55 Gallon Drums

Storage has moved from simple warehousing to complex sets of equipment, devices, and methods designed to fit the needs of the many varying types of items that need to be stored. At one time, storage meant having a large building with open space to be filled with furniture, machines, products, and other items that needed to be stowed before being put to use.

From the early days of filling a space, storage has progressed and advanced to the point where special conditions and containers have to be used to ensure the safety of the items to be stored. These changes include the development of tanks, containers, and barrels that can withstand being out of use for days, months, or years.

The first storage item that comes to mind when thinking about storage devices is the reliable and dependable 55 gallon barrel or drum. Barrels began centuries ago as slats of wood that were strapped together to form a vessel to store liquids, grain, and granules. Though it is centuries old, it has progressed to be part of modern storage manufacturers‘ fundamental means for storing the same products it did years ago.

Of course, modern 55 gallon drums, which are no longer exclusively 55 gallons, have been updated and grafted to fit the needs of today‘s shipping companies. They are made of a variety of materials from ones made of metal, such as steel, to others that are made of plastic. Regardless of their size or shape, they are a major part of modern storage.

Another type of container that has had continued use over the years is tanks, which are used for larger amounts of materials that measure into several gallons. These huge pieces of equipment, much like barrels, have evolved from their former state of being made of wood to being made of steel, plastic, and other materials. The ability of these huge devices to store all forms of substances is the reason for their continued use.

Producers found that barrels had a limited capacity and tanks were just too large so they needed to find something that fit in between the two. Their need led to the development of the plastic tank. Though barrels and tanks have continued to be a reliable means for storing a variety of materials, with the development of strong and sturdy plastics, a new form of storage device developed in the middle of the 20th Century, the plastic tank.

Plastic tanks come in several varieties and can be designed for one time use or for multiple uses depending on the type of materials from which they are made. This innovation has offered storage manufacturers another choice when planning a customer‘s storage needs.

Storage manufacturing is not something that many of us consider since it isn‘t a common part of life. The products that are sold and produced require a clearly delineated supply chain that gets products to market and supplies to producers. A critical part of the process is storage manufacturers who design, create, and plan the storage needs for industry.

