Grey Iron Casting

Grey iron casting is performed in a foundry, where molten iron alloys are poured into molds to create the final shape. Unlike some metals, grey iron cannot be forged or extruded at any temperature, so casting is the only viable method of forming it. While grey iron castings have lower tensile strength compared to other types of cast iron, they offer exceptional damping capacity by absorbing vibrational energy and converting it into heat. Thanks to its high thermal conductivity, durability, strength, excellent machinability, and cost-effectiveness, grey iron is commonly used in the production of valves, engine blocks, brake drums, pump housings, and cast-iron cookware.

The History of Iron Casting

The earliest iron castings were produced in China around the fifth century B.C., where they were used to create ploughshares, basic cooking pots, and weapons. Evidence suggests that the practice of iron casting spread along the Silk Road, eventually being used to produce shot. However, it did not reach Western culture until the fifteenth century, when Henry VIII employed the process to manufacture heavy cannons for the Royal Navy.

In 1707, Abraham Darby developed a method for casting thinner-walled pots, which led to the introduction of cast iron cookware. His innovation also allowed for the casting of items such as shields and certain pieces of body armor, which continued to be produced until the mid-1700s.

The structural use of cast iron began in the 1770s when James Watt improved upon Thomas Newcomen's steam engine design, enhancing foundry and forge capabilities. One of the first architectural applications of cast iron was in bridge construction. However, iron proved to be short-lived under heavy structural loads and was eventually replaced by steel in the early 1800s.

During the Industrial Revolution, cast iron became popular in building construction, primarily as a fire prevention measure. Textile mills, which were highly susceptible to combustion from flammable dust and fibers, benefited greatly from the introduction of cast iron components. This not only improved fire resistance but also made it possible to construct larger and more robust buildings. Over time, cast iron was also used to manufacture the structural frameworks and machine components housed within these industrial facilities.

Advantages of Gray Iron Casting

Iron casting is relatively inexpensive, and castings can be produced in a short amount of time. Gray iron, in particular, is known for its high compressive strength, excellent damping capacity, and ease of welding and machining. It also experiences less shrinkage during the cooling process compared to other iron casting methods. However, a key drawback of gray iron is its low shock resistance—it can fracture or shatter upon impact.

Creation of Iron

Iron is the final element formed in a collapsing supernova. It exists in both the inner and outer cores of the Earth and is the planet’s most abundant element. As a transition metal, iron occurs naturally in a variety of forms. In its purest state, it is soft and malleable, though rarely found in an uncontaminated form in nature. Iron must be mined and extracted from ore, after which it can be alloyed with other elements to create cast iron or steel products in various grades, each designed for specific applications and strength requirements.

Graphite is a crystalline form of carbon, created under conditions of extreme heat and pressure. It naturally forms in layered sheets of hexagonal flakes, each only one atom thick. This flat, layered structure gives graphite its smooth, lubricated feel. In its pure form, graphite is soft and cleaves easily, which makes it ideal for pencil cores, as the layers slide off onto paper one at a time. When alloyed with iron, the graphite flakes act as self-lubricating agents, giving gray iron its excellent machinability and wear resistance.

Graphite occurs naturally in igneous and metamorphic rocks, forming in areas where shale and limestone have been subjected to the intense heat and pressure of tectonic movement. Natural graphite is refined through a process of crushing and froth flotation, which separates and liberates the flake graphite. Graphite is also synthetically produced by superheating coal-tar pitch or petroleum coke to remove volatile materials and vaporize undesirable metals, leaving behind sheets of nearly pure carbon—up to 99 percent purity.

Silicon plays a key role in the crystallization process by accelerating graphitization and reducing the formation of unstable iron carbides. The rate at which the molten alloy solidifies also affects the outcome of graphitization. A slower cooling period allows carbon to diffuse into the iron matrix, resulting in gray cast iron. In contrast, rapid solidification produces a pearlitic or ferritic structure, yielding white iron, or cementite.

