Heat Exchanger

Heat exchangers are devices made from thermally conductive materials, designed to transfer heat between fluids. Depending on the type of heat exchanger, the fluids may either come into direct contact or remain separated. These devices are primarily used to facilitate heat transfer for processes that involve cooling or heating substances, which are later used in various applications.

Heat exchangers play a critical role in industries involved in heating systems design, power generation, air-conditioning systems, chemical processing, engineering, and waste heat recovery. The fundamental principle behind heat exchangers is also applied in the design of boilers, which are used to heat large spaces by transferring heat from a centralized source to the surrounding area.

Heat Exchangers FAQ

What is a heat exchanger and how does it work?

A heat exchanger transfers heat between two fluids without mixing them. It uses thermally conductive walls to move heat from the hot fluid to the cooler one, improving heating or cooling efficiency in various industrial processes.

What are the main types of heat exchanger flow configurations?

The main flow configurations include counterflow, cocurrent flow, crossflow, and hybrid designs. Counterflow systems, where fluids move in opposite directions, are the most efficient due to their large temperature differentials.

What is the difference between recuperative and regenerative heat exchangers?

Recuperative exchangers keep fluids in separate channels divided by walls, while regenerative exchangers use a shared matrix that alternately absorbs and releases heat. Recuperative designs are more common due to reduced risk of cross-contamination.

Where are shell and tube heat exchangers used?

Shell and tube heat exchangers are widely used in power generation, HVAC, and chemical processing. Their design allows fluids to flow inside and outside metal tubes, efficiently handling high temperatures and pressures in industrial environments.

How are plate heat exchangers different from tubular models?

Plate heat exchangers use thin metal plates to separate fluids, offering a large surface area for efficient heat transfer. Tubular models use cylindrical tubes, making them more durable under pressure but less compact than plate designs.

How is fouling prevented in heat exchanger systems?

Fouling can be minimized through water treatment, chemical additives, and technologies like water-borne oscillation, which help reduce impurities and biofilm buildup on heat transfer surfaces, maintaining system efficiency over time.

What should be considered when selecting a heat exchanger manufacturer?

Buyers should evaluate a manufacturer’s experience, material quality, reputation, and delivery capability. Long-standing companies with strong quality control and reliable distribution networks ensure durable and efficient heat exchangers for industrial applications.

History of Heat Exchangers

The earliest known methods of heat transfer involved rocks used to warm homes during the early stages of human evolution. These stones were heated in a fire and then transferred inside dwellings to provide warmth. The Romans later advanced home heating with the invention of hypocaust technology, which created a space under the floor to allow hot air to circulate and warm the room. The floors were made of concrete materials that retained heat and transferred it efficiently.

In Korea, a similar technology known as Ondol heating was developed. This system channeled hot air and smoke from wood fires through pipes running under the floors. A major leap forward came in the 1700s when Jean Simon Bonnemain, a Frenchman, designed a water system to incubate chicken eggs. In the 1800s, Marquis de Chabannes created a heat exchanger for growing grapes in a greenhouse. By 1829, the Price brothers pioneered steam heating in England, marking a significant step in the development of modern heat exchange systems. The use of hot water and steam continued to revolutionize heating technology, leading to the advanced heat exchangers we use today.

Heat Exchangers Images, Diagrams and Visual Concepts

Heat exchangers, devices that transfer heat between fluids separated by a wall with high thermal conductivity to prevent mixing of the fluids.

Heat exchangers, devices that transfer heat between fluids separated by a wall with high thermal conductivity to prevent mixing of the fluids.

