Hydraulic Lifts

Hydraulic lift systems serve as essential tools for raising and lowering work platforms and other surfaces that cannot be moved through manual labor. These systems operate using liquid mechanics, relying on the interaction between a hydraulic cylinder and hydraulic fluid to generate the necessary force for smooth and controlled movement.

Hydraulic Lifts FAQ

How do hydraulic lifts work?

Hydraulic lifts work by applying force to hydraulic fluid, which transfers energy to a cylinder. This amplified force powers the piston, allowing controlled raising or lowering of platforms, vehicles, or materials with efficiency and precision.

What are common applications of hydraulic lifts?

Hydraulic lifts are used in warehouses, construction sites, manufacturing plants, transportation hubs, and automotive repair. They handle tasks like loading, unloading, worker transport, maintenance, and accessibility in both industrial and residential settings.

What types of hydraulic lifts are available?

Types include automotive lifts, post car lifts, scissor lift tables, aerial lifts, pallet lifts, platform lifts, electric lifts, portable lifts, and rotary lifts. Each is designed for specific industries such as automotive, logistics, construction, and aviation.

What industries rely on hydraulic lifts in the United States?

In the U.S., hydraulic lifts are critical in manufacturing, automotive repair, construction, aviation, and shipping. From New York’s earliest hydraulic elevators to modern vehicle lifts, these systems streamline operations across many sectors nationwide.

What safety standards apply to hydraulic lifts?

Hydraulic lifts must meet OSHA standards in the U.S., along with ISO and European EN regulations. Safe use requires trained operators, proper load limits, and adherence to compliance codes to ensure workplace safety and equipment longevity.

What are the benefits of using hydraulic lifts?

Hydraulic lifts improve efficiency, reduce manual labor, enhance safety, and lower workplace injury risks. Their durability and adaptability across industries make them cost-effective solutions for material handling and personnel transport.

Can hydraulic lifts be customized for specific operations?

Yes. Hydraulic lifts can be customized with added safety features, increased load capacities, specialized coatings, and mobility options. Manufacturers tailor designs to meet industrial, commercial, and residential needs across varied environments.

Hydraulic Lift Applications

Hydraulic lifts play an indispensable role in industrial plants and facilities, enabling efficient movement across manufacturing plants, mezzanines, construction sites, warehouses, transportation hubs, and shipping operations. These powerful systems streamline key applications such as loading and unloading, resource relocation, accessibility, and warehouse maintenance, making material and personnel handling seamless and safe.

- Loading and Unloading

- Designed for repetitive and secure operations, hydraulic lifts facilitate the effortless lifting and placement of items precisely where needed. With their ability to perform continuous loading and unloading, they eliminate the strain of manual labor while improving efficiency in material handling processes.

- Resource Relocation

- Beyond moving materials, hydraulic lifts are essential for transporting workers between different levels or locations. In construction and manufacturing sites where staircases may be absent or multiple floors require access, hydraulic lifts provide a reliable, timely, and secure means of worker transportation, ensuring smooth and efficient workflow.

- Accessibility

- Hydraulic lifts grant immediate access to hard-to-reach areas, proving essential for on-site technicians who need to perform critical maintenance tasks in elevated or remote locations. By offering a stable and controlled platform, these lifts enable workers to conduct inspections, repairs, and other tasks with precision and safety.

- Warehouse Maintenance

- Custom hydraulic lifts significantly enhance warehouse efficiency by simplifying essential tasks. Whether facilitating routine inspections or expediting the movement of goods and materials, these systems make maintenance operations effortless, reducing downtime and increasing productivity.

- Widely utilized in the manufacturing sector—where both personnel lifts, such as scissor lifts, and material handling lifts, like pallet lifts, are in high demand—hydraulic lifts also serve a diverse range of industries. In construction, they support roofing and masonry work; in automotive and transportation, they assist in vehicle repairs and inspections; in docking and shipping, they streamline logistics operations. Even in aviation, hydraulic lifts play a crucial role in passenger and luggage transportation. Additionally, in private residential settings, they enhance mobility by improving handicap accessibility, demonstrating their versatility across various applications.