Physical Makeup of Gray Iron

Graphite is what gives grey iron its characteristic gray color—and its name, which may be spelled either “gray” or “grey.” When an iron casting is fractured, the color visible at the break—gray, white, or black—can reveal key insights into its composition. According to ASTM International Standard A 48, grey iron is classified by tensile strength, measured in thousand pounds per square inch (1k psi). For example, Class 20 indicates low tensile strength but higher ductility, while Classes 30, 40, and 60 reflect increasing strength, though at the cost of reduced ductility. Class 80, while offering very high tensile strength, is also quite brittle. ASTM A 247 further specifies the graphite structure present within the gray iron casting. To meet ASTM A 48 requirements, an iron alloy must contain between 6 and 10 percent graphite by volume in its microstructure to qualify as grey iron.

Graphite is either added to or formed within the molten metal during the casting process, and the volume and structure of this graphite must comply with ASTM standards to achieve the mechanical properties required for the final application. Additional standards relevant to grey iron classification and production include ASTM A126, ASTM A278, and ASTM A319.

While various standardized grading systems exist, the general composition of grey cast iron consists of approximately 95% iron by weight, with 2.1 to 4% carbon and 1 to 3% silicon. Manganese and other elements are often present, either as impurities or added intentionally to tailor specific properties. For example, sulfur may be introduced to increase hardness, which is otherwise low in many cast iron components. In grey iron, the high silicon content plays a crucial role in promoting graphite formation during heating, which results in the signature gray appearance due to the deflection of light by the flake-like graphite microstructure. Though graphite usually forms as flakes in grey iron, in ductile cast iron, slower cooling rates allow the graphite to develop into spheroidal particles instead. Both temperature and timing significantly influence the final structure and properties of grey iron castings.

In the automotive industry, the SAE (Society of Automotive Engineers) uses a grading system based on the Brinell hardness scale rather than tensile strength classes. These grades serve a similar purpose in categorizing the performance characteristics of cast metals.

