Friction Materials

Friction is defined as the resistance to relative motion that acts in opposition to the direction of an object’s movement. It arises from the contact between one solid body and a differing or uneven surface.

Friction materials are engineered substances specifically designed to utilize this resistance, enabling the slowing or complete stopping of an object or machine through controlled application of friction.

The History of Friction Materials

Friction is a natural phenomenon, and since the time of the ancient Greeks, people have been striving either to harness it or overcome it. Early thinkers such as Aristotle, Pliny the Elder, and Vitruvius explored both the causes of friction and ways to mitigate its effects.

The foundational principles of sliding friction were first identified by Leonardo da Vinci in 1493, though his observations remained unpublished during his lifetime. It wasn’t until 206 years later that Guillaume Amontons rediscovered these ideas, which became known as Amontons’ three laws of dry friction. As scientific inquiry progressed, researchers expanded upon these early insights. Key developments included the distinction between static and kinetic friction, uncovered by later investigators. In 1734, John Theophilus Desaguliers introduced the concept of adhesion’s role in friction, proposing that friction is the force required to separate adhering surfaces. By 1833, Arthur Jules Morin had differentiated between sliding and rolling friction, and approximately three decades later, Osborne Reynolds formulated the equation for viscous flow. These contributions formed the classic empirical model of friction—static, kinetic, and rolling—that remains a cornerstone in engineering practice today.

Building on this knowledge, Bertha Benz, during one of the first long-distance automobile journeys in August 1888, developed brake lining and brake pads to improve vehicle safety. Early versions of manufactured brake linings were made using asbestos, a material favored for its durability and heat resistance. This continued until 1989, when the National Institutes of Health (NIH) announced the dangers of asbestos exposure, linking it to serious health risks including lung disease and cancer. In response, manufacturers began phasing out asbestos, replacing it with safer alternatives such as synthetic aramid fibers.

Today, although friction is essential across countless industries, the production of friction materials has evolved into a specialized field of its own. The modern friction materials industry is dynamic and highly competitive. Innovations like the introduction of ceramics have transformed the landscape, prompting companies to closely guard their proprietary formulas and technologies. With ongoing research and development, friction materials continue to advance, and new breakthroughs remain a constant in the marketplace.

Friction Material Design

When manufacturing friction materials, producers focus on achieving essential performance characteristics such as heat resistance, a high coefficient of friction, strong energy absorption, durability, and resistance to wear and tear. To accomplish this, they typically create materials with rough or textured surfaces, since smooth surfaces generate minimal friction and are therefore less effective. Manufacturers also tailor their designs to meet application-specific requirements like torque capacity and stopping speed. For applications where rapid stopping is critical, the selected material must be capable of generating a significant amount of friction.

Another key consideration in the design process is the type of frictional force the material is intended to produce. The most suitable material for a given task depends on the specific kind of friction at play. There are three primary types of frictional force: static, kinetic, and rolling.

Static Friction

This type of friction exists between two solid objects that are not moving relative to each other. It prevents any movement from starting. Slope or incline is an important factor in applications that rely on static friction, as it affects the threshold at which movement begins.

Kinetic Friction

Also referred to as dynamic friction, kinetic friction occurs between two objects that are moving relative to one another. In such cases, both surfaces may be in motion, or one may be sliding across a stationary surface.

Rolling Friction

This form of friction involves the use of wheels or balls. The textured surface of friction materials grips the rolling object to prevent it from slipping or sliding. For example, a car tire that spins on ice or snow illustrates low rolling friction—the tire fails to catch the surface, continuing to spin without effectively moving the vehicle forward.

By carefully selecting and engineering materials based on the type of friction required and the demands of the application, manufacturers ensure that their friction materials perform reliably across a wide range of settings.