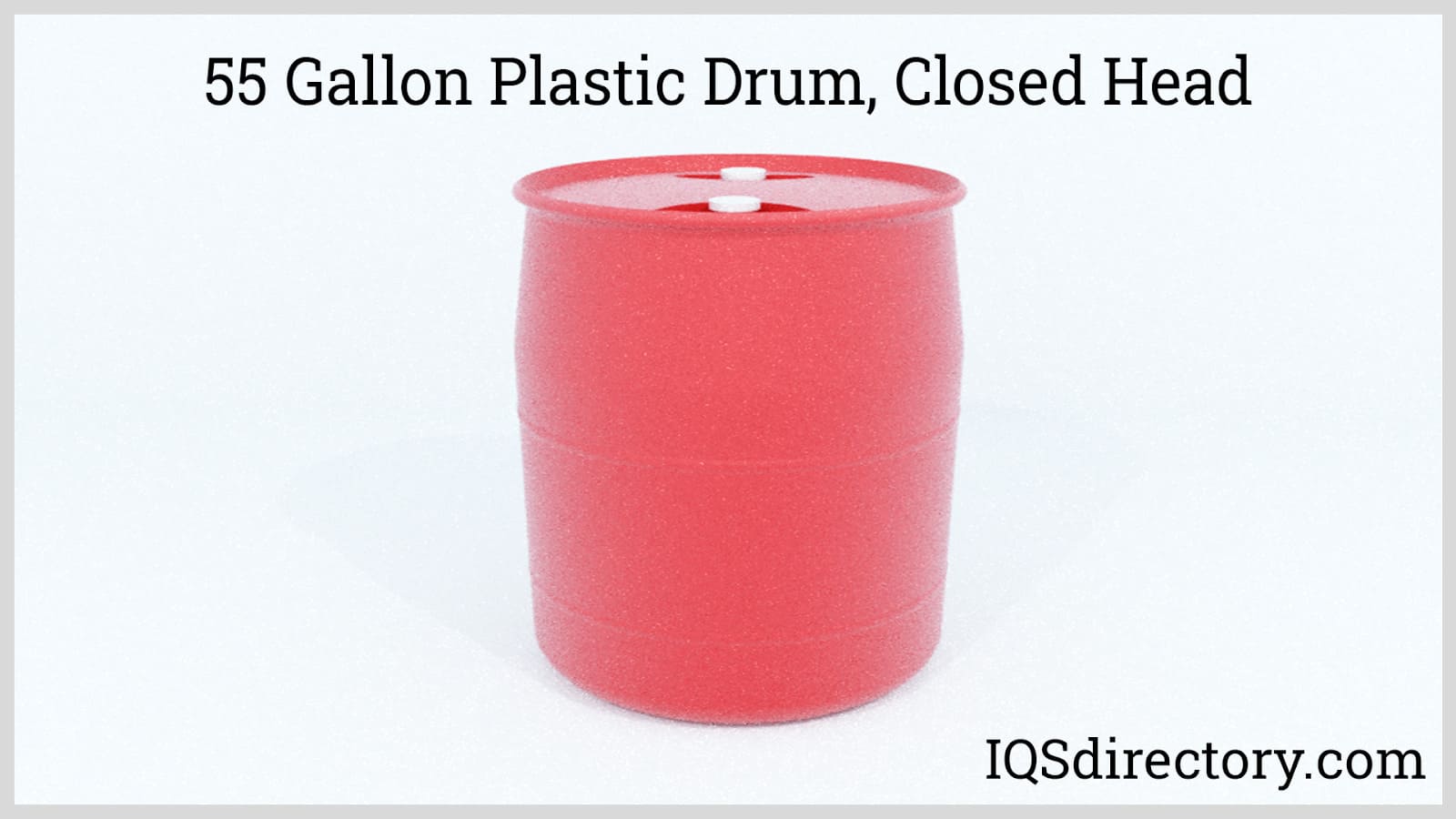

55 gallon drums are cylindrical containers used for shipping bulk goods.

55 gallon drums are large, cylindrical industrial containers with a nominal capacity of 55 gallons that are mainly used for shipping and storage applications.

55 gallon drums are cylindrical containers used for shipping bulk goods.

55 gallon drums are large, cylindrical industrial containers with a nominal capacity of 55 gallons that are mainly used for shipping and storage applications.

A note on terminology: Drums and barrels are for all practical purposes the same thing. Industrial manufacturers use the two terms synonymously, and there is no distinctive structural difference between "drums" and "barrels;" both can be made of plastic, fiberglass, or metal, both are used to transport goods, and both have standard sizes, such as the 55 gallon drum.

There are only two cases in which a slight distinction is made between drums and barrels. The first is in the oil industry; oil is transported in standard, metal, 42 gallon containers referred to as "oil barrels", not as "drums"; the distinction made between oil "barrels" and drums which transport other material helps clarify volume, which in a standard drum is 55 gallons. The other industry in which a small distinction between drums and barrels is made is in the alcoholic beverage industry, which also refers to its containers as "barrels" and not usually as "drums". Alcoholic beverage industries have traditionally used wooden barrels, and although wooden barrels have largely gone out of use in modern manufacturing, the sanitary-grade stainless steel containers used to ferment and transport beer, wine and liquor are referred to as wine or beer barrels. A distinction is made with beer and wine "barrels" partially out of a linguistic nostalgia for the industry and partially as a way of verbally clarifying a beer or wine barrel's contents as such. Outside of these two industry-specific slight distinctions, the terms "drums" and "barrels" refer to the same item. Learn more about 55 gallon drums.

The term "floor grating" is a term that covers the wide variety of frameworks used as flooring or flooring supplemental features.

In general, grates are made up of patterned, slotted and/or perforated bars and sheets, configured to a grid. Bars and sheets are typically made either from metal or from fiber-reinforced plastic. Floor grating in particular is used to improve flooring with better grip, filtering, draining and the like. Floor gratings can boost slip resistance and decrease the risk of falls because their grid work creates a textured surface. They improve ventilation and/or visibility in high risk workplaces like warehouses and factories by allowing air, light and sound to pass through them. Also, when they function as drain grates, floor gratings allow water, oil and other potentially hazardous liquids and debris to exit from floor surfaces.

The term "floor grating" is a term that covers the wide variety of frameworks used as flooring or flooring supplemental features.

In general, grates are made up of patterned, slotted and/or perforated bars and sheets, configured to a grid. Bars and sheets are typically made either from metal or from fiber-reinforced plastic. Floor grating in particular is used to improve flooring with better grip, filtering, draining and the like. Floor gratings can boost slip resistance and decrease the risk of falls because their grid work creates a textured surface. They improve ventilation and/or visibility in high risk workplaces like warehouses and factories by allowing air, light and sound to pass through them. Also, when they function as drain grates, floor gratings allow water, oil and other potentially hazardous liquids and debris to exit from floor surfaces.

