Fractional Horsepower Motors

A fractional horsepower motor (FHP motor) is a compact electric motor whose power output is measured as a portion of one horsepower. These motors are typically mounted on frames, and while there’s no formal standard that defines a minimum size, most are large enough that they wouldn't fit in a pocket. Nearly all fractional horsepower motors have power ratings under one horsepower; motors exceeding that threshold are classified as integral horsepower motors, with their output rated in whole-number multiples of one horsepower. Interestingly, motors built on frame sizes 42, 48, and 56 are still regarded as fractional horsepower motors, even if their power surpasses one horsepower.

Fractional horsepower motors are widely used across residential, commercial, and industrial applications. They generally fall into two categories. Standard fractional horsepower motors, producing more than 1/20 horsepower, are found in common appliances and equipment such as kitchen tools, grocery store conveyors

, and vacuum cleaners. Those producing 1/20 horsepower or less are known as sub-fractional horsepower motors or micro motors. These smaller variants are typically used in compact consumer products like electric toothbrushes and toys.

In some cases, the term “fractional horsepower motor” is also applied to small internal combustion engines, even though they are not electric.

The History of Fractional Horsepower Motors

The earliest commercially significant example of a fractional horsepower motor dates back to Nikola Tesla’s 1888 U.S. patent for the induction motor. However, these motors remained relatively rare until around 1915, when electrical utility services began reaching major urban centers. As electrification expanded, the emerging fractional horsepower motor industry began to grow to meet the rising demand for consumer appliances like washing machines. By 1920, more than half a million fractional horsepower motors were already in operation across the United States.

As these motors gained popularity, they helped reshape the landscape of powered woodworking. Machines such as band saws, circular saws, and drill presses became smaller, more affordable, and far more portable. This transformation made the production of furniture and wooden structures significantly less expensive and labor-intensive. Fractional horsepower motors played a key role in accelerating the momentum of the Industrial Revolution, which had already been underway since the early 19th century. Assembly lines

operated faster with fewer workers, and machines of all sizes became more widely available, more affordable, and of higher quality.

Following World War II, demand for fractional horsepower motors surged as electrically powered devices became increasingly common in American households and workplaces. That demand has continued to rise steadily ever since. Today, fractional horsepower motors are found virtually everywhere—from automobiles and home appliances to compact machinery. By 2017, the European market alone was estimated to account for roughly 300 million motors, representing a value of $4.5 billion USD.

Fractional Horsepower Motors Images, Diagrams and Visual Concepts

A fractional horsepower motor is an AC or DC current motor that produces less than one horsepower at an output rating of 746 watts or less.

A fractional horsepower motor is an AC or DC current motor that produces less than one horsepower at an output rating of 746 watts or less.

Fractional horsepower motors have an output power of 746 watts or less with a size of less than 104 mm2.

Fractional horsepower motors have an output power of 746 watts or less with a size of less than 104 mm2.

