Gaskets

In industrial settings, a gasket, also known as an industrial gasket, is a mechanical seal designed to fill the space between two surfaces. Gaskets function by creating a pressure-tight barrier that prevents any leakage into or out of the sealed component. Positioned between two parts, they eliminate the risk of leaks while ensuring the efficient and reliable operation of machinery, devices, and equipment that play a crucial role in daily life.

Gasket FAQ

What is the primary function of a gasket in industrial applications?

A gasket creates a pressure-tight seal between two surfaces, preventing leaks of gases, liquids, or contaminants. This ensures machinery, engines, and piping systems operate efficiently and safely in industrial settings.

Which industries rely most on gaskets?

Gaskets are used across aerospace, automotive, food and beverage, electronics, medical, military, and transportation industries. They provide critical sealing solutions in equipment like pumps, valves, turbines, compressors, and engines.

What materials are commonly used to manufacture gaskets?

Gaskets are often made from synthetic rubbers such as neoprene, silicone, nitrile, and EPDM. Other options include metals, plastics like Teflon, fibers, composites, and non-asbestos materials such as graphite, Kevlar, or fiberglass.

How should a gasket be installed to ensure a proper seal?

Before installation, surfaces must be clean and flat. The gasket should be positioned carefully, with adhesive if required, then compressed evenly using bolts or a wrench to achieve uniform sealing pressure and prevent leaks.

What are signs that a gasket needs replacement?

Visible cracks, leaks, or loss of sealing performance indicate a gasket needs replacement. Residue from old gaskets should be cleaned off before installing a new one to ensure a secure and reliable seal.

What standards must gaskets meet for compliance?

Depending on industry and region, gaskets may need to meet FDA or USP Class VI standards for sanitary use, and comply with international codes such as ASME, ISO, ASA/ANSI, DIN, BS10, and JIS/KS.

How do gasket materials resist heat and pressure?

Different materials withstand different conditions. For example, neoprene operates from -35°F to 225°F, while PTFE gaskets can handle -450°F to 500°F. Material choice depends on the required heat, pressure, and chemical resistance.

Applications of Gaskets

Gaskets serve the essential function of creating seals at connection points between two pieces of equipment or stationary components. They are used wherever a secure and pressure-tight connection is necessary, ensuring that the internal environment remains free from air, liquid, contaminants, or any external elements. In applications where liquids or gases flow through pipes, hoses, or tubing, gaskets prevent leaks and maintain pressure at connection points.

Available in a wide range of shapes, sizes, and materials, gaskets are indispensable across numerous industries, including aerospace, automotive, appliance, aviation, consumer goods, electronics, food and beverage, military, and transportation.

For instance, in commercial aircraft, gaskets play a critical role in preventing cabin depressurization. They are also essential for the proper functioning of pressure cookers. Additionally, they are found in airframes, appliances, business machines, compressors, elevators, escalators, medical equipment, meters, turbines, pumps, valves, engines, plumbing systems, and countless other applications that rely on gaskets for safe and efficient operation.

History of Gaskets

Gaskets have long played a crucial role in ensuring the safe operation of equipment. When a gasket fails, the consequences can be catastrophic, as demonstrated by the explosion of the Challenger space shuttle in 1986. The disaster was traced to the failure of an o-ring seal in the shuttle's fuel system, which became brittle due to low-temperature exposure.

The earliest forms of gaskets emerged in 1820, when manufacturers crafted solid iron sulphate seals from a mixture of water, pack iron filings, and sulfur powder. Before the 1840s, people improvised gaskets by unraveling rope and packing the fibers into seams with lubricant or tar. Leather gaskets were also commonly used in water pumps, though they would eventually degrade and tear apart over time.

Asbestos once played a dominant role in gasket manufacturing. The first asbestos gasket was introduced in 1899, and for decades, asbestos gaskets were widely used in locomotives, Navy ships, and mechanical systems that transported hot oil, grease, and gases. This practice continued until the 1980s when the severe health risks associated with asbestos exposure, including links to cancer, led to strict regulations. Since the early 2000s, asbestos has been largely phased out of gasket production.