Grey Iron Castings Images, Diagrams and Visual Concepts

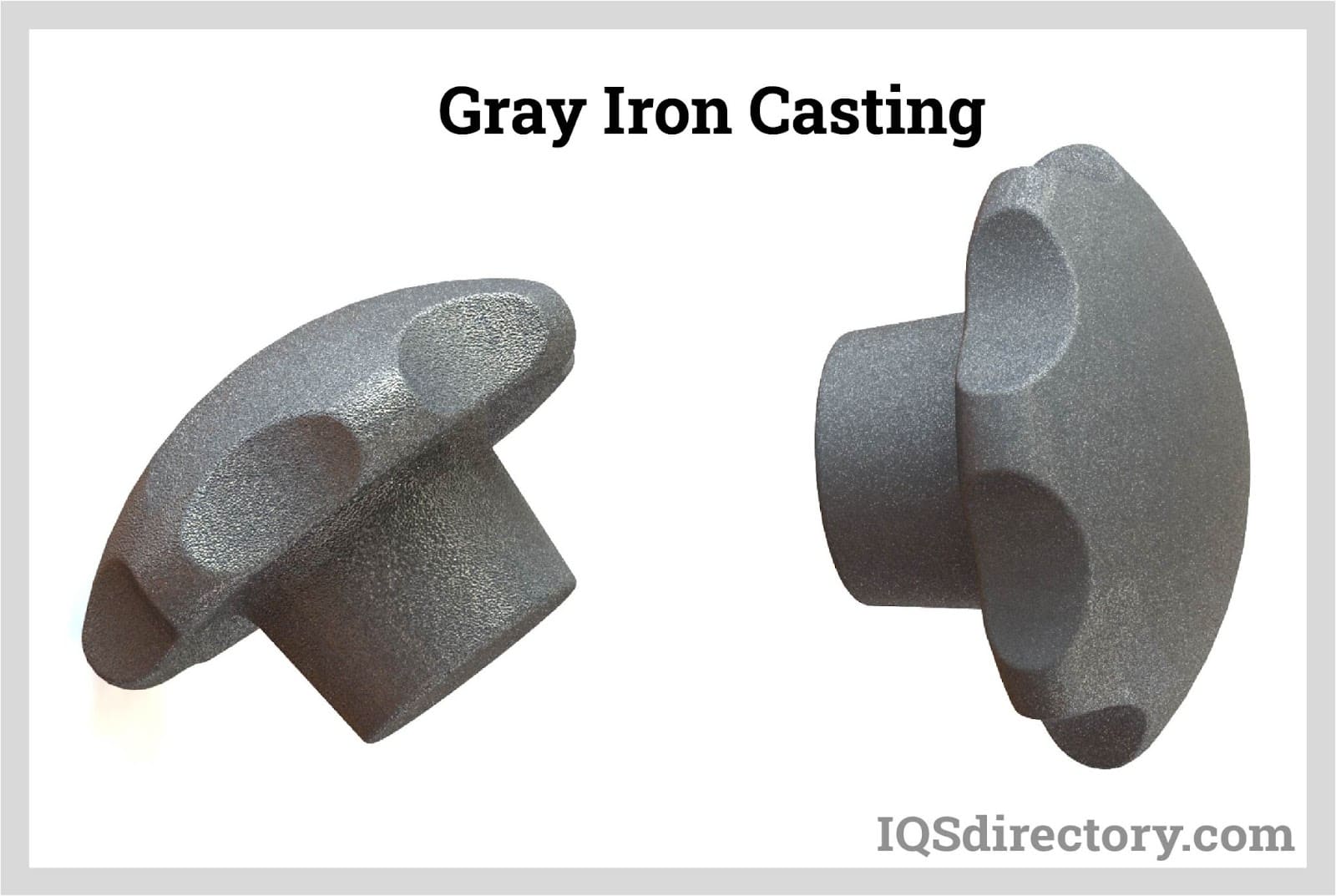

Gray cast iron is the graphic microstructure, which is able to cause fractures to the material and has a gray appearance.

Gray cast iron is the graphic microstructure, which is able to cause fractures to the material and has a gray appearance.

