Hydraulic Pumps

Hydraulic pumps (often mistakenly called ”hydrolic” pumps) are essential components within hydraulic systems, responsible for transporting hydraulic fluid from one point to another to initiate and maintain the creation of hydraulic power. They play a central role in hydraulics—a specialized area of power transmission that channels the energy carried by pressurized liquids and converts it into mechanical force. While other devices that move hydraulic fluids may also be referred to as hydraulic pumps, the term typically refers to the pump that initiates fluid movement and enables the generation of force. Due to the broad range of applications in which hydraulic systems operate, hydraulic pumps are vital across industrial, commercial, and consumer sectors.

Power transmission refers to the technological process of transforming energy into a usable form for practical tasks. The field is broadly divided into three branches: electrical, mechanical, and fluid power. Fluid power itself includes systems that use both gases and liquids to transfer energy. Within fluid power, hydraulics focuses specifically on liquid-based systems, in contrast to pneumatics, which uses compressed gases to store and release energy for motion and control.

Advantages of Hydraulic Systems and Pumps

The use of hydraulic systems offers several notable advantages within the broader scope of power transmission.

Efficiency Advantage

Because fluids are incompressible, hydraulic systems can transfer energy with minimal loss. Nearly all the force generated in a hydraulic system is directed to its intended load, making it highly efficient in converting input into mechanical output.

Hydraulic System Customizability

The foundational formula of hydraulics—force equals pressure times area (F = P × A)—makes it relatively easy to adjust the force output of a system. By changing component sizes, designers can fine-tune pressure and force levels to meet specific application requirements.

Simplicity Advantages

Hydraulic systems often achieve comparable power transmission to electric and mechanical systems but with fewer parts and less complexity. For instance, they create linear motion directly, whereas electrical or mechanical systems typically require additional components to convert rotary motion into linear motion.

System Compactness

Hydraulic systems can produce high power output from relatively compact setups. This is particularly useful in applications with limited space, as hydraulic components often occupy less room than their mechanical or electrical equivalents.

Physical Versatility

Their modular design—comprising a pump, reservoir, actuator, and tubing—makes hydraulic systems highly adaptable across many industries and environments. They can also operate in locations where electric systems pose risks or limitations, such as underwater or in flammable atmospheres.

System Safety

Replacing electrical power transmission with hydraulic systems can reduce exposure to electrical hazards like short circuits, sparks, and electrocution, thereby improving workplace safety in sensitive environments.

Power Generation

Hydraulic pumps are capable of producing far more power than similarly sized electric motors. Though certain hydraulic components—like piston pumps—may be more expensive upfront, their ability to handle high pressures and transmit thick or viscous fluids makes them a valuable asset in demanding applications. Their strength, durability, and overall efficiency often justify the investment.

How Hydraulic Power Works

The foundation of hydraulics rests on a key physical fact: liquids are incompressible. Unlike gases, which can be compressed, liquids behave much more like solids in this regard. This property allows them to transmit force with remarkable efficiency, both in terms of pressure and motion. The principle that governs this behavior is known as Pascal’s Law, which states that any pressure applied to a confined fluid is transmitted equally in all directions throughout the fluid.

What makes this especially powerful is the fluid's ability to multiply force during transmission. Because pressure must remain constant as the fluid moves, and pressure is defined mathematically as force divided by area (P = F/A), we can rearrange the equation to show that force equals pressure multiplied by area (F = P × A). This means that by adjusting the size of components within a hydraulic system—specifically, the surface area where pressure is applied—the resulting force can be increased or decreased. For instance, if one piston in a hydraulic system is five times the size of another, and 50 pounds of force is applied to the smaller piston, the larger piston can exert up to 250 pounds of force, assuming constant pressure.

This relationship between force, pressure, and area, along with the chemical stability of liquids, underpins all hydraulic operations. The result is a system that allows operators to generate significant mechanical force with minimal physical input. While both water and oil can serve as hydraulic fluids, oil is more widely used due to its superior incompressibility and lubricating properties, which enhance system efficiency and longevity.

How Hydraulic Pumps Work

As previously discussed, Pascal’s Law only applies to confined liquids—meaning hydraulic action requires an enclosed system. Such a system is known as a hydraulic power pack or hydraulic power unit. While the configurations of these systems may vary depending on the application, all hydraulic power units share a foundational set of components that operate in coordinated fashion to convert fluid power into mechanical work.