Significant advancements in gasket technology did not occur until after the discovery of vulcanization in 1850, which enabled scientists and engineers to experiment with rubber. The development of synthetic rubber proved particularly transformative, allowing for the creation of gaskets with heat resistance, chemical resistance, and other specialized properties. Today, while gaskets can be made from plastic polymers, metals, fibers, and other materials, they are most commonly manufactured from synthetic rubbers, including custom-engineered rubbers like neoprene.

Gasket Design and Customization

Most rubber gaskets are produced using die cutting or punching techniques from flat rubber or metal sheets. When a gasket is punched from a sheet, it is called a sheet gasket, while a gasket created through die cutting is known as a die cut gasket. Die cutting provides manufacturers with significant design flexibility, enabling the creation of gaskets ranging from simple rings to intricate automotive engine block designs. However, not all gaskets are suited for die cutting. Applications requiring thick, durable gaskets may instead utilize rubber molding, compression molding, or liquid injection molding. Additionally, some gaskets are cut using laser or water jet cutting, both of which offer precision and minimize material waste. Another method involves placing a rubber sealing ring in the center of a washer, where it is molded to fit over a bolt.

A variety of elastomeric materials are commonly used in gasket production, including silicone, neoprene, nitrile rubber (NBR), EPDM, Viton, and custom rubber formulations. While rubber is the most effective material for gaskets, manufacturers also utilize a broad range of metals, semi-metals, foams, fibers, and composite materials. Plastics such as Teflon, nylon, polyethylene (PE), polyurethane, and Mylar are frequently employed either as gasket materials themselves or for jacketing. Sponge rubber, including open or closed-cell silicone, is preferred for applications requiring a flexible rubber seal. Additionally, gaskets can be made from non-asbestos sheets composed of materials like carbon filament, flexible graphite, fiberglass, ceramics, or Kevlar, leading to the designation of non-asbestos gaskets.

Gaskets are unique in their ability to accommodate imperfectly matched mating surfaces, filling in gaps regardless of shape. This adaptability allows for extensive customization in gasket design, from simple to highly complex configurations. They can be manufactured in a wide range of shapes and sizes to suit various sealing applications. Even the simplest type of gasket, the O-ring, can be customized, while more complex gaskets can be designed with textured surfaces such as tapered, ridged, or grooved finishes for a more secure fit. Whether die cut or molded, gaskets can be tailored to create the tightest possible seal between components.

Advantages of Gaskets

- Control Over Connections

- The advancement of gasketing materials and innovative gasket configurations has given professionals greater control over even the most demanding and irregular connections.

- Efficiency

- The soft, malleable nature of gaskets allows them to seamlessly conform to the surfaces between which they are placed, ensuring a reliable and efficient seal.

- Effectiveness

- Gaskets provide highly effective pressure-tight closures, capable of withstanding extreme pressure, temperature variations, and external influences such as electromagnetic fields.

- Improved Safety

- Advancements in gasket design and manufacturing have significantly enhanced the safety and efficiency of industrial systems, including vehicles, pumping equipment, and pipelines. Gaskets play a critical role in preventing leaks, particularly in systems handling toxic chemicals or hazardous liquids, where spills could endanger both people and the environment.

Gasket Installation

Before installing a gasket, ensure that the mating surfaces are completely clean and free of dirt, oil, water, or any other contaminants that could compromise the seal. Lay the mating surface flat and, if required, apply a thin layer of pressure-sensitive adhesive. Carefully position the gasket onto the surface, ensuring proper alignment. If adhesive is used, continue applying it as needed to achieve a secure seal.

Once the gasket is in place, connect it to the other mating surface. If adhesive has been applied, allow it to set as instructed. If adhesive is not being used, tighten the gasket using a wrench to create uniform compression and enhance the seal.

Gasket installation methods may vary depending on the application and the type of gasket being used. For specific installation guidance tailored to your needs, consult your gasket supplier.

