Glass Cutting

The term "glass fabrication" refers to all processes involved in transforming raw glass material into a functional component or product. These processes include cutting, grinding, drilling, polishing, tempering, finishing, and edging.

Glass cutting manufacturers, also known as glass fabricators, produce a variety of glass types used across numerous industries. These glass products serve in applications ranging from transparent barriers and insulators to containers and optical or laboratory instruments. The properties of transparency, heat resistance, and relative strength make glass an essential material for applications that require these characteristics.

Glass Cutting FAQ

What is glass cutting in fabrication?

Glass cutting is the process of scoring and breaking glass into desired shapes and sizes. It can be performed using hand tools, diamond saws, CNC machining, laser cutting, or water jet technology depending on precision needs.

What is the difference between tempered and laminated glass?

Tempered glass is heat-treated for strength and breaks into small blunt fragments. Laminated glass sandwiches a plastic interlayer between panes, holding shards in place when broken, making it ideal for windshields and safety glazing.

How is float glass manufactured?

Float glass is made by pouring molten glass onto a bed of molten tin. The glass floats to form flat, parallel surfaces, then cools, anneals, and is cut to size for use in windows, mirrors, and construction panels.

What tools are used for cutting thick glass?

For thicker glass, diamond saws, CNC grinders, and water jet systems are commonly used. These tools provide precise, clean cuts and are preferred for industrial and architectural applications requiring accuracy and strength.

What are common applications of quartz glass?

Quartz glass withstands extreme temperatures and UV exposure. It is widely used in fiber optics, analytical instruments, semiconductor processes, and laboratory equipment where clarity and durability are critical.

What is the purpose of annealing in glassmaking?

Annealing is controlled cooling that relieves stress in glass after forming. This process strengthens the glass, prevents fractures during cutting, and ensures durability in applications like windows and construction panels.

How does water jet cutting work for glass?

Water jet cutting uses a high-pressure stream of water, often mixed with abrasives, to erode and cut glass along programmed lines. It allows intricate shapes and is effective for custom designs in industrial and decorative applications.

The History of Glass

Pliny the Elder documented the manufacturing of glass as early as 5,000 B.C., though archaeological evidence only confirms its existence around 3,500 B.C. in Egypt, where the locals used pure sands to create beads. The first glass vessels were crafted around 1,500 B.C. by winding ductile glass ropes around a core made of sand and clay, then fusing the ropes through repeated heating. Once the ropes were fused together, the core was scraped out, leaving behind a usable vessel. The earliest written instructions for glassmaking date to 650 B.C. and were found on cuneiform tablets in the library of Assyrian king Ashurbanipal. The invention of the glass blowpipe around 1 B.C. in Syria revolutionized the industry, making glass production faster, easier, and more cost-effective. Stained glass, which has been around for over a thousand years, was originally used in windows for churches and cathedrals. Today, stained glass is both an art form and a medium for colorful windows and three-dimensional sculptures.

In 1932, James Slayter accidentally invented fiberglass when he directed compressed air into molten glass. This process resulted in a mass of wooly fibers that trapped air between them, offering excellent insulation properties. Owens Corning patented this product and named it "Fiberglass." In 1936, Du Pont combined glass wool with polyester resins to create plastic sheets that could conform to various surface shapes and be cured into a hard shell. The first fiberglass car prototype, the Stout Scarab, was created in 1946, although it did not go into mass production. Today, fiberglass is widely used in the production of sports equipment, boats, wire coatings, and storage tanks.