History of Hydraulic Lifts

For as long as humans have been constructing tall buildings, they have relied on lifts to transport people and materials. Ancient Romans used rudimentary platforms lifted by ropes pulled by slaves, an early precursor to modern lifting technology. However, hydraulic power did not become part of the equation until centuries later.

The first significant breakthrough came with Joseph Bramah, who patented the hydraulic press in England. His invention revolutionized agriculture and later transformed the industrial world. Across Europe, hydraulic power became instrumental in operating trains, elevators, canal locks, rotating bridge sections, and cranes, marking the beginning of a new era in mechanical lifting.

Throughout the 19th and 20th centuries, inventors continuously improved lift designs, making them stronger and more adaptable. Initially, hydraulic lifts found their primary use in elevators. In 1846, Sir William Armstrong introduced the hydraulic crane, which became essential for lifting applications. The United States saw its first hydraulic elevator lift installed in New York in 1870, replacing earlier steam-powered lifts that relied on coal combustion.

Innovation in hydraulic lifts continued into the 20th century. In 1925, Peter Lunati patented the first fully hydraulic automotive lift, revolutionizing vehicle maintenance. By the 1940s, the growing number of lift manufacturers led to the formation of the Automotive Lift Institute (ALI), an organization dedicated to establishing industry standards.

The 1960s brought further advancements, including the scissor lift, patented in 1963 by Charles L. Larson. Around the same time, Kaspar Klaus of Germany developed the sidelifter, expanding the range of lifting solutions available. The 1980s saw engineers integrate technologies to create a hydraulic scissor-type car lift, while the year 2000 marked the introduction of the four-post hydraulic vehicle platform lift.

Today, the hydraulic lift industry remains a hub of innovation. While existing equipment continues to perform reliably, engineers persist in refining lift technology, striving to make lifts even stronger, more efficient, and easier to use.

How Hydraulic Lifts Work

All hydraulic lifts operate using the same fundamental principles. Rooted in the science of hydraulics, these lifts rely on the application of force to a hydraulic fluid, enabling the transfer of energy from one point to another.

As this energy moves through the system, it undergoes a multiplication effect, significantly amplifying the applied force. This characteristic makes hydraulics one of the most powerful methods for generating movement. The transferred energy powers the hydraulic cylinder within the lift, providing the necessary force to raise or lower an object with precision and efficiency.