The reservoir stores hydraulic fluid when it is not actively circulating through the system. It plays a key role in maintaining fluid volume, allowing for thermal expansion, and helping to dissipate heat.

The pump initiates movement within the system by pushing hydraulic fluid from the reservoir into the circuit. This action creates the pressure required to power the system.

Tubes or hoses then carry this pressurized fluid through the system. These conduits are designed to withstand high pressure and direct the fluid to specific components—most often, a hydraulic actuator.

Actuators are the parts of the system that perform the critical function of converting hydraulic energy into mechanical energy. These take the form of either hydraulic cylinders, which produce linear motion, or hydraulic motors, which generate rotary motion. The type of actuator used depends on the type of movement required for the application.

Valves within the system manage and direct the fluid flow. Directional control valves steer fluid toward specific actuators and regulate its flow path and rate. Pressure relief valves act as safety mechanisms, rerouting fluid back to the reservoir when system pressure exceeds safe operating thresholds, protecting components from overload or failure.

Despite the range of configurations and use cases, all hydraulic power units rely on this common architecture—each component playing a crucial role in the overall performance and reliability of the system.

Categories of Hydraulic Pumps

Although hydraulic pumps operate according to the same fundamental principles, they can be divided into several basic categories based on their internal design and motion characteristics.

Two of the most widely used classifications are piston pumps and gear pumps. Piston pumps include axial and radial designs. Axial piston pumps generate force through linear motion, while radial piston pumps produce mechanical energy through a rotary motion, allowing for more dynamic operation in certain systems.