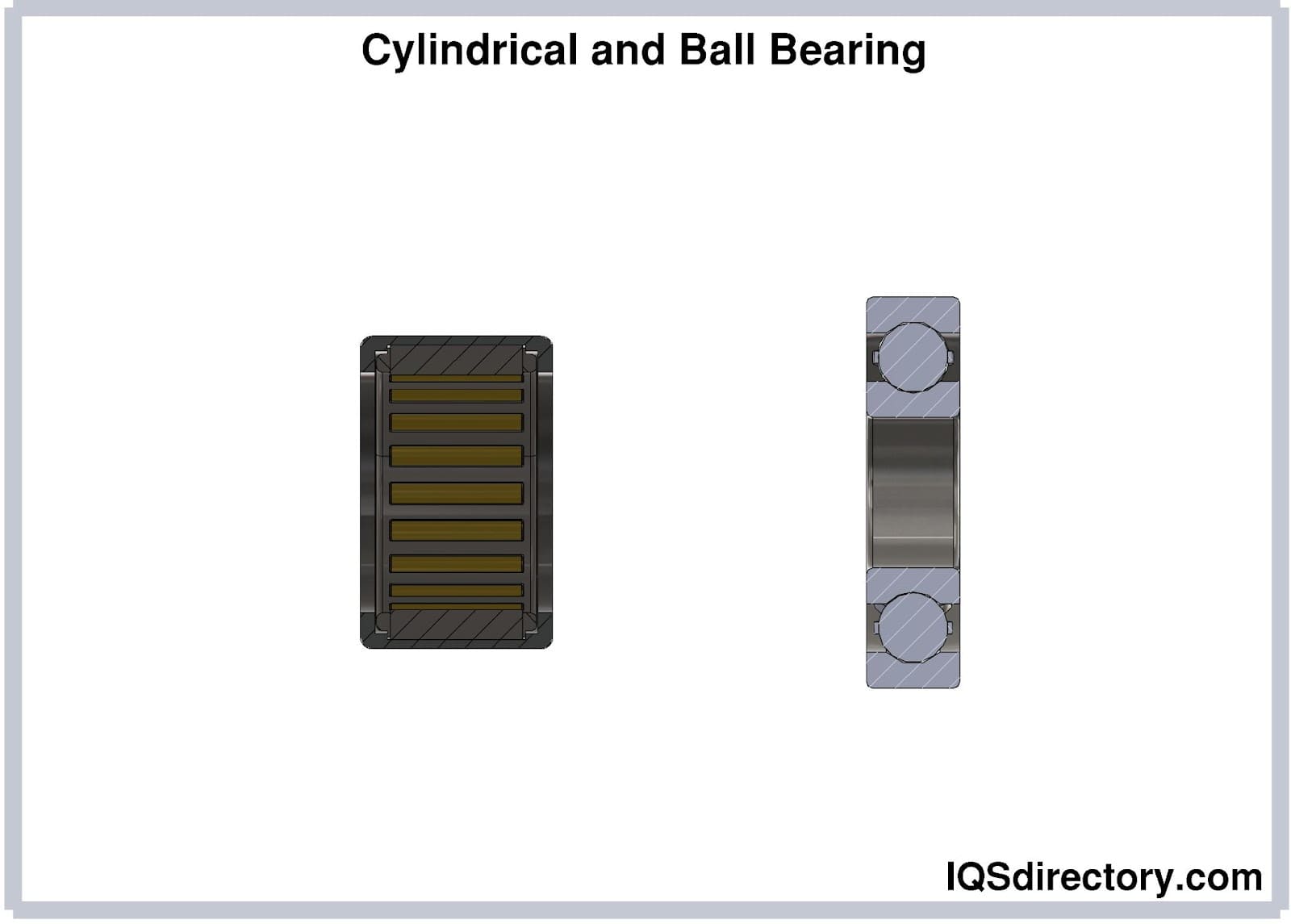

Bearings are an essential part of electric motors for reducing friction and wear.

Bearings are an essential part of electric motors for reducing friction and wear.

The power supply for fractional horsepower motors can be AC or DC, with AC being single or three phase.

The power supply for fractional horsepower motors can be AC or DC, with AC being single or three phase.

Types of Fractional Horsepower Motors

There are numerous types of fractional horsepower motors, yet all electric motors share a common set of core components: a rotor, coil, field magnet, axle, and enclosure. Most also include a stator, which may be integrated into the enclosure itself. As a general rule, the rotor is the moving part that rotates, while the stator remains stationary. In some motors, internal brushes are included to deliver precisely timed electrical currents to specific parts when power is needed. Brushless DC motors, which eliminate the need for these brushes, typically come at a higher cost because they require an external power supply to function.

Field magnets are central to how all electric motors operate. Some motors use permanent magnets, while others—known as induction motors—rely entirely on electromagnets. When current flows through the coil, the resulting magnetic field either attracts or repels components within the motor, creating rotational force. This force acts on the rotor and is transferred to the axle, producing motion.

½ HP Motor

Fractional horsepower motors rated at ½ HP produce approximately 373 watts of power output, making them a common size for light-duty applications.