Glass Cutting Images, Diagrams and Visual Concepts

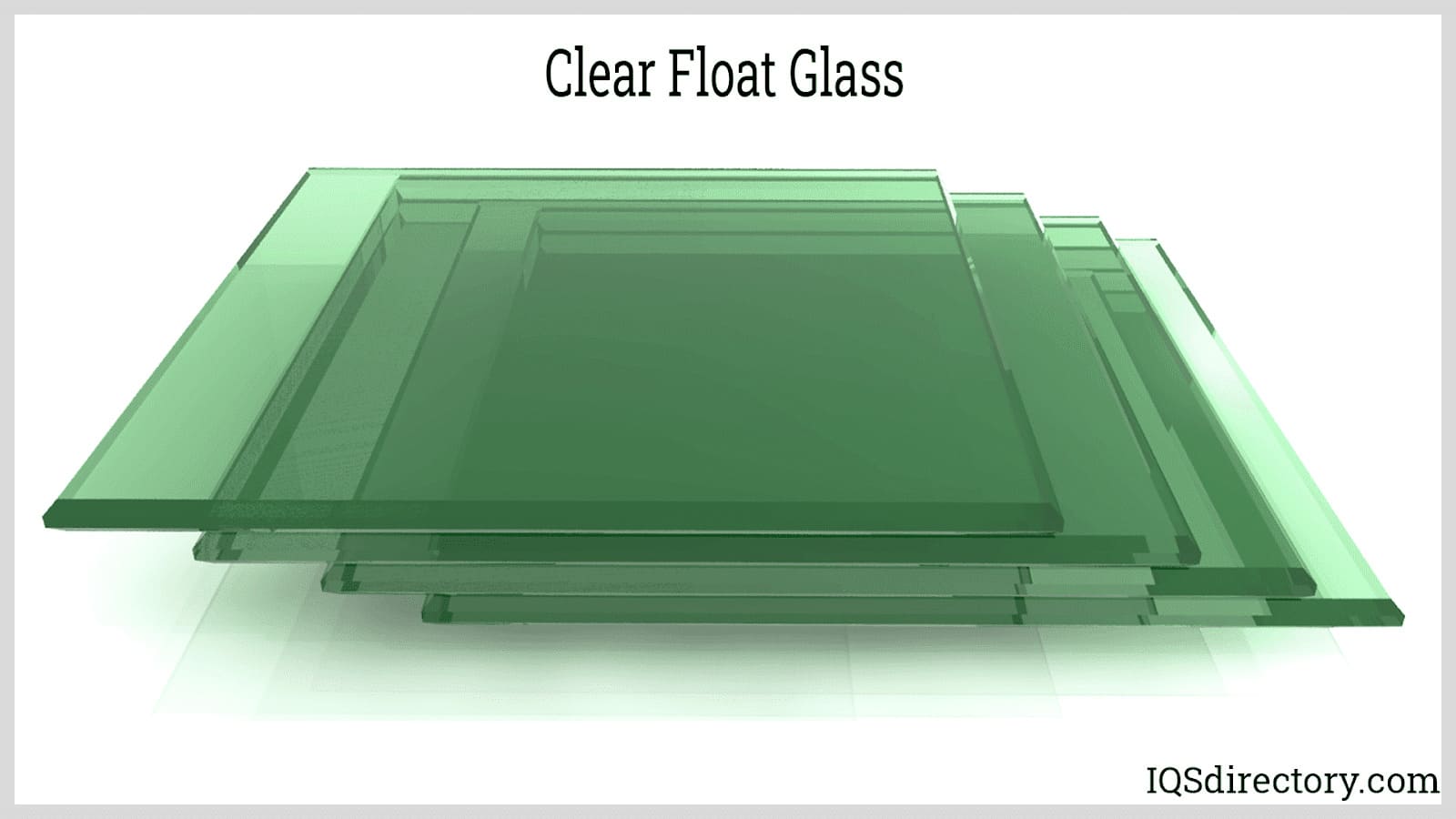

Float glass is the most common type of glass and is manufactured by floating the glass on a lake of molten tin.

Float glass is the most common type of glass and is manufactured by floating the glass on a lake of molten tin.