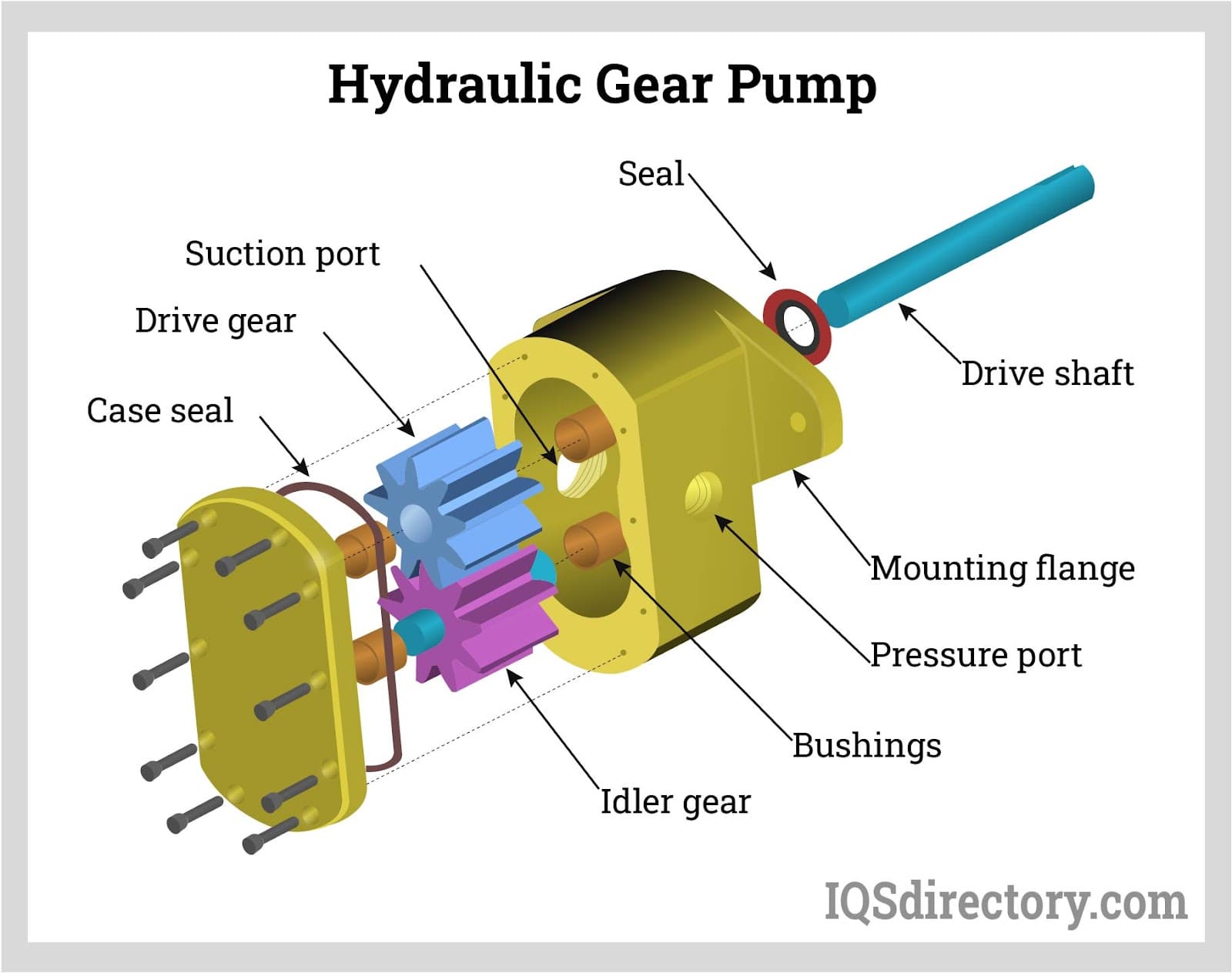

Gear pumps, on the other hand, are divided into internal and external configurations. Internal gear pumps feature a gear set where one gear rotates inside another, while external gear pumps rely on a pair of meshing gears to move fluid through the system.

Regardless of whether a pump is a piston or gear type, each can function as either a single-action or double-action pump. Single-action pumps are limited to producing force in one direction—either pushing, pulling, or lifting—whereas double-action pumps can perform these tasks in both directions, offering more versatility for complex applications.

Hydraulic Pump Images, Diagrams and Visual Concepts

Hydraulic pumps changes hydraulic energy to mechanical energy which allows for the transport of hydraulic fluid from point to point.

Hydraulic pumps changes hydraulic energy to mechanical energy which allows for the transport of hydraulic fluid from point to point.