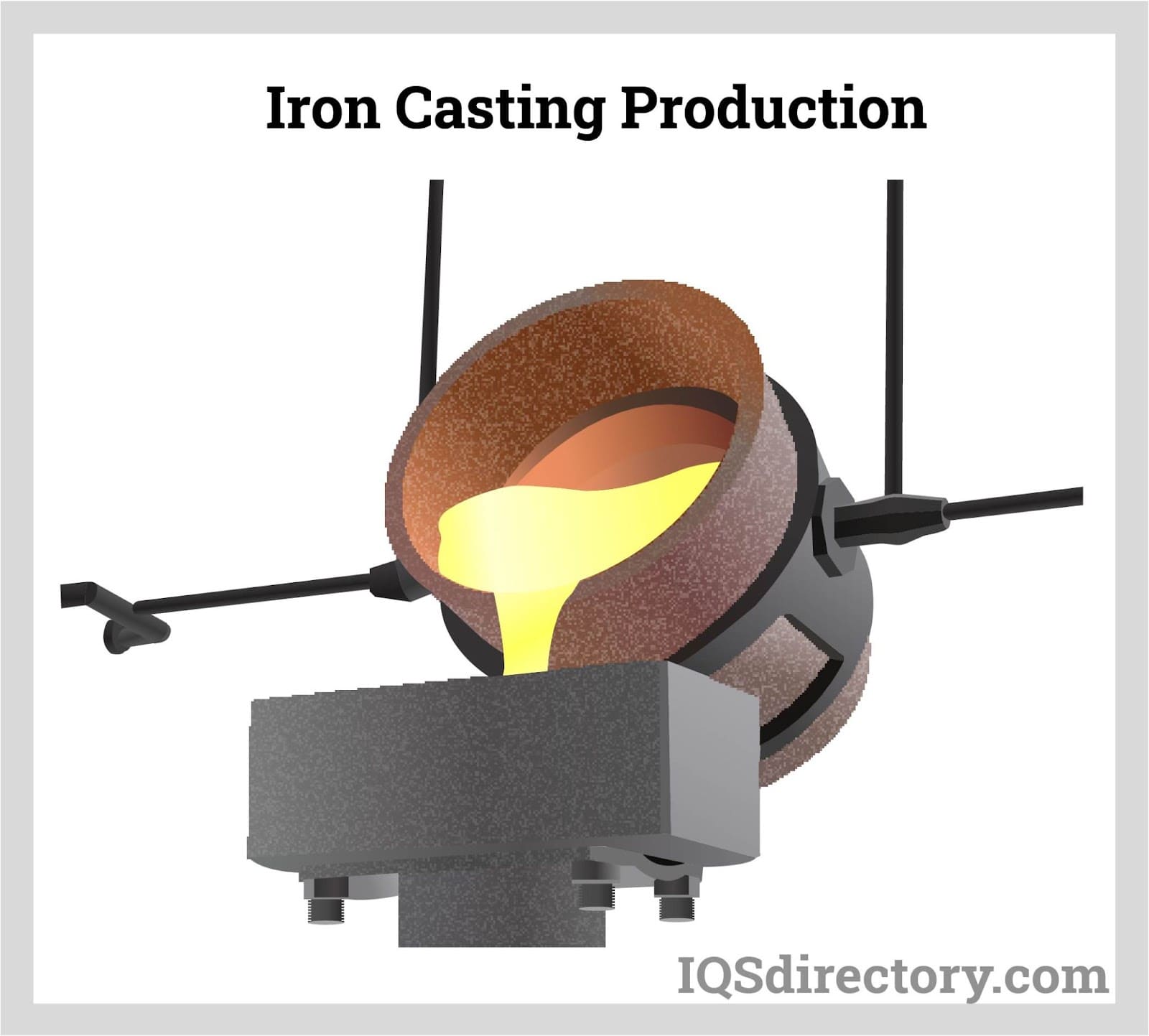

Cast iron is made from pig iron and is the product of melting iron ore in a blast furnace.

Cast iron is made from pig iron and is the product of melting iron ore in a blast furnace.

Ductile cast iron is made from pig iron and the product of melting iron ore in a blast furnace

Ductile cast iron is made from pig iron and the product of melting iron ore in a blast furnace

