Heating Elements

Heating elements play an integral role in our daily routines. Whether we're adjusting the thermostat, taking a hot shower, styling our hair with a blow dryer or curling iron, brewing coffee or tea, making breakfast, or toasting bread, we are utilizing various heating elements. These components are often hidden within the appliances and devices we use, functioning without us even noticing.

Electric heating elements are devices that convert electrical energy into heat. This generated heat is then utilized to perform various tasks. These elements are made from materials that can endure frequent high and low temperature cycles without deteriorating or melting. They rely on radiation, conduction, or convection to transfer heat to surrounding solids, liquids, or gases. For instance, in a hair dryer, the heating element transfers heat through the air using convection. In a toaster, the heating element uses radiation to transfer heat to the bread, evaporating the water content and turning it into toast.

Heating Elements – Frequently Asked Questions

What materials are commonly used to make heating elements?

Common materials include NiChrome, PTC ceramic, silicon carbide, molybdenum disilicide, quartz, stainless steel, and mineral insulation. Each material offers unique heat resistance, temperature capacity, and durability suited for different residential, commercial, and industrial heating applications.

How do electric heating elements generate heat?

Electric heating elements convert electrical energy into heat through resistance. As current passes through a material with high resistivity, it produces heat, which is transferred via conduction, convection, or radiation depending on the application.

What are the main types of heating elements used in industry?

Industrial settings use cartridge, tubular, immersion, quartz, ceramic, silicon-carbide, and infrared heating elements. These types convert electrical energy to heat for processes involving air, liquids, or solids in sectors such as glass, steel, and ceramics manufacturing.

Why is NiChrome popular for heating element manufacturing?

NiChrome, an alloy of nickel and chromium, is flexible, oxidation-resistant, and capable of reaching up to 1300°F. Its durability and shape retention make it ideal for heating elements in toasters, hair dryers, and industrial heaters across North America.

What industries rely most on heating element technology?

Heating elements are essential in the food, glass, steel, and ceramics industries, as well as in electronics and manufacturing sectors throughout the Midwest and Southern U.S. They’re used in ovens, furnaces, medical devices, and industrial curing systems.

How can heating elements be customized for specific applications?

Heating elements can be customized in shape, size, and material. Options include coiled, ribbon, or flexible etched foil designs made from nickel, ceramic, or molybdenum to suit applications ranging from electric kettles to precision aerospace equipment.

What standards ensure heating element safety and performance?

Heating elements must comply with UL 197, UL 499, UL 1030, and UL 1996 for safety and performance. The National Electrical Code (NFPA 70) also governs installation standards adopted by many U.S. states for electrical heating systems.

When should a heating element be replaced instead of repaired?

For small appliances like toasters and hair dryers, replacing the entire unit is often more economical. In larger systems such as water heaters or furnaces, replacing the heating element can extend equipment life and improve efficiency.

How Heating Elements Work

For a material to be suitable for use in a heating element, it must have the ability to resist the flow of electricity when a current is applied. This resistance causes electrical energy to be converted into heat energy. The amount of heat generated depends on how much the material resists the electrical current. The resistivity of a heating element is determined by the resistance per unit length and cross-sectional area, and it is measured in Ohms per meter. These Ohms values are then used to calculate the kilowatt (kW) load of the element. Specific calculations are employed to determine the resistivity of various element types, including round wires, tape elements, and coiled or spiral designs.

Applications That Use Heating Elements

Heating elements are widely used across residential, commercial, and industrial sectors. In the home, they can be found in appliances such as electric water heaters, oven, furnace, radiators, and clothes dryers, as well as other small and large household devices. In commercial settings, heating elements are used in food warmers, fryers, steam tables, espresso machines, saunas, and steam cleaners. Industrial applications include medical devices, pipe heaters, oil diffusion pumps, liquid immersion heaters, gas heating systems, kilns, and curing processes. Industries such as food production, glass, steel, ceramic electronics are significant consumers of heating element technologies.

The History of Heating Elements

Thomas Edison is often credited with the creation of the first heating element when he used a carbon filament to produce the incandescent light bulb in the late 19th century. Because this filament generated light by heating up to high temperatures, Edison's invention is closely associated with the early development of heating elements. However, it wasn't until later that heating elements specifically designed to generate heat were developed. In the late 19th century, scientists James Prescott Joule and Julius Robert Mayer formulated the first law of thermodynamics, which established a connection between heat and work. This foundational knowledge soon inspired inventors to apply it to their own innovations.

In 1868, British painter Benjamin Waddy Maughan invented the first gas water heater, known as a geyser. Unfortunately, it wasn't suitable for residential use as it lacked proper ventilation for the produced vapors. It took another 21 years before Norwegian-American engineer Edwin Ruud invented the electric water heater.

The invention of the first electric heater is credited to Albert Marsh, who discovered chromel (now known as NiChrome), an alloy of nickel and chrome, in 1905. This material was 300 times hotter than previous alternatives and was patented in 1906. Marsh's discovery was quickly applied to electric heaters. In 1909, General Electric launched its first successful toaster utilizing Marsh's invention. Around the same time, tea kettles began to be electrified. Initially, they were heated using coiled elements, but they were eventually designed with integrated electric heating elements.

In 1891, American inventor Edward G. Acheson created silicon carbide while attempting to make artificial diamonds. Instead, he produced one of the hardest synthetic materials, which also functioned as a semiconductor. Silicon carbide has since been used in heating elements for high-temperature applications. By the 21st century, heating elements had expanded to include a wide variety of materials, designs, and applications, further revolutionizing the way we use heat in everyday life.

Heating Element Images, Diagrams and Visual Concepts

Heating elements materials or devices that directly converts electrical energy into heat or thermal energy through Joule heating.