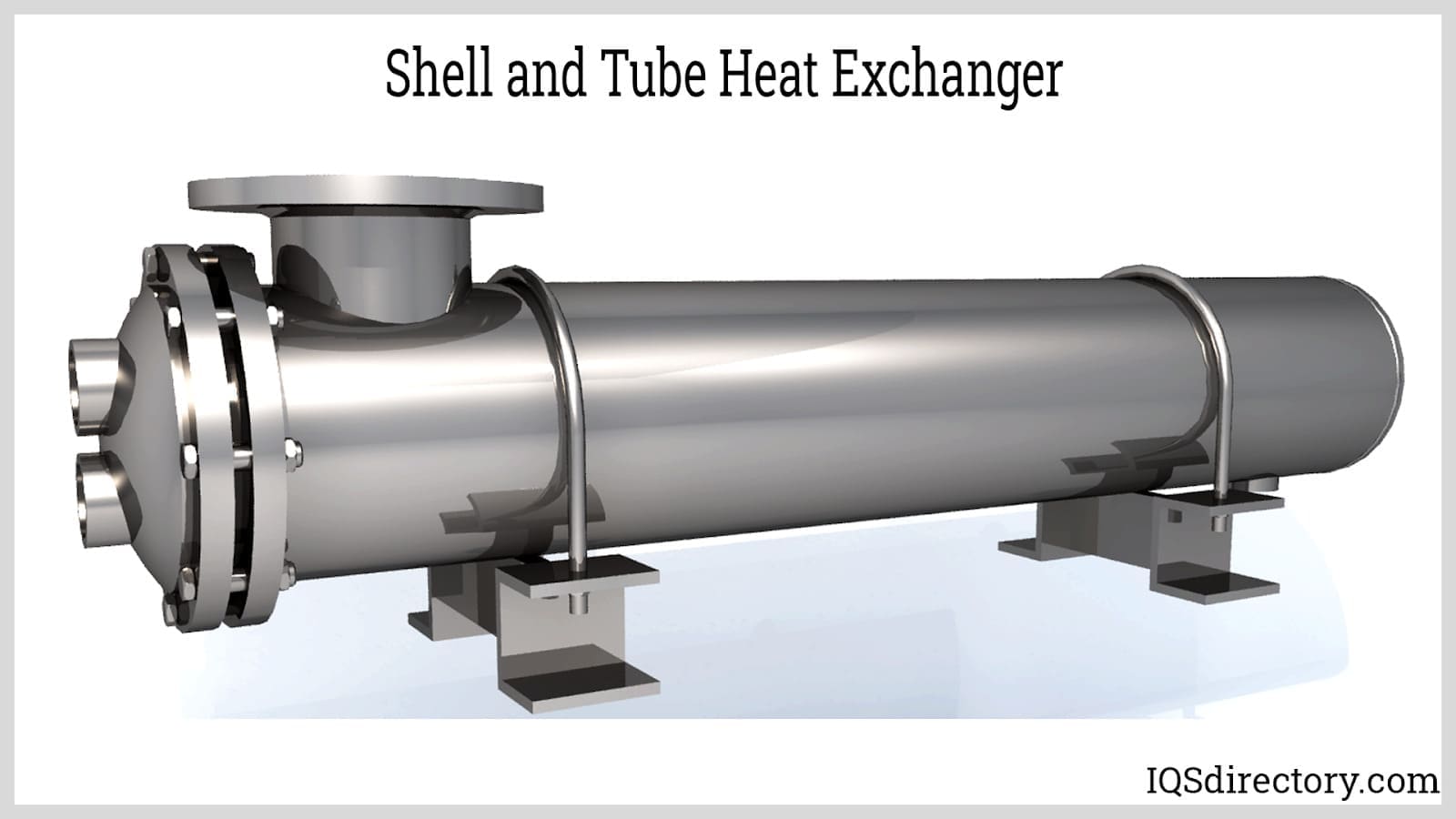

Shell and tube heat exchanger using a large cylindrical enclosure whaich has bundles of spaced tubing compacted in the interior.

Shell and tube heat exchanger using a large cylindrical enclosure whaich has bundles of spaced tubing compacted in the interior.

