High Strength Ropes

What is a rope? To answer that in simple words, a rope is a mere collection of strands, fiber, and yarns joined to form a long structure. Having twists and braids in their structure, these ropes become stronger and more resistant to external conditions into what we can call “High-strength ropes.”

High-strength ropes find their use in dragging and lifting. Not only this but since prehistoric times, humans have experimented with different materials and techniques to make robust and flexible ropes. Natural Fibers are one of the oldest materials to be used in making ropes. In the 1950s, synthetic fibers also started getting employed for the preparation of high-strength ropes.

Quick links to High Strength Ropes Information

Classification of High-Strength Ropes

There are many different types of high strength ropes. Broadly, these are categorized into two different types based on the nature of the material used in manufacturing:

- Natural High-Strength Ropes

- Made from natural material and the by-products formed during their manufacturing are environmentally-friendly. Natural fibers used include cotton, hemp, sisal, etc. These types of high-strength ropes show exceptional performance under high-temperature conditions. However they are prone to damage if exposed to a moist environment.

- Synthetic Fiber High-Strength Ropes

- Ropes made from synthetic fibers such as nylon, polyester, polypropylene, vectran, and aramids are called synthetic fiber high-strength ropes. High-strength ropes are relatively 30% stronger than the natural ropes. Unlike natural high-strength ropes, many of these ropes are not affected by wet conditions. They also offer good performance when exposed to UV rays or other organic solvents. However high-temperature environments can cause damage to them.

Types of High-Strength Ropes

Raw materials are treated and processed into a final product. But the final product of a rope differs based on it’s applications. Following are some of the types of end products of high strength ropes:

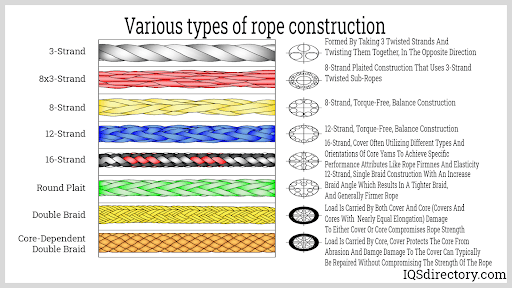

- Single Braid Ropes

- Have a frim braid rather than a twist and are suitable to be used for lifting heavy weights and in pulleys due to their brilliant durability.

- Plaited Ropes

- Have a coarser texture and have a square braid in their structure. These ropes are very strong but because all the strands are twisted around the core.

- Twisted Ropes

- Find their application in towing or in dock lines. These ropes are one of the strongest high-strength ropes out there as they are prepared by twisting or coiling three strands in the same direction, making them perfect for a firm grip.

- Hollow Ropes

- Hollow from within. Being lightweight, they can be used for ski towing and anchor lines because of their water-resistant nature.

- Diamond-Braid Ropes

- Expensive compared to other high-strength ropes because of their elegant structure that is neatly and firmly woven. Moreover, these ropes show the efficient performance of resistance and strength under extreme application of stress.

-

Applications of High-Strength Ropes

The wide range of variations in their structure makes them suitable for a lot of applications. Due to their flexibility, endurance and toughness these can be used for pulling and lifting, hunting, as pulleys, in dock lines, marine operations, swimming-lane barriers, fishing lines, sheet preparation, shock absorbers, climbing, paragliding, body armor, etc.