Hydraulic Lift Images, Diagrams and Visual Concepts

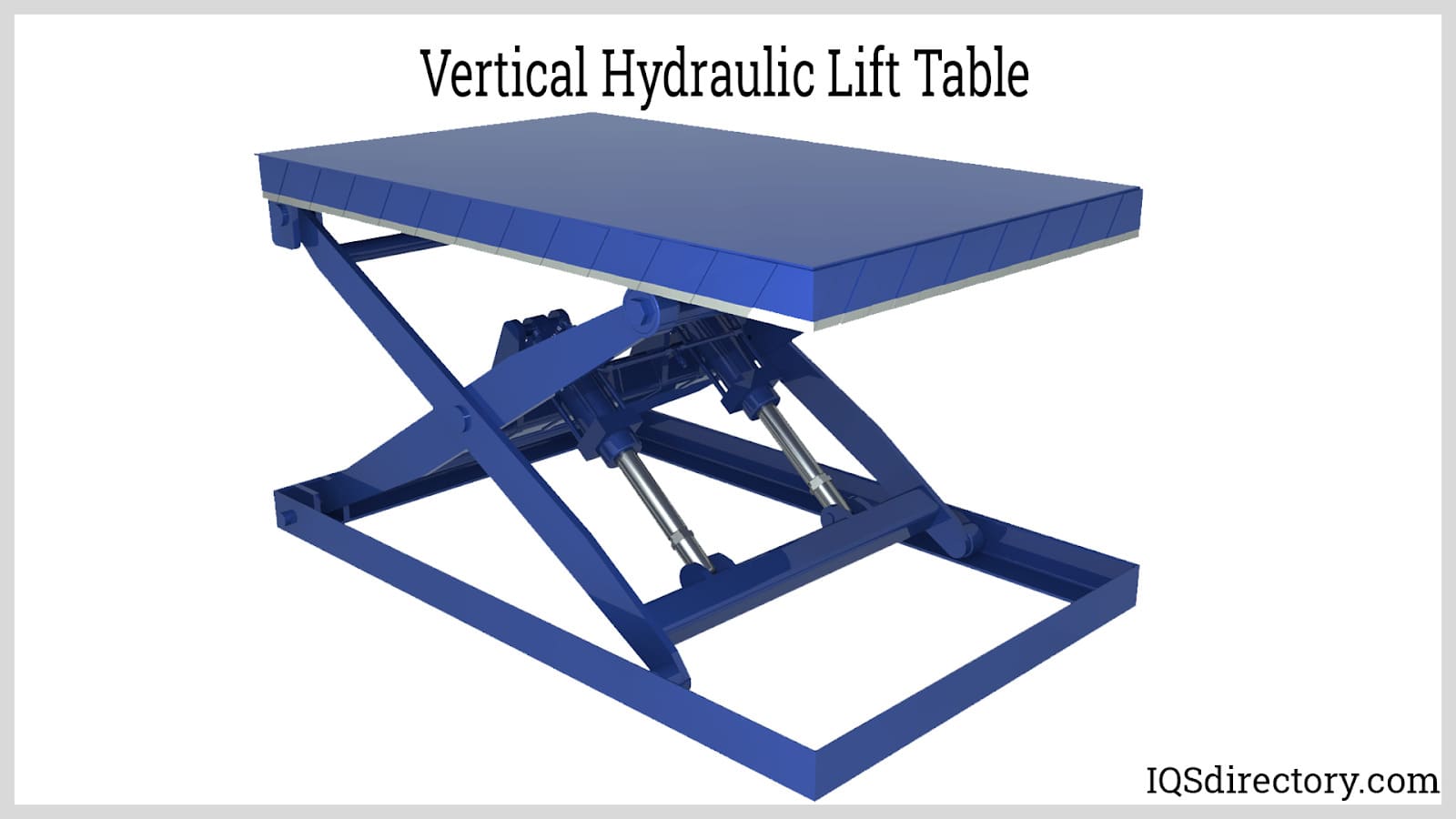

hydraulic lift, a device for moving objects using force created by pressure on liquid inside a cylinder that moves a piston upward.

hydraulic lift, a device for moving objects using force created by pressure on liquid inside a cylinder that moves a piston upward.

The principle of a hydraulic lift is by transfering the pressure to all points of the fluid.

The principle of a hydraulic lift is by transfering the pressure to all points of the fluid.

Hydraulic fluids transfers power in the hydraulic system and is mostly mineral oil or water.

Hydraulic fluids transfers power in the hydraulic system and is mostly mineral oil or water.

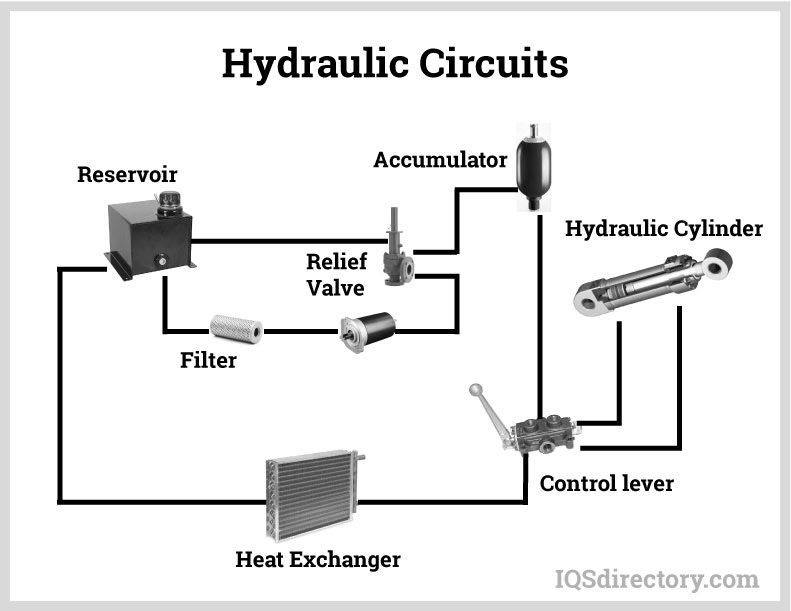

Hydraulic Circuits control the flow and pressure of hydraulic fluid.