Heating elements materials or devices that directly converts electrical energy into heat or thermal energy through Joule heating.

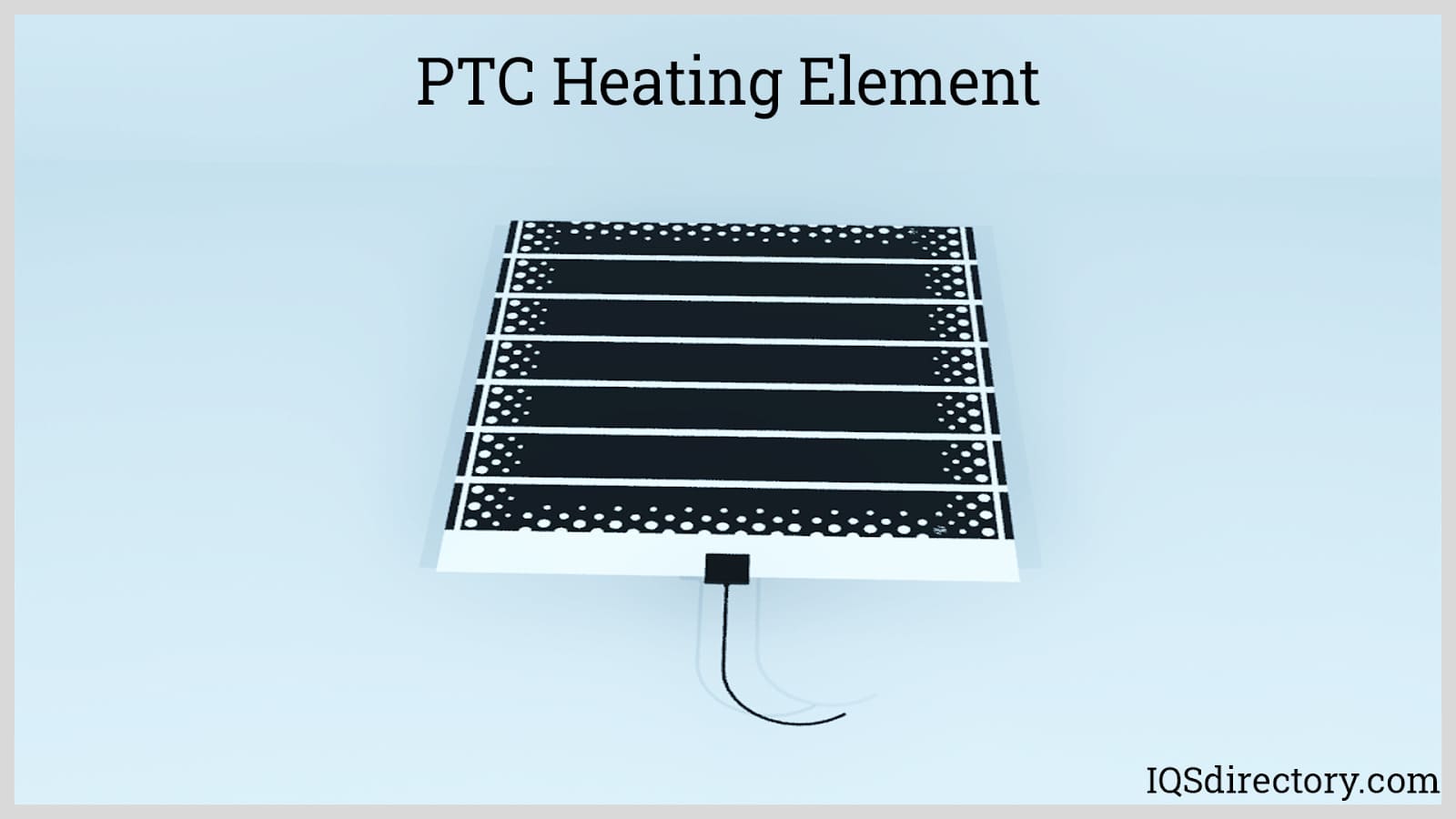

PTC heaters have a unique property which the heater maintains or limits the currents flow by having an increased electrical resistance as the temperature increases.

PTC heaters have a unique property which the heater maintains or limits the currents flow by having an increased electrical resistance as the temperature increases.