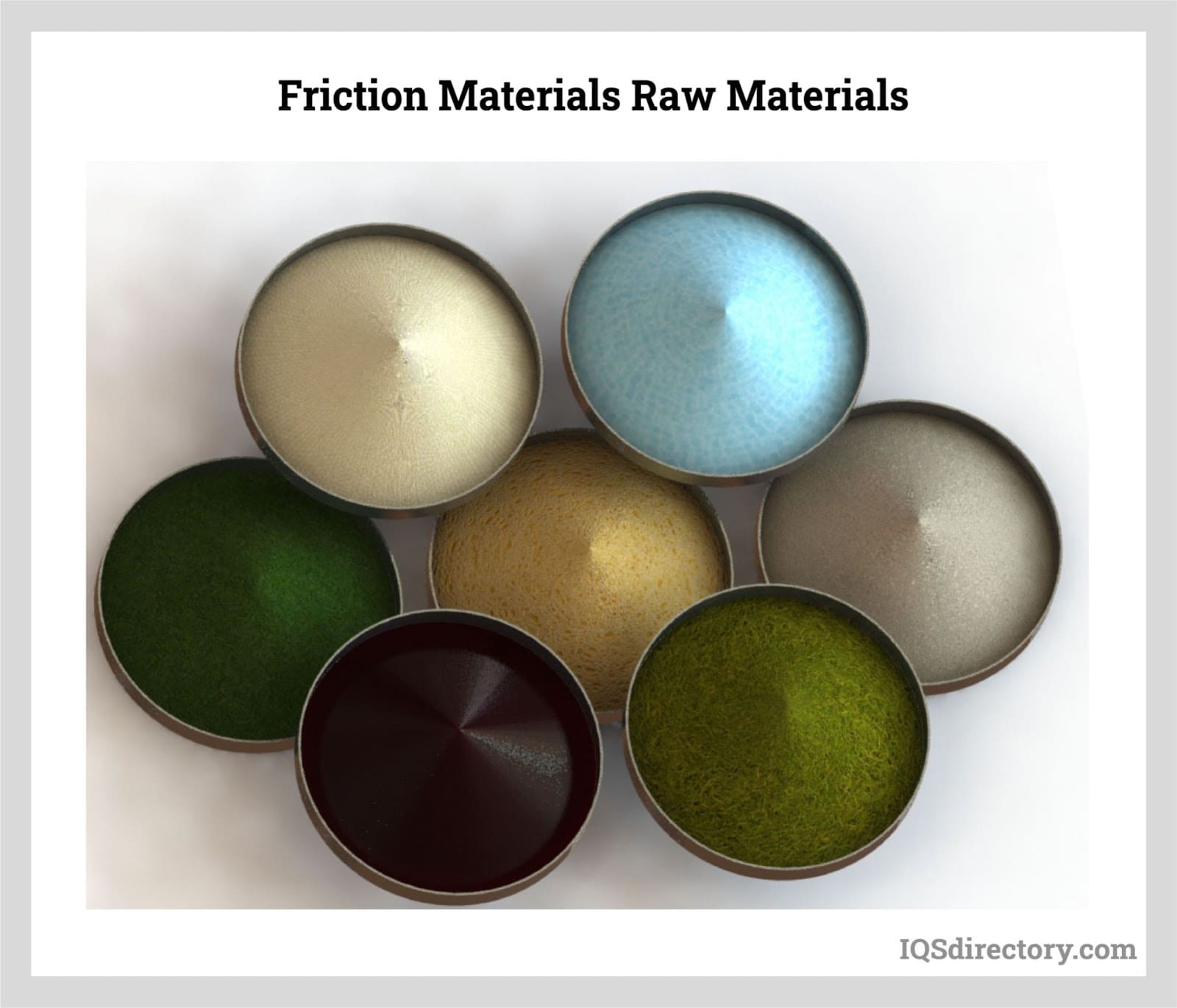

Materials Used for Friction Materials

The raw materials used in the production of friction materials span a wide spectrum, including organic compounds, ceramics, fibers, and metallic substances. Ceramic materials are typically chosen for applications involving heavy loads and high temperatures, as they can endure greater thermal energy than any other option. However, despite their heat resistance, ceramics tend to wear relatively quickly. Organic friction materials often incorporate fiberglass and similar components, especially since asbestos—once commonly used—has been identified as hazardous to human health. Aramid fibers like Kevlar are also utilized in friction material production; they offer the smooth engagement of organic materials while delivering the braking performance associated with ceramic pads.