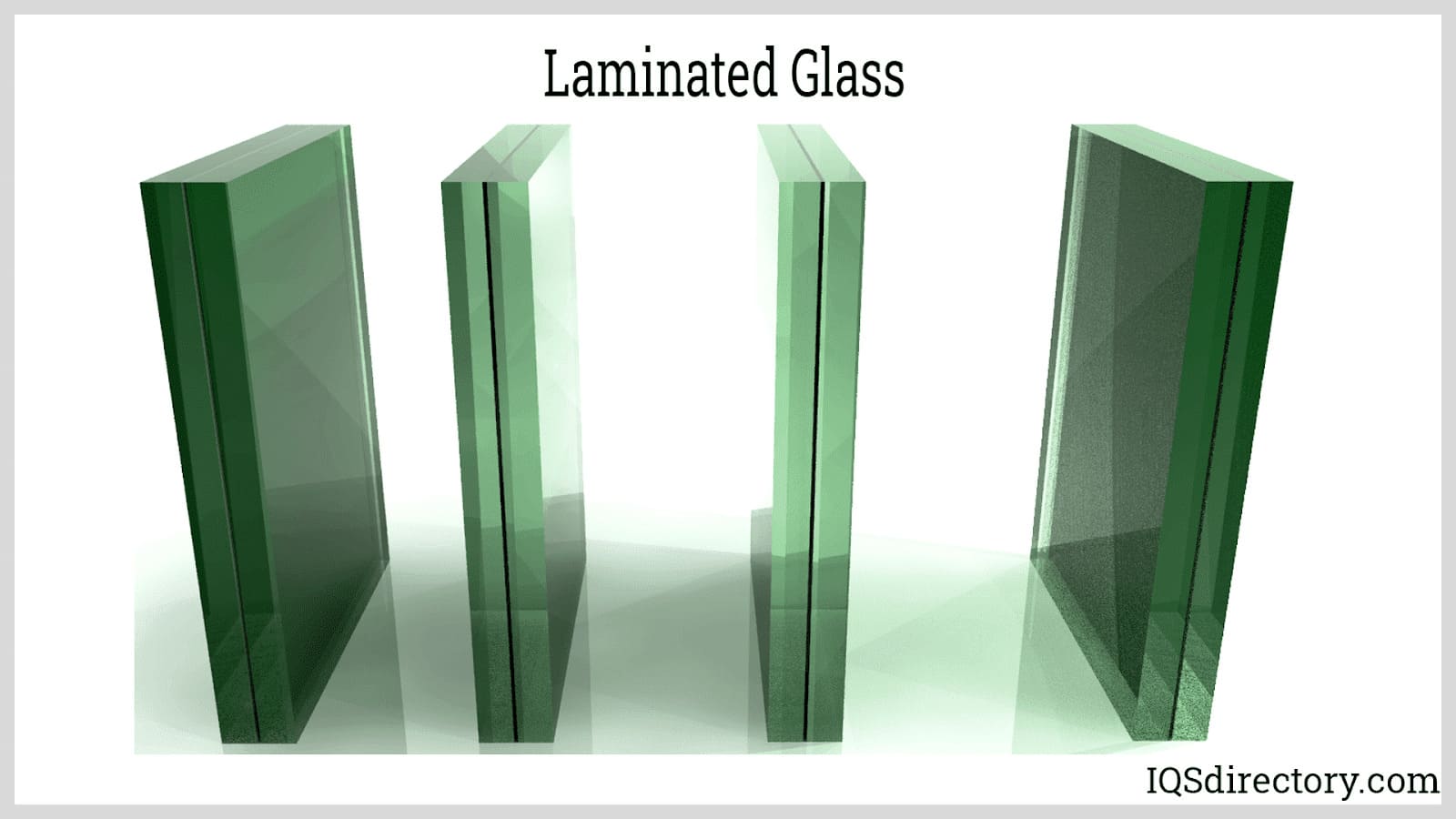

Laminated glass are two pieces of glass with an inner layer made from polyvinyl butyral to prevent shattering and pressed together under heat and pressure to create a strong chemical bond.

Laminated glass are two pieces of glass with an inner layer made from polyvinyl butyral to prevent shattering and pressed together under heat and pressure to create a strong chemical bond.