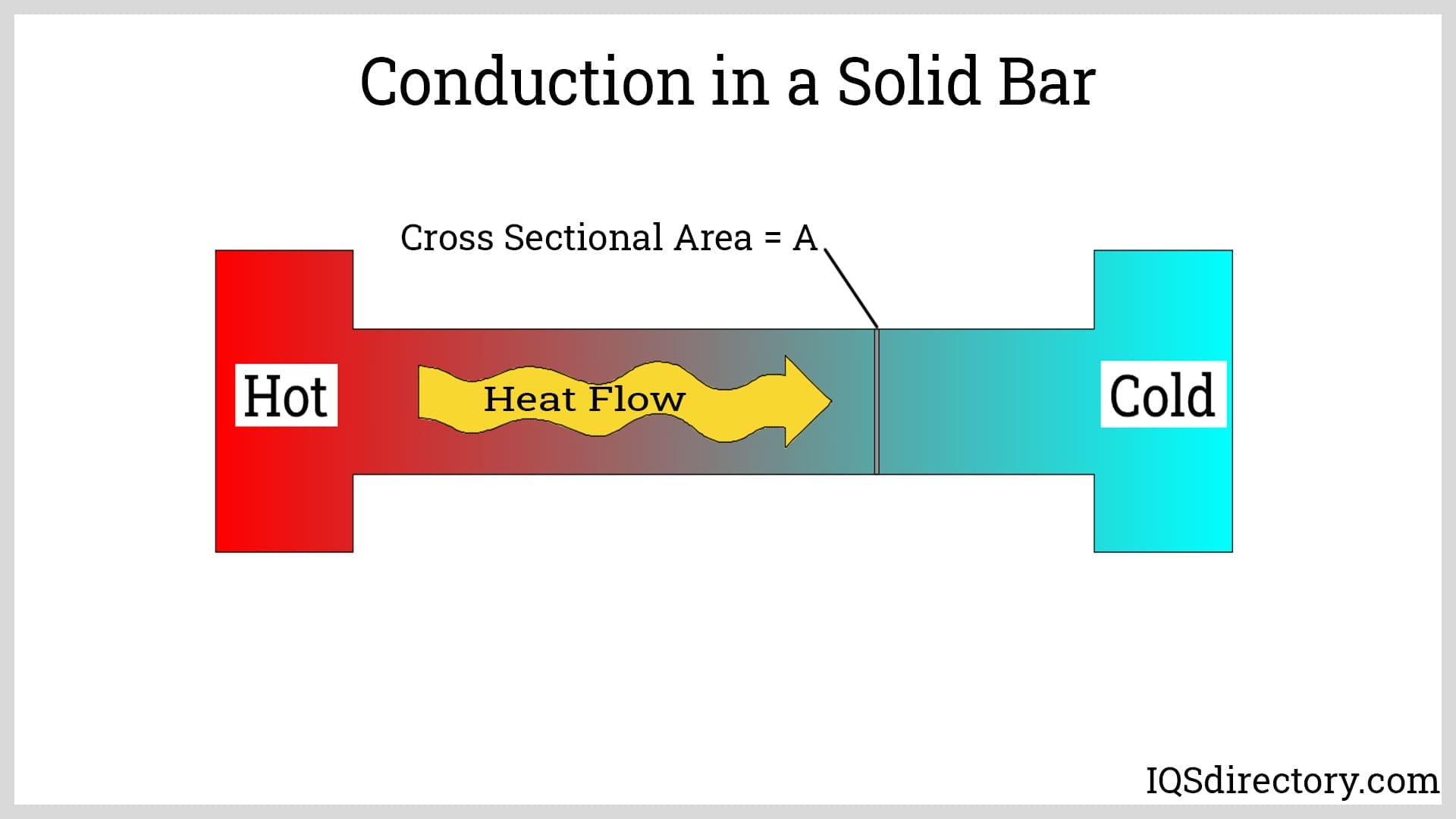

Transfering heat energy with molecules with high kinetic energy by direct collisions of adjacent molecules with lower kinetic energy.

Transfering heat energy with molecules with high kinetic energy by direct collisions of adjacent molecules with lower kinetic energy.

Plate heat exchanger a compact heat exchanger that uses a series of thin metal plates transfering heat from one fluid to another.

Plate heat exchanger a compact heat exchanger that uses a series of thin metal plates transfering heat from one fluid to another.