In addition to these, high-performance metallic materials such as sintered steel and phosphate steel are also used. These metallic pads require no extra additives during production but are harsh on machinery, which is why they are generally reserved for use in performance or high-demand vehicles. Semi-metallic friction materials represent another category, combining elements like copper, brass, and steel wool bound together with resin. These composites exhibit many of the same durable qualities found in ceramic-based materials, offering a balanced alternative for a variety of applications.

Friction Material Images, Diagrams and Visual Concepts

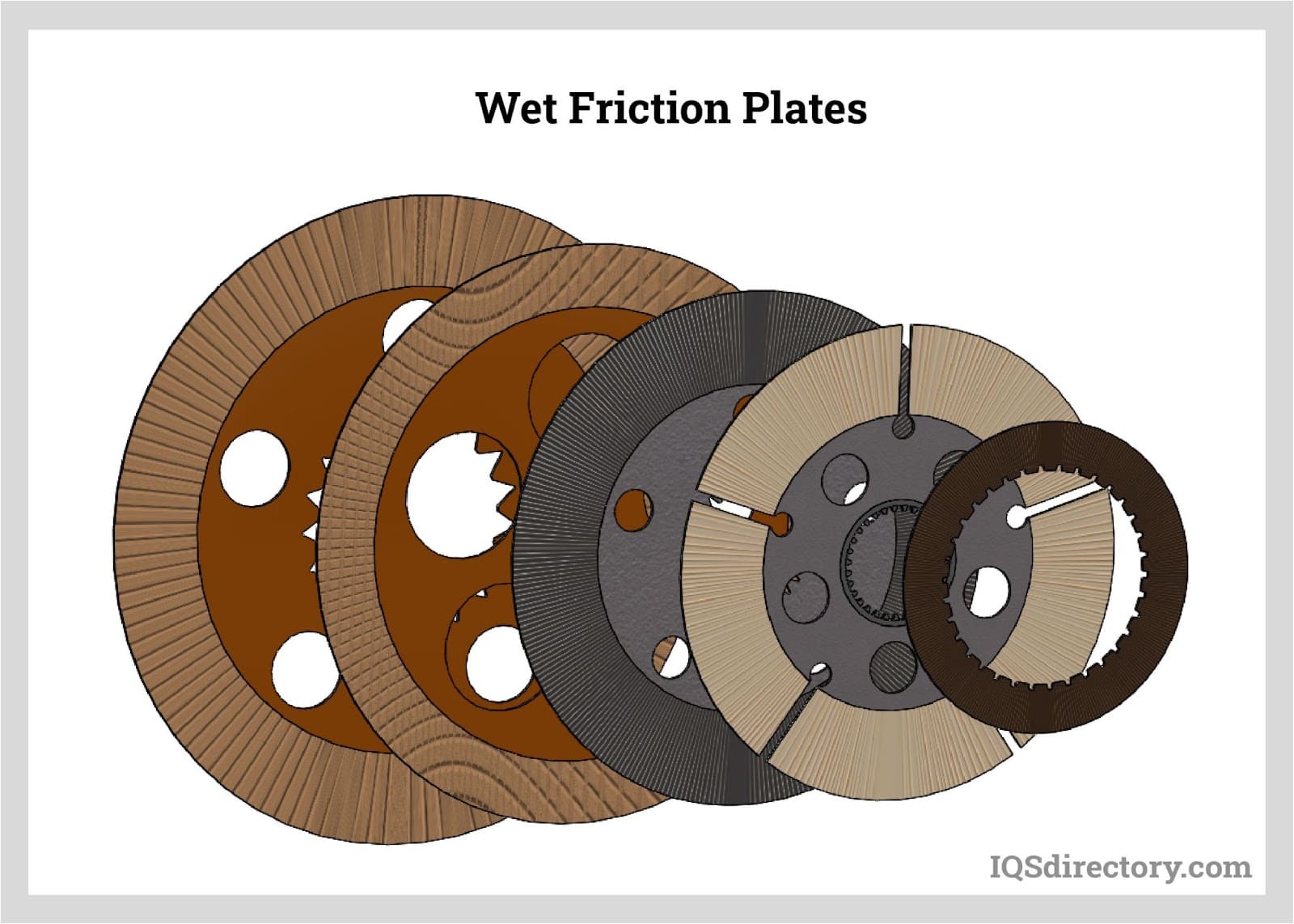

Friction materials, substances that produce friction between solid surfaces in order to control or stop forward or backward motion.

Friction materials, substances that produce friction between solid surfaces in order to control or stop forward or backward motion.