¼ HP Motors

These motors also fall within the fractional horsepower category, delivering less than one horsepower—or under 746 watts—when converting electrical energy into mechanical power.

AC Motors (Alternating Current)

These can be either induction or synchronous motors, operating with a current that alternates direction. They typically run on standard electric power sources.

DC Motors (Direct Current)

DC motors operate with a unidirectional flow of current and are often prized for their variable speed capabilities. Like AC motors, they convert electric power into motion.

Electric Motors

A general term describing any device that converts electrical energy into mechanical movement through magnetic interaction.

FHP Motors

An abbreviation for fractional horsepower motors—typically enclosed in a frame and defined by their output of less than one horsepower.

Gearmotors

These are motors combined with gearheads, which reduce the motor's output speed to a specific RPM while increasing torque.

Induction Motors

Induction motors work by modulating current in the stator coil, generating a rotating magnetic field that exerts force on the rotor. The magnetic field typically rotates at a speed slightly below synchronous speed. While three-phase induction motors dominate industrial use, single-phase induction motors are extremely popular in fractional horsepower applications because they are affordable, durable, and easy to maintain.

Integral-Horsepower Shunt Motors

These motors are used in applications where constant speed is required across varying loads. They deliver consistent performance under full to no load conditions.

Miniature Motors

Also known as micro motors or small motors, these are compact fractional horsepower motors designed to meet both power output and physical size constraints—often only a few inches in dimension.

Multi-Speed Motors

Available in two, three, or four-speed models, these motors are wired in ways that allow users to change operating speed by adjusting connections at the starter.

NEMA Motors

Motors designed to meet standards set by the National Electrical Manufacturers Association (NEMA), ensuring compatibility and consistency across industrial applications.

Permanent Magnet Motors

These motors feature permanent magnets embedded in the rotor. The magnetic field aligns precisely with the rotating field of the stator, eliminating slip and enhancing torque efficiency. Permanent magnet motors are more energy efficient and powerful than similarly sized induction motors and can deliver high torque across a wide speed range—including low speeds. However, they are often more expensive due to the use of rare earth magnets in their construction. They also run at synchronous speed, meaning their rotor turns in perfect sync with the power source frequency.

Reversible Motors

Both AC and DC motors can be reversible. DC motors typically reverse direction by switching the polarity of the magnetic field. For AC motors, reversing is achieved either by altering the phase connections in a three-phase setup or by switching lead wires in single-phase models.

Small Electric Motors

Motors that generate less than one horsepower of power output fall into this category, making them a staple in countless low-power applications.

Small Motors

These motors use only a fraction of one horsepower—defined as 745.7 watts—to operate, placing them firmly within the fractional horsepower category.

Synchronous Motors

Synchronous motors maintain a constant speed from startup through full load. They are often used when precise speed control is critical, as the rotor speed is equal to the rotating magnetic field speed.

Universal Electric Motors

These versatile motors can operate on both AC and DC power sources, making them ideal for devices where flexibility is required.

Universal Motors

Similar to universal electric motors, these operate interchangeably on alternating or direct current and are often found in portable power tools and household appliances.

Variable Speed Motors

These motors offer adjustable rotational speeds and are commonly used in HVAC systems and other applications that require adaptable performance.

Variable Torque Motors

A subset of multi-speed motors, these are specifically designed for systems where both speed and torque requirements vary, such as pumps and blowers.

Uses of Fractional Horsepower Motors

Fractional horsepower motors are widely used across both industrial settings and everyday consumer devices. Their versatility allows them to serve an extraordinarily broad range of sectors, extending from agriculture to HVAC systems. These compact motors support thousands of applications, including powering cooling fans, electric drills, meat slicers, and electric shavers.

The global automotive industry alone accounts for more than one-third of all fractional horsepower motors sold. While these motors are typically used in secondary systems rather than main propulsion, they play critical roles in functions such as engine starters, door openers, air conditioning units, and power-adjustable seating.

Over 10% of all fractional horsepower motors are employed in household appliances. They’re found in devices like microwave turntables, blenders, mixers, refrigerators, washing machines, dryers, and automated garage door systems—enabling consistent, efficient operation in day-to-day tasks.