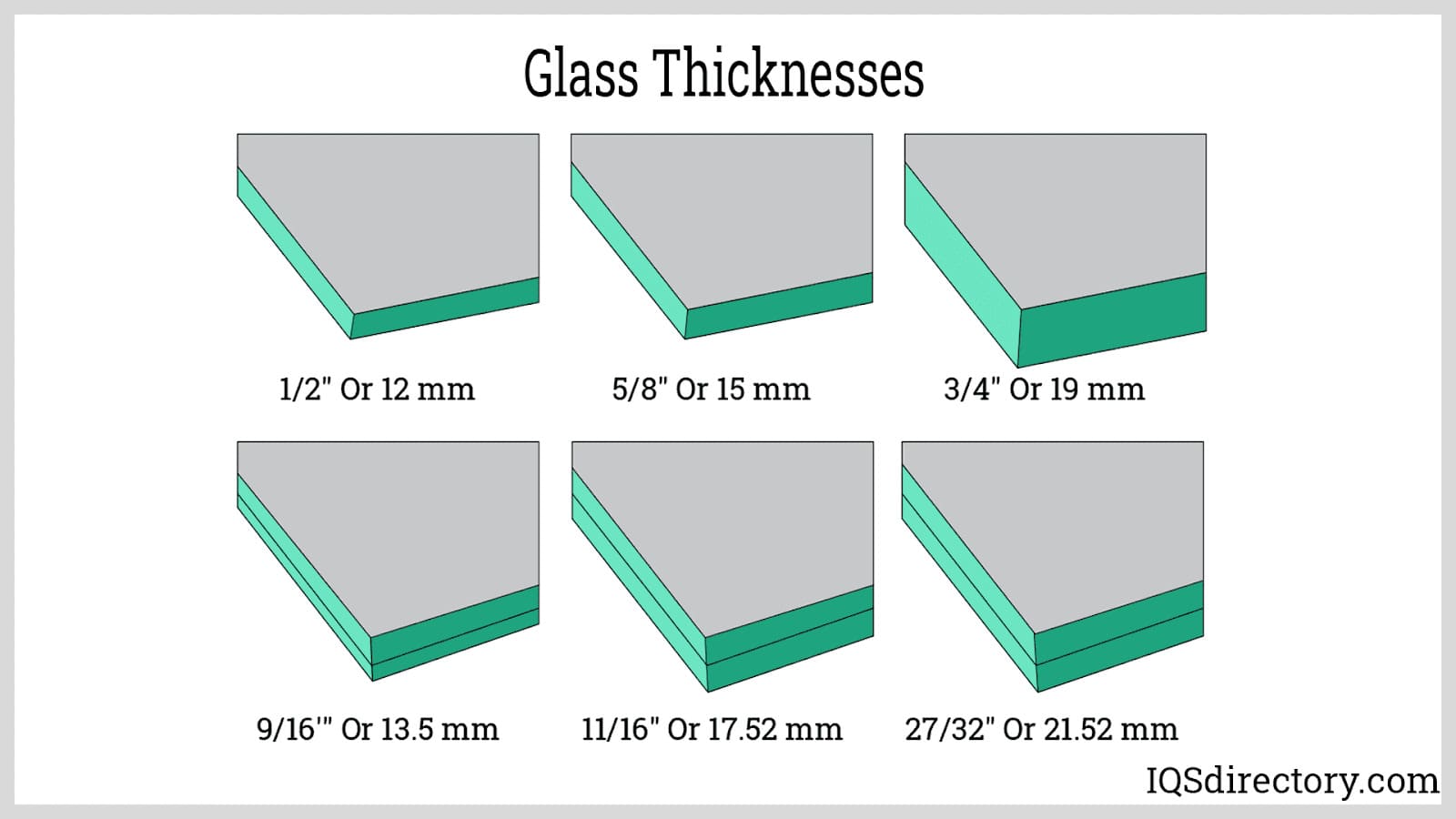

Glass thickness effects the type of tools required to cut the glass for example glass under 0.6 cm not much force is needed and the usage of light tool.

Glass thickness effects the type of tools required to cut the glass for example glass under 0.6 cm not much force is needed and the usage of light tool.

