Hydraulic Motors

Hydraulic motors (often misspelled as “hydrolic” motors) function by transforming hydraulic pressure into force capable of producing substantial power. These motors act as actuators, converting the pressure and flow of hydraulic fluid into torque and rotational motion.

They play a critical role in the broader field of hydraulics, a specialized branch of power transmission that utilizes pressurized liquids to generate mechanical energy. Power transmission itself refers to the process of converting energy into usable, functional forms. This field includes three major categories: electrical power, mechanical power, and fluid power. Fluid power is further subdivided into hydraulics, which relies on liquid pressure, and pneumatics, which involves the energy of compressed gases.

History of Hydraulic Motors

Hydraulic power can arguably be traced back to the dawn of civilization, as humans have long harnessed the energy of flowing water. One of the earliest and simplest hydraulic concepts involved using moving water to turn wheels. For a broader look at hydraulic history, see our article on Hydraulic Cylinders.

The development of hydraulic motors took a significant step forward during the Industrial Revolution. Around that time, English industrialist William Armstrong began exploring more efficient uses of hydraulic power after noticing the shortcomings of traditional water wheels during a fishing trip. One of his early innovations was a rotary engine powered by water. While it didn’t gain much traction at the time, this design served as a foundational model for what would eventually evolve into rotary hydraulic actuators.

Advantages of Hydraulic Systems and Motors

Hydraulic systems offer several benefits within the broader domain of power transmission, including efficiency, simplicity, adaptability, and a generally high level of safety. These and other advantages are explored in more detail in our article on Hydraulic Pumps.

Hydraulic motors specifically bring two notable advantages to the table:

Hydraulic Power

Hydraulic motors are capable of delivering significantly more power than similarly sized motors from other categories, making them well-suited for heavy-duty applications where larger loads must be moved.

Compactness

When space is limited, compact hydraulic motors provide an effective solution. These motors often feature short stroke lengths—sometimes under an inch—making them ideal for use in tight or constrained spaces.

One notable drawback of hydraulic motors is their relatively inefficient use of energy sources. Systems that rely on hydraulic motors can consume considerable quantities of hydraulic fluid. On large-scale job sites, for instance, it’s common for hydraulic machinery to require 100 gallons or more of hydraulic oil for operation.

Differences Between Hydraulic Motors and Hydraulic Power Units

Because they’re frequently used interchangeably in casual conversation, it’s important to clarify the distinction between hydraulic motors and hydraulic power packs (also called hydraulic power units). Technically, a hydraulic power pack refers to a complete, enclosed mechanical system that uses fluid to generate hydraulic power. These units typically include a fluid reservoir, a pump, a network of tubing or piping, control valves, and actuators—namely, cylinders and motors.

It’s not unusual to hear someone describe a hydraulic motor as if it includes all these components—reservoir, pump, and so on. In reality, however, it’s more accurate to understand the hydraulic motor as just one part of the full system. Specifically, the motor is an actuator within the hydraulic power unit—a device responsible for converting the system’s hydraulic energy into usable mechanical motion.

How Hydraulic Power Works

Liquids exist as a “middle” state of matter between gases and solids. However, in a crucial way, they behave more like solids: they are nearly incompressible. This characteristic allows force applied at one point in a confined liquid to be transmitted efficiently to another point within the same fluid. That principle underpins the generation of mechanical energy in hydraulic systems. For a more detailed look at how hydraulic power operates, see our article on Hydraulic Pumps.