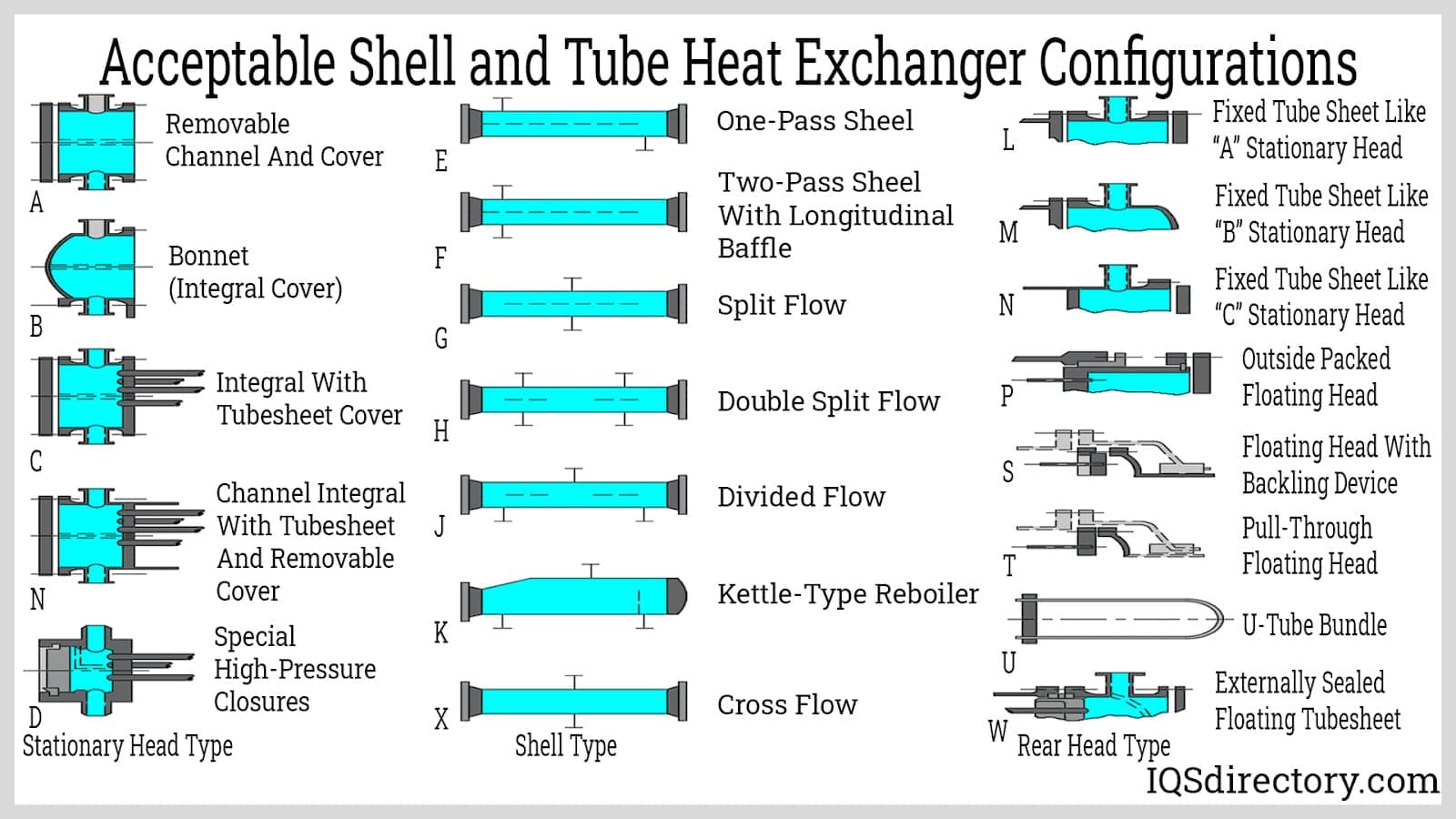

The different configurations for the cover, flow, and head of heat exchangers.

The different configurations for the cover, flow, and head of heat exchangers.