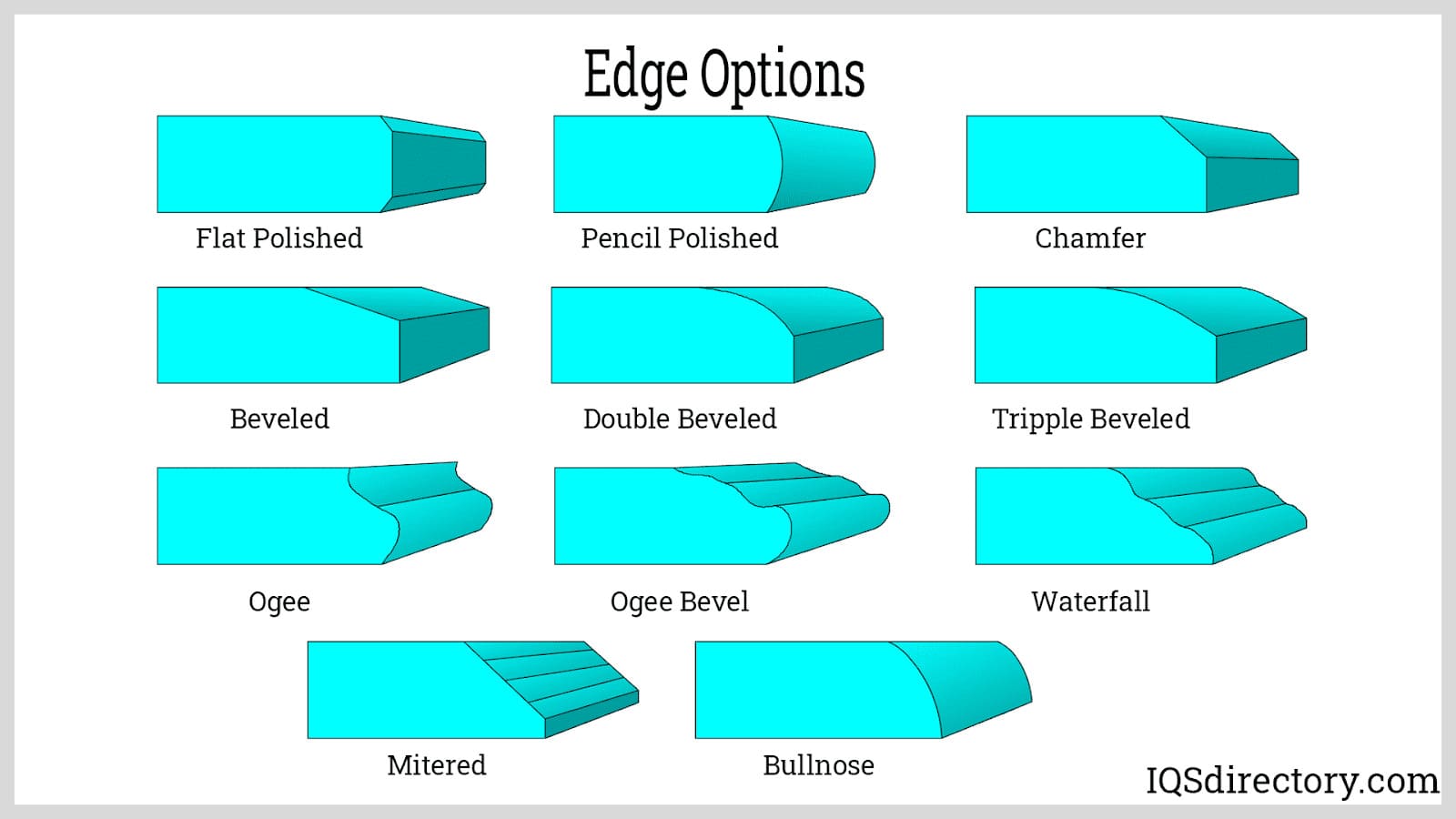

Edge treatments affect the functionality of the finished piece, to improve safety, add aesthetic appeal, improve functionality, and improve dimensional tolerance to prevent chipping and cracking.

Edge treatments affect the functionality of the finished piece, to improve safety, add aesthetic appeal, improve functionality, and improve dimensional tolerance to prevent chipping and cracking.

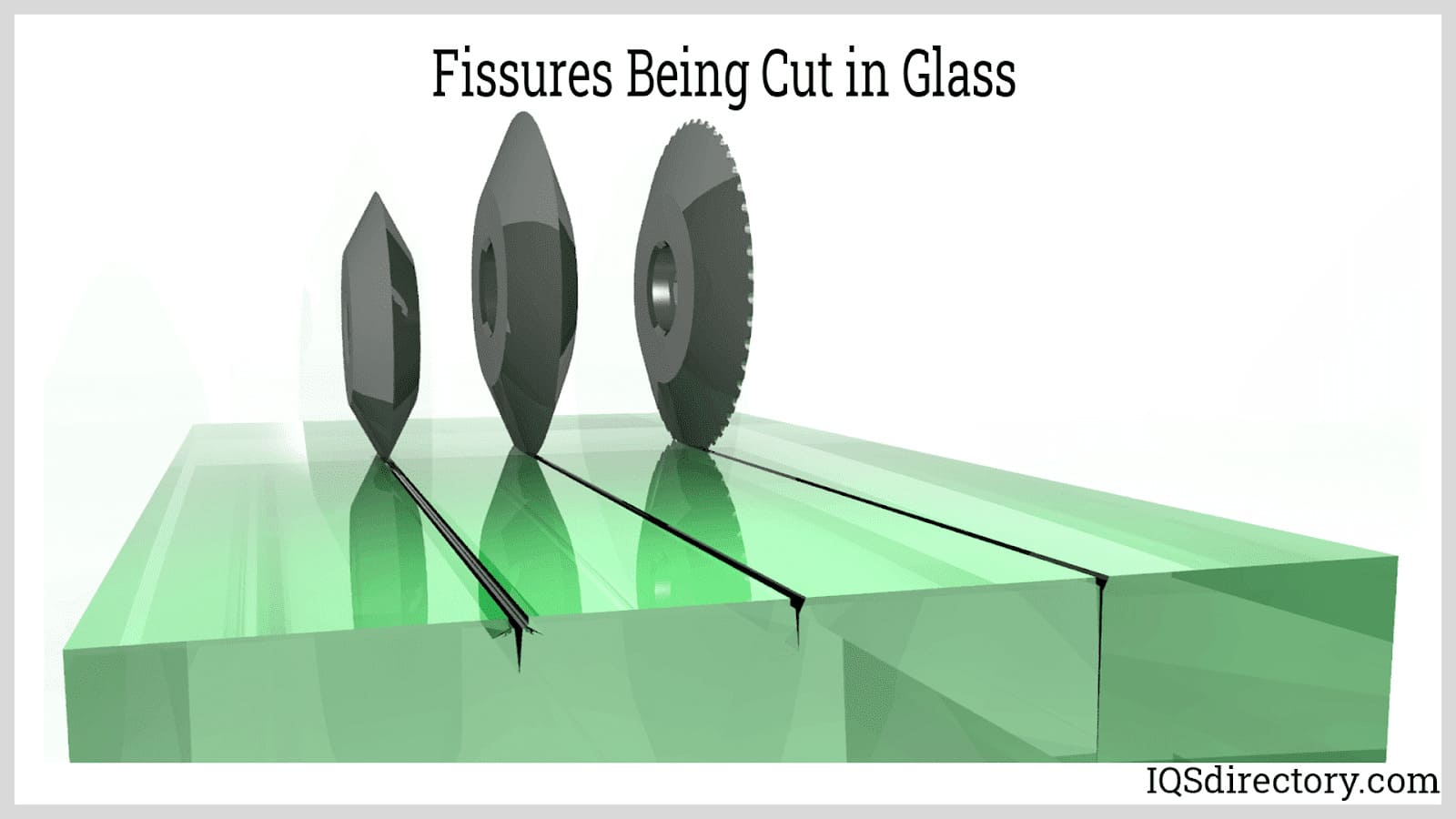

As the cutting wheel crosses the glass surface, it fractures the surface of the glass to create a fissure.