How Hydraulic Motors Work

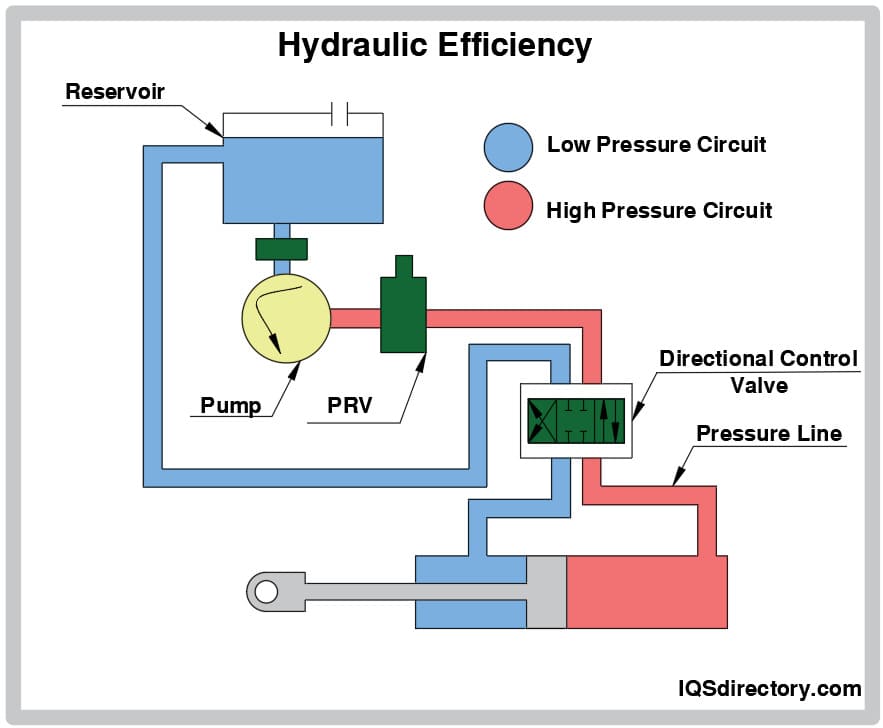

As previously mentioned, Pascal’s Law applies specifically to confined liquids. For a liquid to behave hydraulically, it must function within an enclosed system—commonly referred to as a hydraulic power pack. These systems consist of three essential components: a reservoir, a pump, and an actuator. Working in unison, they convert the energy stored in pressurized liquid into usable mechanical energy.

Hydraulic motors are critical to this process, as they serve as the actuator that completes the energy conversion. These motors, which transform hydraulic energy into rotational mechanical motion, are relatively simple devices made of rotating elements housed in durable enclosures—typically constructed from steel or iron to endure the high pressure and rapid operating speeds. Conceptually, a hydraulic motor can be considered the reverse of a hydraulic pump, functioning in the opposite direction.

In a typical setup, a hydraulic power unit draws fluid—usually oil—from a reservoir and pumps it through the system using a small pneumatic engine. The pressurized fluid travels from the inlet valve to the outlet valve, passing through a configuration of gears, vanes, or cylinders, depending on the type of motor. As the fluid pushes through, it forces the motor’s internal components to spin, generating rotary motion that is transferred to the connected machinery. Often, not all rotating parts within the motor contribute directly to driving the load; for instance, in a gear motor, only one gear may be linked to the motor shaft. This mechanical transfer of energy differs fundamentally from that of electric motors, which rely on electromagnetic fields generated by current flow to produce rotation.

Hydraulic Motor Images, Diagrams and Visual Concepts

Hydraulic motors, rotary or mechanical actuators which is operated by the conversion of hydraulic pressure or fluid energy to torque and angular displacement.

Hydraulic motors, rotary or mechanical actuators which is operated by the conversion of hydraulic pressure or fluid energy to torque and angular displacement.

Mechanical efficiency, measures the effectiveness in a machine or mechanical system.

Mechanical efficiency, measures the effectiveness in a machine or mechanical system.