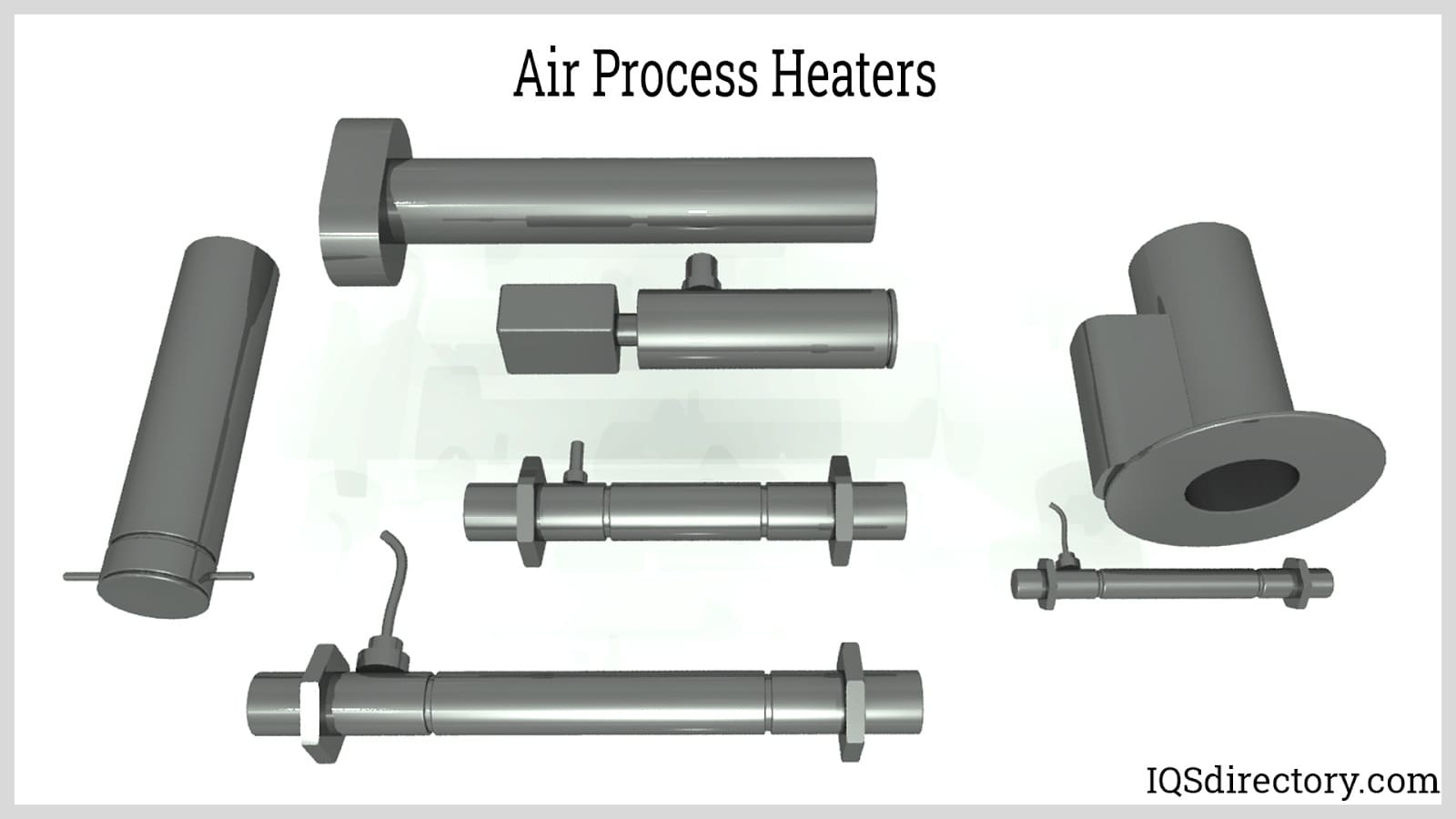

This type of heater heats up flowing air, the air is heated with a tube or pipe.

This type of heater heats up flowing air, the air is heated with a tube or pipe.

Cartridge heaters are a tube shaped heater with a resistance wire coiled around a ceramic core.

Cartridge heaters are a tube shaped heater with a resistance wire coiled around a ceramic core.