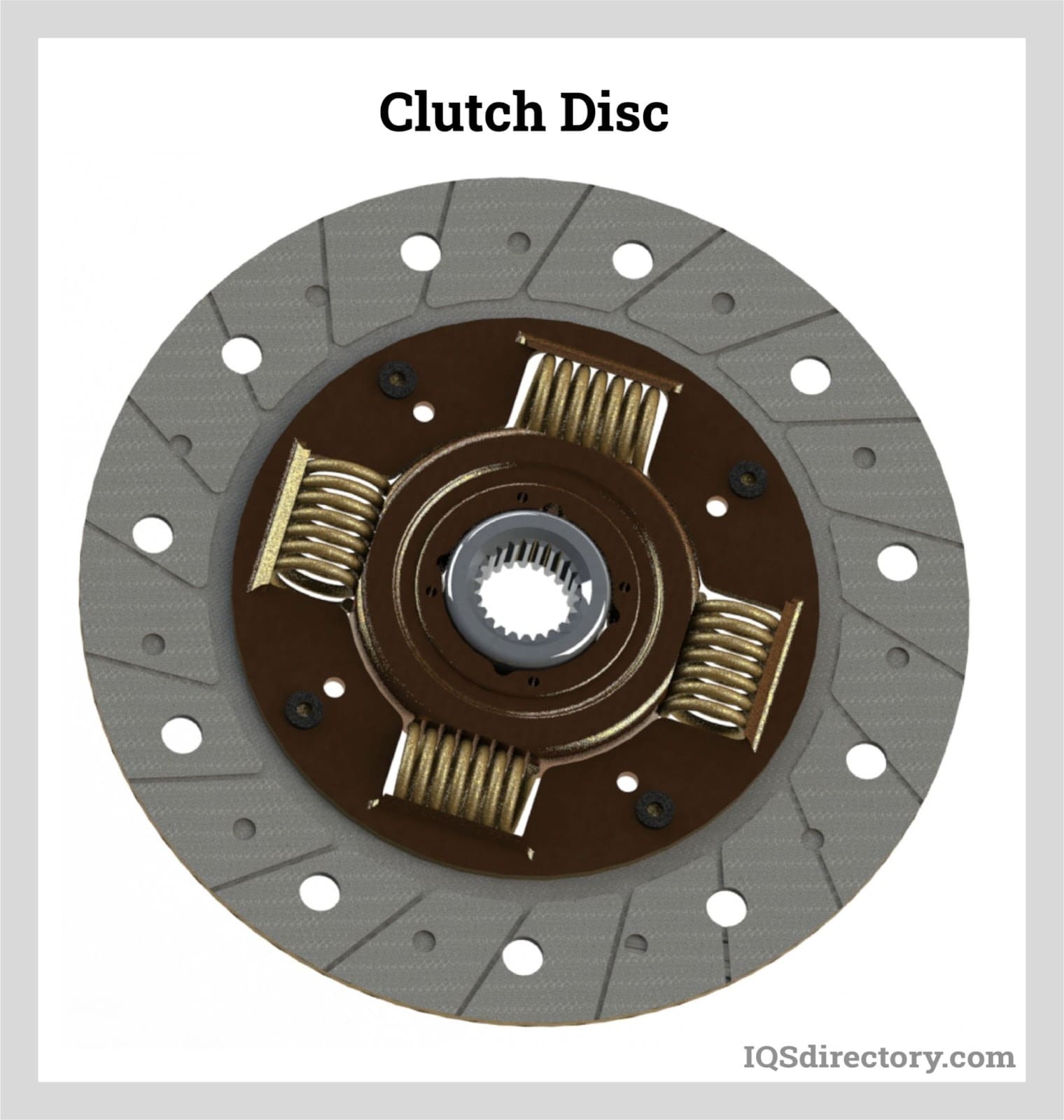

The clutch discs, or linings is attached to the shaft of the transmission and engages the engines when the clutch is released, when the clutch is disengaged, the transmission is disengaged and allows for the changing of gears.

The clutch discs, or linings is attached to the shaft of the transmission and engages the engines when the clutch is released, when the clutch is disengaged, the transmission is disengaged and allows for the changing of gears.