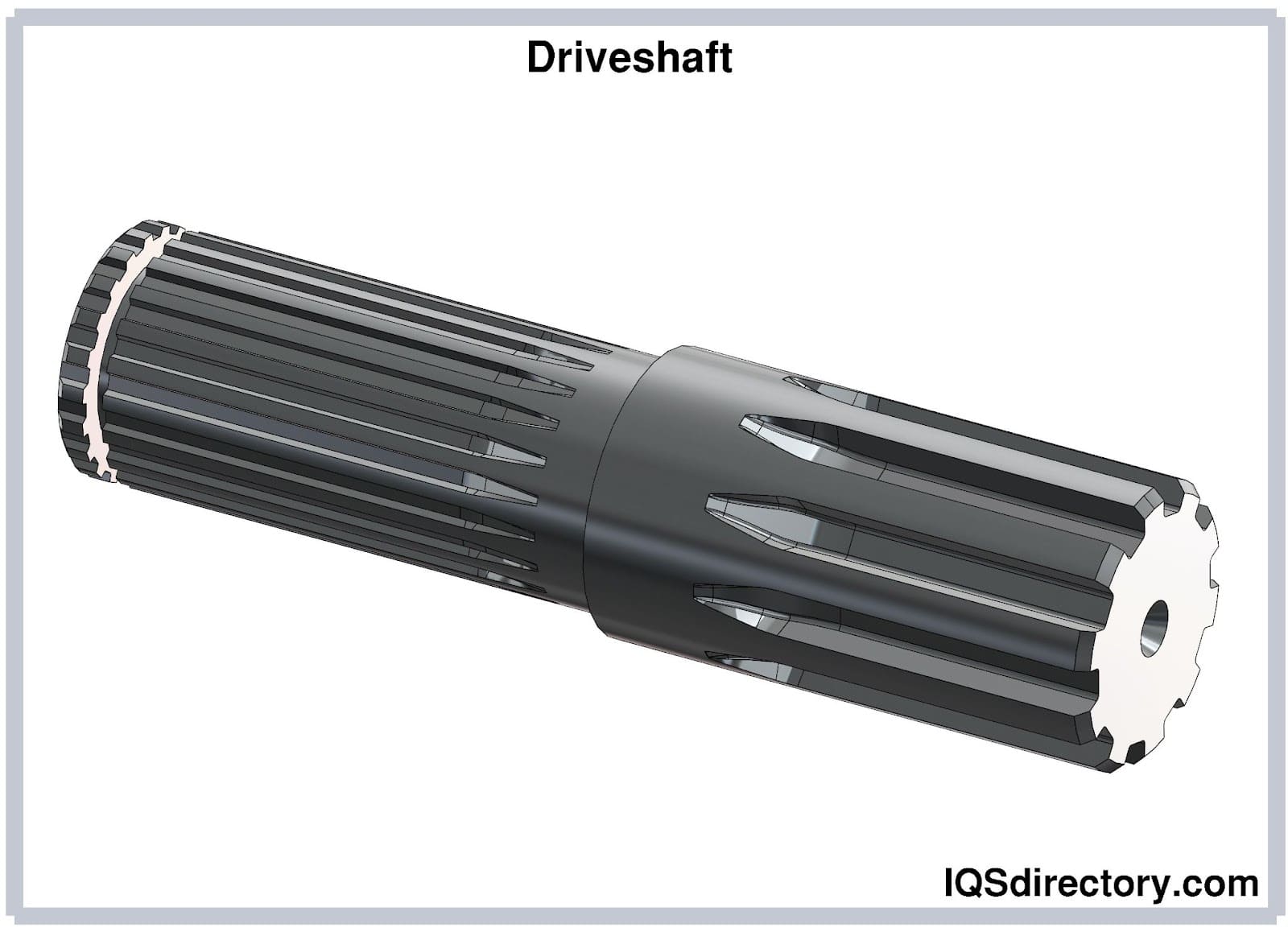

Driveshaft, a part of the hydraulic motor that delivers or transfers the torque created inside the motor to the outside environment where it is used for lifting loads and other applications.

Driveshaft, a part of the hydraulic motor that delivers or transfers the torque created inside the motor to the outside environment where it is used for lifting loads and other applications.