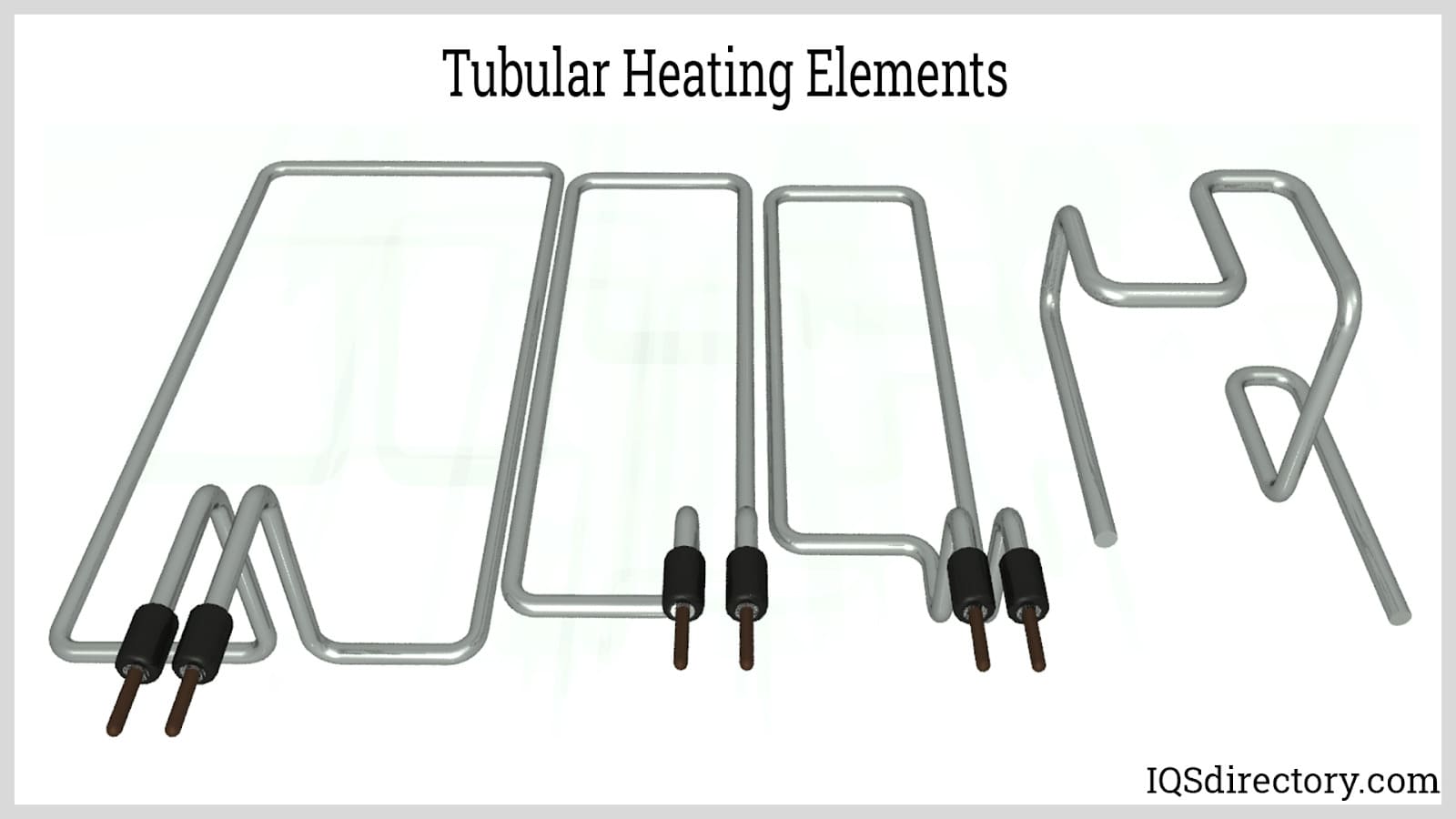

Tubular heaters are the same as cartidge heaters but the lead terminals are on the opposite ends of the tubing.

Tubular heaters are the same as cartidge heaters but the lead terminals are on the opposite ends of the tubing.

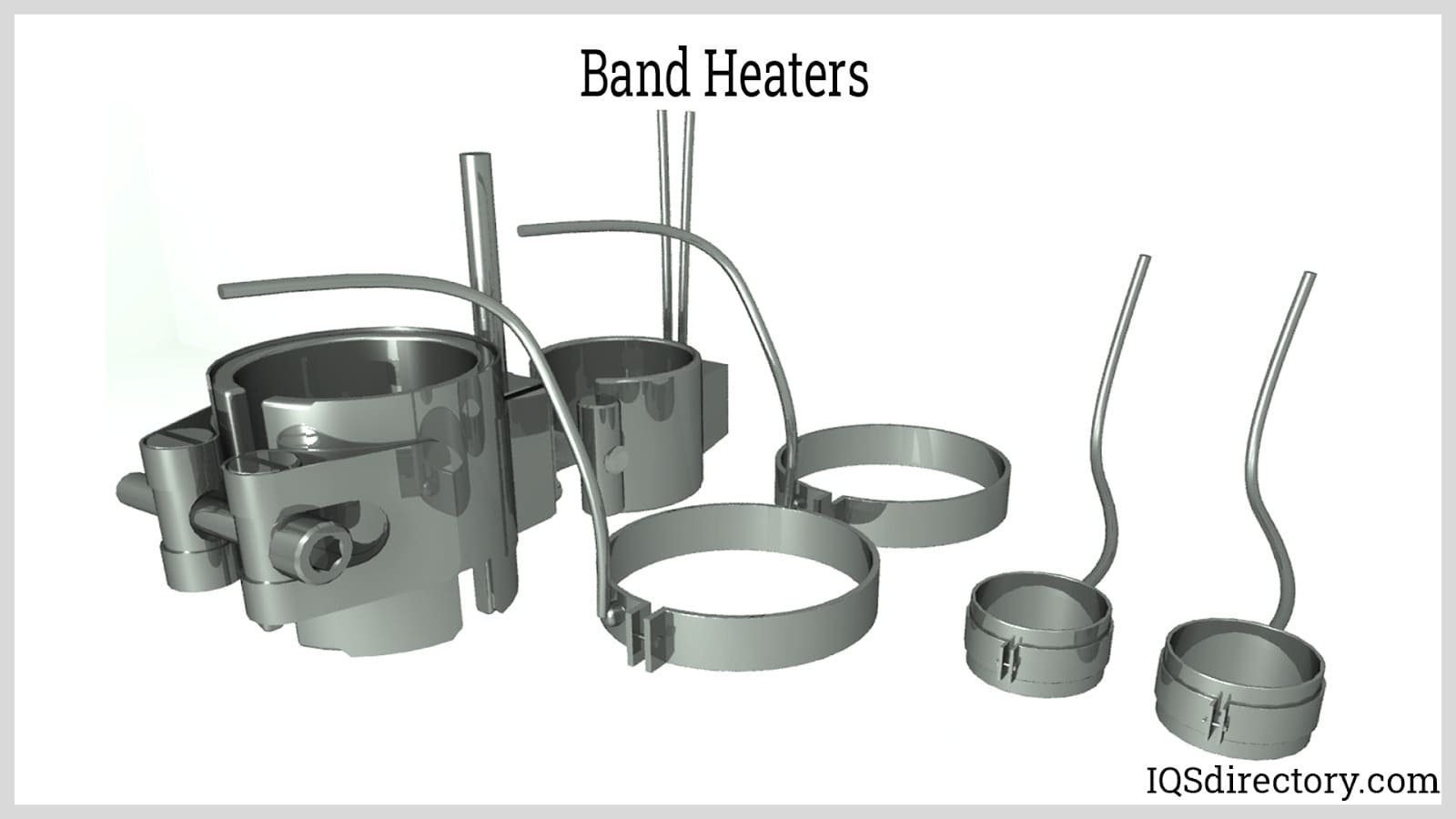

Band heaters wraps around cylindrical metal surfaces which can indirectly heat fluids in inside the vessal.

Band heaters wraps around cylindrical metal surfaces which can indirectly heat fluids in inside the vessal.