Proper Care of Gaskets

To maintain performance, gaskets require periodic cleaning, with the method varying based on their application. Refrigerator gaskets benefit from a gentle scrub using warm water, baking soda, and a brush—this not only cleans but also neutralizes odors. Submersible gaskets, like those in pressure cookers, should be washed in warm, soapy water and left to air dry. For gaskets in vehicles or other applications, a soft cloth and mild soap work well to avoid scratches or damage.

Despite regular maintenance, gaskets will eventually need replacement. A clear sign it's time to replace them is visible cracking or leaks. Before installing a new gasket, remove any residue from the previous one to ensure a clean, even sealing surface.

To maximize durability, consider applying a wax solvent or rubber protectant. These products help shield gaskets from UV exposure, heat, and moisture, preventing premature wear and maintaining their sealing capabilities.

Gasket Standards and Compliance

The specific standards that gaskets must meet depend on their intended application and industry. For example, sanitary gaskets or those used in pharmaceutical applications must comply with FDA regulations and USP Class VI standards. Additionally, gaskets must meet the regional or national standards where they will be used. Some of the most widely recognized standards include BS10 (British/Australian), PN/DIN (European), ASA/ANSI (USA), and JIS/KS (Japanese/Korean).

For added assurance of quality and performance, it is also advisable to select gaskets that adhere to ASME and/or ISO standards.

Points to Consider When Selecting a Gasket

When you’re searching for the perfect product for your gasket and seal application, keep these things in mind:

- Heat Resistance

- Ensure that the gasket material you choose can withstand the temperatures in your process. Different materials have different temperature ranges. For example, a neoprene gasket functions between -35°F and 225°F, while a Garlock Gylon PTFE gasket can handle temperatures from -450°F to 500°F. Confirm temperature resistance with your supplier.

- Environmental Resistance

- Check whether the gasket can withstand exposure to gases, liquids, air, and pressure in your application. EPDM (ethylene propylene diene monomer) is a highly resilient synthetic rubber suitable for a wide range of environments. Consult with your internal engineers or external gasket suppliers to see if EPDM is the right fit.

- Pressure Resistance

- Understand the pressure limits of the gasket material. It should be firm enough to withstand the load applied by the mating surfaces. Request compression and pressure test results from a trusted lab to ensure durability.

- Have the Measurements On-Hand

- A gasket’s ability to create a perfect seal depends on getting the right size. Incorrectly sized gaskets often fail, leading to leaks and inefficiencies. Prepare accurate measurements ahead of time and consult with process engineers for recommendations.

- Consider the Material Properties

- Gaskets come in various materials, from thermoplastic rubber to fiber. Not all materials suit every industrial application. Some processes require extreme temperature resistance, shock absorption, or rigid sealing. Carefully evaluate material benefits before making a selection.

- Determine Chemical Resistance

- While metal gaskets excel in heavy-duty applications, they may not be ideal for environments with acidic or alkaline fluids. Ensure the gasket material resists the chemicals it will be exposed to. For example, polytetrafluoroethylene (PTFE) offers strong resistance to fluids with pH levels from 0 to 14 but may not be suitable for high-impact applications.

- Conduct or Request Performance Tests

- Verify gasket performance by conducting tests such as hot and cold compression and creep relaxation. These tests help assess the gasket’s resistance to temperature, pressure, and negative force, ensuring it meets your application’s requirements.

- Here are two ways to select a reliable gasket manufacturer:

- The Google Method

- Search for "gasket manufacturers/suppliers in [your city]" online.

- Review different vendor websites and their offerings.

- Request quotes from multiple suppliers.

- Choose a manufacturer that best fits your needs.

- Through a Business Directory

- Use a business directory like IQSdirectory.com.

- Enter relevant search terms in the directory’s search box.

- Browse the list of manufacturers and suppliers, then contact them.

- Compare quotes and finalize a contract.

- Regardless of how you find a manufacturer, make sure they are the right fit for you. A good manufacturer will treat you with professionalism and care, working within your timeline, budget, and custom gasket requirements. Excellent customer service is key to a successful partnership.

Gasket Images, Diagrams and Visual Concepts

Gaskets are mechanical seals that prevent leakage by filling the gaps between static mating surfaces.

Gaskets are mechanical seals that prevent leakage by filling the gaps between static mating surfaces.