As the cutting wheel crosses the glass surface, it fractures the surface of the glass to create a fissure.

Every glass cutter has a cutting wheel that does consistent, precise, and accurate scoring.

Every glass cutter has a cutting wheel that does consistent, precise, and accurate scoring.

Glass cutting machines have servo motors, drivers, CNC control systems, and many forms of cutter wheels designed for a wide range of cuts.

Glass cutting machines have servo motors, drivers, CNC control systems, and many forms of cutter wheels designed for a wide range of cuts.

Laser cutting machines are programmed using CNC G codes, which are used for cutting flat and curved glass.

Laser cutting machines are programmed using CNC G codes, which are used for cutting flat and curved glass.

Glass Cutting Types

- Blown Glass

- Glass shaped by air pressure, typically created by blowing through a metal pipe, either by mouth or using compressed air. This method is commonly used for mass-produced items like bottles, through highly automated systems that inject air into the glass gob to shape the final product.

- Cut Glass

- Glass objects decorated with cut or ground facets, mainly for decorative purposes. This includes items like ornamental plates and various knick-knacks.

- Flat Glass

- A broad category of glass that includes wired and tempered glass. The main methods of production are rolled and float glass techniques. Rolled glass is produced by pouring molten glass between water-cooled rollers, while the float glass process, the most common, involves holding the glass in a chemically controlled environment at high temperatures to achieve flat, parallel surfaces.

- Glass Blowing

- The process of shaping glass by blowing air into it.

- Glass Cutting

- Involves various techniques such as diamond saw cutting, thermal or hot cutting, score and break cutting, and laser cutting.

- Glass Rods

- Long, cylindrical pieces of glass.

- Glass Tube

- A cylindrical form made of glass material.

- Heat Strengthened Glass

- Glass subjected to a heating and cooling cycle, making it about twice as strong as standard annealed float glass. When broken, it produces larger fragments compared to fully tempered glass.

- Precision Optics

- High-quality glass designed for applications requiring superior clarity and accuracy, such as lenses, prisms, and medical visual systems.

- Quartz Glass

- Made from melted silica, quartz glass can withstand extreme temperature changes and is typically transparent to ultraviolet radiation. It is used in fiber optics, analytical instruments, semiconductor technologies, and casting processes.

- Sight Glass

- A type of optical glass, typically tubular or lens-shaped, used for observing liquids in industrial processes and for gauging levels.

- Specialty Glasses

- Glass products made for specific purposes, such as bent glass, bulletproof glass, silk-screened glass, colored glass, and other specialized industrial or commercial glass parts.

- Tempered Glass

- A type of safety glass that is heat-treated, making it about five times stronger than regular annealed float glass. When broken, it shatters into small, rectangular pieces, making it ideal for safety glazing in doors, windows, and shower enclosures.

- Textured Glass

- Glass with a patterned or uneven surface for decorative or functional purposes.

- Wired Glass

- Glass embedded with a wire mesh, which enhances its resistance to impact. While similar to regular glass, the wire mesh helps hold broken pieces together. Historically, it was used for fire safety due to its strength and impact resistance.

When Glass Gets Stranded

In its purest form, glass is clear and transparent across the entire light spectrum. Strands of glass thinner than a human hair can be spun from pure silica to create optical fibers. These fibers are bundled into hollow cables, which are coated with a mirrored shell. Light travels through the hollow core, reflecting endlessly within the transparent fibers, allowing them to transmit communication signals through a process called total internal reflection. Today, an estimated 300 million kilometers of fiber are used globally for telecommunications.

Coloring Glass

Metallic oxides are used to color glass. Cobalt, nickel, and manganese impart blue, violet, and purple shades, while sulfur, lead, cadmium, and uranium create yellow hues. Chromium and copper compounds can add green tones, and carbon oxides produce amber or brown colors. Tin compounds are used to make white glass. For centuries, selenium was added to create red glass, though its color would often fade over time. A formula using gold to make the ruby color permanent was documented as early as the 10th century A.D., but was initially regarded as alchemy. It wasn't until the 15th century that this technique became widely used.

Glass Blowing

Hand-blown glass manufacturing is typically reserved for art glass, custom pieces, and specialty fabrications due to its small-scale nature and the risks involved, including burns and exposure to toxic fumes. In the free-blowing technique, short bursts of air are blown through the blowpipe into the gather—a glob of molten glass at one end of the pipe. The glassblower then inflates the gather, forming a hollow shape that can be shaped into custom glass fabrications.