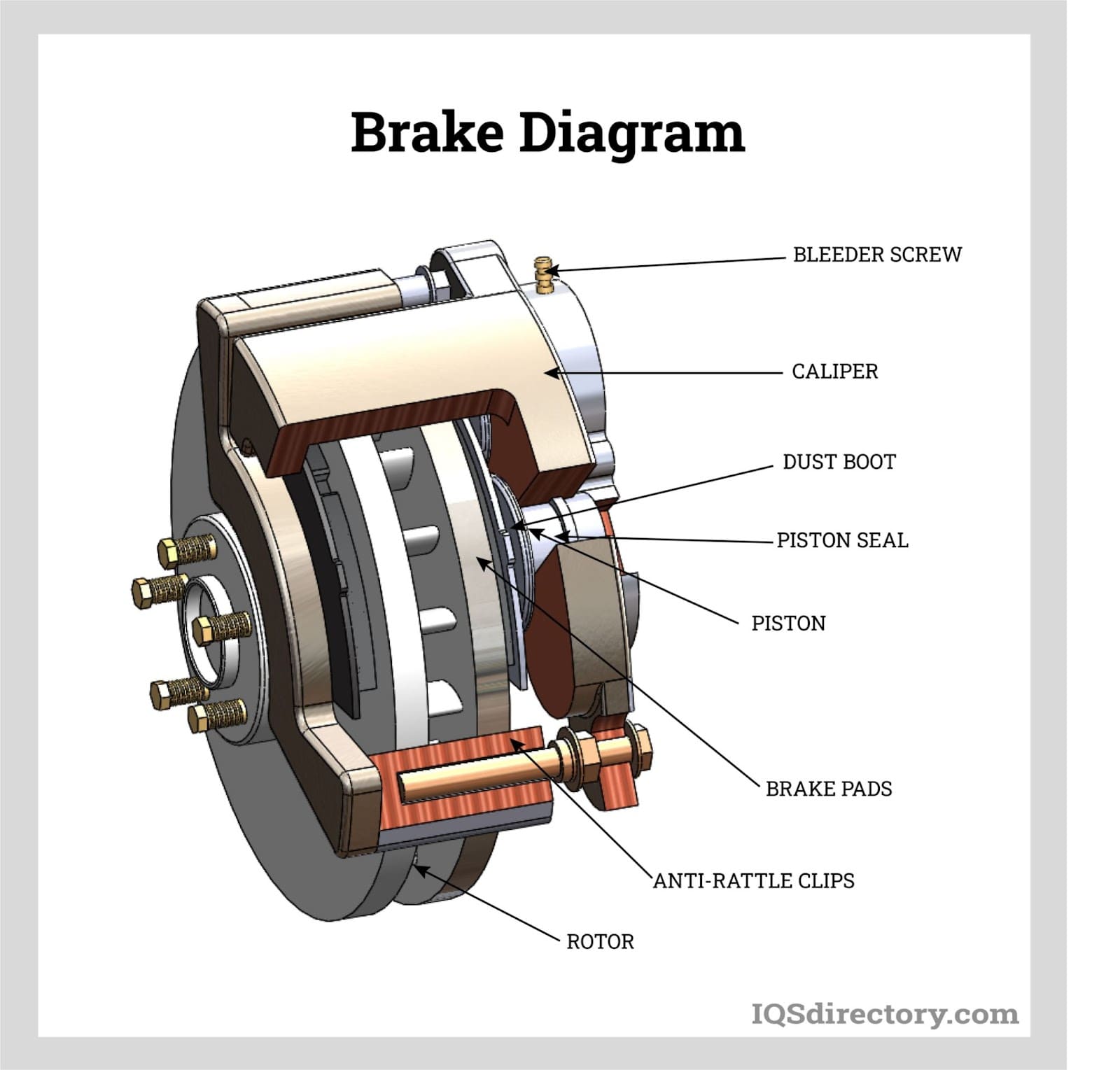

Diagram of disc brakes mainly used in vehicles.

Diagram of disc brakes mainly used in vehicles.

The three types of friction materials are organic, metallic, and inorganic.

The three types of friction materials are organic, metallic, and inorganic.

Semi-metallic friction materials are made of sintered metals and synthetic fibers, which are the longest lasting type of friction material.

Semi-metallic friction materials are made of sintered metals and synthetic fibers, which are the longest lasting type of friction material.

Friction Material Types

-

Friction Disc

Also referred to as a friction plate, this component is a metal disc bonded with friction material and used in automotive braking systems. These discs are typically made from durable metal, and because they can produce noise during operation, manufacturers often coat them with rubber or other high-friction materials to reduce sound and enhance performance.

Clutch Disc

A specific type of friction disc, the clutch disc connects a vehicle’s engine to the transmission’s input shaft. This connection enables the temporary separation needed to shift gears smoothly, playing a critical role in manual transmission systems.

Clutch Facing

Designed for systems that require a lower coefficient of friction, clutch facings help ensure smoother and more stable clutch engagement and disengagement. They also contribute to quieter system operation by minimizing noise during gear transitions.

Brake Pad

Also known as brake bands

, brake pads are essential friction components in braking systems. They slow or stop motion by pressing against the friction disc. Each brake pad features a friction surface bonded to a metal backing plate. Various types exist, including disc brake pads and ceramic brake pads

, each suited to different performance needs.

Brake Lining

A heat-resistant friction material, brake lining is a critical element in braking systems due to the intense heat generated during braking. It is used across various types of brakes, including drum brakes and disc brakes, to maintain performance under high thermal stress.