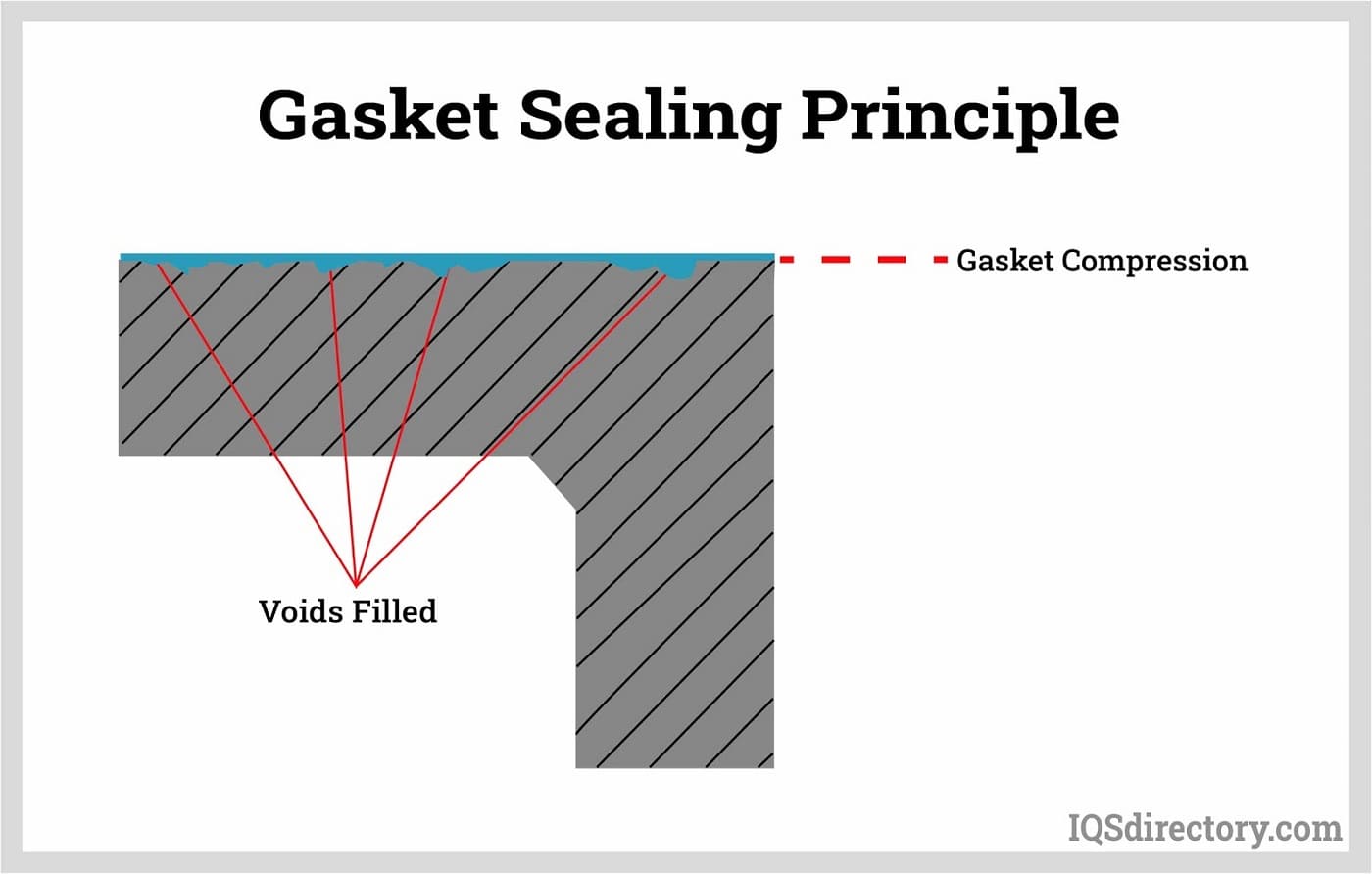

The compressive force deforms the gasket and conforms to the surface profile and fills the gaps between its peaks and troughs.