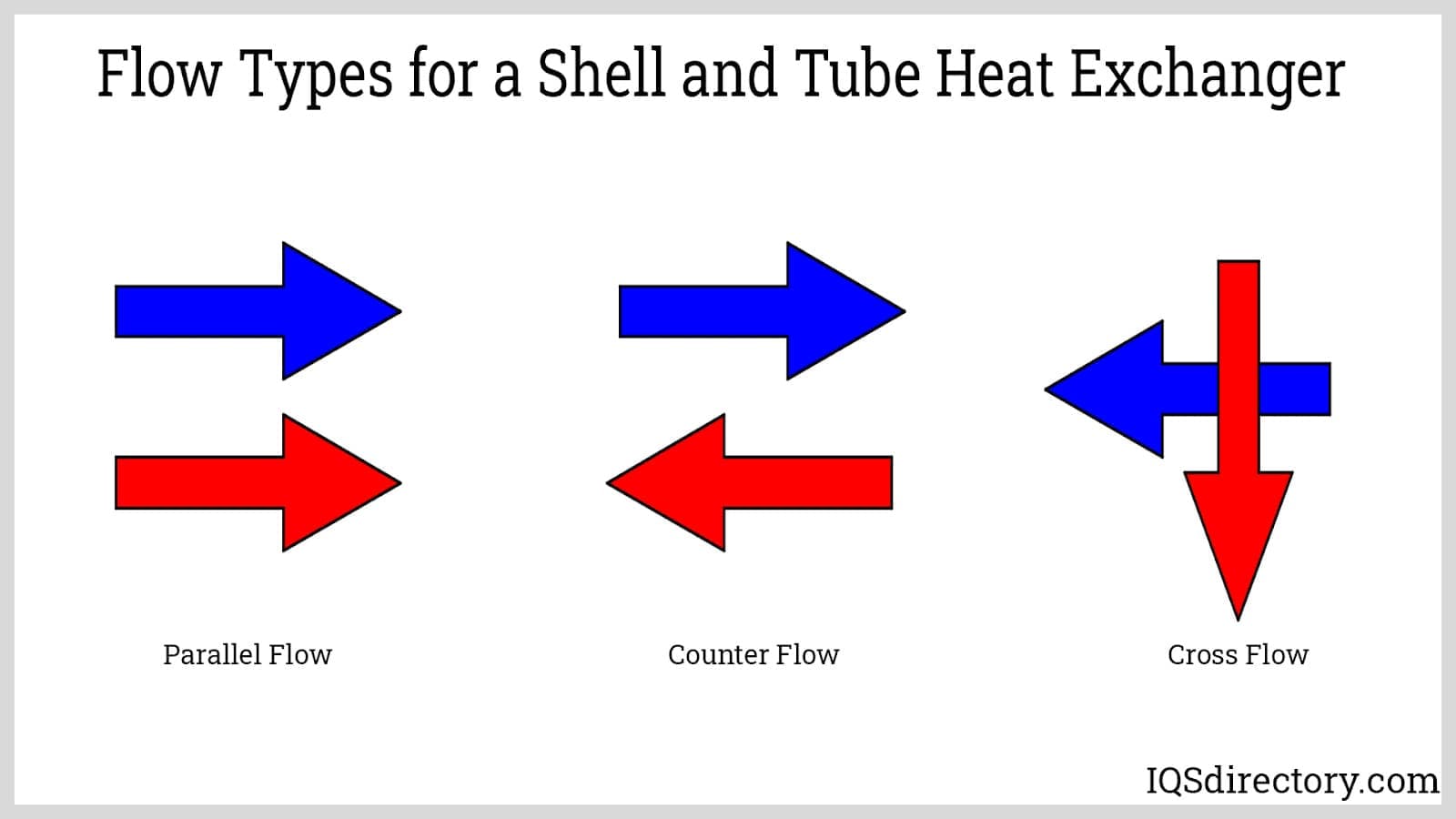

Classification process for heat exchangers is dividing them by their characteristics and one method is the flow directions either parallel, counter, or cross flow.

Classification process for heat exchangers is dividing them by their characteristics and one method is the flow directions either parallel, counter, or cross flow.

Types of Heat Exchangers

To fully understand how heat exchangers work, it's important to examine their two primary classifications: flow configuration and equipment classification, which is based mainly on construction.

Heat Exchanger Classification by Flow Configuration

The four main types of flow configurations include:

- Counterflow

- Cocurrent Flow

- Crossflow

- Hybrid

- Counterflow

- This configuration involves two fluids flowing parallel but in opposite directions. This arrangement allows for a significant temperature change in the fluids, making it the most efficient. To find manufacturers who specialize in this type of heat exchanger, you can check out IQS Directory's list of manufacturers.

- Concurrent Flow

- In this design, the fluids flow in parallel in the same direction. Although the efficiency of this model is lower, it provides uniformity in wall temperatures.

- Crossflow

- This configuration offers an intermediate level of performance between counterflow and concurrent flow. In crossflow, the fluids flow at right angles to each other.

- Hybrids

- Common in industrial applications, hybrid models combine counterflow or concurrent flow with multipass flow heat exchangers, offering enhanced versatility.

Heat Exchanger Classification by Construction

Classification according to design results into two main groups namely:

- Recuperative Heat Exchangers

- Regenerative Heat Exchangers

- Recuperative Heat Exchangers

- These exchangers feature separate flow paths for fluids, which flow continuously within the exchanger. The heat exchange happens across a wall that separates the fluids. Recuperative designs are widely used in different industries and can be divided into several categories, including:

- The Indirect contact exchangers

- The Direct Contact Exchangers

- The Specials

- The Indirect Heat Exchangers

- In this category of heat exchangers, the steam or fluids are separated by a wall which is usually made of metal. They basically include:

- The Tubular Heat Exchangers

- Commonly used due to their flexibility with pressure and temperature variations, especially in the shell-and-tube model. You can find tubular heat exchanger manufacturers on industry directories.