Friction Shoe / Brake Shoe

Friction shoes, often called brake shoes, are among the most recognized forms of friction materials used in braking systems. In disc brake systems, they are positioned within brake calipers and make contact with the disc to convert kinetic energy into thermal energy, effectively slowing the vehicle.

Friction Clutch Set

Every clutch system includes friction materials that enable smooth power transfer and reliable transmission performance. These sets are essential for efficient gear engagement and disengagement in mechanical systems.

Friction Column

Also known as friction blocks, these components are used in specialized applications that require controlled movement, such as in the mining and oil rigging industries. Manufacturers attach them to crane components like winches and hoists to regulate motion during heavy-duty operations.

Applications for Friction Materials

Friction materials are vital to the safe and controlled operation of virtually all types of machinery. They create resistance to slow or regulate speed and movement in a wide range of systems, including industrial equipment, automotive and industrial braking systems, and mechanical operating systems. In addition to controlling motion, they also serve as a medium for power transmission.

Given their critical role, the friction material market remains strong, with demand driven by numerous essential applications. A wide array of products depend on friction materials for proper functionality, including brake pads, clutch sets

, brake bands, brake linings, clutch facings, disc brake pads, clutch discs

, friction discs, brake shoes, and brake blocks.

These materials support operations across many industries, such as automotive manufacturing, general manufacturing, aerospace, aircraft, rail, mining, defense, oil and gas, forestry, and construction, underscoring their importance in both high-performance and heavy-duty environments.