The compressive force deforms the gasket and conforms to the surface profile and fills the gaps between its peaks and troughs.

Rubber gaskets are elastic components for sealing the microscopic gap between two mating surfaces or joints.

Rubber gaskets are elastic components for sealing the microscopic gap between two mating surfaces or joints.

Head gaskets, a motor engine component that seals the combustion part of the engine so that oil and the motor coolant circulate.

Head gaskets, a motor engine component that seals the combustion part of the engine so that oil and the motor coolant circulate.

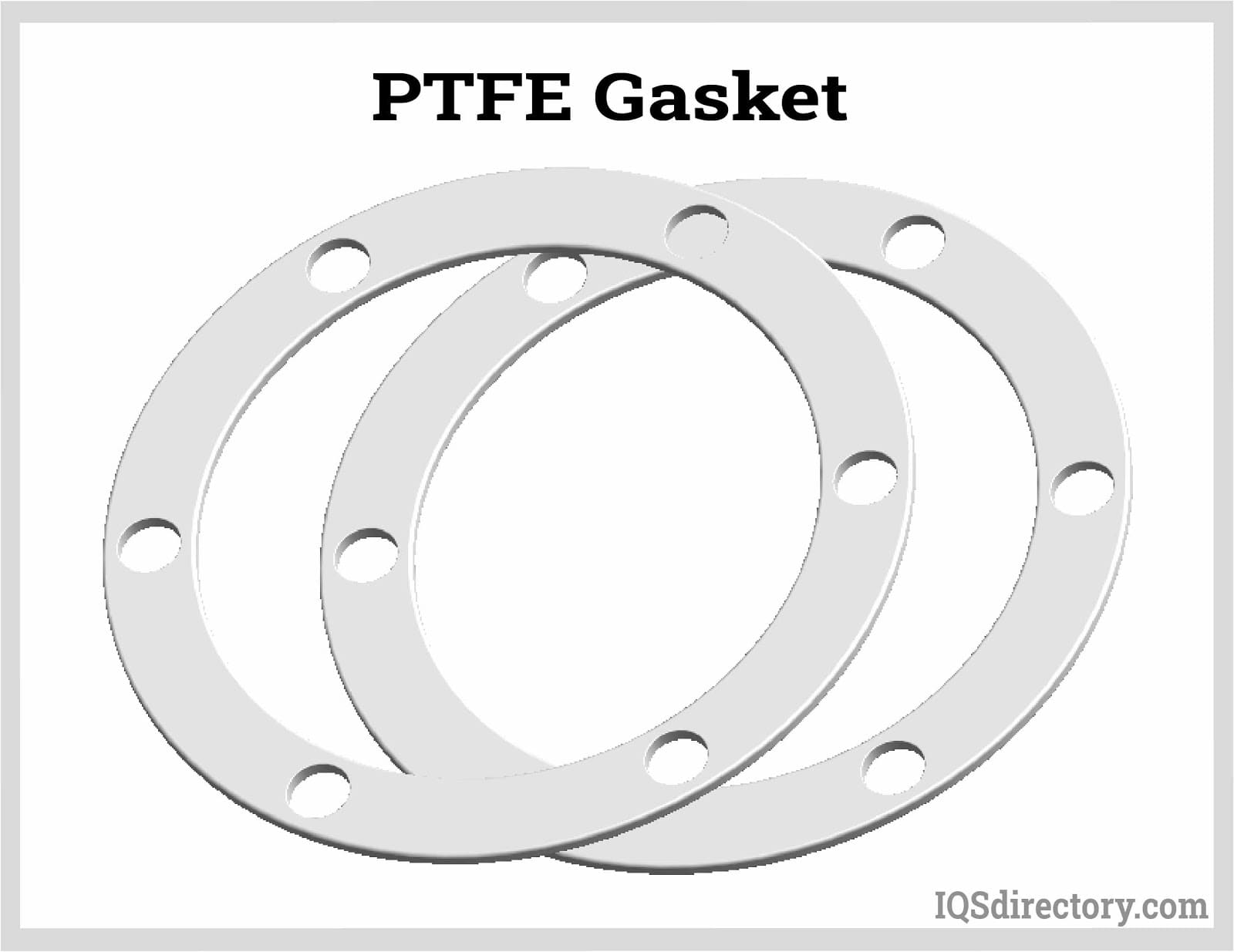

PTFE, a strong material, various materials are added as fillers to reinforce its natural mechanical properties and strength.