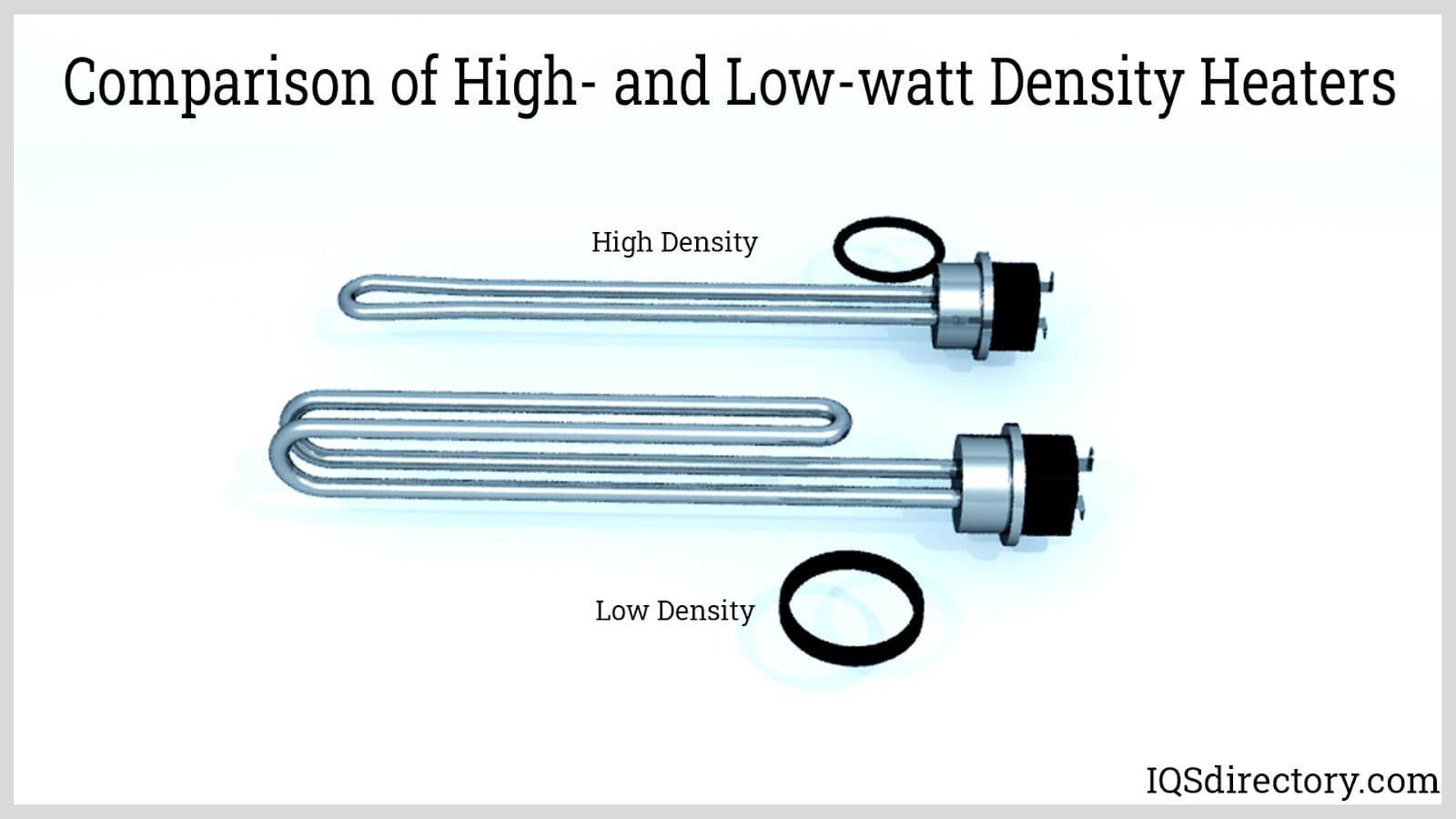

The right watt density must be used for specific application to utilize the service life of the heater.

The right watt density must be used for specific application to utilize the service life of the heater.

Finned surfaces and long wire coils are the usual features of air heaters, since stagnant fluids are easier to heat with a controlled temperature than flowing fluids.

Finned surfaces and long wire coils are the usual features of air heaters, since stagnant fluids are easier to heat with a controlled temperature than flowing fluids.