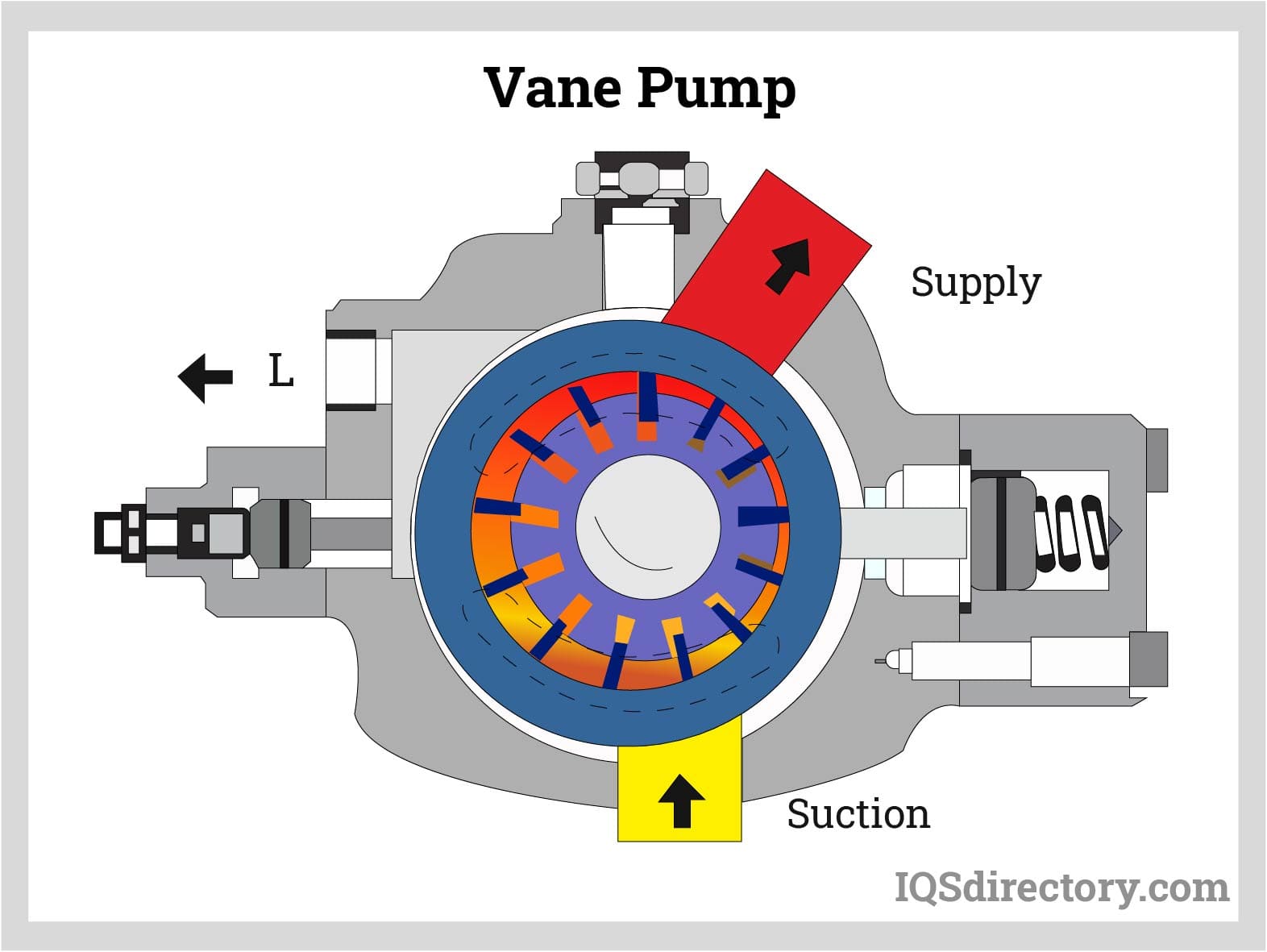

Vane pumps, are positive displacement pumps that maintain a constant flow rate under different pressures.

Vane pumps, are positive displacement pumps that maintain a constant flow rate under different pressures.

Electric hydraulic pumps, hydraulic liquid transmission machines that use electricity.

Electric hydraulic pumps, hydraulic liquid transmission machines that use electricity.

Hydraulic water pumps are machines which moves water from one location to another.

Hydraulic water pumps are machines which moves water from one location to another.

Hydraulic gear pump have internal and external gears pumps types with gears on the interior or exterior.

Hydraulic gear pump have internal and external gears pumps types with gears on the interior or exterior.

Air hydraulic pumps uses compressed air to stimulate a pump mechanism and generates energy from pressurized liquids.

Air hydraulic pumps uses compressed air to stimulate a pump mechanism and generates energy from pressurized liquids.

Hydraulic hand pumps, are fluid transmission machines that utilizes the mechanical force generated manually.

Hydraulic hand pumps, are fluid transmission machines that utilizes the mechanical force generated manually.

Hydraulic ram pumps are cyclic machines that uses hydropower to transport water.

Hydraulic ram pumps are cyclic machines that uses hydropower to transport water.

Types of Hydraulic Pumps

-

Vane Pumps

These are positive displacement pumps that operate by rotating rectangular vanes inside a rotor housed within a cavity. As the rotor spins, the vanes slide in and out, creating sealed chambers that move fluid through the pump.

Electric Hydraulic Pumps

Electric hydraulic pumps serve as the starting point for transforming hydraulic energy into mechanical power. In some setups, the energy is expelled through high-pressure fluid streams that help lift, push, or pull heavy objects with great efficiency.

Hydraulic Gear Pumps

Often used in heavy-duty machinery, gear pumps—as well as clutch and piston pumps—provide reliable flow and direction control. Each design functions a bit differently but serves the same purpose: moving pressurized fluid where it’s needed.

Hydraulic Ram Pumps

Common in water transfer applications, ram pumps require minimal external energy to start. They rely on water weight and inertia to generate enough pressure for continuous operation. With only two moving parts, they demand little maintenance.

Hydraulic Hand Pumps

These manually operated pumps create fluid pressure through hand-actuated movement. They’re especially useful for calibrating instruments or providing hydraulic pressure in small, portable systems.

Portable 12V Hydraulic Pumps

Powered by 12-volt batteries, these mobile pumps are ideal for emergency or field use. They offer reliable hydraulic power without needing a traditional power source.