PTFE, a strong material, various materials are added as fillers to reinforce its natural mechanical properties and strength.

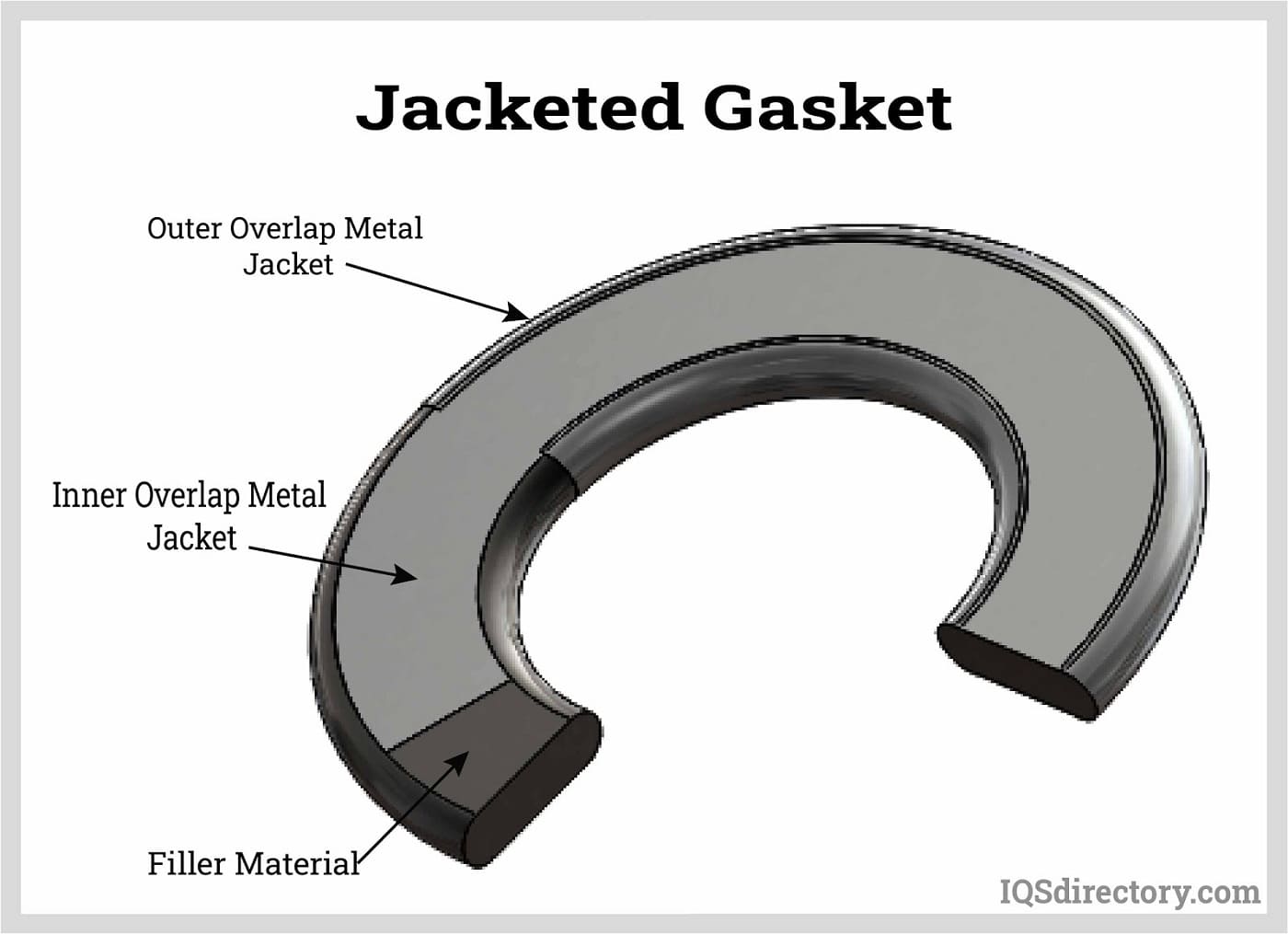

Jacketed gaskets filler material is partially or entirely enclosed in a metal jacket to create a compressive load.