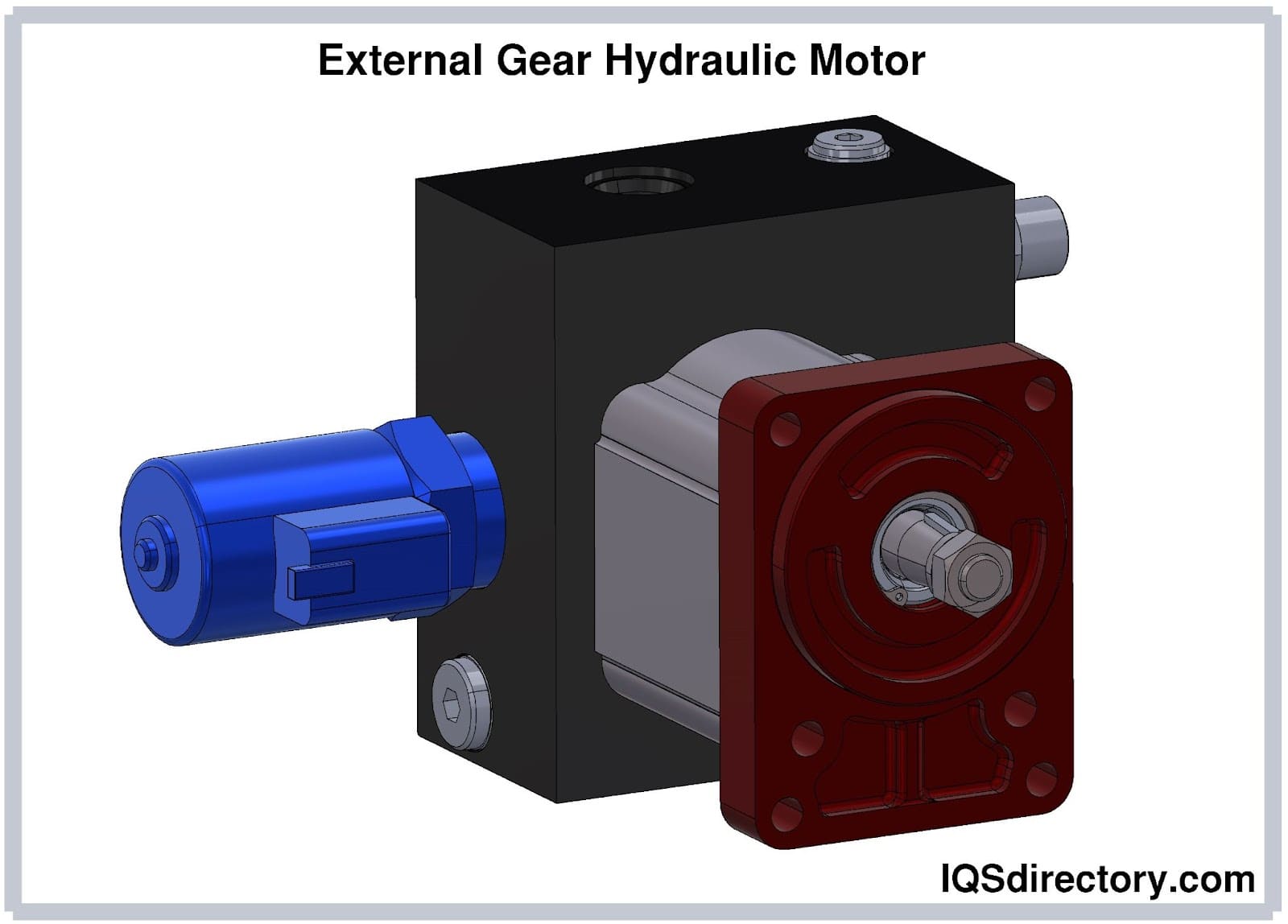

External gear hydraulic motors, operates under high pressure and for longer periods of time.

External gear hydraulic motors, operates under high pressure and for longer periods of time.