12V Hydraulic Pumps

These compact hydraulic units run on 12-volt DC from a battery or motor, often used in mobile or off-grid applications.

Air Hydraulic Pumps

Operating from a compressed air source, air hydraulic pumps convert pneumatic pressure into hydraulic force. They consume no energy to maintain pressure and are available in single- and two-stage versions.

Axial Piston Pumps

With pistons aligned parallel to the cylinder block’s centerline, axial piston pumps create fluid movement along a straight axis and are known for high efficiency and compact design.

Centrifugal Pumps

These non-positive displacement pumps produce continuous fluid flow using centrifugal force. They’re best suited for high-volume, low-pressure applications and come in diffuser or volute variations.

Fixed-Displacement Pumps

With a consistent output volume per cycle, these pumps can only vary their flow rate by adjusting motor speed, making them simple but powerful.

High Pressure Pumps

Designed for systems requiring extreme force, these pumps operate in pressure ranges between 3,000 and 70,000 psi and are used in specialized industrial applications.

Hydraulic Pumps

Hydraulic pumps convert fluid energy into mechanical force to drive a variety of machines. These systems are found in industrial, commercial, and residential applications, transferring energy through the motion of pressurized fluids.

Hydraulic Water Pumps

Specialized pumps that harness hydraulic power to transport water efficiently, often used in agricultural or irrigation systems.

Hydrolic Pumps

A common misspelling of “hydraulic pumps,” these devices are nonetheless the backbone of fluid-driven power systems.

Nonpositive-Displacement Pumps

These pumps move fluid in a steady, uninterrupted flow, commonly used in low-pressure applications.

Positive Displacement Pumps

These pumps deliver fluid in measured bursts, ideal for high-pressure and precision-based hydraulic operations.

Radial Piston Pumps

Featuring pistons arranged like wheel spokes around a shaft, radial piston pumps are effective at producing high-pressure output in a compact footprint.

Reciprocating Pumps

These rely on back-and-forth motion to move fluids from an inlet to an outlet, providing a precise, metered flow.

Rotary Pumps

Using rotating parts to generate flow, rotary pumps fall under the positive displacement category and are used in systems requiring consistent output.

Two-Stage Electric Hydraulic Pumps

These pumps quickly extend cylinders with low-pressure flow in the first stage, then build high pressure in the second stage to hold or complete a task efficiently.

Two-Stage Pumps

These consist of two pump assemblies in one unit, designed to handle a broad range of pressures and flows for multi-phase hydraulic operations.

Variable-Displacement Pumps

Unlike fixed models, these pumps can adjust their internal cylinder volume, allowing them to vary flow rate and pressure on demand, adding efficiency and control to complex systems

Applications of Hydraulic Pumps

The construction, automotive manufacturing, excavation, agriculture, defense contracting, and general manufacturing sectors all rely heavily on hydraulics for daily operations. Because hydraulics are so integral across these industries, hydraulic pumps are similarly indispensable—used in a wide variety of equipment and machinery. No matter the application, hydraulic pumps serve the fundamental purpose of moving hydraulic fluid through a system, generating pressure and energy that actuators convert into mechanical work.

Hydraulic technology powers everything from elevators and automotive lifts to airplane flaps, brake systems, cranes, garage jacks, motorboat steering mechanisms, shock absorbers, and log splitters. On construction sites, large-scale hydraulic equipment—such as excavators, dumpers, and diggers—is standard. In industrial settings like factories or offshore platforms, hydraulic systems are essential for powering heavy equipment, maneuvering large loads, and performing operations like cutting, bending, or pressing materials.

Things to Consider When Purchasing a Hydraulic Pump

e fluids comes with its own viscosity, flash point, and optimal temperature range, making material selection a vital consideration.

Evaluating Pump Capabilities

To avoid overloading the system or compromising performance, manufacturers must ensure that the pump’s operational parameters match its intended use. Key specifications include continuous and maximum operating pressure, flow rate, operating speed, horsepower, and power source. In addition, physical measurements like diameter, overall length, and rod extension should be assessed, particularly in space-constrained applications. Since hydraulic pumps serve a critical role in heavy machinery—such as cranes, lifts, and motors—these factors must be evaluated carefully.