Floor grating may be permanently installed on top of existing floor, permanently installed as primary flooring or placed in areas temporarily as mobile grating. As noted, floor gratings may be constructed either from metal or from fiber reinforced plastics. Typically the metals chosen include brass, iron, stainless steel and, from time to time, aluminum. The fiber reinforced plastics used in floor grating fabrication may be made from a variety of different plastic and fiber combinations. Possible plastics include vinyl ester resin, polyester resin, epoxy and vinylester. The vast majority of the time, the chosen fiber is a glass fiber. Glass fibers may be made with a number of different types of glasses, containing various possible minerals, such as: silica or silicate, limestone, dolomite, colemanite, magnesium, calcium, fluorspar and kaolin clay. When the chosen plastic is reinforced with the glass fiber, it becomes a fiber reinforced plastic known as fiberglass. Learn more about floor gratings.

Mezzanines are raised, often un-walled platforms that are used in a diversity of settings; they can be used to store unused materials, provide working space for equipment and seat people in auditoriums, among many other uses. Industrial mezzanines, however, are used only for purposes related to industrial operations. Manufacturers, suppliers, distributors and service companies all make use of mezzanines. Mezzanines can store unused materials, provide a work platform for equipment, walking space for facility guests, and seat people in auditoriums, among many other uses. Mezzanines can also provide a floor space or a ceiling for offices. A small, in-plant office, for example, could be built beneath a mezzanine; in which case, the mezzanine floor can simultaneously provide the office ceiling and a platform for storage. Conversely, an office could be built above, at mezzanine level, allowing the space below to be used for storage or for other uses.

Learn more about mezzanines.

Mezzanines are raised, often un-walled platforms that are used in a diversity of settings; they can be used to store unused materials, provide working space for equipment and seat people in auditoriums, among many other uses. Industrial mezzanines, however, are used only for purposes related to industrial operations. Manufacturers, suppliers, distributors and service companies all make use of mezzanines. Mezzanines can store unused materials, provide a work platform for equipment, walking space for facility guests, and seat people in auditoriums, among many other uses. Mezzanines can also provide a floor space or a ceiling for offices. A small, in-plant office, for example, could be built beneath a mezzanine; in which case, the mezzanine floor can simultaneously provide the office ceiling and a platform for storage. Conversely, an office could be built above, at mezzanine level, allowing the space below to be used for storage or for other uses.

Learn more about mezzanines.

Modular buildings are a broad class of prefabricated buildings that have become increasingly popular in recent years.

Modular buildings are a broad class of prefabricated buildings that have become increasingly popular in recent years.

They serve as an economical and effective solution for those seeking permanent, long-term, or temporary facilities, such as military barracks, booths, disaster relief housing, temporary medical treatment facilities, schools, libraries, universities, gyms, storage buildings, construction site offices, modular offices, and churches. Modular buildings are built to provide long-term temporary or permanent shelter. They can be found in the form of complete standalone buildings, space partitions, building extensions or small booths and guard houses. They serve as facilities and structures for all sorts of applications, including: church, school and university, modular home, classroom, cleanroom, gym, hospital, construction site office, inplant office, commercial modular building, disaster relief housing, storage building, medical/dental office, emergency medical center, security guardhouse and military barrack. Learn more about modular buildings.

Plastics are a product of the modern age.

The history of plastic as outlined on this site is a story of inventiveness and industrialism. The advent of plastic storage along with mass production helped create America‘s post-war economic boom. Plastic containers are one of the most important and useful items made from this revolutionary material.

Plastics are a product of the modern age.

The history of plastic as outlined on this site is a story of inventiveness and industrialism. The advent of plastic storage along with mass production helped create America‘s post-war economic boom. Plastic containers are one of the most important and useful items made from this revolutionary material.

Plastic containers are enclosures of plastic that are designed to contain something. Varieties of plastic containers distinguish themselves from each other by virtue of their size, shape, function or application. Plastic containers like plastic boxes are easily conceptualized in the abstract, but confining them to a universal, practical description is impossible; there are just too many kinds of plastic containers. Learn more about plastic containers.

Plastic pallets, or plastic skids, are plastic platforms used for storing, organizing, and transporting products. Though skids were commonly made of wood, plastic pallets have become more popular recently.

Plastic pallets, or plastic skids, are plastic platforms used for storing, organizing, and transporting products. Though skids were commonly made of wood, plastic pallets have become more popular recently.

Plastic is more durable and typically demonstrates a higher strength-to-weight ratio, so plastic pallets can be reused longer and can support greater loads than wooden skids. In factories and warehouses, forklifts, hi-lows, and other jacks are used to quickly transport products on plastic pallets which can then be stored efficiently in large stacks. Learn more about plastic pallets.