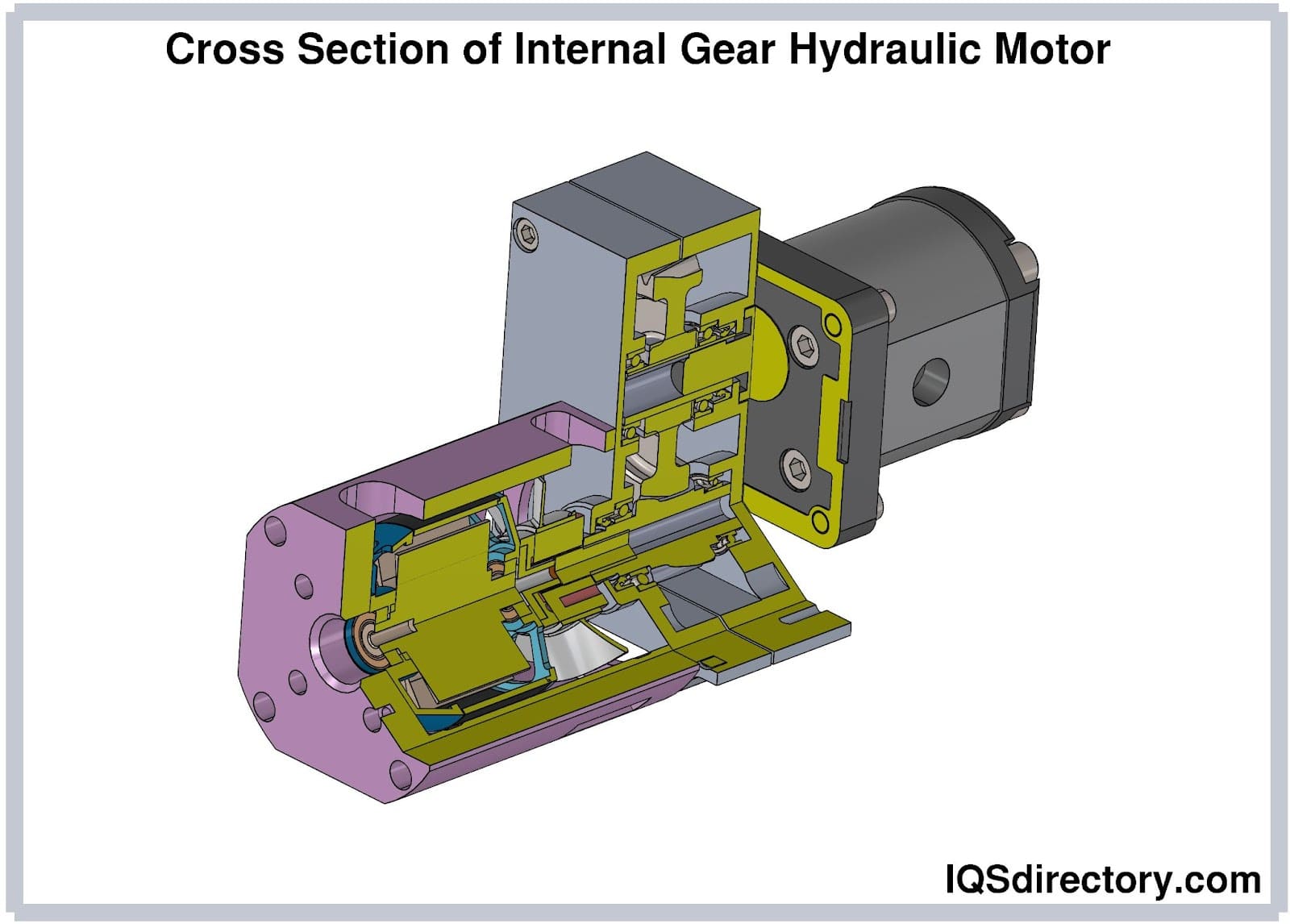

Internal gear motors, low weight and light size allows for smooth operation of the gears.

Internal gear motors, low weight and light size allows for smooth operation of the gears.

Directional control valves are designed to control fluid flow inside the motor.

Directional control valves are designed to control fluid flow inside the motor.

Vane hydraulic motors have a hydraulic balance that prevents the rotor from sideloading the shaft, with the pressure difference develops the torque as the oil from the pump is forced through the motor.

Vane hydraulic motors have a hydraulic balance that prevents the rotor from sideloading the shaft, with the pressure difference develops the torque as the oil from the pump is forced through the motor.