Jacketed gaskets filler material is partially or entirely enclosed in a metal jacket to create a compressive load.

Notable Types of Gaskets

Different types of seals are utilized to make a joint or compartment leak-proof. Some of the most common types include O-rings, head gaskets, spiral wound gaskets, flange gaskets, and shims. Other gaskets are specialized for specific applications. For example, an exhaust gasket is used only for exhaust management purposes. Likewise, high temperature gaskets are designed to be able to work with extremely high temperatures. Still others are categorized by the material with which they’re made. Examples of these include rubber gaskets, plastic gaskets, metal gaskets, solid gaskets, jacketed gaskets, and silicone gaskets.

- Composite Gaskets

- Custom-designed for individual applications, these gaskets are often used with a gasket dressing or adhesive during assembly to create a secure seal. They can be made from a combination of materials such as cork, rubber, paper, and felt.

- Corrugated Gaskets

- These metal gaskets, sometimes treated with ceramic, non-asbestos, or flexible graphite, provide a seal under low seating stress and can be paired with Teflon envelopes.

- Die Cut Gaskets

- Manufactured by cutting materials before assembly, die cut gaskets are shaped to fit a specific application.

- ElastaGraph Gaskets

- Made from a metallic core with a seamless flexible graphite coating, ElastaGraph gaskets are ideal for high-pressure and high-temperature applications. Their high-density inner rings enhance sealability while ensuring low minimum seating stress.

- Encapsulated Gaskets

- These gaskets consist of a core material surrounded by a continuous layer of a different material, typically Teflon, creating a dual-layer seal.

- Envelope Gaskets

- These gaskets feature a core material wrapped in an envelope made of another material, usually Teflon, for additional protection.

- EPDM Gaskets

- Made from synthetic rubber, EPDM gaskets are used to create a durable seal between two mating surfaces in various machine parts.

- Exhaust Gaskets

- Used in vehicles, exhaust gaskets provide a seal for exhaust parts, ensuring that exhaust gases remain contained until expelled.

- Fibre Seal Rings

- Die-cut, water-jet cut, or formed gaskets that seal the connection between two surfaces.

- Flange Gaskets

- These gaskets are designed with protruding rims or lips that aid in the attachment process, commonly used in flanged connections.

- Foam Gaskets

- Made from strips of plastic, foam, or rubber, foam gaskets provide flexible sealing solutions.

- Gasket Materials

- Gaskets are made from a variety of materials with sealing capabilities for different applications.

- Head Gaskets (Cylinder Head Gasket)

- Used to create a seal between the combustion engine block and cylinder heads, head gaskets are designed to withstand heat, chemicals, and pressure in fossil-fuel combustion engines.

- High Temperature Gaskets

- Designed to prevent leakage in high-temperature environments, these gaskets can withstand temperatures exceeding 500°F.

- Hollow Tube Gaskets

- Typically made from rubber or plastic, these gaskets have a tubular cross-section and are used for sealing in various applications.

- Jacketed Gaskets

- Made from rubber or plastic with a metallic coating, jacketed gaskets are available in single or double jackets. Double-jacketed gaskets offer improved resistance to high temperatures, decay, and pressure.

- Laminated Gaskets

- Composed of two or more layers of materials, laminated gaskets often come enclosed in an envelope for added durability.

- Metal Gaskets

- Made from materials like aluminum, stainless steel, brass, and copper, metal gaskets are ideal for high-pressure or high-temperature applications, providing excellent durability and resistance to heat, pressure, and corrosion.

- Neoprene Gaskets

- Synthetic rubber gaskets used to create long-lasting seals for gaps on machine parts in various industries.

- O-Ring

- A simple, O-shaped gasket that is inexpensive and easy to produce, commonly used for both static and dynamic applications like pump shafts and hydraulic cylinder pistons.