Features of Friction Materials

Depending on the market you serve, the way friction materials function can vary slightly based on the specific application.

In braking systems, for instance, friction materials are used to slow or stop the motion of wheels and other moving components. When the brake is applied, the system engages friction material against a rotating disc, creating resistance that slows the connected tire or mechanism.

Traditional braking systems rely on friction to halt movement by converting the kinetic energy of a moving vehicle or object into heat. In contrast, regenerative braking—an innovation most commonly found in hybrid and electric vehicles—transforms that same kinetic energy into electrical energy, which can then be stored and reused. This newer approach adds an element of energy efficiency to the fundamental principles of braking.

Standards and Specifications for Friction Materials

We recommend purchasing RoHS-compliant friction materials. RoHS, or the Restriction of Hazardous Substances, is a directive established by the European Union that limits the use of certain hazardous materials in products. While compliance with RoHS is not mandatory in the United States, it is essential if your products are intended for international markets. Even beyond regulatory requirements, RoHS serves as a valuable guideline for promoting safety and environmental responsibility.

Within the United States, it’s important to ensure that your friction materials meet all applicable regulations set forth by the Environmental Protection Agency (EPA). Additionally, consult with your manufacturer about compliance with standards established by SAE International and the Friction Materials Standards Institute (FMSI) to ensure your materials meet industry-wide expectations for safety, performance, and reliability.

Things to Consider When Purchasing Friction Materials

-

Material Considerations

Given the wide range of friction material options available, it’s essential to evaluate key factors that influence both performance and longevity. Before making a purchase, ask whether the material allows for smooth engagement, whether it resists brake fade as temperatures increase, and whether it can withstand brief exposure to water. If your supplier can confidently answer “yes” to all of these questions, you can move forward knowing the material is built to last and perform reliably over time.

Manufacturer Considerations

Equally important is choosing the right manufacturer. The quality of your friction material often depends on the expertise and integrity of the company that supplies it. To find the best match, scroll to the top of this page and explore the reputable friction material manufacturers we've listed. Visit their websites to review their offerings and capabilities. Narrow your list down to three or four that seem like a strong fit, and contact each one with your specifications and questions. Pay attention not only to the quality of their responses but also to their willingness to collaborate and provide value. A dependable manufacturer won't just sell you a basic product—they’ll work with you to deliver the best possible solution, tailored to your application and budget.

Proper Care for Friction Materials

Friction materials are high-use components, and caring for them isn’t always simple—so it’s important to stay alert for any signs of wear or damage.

Because of the demanding conditions in which they operate, even the most wear-resistant friction materials will eventually degrade. When that happens, replacement is necessary. Failing to replace worn friction materials—especially in automotive applications—can lead to serious problems. If the friction surface wears down completely, the backing plate or rivets may begin grinding against the rotors or drums during braking. This can cause significant damage, requiring you to re-machine or replace those components entirely. To avoid this, pay attention to the early warning sign of brake wear: a high-pitched squealing noise. If ignored, the next indication will likely be a harsh grinding sound or vibration—signals that damage is already underway.

Another risk to brake friction materials is contamination from leaked brake fluid or oil. If you hear brake chatter, a vibration or rattling noise while braking, there’s a strong chance your pads have been contaminated. The solution is to locate and repair the source of the leak, then replace the affected brake pads. Keep in mind: both pads must always be replaced at the same time. Uneven lining thicknesses or mismatched materials can lead to uneven braking performance, which compromises safety and efficiency. Fortunately, friction materials are generally straightforward and cost-effective to replace, making regular maintenance a smart investment in long-term system reliability.

Friction materials are high-use components, and caring for them isn’t always simple—so it’s important to stay alert for any signs of wear or damage.

Because of the demanding conditions in which they operate, even the most wear-resistant friction materials will eventually degrade. When that happens, replacement is necessary. Failing to replace worn friction materials—especially in automotive applications—can lead to serious problems. If the friction surface wears down completely, the backing plate or rivets may begin grinding against the rotors or drums during braking. This can cause significant damage, requiring you to re-machine or replace those components entirely. To avoid this, pay attention to the early warning sign of brake wear: a high-pitched squealing noise. If ignored, the next indication will likely be a harsh grinding sound or vibration—signals that damage is already underway.