Hydraulic Circuits control the flow and pressure of hydraulic fluid.

Personnel lifts, an example of electric hydraulic lift.

Personnel lifts, an example of electric hydraulic lift.

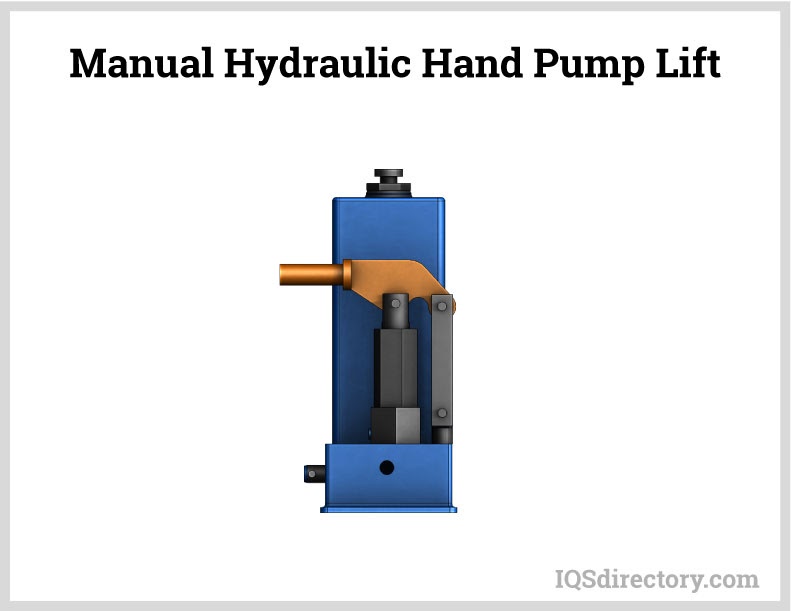

Manual pumped lifts are raised by a manual hydraulic hand pump which makes them very sturdy and maintenance free.

Manual pumped lifts are raised by a manual hydraulic hand pump which makes them very sturdy and maintenance free.

Notable Types of Hydraulic Lifts

To meet the diverse demands of hydraulic lift applications, manufacturers offer a wide range of hydraulic lift table designs, each tailored to specific tasks and industries. These lifts enhance efficiency in automotive repair, material handling, construction, and industrial operations by providing powerful and reliable lifting solutions.

- Automotive Lift

- Commonly referred to as vehicle lifts, car lifts, or truck lifts, these heavy-duty hydraulic systems are essential for automotive repair and inspection. Designed to lift everything from passenger cars and trucks to large commercial vehicles like school buses and dump trucks, automotive lifts rank among the most robust hydraulic lift types.

- Post Car Lift

- A specialized variation of the car lift, post car lifts are designed to elevate vehicles for easy access to their undersides. These lifts typically feature two upright support columns, four adjustable arms connected to a carriage assembly, and a combination of hydraulic cylinders, hoses, pulleys, and cables. Mounted on concrete floors, they provide a stable and secure lifting platform for maintenance and repair work.

- Scissor Lift Table

- One of the most widely used hydraulic lift varieties, the scissor lift table operates through a crossed, accordion-like base. As the base expands, the platform above rises to the required height. Characterized by scissor-shaped arms that extend and contract, these lifts use a motorized hydraulic system to generate pressure, enabling smooth and controlled movement.

- Mobile Scissor Lift Table

- Unlike stationary scissor lifts, mobile scissor lift tables are equipped with castors, allowing them to be repositioned as needed. Many models also incorporate foot pumps and tiltable tables, minimizing strain and reducing the risk of injury when handling heavy or bulky objects.

- Aerial Lift Table

- Typically designed as a type of scissor lift, aerial lift tables are engineered to reach significant heights, often ranging from ten to fifty feet. These lifts are particularly beneficial for warehouse personnel who require safe and efficient access to high shelving units and elevated storage areas.

- Platform Lift

- Also known as elevated work platforms, these lifts function similarly to hydraulic lift tables but on a much larger scale. Designed for substantial lifting tasks, platform lifts accommodate both personnel and materials in industrial and commercial environments where height access is essential.