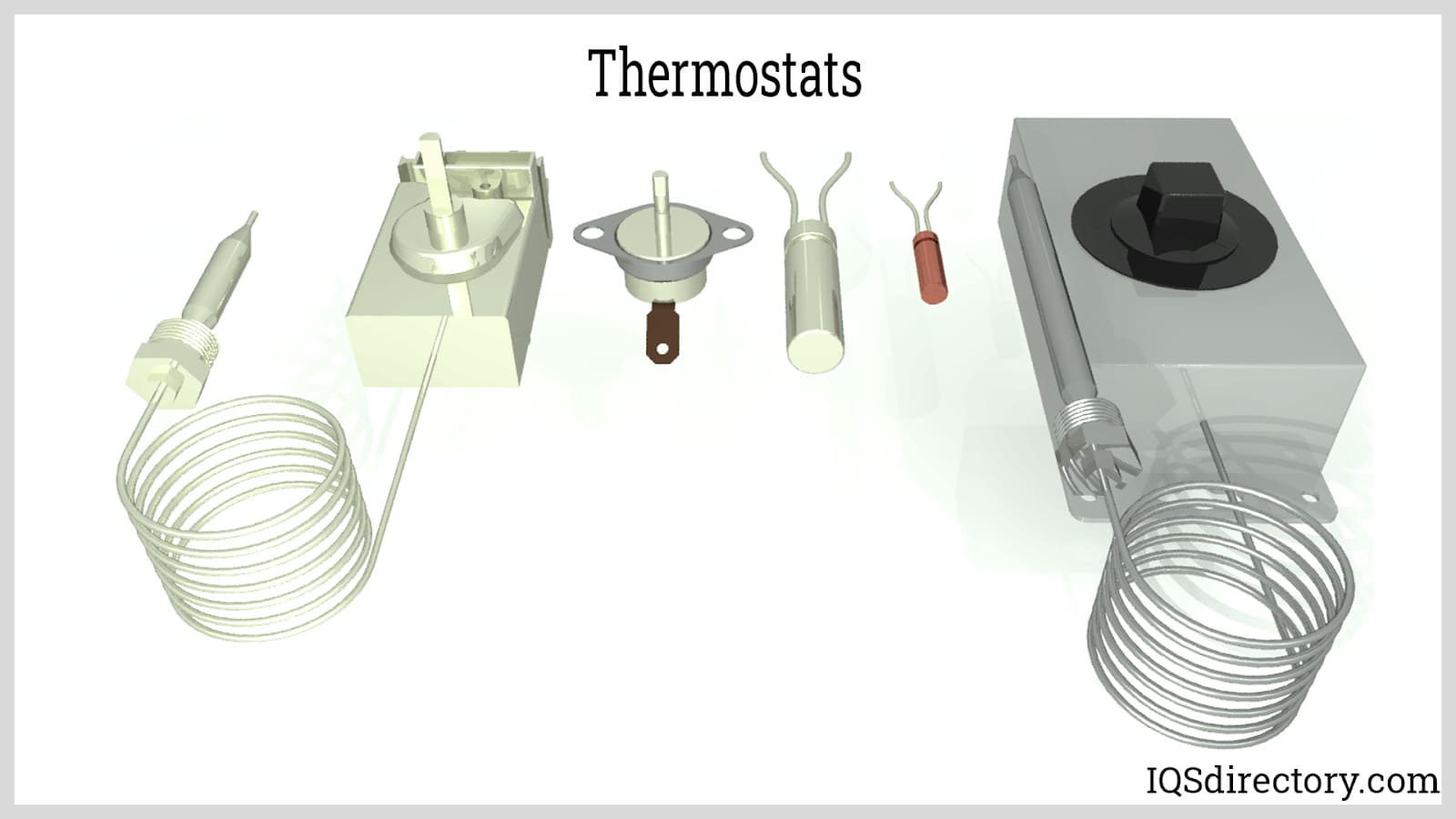

Conventional heaters have a temperature sensor and a therostat to adjust the temperature when needed.

Conventional heaters have a temperature sensor and a therostat to adjust the temperature when needed.

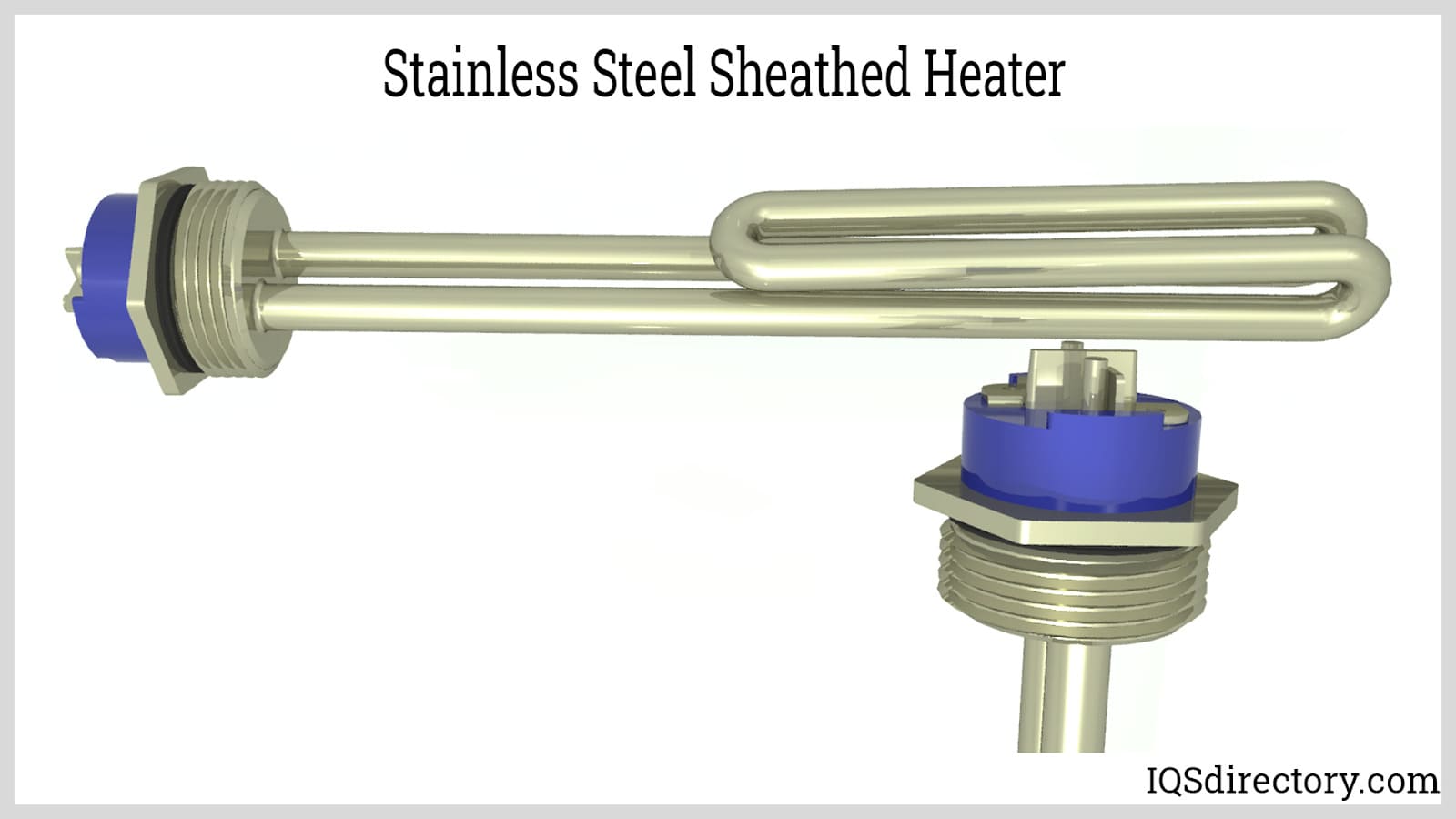

To avoid corrosion sheathing material is required using stainless steel, brass, copper, or other special alloys.