Another risk to brake friction materials is contamination from leaked brake fluid or oil. If you hear brake chatter, a vibration or rattling noise while braking, there’s a strong chance your pads have been contaminated. The solution is to locate and repair the source of the leak, then replace the affected brake pads. Keep in mind: both pads must always be replaced at the same time. Uneven lining thicknesses or mismatched materials can lead to uneven braking performance, which compromises safety and efficiency. Fortunately, friction materials are generally straightforward and cost-effective to replace, making regular maintenance a smart investment in long-term system reliability.

Friction Materials Terms

-

Balance

Refers to the even distribution of braking force between the front and rear brakes, ensuring stability and control during deceleration.

Bleeding

The process of removing overheated or contaminated brake fluid and air bubbles from the brake system to maintain optimal hydraulic pressure and braking efficiency.

Brake Drum

A large, circular metal housing bolted to the axle and wheel of a vehicle, resembling a jar lid. When the brakes are applied, brake shoes press against the drum's inner surface to stop wheel rotation.

Brake Lining

A heat-resistant friction material that presses against the brake disc or drum to generate the braking force necessary to reduce speed or bring a vehicle to a stop.

Brake Pad

Composed of friction material bonded to a metal backing plate, brake pads press against the rotor to slow or stop the vehicle. Due to regular wear, they require periodic replacement.

Brake Materials

A broad category of durable, heat-resistant materials used in braking systems. These materials form the basis of components such as brake pads, brake shoes, brake linings, brake bands, and brake blocks, all of which increase friction to reduce wheel speed or stop movement.

Burnish

The process of bedding in brakes to ensure stable and consistent contact between the friction material and the rotor or drum, optimizing braking performance.

Caliper

The component of the disc brake system that holds the brake pads and presses them against the rotor. It contains hydraulic pistons that activate the braking force.

Clutch

A mechanism used to engage or disengage two rotating shafts or components. When the clutch pedal is pressed, the connection is interrupted, allowing gear changes or coasting. Releasing the pedal re-engages the connection, transmitting motion through the drivetrain.

Clutch Materials

Durable, heat-resistant substances used to construct clutch systems that temporarily connect the engine to the transmission’s input shaft. These systems include parts like clutch discs, pressure plates, clutch facings, and flywheels.

Coefficient of Friction

A numerical value representing the ratio between the force required to move an object and the object’s weight. It indicates how much grip a material provides.

Disc Brake

A brake assembly consisting of a rotor, caliper, and brake pads. It is the component of the braking system responsible for physically slowing or stopping the vehicle.

Drum

A circular metal housing, similar in appearance to a jar lid, attached to a vehicle’s axle and wheel. Brake shoes are pressed against the drum’s interior to stop the wheel from rotating.

Dynamometer

A laboratory device used to evaluate the performance of brake systems under controlled conditions.

Fade

A temporary loss of braking effectiveness caused by the overheating of friction materials. This condition reduces the system’s ability to slow or stop the vehicle.

Groove Patterns

Channels designed into friction materials to help dissipate heat, remove fluids, and minimize noise during braking.

Master Cylinder

The component of a braking system that holds hydraulic fluid and houses a piston connected to the brake pedal. It transmits hydraulic pressure to the rest of the braking mechanism.

Recovery

The process by which a brake system regains full performance following a period of fade. It reflects a friction material’s ability to function effectively after thermal stress.

Rotor

Also called a disc, the rotor is a round metal component attached to the wheel. Brake pads clamp onto the rotor to create friction, slowing or stopping the vehicle.

Shoe

A curved steel component lined with friction material that presses against the inside of a brake drum when activated, creating the force needed to slow or stop the wheel.

Squeal

A high-pitched sound produced during braking, often indicating that the brake pads or linings are worn and should be inspected or replaced.