- Pallet Lift

- Primarily used in material handling and shipping, pallet lifts, also referred to as transporters, facilitate the movement of pallet-loaded goods. These lifts elevate pallets from ground level to a raised position, enabling easy transport and streamlined warehouse operations.

- Electric Lifts

- Manufactured in various styles and sizes to suit a wide range of industrial lifting applications, electric lifts often integrate hydraulic pressure components for enhanced lifting power. While controlled by an electric motor and operated through a control unit, these lifts maintain the strength and versatility of traditional hydraulic systems.

- Portable Lifts

- Ideal for indoor industrial and commercial settings, portable lifts are designed for easy mobility across flat surfaces. Some basic models operate without a motor, relying instead on a manual scissor mechanism with a small platform that can be adjusted to the desired height by hand.

- Rotary Lifts

- Originating from an Indiana-based company that pioneered vehicle lift equipment in 1925, Rotary Lifts set the standard for automotive repair solutions worldwide. Since their inception, these lifts have remained a staple in vehicle maintenance, with numerous manufacturers following their lead in developing high-performance lifting products.

Hydraulic Lift Equipment Components

A standard hydraulic lift table consists of several critical components that ensure smooth and efficient operation. These include hydraulic fluid or hydraulic oil, a hydraulic pump, hydraulic valves, a hydraulic roller (responsible for opening and closing hydraulic valves), hydraulic cylinders, a drive machine, a rotary joint, and a landing surface for the materials or personnel being transported. Each component works in unison to provide controlled lifting and lowering functions, reinforcing the reliability and versatility of hydraulic lift systems.

Tips for Operating Hydraulic Lift Equipment

Every hydraulic lift operates slightly differently, but a few key best practices apply to all models to ensure safe and efficient use.

Before powering up the machine, confirm that it is properly set up. If the lift is equipped with castors, lock them to prevent any unexpected movement. Survey the area to ensure that no one is in harm’s way, and make sure nearby personnel are aware that machinery is about to be operated.

Once the environment is secure, load the lift and activate it. Some hydraulic lifts engage with a simple switch, while others require a control lever to be moved into the unlocked position. If the lift is mobile, unlock the castors and position it as needed before raising any safety bars to secure the load. After ensuring that all mobile components are locked in place, either press the foot pump or engage the control system to elevate the lift to the required height.

Benefits of Using Hydraulic Lifts

Hydraulic lifts offer a range of advantages, making them an essential asset in industrial and commercial environments. Their cost-effectiveness, durability, and ability to enhance worker safety contribute to increased operational efficiency. These systems support various lifting applications, from passenger transport to supply movement, streamlining processes across multiple industries.

Beyond their versatility, hydraulic lifts play a crucial role in reducing workplace risks by promoting safe handling practices. By minimizing the need for manual lifting and lowering the likelihood of workplace accidents, these lifts contribute to a safer, more productive facility. Implementing the most efficient hydraulic lift systems can significantly enhance production output and maximize returns on operational investments.

Design and Customization of Hydraulic Lifts

With a variety of hydraulic lift types available, manufacturers have extensive design possibilities to meet specific operational needs. Some hydraulic lifts are built for mobility, incorporating wheels for easy transport, much like a forklift, while others are designed to remain stationary as an integral part of a process line. In manufacturing settings, compact hydraulic lifts provide controlled movement for handling products efficiently.

Regardless of the lift’s function, it is always constructed from materials engineered to withstand high-pressure conditions. Common materials include stainless steel, woven wire, and rubber, chosen for their durability and load-bearing properties. The level of automation varies based on user needs, with hydraulic lifts available in fully automated, semi-automated, or manual configurations.

Manufacturers offer a range of customization options to tailor hydraulic lifts to specific applications. Adjustments can be made to increase weight capacity, improve structural stability, or enhance functionality. Customizable components include additional arms, foot controls, safety skirting, and warning lights. Aesthetic and protective modifications, such as specialized coatings and custom color options, further refine the equipment to align with workplace requirements.

Safety and Compliance Standards for Hydraulic Lifts

Ensuring the safe operation of hydraulic lift systems is critical, both for the longevity of the equipment and the well-being of workers on-site. Proper training, adherence to industry standards, and responsible equipment use all contribute to a secure and efficient workplace.