In addition, significant numbers of these motors are built into electric tools, office equipment, and medical devices, as well as in heating and cooling units. Industries across the board rely on fractional horsepower motors for material handling and processing applications, underscoring their value in both precision-driven and high-volume environments.

Choosing a Fractional Horsepower Motor

With few exceptions, fractional horsepower motors that share the same specifications are interchangeable. If a motor from one manufacturer is removed, a similar motor from a different manufacturer can usually be installed in its place without affecting performance or operating characteristics.

Replacing a Motor

When replacing a fractional horsepower motor, it’s essential that the new motor matches the correct specifications. The most straightforward way to ensure compatibility is by copying the information from the nameplate of the old, damaged, or worn-out motor. However, when a motor fails without a known cause, it’s wise to reevaluate whether the original motor was appropriate for the application. If it was undersized or not built to withstand the operating conditions, then a more suitable motor type should be selected. Special or custom motors—often marked accordingly—should generally be replaced with exact duplicates to preserve function and safety.

While there is a wide variety of fractional horsepower motors on the market, most general-purpose motors can be evaluated by examining a few key dimensions: power supply, motor type, power characteristics, enclosure, bearings, direction of rotation, mount, and thermal protection. Each of these factors must be assessed carefully before choosing a replacement motor.

Power Supply

Fractional horsepower motors may run on alternating current (AC) or direct current (DC). AC motors are commonly either single-phase or three-phase. Although single-phase motors are most prevalent in fractional horsepower applications, a three-phase motor cannot operate on a single-phase supply. Regional power standards also vary: motors designed for the U.S. market typically require 60 Hz, while those intended for European or Asian markets usually operate at 50 Hz. Voltage compatibility is critical for both AC and DC motors, and must align with the intended power source.

Motors with continuously variable speed require controllers to regulate the electrical current. These controllers must be matched not only to the motor type but also to the available power supply. They function by intermittently powering different poles of the motor, altering power levels, or modulating the AC frequency. Motors such as stepper or servo models

come with their own specific power and timing requirements, all of which must be met to ensure proper operation.

Power Characteristics

Motors are defined by three primary characteristics: horsepower, torque, and speed. Horsepower represents the rate of work over time. Torque describes the angular force a motor can exert, and speed measures the rate of rotation. These three variables are interrelated—multiplying torque by speed gives a value proportional to horsepower. Gear mechanisms can trade off speed for torque and vice versa. A motor’s horsepower should be adequate for its intended workload, but oversizing unnecessarily increases cost and energy consumption. In scenarios demanding high torque or low speed, gearmotors may offer an optimal solution.

Motor Class

The internal construction of fractional horsepower motors varies widely. Some include brushes; others are brushless

. Some require large capacitors for startup, while others ramp up torque gradually as they accelerate. Motor classes differ in reversibility, speed variability, and winding configuration. Certain motors have multiple windings for startup and running conditions, while others operate with just one. In most cases, selecting the appropriate motor comes down to matching the startup current and torque requirements to the application.

Motor Enclosure

Enclosures must be appropriately sized and compatible with the equipment they’re powering. They also serve to protect the motor from environmental factors. For use in marine or corrosive environments—such as chemical processing plants—fully sealed enclosures may be necessary. For outdoor use, drip-proof housings often suffice to shield motors from weather exposure.

Bearings

The choice of bearing depends on how the motor will be used. Sleeve bearings are common for standard applications, while ball bearings are preferred when the motor must handle heavy axial loads. Needle bearings are ideal for high-speed applications. If a motor is to be mounted vertically, the bearings must be rated for vertical operation to ensure longevity and stability.

Motor Rotation

The motor’s direction of rotation must be suitable for its application. Some motors can reverse direction by switching the polarity of the power supply, but not all are designed to do so. Most motors indicate their rotation direction on the end opposite the output shaft, using CW (clockwise) or CCW (counterclockwise) markings. Notably, pump motors may reverse these notations, so care must be taken when interpreting them.