Types of Hydraulic Motors

Hydraulic motors come in three fundamental types—gear, vane, and piston—each distinguished by the configuration of its internal rotating component. These variations are designed to meet the needs of specific applications, performance demands, and environmental conditions.

Hydraulic Gear Motors

These motors operate by forcing pressurized fluid into a gear chamber, where the flow of fluid turns interlocking gears. This rotation generates the mechanical energy required to drive a load.

Piston Type Motors

Piston hydraulic motors are widely used due to their efficiency and strength. Radial piston motors feature pistons arranged around a central shaft with an off-center cam. As fluid enters, it pushes the pistons outward, creating a rotary motion. Axial piston motors, though similar in function, rely on pistons moving parallel (axially) to the motor shaft instead of radially.

Hydraulic Vane Motors

These motors contain a slotted rotor with vanes that extend and retract as fluid flows through the motor’s inlet. The varying pressure against the vanes creates the rotary motion necessary to power machinery.

Hydraulic Wheel Motors

Integrated into wheel hubs, these motors are designed to provide direct rotational force to the wheels of a vehicle. Depending on the system’s size and power needs, a hydraulic wheel motor may drive one wheel or multiple wheels simultaneously.

Speed and Torque Variants

Motors designed for high-speed operation convert hydraulic energy into high-RPM output for applications requiring fast, consistent rotation. In contrast, high-torque models—known as low-speed, high-torque (LSHT) motors—operate at slower speeds but deliver greater rotational force, making them ideal for heavy-duty tasks.

Hybrid Hydraulics

Ongoing innovation continues to enhance hydraulic motor technology. One such advancement is the hybrid hydraulic vehicle, which uses fluid power to recover braking energy more efficiently than traditional electric hybrids.

Hydraulic Drive Motors

These motors are key elements in hydraulic power transmission systems, working in tandem with pumps, valves, and actuators to drive machinery in a coordinated manner.

Hydraulic Drum Motors

A compact and enclosed conveyor solution, drum motors integrate the motor, gearbox, and bearings inside the conveyor drum, offering improved efficiency and easy maintenance.

Hydraulic Pump Motors

Used in tandem with hydraulic pumps and cylinders, these motors serve as the driving mechanism that enables fluid movement and mechanical action within hydraulic systems.

Roller Hydraulic Motors

A form of orbital motor, these motors reduce internal friction using hydro-dynamically supported rollers. This design improves durability and supports high-pressure performance.

Rotor Hydraulic Motors

Another orbital type, rotor motors operate using fixed lobes set into the stator. Their construction makes them particularly well-suited for continuous operation under moderate pressure, delivering long-lasting, steady output.

Applications of Hydraulic Motors

Hydraulic systems are widely utilized across numerous sectors, including construction, agriculture, manufacturing, transportation (such as automotive and aerospace), and various marine environments. Hydraulic motors, in particular, are essential components in machinery that requires high-force, pressurized movement. They are commonly found in aircraft systems—where they raise and lower wing flaps—as well as in heavy-duty construction equipment like backhoes and cranes, where they power lifting mechanisms and other large-scale operations. Additionally, hydraulic motors are integral to trenchers, automobiles, and conveyor and auger systems. They're used to drive marine winches, support waste management and recycling processes, operate wheel motors on military vehicles, and power self-driven cranes, excavators, dredging equipment, forestry machinery, and a wide range of agricultural and industrial processing systems.

Things to Consider When Purchasing Hydraulic Motors

While hydraulic power transmission is highly effective across many professional applications, relying solely on one form of power transmission is generally not advisable. Interestingly, the greatest performance benefits are achieved when multiple forms—electrical, mechanical, pneumatic, and hydraulic—are strategically combined into a comprehensive power transmission system. For this reason, it’s worth investing the time to connect with knowledgeable and trustworthy hydraulic manufacturers or suppliers who can help you design and implement a well-rounded hydraulic strategy.