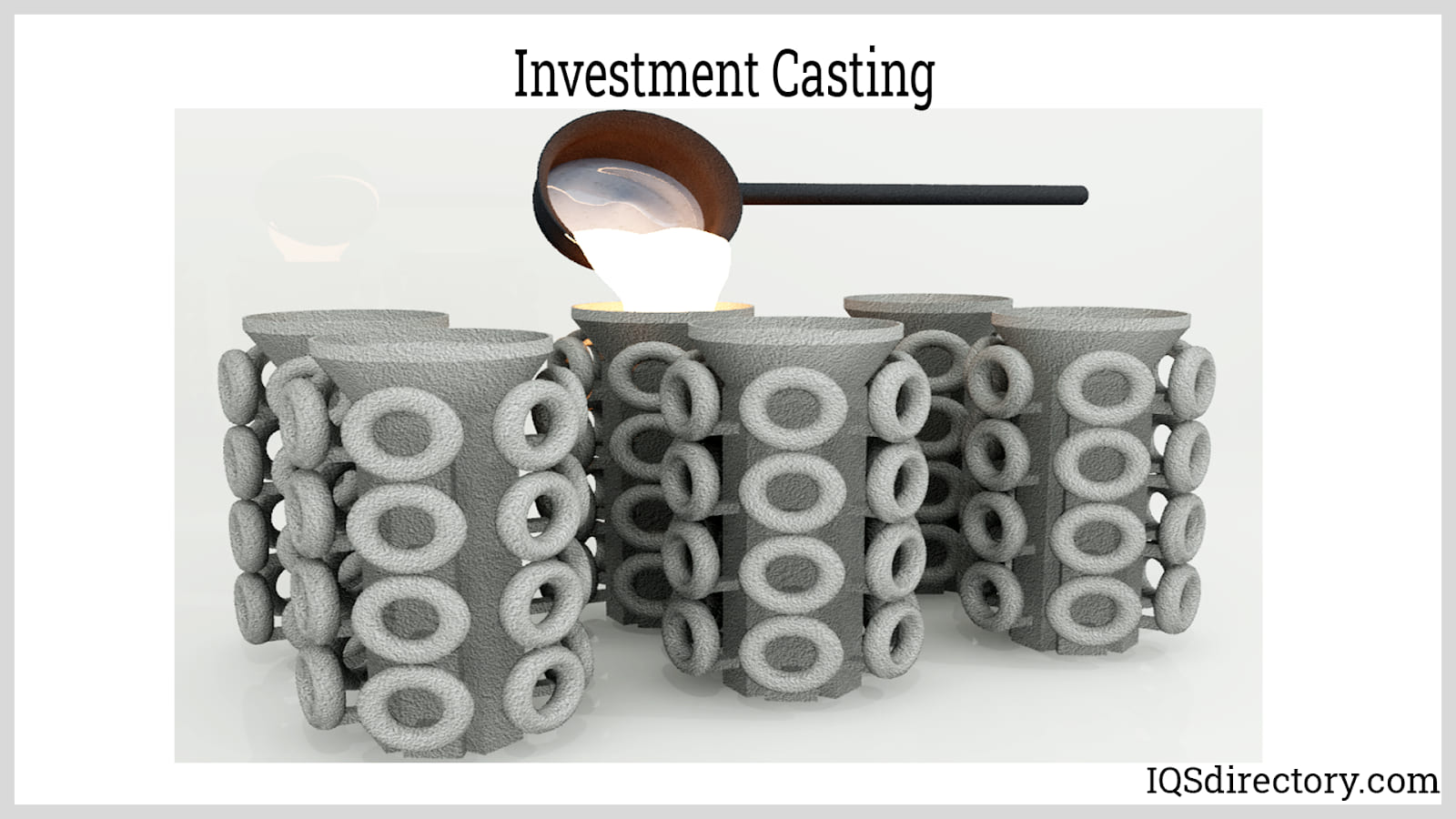

Investment casting, uses a ceramic shell built over a wax pattern to produce parts with uniform and smooth surfaces.

Investment casting, uses a ceramic shell built over a wax pattern to produce parts with uniform and smooth surfaces.

Sand casting, a process were liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then solidified.

Sand casting, a process were liquid metal is poured into a sand mold, which contains a hollow cavity of the desired shape and then solidified.

Centrifugal casting, a process where molten metal is poured in the mold, and it is then solidified while the mold will be rotating.

Centrifugal casting, a process where molten metal is poured in the mold, and it is then solidified while the mold will be rotating.

Types of Grey Iron Castings

-

Alloy Castings

Cast components made from a combination of metals. Nearly all castings are alloys, as it is generally difficult to mold a single pure metal due to its lack of fluidity or inconsistent solidification.

Cast Iron

A broad category of ferrous alloys containing approximately 95% iron by weight, along with 1–3% silicon and 2–4% carbon. The two primary types of cast iron are grey iron and white iron.

Core Processes

Techniques that use a solid barrier or insert, known as a core, around which the casting is formed. This allows for the creation of internal cavities and complex shapes such as reentrant angles within solid iron castings.

Ductile Castings

Iron components molded from a specialized group of iron alloys engineered for enhanced flexibility. These castings offer more elasticity than traditional grey iron, which is typically brittle.

Ductile Iron Casting

Thin molded parts made from ductile iron or ductile iron alloys. These castings can be stretched, drawn, or shaped without fracturing, offering a balance of strength and malleability.

Gray Iron Castings

Produced by molding molten gray iron alloys. While traditionally referred to as "cast iron," the modern distinction identifies grey iron by its flake graphite structure, while other cast irons may offer greater ductility.

Gray Iron

Also known as cast iron, this is an affordable and widely used metal for cast products. While historically synonymous with all cast iron, modern cast iron now includes more ductile variations of iron-carbon alloys.

Green Sand Casting

A process that utilizes disposable molds made from sand-based slurries. The term “green” refers to the moist condition of the mold at the time of casting, not the color. It is commonly used for casting iron parts across a variety of industries.

Grey Casting

The formation of molded components using a family of iron alloys with elevated carbon and silicon content, recognized for their gray, flake-like graphite microstructure.

Iron Castings

Any cast product primarily made from iron. Iron’s abundance and strength make it an ideal material for foundries producing components for various structural and industrial applications.

Iron Foundries

Facilities equipped to carry out all stages of iron casting, including melting, molding, finishing, and inspection for cast products in diverse sizes and configurations.