Motor Mount

Mounting compatibility is essential. The replacement motor must be equipped with mounting features that correspond to the supports or equipment to which it will be attached.

- Thermal Protection

Many fractional horsepower motors include thermal protection to prevent damage from overheating. This feature allows a motor to shut off once a specified temperature threshold is reached. There are two main types of thermal protection switches. Automatic reset switches allow the motor to resume operation once it cools down. Manual reset switches, by contrast, require a human operator to press a button or toggle a switch to restart the motor. While automatic reset is suitable for non-critical systems like fans, manual reset is essential for applications where unintended restart could be dangerous, such as power tools like circular saws. Safety must always guide the decision between reset types.

Standards and Specifications for Fractional Horsepower Motors

A number of standards apply to fractional horsepower motors. In the United States, these motors are built using frame sizes established by NEMA, the National Electrical Manufacturers Association. While they adhere to structural standards, fractional horsepower motors are generally exempt from the energy efficiency regulations that govern larger motors, such as those set forth by the U.S. Energy Policy Act of 2005 and the EN 60043-30:2009 directive issued by the European Commission. However, in many operational settings, fractional horsepower motors must comply with radio interference standards. This means they are required to both tolerate a certain level of external radio interference and operate without generating excessive electromagnetic disruption themselves.

Choosing a Fractional Horsepower Motor Manufacturer

Several factors should be taken into account when selecting a manufacturer to fulfill your fractional horsepower motor requirements. A reliable manufacturer will deliver a high-quality product designed to perform effectively for at least five years of use. Just as importantly, the right manufacturer will offer long-term support and provide replacement parts or service not just in the immediate weeks following purchase, but many years—potentially even decades—down the line.

Fractional Horsepower Motors Terms

-

Actuator

A device that produces mechanical motion by converting various forms of energy into either rotational or linear mechanical energy.

Coil (Stator or Armature)

Electrical conductors placed within the core slots and insulated from the iron core. As current flows through these conductors, they generate and transmit the motor’s magnetic field.

Commutator

A cylindrical component mounted on the armature shaft, composed of copper segments arranged around the shaft. It serves as the contact surface for the motor brushes.

Constant H.P.

A term used for motors that operate at variable speeds but maintain the same horsepower output regardless of those speed changes.

Core

The section of both the stator and rotor, typically made from cylindrical laminated electrical steel, which forms the magnetic circuit of the motor.

Cycles Per Second (HERTZ)

A measurement representing one complete reversal of alternating current within one second.

Duty Cycle

The ratio of a motor’s operating time to its rest time, determined by the motor's ability to manage its normal operating temperature.

Efficiency

A comparison of the motor’s mechanical output to its electrical input, indicating how effectively it converts electrical energy into mechanical energy.

Enclosures

The motor's frame or housing, which may be open or closed, designed to protect internal components and sometimes to aid in cooling.

Endshield

A structural part of the motor housing that supports the bearings and acts as a guard for internal electrical and rotating elements. Also referred to as an "end bracket" or "end bell."

Horsepower (HP)

A unit of power that represents work done over time. One horsepower equals 33,000 foot-pounds per minute or approximately 746 watts. Motors used in pumping systems often have horsepower ratings.

Jackscrew

An adjustable screw mechanism used to position and secure a motor on its base or mounting frame.

Load

The amount of resistance or demand placed on a motor by the machine or system it is driving, representing the power required to overcome that resistance.

Motor

A device that converts electrical energy into mechanical energy to drive a rotating shaft.

Rotor

The rotating part of an induction motor, made from stacked laminations, that turns inside the stator.

Shaft

The rotating element that extends from the motor through the bearings and connects to the driven machinery.

Skew

The angled arrangement of laminations on a rotor or armature. This design helps eliminate low-speed cogging effects and reduces vibration in the rotor.

Stator

In an AC induction motor, the stationary component made of laminated steel with a central opening for the rotor. It contains slots for windings that generate the rotating magnetic field.

Thermocouple

A temperature-sensing device made of two dissimilar metals joined together, which produce a voltage signal that varies with temperature.