- The Shell and Tube Heat Exchangers

- Consist of multiple tubes inside a cylindrical metal shell, allowing fluid to flow both inside and outside the tubes. These exchangers are used in applications where fluid flows in single or two-phase conditions. They have four key parts: the frontend (entry point for fluid), the rear end (exit point), the tube bundle (holding the tubes together), and the shell (housing the tube bundle). These heat exchangers are built to withstand heat, pressure, and corrosion, typically using materials like stainless steel, titanium, and copper.

- Furnaces

- Use electric heaters or burners to generate heat.

- The Tube in Plate

- Their application is mainly in heat recovery and air conditioning. Plates act as the support and as well provide more surface area due to extensions.

- Electrically Heated System

- Use heated pipes that deliver heat to the fluid through external pipes.

- Air Cooled System

- Incorporate fans and tube bundles to cool fluids when water is unavailable.

- Air-to-Air Heat Exchangers

- Replace stale indoor air with fresh air from outside, similar to how a fan might circulate air in a house.

- Brazed Plate Heat Exchangers

- Plates are brazed together to eliminate leaks.

- Flat Plate Heat Exchangers

- Transfer heat through flat, corrugated plates.

- Gasketed Plate Heat Exchangers

- The most common. Elastomer gaskets are used in the plates, which contain the pressure and control the flow of each medium.

- Heat Pipes

- Mainly comprises of a working fluid as well as wack material. The fluid absorbs heat, then it evaporates and passes through the pipe to the end where it condenses and releases heat.

- Marine Heat Exchangers

- Designed for use on boats.

- Oil Coolers

- Heat exchangers that are specifically designed for the transfer of heat, or thermal energy, by carrying the oil through cooling units in order to cool.

- Agitated Vessels

- Play a crucial role in heating viscous fluids. These devices consist of a vessel that contains tubes inside as well as an agitator, like the helical ribbon impeller or propeller. The tube is for transporting the hot liquid while the agitator ensures uniform heat distribution through the cold liquid.

- Water to Air Heat Exchangers

- Devices used to transfer processed heat from water into the air.

- Water to Water Heat Exchangers

- Transfer heat energy from one liquid to another without bringing the two liquids into direct contact.

- Welded Plate Heat Exchangers

- Fully welded and require no gaskets. These are usually constructed of one material, generally stainless steel.

- Carbon Block Exchangers

- Come in handy in heating or cooling of corrosive fluids. They comprise of carbon steel blocks in which holes are drilled to enable fluid passage. The blocks are finally bolted together.

- Plate Heat Exchangers

- Plate heat exchangers by design separate the fluids using plates. The plates have increased surface area either by using fins or embossing. More so, they can be bolted, brazed or welded together. The plate exchangers are common in food processing and cryogenic industries. Due to their desirable aspects such as high surface area to volume ratio, ability to handle more than two types of steam and low fluid inventory, plate heat exchangers are being incorporated in the manufacturing of chemicals.

- They include:

- Plate and Frame Heat Exchangers

- Easy to disassemble for cleaning, using elastomer gaskets to seal the plates.

- Plate-Fin Heat Exchangers

- Used for gas liquefaction, allowing multiple fluid streams within one exchanger.

- Lamella Heat Exchangers

- Bear a resemblance to the shell and tube model. They therefore comprise of tubes that are joined together forming a bundle. In this design, one of the fluids flows through the tube while the other flows through the gaps between the tubes. These exchangers are prevalent in paper industries.

- Spiral Plate Exchangers

- Developed through winding of two flat and parallel plates forming a coil. The terminals are either welded or sealed with a gasket. Their usage lies in viscous, heavy fouling fluids or fluids that contain particles or fibers.

- Steam Coils

- A type of heat exchanger that utilizes steam on a coil to transfer heat to a particular area. Since steam is relatively inexpensive many will turn to this style of heat exchanger. Steam coils are typically manufactured from reliable materials such as stainless steel.

- Coil Heat Exchangers

- Work to increase or decrease the heat of fluids. They may facilitate exchanges between two liquids, a liquid and a gas or vapor or two gases or vapors. Coil heat exchangers, again, like many of their cousins, are built to disallow any physical contact between the substance being cooled and the substance doing the cooling.

- Direct Contact

- Do not make use of the heat transfer surface. However, to use the design with two fluids, they ought to be immiscible. For usage of one type of fluid, it has to undergo a phase change.