- Plastic Gaskets

- Made from a combination of plastic and rubber, plastic gaskets offer strong sealing properties but are not suitable for high-temperature applications due to their low melting point.

- Profiled and Serrated Gaskets

- Solid metal gaskets with surface grooves that facilitate a good seal with low seating stress, often used with profiled and serrated jackets to protect flange surfaces.

- Rubber Gaskets

- Known for their elastomeric characteristics, rubber gaskets are suitable for high-pressure applications and can maintain tight seals under extreme conditions for extended periods.

- Rubber Window Gaskets

- Used for weatherproofing and weatherstripping around windows and doors, rubber window gaskets are commonly found in cars and homes.

- Silicone Gaskets

- Made from silicone rubber, these gaskets can handle extreme temperatures ranging from -140°F to 480°F. They also provide resistance to ultraviolet light and can be used in conjunction with other gasket materials to enhance pressure and temperature resistance.

- Solid Gaskets

- Made from soft or hard materials, solid gaskets are best suited for high-pressure and temperature environments and are commonly used between metal parts or in machinery that generates extreme conditions.

- Spiral Wound Gaskets

- These gaskets are designed for applications that may be subject to stress or movement, offering flexibility and the ability to maintain a tight seal. They feature a combination of metal and filler material for strength and sealing efficiency.

- Teflon Gaskets

- These gaskets are designed to resist sticking to adjacent materials, making them ideal for certain sealing applications.

- Viton Gaskets

- Made from synthetic rubber, Viton gaskets are resistant to heat, oil, and various acids, making them suitable for demanding industrial applications.

Gasket Terms

- Anti-Extrusion Rings

- Also known as back-up rings, these are designed to sit behind rubber o-ring seals to prevent the material from being forced into the gap between metal components.

- Beryllium Copper

- A lightweight, corrosion-resistant metal commonly used in aerospace applications, springs, and gaskets due to its strength and durability.

- Blowout Pressure

- The pressure exerted on a gasket that could lead to the unsealing of the joint if it becomes too high, potentially causing gasket failure.

- Bonded Seals

- These seals feature a rubber sealing ring molded into the center of a flat steel washer, typically used to fit around bolts and ensure a leak-tight seal.

- Die Cutting

- A process in which shapes are cut from materials using a die, a pre-formed stencil that allows for precision cuts and consistent shapes.

- Electromagnetic Interference

- Interference caused by electric currents, which can affect nearby electronic devices. Some gaskets are designed to filter out or block this interference.

- Flange Load

- The total compressive force required to compress the gasket and create a tight seal at the flanged connection between two surfaces.

- Hydrostatic End Force

- The pressure forces acting on the flanges that hold the gasket in place, helping to maintain its seal in systems under high pressure.

- Mismatch

- When the surfaces being sealed by a gasket are uneven, resulting in improper sealing and potential leakage.

- Nebar

- A specialized material used for gaskets in electrical transformers, designed to withstand the unique pressures and conditions of transformer applications.

- Neoprene

- A synthetic rubber commonly used for gaskets due to its resistance to weathering, oils, and chemicals, making it suitable for various sealing applications.

- Parback

- A type of back-up ring that serves as an anti-extrusion device for o-rings, featuring a concave design on one side for additional support.

- Rings

- Circular-shaped sealing devices used in various applications to create seals between two parts, ensuring tightness and preventing leaks.

- Seal Strips

- Made from multiple layers of metal welded together, these strips enable gaskets to function effectively in high-heat or high-pressure environments.

- Slip O-ring

- A ring that fits over an o-ring to reduce friction and wear, allowing for smoother movement in dynamic applications.

- Shims

- Thin, flat spacers used to fill gaps between a gasket and adjacent surfaces, ensuring proper alignment and sealing.

- Static Seal

- A type of seal formed by a gasket between two stationary parts, ensuring no leakage occurs at the connection point.

- Washers

- Flat, circular rings that are placed under the head of a bolt to serve as spacers, gaskets, or friction reducers, ensuring proper sealing and alignment.