- Get Certified Equipment

- All hydraulic lift systems must meet industry-specific safety regulations. While exact standards vary by region and industry, common compliance requirements include OSHA standards in the United States, ISO certifications, and European EN or BS EN (British) standards. Consulting with suppliers and industry experts ensures that all hydraulic equipment adheres to the necessary regulatory codes.

- Hire Trained and Experienced Staff

- Only certified and experienced operators should be assigned to operate hydraulic lifts, as untrained personnel pose a risk to both safety and efficiency. When hiring operators, verifying their industry experience, professional certifications, and familiarity with specific hydraulic lift models is essential. If additional training is needed, enrolling operators in technical courses minimizes the risk of accidents caused by operator errors.

- Do Not Abuse Equipment

- To maintain safety and operational integrity, hydraulic lift systems must be used within their designated limits. Exceeding weight capacity can cause severe strain on internal hydraulic components, including cylinders and hydraulic fluid systems, leading to mechanical failure. By ensuring that lifts are operated within their designed specifications, businesses can extend equipment lifespan and prevent costly downtime due to avoidable damage.

Selecting a Hydraulic Lift System

Before finalizing a hydraulic lift system for your operations, collaborate with engineers and internal teams to define your exact requirements. Carefully document all aspects of your process, including the type of materials or equipment the lift will handle, the height it needs to reach, and the frequency of its use. Additionally, assess the physical space available for installation to ensure that your facility can accommodate the machine’s operational footprint. Having a detailed list of these considerations will provide a solid foundation when engaging with hydraulic lift manufacturers or suppliers.

Once you have determined the most suitable hydraulic lift system for your needs, focus on finding a reputable manufacturer or supplier. Conduct thorough research through web searches and trusted online directories to identify industry leaders with strong reputations. If you come across any negative feedback during your research, take the time to review verified customer testimonials to ensure that your chosen supplier maintains high standards. Selecting a manufacturer known for exceptional customer service is crucial, as ongoing support and maintenance play a key role in the longevity of your equipment. After narrowing down your options, confirm that the supplier offers comprehensive service packages tailored to your business needs. Clearly communicate your specifications, request expert recommendations, and secure a system that aligns with both your budget and operational requirements.

Hydraulic Lift Terms

- Apron

- The angled, smooth section at the entrance of a landing or lift car.

- Cycle

- A full up-and-down motion of a lift table, completing one lifting operation.

- Cylinder

- A fluid-filled vessel containing a shaft and piston that moves in response to pressure changes.

- Direct Acting Lift

- A lift system in which the hydraulic cylinder is directly connected to the lift car for movement.

- Drive Machine

- The power unit responsible for supplying energy to raise and lower the lift.

- Drum

- A horizontally positioned cylinder used for compaction as part of a winch system.

- Elevator

- A lifting system designed to transport equipment or materials between different levels.

- Ergonomics

- The study of optimizing workplace conditions to minimize injury and enhance efficiency through proper posture, training, and equipment design.

- Hydraulic

- A system powered by pressurized fluid, typically transferred through tubes or valves.

- Hydraulic Cylinder

- A mechanical device composed of a piston and ram, generating push-and-pull force to drive movement.

- Hydraulic Oil

- A specialized lubricating fluid used within hydraulic systems to create pressure and ensure smooth operation.

- Hydraulic Pump

- A mechanism that moves hydraulic fluid, generating the pressure needed to drive hydraulic lifts.

- Jog

- The controlled raising or lowering of a lift platform in small, incremental movements.

- Landing

- A designated, stationary surface used for loading and unloading lift devices.

- Lifting Capacity

- The maximum load a hydraulic or scissor lift can support under evenly distributed weight conditions.

- Lift Piston

- A hydraulic cylinder specifically designed to facilitate vertical movement, commonly found in buckets or bulldozers.

- Outrigger

- A stabilizing support system that extends hydraulically to enhance the balance and security of equipment.

- Pitch Cylinder

- A hydraulic cylinder that regulates the tilting motion of a bucket or similar attachment.

- Rotary Joint

- A component that enables the continuous transfer of hydraulic fluid between moving parts. It consists of two interconnected sections: one attached to the operating mechanism and the other fixed to the machine’s undercarriage.