- An example is the cooling system used in power generation. The cooling water is sprayed from the top onto the packing and in the meanwhile, air passes via the packing bottom. A disadvantage of this model is that the cooling water needs to be continuously replenished as a result of high evaporation. For maximum efficiency, water has to be maintained in a constant state.

- Specials Air Heat Exchangers

- Consists of two air heat exchangers that are:

- The Wet Surface Exchanger

- These exchangers use water to cool the air, and a fan circulates air through the bundle for cooling. It is confined to prevent moisture from being released into the surroundings.

- Scraped Surface Exchangers

- Used in industries like pharmaceuticals and food processing, these exchangers have rotary scrapers to remove deposits from the heat exchange surface.

- The Regenerative Heat Exchangers

- Here, the flow path is designed to contain a matrix that acquires heat through contact with hot fluid. The resultant heat is therefore passed along to the other fluid.

- They are commonly used in gas heat recovery at power stations. They are further classified into two namely:

- Static

- Dynamic

- It is worth noting that regenerative heat exchangers pose the possibility of cross-contamination of streams of different temperature. For this reason, they are less preferred compared to recuperative exchangers.

- Static Regenerators

- These exchangers have no moving parts, except for valves. Hot gas flows past a matrix until the flow is stopped and the cold gas flows through.

- Dynamic Regenerator

- These exchangers have rotating elements, allowing hot and cold gases to flow simultaneously through the matrix.

Maintenance for Heat Exchangers

- Plate and frame exchangers can be maintained by periodically disassembling and cleaning them.

- It's important to monitor the heat transfer coefficient, as it tends to decrease over time due to fouling, which is caused by the deposition of impurities within the exchanger.

- Tube exchangers can be cleaned using methods like bullet cleaning or high-pressure water jets, which effectively flush out foreign objects and debris.

- To minimize fouling in heat exchanger systems, water treatment and the addition of chemicals can be used. Additionally, water-borne oscillation technology is being increasingly adapted to help eliminate biofouling.

Things to Consider When Choosing a Heat Exchanger

- Heat Exchanger Manufacturers

- Before settling for a particular manufacturer, it's important to consider the below factors:

- How long has the manufacturer been in business?

- Do they have a good business reputation?

- What materials do they use in the manufacture of the heat exchangers?

- Do they have a good distribution network?

- Are they in a position to deliver your order promptly and with top quality assurance?

- By addressing these questions, you can make a more informed decision about which manufacturer can best meet your needs.

- Mechanical Considerations

- When designing heat exchangers, any model operating above atmospheric pressure must comply with the ASME code (American Society of Mechanical Engineers). This code is crucial in establishing the requirements for pressure vessels and ensuring the safe and efficient operation of the heat exchangers.

Heat Exchanger Terms

- 1, 2, 4 Pass

- The number of times the liquid passes through the tube bundles of heat exchangers, whether it be once, twice, or four times. Any number greater than one is considered a multi-pass unit.

- Baffle Plate

- A plate that supports the tubes and provides a blocked path for the shell-side flow, forcing the fluid across the tubes to improve heat transfer performance. These heat exchangers are typically segmental in shape.

- Baffle Spacing

- The spacing between the baffle plates in the tube bundle, which can be adjusted to optimize the effectiveness of heat exchangers.

- Bonnet

- A component resembling a channel with straight tubes but without a removable cover. These heat exchangers lack divider walls and are found at both ends of the heat exchangers.

- Bonnet Assembly

- Manages the circulation of the tube-side liquid through the heat exchanger tubes. It may also house the tube-side inlet and outlet connections, as well as pass ribs.

- Box Linear Style

- A design where the tubes of the heat exchanger are aligned parallel to each other, from the inlet to the outlet manifold.

- Bundle Assembly

- The assembly of tubes in removable bundle heat exchangers, including the tubes, tube sheets, baffles, spacers, and tie rods.

- Cap Screw

- A threaded bolt that secures the bonnet onto the core of some types of heat exchangers.

- Channel

- A front-end component with a removable cover, through which the tube-side fluid flows in and out. It features a dividing wall separating the inlet and outlet flows.

- Channel Assembly

- Similar to a bonnet assembly, but with a removable cover that provides access to the tube ends.

- Collector

- The component into which the tubes in a heat exchanger drain.

- Core Assembly

- The shell and tube assembly in fixed tube sheet heat exchangers.

- Coupling

- Parts used to connect the piping to the heat exchanger, available in various types.

- Cover/Cover Assembly

- Covers used to seal openings on heat exchangers. Unlike end plates, covers can be removed for cleaning the interior of the tube side without disturbing any piping.