Malleable Iron Castings

Castings composed mostly of iron, but with microstructures altered through heat treatment to allow for bending and shaping without cracking—unlike standard brittle iron castings.

Spheroidal Graphite Cast Iron

Also known as ductile iron, this family of iron alloys is designed to promote the formation of spherical graphite particles, resulting in molded components with superior tensile strength, durability, and elasticity.

Manufacturing Grey Iron

The foundry is the facility where iron casting is carried out. Raw materials are delivered to the site and processed through detailed systems of sorting, measuring, and mixing, all in accordance with ASTM standards. These prepared materials are then introduced into a furnace, where they are melted to form molten metal.

Iron foundries commonly use one of three types of furnaces to reach pouring temperature: electric arc furnaces (EAFs), induction furnaces, or cupolas. EAFs generate heat through electrical arcs and are typically used for small batches of one ton or less. Induction furnaces rely on gas-generated heat to melt the metal. Cupolas, on the other hand, are tall, cylindrical structures that resemble smokestacks supported by legs. They include doors at the base for discharging molten metal. Ranging in diameter from about 1.5 to 13 feet, cupolas are constructed from steel and lined with refractory materials. They burn coke to generate heat and facilitate graphitization of the molten iron.

During the melting process, agitation of the alloy causes degassing—the release of hydrogen bubbles formed through chemical reactions. If not properly removed, these gas bubbles become trapped in the mixture and result in porosity, which compromises the final product’s strength and long-term durability.

In early foundries, molten metal was poured manually using ladles—a practice that was extremely hazardous and only feasible for small parts. Today’s foundries prioritize both safety and efficiency by utilizing robotic arms and automated systems to handle pouring, significantly reducing risk and increasing precision in the casting process.

Molding of Cast Iron

Once the molten metal reaches the proper temperature, it is poured into molds. These molds may be made from a single solid pattern or designed as two-piece split pattern molds, consisting of a cope (top half) and a drag (bottom half) that meet at the parting line.

Molds are built with a slight taper, or draft, along the edges to ensure the cast part can be removed without damage. In more complex castings, a core is used to create internal voids that cannot be formed by the mold alone. Since the core is typically broken apart during removal, it is usually made from disposable materials.

To begin the process, a full-scale pattern of the desired product is made from wax, wood, plastic, or metal. This pattern is then used to create the mold. The method used to produce the mold depends on several factors, including the size, complexity, material, and quantity of the final product.

Sand casting is one common technique that employs green sand—a blend of natural silica sand and clay as a bonding agent—or resin-bonded sand, which uses polymer resins to hold the sand in place. A pattern is pressed into the sand to form an impression, then removed, leaving a cavity. Molten metal is poured into this space, and after cooling, the mold is broken apart in a process known as shakeout. Shaking or tumbling the mold loosens the sand and frees the casting.

Investment casting is more often used for precision steel castings. A wax replica of the product is created, and through repeated steps of coating and curing, a detailed ceramic shell is formed around it. Once the shell has hardened, it is inverted and heated so the wax melts and drains out, leaving behind a cavity that can be filled with molten metal. The resulting casting is highly accurate and often requires little or no post-processing or machining.

After Molding Cast Iron

Some cast iron pieces require heat treatment—a secondary process involving controlled heating and/or cooling—to achieve desired mechanical properties such as annealing, case hardening, tempering, or quenching. These treatments are used to enhance the strength and durability of the casting.

If a cast piece contains internal porosity, it can be sealed through a process called metal impregnation. This technique uses high vacuum pressure to force fine metal particles into the voids, effectively sealing the surface and preventing leakage or corrosion.

Another post-casting process is shot peening, a form of surface treatment similar to sandblasting. This method involves "hammering" the outer layer of the metal with small spherical media, which compresses the surface and increases its resistance to cracking. Shot peening is particularly useful in applications like bell casting, where enhanced surface strength is essential.

Finding a Foundry

The strength of a foundry is defined by its ability to consistently deliver high-quality iron castings. When selecting a partner, look for a company with a proven reputation for producing reliable cast products on schedule and at fair pricing. Since pattern and mold creation can be one of the most time-consuming aspects of iron casting, it’s important to ensure the foundry offers design services and set-up procedures that align with your project timeline.

