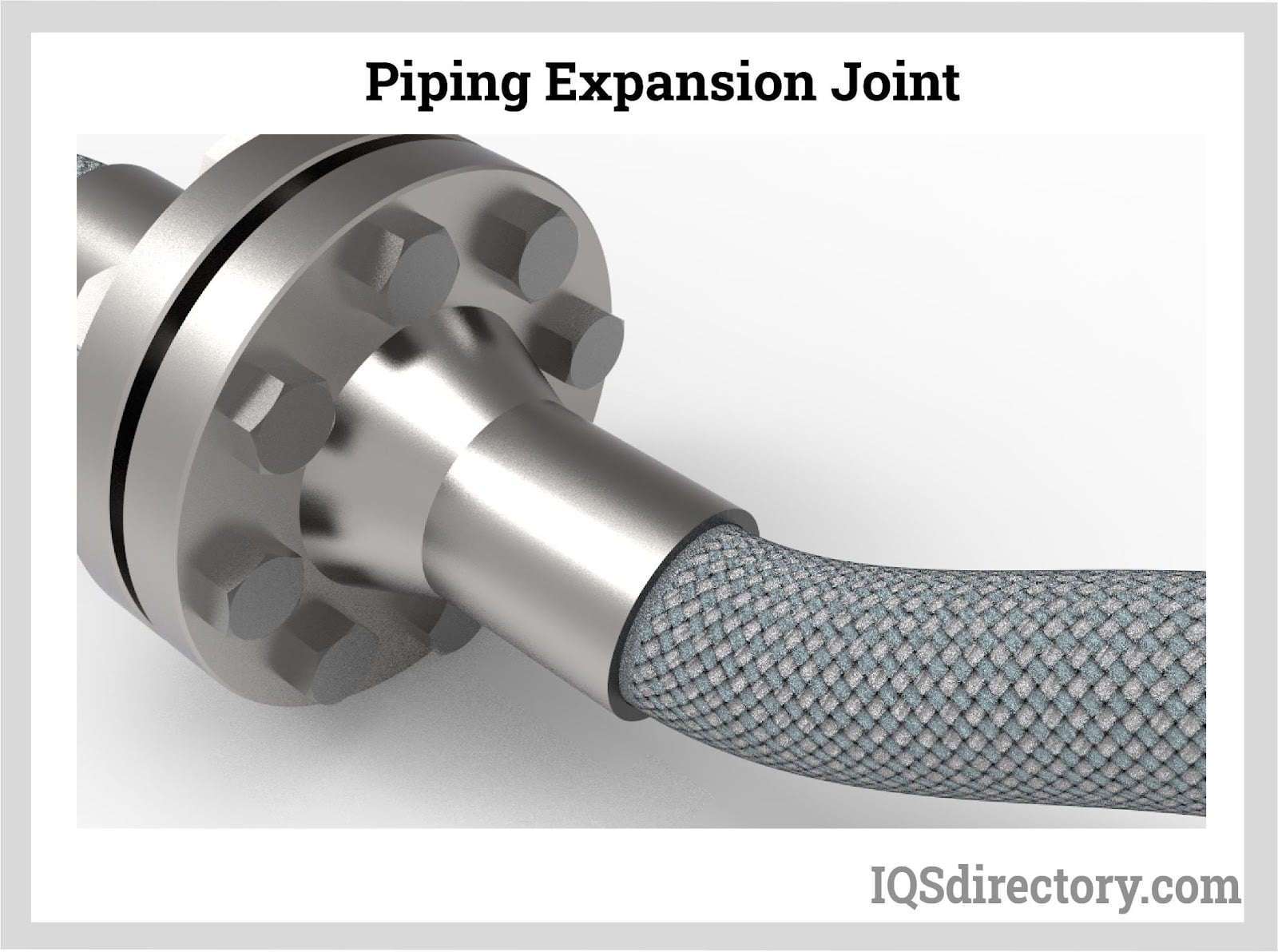

Stainless Steel Braided Joints

While technically more like flexible connectors than expansion joints, stainless steel braided hoses with flexible or metal liners excel in applications where pipe misalignments or vibration dampening are needed, particularly in high-pressure and high-temperature environments.

How Expansion Joints Work

Bellow to Tube Construction

The creation of metal bellows begins with the production of corrugated tubes. Precision shearing is used to cut coil or sheet stock to the required size, which is then coiled into tubes. It's essential that the tubes maintain a round shape to ensure they fit properly over the dies used in the bellows formation process. Once shaped, the tube's longitudinal seam is joined using an automatic seam welder. This technique is integral to producing the bellows.

Forming Method

The two most common methods for corrugating tubes are mechanical die-forming and hydroforming. In hydroforming, a pressurized liquid solution is used to shape tubes or sheet metal into bellows. For example, a hollow aluminum tube is placed into a negative mold designed to shape the bellows. High-pressure hydraulic pumps then force the fluid into the tube, causing it to expand and fit the mold. Once the aluminum tube is fully expanded, it is removed from the mold. The machine is calibrated to create the desired bellows corrugation diameter, and the overall joint is formed as the other components of the joint are developed.

Re-Rolling Method

In the re-rolling secondary process, the shape of the metal bellows is finished and cold worked to meet the precise geometry defined by the design engineer. Cold working involves plastic deformation of the material below its recrystallization temperature. This strengthens the bellows and ensures tight dimensional control. However, some expansion joint manufacturers skip this crucial step and use a press to compress the bellows to size, which can ultimately reduce the performance of the bellows.

Welding Method

The tubes are joined at the neck of the bellows using a continuous series of overlapping spot welds for multi-ply bellows. This technique, known as roll seam welding, involves first constructing the bellows and then welding them to the other parts of the connection.

Benefits of Expansion Joints

Plumbing systems rely on bellows and expansion joints, which are equipped with accessories such as tie rods, covers, and flow liners. Metal bellows function like springs, although they are designed to manage pressure within set limits. To ensure optimal flow, it is crucial for the connecting pipes to be able to move.

Without expansion joints in the piping system, the thermal expansion of the pipes would lead to significant strain. This pressure could cause pipes to flex and welds to break due to the forces generated by thermal expansion.

Choosing the Correct Expansion Joint Supplier

To achieve the best results when purchasing expansion joints, it’s essential to compare multiple suppliers using our directory of expansion joint providers. Each supplier has a dedicated business profile page that showcases their expertise, capabilities, and a contact form for direct communication to request more details or a quote. Utilize our patented website previewer to quickly explore each supplier's specialization, then easily contact several companies with our streamlined RFQ form.