Mechanized glass blowing consists of three major phases, using advanced equipment to produce bottles, jars, and other containers. The first phase is batch processing, which involves handling raw materials. The batch house, a large silo, stores enough material to run continuously for 1 to 5 days. The ingredients may be screened, dried, or preheated before being measured and mixed. The combined ingredients are then fed into a furnace via the batch charger, where they enter the glory hole, a part of the furnace operating at temperatures up to 2,867 degrees Fahrenheit.

In the hot end, molten glass is formed into functional shapes. In the blow and blow method, a stream of molten glass is cut into predetermined lengths, or “gobs,” with each gob forming one container. The gob is placed into a two-piece mold, which is sealed with a baffle equipped with an air valve. Compressed air is applied in a measured sequence: the first blast shapes the outer features of the container, such as the cap-sealing lip or screw threads; the second blast hollows out the shape; and the third blast finalizes the shaping. In the press and blow method, a plunger is used for the first three steps instead of compressed air.

The parisons, or initial shapes, are smaller than the finished products. As they exit the hot end, a final blast of air is used to bring them to the correct size. Once fully formed, the containers may be treated with sulfur or fluorine gas, introduced into the compressed air or directly fed into the open end of the containers. This treatment de-alkalizes the interior to enhance chemical resistance. The finished glass products are then transported through an annealing oven for even cooling. During the cold end phase, each piece is inspected for defects. If no defects are found, the items are packaged and shipped.

Creating Float Glass

Float glass is mainly used for windows, mirrors, and construction panels. In 1952, Sir Alastair Pilkington revolutionized the glass industry by inventing a method of flat glass fabrication in which molten glass floats on a bed of molten metal, typically tin. The process begins with raw materials being slowly melted into a viscous liquid, which is then homogenized to eliminate impurities and bubbles. The molten glass is poured through a refractory spout into the float bath, where it floats on the molten tin. The sheet glass cools gradually, forming a solid ribbon, which is inspected for any surface anomalies or impurities. At this stage, coatings that alter the optical properties of the glass may be applied through chemical vapor deposition (CVD).

To prevent stress fractures during the cutting process, the glass undergoes annealing, which also enhances its strength. Once the float glass ribbons have cooled, a diamond wheel trims off the selvedge, which is pre-stressed to avoid cracking. The ribbons are then cut to specifications for use as windows, mirrors, or screens.

Annealing is also employed in tempering glass, making it 4 to 5 times stronger than standard glass. Tempered glass is heated and rapidly cooled, and if broken, it shatters into small, oval-shaped pieces, which reduces the risk of sharp edges and shards. As a result, tempered glass is commonly used in safety applications like coffee carafes, oven windows, shower doors, computer screens, and construction projects. Spandrel glass, an architectural product, is used on building exteriors to conceal framework and provide a smooth, uninterrupted finish. These panels are typically opaque from the outside, but reflective coatings are often applied during the annealing process.

Laminated glass, another type of safety glass, is created by sandwiching a plastic layer between two layers of glass, which are then annealed to bond them. This type of glass is often used in automotive windshields, as the shattered glass remains adhered to the plastic layers, preventing pieces from scattering.

Glass Cutting

Glass cutting on a small scale is typically done using a handheld cutting wheel. The wheel scores the surface of the glass along the desired break line. When cutting a straight edge, pressure is applied to either side of the score, resulting in a clean break. For smoother lines and curves, tools like grozer pliers and grinders are used to refine the cuts. The score and break technique is commonly employed for straight lines and cutting sheet glass or small tubes.

For more precise cuts, diamond saw cutting is used. This involves a power grinder with a diamond-encrusted wheel or a band saw with a diamond-coated blade to score and make highly accurate glass cuts with tight tolerances.

CNC Machining

Complex glass cutting and shaping can be achieved using CNC (Computer Numerical Control) machining. This process allows glass fabricators to use computerized machinery to perform precise grinds or cuts. The machine is programmed to replicate the desired specifications, and services like boring, drilling, grooving, slotting, pocketing, grinding, polishing, and engraving can all be performed on the glass.

Thermal cutting, also referred to as hot cutting, is another method that utilizes CNC machining. By controlling the heating and cooling of the glass along a designated break line, this technique produces accurate cuts. When cutting laminates, the heat also seals the edges of the plastic layer, ensuring a clean finish.

Water jet cutting employs a high-pressure stream of water, sometimes combined with an abrasive material, to score and cut glass. The stream mimics the process of natural erosion, carefully removing glass along the programmed cut line. This method is versatile and can be used to shape glass for a variety of applications. Similarly, an air jet cutter can also be used, where compressed air mixed with abrasive materials helps score and cut the glass.