- Cradle Assembly

- A part used to support the heat exchanger and secure it to the mounting surface, whether welded or strapped to the shell. Cradles can be fixed or movable.

- Design Pressure

- The calculated pressure and thickness of parts based on the most severe conditions or highest operating pressures encountered by heat exchangers.

- Dome

- A nozzle connection providing a larger opening between the pipe and tube bundles of heat exchangers, typically designed to prevent tube erosion due to high inlet velocities.

- End Plate

- Covers welded to heat exchangers, commonly used on bonnet assemblies.

- End Zone

- The first baffle space on a tube bundle, positioned between the tube sheet and the first baffle plate. It helps maintain the baffle plates within the two shell-side nozzles.

- Ferrule

- A small piece of copper or stainless steel tubing that is crimped or squeezed onto the tie tube, securing the baffles in position.

- Fixed Tube Sheet

- A tube sheet that is part of the core shell assembly of heat exchangers.

- Floating Tube Sheet

- Located at one end of a removable tube bundle, it moves freely with the expansion and contraction of the tube bundle during operation due to temperature changes.

- Gasket

- A sealing device used between two parts of a heat exchanger to prevent leakage.

- Heat Transfer Equipment

- Devices used to transfer heat from one medium to another. There are various types, each with distinct advantages and disadvantages depending on the application.

- Impingement Plate

- A small perforated plate or bar assembly placed in the shell-side nozzle, also attached to the bundle. It helps protect and prolong tube life by disrupting and slowing down the shell-side fluid flow, preventing erosion of the tubes.

- In and Out End

- The side of heat exchangers that contains the tube-side inlet and outlet connections, typically found in multi-pass units.

- Lantern Ring

- A metal or nylon ring used in some packed joint heat exchangers to hold the packing rings in place.

- Operating Pressure

- The pressure at which heat exchangers operate during normal use.

- Packed End

- The end of a heat exchanger that contains the packed joint and packing rings.

- Pass Lane

- A space in a tube layout where no tubes are present, allowing the pass ribs to mate.

- Pass Rib

- A separator plate inside a bonnet or channel, used to form multi-pass heat exchangers by directing the flow of the tube-side substance.

- Protector Rod

- A component that protects the tubes, tube sheets, and bonnets from corrosion by acting as a sacrificial anode.

- Range Temperature

- The temperature difference experienced by a single fluid as it flows through a heat exchanger.

- Removable Bundle

- Heat exchangers with a tube bundle that can be removed from the shell casing for easier cleaning and tube replacement.

- Reversing End

- The end of multi-pass heat exchangers where the tube-side fluid changes direction. It typically has small vent and drain connections.

- Shell

- The outer casing of the heat exchanger that holds the tube bundle and serves as the conduit for one of the fluids.

- Shell Assembly

- The housing into which the tube bundle is placed, also containing the shell-side connections.

- Shell Head

- A formed plate welded to the shell or bonnet pipe, available in various shapes, including flanged, dished, elliptical, and hemispherical.

- Shell Side

- The section of a heat exchanger where fluid flows around the tubes.

- Spacer

- A component used to hold the baffle plate in position within the heat exchanger.

- Stacking

- The process of connecting two or more heat exchangers side by side or stacked on top of one another, with interconnecting piping.

- Stationary Tube Sheet

- The tube sheet located at one end of a removable tube bundle, permanently fixed in place between the bonnet and shell flanges.

- Stuffing Box Flange

- A flange used at a packed end joint, where the packing ring is compressed into place by the lantern ring or lantern gland.

- Support Foot

- A part bolted to the heat exchanger using the bonnet-to-shell flange bolts to provide additional support.

- Test Pressure

- A pressure test used to check for leaks at the joints of heat exchangers.

- Tie Rods

- Bars placed between the tube sheets to provide structural support for the baffles.

- Tie Tube

- A small tube used instead of tie rods in smaller diameter heat exchangers, serving the same purpose.

- Tube

- A flow channel within the heat exchanger through which one of the fluids passes. Tubes are typically arranged in parallel within the shell to maximize the heat transfer surface area.

- Tube Layout

- The arrangement of tubes inside the heat exchanger and the positioning of the tie rods.

- Tube Sheet

- The apparatus that holds the tubes in place and provides a seal between the tube-side and shell-side fluids.

- Tube Side

- The fluid that circulates through the inside of the tubes in a heat exchanger.