Addressing System Inefficiencies

Every hydraulic drive system has potential inefficiencies that can reduce overall effectiveness. Air bubbles in the hydraulic fluid, for instance, absorb energy that would otherwise power the actuators, leading to lost performance. Identifying these inefficiencies and addressing them with the right components is essential to maximizing system output. The hydraulic pump acts as the generator within the system—initiating the energy transfer by moving fluid from the reservoir into the actuator pathway. Regardless of the specific pump type, the goal remains the same: to displace fluid efficiently and consistently as part of a well-balanced hydraulic power system.

Proper Care for Hydraulic Pumps

Hydraulic System Safety and Monitoring

Although hydraulic systems are generally simpler than their electrical or mechanical counterparts, they remain complex and high-pressure systems that must be approached with caution. One of the most important safety principles when dealing with hydraulic equipment is to minimize physical contact wherever possible. Even when not actively engaged, the fluid pressure within a hydraulic system can pose significant hazards—making proper safety protocols essential.

Preventing Pump Failure

Undersized or poorly functioning pumps can lead to critical mechanical failures, putting both personnel and equipment at risk. These failures can result in costly downtime and potentially hazardous conditions. In the past, predicting pump failure was a challenge, often relying solely on vibration analysis. Today, however, advancements in diagnostic technology have significantly improved early detection methods.

Smart Monitoring Integration

Modern systems benefit from sensors that measure discharge pressure to identify wear patterns and anticipate failure before it occurs. By incorporating discharge sensors into hydraulic setups, manufacturers can enhance the overall reliability and efficiency of their systems. These sensors are relatively easy to install and offer a low-impact way to boost safety, reduce maintenance costs, and extend the operational life of hydraulic pumps.

Hydraulic Pumps Terms

-

Accumulator

A vessel that stores pressurized hydraulic fluid and functions either as an energy reserve or to absorb shocks in a system. Common types include piston, bladder, and diaphragm accumulators.

Cavitation

A condition in pumps where insufficient fluid fills the available space, leading to vapor bubble formation. This can degrade hydraulic oil and erode pump inlet components.

Closed-Center System

A hydraulic configuration in which the pump consistently operates under load, even when system valves are in the neutral position.

Cylinder

An actuator consisting of a piston or plunger housed within a cylindrical chamber. Pressurized liquid drives the piston to create linear motion.

Displacement

The volume of fluid moved from the pump’s inlet to outlet per revolution. Pumps may have either fixed or variable displacement capacities.

Flow Rate

The quantity of fluid that passes through a point over time, typically measured in gallons per minute (GPM).

Head

A vertical measurement of liquid distance between two levels or stages, indicating pressure potential.

Hydraulic Actuator

A device that receives pressurized fluid and transforms it into motion and mechanical force.

Hydraulic Filter

A system component that removes contaminants from hydraulic fluid to protect system integrity.

Hydraulic Hoses

Thick, flexible conduits used to carry pressurized fluid to and from components like pumps and actuators.

Hydraulic Power Unit

The assembly that drives hydraulic energy by converting potential energy into kinetic energy, using motors or manual input.

Hydraulic Tester

An instrument used to diagnose issues and verify the performance of hydraulic components.

Hydraulic Valve

A control mechanism that adjusts the direction, pressure, or flow of hydraulic fluid.

Hydraulics

The scientific discipline focused on the use of confined liquids to transmit force and perform mechanical work.

Oil

A non-water-miscible, viscous liquid often used in hydraulics due to its incompressibility and lubrication properties.

Open-Center System

A system configuration where fluid from the pump flows freely back to the reservoir when control valves are in the neutral position.

Piston

A key moving part that transmits energy within a hydraulic cylinder by driving or being driven by fluid pressure.

Pump

A mechanical apparatus that moves hydraulic fluid by generating suction or applying pressure.

Ram

A type of hydraulic actuator that relies on the momentum of a moving fluid to elevate a portion of it to a higher reservoir.

Resistance

A force in a hydraulic system caused by any blockage or narrowing in the fluid’s flow path.

Seal

A device used to tightly enclose system components and prevent fluid leakage or contamination.

Valve

A control device for regulating hydraulic or air flow, with settings ranging from fully closed (no flow) to fully open (unrestricted flow).

Velocity Pressure

The hydraulic pressure generated as a result of fluid motion, stemming from its kinetic energy.