A dependable foundry will also maintain a steady supply of raw materials and implement a comprehensive waste management program. Iron casting generates by-products such as emissions, dust, and slag, which may vary in toxicity and must be properly handled to meet environmental and safety standards.

If your castings require finishing work, the foundry should either provide these services in-house or have trusted partners capable of performing tasks such as milling, polishing, or painting to complete the final product.

Similar Casting Processes

In 1943, Keith Mills discovered the process of ductile iron casting. Ductile iron refers to a group of iron alloys with carefully controlled microstructures. Also known as nodular iron casting, spheroidal graphite casting, or SG iron casting, this method introduces magnesium as a nodulizing agent in the casting process—much like how silicon is used as a stabilizer in gray iron casting. The formation of nodular graphite inclusions within the ductile iron enhances its tensile strength and improves resistance to fatigue and impact.

Ductile iron castings possess significantly greater tensile strength than traditional gray iron castings. This makes ductile iron ideal for applications such as water and sewer lines, where polymer-based alternatives cannot match its durability and structural performance. It is also widely used in the manufacture of components for automobiles, trucks, tractors, oil rigs, piano harps, and windmills. Ductile iron is especially well-suited for casting large, complex shapes and is capable of withstanding repetitive mechanical loads.

Malleable iron casting, one of the earliest iron casting techniques dating back to between four and nine centuries BC, was developed in response to the brittleness of early cast iron products. By slowly reheating finished iron castings over extended periods—sometimes lasting several days—the material gained improved tensile strength, ductility, and resistance to fracture. This heat treatment process made the iron castings more workable, allowing them to be shaped or cold worked after casting.

Grey Iron Castings Terms

-

As–Cast Condition

Refers to a casting in its original state, without undergoing any subsequent heat treatment.

Brinell Hardness Number (BHN)

A numerical value assigned to a grey iron casting after it has undergone the Brinell hardness test. A higher BHN indicates a harder material.

Brinell Hardness Test

A method used to determine the hardness of a material. For grey iron castings, this involves pressing a 3000 kg metal ball into the flat surface of the material. After the ball is removed, the resulting indentation is measured to calculate the material’s hardness.

Chaplet

A small metal insert or spacer used during molding to support and secure the core in place.

Cope

The top half of a mold or a casting formed in a horizontal position.

Deflection

The degree to which an iron casting bends or deforms when subjected to an external load. This is a key factor for applications where the casting will be load-bearing.

Drag

The bottom half of a horizontally formed mold.

Ductility

Describes a grey iron casting’s ability to deform without fracturing. Grey iron castings exhibit a notable level of ductility.

Ferrous

A term for materials that are made of or contain iron.

Foundry

A facility where molten metal is poured into molds to produce metal castings.

Galling

A surface condition caused by excessive friction between metal surfaces, leading to deformation and potential adhesion. Grey iron is known for its resistance to galling.

Hypereutectic Iron

Iron alloy containing more than 4.3% carbon by weight.

Hypoeutectic Iron

Iron alloy composed of 4.3% carbon or less.

Malleable

A material property describing the ability to be pressed, hammered, rolled, bent, or otherwise formed without cracking.

Modulus of Elasticity

The ratio of stress to strain in an elastic material, representing its stiffness.

Permeability

A property of molds or cores that allows gases to escape during the pouring of molten metal.

Pilot Casting

Also known as a sample casting, this is a test piece produced using a production die to verify dimensional accuracy and quality before a full production run.

Porosity

Holes or voids in a casting caused by trapped gases or chemical reactions between molten metal and substances such as chaplets.

Pounds per Square Inch (PSI)

A unit of pressure that describes the force a material exerts on the walls of an enclosed space. Standard atmospheric pressure at sea level is 14.7 psi.

Shrinkage

The reduction in size that occurs as a material solidifies. Grey iron undergoes minimal shrinkage during solidification.

Tensile Strength

The maximum stress a material can withstand while being stretched or pulled before breaking. Grey iron castings typically exhibit tensile strengths ranging from 20,000 psi to 60,000 psi.