When choosing a glass manufacturer, it's important to consider both the customer's needs and the manufacturer’s capabilities. A quality commercial glass fabricator should have a well-equipped facility staffed with skilled designers and craftsmen. They should have ready access to raw materials and the proper machinery to deliver the desired outcomes. A responsible facility will operate with consideration for both environmental impact and economic sustainability. The ideal manufacturer will fully understand the client's requirements and help them engineer a satisfactory final product.

What Is Glass?

Glass is an inorganic, amorphous solid that maintains its rigid and brittle structure without crystallizing. Early humans used volcanic glass, or obsidian, to craft tools. During the Iron Age, glass beads made from slag—byproduct from early forging processes—were traded. Today, glass is a versatile material found in architecture, transportation, technology, and a wide array of everyday products. It is known for its resistance to heat, chemicals, corrosion, pressure, and its strength. Glass can also be reflective or refractive and comes in various forms, including transparent, translucent, or opaque barriers. It is used to create vessels in diverse shapes, sizes, and colors, ground into fine optical lenses, molded into laboratory instruments, or crafted into delicate works of art. Glass can also be spun into fibers, pressed or poured into molds, blown, blocked, and laminated. Glass fabrication is diverse and adaptable depending on the intended end product.

The properties of glass that make it suitable for customization are what make it a valuable material in manufacturing. It is made from silica, one of Earth's most abundant elements, and is 100% recyclable. By introducing other elements during production, the properties of glass can be tailored for specific uses. Soda-lime glass, made from silica, soda, and lime, is primarily used for bottles, jars, and float glass. Adding boron to silica produces borosilicate glass, which is heat resistant and expansive, making it ideal for Pyrex containers, known for maintaining accurate dimensions despite temperature changes. With the addition of phosphorus, it becomes borophosphosilicate, which is used in the production of semiconductors due to its electrical resistance. When alloyed with fluorite, the resulting fluorosilicate is used in the creation of CDs and DVDs. Lead added to silica results in optical glass, which is commonly used in eyewear lenses and optical scopes. Leaded glass is predictable and reproducible, ensuring consistent results.

Glass Cutting Terms

- Annealing

- A process in the manufacturing of float glass where the cooling of glass is controlled to prevent residual stresses. This process, done in a lehr, results in glass with a breaking strength of approximately 500psi.

- Annealing Lehr

- An apparatus in the float glass production line, located after the tin bath and before the cooling conveyor, that controls the heating and cooling processes. It relieves pressure from the flat glass to allow for normal cold-end processing.

- Anti-Walk Blocks

- Elastomer blocks used to prevent lateral movement of glass as it moves through the glazing channel, caused by forces such as seismic activity, thermal expansion, building movement, wind load, or other applicable factors.

- Autoclave

- A container used in the glass industry, where heat and extreme pressure create a bond between glass and PVB or urethane sheets, producing laminated glass.

- Bent Glass

- Glass that has been curved from a flat shape into the desired form during its molten state.

- Beveling

- The process of creating a bevel edge on finished cut glass.

- Bow/Warp

- An imperfection in flat glass where the surface bends, curves, or otherwise alters.

- Bubbles

- Imperfections in laminated glass where air or gas pockets form between the interlayer and the glass. A bubble is defined as any inclusion larger than 0.8 mm (1/32”) in diameter in float glass.

- Chemically Strengthened Glass

- Glass that has been strengthened through ion-exchange processes, creating a compressive pressure layer on the surface.

- Chipped Edge

- A flaw resulting from small pieces breaking off the edge of cut glass. This is particularly significant in heat-absorbing glass.

- Cullet

- Waste or broken glass, which can often be remelted and reused.

- Double Strength

- Float glass that is approximately 3 mm thick (1/8").

- Flare

- A protrusion along the edge of a piece of glass.

- Flat Glass

- A general term used to describe float glass, sheet glass, plate glass, and rolled glass.

- Float Glass

- Glass formed on a bath of molten tin. The surface in contact with the tin is known as the tin surface or tin side, and the top surface is referred to as the atmosphere surface or air side.

- Gob

- A portion of hot glass delivered by a feeder or gathered on a punty or pipe.

- Heat Absorbing Glass

- Glass specifically designed to absorb significant amounts of solar energy.

- Laminated Glass

- Glass consisting of two or more panes (lites) bonded with one or more interlayers, typically plastic. The glass lites can vary in color, thickness, or be mirrored or stenciled, with various interlayer materials used to achieve the desired effect.

- Lite

- An industry term for a pane of glass, spelled differently from "light" to avoid confusion.

- Moil

- The leftover glass remaining on a punty or blowpipe after the desired piece has been completed and cut off.

- Polished Wired Glass

- Wire glass that has been polished and ground on both sides.

- Punty

- A device used to hold glass during fire polishing or finishing.

- Quartz Glass

- Glass composed almost entirely of silica.

- Seam

- The mark left on a glass surface from the joining of matching mold parts.

- Temper

- The level of enduring stress present in annealed glass.