To avoid corrosion sheathing material is required using stainless steel, brass, copper, or other special alloys.

Heating Element Types

- Cable Heating Elements

- These are made of wire wound around a fiberglass core and insulated with PVC or silicone rubber.

- Cartridge Heating Elements

- These devices provide localized heating for a variety of applications. Typically inserted into a substance or positioned to heat a specific area, cartridge heaters are composed of seven primary components: heating coil, insulation, sealing, sheath, watt density, lead wire type, and termination.

- Ceramic Heating Elements

- Used in both low and high-temperature ovens and furnaces, these elements come in shapes such as rectangular, square, flat, cylindrical, or partial cylinder.

- Coil Heating Elements

- Commonly found in many products, these elements provide heat to a general area. Coil heating elements are shaped according to their specific application and can be free radiating or enclosed.

- Dryer Heating Elements

- Metallic components that generate heat in various products, including clothes dryers and hair dryers.

- Electric Heating Elements

- These are the components inside devices that use electricity to generate heat.

- Flexible Heating Elements

- Extremely thin elements that can be bonded to different shapes and compounds, providing heating directly where it is needed.

- Heater Elements

- The central component within all electric heaters, used for both solid-to-gas/liquid heating and solid-to-solid heating.

- Heating Coils

- Designed to have a large surface area without occupying much space, these coils efficiently distribute heat.

- Immersion Heater Elements

- These allow electric heaters to be submerged in the liquid or gaseous materials they are intended to heat.

- Industrial Heating Elements

- They convert electrical energy into heat, which is then transferred to air, liquids, or solids via convection or conduction.

- Infrared Heating Elements

- Used in infrared heaters, these elements heat a surface that, in turn, distributes the heat. They are utilized in many different applications.

- Mica Elements

- Often encapsulated in steel sheaths, mica elements have ribbon or wire wound on mica sheets or tubes and are insulated with mica.

- Plug or Rack Type Heating

- Commonly used in convection furnaces and ovens with open coil heaters, plug or rack types typically consist of multiple heating elements assembled in a rack or plug configuration.

- Quartz Heating Elements

- These elements are typically used in infrared heaters to provide rapid heating.

- Silicon-Carbide Heating Elements

- Used in high-temperature applications requiring higher watts, these elements are typically long tube-like structures.

- Tubular Heating Elements

- Widely used and sometimes equipped with a protective casing, these elements can be formed to fit specific applications.

Materials Used to Manufacture Heating Elements

- Manufacturing With NiChrome

- NiChrome, an alloy consisting of 80% Nickel and 20% Chromium, is commonly used for heating elements due to its flexibility, which makes it easy to shape into the required form. With a melting point of 2550 degrees Fahrenheit and its resistance to oxidation, NiChrome is a popular choice for heating elements. It is commonly found in appliances such as toasters, hair dryers, and clothes dryers. NiChrome heating elements can be designed to reach temperatures as high as 1300 degrees Fahrenheit.

- PTC Ceramic

- Portable ceramic space heaters, commonly found in homes and offices, often use a Positive Temperature Coefficient (PTC) ceramic element to generate heat. Instead of using wire, these elements utilize ceramic chips or stones made from a barium titanate or lead titanate composite. PTC ceramic heating elements are safer and have a longer lifespan, operating at a temperature of 518 degrees Fahrenheit, compared to the 900 degrees Fahrenheit of traditional metallic elements.

- Silicon Carbide

- Silicon carbide (SiC) elements can operate at higher temperatures and watt loads than metallic elements. SiC elements can reach temperatures up to 1625 degrees Celsius (2927 degrees Fahrenheit). Due to the hardness of SiC, these elements maintain their shape even at maximum temperatures, allowing them to be integrated into equipment designs without requiring additional structural support typically needed by other material-based elements.

- Molybdenum Disilicide

- Molybdenum disilicide (MoSiO2), also known as MolyD, is used for heating elements that can reach temperatures up to 1850 degrees Celsius (3362 degrees Fahrenheit). These elements are commonly found in electric furnaces within industries such as electronics, steel, ceramics, and glass.

- Quartz in Heating Elements

- Quartz is an excellent material for heating elements due to its ability to aid heat transmission while absorbing minimal heat itself. Quartz elements heat up rapidly and are used in infrared heaters. Industrial applications of quartz heating elements include paint drying, film curing, thermoforming and adhesive sealing.

- Stainless Steel

- Stainless steel is commonly used in water immersion applications such as kettles and beer brewing equipment. It is resistant to rust, even when exposed to water for extended periods. Electric brewers that use materials other than stainless steel for their elements typically require a magnesium anode to prevent rusting at the element base.

- Mineral Insulation

- Mineral insulation, such as Fiberglass, magnesium oxide, and mica, is used to coat heating elements based on the specific requirements of the application. One significant benefit of mineral insulation is its ability to oxidize, which protects the element from further damage over time.