Plastic tanks, also known as poly tanks, are versatile containers used for bulk storage of a wide range of industrial substances or liquids.

The tanks are available in an array of sizes and configurations. They can be vertical or horizontal, rectangular, circular or square shaped. Plastic tanks may store substances from as little as 15 gallons to as large as 20,000 gallons.

Plastic tanks, also known as poly tanks, are versatile containers used for bulk storage of a wide range of industrial substances or liquids.

The tanks are available in an array of sizes and configurations. They can be vertical or horizontal, rectangular, circular or square shaped. Plastic tanks may store substances from as little as 15 gallons to as large as 20,000 gallons.

Plastic tanks are the preferred choice for many applications--both in large or small scale industrial use--because they hardly react to any liquid it contains. Most of the tanks, especially the bulk storage tanks, feature slots for tying them down, while others have centered and offset self-vented and slosh-proof lids. Learn more about plastic tanks.

Steel shelving, sometimes called steel shelving racks or steel racks, are shelving units built from alloyed steel sheets and supports.

The goals of steel shelving are to 1) convert unused space into storage areas and 2) increase organization while optimizing space.

Steel shelving, sometimes called steel shelving racks or steel racks, are shelving units built from alloyed steel sheets and supports.

The goals of steel shelving are to 1) convert unused space into storage areas and 2) increase organization while optimizing space.

Shelving systems and racks have extremely diverse applications. Shelving systems encompass the complete storage arrangement in a given industrial, commercial or residential area. They may stand alone as individual pieces, or they may be part of an entire mezzanine flooring scheme. You may find steel shelving racks anywhere, from commercial coolers and freezers, to manufacturing facilities and shipping warehouses, to firehouses, to hospitals. Learn more about steel shelving.

Stainless steel tanks are thin-walled constructions manufactured through a rolling process or welding. Although stainless steel is strong, it is vulnerable to buckling when the material is thin. Stainless steel tanks are most susceptible to damage during construction, transportation and installation.

Stainless steel tanks are thin-walled constructions manufactured through a rolling process or welding. Although stainless steel is strong, it is vulnerable to buckling when the material is thin. Stainless steel tanks are most susceptible to damage during construction, transportation and installation.

The contents of full stainless steel tanks actually aid its stability. The shape of the tank is dependent on its diameter or height and the efficient use of material. Stainless steel tank manufacturers can make the ends of their products flat or in the shape of a dome or cone. In determining the size that a tank needs to be, consider how much extra volume should be included to cover for future process needs, such as thermal expansion or foaming, and also filling control, especially in the applications that require high speed pumping. Learn more about stainless steel tanks.

Storage racks are stands or frameworks that are used to display, store, and organize products, parts, equipment, tools, materials, boxes, and pallets for the efficient use of space within warehouses, manufacturing facilities, shipping areas, and product assembly rooms.

Storage racks are stands or frameworks that are used to display, store, and organize products, parts, equipment, tools, materials, boxes, and pallets for the efficient use of space within warehouses, manufacturing facilities, shipping areas, and product assembly rooms.

Storage rack manufacturers produce industrial storage racks for heavy duty usage according to the product specifications and required accessibility. Racks are commonly designed to hold inventory that has been palleted, and are constructed using metals such as aluminum and steel which are strong and durable. Metal storage racks, especially steel storage racks are employed for these applications, but some lighter weight racks are made of materials such as titanium, wood or particle board. Storage racks hold many kinds of inventory, from boxed goods to long carpet rolls or tubing. Learn more about storage racks.

Workbenches and work stations are equipment or furnishings that create an efficient space in which people perform a set of specific duties, whether in offices, plants or manufacturing processes.

Workbenches and work stations are equipment or furnishings that create an efficient space in which people perform a set of specific duties, whether in offices, plants or manufacturing processes.

Ergonomic workstation design remains important in order for workers to accomplish given tasks effectively.

Workstations and work benches are manufactured for a variety of facilities and processes; industrial workstations and industrial workbenches provide workspace for machinists, assembly workers and many other industrial manufacturing processes. Custom industrial work stations can be portable stations made from lightweight materials, or they may be permanent workstations fabricated from steel or wood, depending on the needs of the industrial job site or garage workshop it is made for. Suitable for use in areas with water, dust, vibrations and wide temperatures are apart of the environment, industrial workstations can be used as clean room tables, light tables, drafting tables, packaging tables, laboratory tables, and more. They can be built for rugged durability and harsh work environments and can be made to fit packing, process control, shipping, factory automation or laboratory requirements. Learn more about work benches.