In addition, it's essential to have a detailed conversation with your manufacturer about the advantages and limitations of different motor types to ensure the best fit for your application. For instance, while vane motors are often more cost-effective than piston motors, they typically offer lower efficiency and a shorter operational lifespan. By thoroughly evaluating trade-offs like these, you can make informed decisions and select the most suitable motor to meet your performance and budgetary requirements.

Proper Care for Hydraulic Motors

Despite their apparent simplicity, hydraulic systems require engineers and manufacturers to account for several key variables to ensure performance, safety, and longevity. One of the most crucial factors is the fluid itself—it must serve as an effective lubricant while also being chemically stable and compatible with the system’s internal materials. In addition, the pump, reservoir, and relief valve must be matched in power and capacity to support the motor's performance without overstraining the system.

Common Issues in Hydraulic Motors

Hydraulic motor problems frequently stem from poor maintenance, using the wrong type of fluid, or misapplying the motor beyond its intended parameters. Typical causes of failure include internal leakage from supply lines, misalignment of the motor shaft during installation, and contamination from dirty hydraulic fluid. When a malfunction does occur, identifying and correcting the root cause immediately is essential to prevent further damage.

Motor Operation Limits

Every hydraulic motor is engineered to operate within specific boundaries—torque, pressure, speed, temperature, and load. Exceeding these thresholds can quickly degrade performance. For instance, running a motor at excessively high temperatures causes the hydraulic fluid to thin, undermining its lubricating properties and reducing the overall efficiency of the system. Adhering to a motor’s design limitations is vital to preventing avoidable breakdowns.

Safety Considerations

Though hydraulic systems are often simpler than mechanical or electrical alternatives, they must still be treated with caution. One core safety rule is to avoid direct contact with pressurized components whenever possible. Even when a system appears idle, residual pressure within hydraulic lines can be dangerous if not properly managed.

Hydraulic Motor Terms

-

Aeration

The presence of air bubbles within hydraulic fluid, which can reduce efficiency and cause erratic system behavior.

Accumulator

A pressurized container used to store hydraulic fluid. Common types include piston, bladder, and diaphragm accumulators. They function as energy reserves or shock absorbers within a hydraulic system.

Cylinder

A mechanical device that transforms hydraulic energy into linear motion and force.

Displacement

The volume of hydraulic fluid moved through a pump, motor, or cylinder during a set period or single event, such as one revolution or stroke.

Dry Friction Coefficient

A measure of the resistance generated by contact between dry, moving surfaces, such as a motor shaft and its housing.

Filter

A component that removes impurities from hydraulic oil to protect and extend the life of system parts.

Fluid Power System

A power transmission system that uses pressurized fluid to generate, control, and transmit energy.

Gear

A toothed component that transfers mechanical energy by meshing with another gear or toothed element.

Hydraulics

The study and application of force transmission through the use of contained, pressurized fluids.

Hydraulic Tester

An instrument designed to evaluate and diagnose hydraulic system components.

Line

A hose, pipe, or tube used to direct the flow of hydraulic fluid through the system.

Oil

A non-water-soluble, lubricating fluid commonly used in hydraulic systems due to its incompressibility.

Piston

A cylindrical component that moves within a hydraulic cylinder, translating fluid pressure into linear mechanical movement.

Pressure Plate

A flat component in gear or vane pumps and motor cartridges that minimizes slippage and maintains proper clearance between moving parts.

Pump

A mechanical device that moves fluids by creating suction or pressure.

Resistance

A condition in which the flow of hydraulic fluid is hindered by restrictions or obstructions in the system.

Shaft

A rotating component mechanically connected to the workload, delivering torque and rotational motion from a hydraulic motor.

Stroke

The distance an internal component travels in a straight line during actuation, defining the extent of linear movement.

Throttle

A mechanism or restriction that limits the flow rate of hydraulic fluid.

Torque

A measurement of rotational force, often expressed in foot-pounds, applied to produce turning motion.

Valve

A control device that regulates the direction, flow rate, or pressure of hydraulic fluid within a system.

Vane

A flat, moving element in a vane motor or pump that rotates and interacts with hydraulic fluid to generate motion.