Customizing Heating Elements

Heating elements can be tailored to suit specific applications, and they can be made from materials such as nickel, iron, molybdenum, and ceramic. The configuration of these elements can vary, with options including wire, tape (ribbon), coil, chips, or stones. The size and shape of the heating element depend on the intended use. For instance, the elements in electric stovetops and kettles are typically coiled, while industrial immersion heaters are often bent into a hairpin shape. Tubular elements are commonly used in electric ovens, grills, diffusion equipment, water immersion heaters, and kettles. Mica-wound elements are found in band heaters and toasters, while spiral heating elements are used in convectors and fan heaters. Flexible heating elements are ideal for specialized equipment in fields such as medical, aviation, and automotive industries. Made from etched foil, these flexible elements can be used in applications like LCD displays, optical equipment, PC boards for computers, and devices designed to prevent outdoor equipment from freezing.

Heating Element Maintenance

Heating elements typically fail before the surrounding equipment, and in some cases, it may be more cost-effective to replace the entire appliance or equipment rather than just the heating element. This is often the case with small appliances like hair dryers, toasters, and space heaters. However, in other situations, it is more desirable to replace the element to extend the life of the equipment, such as with water heaters, furnaces and ovens. The wire diagram provided with the equipment can guide the process of removing the old element and installing and rewiring the new one. In some cases, the electrical box may need to be opened to connect the heating cables to other wires and the power source.

In addition to the heating elements themselves, certain accessories are essential for safe and effective operation. For example, water heater elements require a silicone o-ring to ensure a proper seal. Electric furnaces often use braided wires, clips, and bolts. Various other components like electrical boxes, power cords, extensions, and adapters may be needed for different applications.

Standards and Specifications for Heating Elements

UL (Underwriters Laboratories) compliance is mandatory for all heating element manufacturers to ensure safety in their use. The UL 197, UL 499, and UL 1030 standards apply to commercial electric cooking and electric heating appliances. For electric sheathed heating elements to gain approval, their design specifications must meet these standards. Additionally, electric duct heaters must adhere to UL 1996 to be compliant.

The National Electrical Code (NFPA 70) outlines standards for the installation of electric wiring, including heating elements. Although not a federal law, many states have adopted these guidelines for electrical installations.

Things to Consider Before Selecting a Manufacturer

Choosing the right heating element manufacturer depends largely on the specific customizations and intended use of the heating elements. For instance, toasters require small, exposed NiChrome tape or ribbons, radiators use long bars, some space heaters rely on PTC ceramic elements, and diffusion pump heaters need specialized processes.

When selecting a manufacturer, it’s essential to ensure they can meet your needs while adhering to industry standards and regulations. The manufacturer must have expertise in matching the right type of element to each application. Using the wrong heating element can lead to product damage, fires, short circuits, and equipment failure.

Several factors need to be considered before choosing a manufacturer. Do they design products for residential, commercial, or industrial use? Are they compliant with UL standards? Can they produce heating elements for specific temperature ranges and materials? Are they familiar with industry standards for different applications? What maintenance services do they offer? Do they provide warranties on purchased elements and parts? What is their reputation in the industry for response times when replacement elements are needed? These questions must be thoroughly addressed before proceeding. Choosing the right manufacturer and maintenance schedule will enhance product safety and extend its lifespan. For a list of top heating element manufacturers, you can visit the top of this page.

Heating Element Terms

- Alloy

- A mixture of two or more metals, or a metal and a non-metal, that are fused together while molten.

- Annealing

- The process of heating and cooling a solid (typically steel or glass) to soften it, slowly cooling in a furnace to reduce brittleness.

- Brazing

- A method of joining metals using heat and a filler metal to form a strong bond, typically using a silver alloy for the filler metal.

- BTU

- British Thermal Unit; the amount of heat required to change the temperature of one pound of water by one degree Fahrenheit.

- Carburizing

- A process in which a metal is combined with carbon.

- Celsius

- The metric temperature scale where water freezes at 0°C and boils at 100°C.

- Ceramic

- A nonmetallic product made from minerals (such as clay) that is fired at high temperatures; examples include porcelain and brick.

- Coil

- A heating element that is shaped into a coil and serves as a source of heat.

- Condenser Coil

- In a heat pump system, the coil that absorbs heat from the outdoor air.

- Ductwork

- Pipes or conduits through which air is delivered, typically made of metal, fiberboard, or flexible materials.

- DX

- Direct expansion; a system where heat is transferred through the direct expansion of refrigerant.

- Fahrenheit

- A temperature scale where water freezes at 32°F and boils at 212°F.

- Firebrick

- A brick designed to withstand high temperatures, often used for lining furnaces or fireplaces.

- Grounded Element

- An element that has broken and is touching something metal, such as the metal housing that is meant to hold the element.

- Heating Element

- The component of a heater that conducts and generates heat.

- Infrared

- Invisible heat waves with wavelengths longer than red visible light and shorter than microwaves.

- Kilowatts

- A unit of energy equal to 1000 watts.

- Mica

- A shiny, transparent mineral made of flat chemical crystals, commonly used as an electrical insulator.

- Plenum Chamber

- A space or duct used for distributing air evenly during cooling, heating, or humidifying processes.

- Surface Load

- Calculated by dividing the total bearing load by the bearing's projected area (inner diameter * width).

- Therm

- A unit of heat measurement equal to 100,000 BTUs.

- Thermocouple

- A device used to measure the difference in potential created at the junction of two different metal wires.

- Thermostat

- A device used to control temperature by regulating heating or cooling.

- Watts

- The unit of power, equivalent to the power produced by a current of one ampere across a potential difference of one volt, or 1/746 horsepower.